Method for preparing RPC (Reactive Powder Concrete) trench cover plate of high-speed railway passenger-dedicated line

A technology of passenger dedicated line and ditch cover, which is applied in the field of building materials, can solve the problems of difficult RPC forming and processing, large plastic shrinkage of concrete, and lower RPC quality, and achieve high performance and economic benefits, easy forming and processing, and high safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

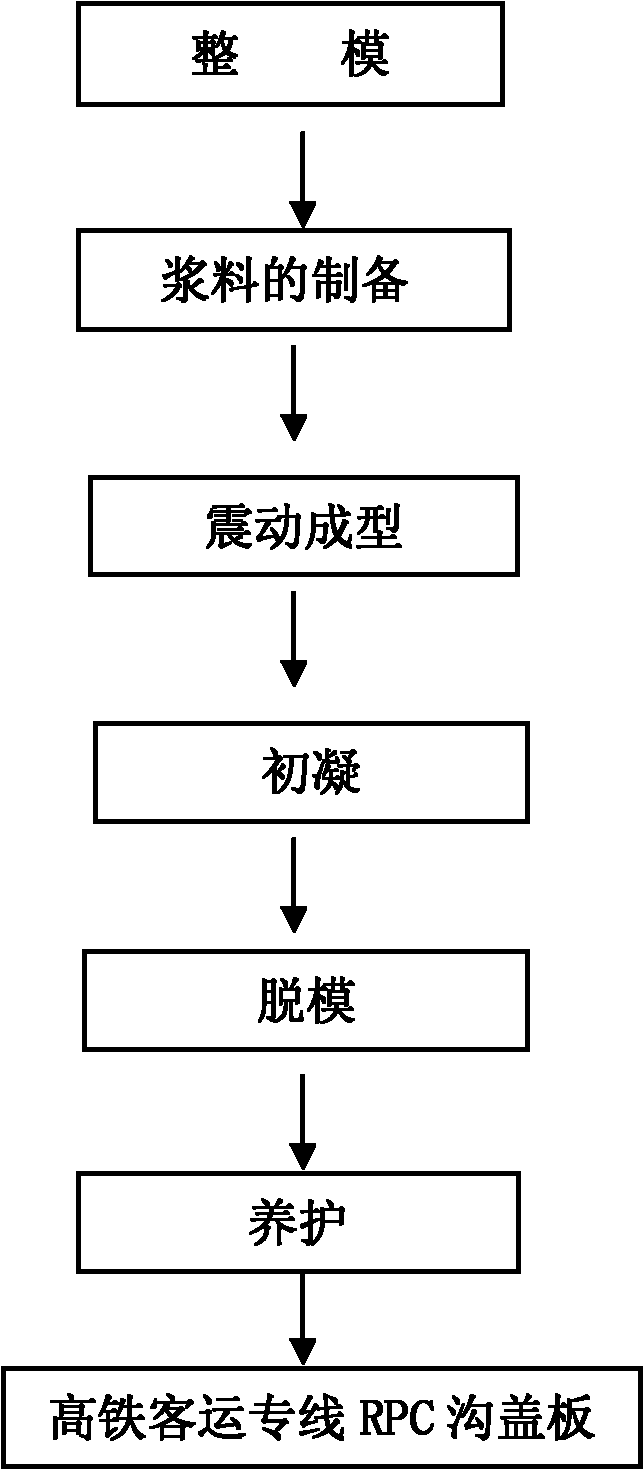

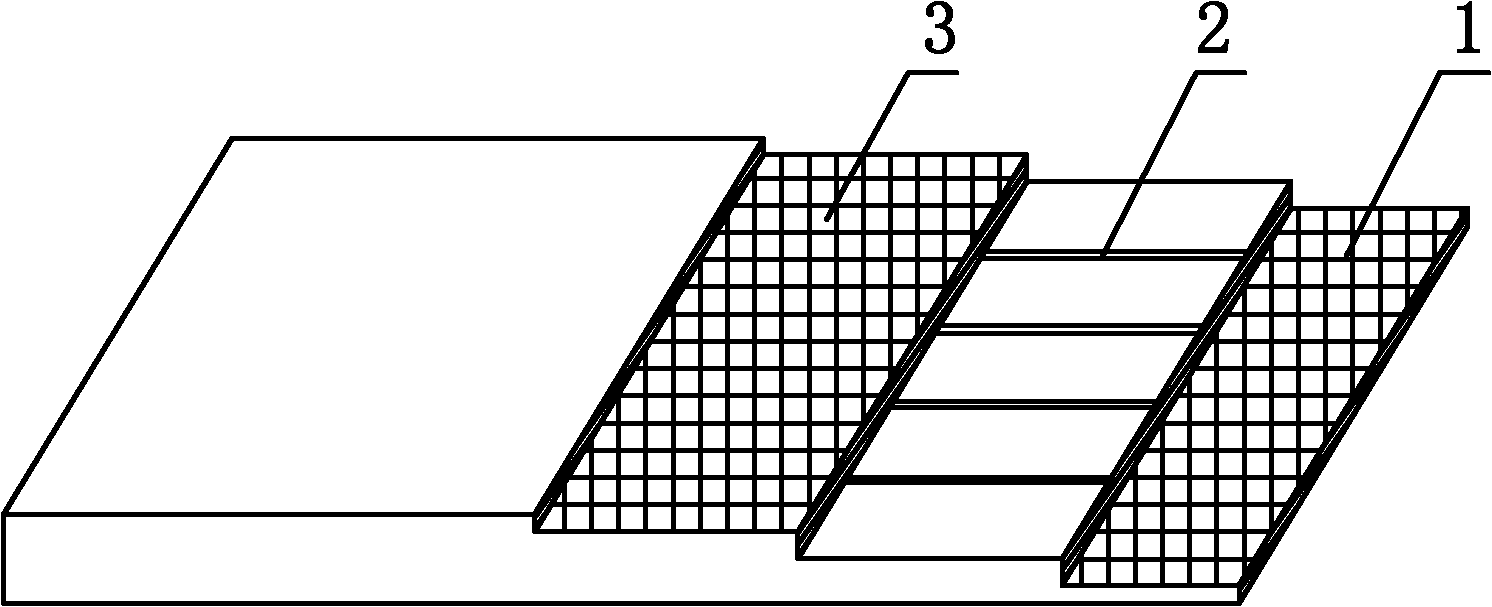

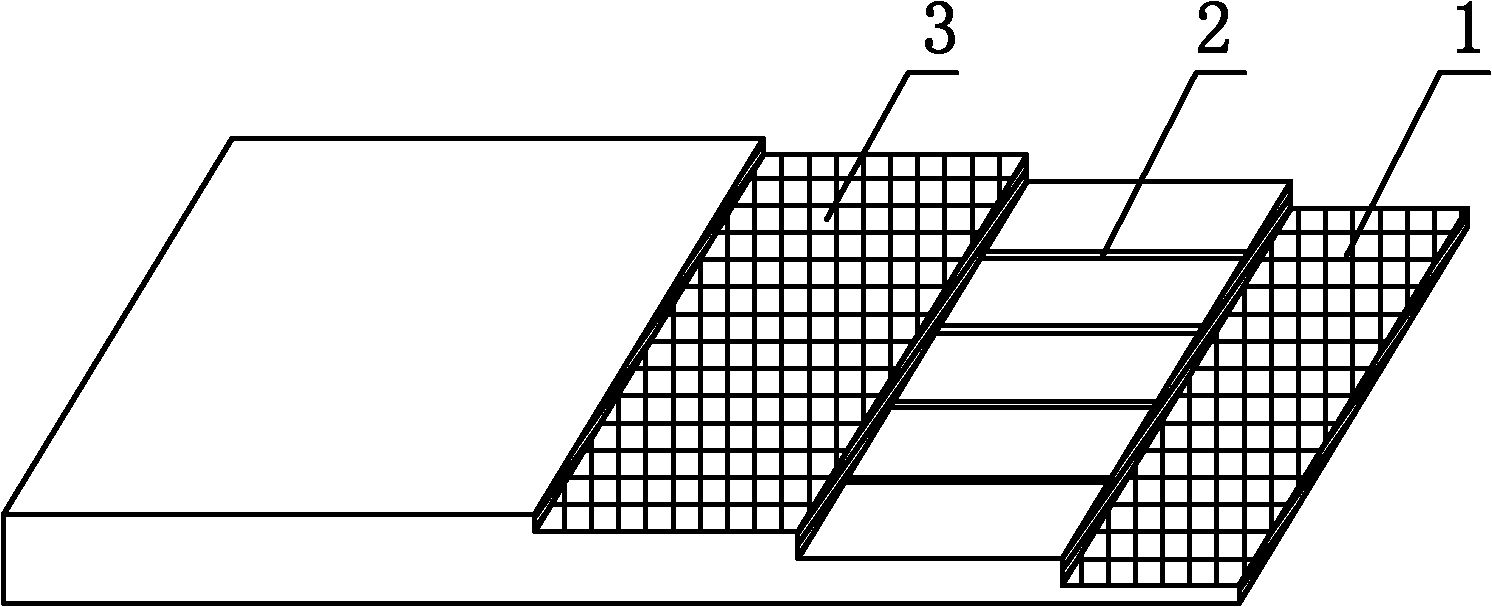

[0033] Such as figure 1 , figure 2 Shown, a kind of preparation method of high-speed rail passenger dedicated line RPC ditch cover plate, it comprises the steps:

[0034] 1), the whole mold: wipe the mold carefully with a rag, and then evenly apply a layer of organic wax, such as meguiars mirror giaze no 8 maximum mold release wax (Meguiars mirror giaze no 8 maximum mold release wax), and dry it with a dry silk cloth polishing;

[0035] 2) Preparation of the slurry: according to the parts by weight of each raw material: Portland cement: 100, silica fume: 10, quartz sand: 110, active mineral admixture (i.e. silica powder): 10, quartz powder : 35, water reducing agent: 2.5, water (pure water): 28 ~ 31, polypropylene fiber: 0.2, selection: Portland cement, silica fume, quartz sand, active mineral admixture, quartz powder, water reducing agent , water and polypropylene fiber, spare;

[0036] Put Portland cement, silica fume, quartz sand, active mineral admixture, quartz powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com