Roller kiln temperature prediction integrated modeling method capable of combining mechanism with data

A modeling method and roller kiln technology, applied in the direction of electrical digital data processing, special data processing applications, computer-aided design, etc., can solve the problems that the mechanism model cannot reflect the factors affecting the temperature, and the temperature has errors, so as to improve the product quality. Production quality and qualified rate, good guidance, and accurate output results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

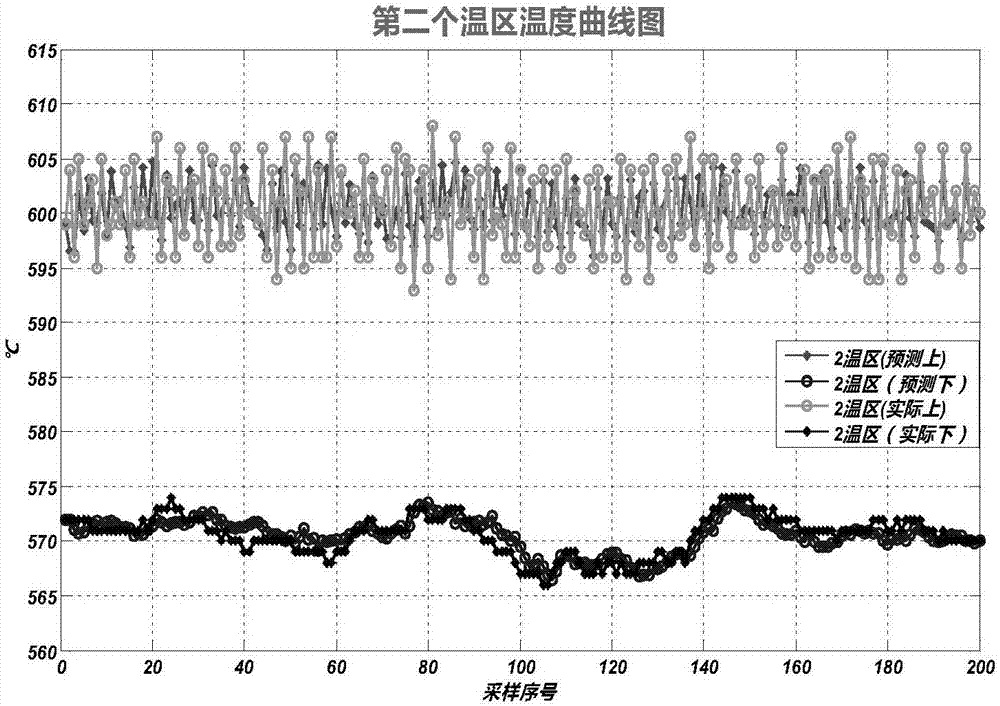

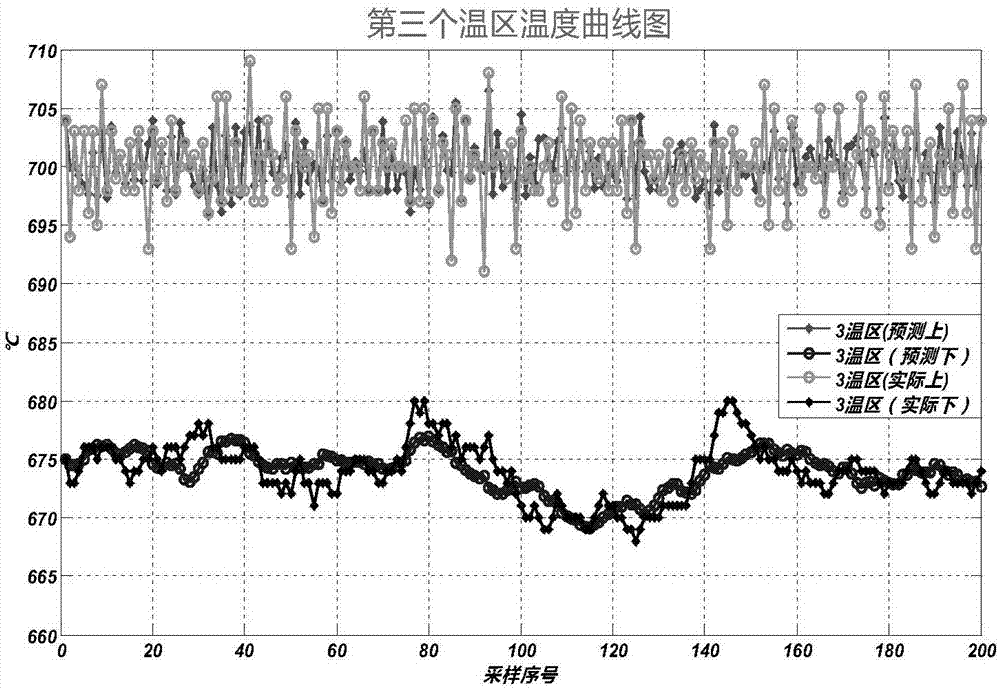

[0052] Step 1: Data preprocessing: pre-organize the operation data of the roller kiln process, including displaying wrong data, missing data, etc., and store them in the created database after sorting. The database mainly includes the following data: The temperature of the upper / lower temperature zone of the i-th temperature zone of the roller kiln x i1 ,x i2 , Heating power P in the upper / lower temperature zone i1 ,P i2 , the temperatures before and after the i-th temperature zone are respectively x (i-1)1 ,x (i-1)2 ,x (i+1)1 ,x (i+1)2 , the air flow v into each temperature zone i , the moving speed V of the material and bowl; the obtained data is transferred to a certain amount as training sample data, which is used to identify model parameters and establish a data error prediction model;

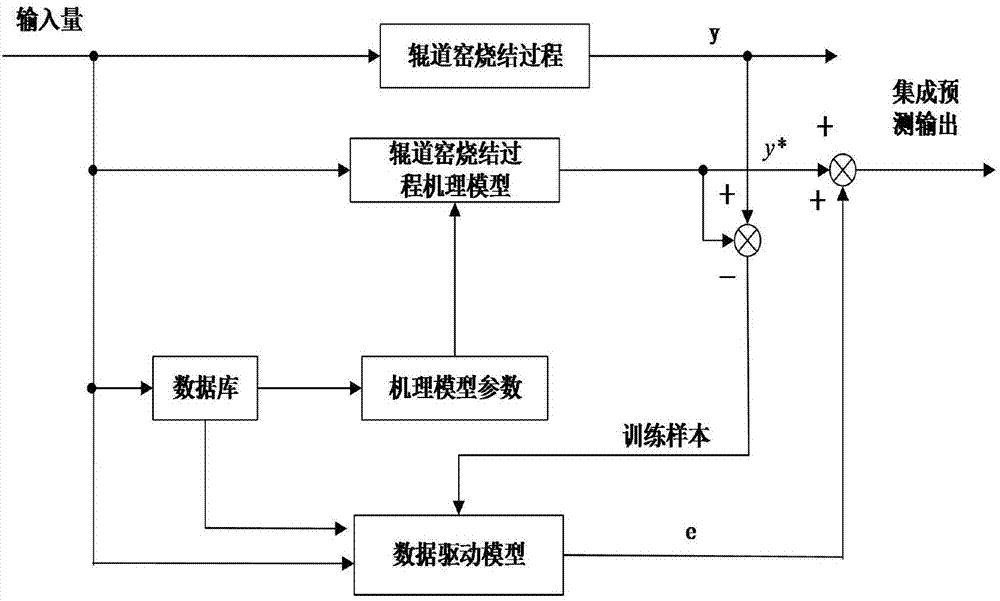

[0053] Step 2: First, through in-depth analysis of the factors affecting the temperature change in the i1th temperature zone, the temperature change is mainly affected by the follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com