Biodegradable polylactic acid agricultural mulching film and processing technology thereof

An agricultural mulch film and biodegradable technology, which is applied in horticulture, application, plant protection, etc., can solve the problems of reducing the film’s permeability to visible light, poor transparency of visible light, and easy seepage stability, etc., and achieve good visible light transmission. Excellent UV shielding effect, enhanced effect of UV shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

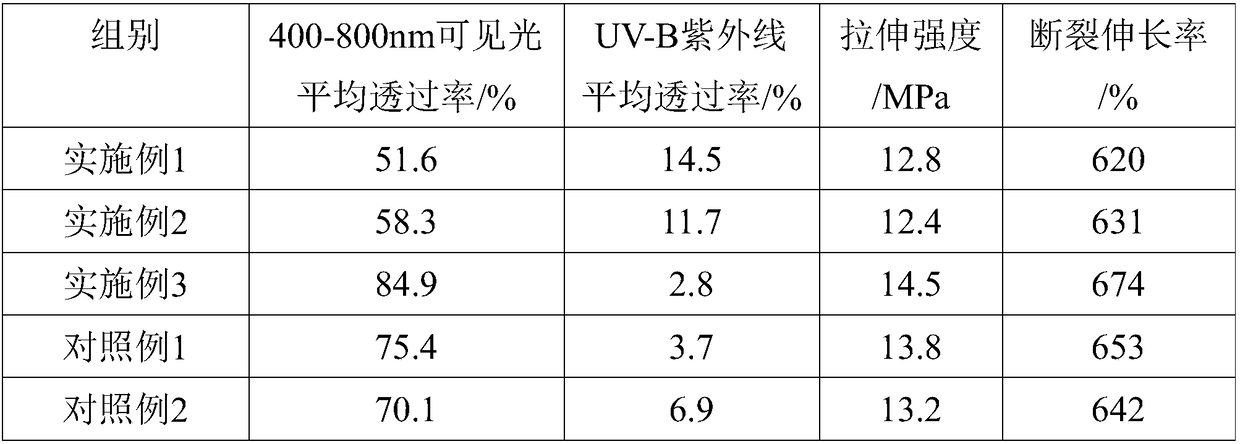

Examples

Embodiment 1

[0027] Processing of polylactic acid film:

[0028] (1) Dry 12kg polylactic acid resin in an oven at 80-90°C to constant weight;

[0029] (2) The dried polylactic acid resin and 1.5kg light calcium carbonate, 1kg polypropylene carbonate, 0.5kg carboxymethyl-β-cyclodextrin, 0.5kg PEG-60 hydrogenated castor oil, 0.3kg hexahydroxy Add methylmelamine hexamethyl ether, 0.2kg ultraviolet shielding agent nano-zinc oxide, and 0.08kg antioxidant 1010 into a high-speed mixer, and mix at a high speed of 300r / min for 5min to obtain the mixture;

[0030] (3) Add the above-mentioned mixture into a twin-screw extruder, and cool and granulate after melt extrusion to obtain polylactic acid masterbatch. The temperature in the first zone is 175-180°C, the temperature in the second zone is 180-185°C, The zone temperature is 185-190°C, the tenth zone temperature is 180-185°C, the residence time of the entire extrusion process is 5min, and the pressure is 50MPa;

[0031] (4) Add the prepared poly...

Embodiment 2

[0033] Processing of polylactic acid film:

[0034] (1) Dry 12kg polylactic acid resin in an oven at 80-90°C to constant weight;

[0035] (2) The dried polylactic acid resin and 1.5kg light calcium carbonate, 1kg polypropylene carbonate, 0.5kg carboxymethyl-β-cyclodextrin, 0.5kg PEG-60 hydrogenated castor oil, 0.3kg hexahydroxy Add methyl melamine hexamethyl ether, 0.2kg ultraviolet shielding agent nano-titanium dioxide, and 0.08kg antioxidant 1010 into a high-speed mixer, and mix at a high speed of 300r / min for 5min to obtain the mixture;

[0036] (3) Add the above-mentioned mixture into a twin-screw extruder, and cool and granulate after melt extrusion to obtain polylactic acid masterbatch. The temperature in the first zone is 175-180°C, the temperature in the second zone is 180-185°C, The zone temperature is 185-190°C, the tenth zone temperature is 180-185°C, the residence time of the entire extrusion process is 5min, and the pressure is 50MPa;

[0037] (4) Add the prepar...

Embodiment 3

[0039] Processing of polylactic acid film:

[0040] (1) Dry 12kg polylactic acid resin in an oven at 80-90°C to constant weight;

[0041] (2) The dried polylactic acid resin and 1.5kg light calcium carbonate, 1kg polypropylene carbonate, 0.5kg carboxymethyl-β-cyclodextrin, 0.5kg PEG-60 hydrogenated castor oil, 0.3kg hexahydroxy Methyl melamine hexamethyl ether, 0.2kg ultraviolet shielding agent, 0.08kg antioxidant 1010 were added in the high-speed mixer, and mixed at a high speed of 300r / min for 5min to obtain the mixture;

[0042] (3) Add the above-mentioned mixture into a twin-screw extruder, and cool and granulate after melt extrusion to obtain polylactic acid masterbatch. The temperature in the first zone is 175-180°C, the temperature in the second zone is 180-185°C, The zone temperature is 185-190°C, the tenth zone temperature is 180-185°C, the residence time of the entire extrusion process is 5min, and the pressure is 50MPa;

[0043] (4) Add the prepared polylactic aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com