Preparation method of flexible pressure sensor based on regenerated collagen film

A pressure sensor and collagen technology, applied in the field of preparation of flexible pressure sensors, can solve the problems of lack of biocompatibility, environmental pollution, difficult to degrade, etc., and achieve the effect of loose environmental requirements, abundant sources, and simple production methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

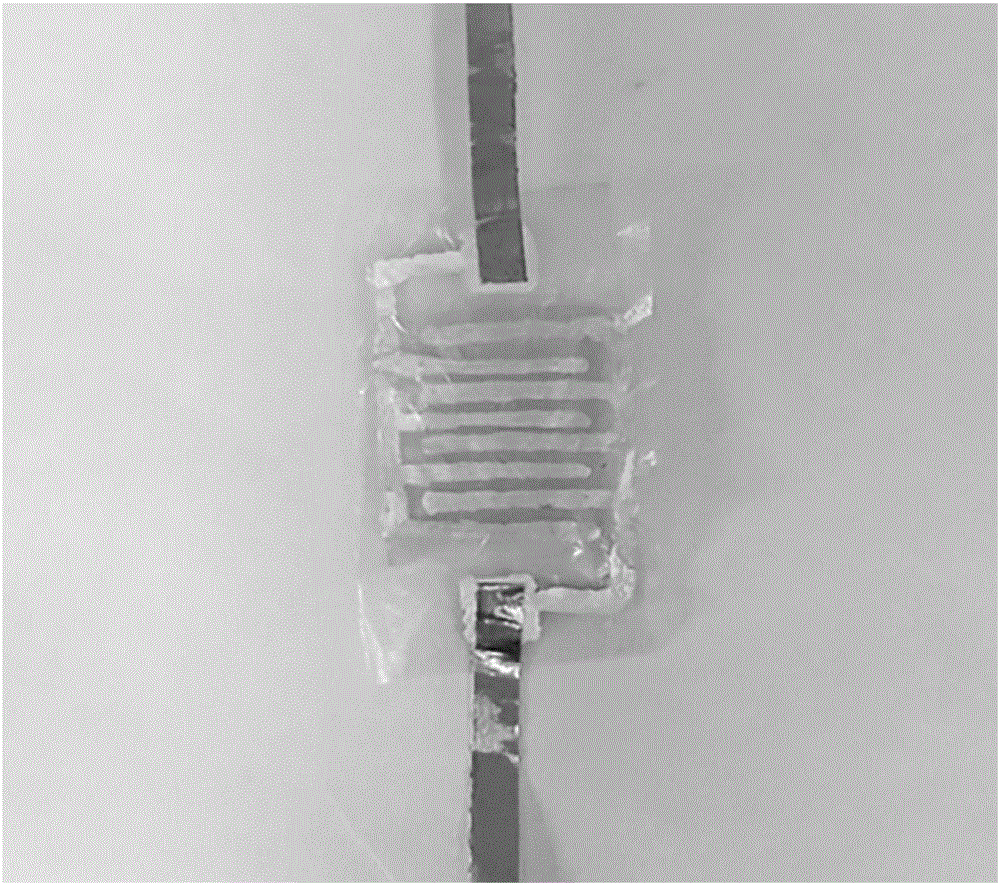

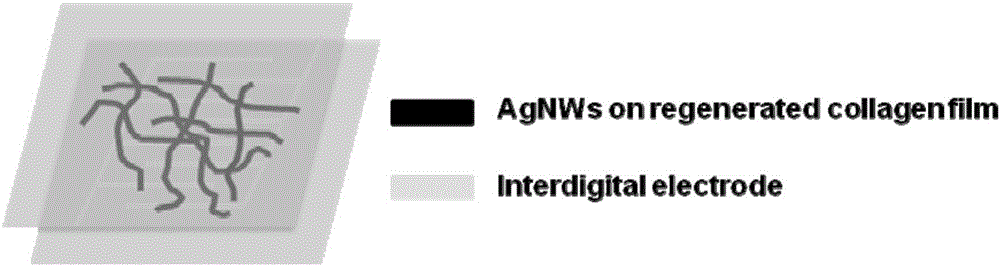

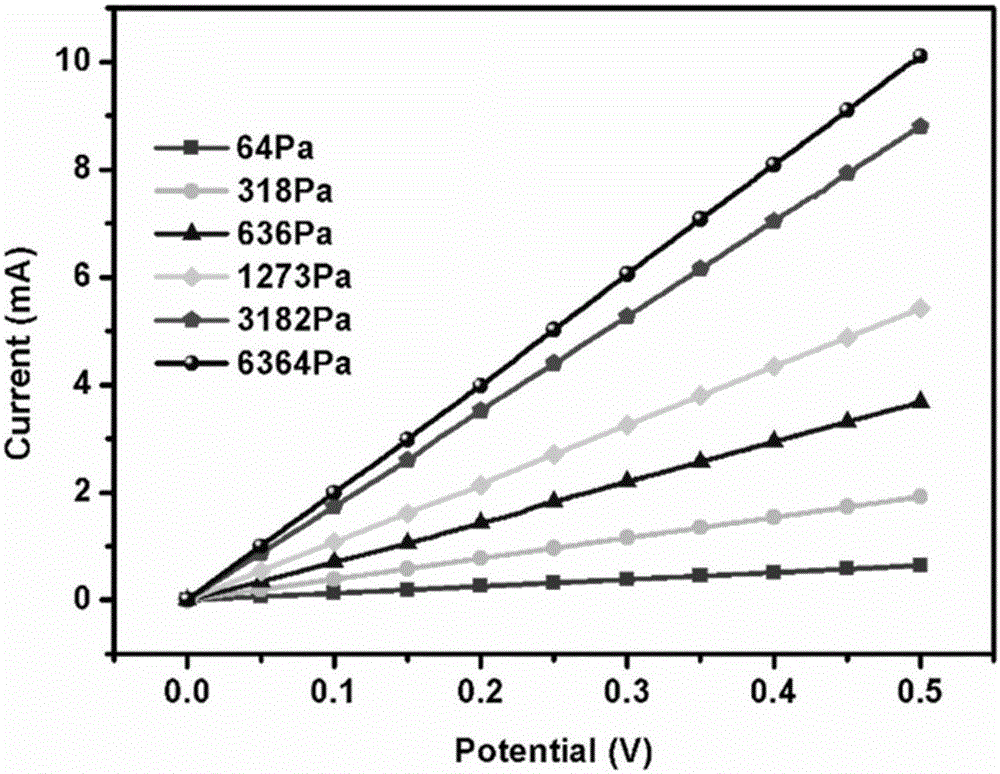

[0029] Weigh 5g of ionic liquid [BMIM]Cl into a 50ml round-bottomed flask, gradually add 300mg of kraft powder to dissolve to form a uniform and transparent solution, and spin-coat it on a glass sheet to form a uniform 3μm film, then place the glass sheet Stand and soak in deionized water, and replace the deionized water every 0.5h for a total of 3 times. The membrane was then taken out and dried to constant weight to obtain a regenerated collagen film. A layer of interdigitated electrodes is coated on one film by the template method, and a layer of silver nanowires is coated on the other film by spin coating, and then the two layers are contacted (the interdigitated electrodes and the silver nanowires are placed between two layers of collagen film), and press it tightly to complete the preparation of the flexible pressure sensor. The current-voltage test curves of the obtained flexible pressure sensor under different pressures are as follows: image 3 As shown, it is used i...

Embodiment 2

[0031] Weigh 5g of ionic liquid [EMIM]Ac in a 50ml round-bottomed flask, gradually add 500mg of crushed cowhide powder to dissolve, and form a uniform and transparent syrup-like solution, which is spin-coated on a glass sheet to form a uniform 1 μm film. Then the glass plate was soaked in deionized water, and the deionized water was replaced every 0.5 h, for a total of 3 times. The membrane was then taken out and dried to constant weight to obtain a regenerated collagen film. A dendritic electrode is coated on one film by template method, and carbon nanotubes are coated on the other film by spin coating method, and then the two layers are contacted (interdigitated electrodes and silver nanowires are placed on two sides). between the layers of collagen film) and pressed tightly, the preparation of the flexible pressure sensor is completed. Use it for pronunciation recognition test curves such as Figure 5 shown.

Embodiment 3

[0033] Weigh 5g of ionic liquid [BMIM]Cl in a 50ml round-bottomed flask, gradually add 1000mg of crushed cowhide powder to dissolve, and form a uniform and transparent syrup-like solution, which is then spin-coated on a glass sheet to form a uniform 5 μm film. Then the glass plate was soaked in deionized water, and the deionized water was replaced every 0.5 h, for a total of 3 times. The membrane was then taken out and dried to constant weight to obtain a regenerated collagen film. A dendritic electrode is coated on one film by template method, and carbon nanotubes are coated on the other film by spin coating method, and then the two layers are contacted (interdigitated electrodes and silver nanowires are placed on two sides). between the layers of collagen film) and pressed tightly, the preparation of the flexible pressure sensor is completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com