Fracture plate metal inert-gas (MIG) arc welding additive remanufacturing method

A remanufacturing and arc welding technology, applied in the field of MIG arc welding additive remanufacturing of fractured plates, can solve the problems of large heat accumulation effect, difficulty in determining the number of welds and welding layers, and poor size uniformity of single-pass welds. , to achieve the effect of strong operability, reducing heat accumulation effect, improving dimensional accuracy and service performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

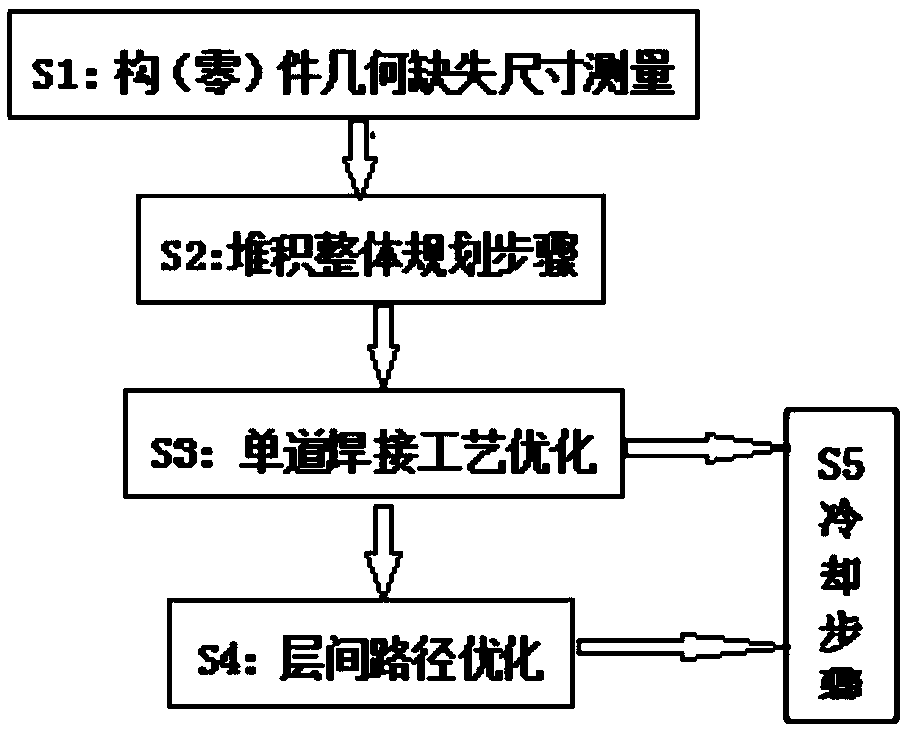

[0041] In Embodiment 1, the MIG arc welding additive remanufacturing method of the fractured plate provided by the present invention includes the following steps:

[0042] S1: Measurement of the defect volume of the fractured part. Through the reverse engineering method, the defect size of the fractured part is determined; the obtained defect size is 35.3mm×20.4mm×4.7mm in length, width and height.

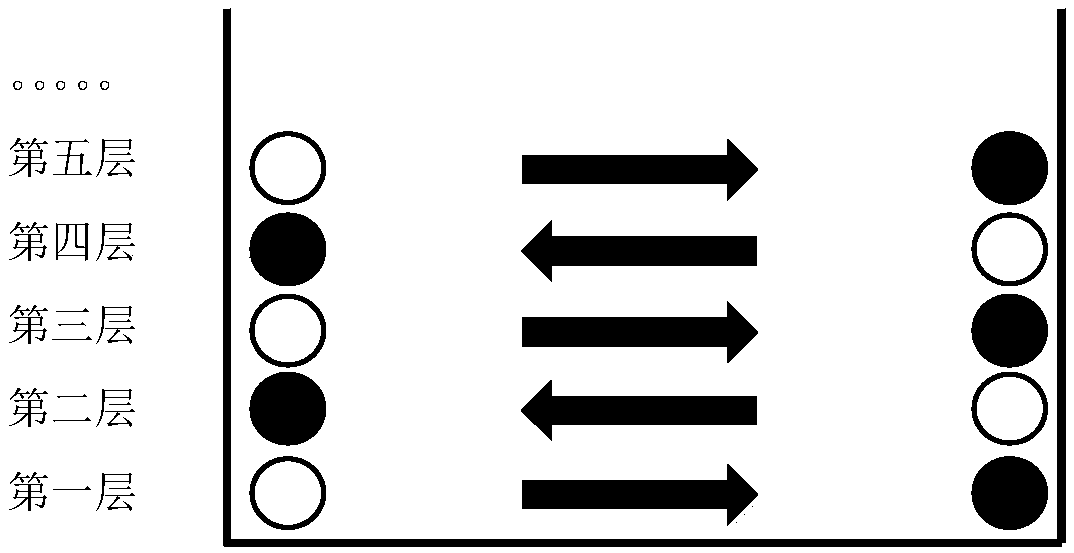

[0043] S2: The overall planning of stacking, with a stacking rate of 8mm 2 , under the accumulation rate condition, the height of each repair is 1.0mm~1.5mm, and the repair width is 4.0mm~6.6mm, and the number of single-layer welds can be determined as [20.4 / 6.6+0.5]~[20.4 / 4+0.5 ], that is, 3~5 layers, the total number of welding layers is: [4.7 / 1.5+0.5]~[4.7 / 1+0.5], that is, 3~5 layers.

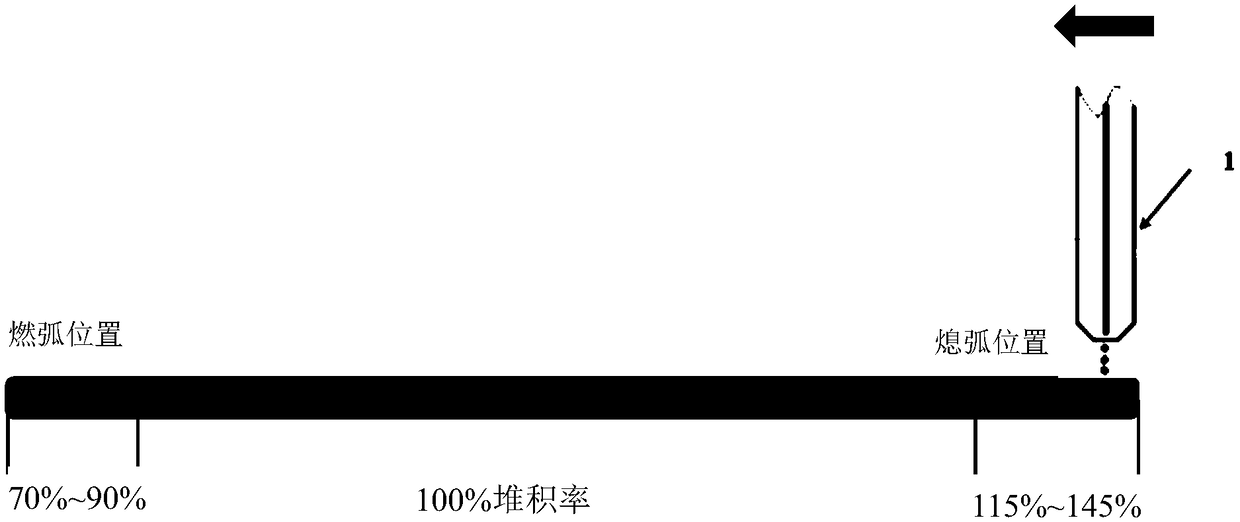

[0044] S3: In terms of single-pass weld optimization, the welding accumulation rate at the arc burning position is reduced (10% to 30%) compared with the welding process accumulation rate, whic...

Embodiment 2

[0050] In the second embodiment, the MIG arc welding additive remanufacturing method of the fractured plate provided by the present invention includes the following steps:

[0051] S1: Measurement of the defect volume of the fractured part. The length, width and height of the defect obtained from the measurement are 47mm×37mm×9.3mm, respectively.

[0052] S2: The overall plan for stacking, with a stacking rate of 30mm 2 , under the accumulation rate condition, the repair height of each layer is 2.3mm-2.7mm, and the repair width is 7.8mm-11.0mm, so the number of single-layer welds can be determined as [37 / 11+0.5]~[37 / 7.8+0.5] , that is, 4~6 layers, the total number of welding layers is: [9.3 / 2.7+0.5]~[9.3 / 2.3+0.5], that is, 3~4 layers.

[0053] S3: In terms of single-pass weld optimization, the welding accumulation rate at the arc burning position is reduced (10% to 30%) compared with the welding process accumulation rate, which is 30% in this embodiment. The welding accumulatio...

Embodiment 3

[0059] In the third embodiment, the MIG arc welding additive remanufacturing method of the fractured plate provided by the present invention includes the following steps:

[0060] S1: Measurement of the defect volume of the fractured part. The length, width and height of the defect obtained from the measurement are 115mm×76mm×26mm, respectively.

[0061] S2: The overall planning of stacking, with a stacking rate of 15mm 2 , under this accumulation rate condition, the height of each repair is 1.5mm-2.3mm, and the repair width is 6.6mm-7.8mm, and the number of single-layer welds can be determined to be [76 / 7.8+0.5]~[76 / 6.6+0.5 ], that is, 10 to 12 layers, the total number of welding layers is: [26 / 2.3+0.5] to [26 / 1.5+0.5], that is, 11 to 17 layers.

[0062] S3: In terms of single-pass weld optimization, the welding accumulation rate at the arc burning position is reduced (10% to 30%) compared with the welding process accumulation rate, which is 20% in this embodiment. The weldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com