Fixture for solder paste printing and method for repairing integrated circuit board by utilizing same

An integrated circuit board and solder paste technology is applied in the field of printing solder paste fixtures and using the fixture to repair integrated circuit boards, which can solve the problems of difficulty in printing solder paste, partial damage to products, and high circuit board integration, and reduce repair costs. , The effect of solving the difficulty of printing solder paste and reducing the difficulty of repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

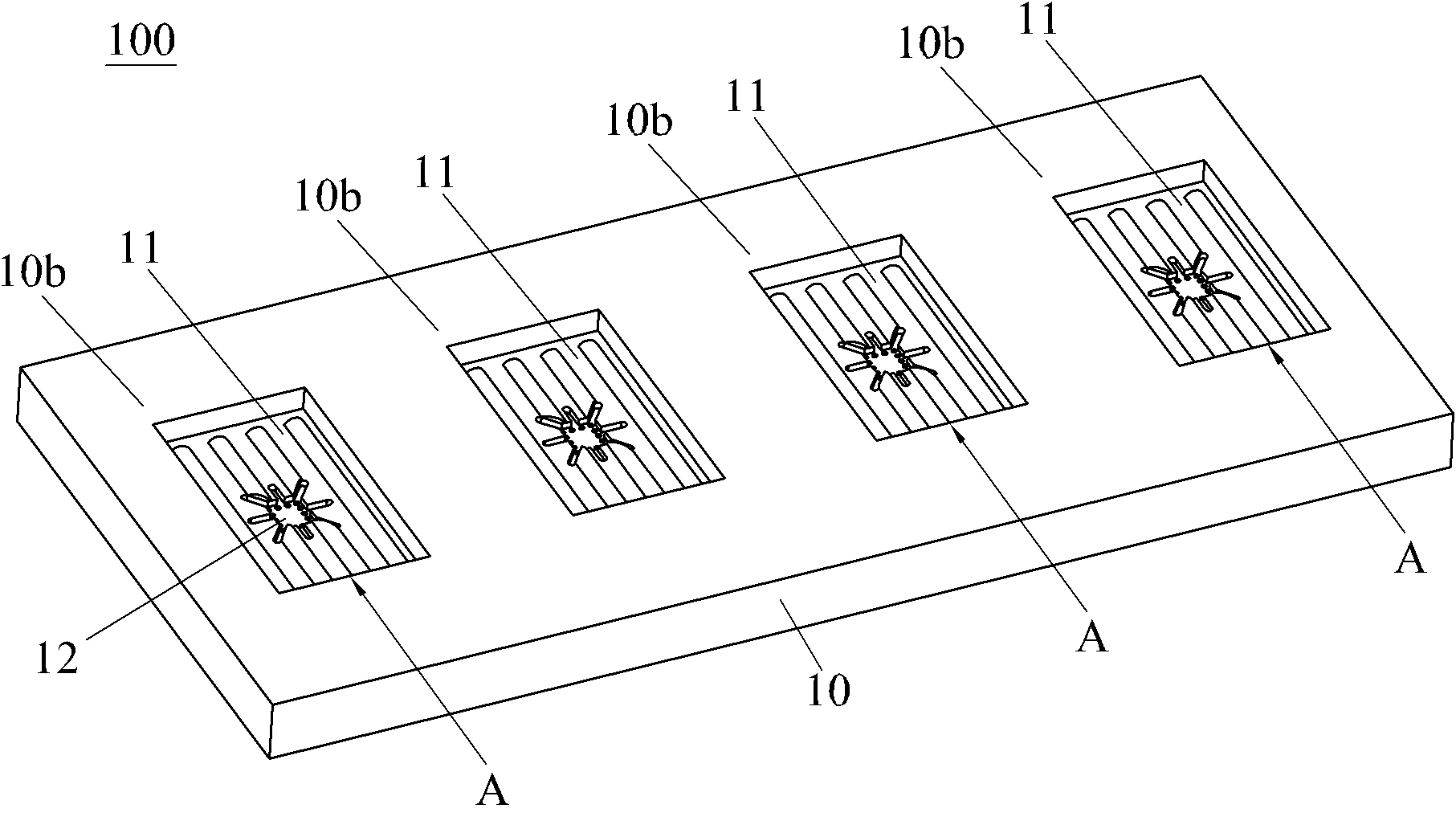

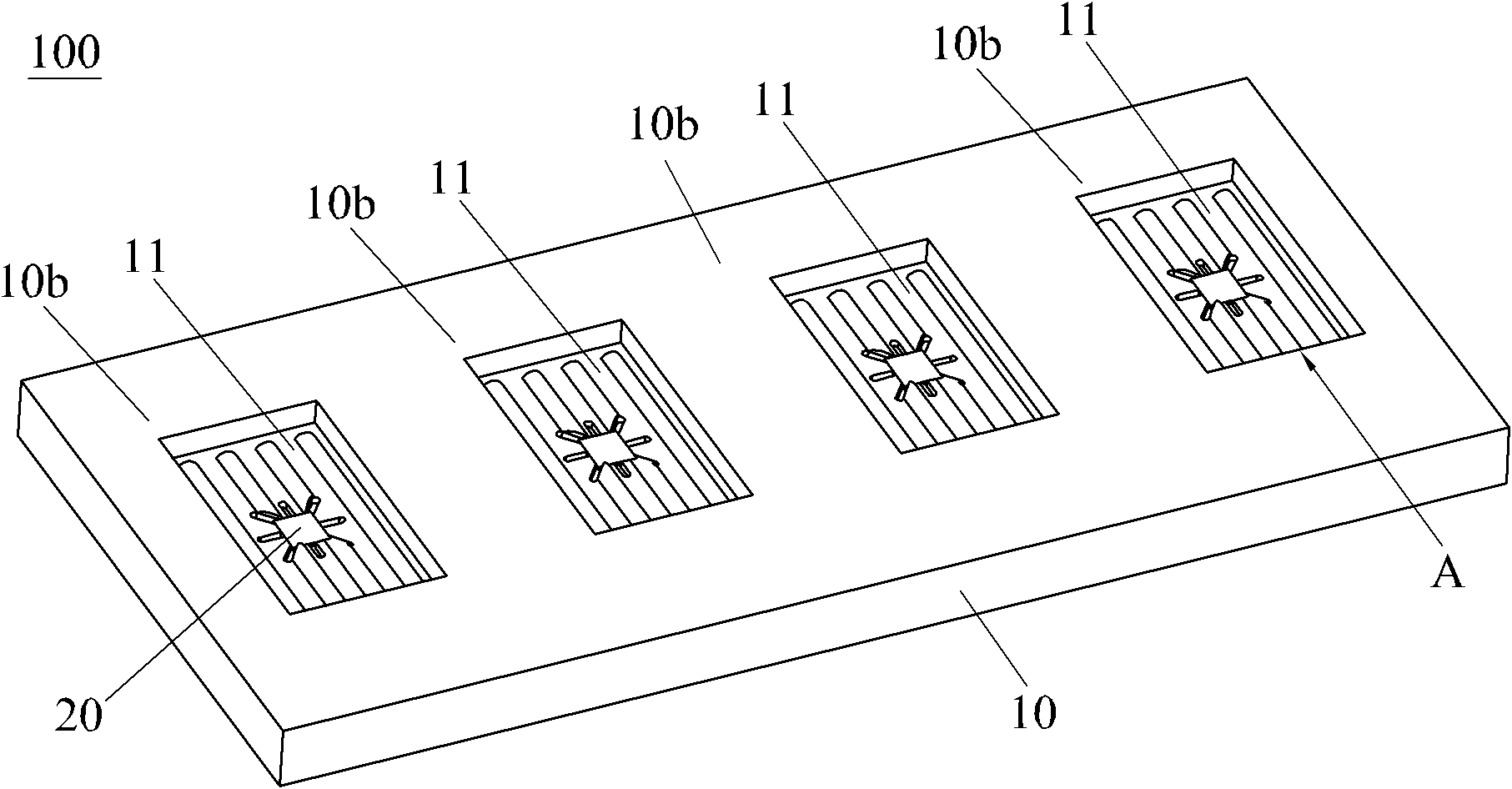

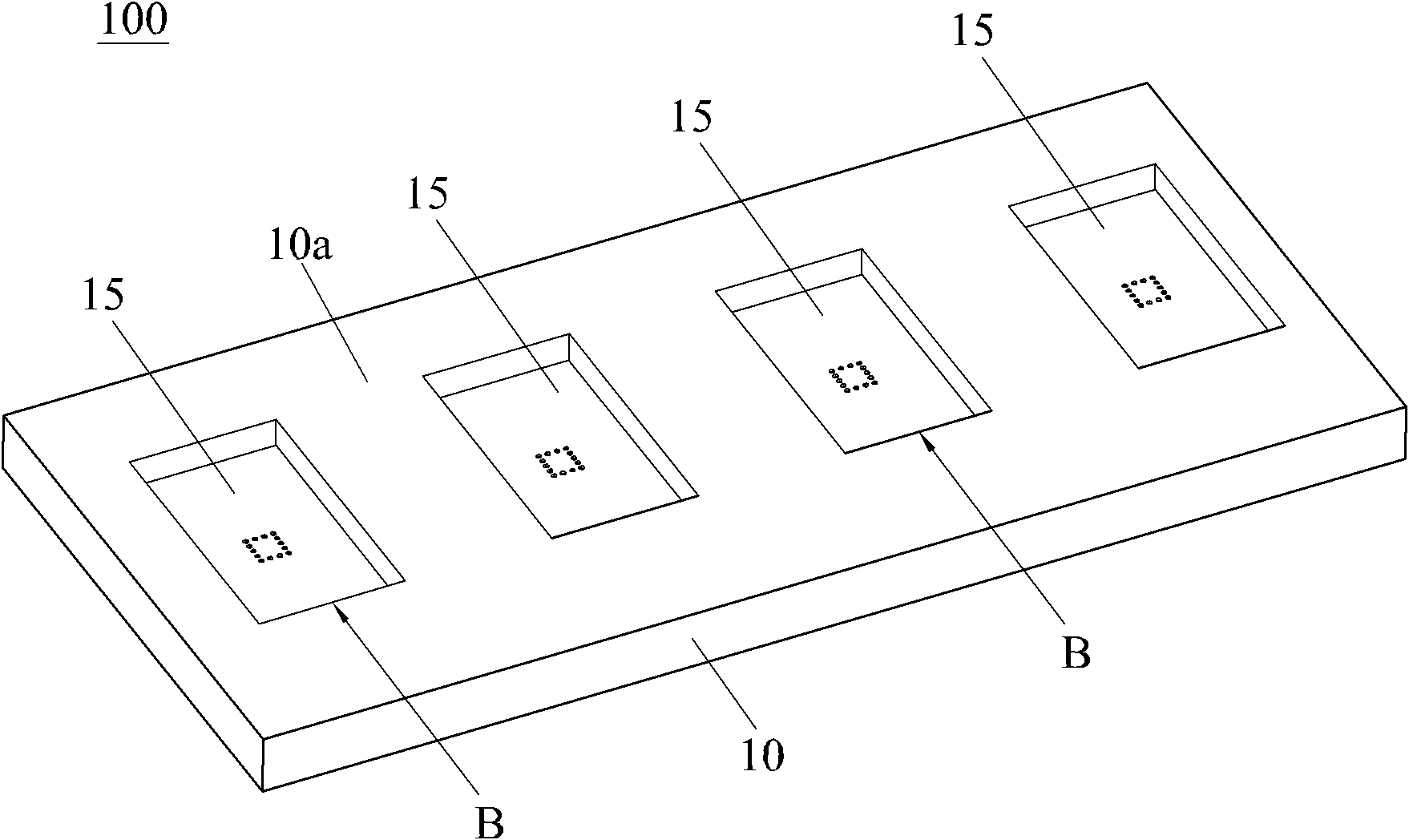

[0027] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, such as Figure 1-5 As shown, the printing solder paste jig 100 provided by the present invention includes a support plate 10, the front side 10b of the support plate 10 is provided with four chip accommodating grooves 11, and the back side 10a of the support plate 10 is recessed to form a soldering slot 15. The tin brushing slot 15 is directly opposite to the chip accommodating slot 11, and the bottom of the chip accommodating slot 11 is provided with a pin hole 13, and the pin hole 13 runs through the back of the support plate 10 10a, and the pin holes 13 correspond to the pins of the contained chip. Specifically, the pin hole 13 runs through the solder brush slot 15 and the chip accommodating slot 11 . The solder brush tank 15 is provided on the back side 10a of the support plate 10 to better hold t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com