Modeling method of roller kiln temperature based on local quadratic weighted kernel principal component regression

A core principal component and modeling method technology, applied in the field of roller kiln smelting, can solve problems such as difficult online prediction of temperature, difficulty in solving partial differential equations, etc., to improve product production quality and pass rate, good guidance, output Precise results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

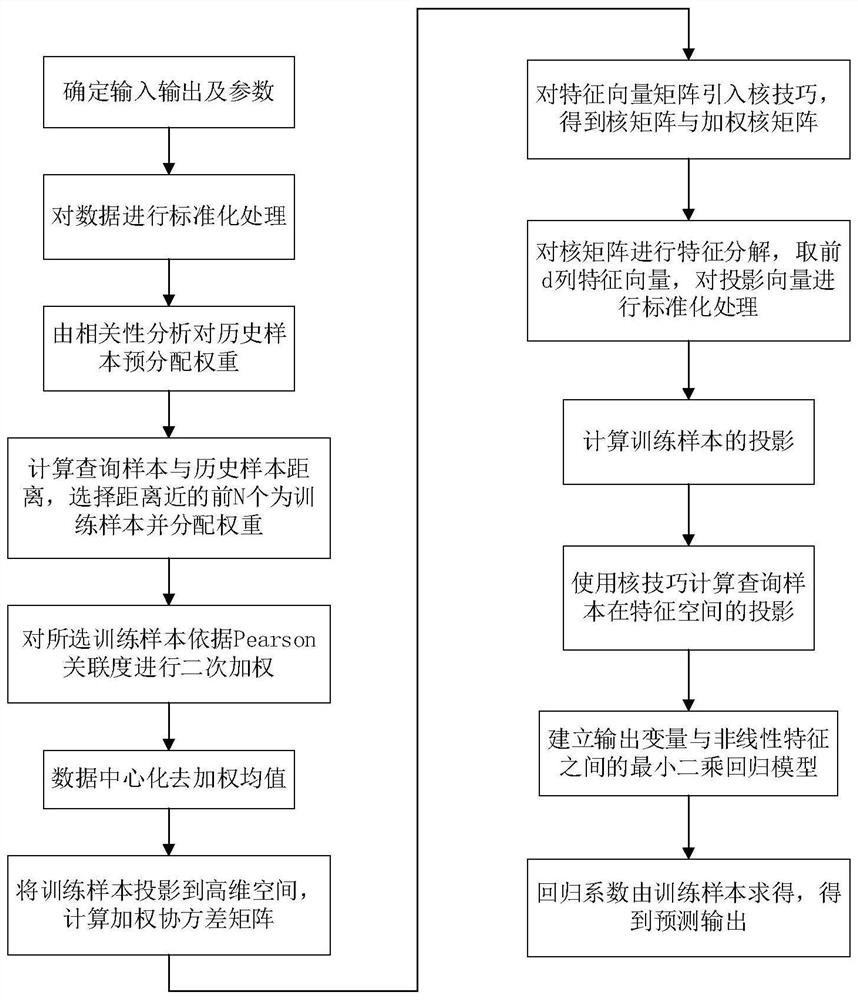

Method used

Image

Examples

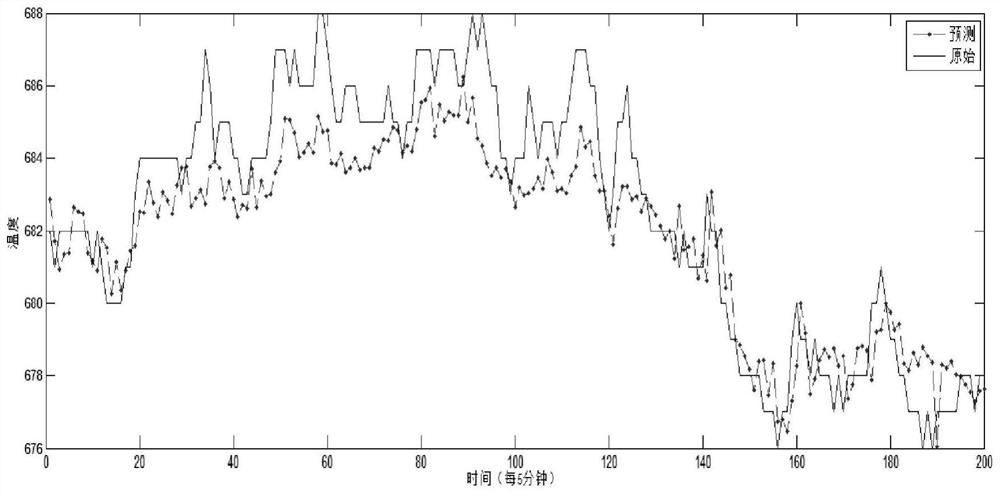

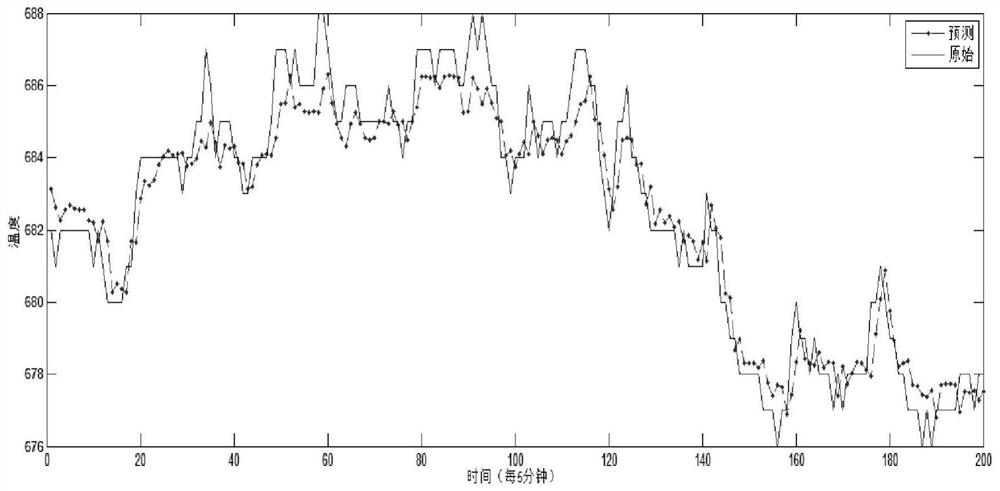

Embodiment 1

[0083] Step 1: Data preprocessing: pre-sort the operation data of the roller kiln process, including displaying wrong data, missing data, etc., and store them in the created database after sorting. The obtained data is used as training sample data for identification of model parameters, establishment of temperature soft sensor model and simulation verification;

[0084] Step 2: Selection of training samples: First, consider the lower temperature zone of i=3 and 12 temperature zones as the research object. Through mechanism analysis, it can be known that the temperature change in this temperature zone is mainly affected by the following factors, including: The temperature in the upper temperature zone of the i-th temperature zone x i1 , the temperature at the previous moment in the lower temperature zone of the i-th temperature zone The temperature of the lower temperature zone of the i-1th temperature zone x (i-1)2 , temperature x in the lower temperature zone of the i+1th ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com