A high-precision laser processing device and system

A laser processing and high-precision technology, applied in the fields of high-precision laser processing of devices, high-precision laser methods and devices, can solve existing problems, achieve the effects of simple operation, improved processing resolution, and reduced heat accumulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

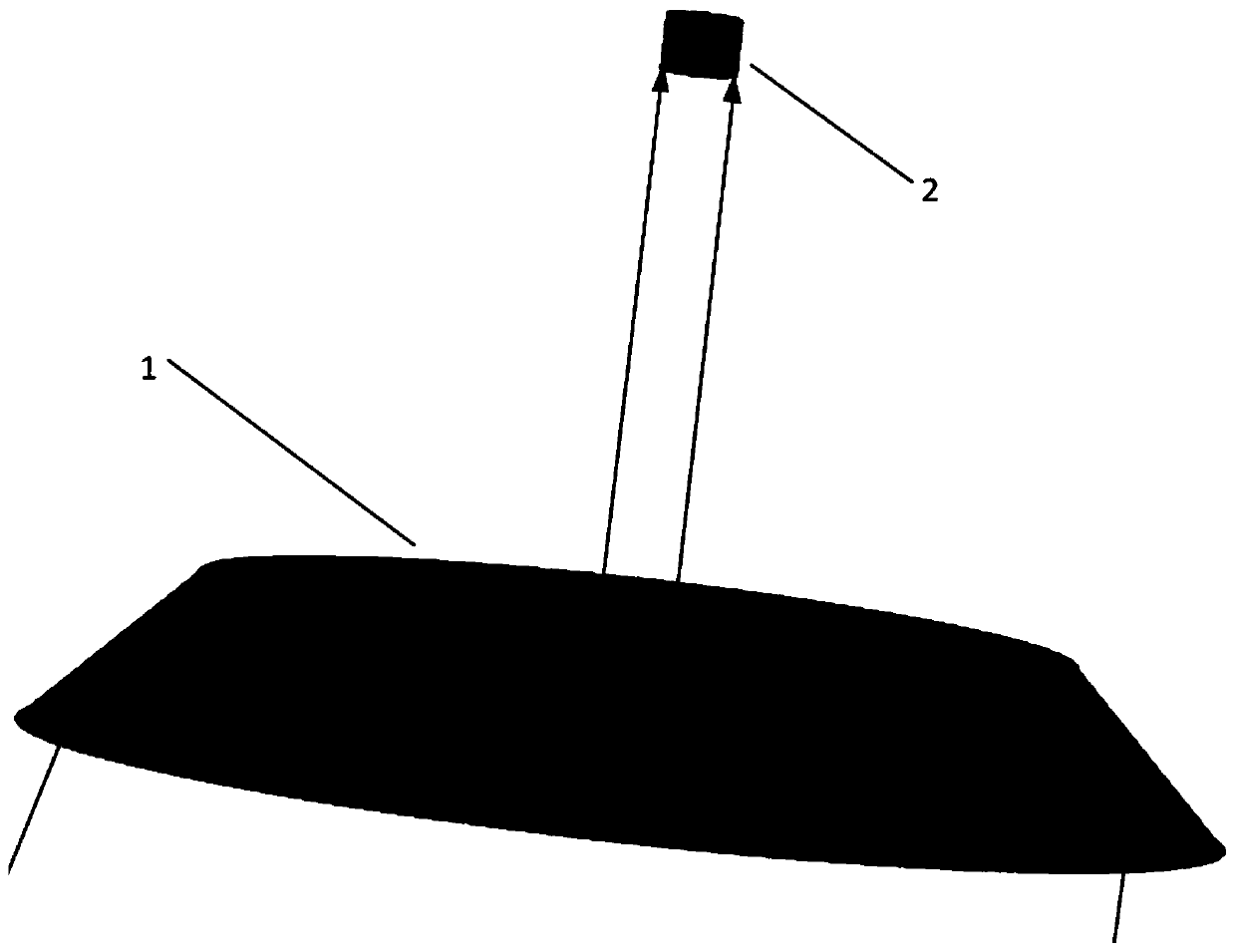

[0036] The material processing process of the high-precision laser processing device and system provided by this application is as attached figure 1 , attached figure 2 and attached Image 6 shown.

[0037] First, the system control parameters are transmitted to the control system through the input signal, and the control system controls the laser to turn on and the system to move; the optical element is a combination of multiple sets of total reflection mirrors. After the laser is turned on, the laser beam uses the optical element to achieve parallel beam transmission;

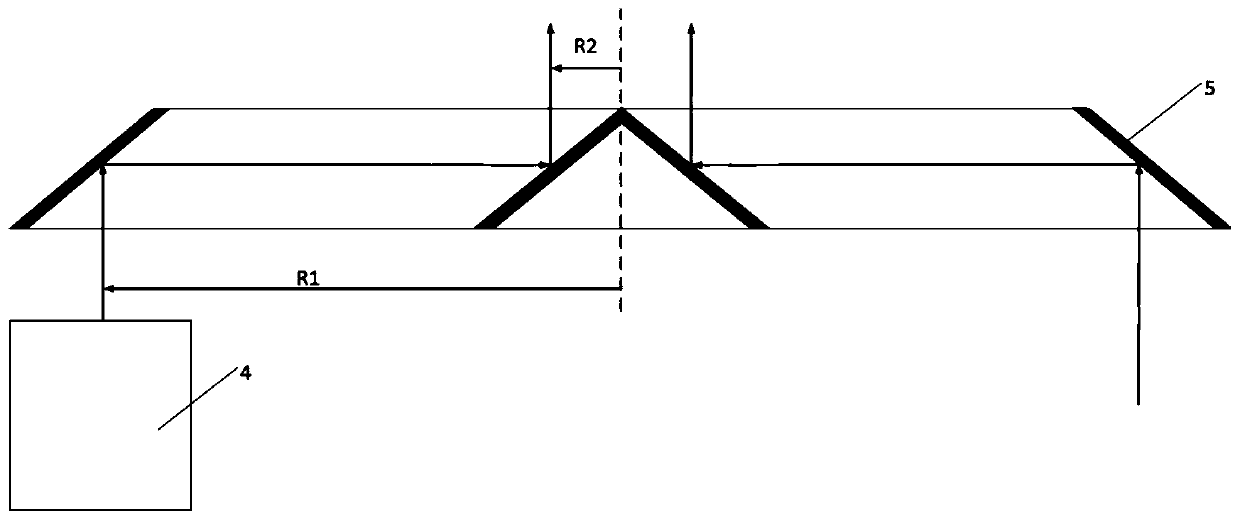

[0038] The transmitted parallel laser beam enters the frustum of the frustum from the bottom surface of the frustum of the cone (geometrically large circle), with the structural axis of the frustum of the cone as the center of the circle, and the radius of rotation of the beam is R1; the outer wall of the frustum of the cone has a total reflection coating , the light beam undergoes the first total reflecti...

Embodiment 2

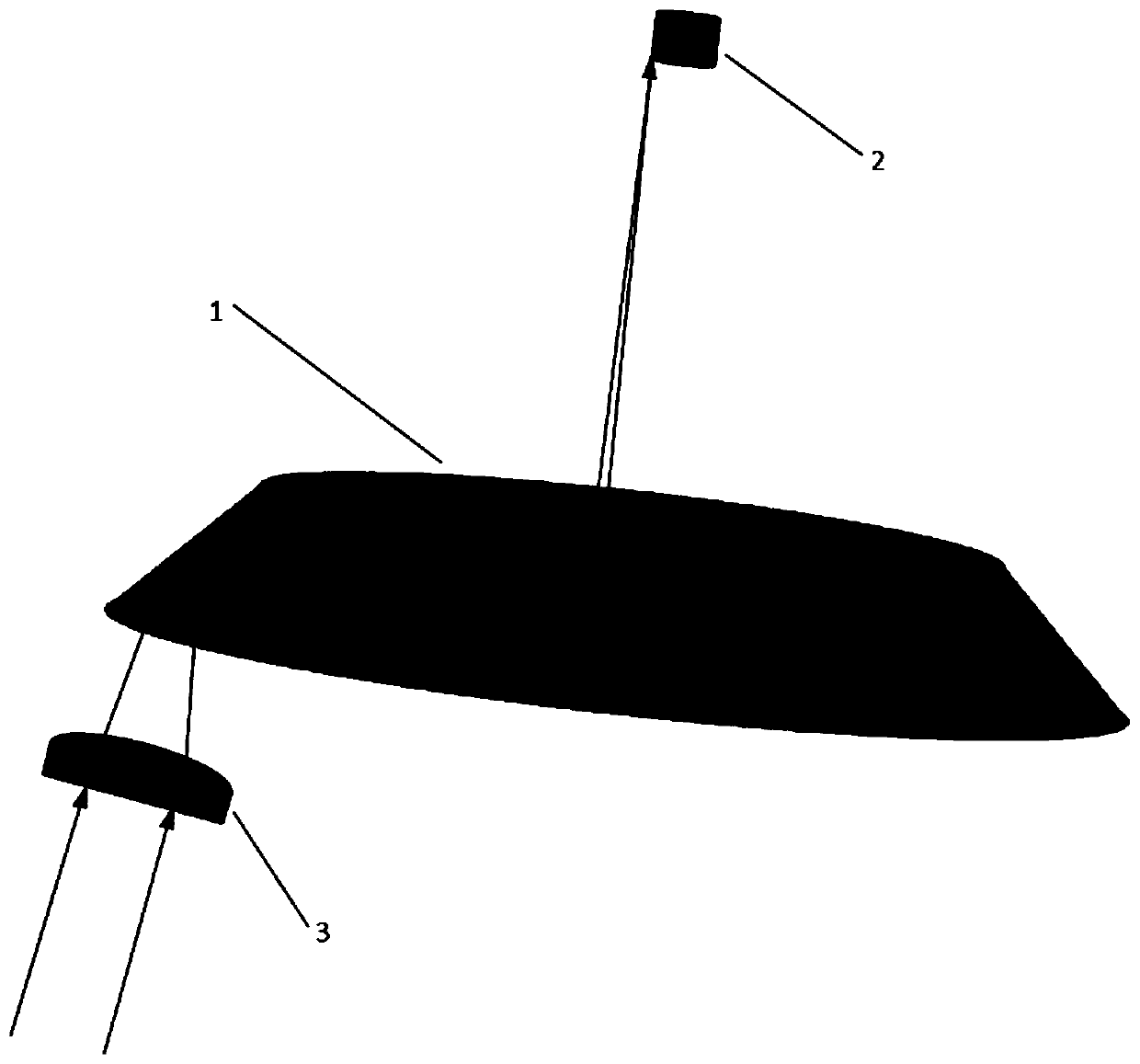

[0045] The high-precision laser processing device and system provided by this application can not only use parallel beams, but also use focused beams. The process of focusing beam materials is shown in the attached image 3 , attached Figure 4 and attached Image 6 shown.

[0046] First, the system control parameters are transmitted to the control system through the input signal, and the control system controls the laser to turn on and the system to move; the optical element is a combination of multiple sets of total reflection mirrors and focusing lenses. After the laser is turned on, the laser beam will use the optical element to achieve parallel beam transmission. converge with light;

[0047] The transmitted focused laser beam enters the frustum reflector from the bottom surface of the frustum reflector (geometrically large circular surface); total reflection;

[0048] The interior of the frustum mirror is coated with a total reflection coating inside the conical hole a...

Embodiment 3

[0054] The above-mentioned embodiment 1 and embodiment 2 are processing schemes for micro-scale structures. In addition, the material processing process for super-large-scale structures is as follows: Figure 5 and Image 6 shown.

[0055] First, the system control parameters are transmitted to the control system through the input signal, and the control system controls the laser to turn on and the system to move; the optical element is a combination of multiple sets of total reflection mirrors and focusing lenses. After the laser is turned on, the laser beam will use the optical element to achieve parallel beam transmission. converge with light;

[0056] The transmitted laser beam enters the conical frustum reflector from the top surface (geometric facet) of the conical frustum reflector;

[0057] The interior of the conical mirror is coated with a total reflection coating inside the conical hole at the axial position, and the light beam undergoes the first total reflection...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com