A kind of remanufacturing method of mig arc welding additive material for fractured plate

A remanufacturing and arc welding technology, which is applied in the field of MIG arc welding additive remanufacturing of fractured plates, can solve the problems of poor uniformity of single-pass weld size, large heat accumulation effect, difficulty in determining the number of welds and welding layers, etc. , to achieve the effects of reducing thermal accumulation effect, strong operability, improving dimensional accuracy and service performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

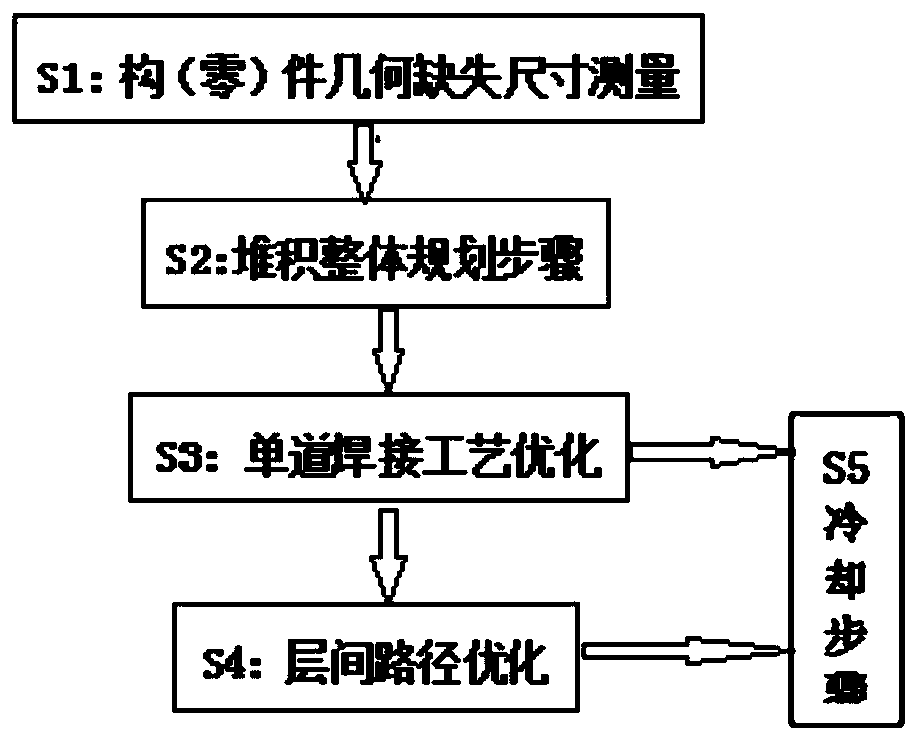

[0041] In Embodiment 1, the MIG arc welding additive remanufacturing method of the fractured plate provided by the present invention includes the following steps:

[0042] S1: Measurement of the defect volume of the fractured part. Through the reverse engineering method, the defect size of the fractured part is determined; the obtained defect size is 35.3mm×20.4mm×4.7mm in length, width and height.

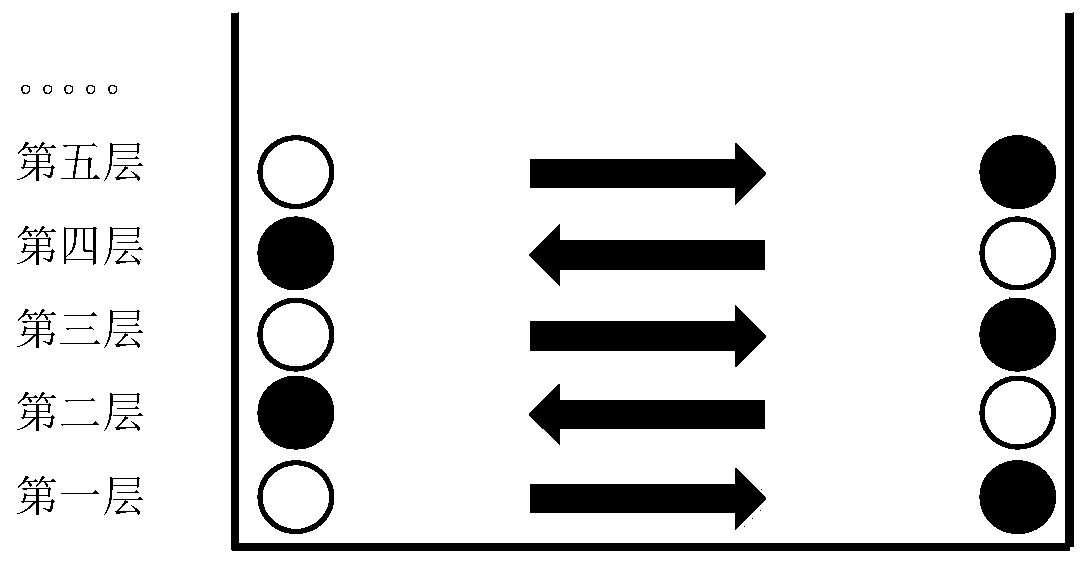

[0043] S2: The overall planning of stacking, with a stacking rate of 8mm 2 , under the accumulation rate condition, the height of each repair is 1.0mm~1.5mm, and the repair width is 4.0mm~6.6mm, and the number of single-layer welds can be determined as [20.4 / 6.6+0.5]~[20.4 / 4+0.5 ], that is, 3~5 layers, the total number of welding layers is: [4.7 / 1.5+0.5]~[4.7 / 1+0.5], that is, 3~5 layers.

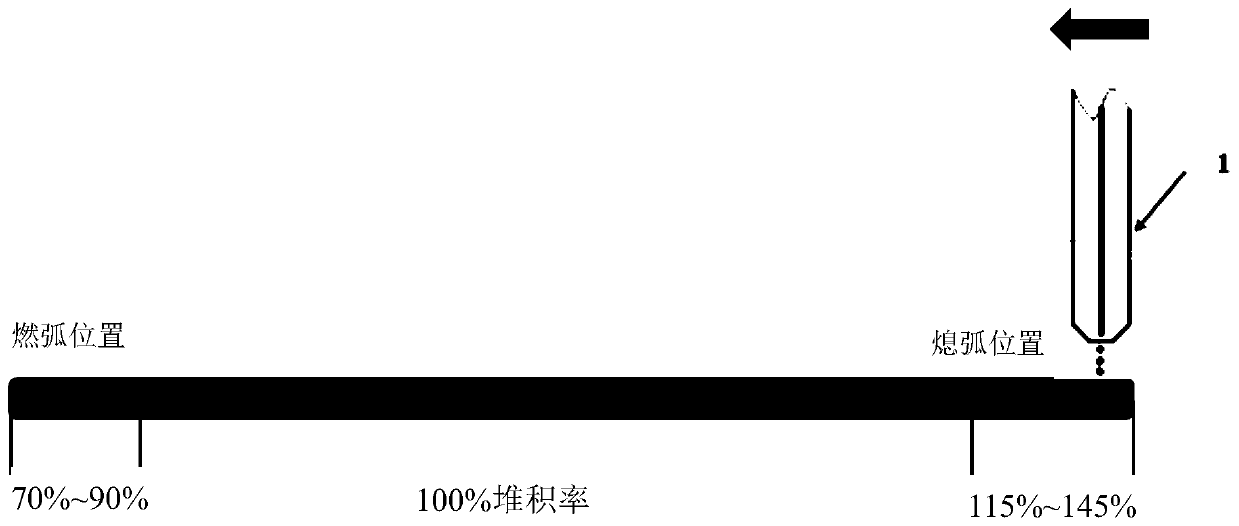

[0044] S3: In terms of single-pass weld optimization, the welding accumulation rate at the arc burning position is reduced (10% to 30%) compared with the welding process accumulation rate, whic...

Embodiment 2

[0050] In the second embodiment, the MIG arc welding additive remanufacturing method of the fractured plate provided by the present invention includes the following steps:

[0051] S1: Measurement of the defect volume of the fractured part. The length, width and height of the defect obtained from the measurement are 47mm×37mm×9.3mm, respectively.

[0052] S2: The overall plan for stacking, with a stacking rate of 30mm 2 , under the accumulation rate condition, the repair height of each layer is 2.3mm-2.7mm, and the repair width is 7.8mm-11.0mm, so the number of single-layer welds can be determined as [37 / 11+0.5]~[37 / 7.8+0.5] , that is, 4~6 layers, the total number of welding layers is: [9.3 / 2.7+0.5]~[9.3 / 2.3+0.5], that is, 3~4 layers.

[0053] S3: In terms of single-pass weld optimization, the welding accumulation rate at the arc burning position is reduced (10% to 30%) compared with the welding process accumulation rate, which is 30% in this embodiment. The welding accumulatio...

Embodiment 3

[0059] In the third embodiment, the MIG arc welding additive remanufacturing method of the fractured plate provided by the present invention includes the following steps:

[0060] S1: Measurement of the defect volume of the fractured part. The length, width and height of the defect obtained from the measurement are 115mm×76mm×26mm, respectively.

[0061] S2: The overall planning of stacking, with a stacking rate of 15mm 2 , under the accumulation rate condition, the height of each repair is 1.5mm-2.3mm, the repair width is 6.6mm-7.8mm, and the number of single-layer welds can be determined as [76 / 7.8+0.5]~[76 / 6.6+0.5 ], that is, 10 to 12 layers, the total number of welding layers is: [26 / 2.3+0.5] to [26 / 1.5+0.5], that is, 11 to 17 layers.

[0062] S3: In terms of single-pass weld optimization, the welding accumulation rate at the arc burning position is reduced (10% to 30%) compared with the welding process accumulation rate, which is 20% in this embodiment. The welding accum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com