Transparent flame-retardant masterbatch, transparent flame-retardant PET film and preparation method

A flame-retardant masterbatch and transparent technology, applied in the field of transparent flame-retardant masterbatch and PET film and preparation, can solve the problems of flame retardancy, light transmission and mechanical properties, etc., to increase the effective range, improve Compatibility, effect of improving transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

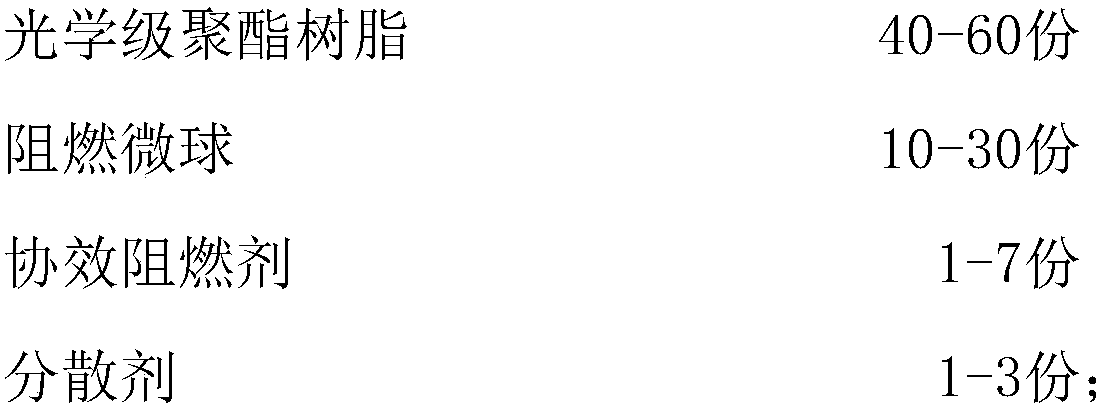

[0032] A transparent flame retardant masterbatch, comprising the following raw materials in parts by weight:

[0033]

[0034] The flame-retardant microsphere is a microsphere with a core-shell structure, the core of which is nano-red phosphorus, and the shell is microcrystalline cellulose.

[0035] Wherein, the preparation method of the flame retardant microspheres comprises the following steps:

[0036] A. At a temperature of 80°C, dissolve microcrystalline cellulose in 1-methyl 3-butylimidazolium chloride ionic liquid in a mass ratio of 7:100 to form a microcrystalline cellulose solution;

[0037] B, add nano-red phosphorus in the microcrystalline cellulose solution that step A obtains, after stirring, obtain suspension, the consumption of described nano-red phosphorus is 4wt% of suspension;

[0038] C. Electrostatically spraying the suspension obtained in step B to obtain the flame retardant microspheres.

[0039] Wherein, the particle size of the nano-red phosphorus ...

Embodiment 2

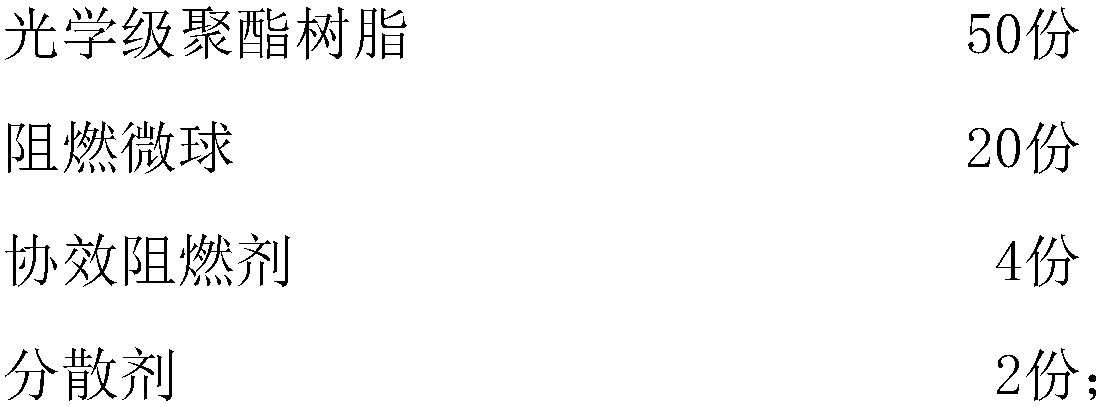

[0053] A transparent flame retardant masterbatch, comprising the following raw materials in parts by weight:

[0054]

[0055] The flame-retardant microsphere is a microsphere with a core-shell structure, the core of which is nano-red phosphorus, and the shell is microcrystalline cellulose.

[0056] Wherein, the preparation method of the flame retardant microspheres comprises the following steps:

[0057] A. At a temperature of 70°C, dissolve microcrystalline cellulose in 1-methyl 3-butylimidazolium chloride ionic liquid in a mass ratio of 4:100 to form a microcrystalline cellulose solution;

[0058] B, add nano-red phosphorus in the microcrystalline cellulose solution that step A obtains, after stirring, obtain suspension, the consumption of described nano-red phosphorus is 2wt% of suspension;

[0059] C. Electrostatically spraying the suspension obtained in step B to obtain the flame retardant microspheres.

[0060] Wherein, the particle size of the nano-red phosphorus is...

Embodiment 3

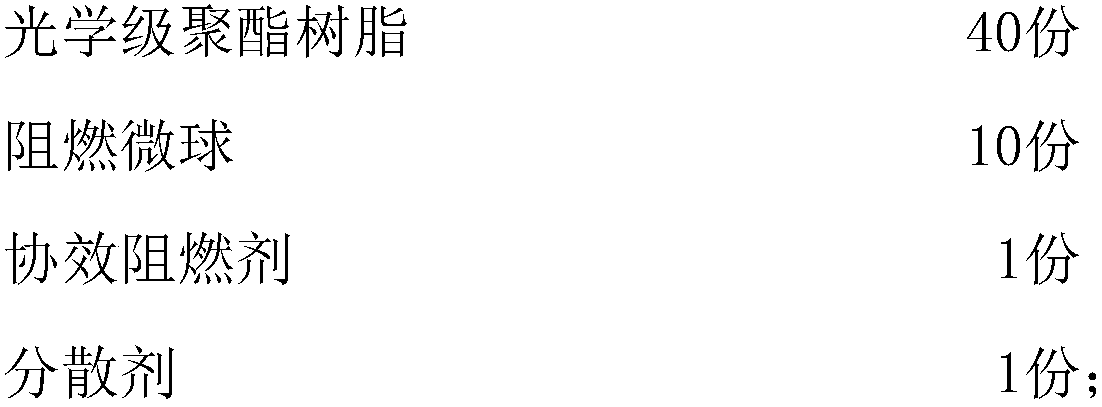

[0074] A transparent flame retardant masterbatch, comprising the following raw materials in parts by weight:

[0075]

[0076] The flame-retardant microsphere is a microsphere with a core-shell structure, the core of which is nano-red phosphorus, and the shell is microcrystalline cellulose.

[0077] Wherein, the preparation method of the flame retardant microspheres comprises the following steps:

[0078] A. At a temperature of 90°C, dissolve microcrystalline cellulose in 1-methyl 3-butylimidazolium chloride ionic liquid at a mass ratio of 10:100 to form a microcrystalline cellulose solution;

[0079] B, add nano-red phosphorus in the microcrystalline cellulose solution that step A obtains, after stirring, obtain suspension, the consumption of described nano-red phosphorus is 6wt% of suspension;

[0080] C. Electrostatically spraying the suspension obtained in step B to obtain the flame retardant microspheres.

[0081] Wherein, the particle size of the nano-red phosphorus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com