Active array substrate, LCD panel and its mending method

A technology for liquid crystal display panels and array substrates, applied in optics, instruments, electrical components, etc., can solve problems such as poor contact of components and disconnection of data lines, and achieve the effect of improving production qualification rate and reducing repair difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

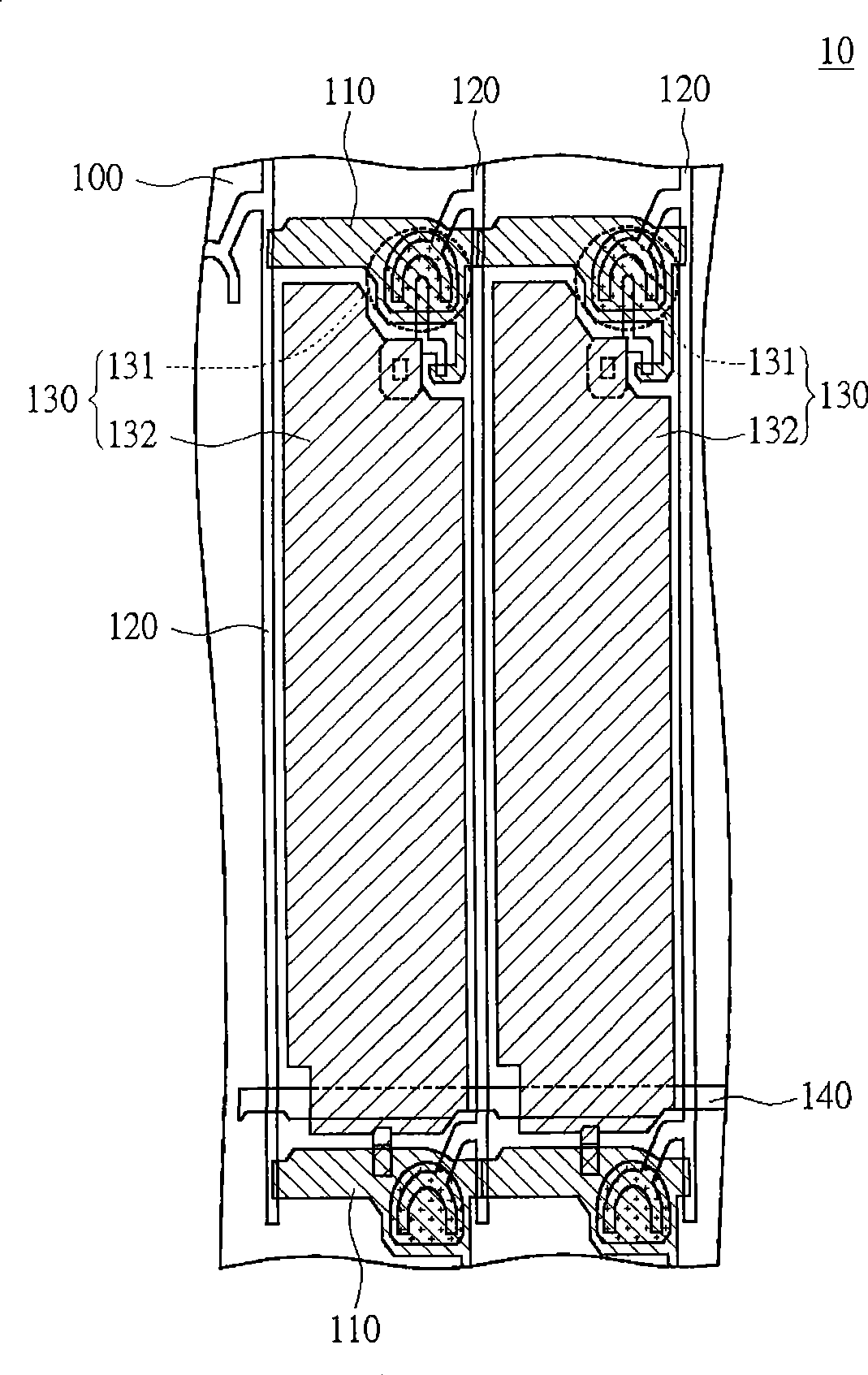

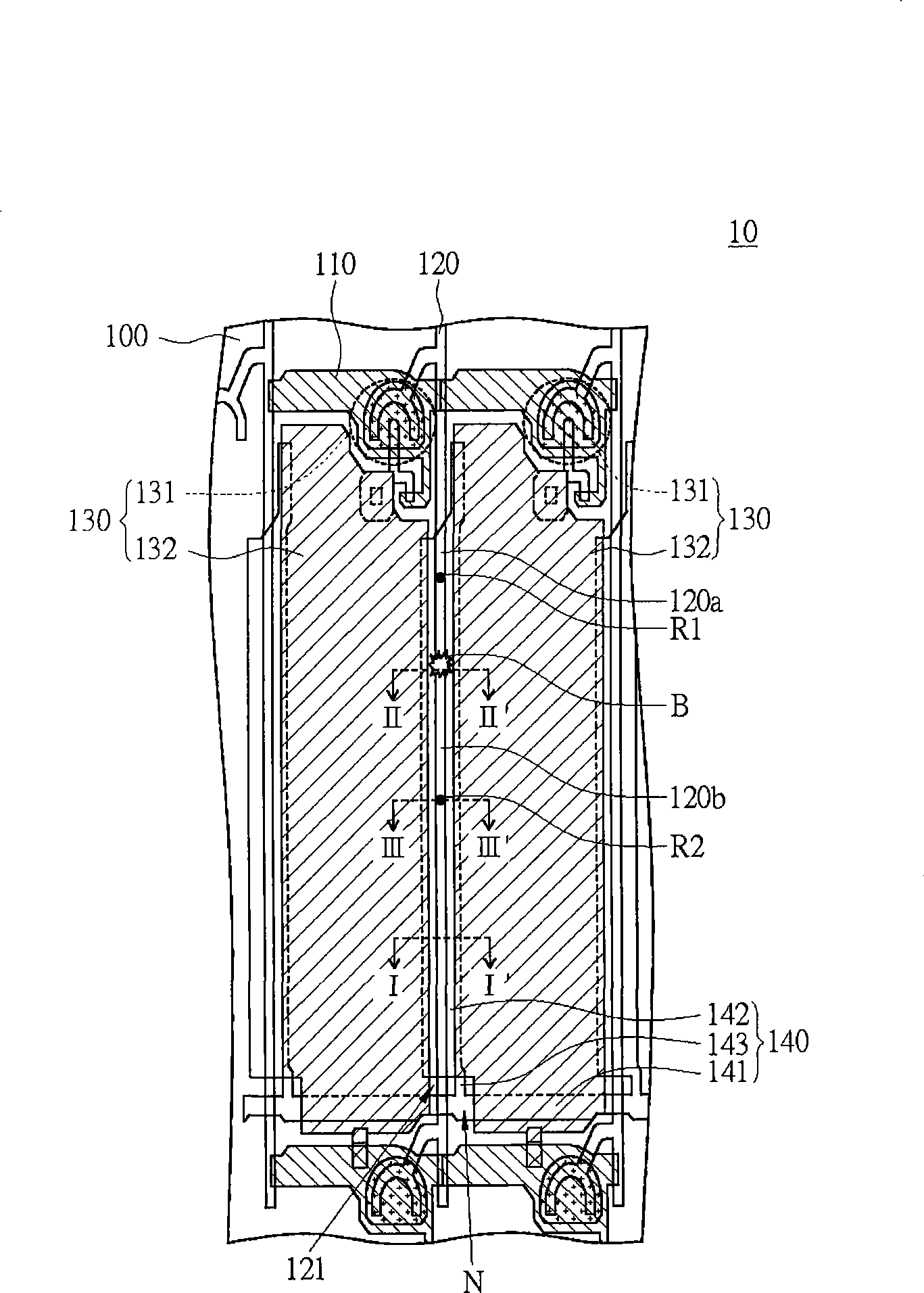

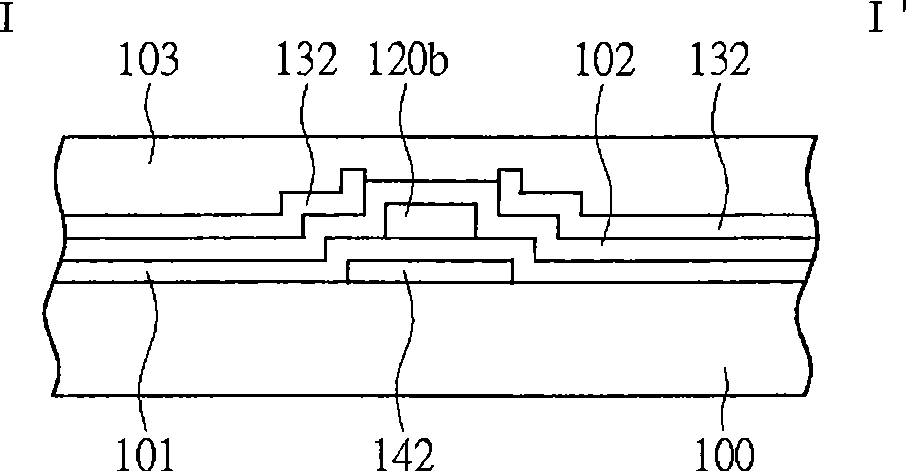

[0042] Figure 2A is a top view of an active matrix substrate according to an embodiment of the present invention, Figure 2B to Figure 2D respectively Figure 2A From the schematic cross-sections of I-I', II-II' and III-III', Figure 2E for Figure 2A Partial enlarged view of region N viewed from the lateral direction of the substrate.

[0043] Please refer to Figure 2A The active array substrate 10 includes a substrate 100 , scan lines 110 , data lines 120 , pixel units 130 and common electrodes 140 . For convenience, only two pixel units are shown as an example, but it is not intended to limit the present invention. The scan lines 110 are disposed on the substrate 100 , and the data lines 120 are disposed on the substrate 100 and are substantially parallel to the plurality of scan lines 110 . The pixel units 130 are respectively connected to the plurality of scanning lines 110 and the plurality of data lines 120 correspondingly, each pixel unit 130 has a switching el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com