Gear micro-modification design method and wear test bench based on wear test

A technology of wear test and design method, which is applied in the direction of machine gear/transmission mechanism test, belt/chain/gear, mechanical equipment, etc., which can solve the problem of long cycle, lack of quantitative indicators for gear modification design, and difficulty in ensuring the effectiveness of modification design and other problems, to achieve the effect of simple structure, improved gear transmission performance, and improved wear test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

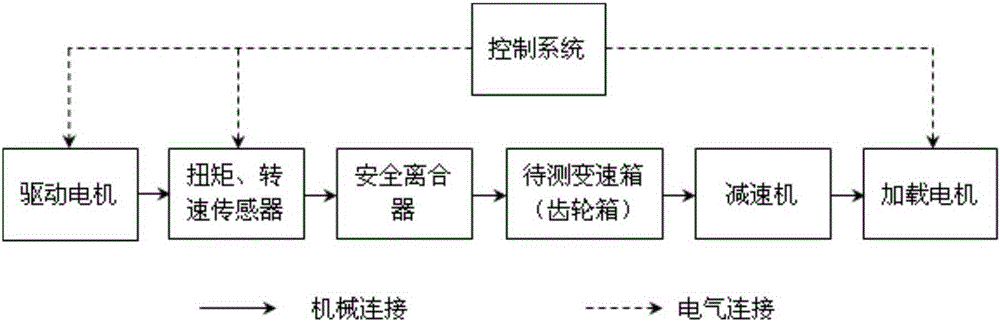

[0038] refer to figure 1 , which shows the structural principle of the bench for wear test used in the embodiment of the present invention. Take the wear test of the automobile gearbox as an example. After the gearbox to be tested is installed on the bench, the output shaft of the driving motor is mechanically connected to the torque and speed sensor, and the output shaft of the torque and speed sensor is mechanically connected to the driving disc of the safety clutch. The driven disc of the clutch is mechanically connected to the input shaft of the gearbox to be tested, the output shaft of the gearbox to be tested is mechanically connected to the input shaft of the reducer, and the output shaft of the reducer is mechanically connected to the output shaft of the loading motor. The control system is electrically connected with the driving motor, torque, speed sensor and loading motor to control the whole test process. In this way, the torque output by the drive motor is transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com