Wet and dry dual-use permanent magnetic separator

A dry and wet dual-purpose, magnetic separator technology, applied in magnetic separation, solid separation, chemical instruments and methods, etc., can solve problems such as increasing the floor space of the workshop, improve the separation magnetic field gradient, improve quality, structure, etc. Simple and compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

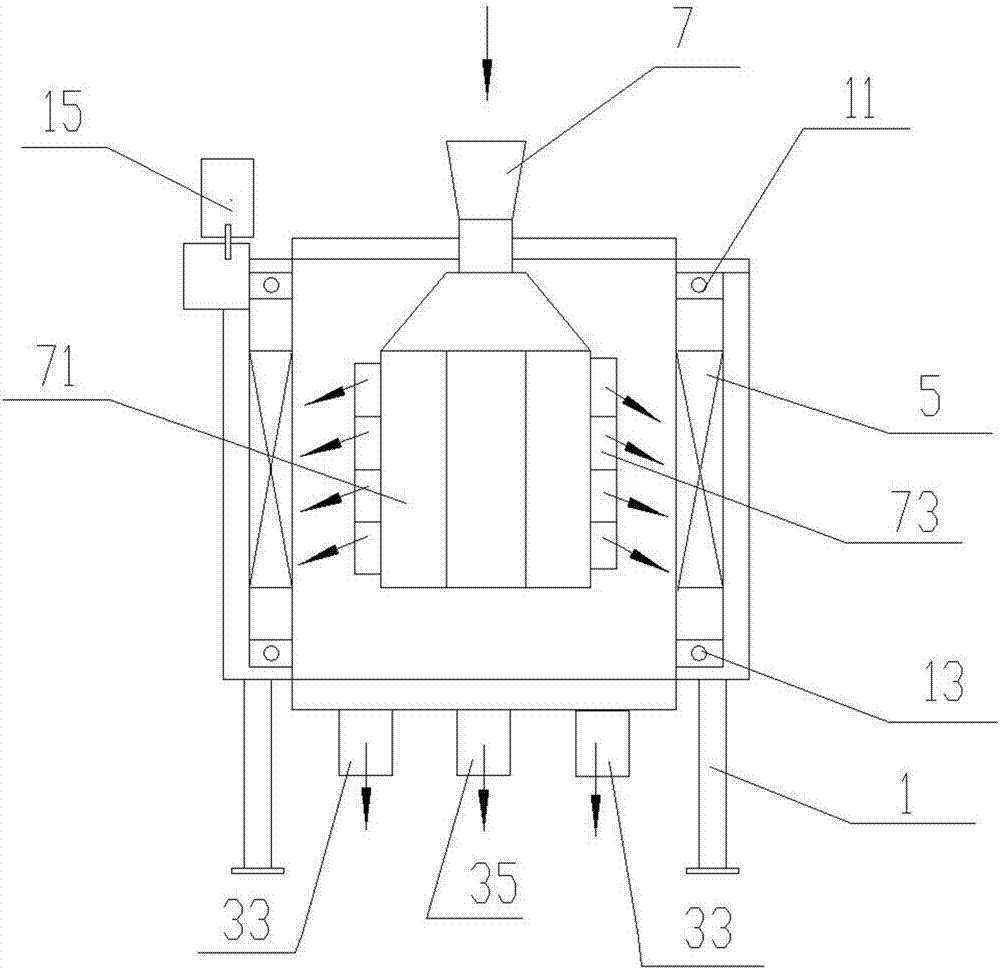

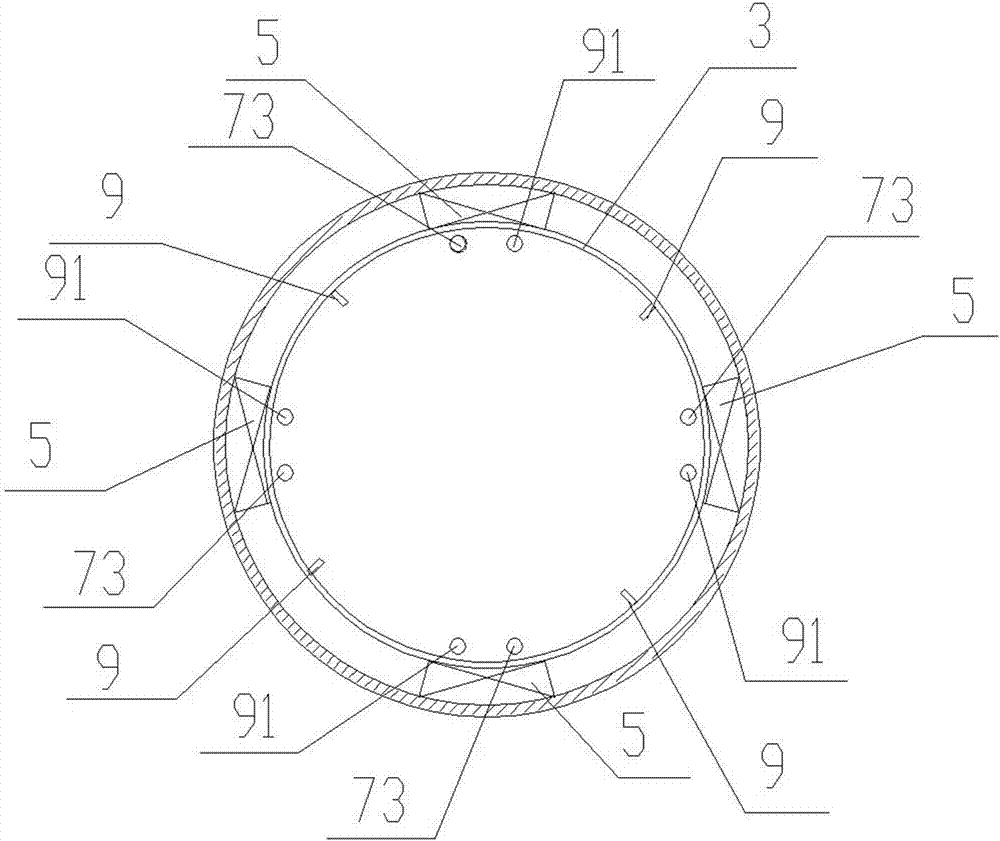

[0033] Such as figure 1 and figure 2 As shown, a wet and dry dual-purpose permanent magnet magnetic separator includes a frame 1, a magnetic separation cylinder 3, four magnetic systems 5, an active rotary device 11, a driven rotary support device 13, a drive device 15, a feeding Hole, feeding device 7, material distribution box 71, four groups of material distribution troughs 73, four non-magnetic product receiving hoppers 33, four magnetic receiving hoppers 35, four magnetic separation areas, slag separation screen, vibrator, four layers of magnetic accumulation Medium, four ore unloading bars 9, four rinsing water pipes 91 (slag separation screen and vibrator are not drawn among the figures).

[0034] Wherein, four magnetic systems 5 are evenly distributed in the circumferential direction on the inner wall of the frame 1 . The wrap angle of each magnetic system 5 is 15°-45°.

[0035] Specifically, the material of the magnetic system 5 is an electromagnet, or a low-tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com