In-situ remediation method for organic matter polluted soil

A technology for in-situ remediation of polluted soil, applied in the field of soil pollution remediation, can solve the problems of complex soil pretreatment, high power consumption, and high equipment cost for ex-situ remediation, and achieve the goals of promoting rapid degradation, easy separation and recycling, and reducing treatment costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

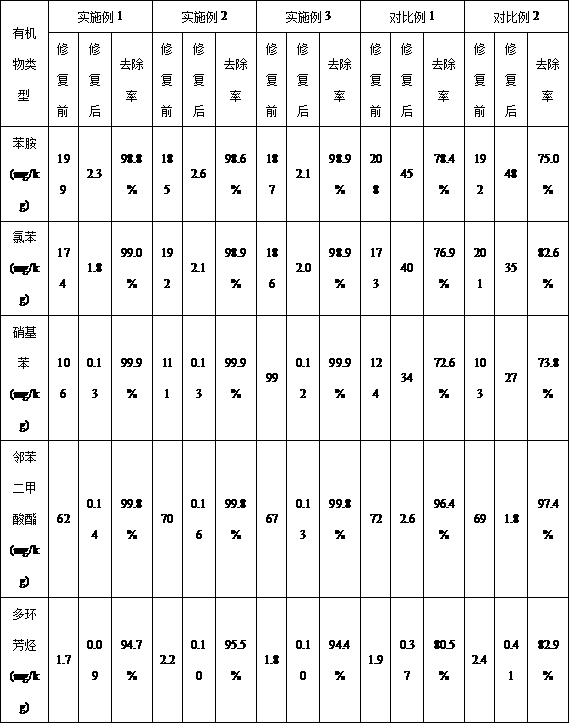

Examples

Embodiment 1

[0027] A method for in-situ remediation of organic-contaminated soil, the method is divided into the following steps:

[0028] Step 1. Loosen and crush the organic-contaminated soil, remove impurities, detect the type and content of organic pollutants in the soil, pour water into it, and keep the soil humidity at 25%;

[0029] Step 2, by mass ratio 1:80 will solubilizer / TiO 2 / CdS bentonite magnetic hydrogel microspheres are sprinkled on the surface of the target soil, and exposed to sunlight or simulated sunlight for 4 hours to photocatalytically degrade organic pollutants, and then use a magnetic field to separate the solubilizer / TiO 2 / CdS bentonite magnetic hydrogel microspheres, washed with water, dried, and irradiated with ultraviolet light for 10 s before use;

[0030] Step 3: Turn the soil, loosen, and crush the soil to keep the soil humidity at 25%, repeat the operation of Step 2 six times, and detect the content of various organic pollutants in the soil.

[0031] F...

Embodiment 2

[0041] A method for in-situ remediation of organic-contaminated soil, the method is divided into the following steps:

[0042] Step 1. Loosen and crush the organic-contaminated soil, remove impurities, detect the type and content of organic pollutants in the soil, pour water into it, and keep the soil humidity at 30%;

[0043] Step 2, by mass ratio 1:100 will solubilizer / TiO 2 / CdS bentonite magnetic hydrogel microspheres are sprinkled on the surface of the target soil, and exposed to sunlight or simulated sunlight for 5 hours to photocatalytically degrade organic pollutants, and then use a magnetic field to separate the solubilizer / TiO 2 / CdS bentonite magnetic hydrogel microspheres, washed with water, dried, and irradiated with ultraviolet light for 15 s for later use;

[0044] Step 3: Turn the soil, loosen, and crush the soil to keep the soil humidity at 30%, repeat the operation of Step 2 five times, and detect the content of various organic pollutants in the soil.

[00...

Embodiment 3

[0055] A method for in-situ remediation of organic-contaminated soil, the method is divided into the following steps:

[0056] Step 1. Loosen and crush the soil contaminated by organic matter, remove impurities, detect the type and content of organic pollutants in the soil, pour water into the soil, and keep the soil humidity at 35%;

[0057] Step 2, by mass ratio 1:110 will solubilizer / TiO 2 / CdS bentonite magnetic hydrogel microspheres sprinkled on the surface of the target soil, exposed to sunlight or simulated sunlight for 6 hours, TiO 2 / CdS for photocatalytic degradation of organic pollutants, followed by magnetic field separation of solubilizer / TiO 2 / CdS bentonite magnetic hydrogel microspheres, washed with water, dried, and irradiated with ultraviolet light for 20 s before use;

[0058] Step 3: Turn the soil, loosen, and crush the soil to keep the soil humidity at 35%, repeat the operation of Step 2 four times, and detect the content of various organic pollutants in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com