Patents

Literature

47results about How to "Easy to work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

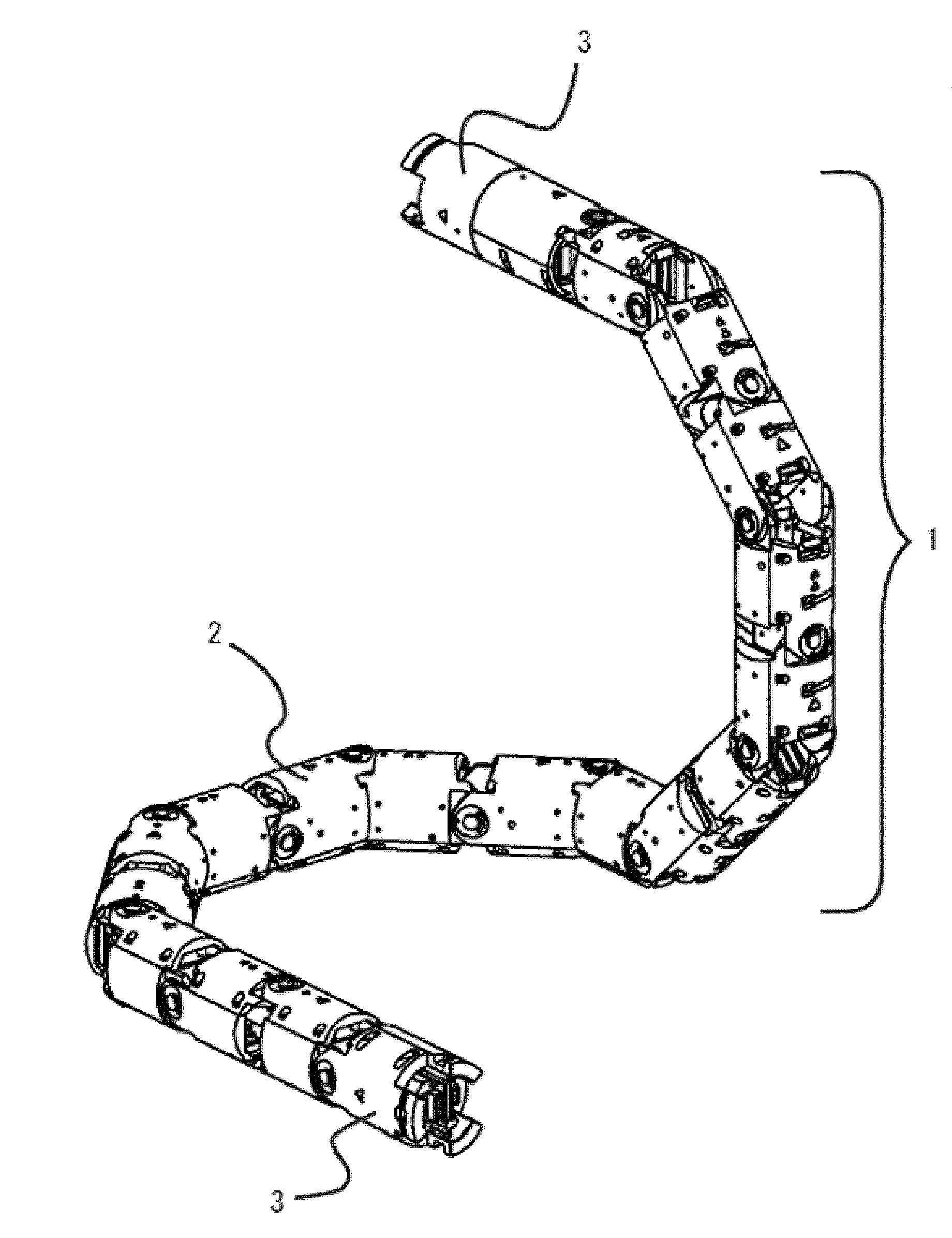

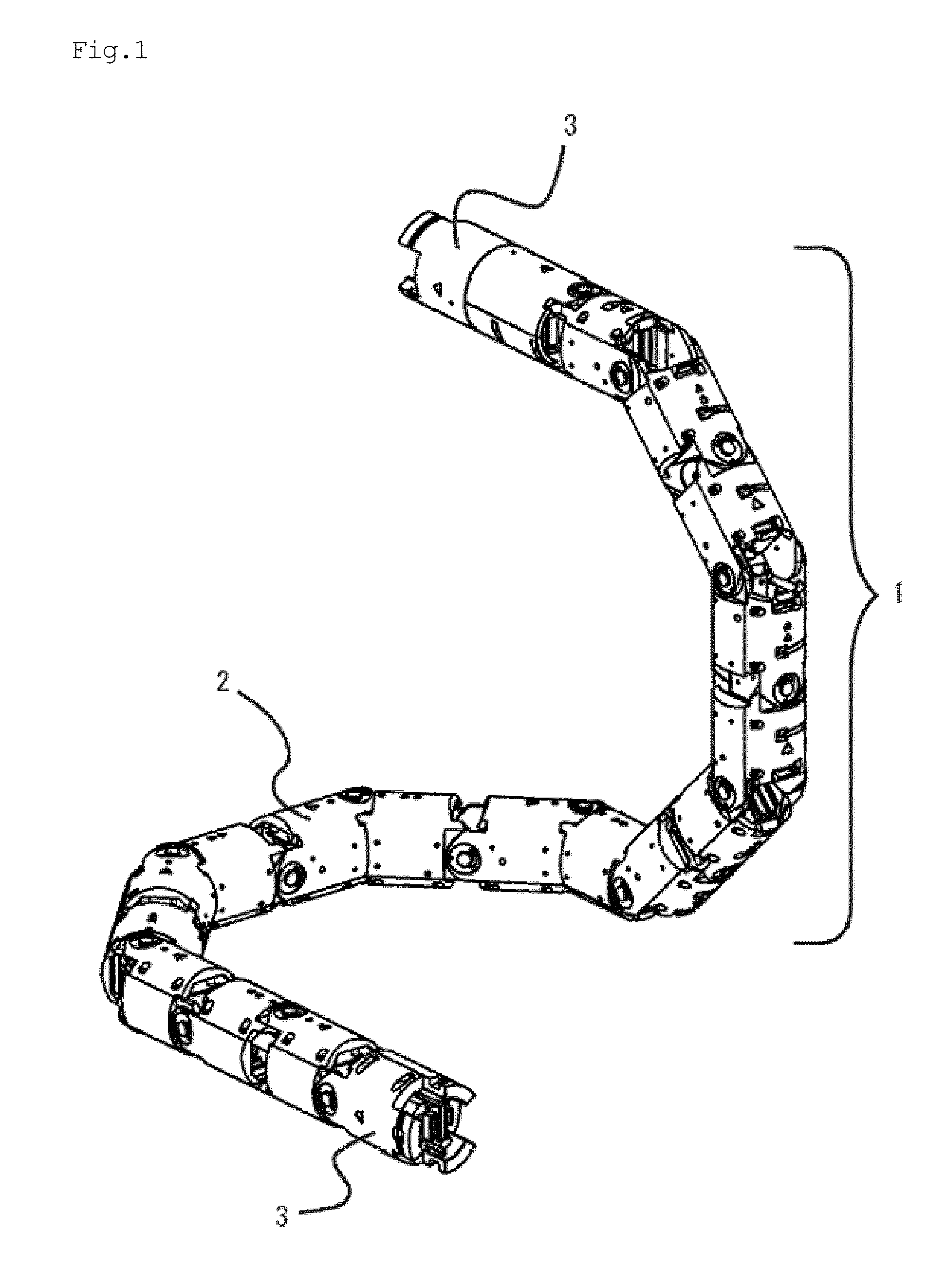

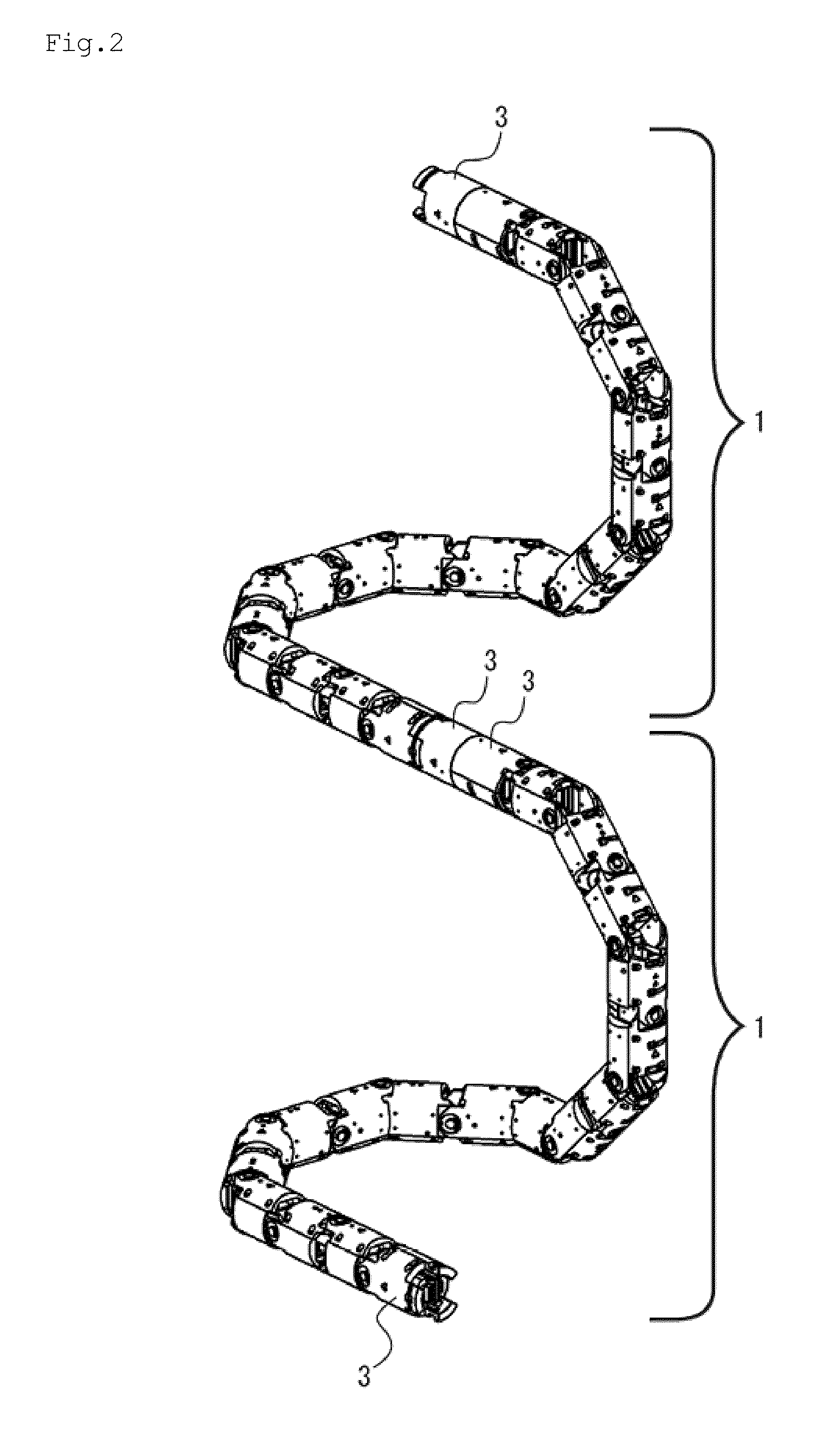

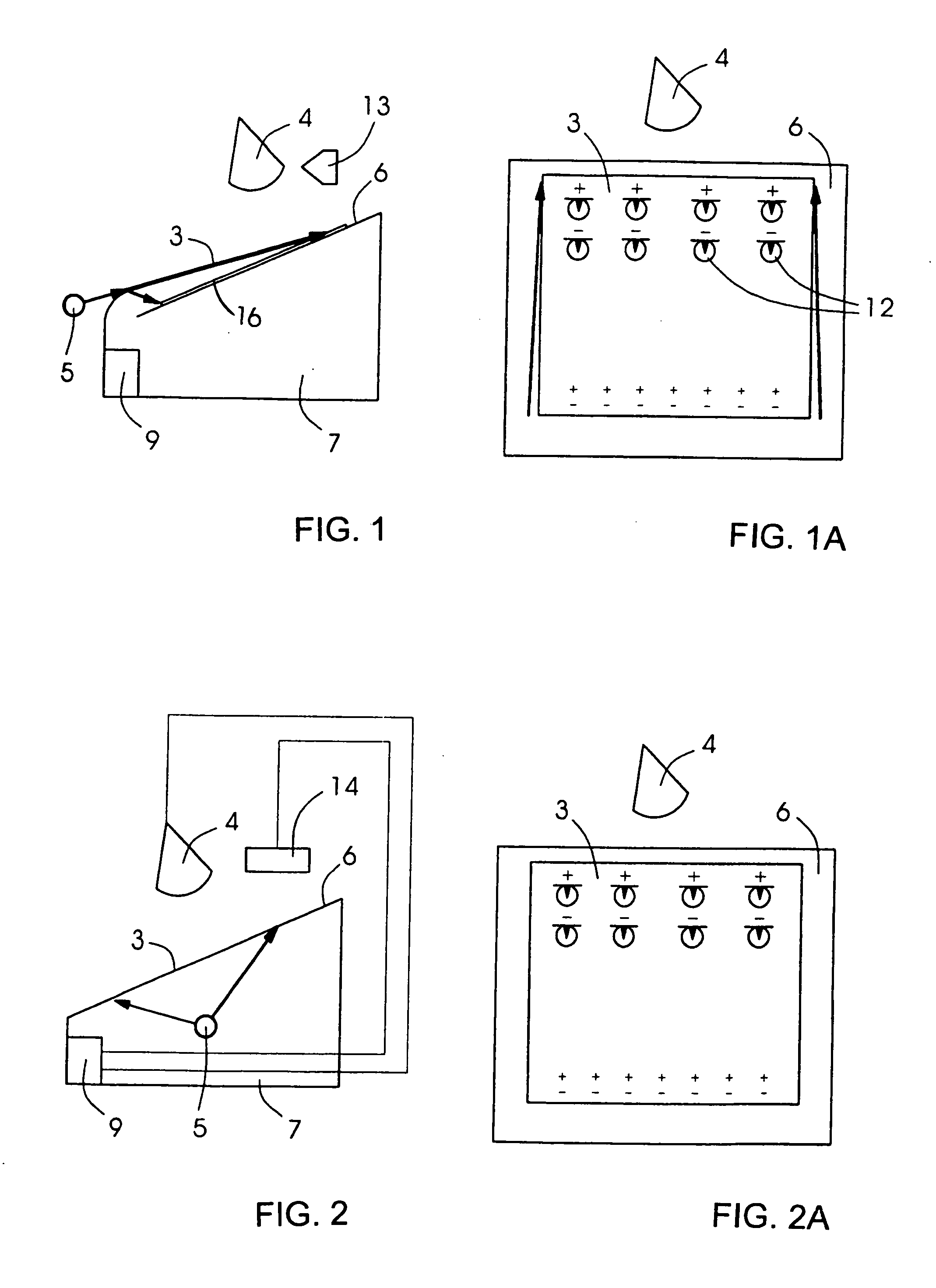

Multi-joint structure, mounting tool using it, system and human machine interface

InactiveUS20090248202A1Easy to workSimple working processProgramme-controlled manipulatorHollow article cleaningPotentiometerHuman–machine interface

To manually and optionally change length of a multi-joint structure, the multi-joint structure of the present invention is constituted so that variation detection sensor such as potentiometers is provided on connecting parts between each of joints, one or a plurality of the sensors are assumed to be a unit of the group, the signals of the sensors are captured by signal processing parts in each unit of the group, the parts between the signal processing parts are connected to the communication network and the signal processing part connected to the communication network computes and processes in accordance with signal data of the sensors, and it is constituted to output moving quantity and vector when the joints move to translate and rotate by detecting variation of the connecting parts between the joints at real time when shape of the multi-joint structure is deformed.

Owner:KYOKKO ELECTRIC

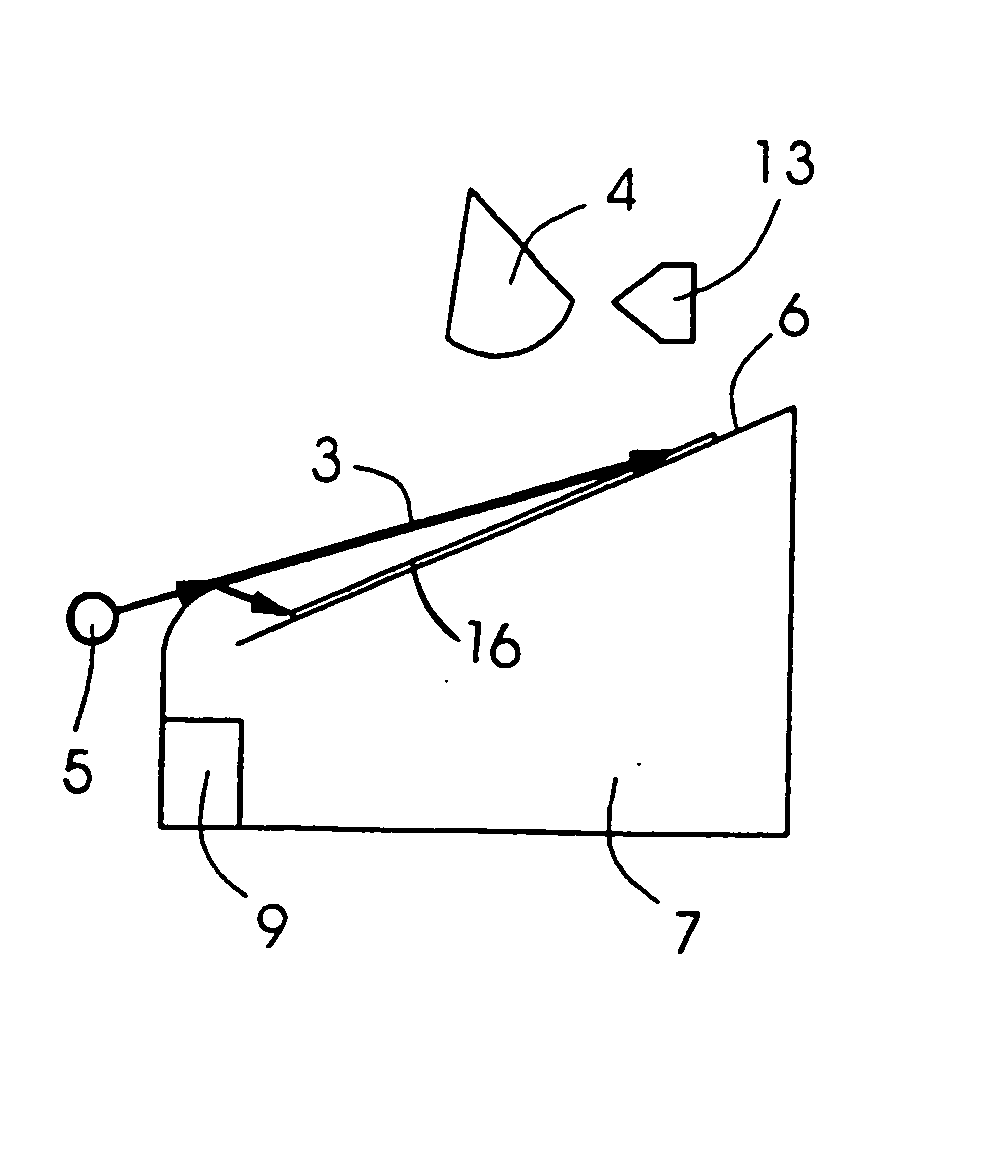

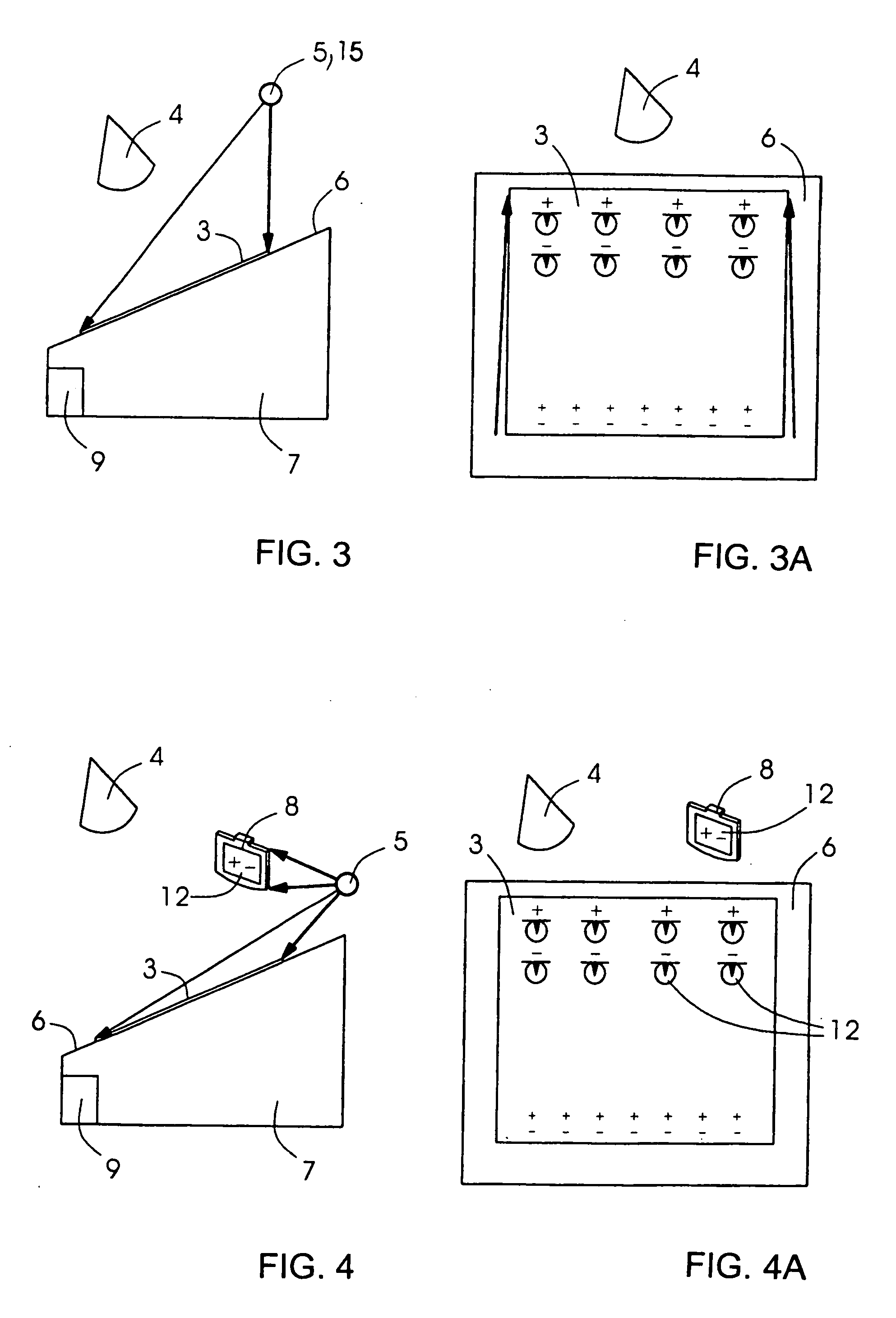

Projection-area dependent display/operating device

InactiveUS20050168700A1Easy to workUnnecessary reflection is avoidedInput/output for user-computer interactionComputer controlComputer engineering

Owner:HEIDELBERGER DRUCKMASHINEN AG

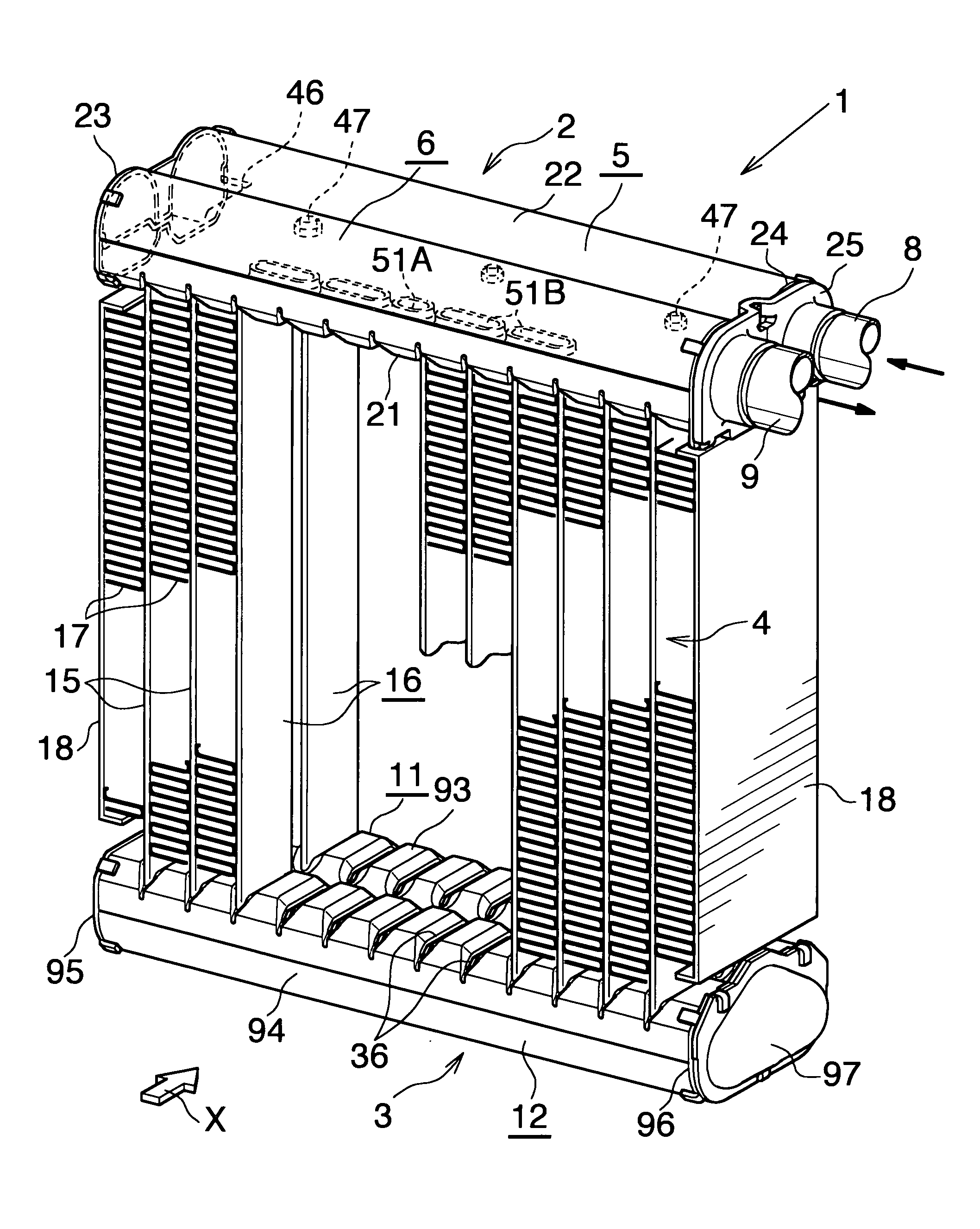

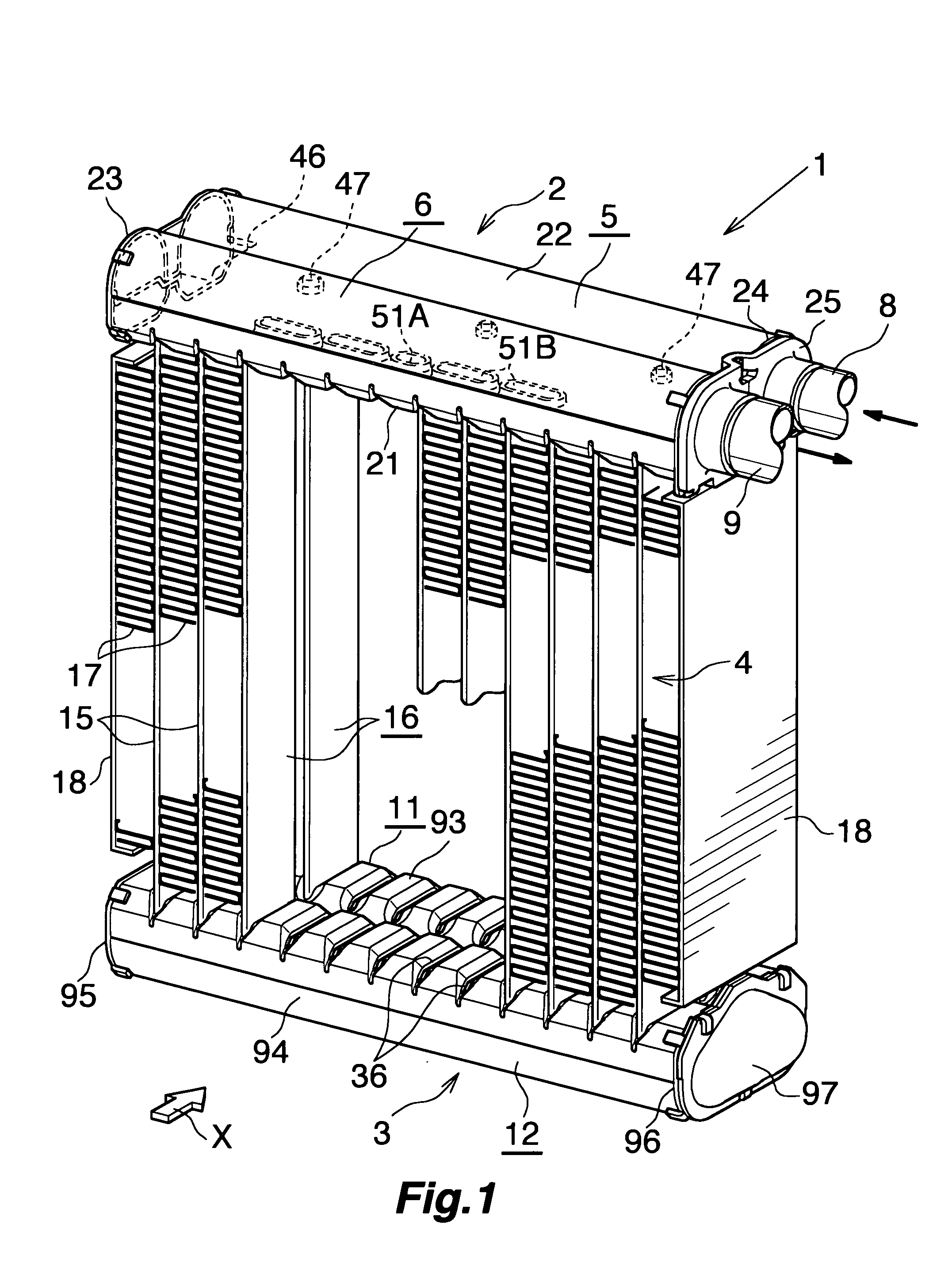

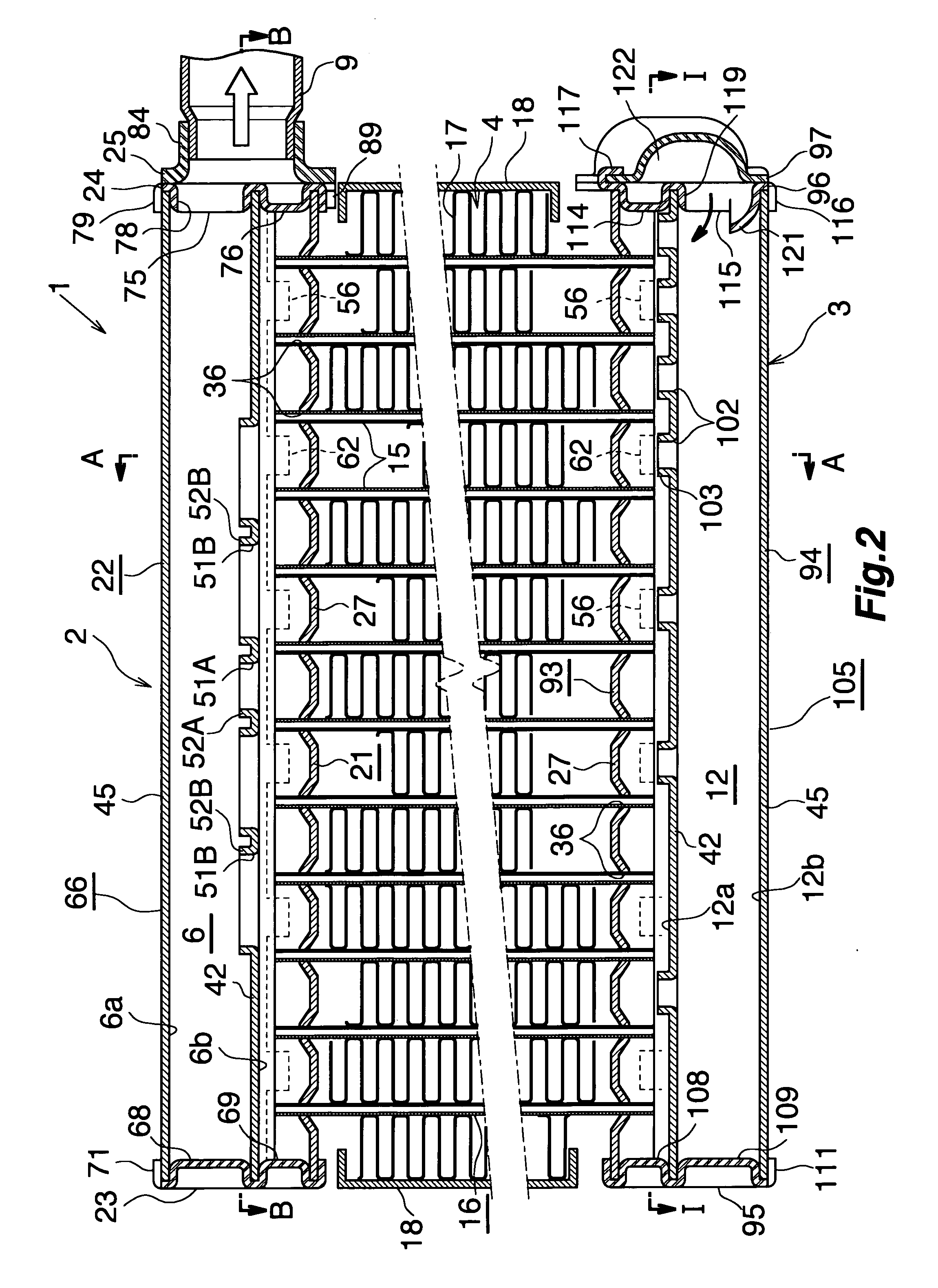

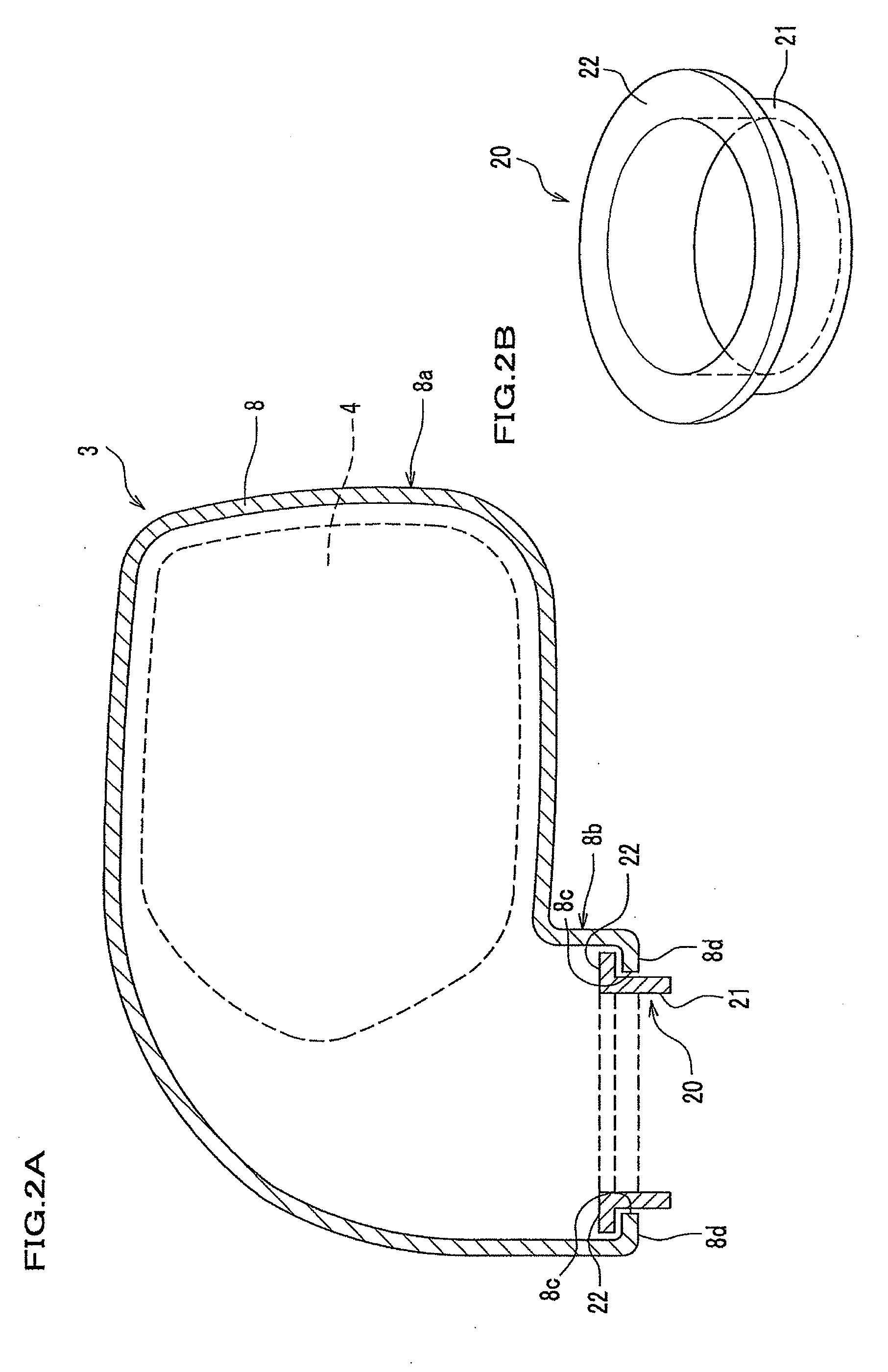

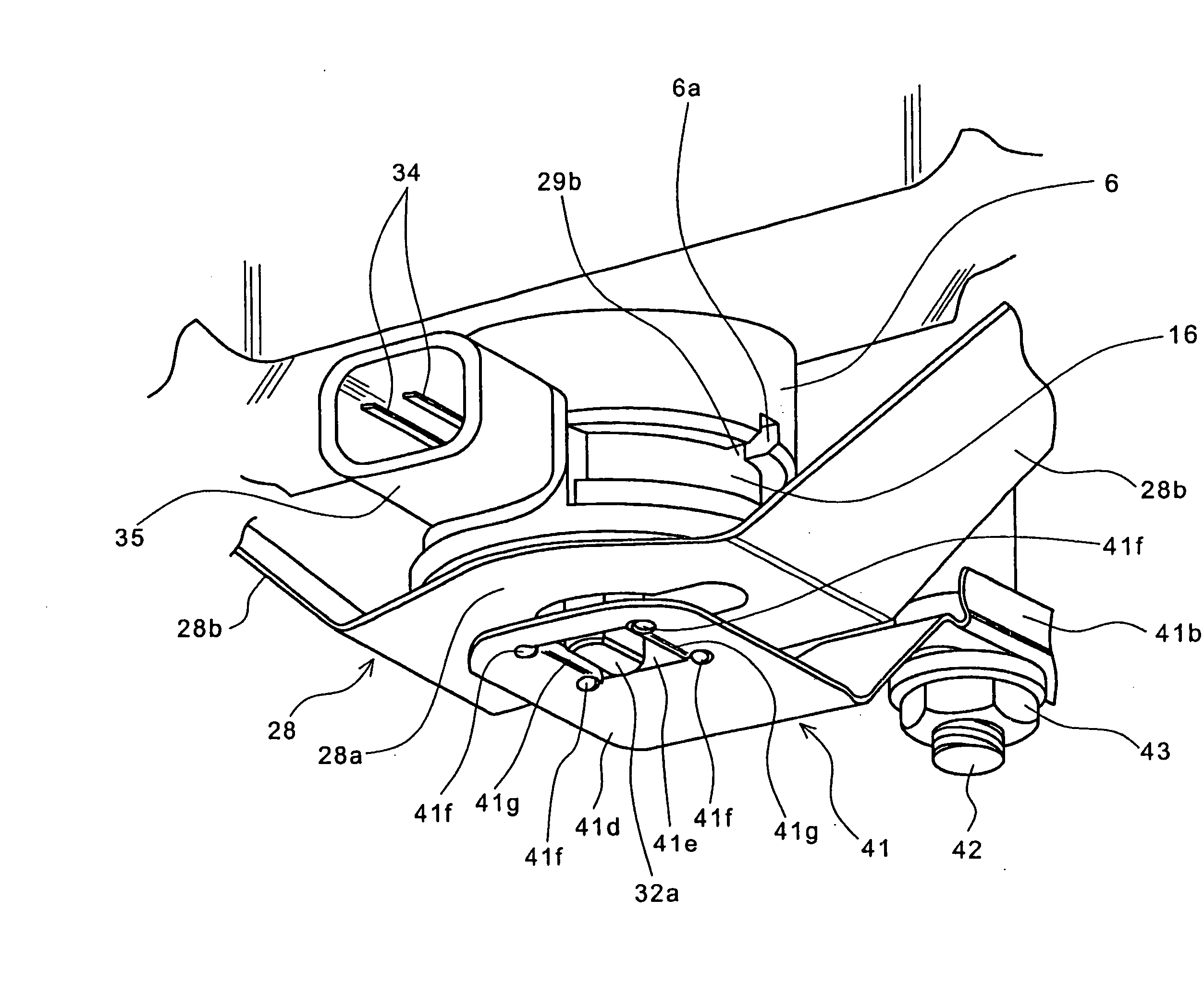

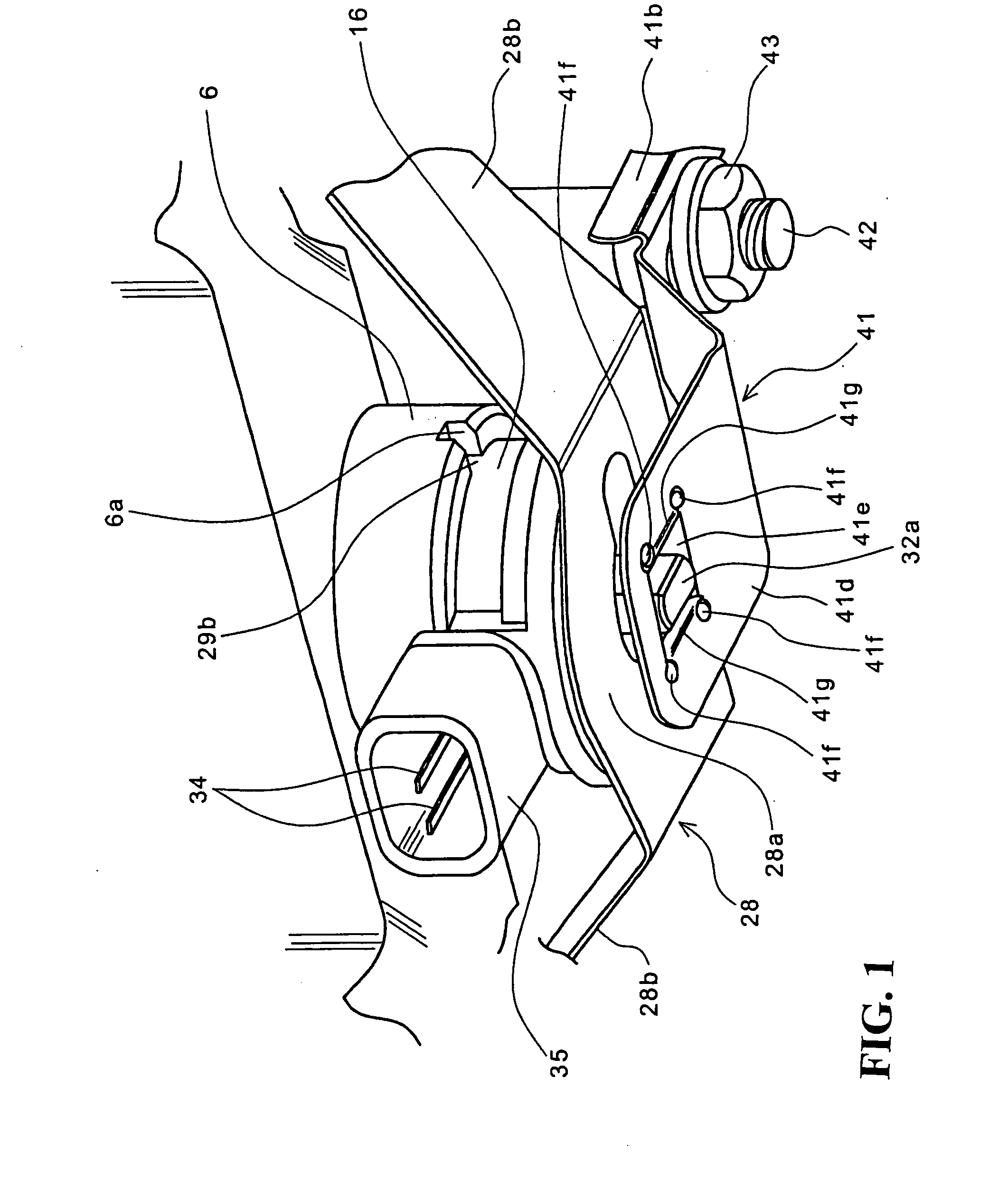

Heat exchanger

InactiveUS20090236086A1Decrease number of componentEasy to workEvaporators/condensersStationary conduit assembliesEvaporatorEngineering

An evaporator 1 is configured such that two heat exchange tube groups 16, each composed of a plurality of heat exchange tubes 15, are provided between a pair of header tanks 2, 3, while being separated from each other in a front-rear direction. Each of the header tanks 2, 3 includes two header sections 5, 6, 11, 12. Each header tank 2, 3 includes a first member 21, 93 to which the heat exchange tubes 15 are connected, and a second member 22, 94 which is joined to the first member 21, 93 and covers the side of the first member 21, 93 opposite the heat exchange tubes 15. Partition portions 41, 42 for dividing the interiors of the header section 5, 6, 11, 12 into upper and lower spaces 5a, 5b, 6a, 6b are provided on the second member 22, 94 of the header tank 2, 3. Through holes 47, 51A, 101, 102 for establishing communication between the upper and lower spaces 5a, 5b, 6a, 6b of the header section 5, 6, 11, 12 are formed in the partition portions 41, 42. The second member 22, 94 is formed by bending a metal plate. This evaporator 1 requires a reduced number of components and facilitates production work.

Owner:KEIHIN THERMAL TECH CORP

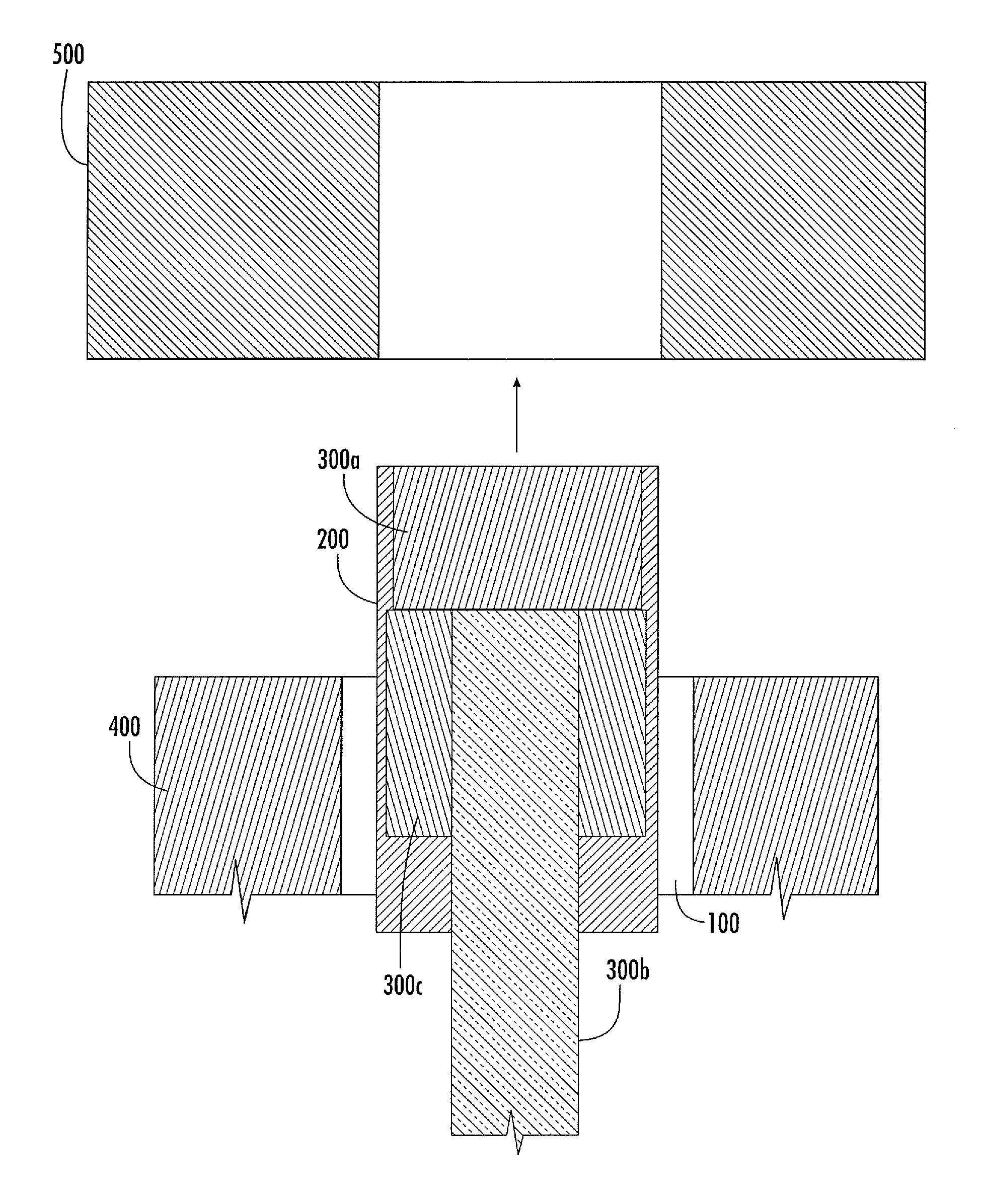

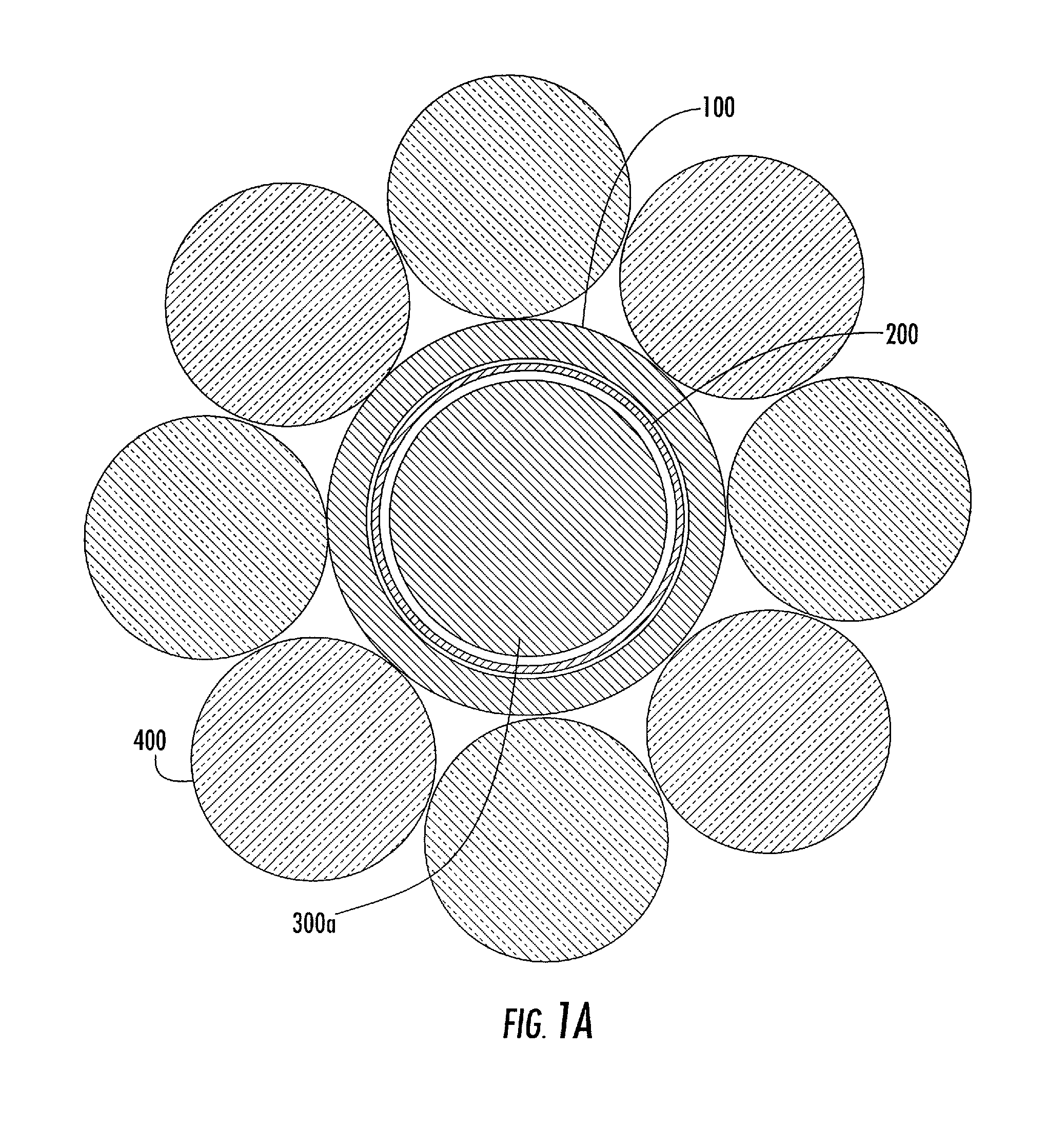

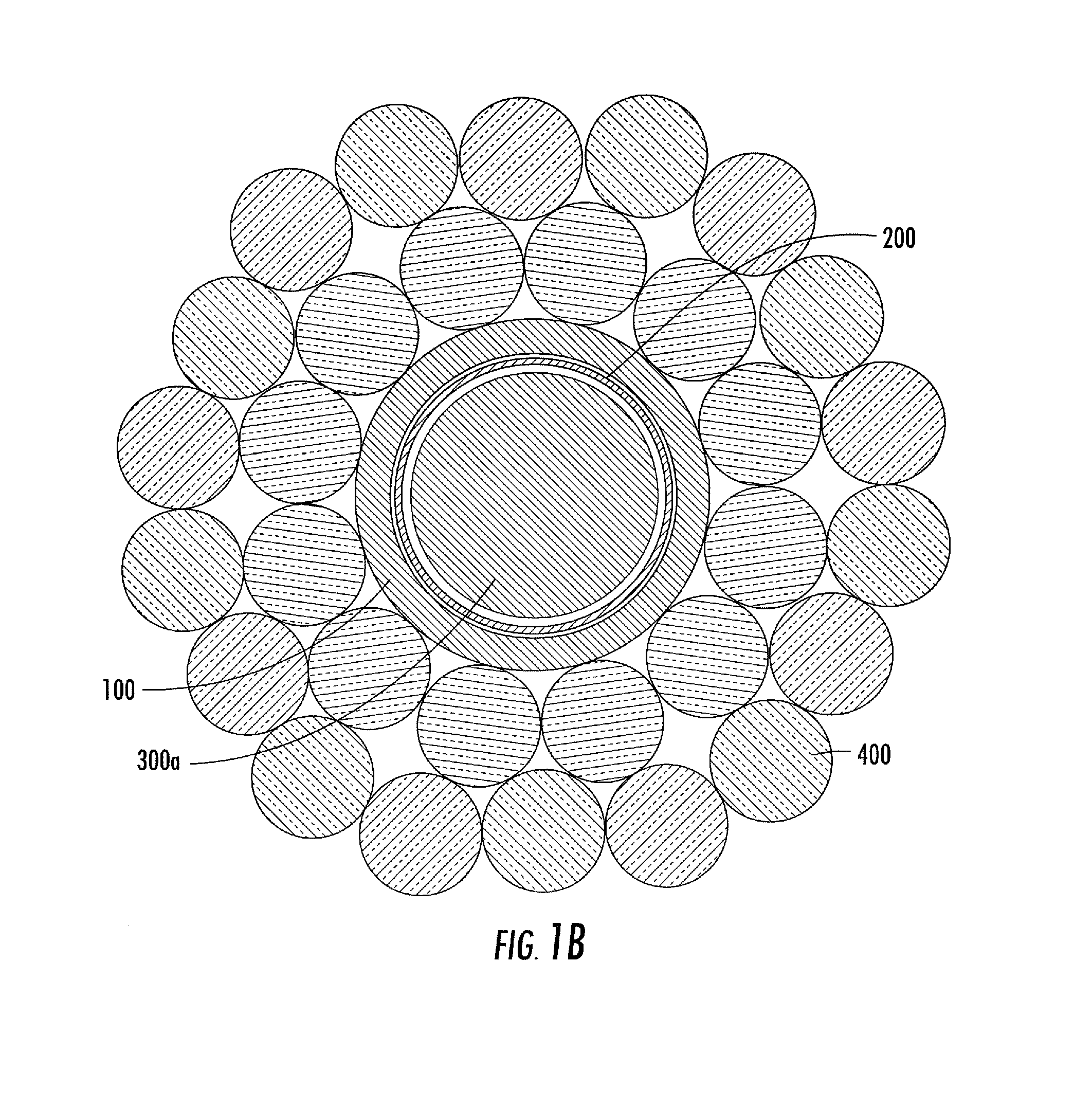

Filtered fiber optic probe

ActiveUS20120236303A1Easy to workSimple working processRadiation pyrometryBundled fibre light guideEngineeringFiber

The invention provides improved multi-fiber, fiber optic probe assemblies in which the component parts are adapted for rapid assembly with precise alignment. Some embodiments are adapted to illuminate and collect light from a sample at a particular depth while minimizing interference arising from within the probe assembly itself. Also provided are methods for manufacturing the probe assemblies and optical apparatuses including the probe assemblies.

Owner:CAPTAIN JRT

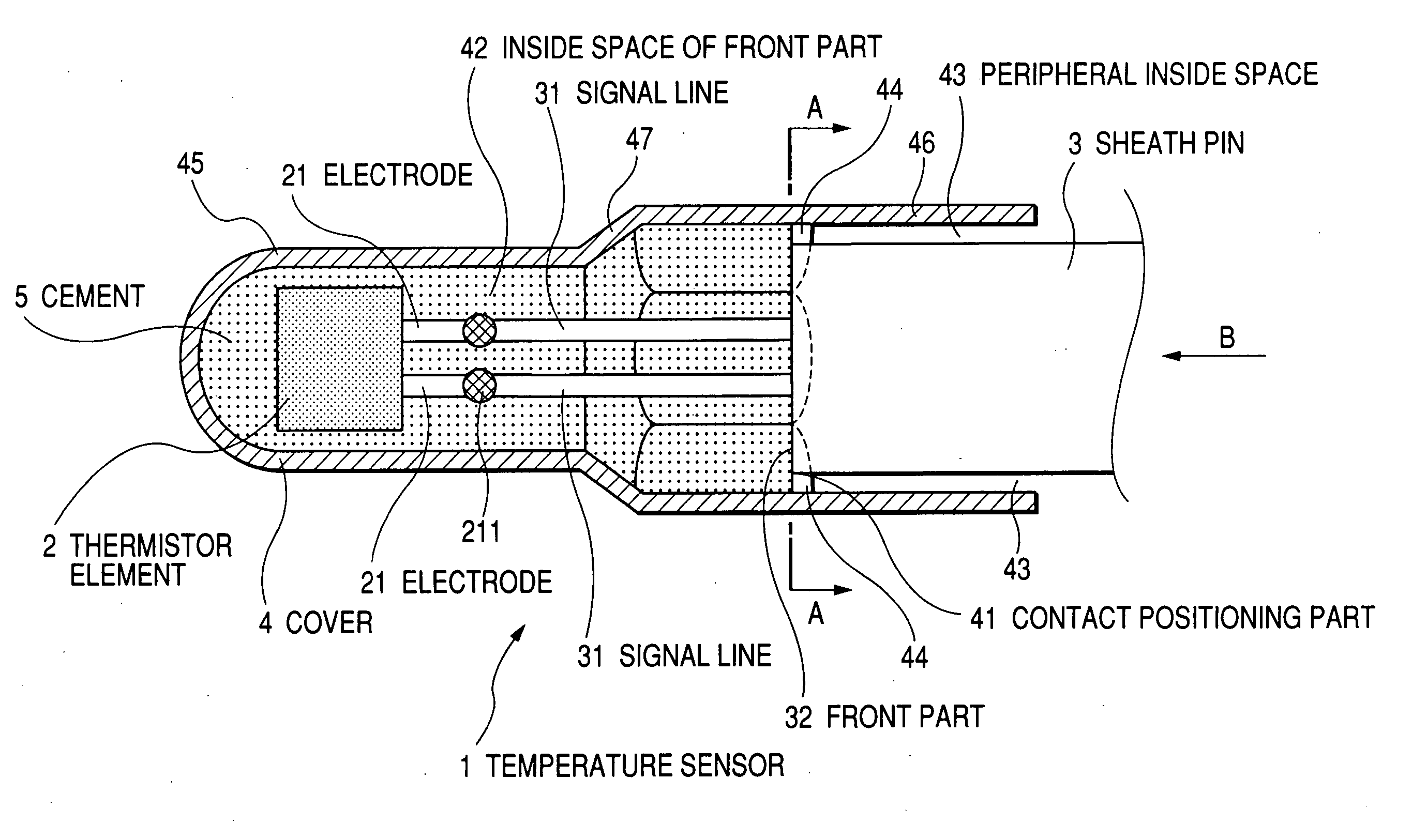

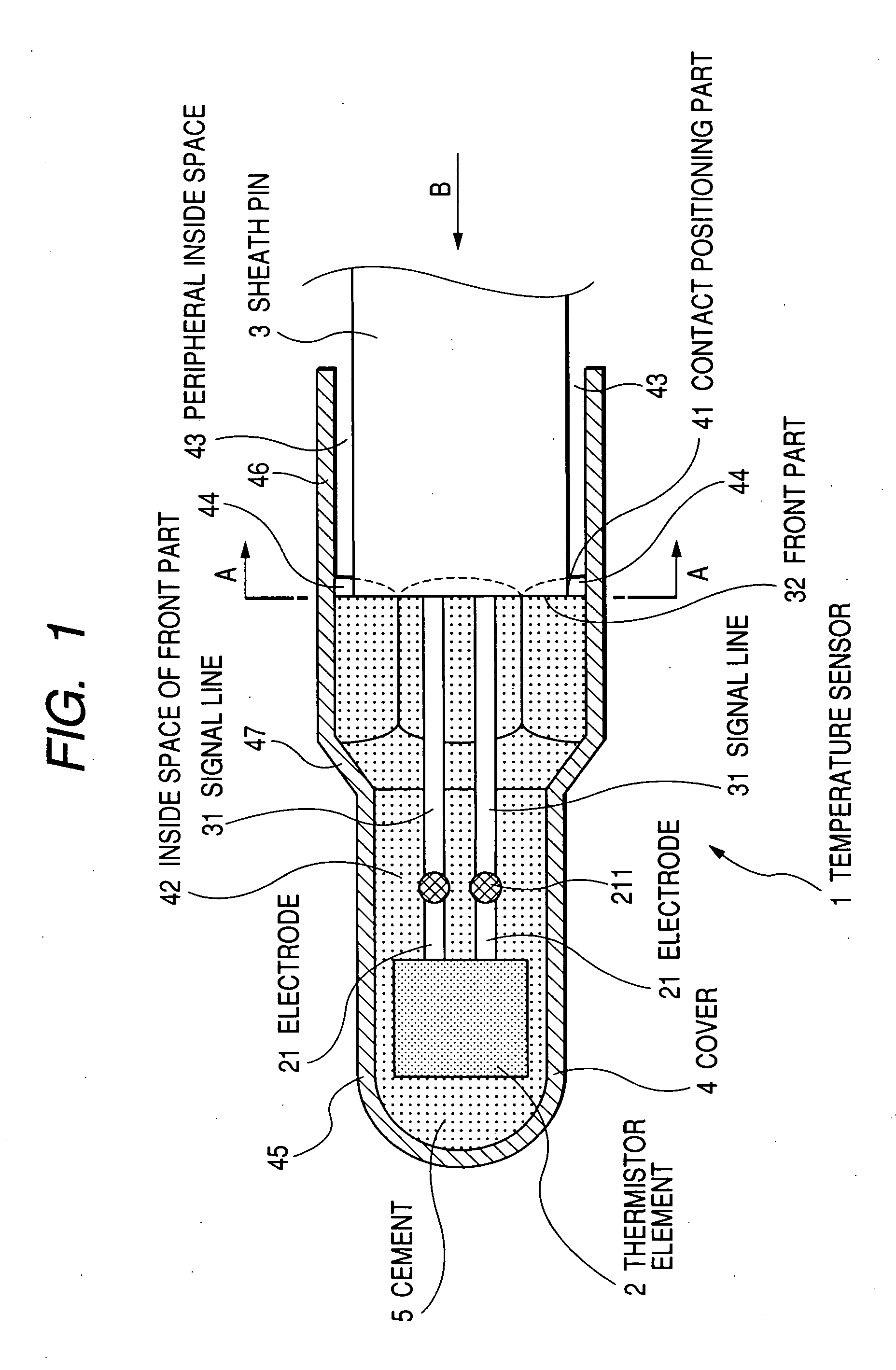

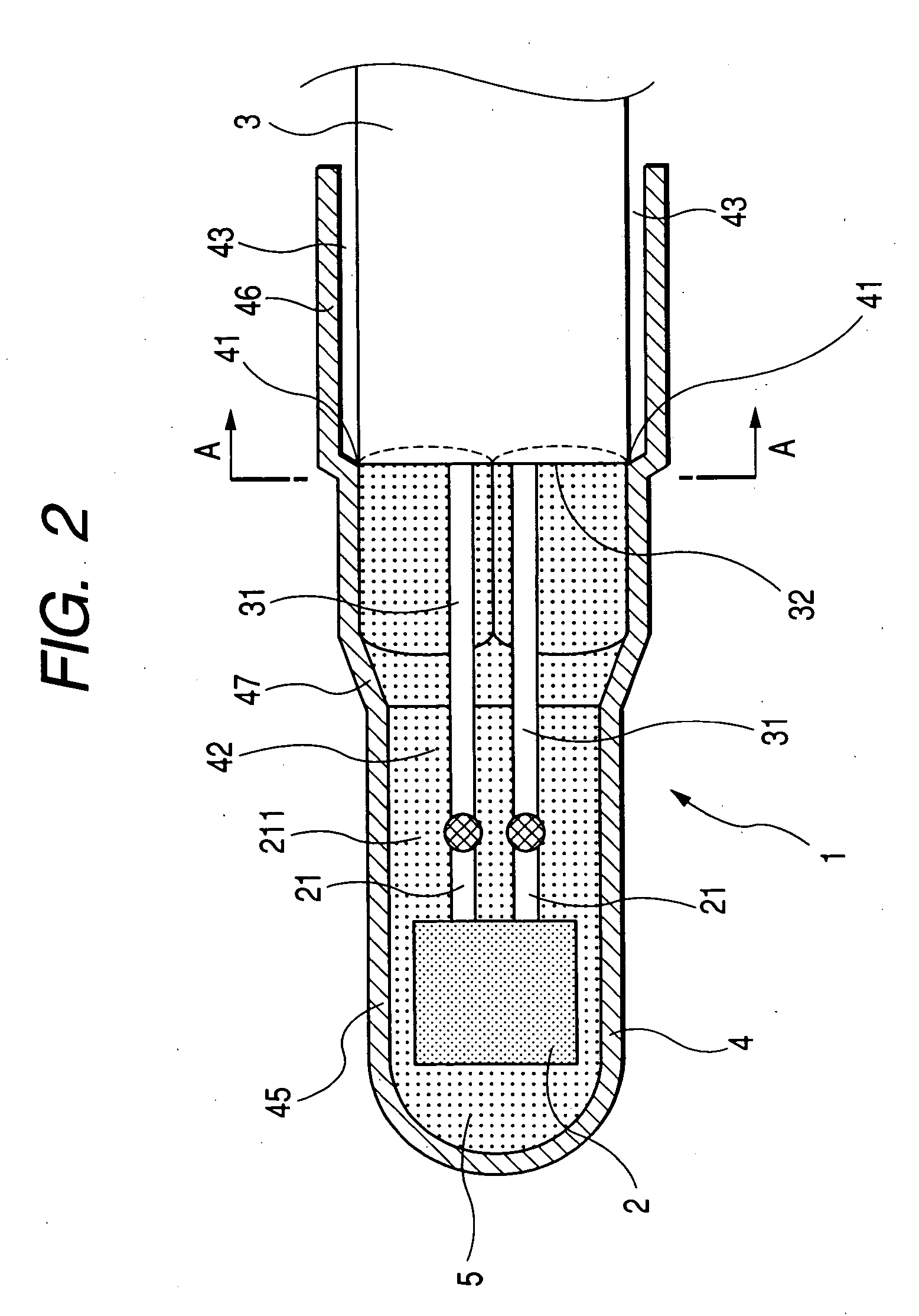

Temperature sensor

ActiveUS20070104247A1Easy to workEasily formThermometer detailsTemperature measurement in motorsThermistorSignal lines

A temperature sensor has a thermistor element equipped with a pair of electrodes, a sheath pin into which a pair of signal lines is built, and a cover surrounding the thermistor element. A front part of each signal line is exposed from the sheath pin. The cover is placed at a front part of the temperature sensor. The cover has a contact positioning part with which the front part of the sheath pin is contacted. Cement is filled into a space between the cover and the thermistor element in front of the front part of the contact positioning part. Through the cement, the thermistor element is supported by and fixed to the cover. A front inside space formed in front of the front part of sheath pin and a peripheral inside space formed in a rear side of the front part of the sheath pin are formed between the front part of the sheath pin and the inside surface of the cover.

Owner:DENSO CORP

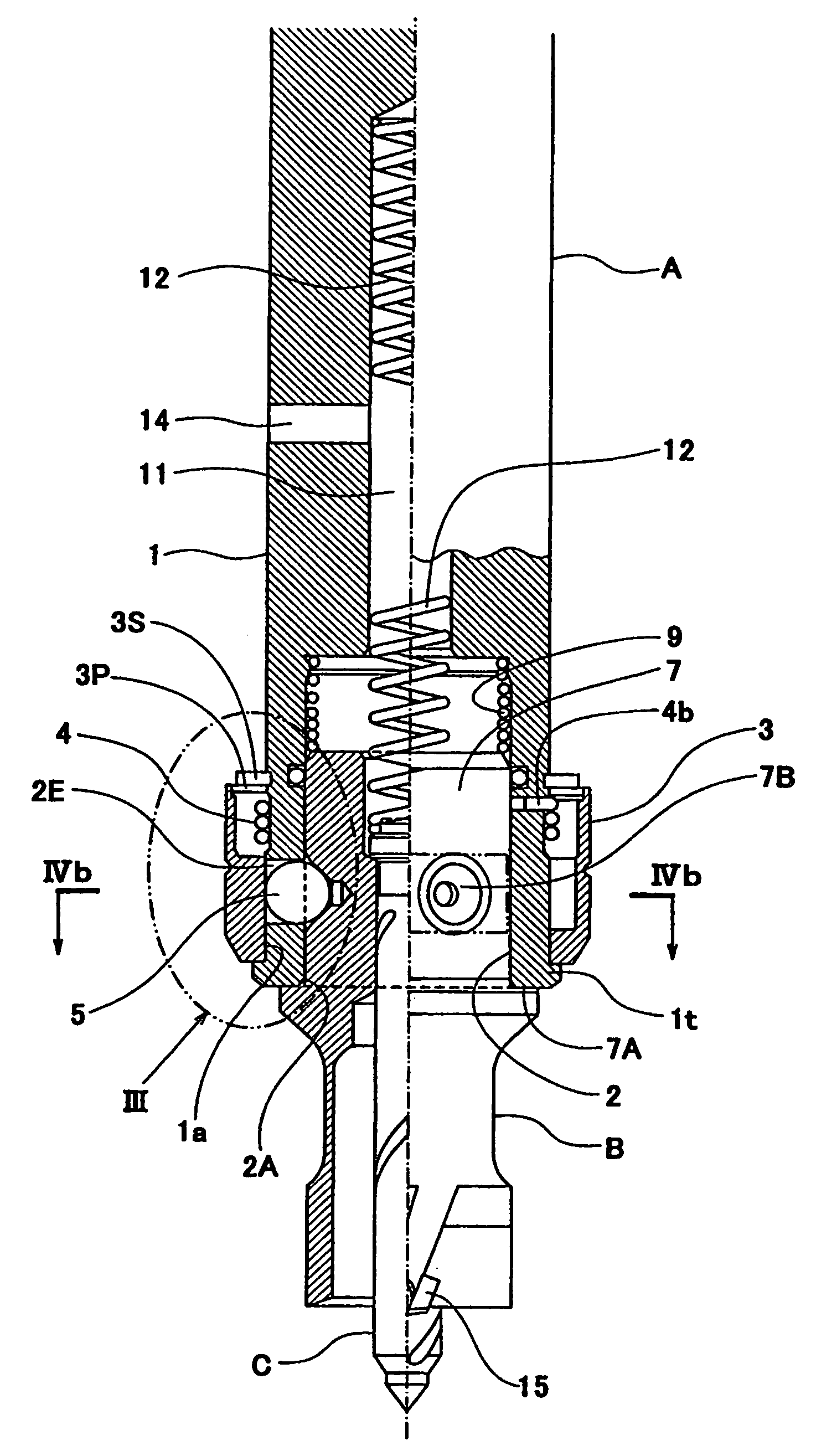

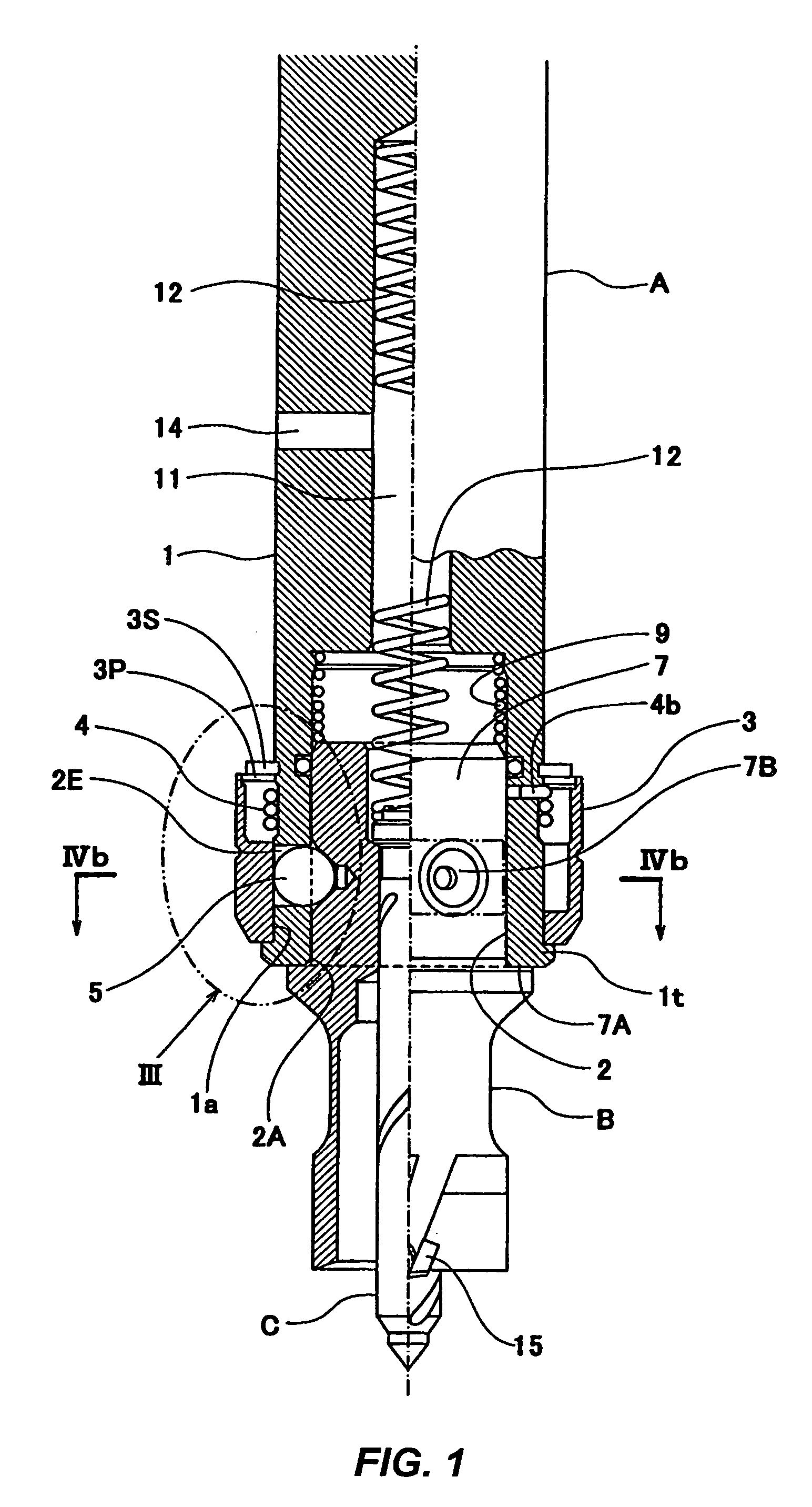

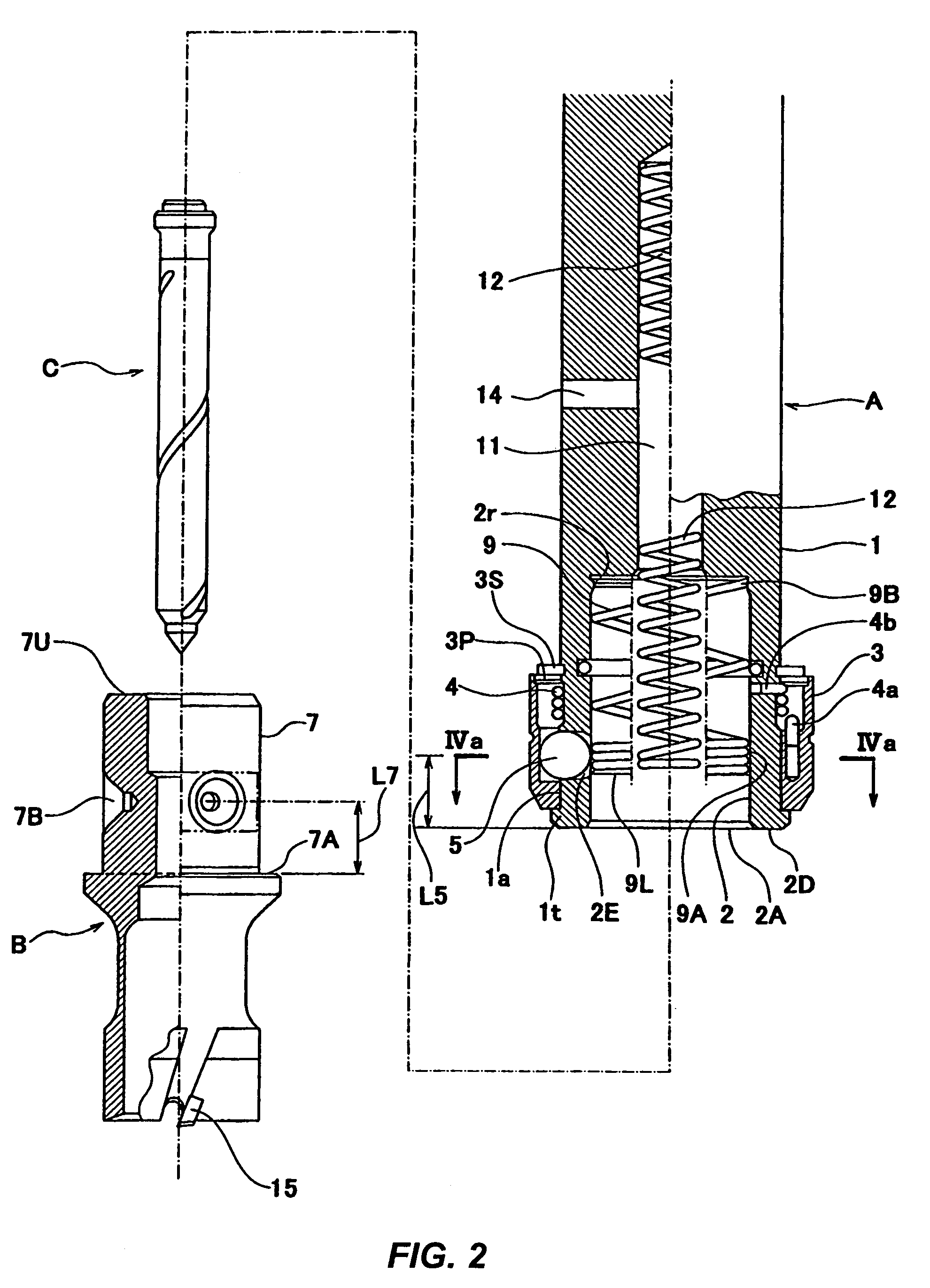

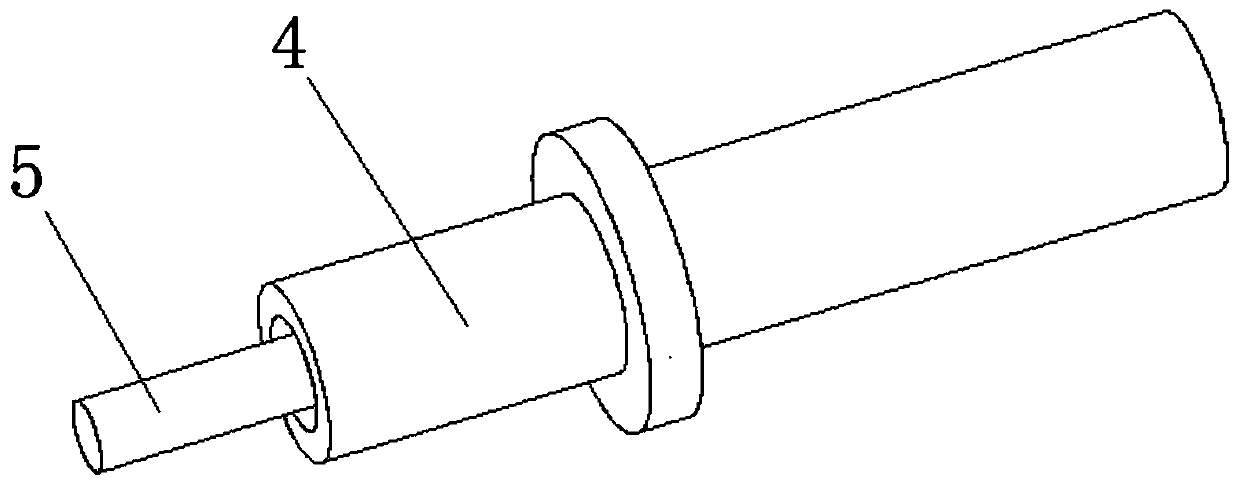

Shank installation structure and cutters

InactiveUS6966730B1Easy to workLow priceThread cutting machinesTransportation and packagingEngineeringAbutment

A shank attaching structure with as less axial free movement as possible and of a simplified construction, a cutter for use with the shank attaching structure, and a cutter for use with the shank attaching structure which is free from an incident that the cutter becomes incapable of coming off even if an impactive rotating torque is exerted thereon, are intended to be provided, wherein the shank attaching structure is constructed such that in a state restricted by a restriction mechanism for restricting a depth to which a shank (7) is inserted into an arbor (A), the position of an engaging portion (7B) relative to the lock member (5) is axially deviated toward the open side of a shank attaching bore to bring the lock member (5) and the engaging portion (7B) into abutment with each other on the base end side of the shank attaching bore. The cutter (B) is constructed such that an outer peripheral edge portion (7C) of a concave portion forming the engaging portion (7B) is dented from an outer peripheral surface of the shank (7).

Owner:MIYANAGA KK

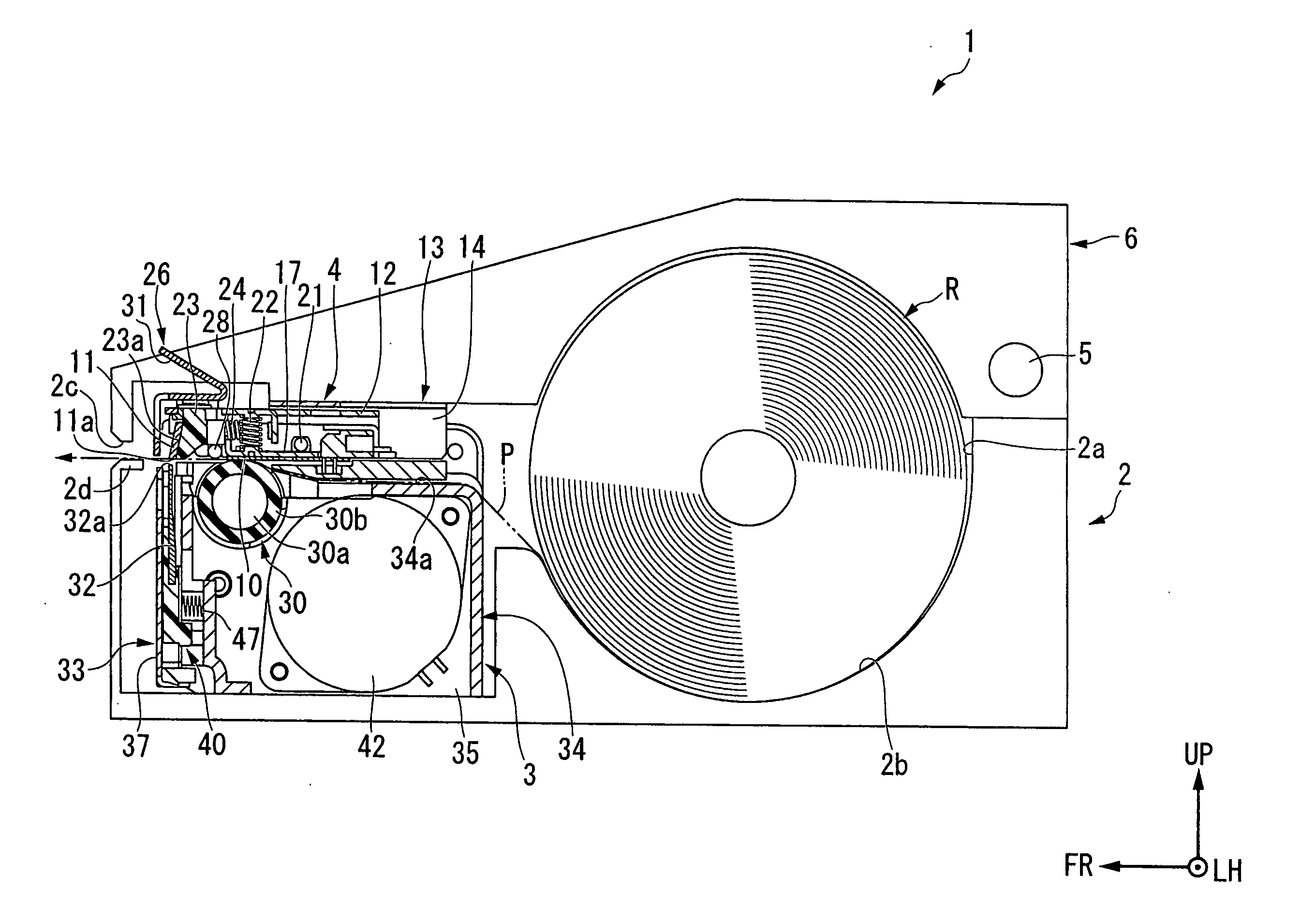

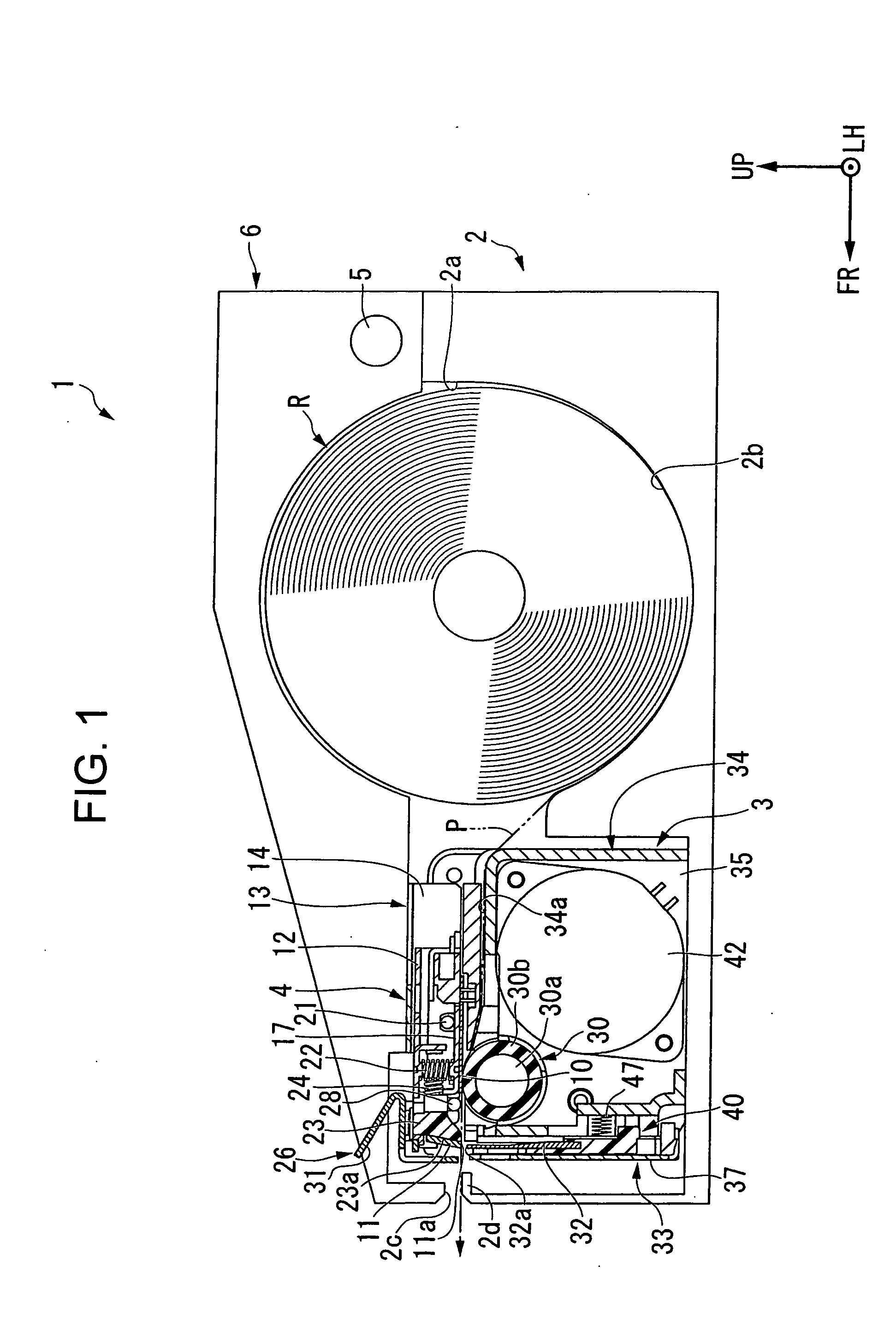

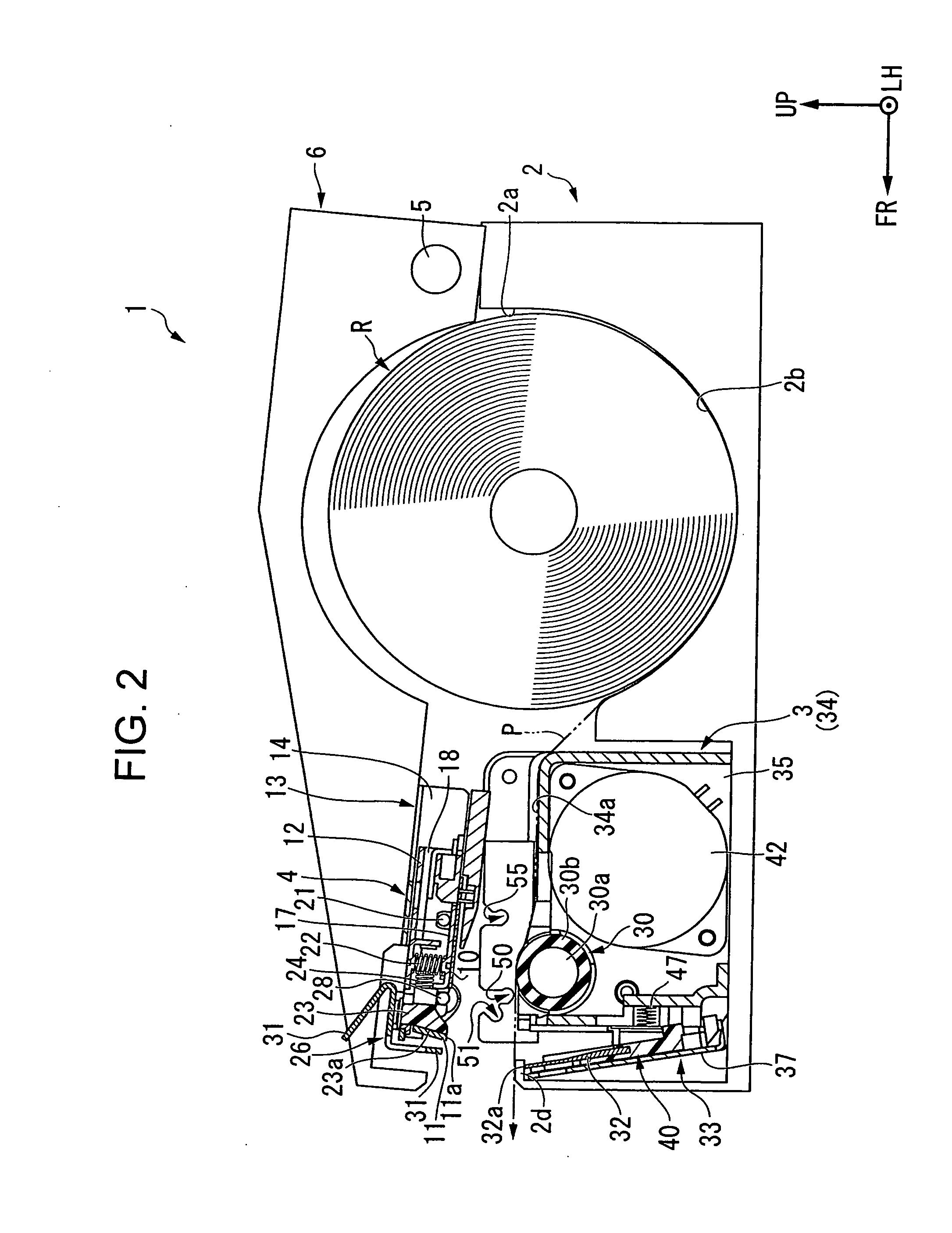

Printer with cutter

InactiveUS20100143018A1Easy to workImprove operativityOther printing apparatusMetal working apparatusHome positionEngineering

Provided is a printer with a cutter, which can easily restore, even when there arises a problem that a movable blade is stopped during sliding due to paper jam or the like, the movable blade to a state before the problem arises, reliably perform positioning between a movable blade frame and a detachable unit, and improve printing accuracy and cutting accuracy. A detachable unit (4) turns in a sliding direction of a movable blade (32) from a mounted position to a dismounted position. Meanwhile, a movable blade frame (33) turns in a direction orthogonal to the sliding direction of the movable blade (32) from a home position to a separated position. Thus, the both blades (32 and 11) retreat in directions orthogonal to each other, respectively.

Owner:SEIKO INSTR INC

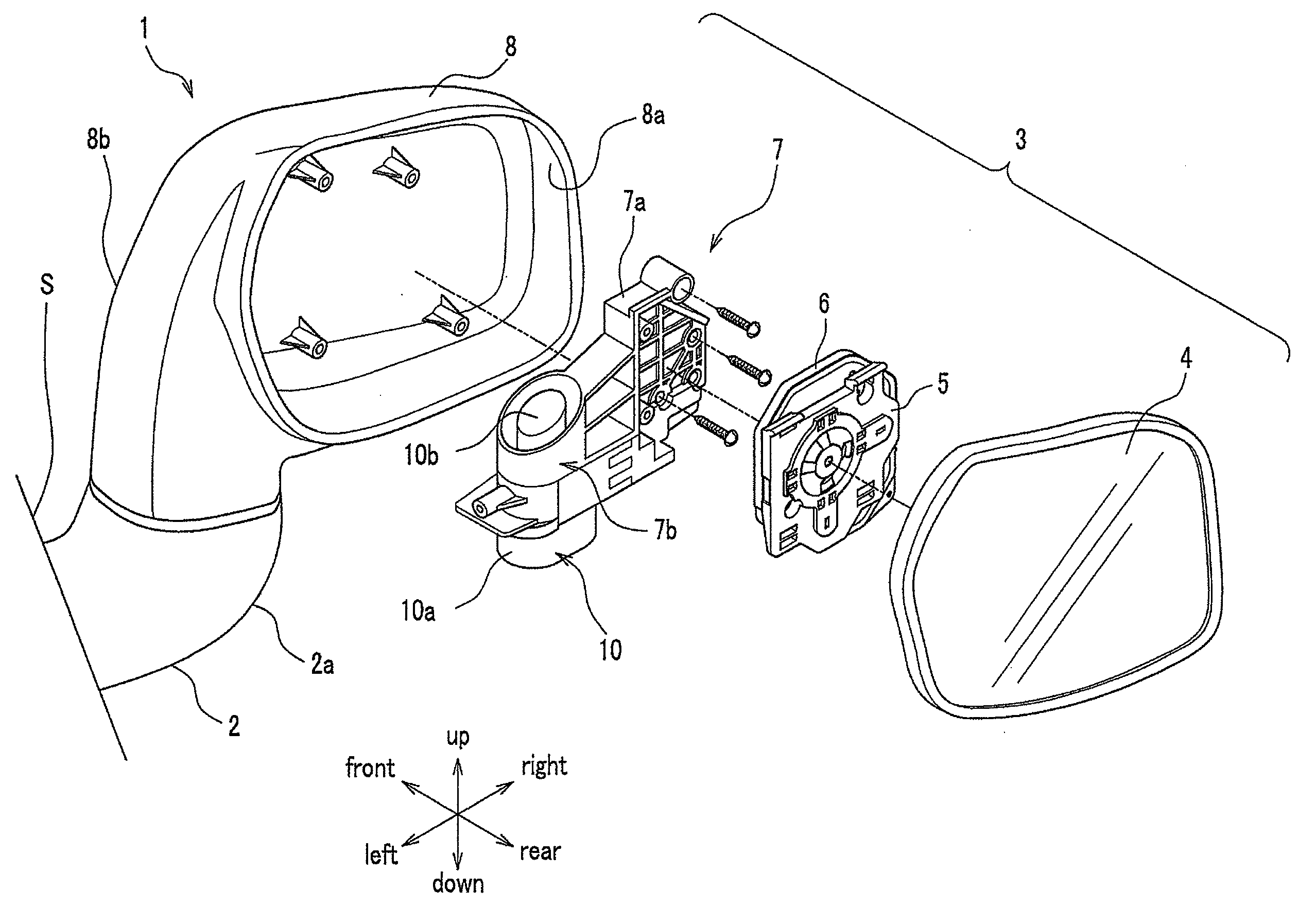

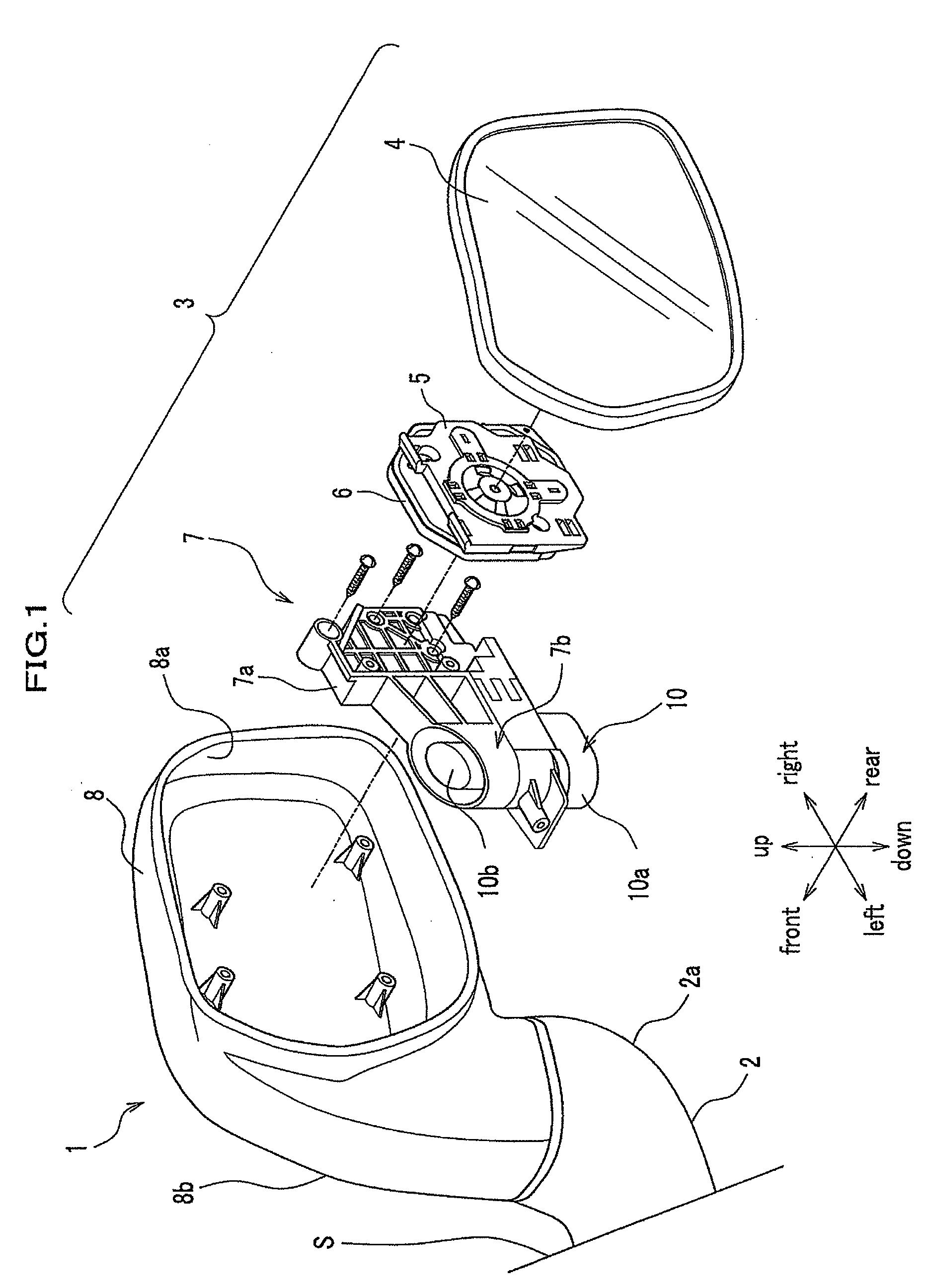

Outer mirror

An object of the present invention is to provide an outer mirror which prevents the whistle noise without the rotation of the mirror assembly being prevented. In order to achieve the above object, an outer mirror which includes a mirror base provided on a vehicle body; a shaft portion fixed to the mirror base; a mirror assembly rotatably mounted on the mirror base around the shaft portion used as a rotational axis; a windshield member to occlude a gap between the mirror base and the mirror assembly, in which the shaft portion includes a mounting seat attached to the mirror base; a shaft body provided uprightly on the mounting seat, the mirror assembly includes a housing having an opening toward the mirror base and the shaft body is inserted into the opening; and a mirror attached to the housing is provided.

Owner:MURAKAMI CORP

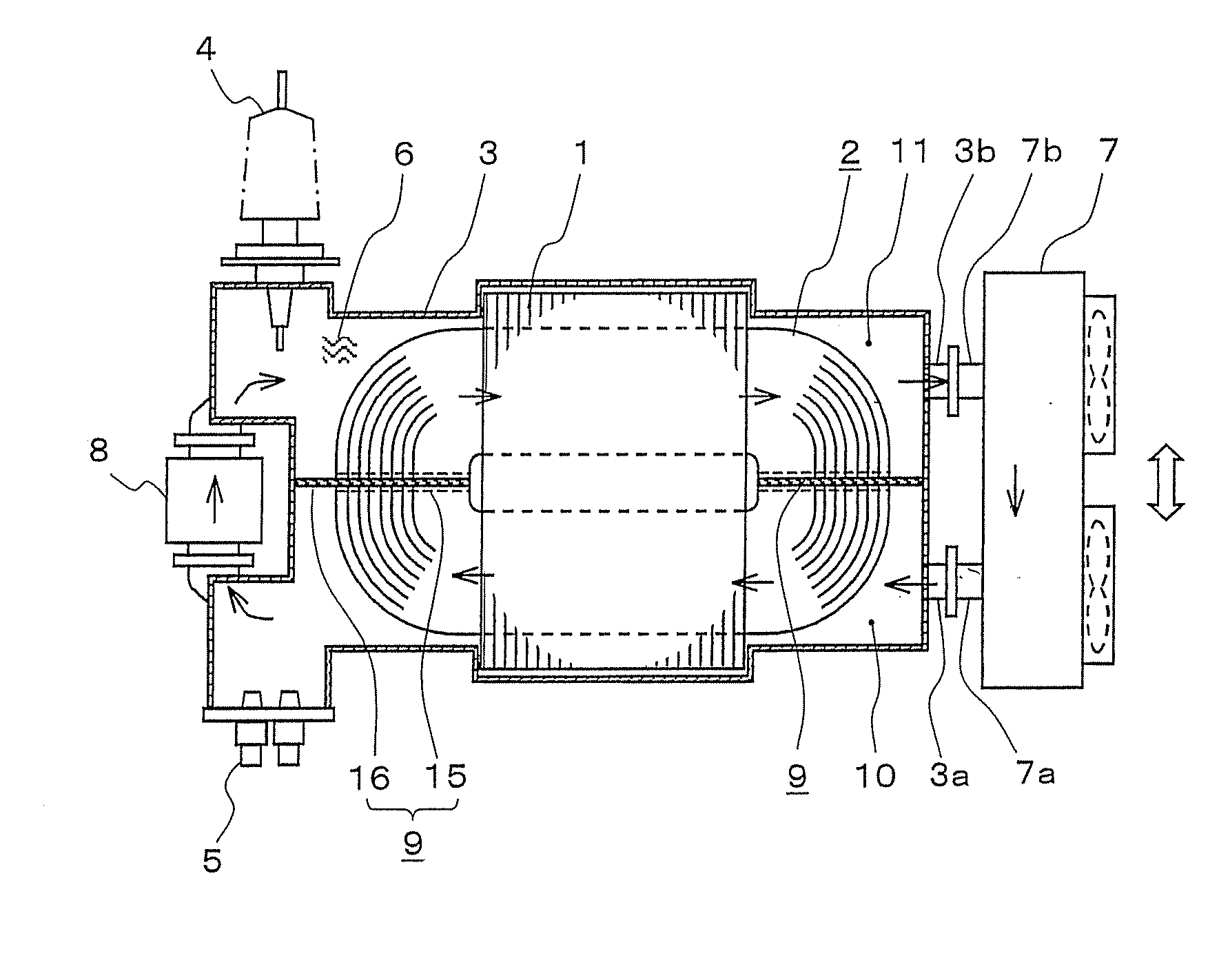

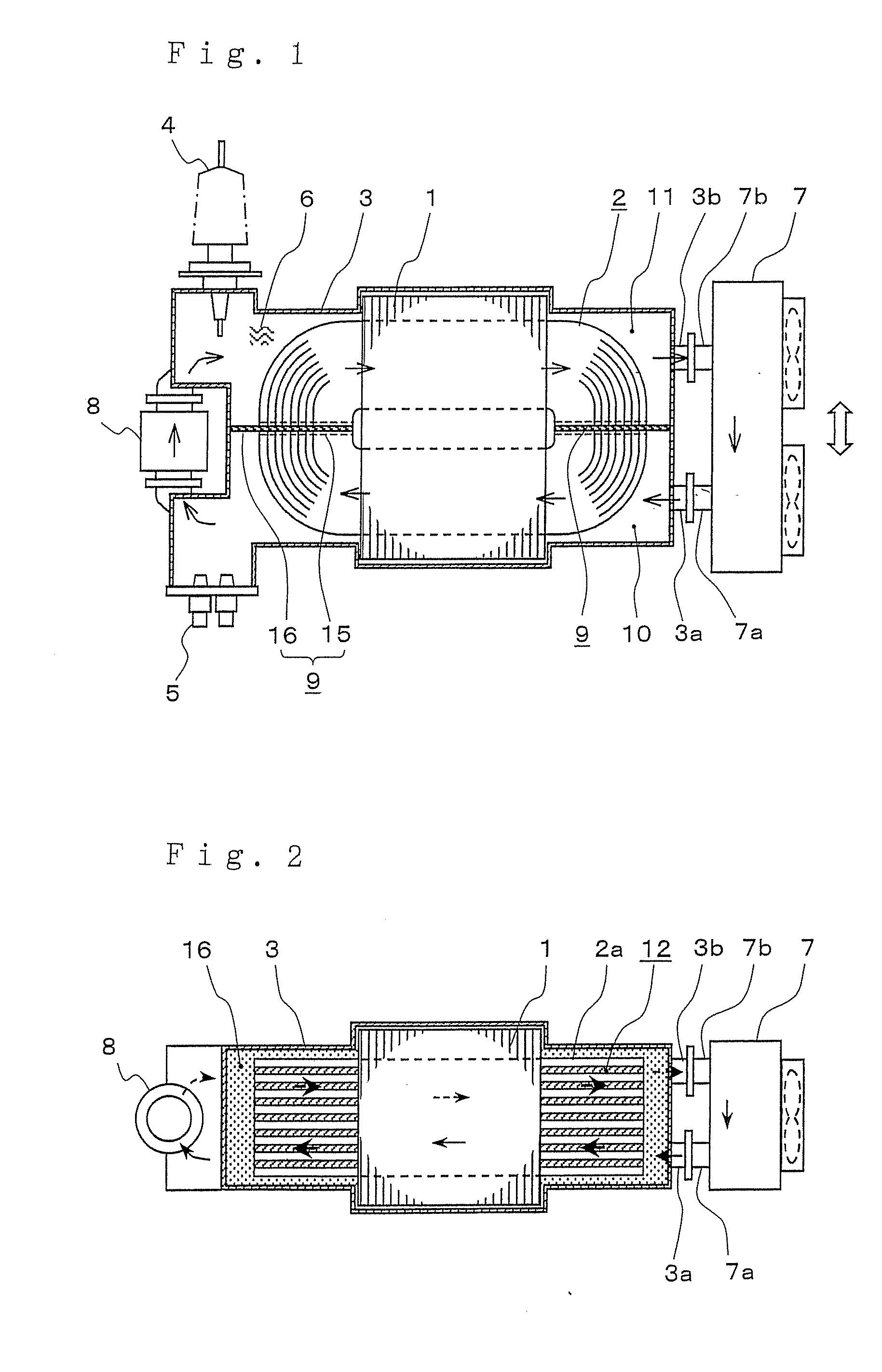

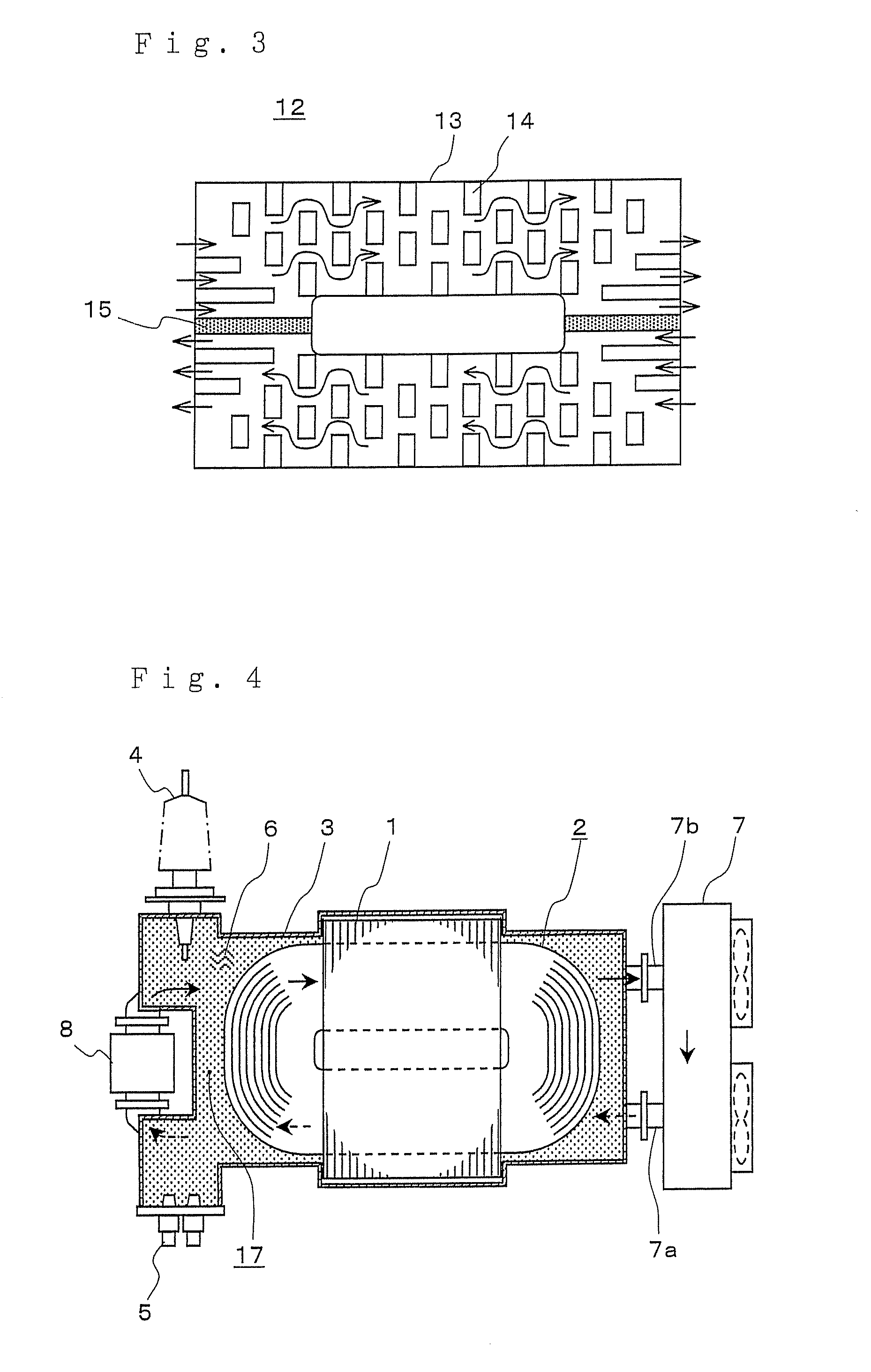

Vehicle Transformer

InactiveUS20090261933A1Reduce size and weightEasy to workTransformers/inductances coolingTransformers/inductances casingsCooling UnitsEngineering

In a vehicle transformer including a core 1, a winding 2, a rectangular tank 3 holding them, a cooling unit 7 for cooling a cooling medium 6 filling the tank 3, and a circulating pump 8 for forcibly circulating the cooling medium 6, a partition member 9 is provided for dividing an interior of the tank 3 into two and the partition member 9 divides a channel of the cooling medium 6 flowing within the winding 2 into a first cooling medium channel 10 and a second cooling medium channel 11, and both of the cooling medium channels 10, 11 are communicated at one end side of the tank 3 and the cooling unit 7 connected to both of the cooling medium channels 10, 11 is provided at the other end for the cooling medium 6 to flow and circulate in the first cooling medium channel 10 and the second cooling medium channel 11. Thereby, the connection between the tank and the cooling unit is simplified and a vehicle transformer reduced in size and weight is obtained.

Owner:MITSUBISHI ELECTRIC CORP

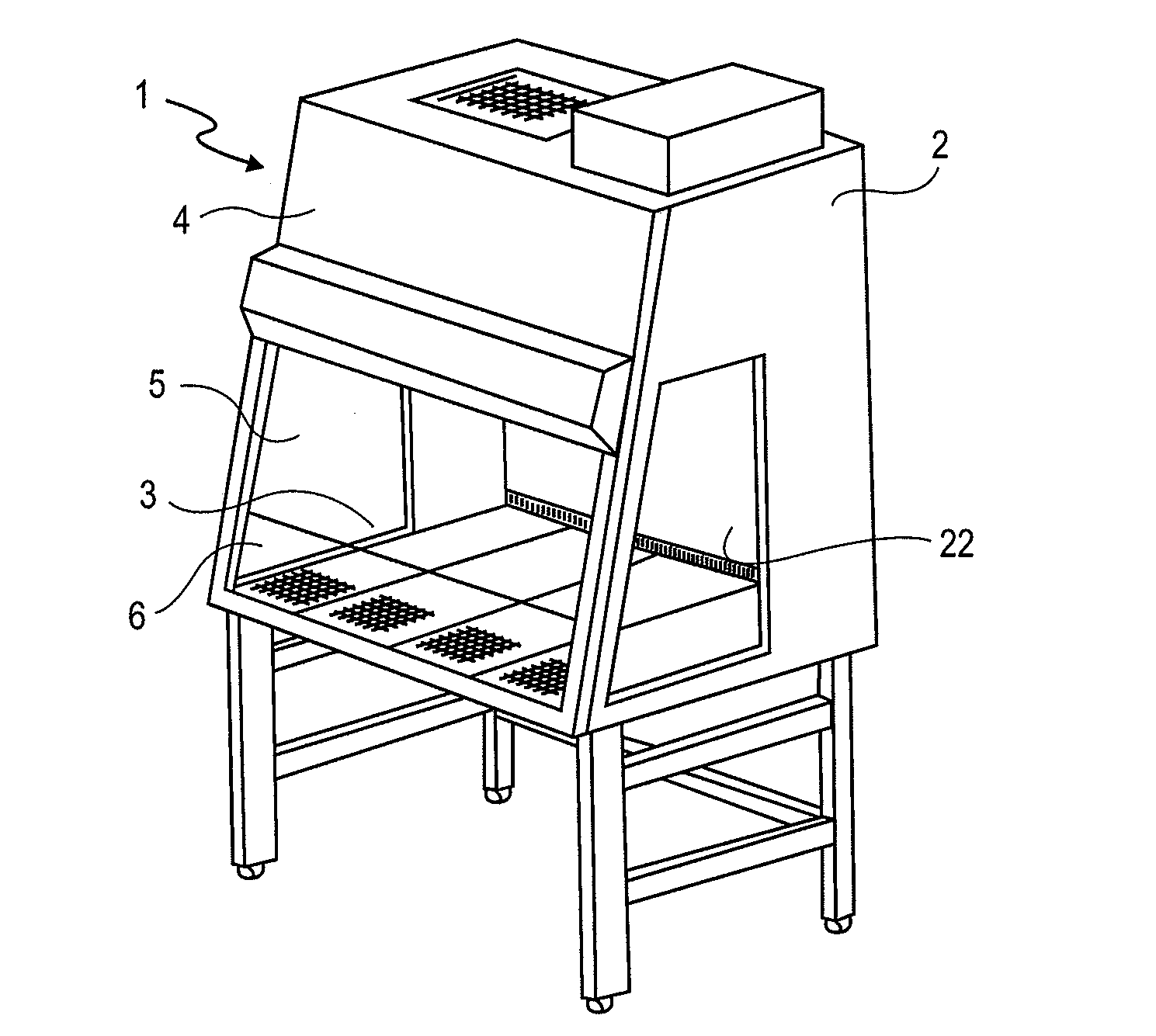

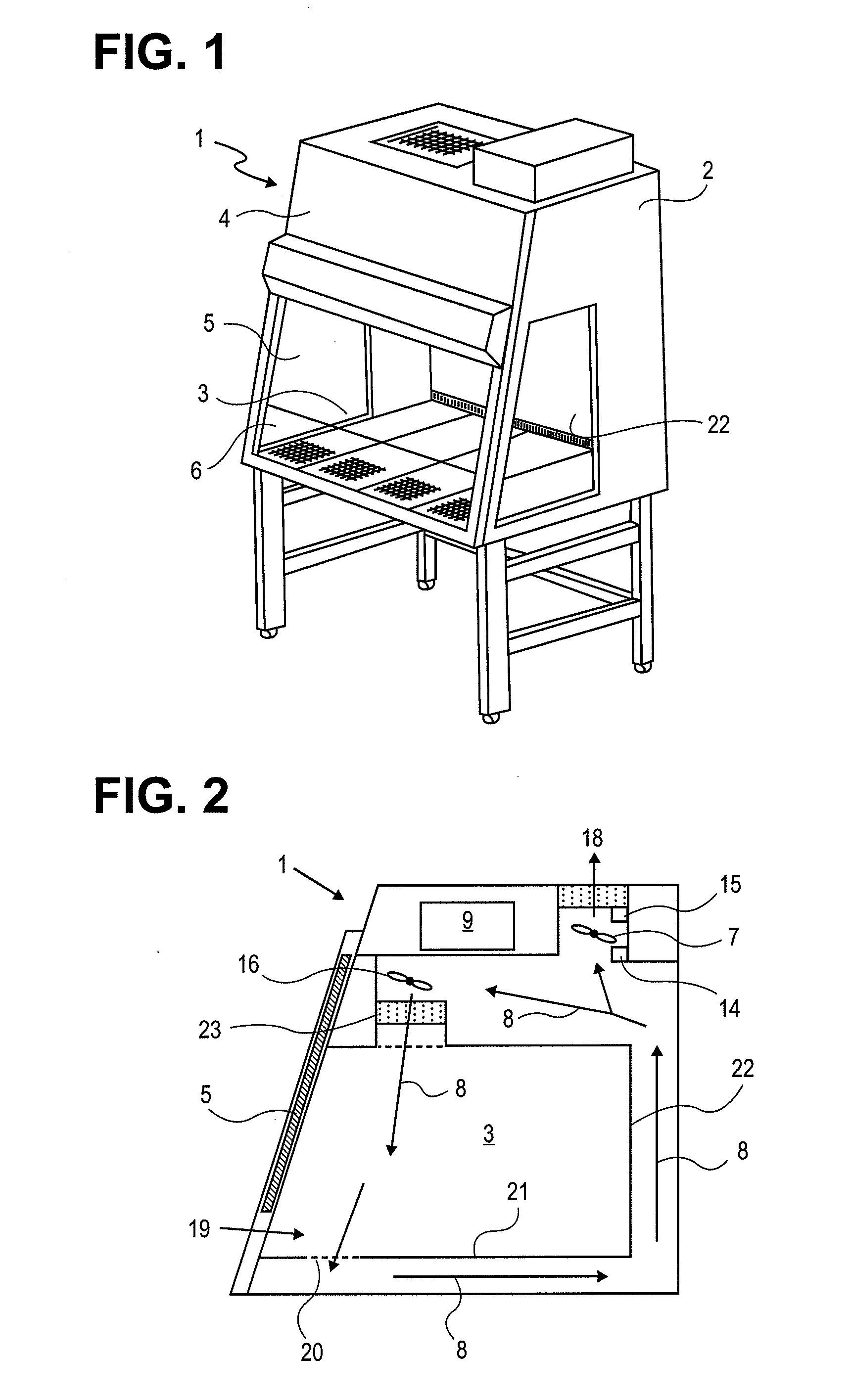

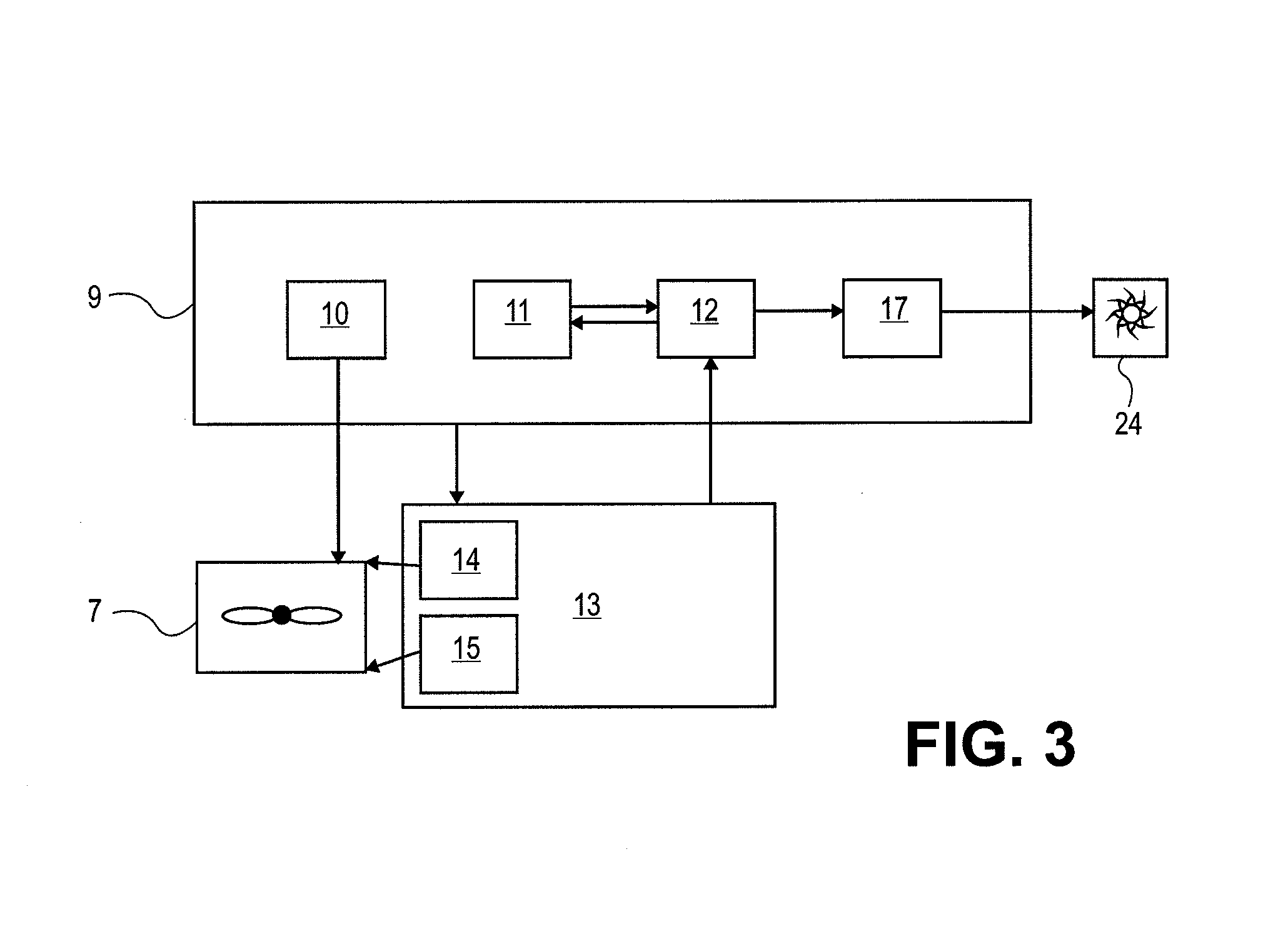

Safety workbench and method for the calibration thereof

ActiveUS20080318509A1Easy to workReduced time expenditureAnalysis using chemical indicatorsDomestic stoves or rangesMeasurement deviceWorkbench

The present invention relates to a safety workbench, in which, for the purpose of calibrating the safety workbench before beginning regular operation, a device control unit is implemented to cause measurement means to ascertain an actual measured value, which is representative of a flow velocity achieved at normal fan performance, an analysis unit is implemented to compare the actual measured value to a starting setpoint value and, in case of an established deviation, to correct a stored starting limiting value in accordance with the deviation, or means for controlling the fan are implemented to operate the fan at a fan performance corresponding to a stored starting limiting value, a device control unit is implemented to cause the measurement means to ascertain an actual limiting measured value which is representative of the flow velocity achieved at the set fan performance, and a storage unit is implemented to store the actual limiting measured value as the corrected limiting value. Furthermore, the present invention relates to a corresponding calibration method.

Owner:THERMO ELECTRONICS LED GMBH

Vehicular direction indicating apparatus

InactiveUS20080061956A1Easy to layoutEasy to workOptical signalOptical signallingVehicle orientationSteering angle

A steering shaft includes a lower end that penetrates through, and projects downwardly from a bracket for supporting an upper end of a front fork tube. A steering angle sensor for a flasher canceler is disposed at the lower end of the steering shaft. The steering angle sensor is held in position by a holding plate mounted to a lower surface of the bracket. A retainer is secured to a stay secured to a portion of a vehicle body frame. The retainer is engaged with an engagement portion of a steering angle sensor shaft of the steering angle sensor. Rotation of the steering shaft results in the steering angle sensor shaft of the steering angle sensor being rotated relative to a vehicle body, which detects a steering angle. A flasher canceler control unit is incorporated in a meter unit.

Owner:HONDA MOTOR CO LTD

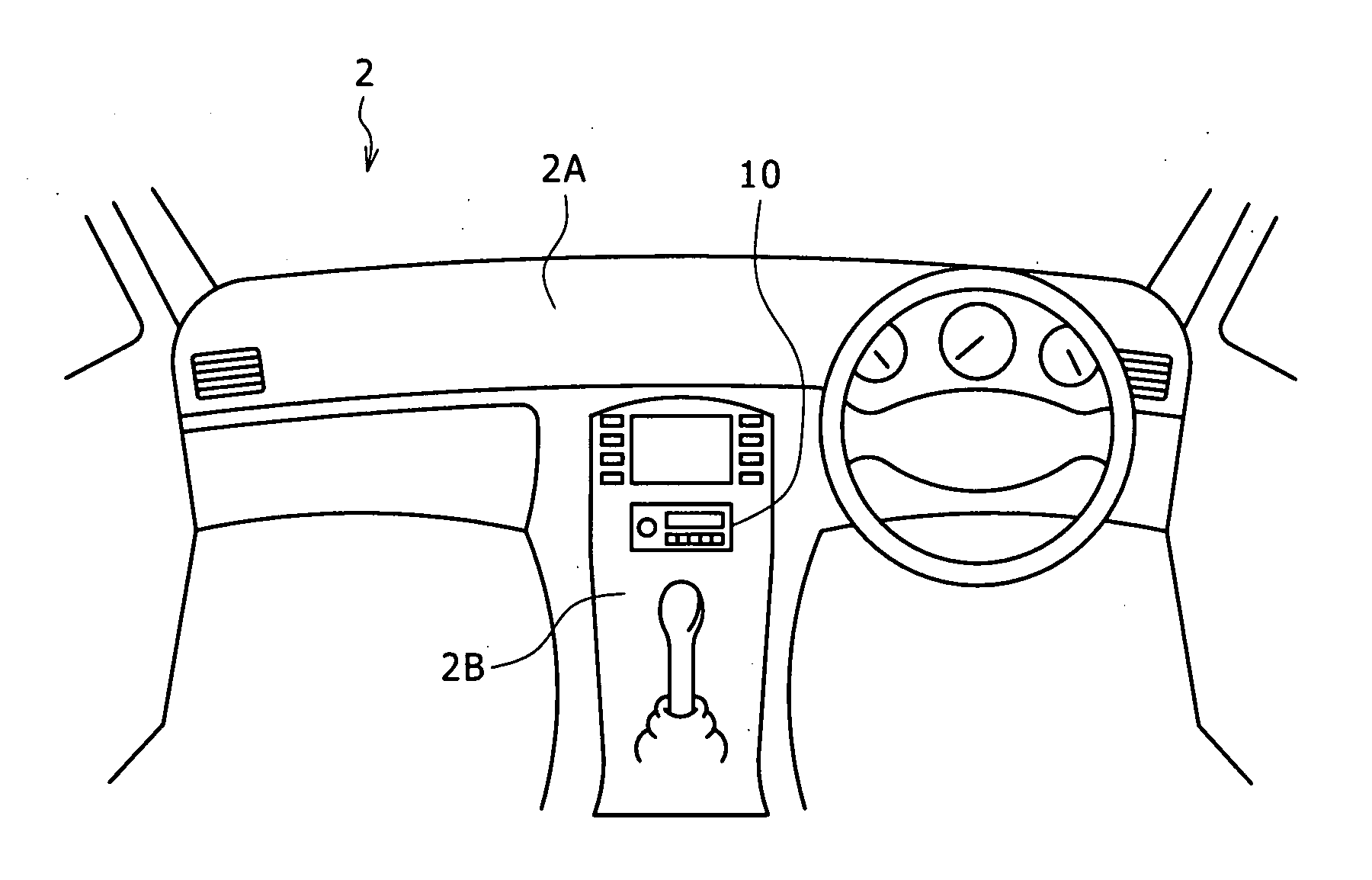

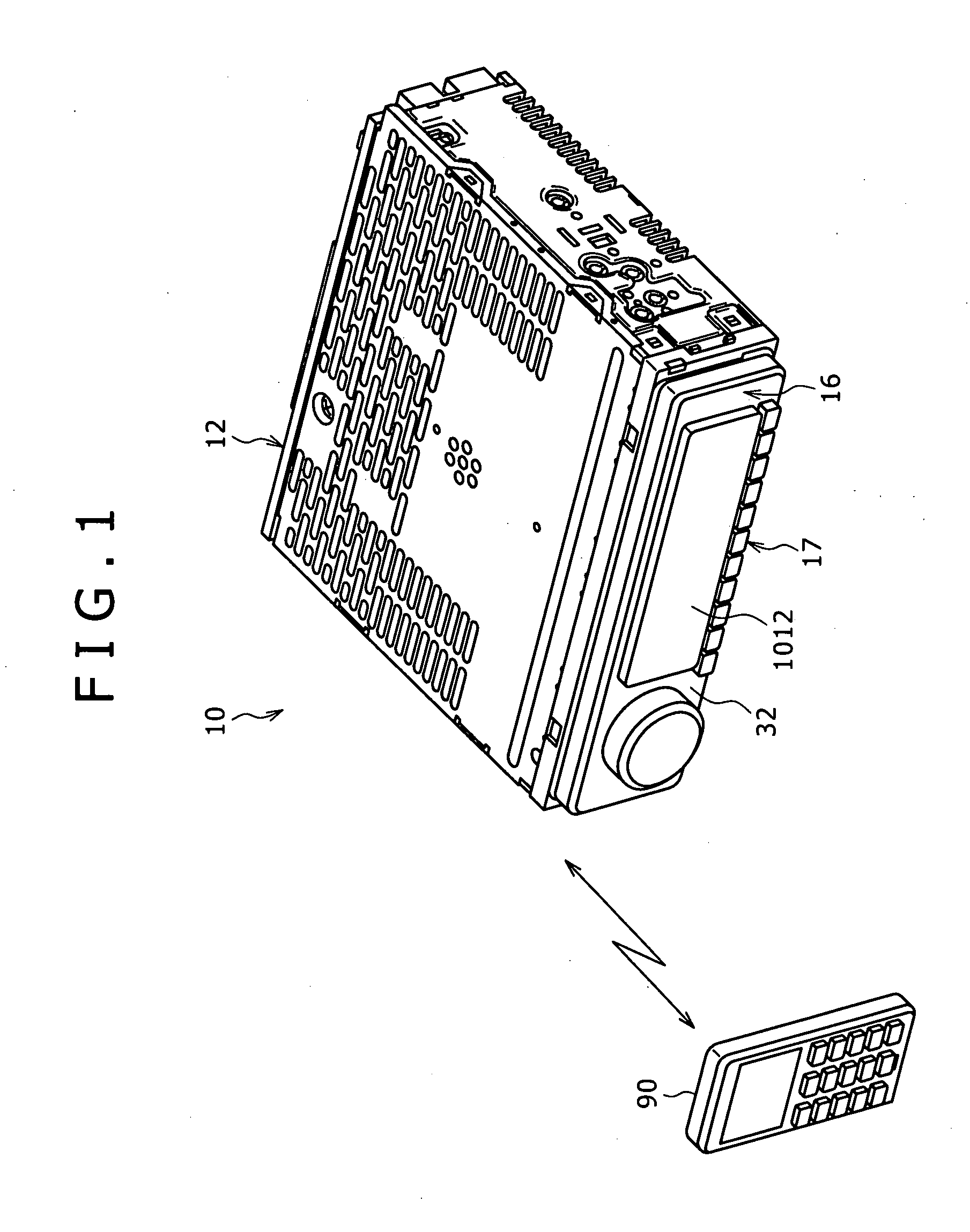

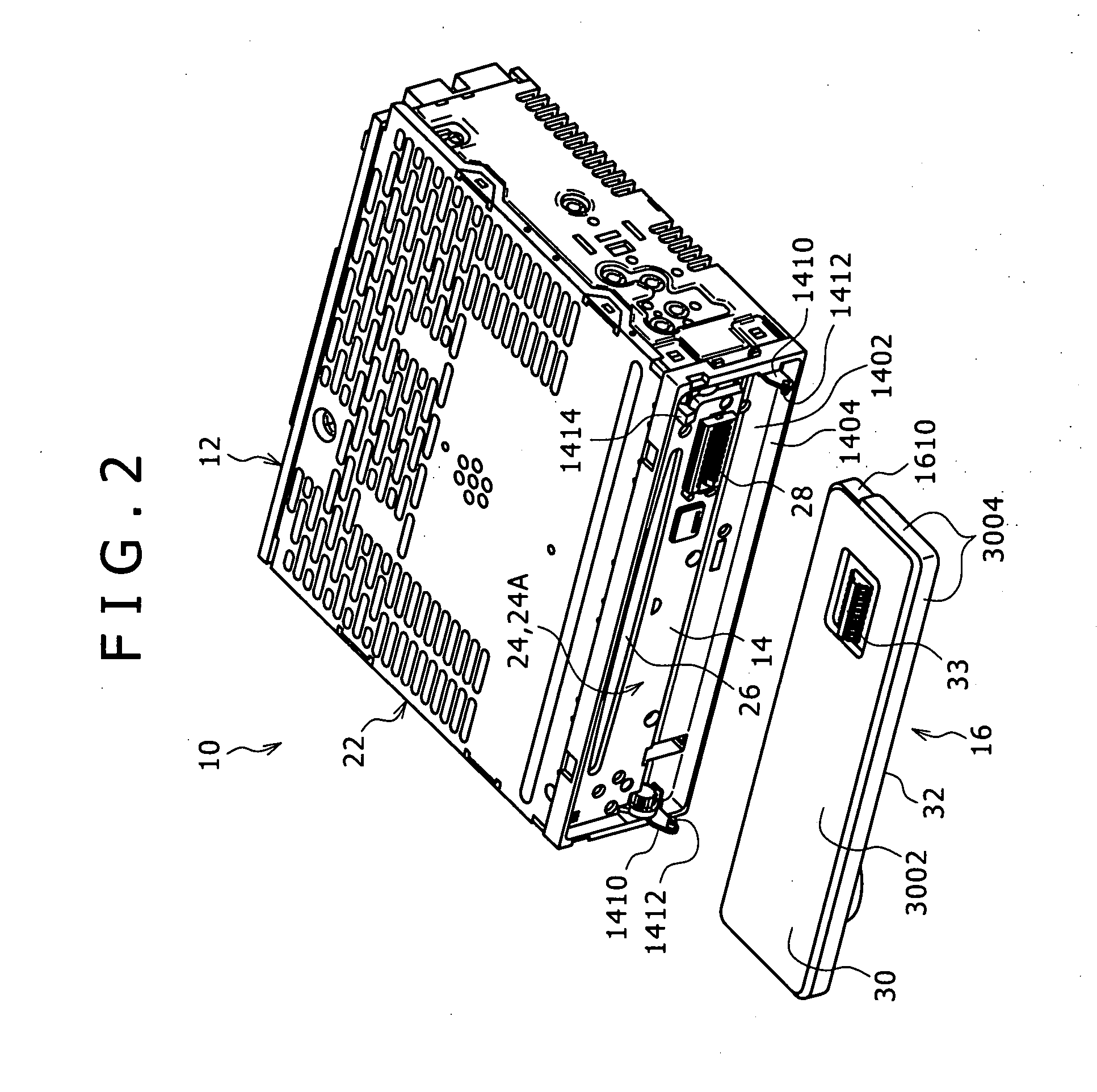

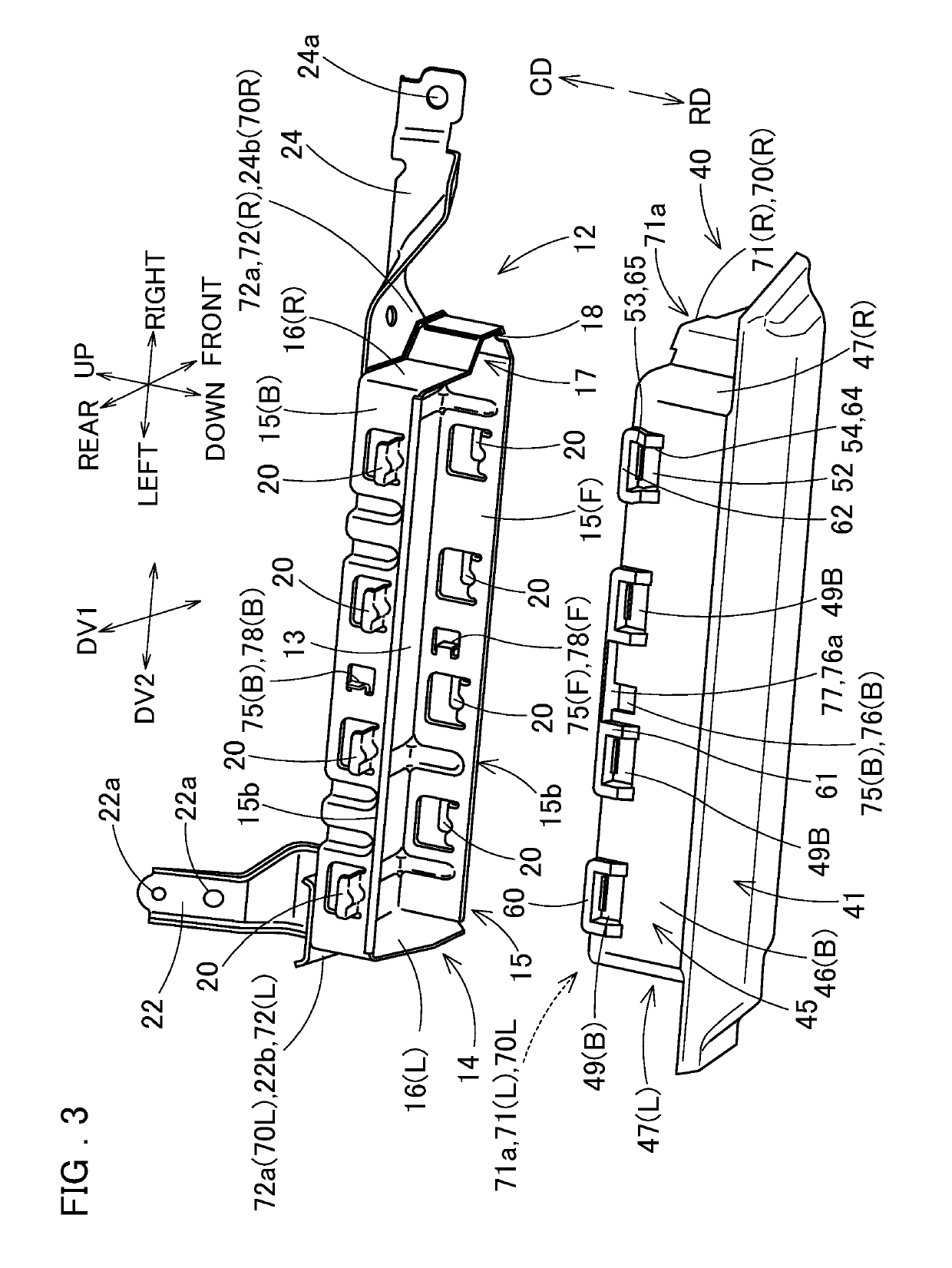

In-vehicle apparatus

InactiveUS20070207840A1Easy to workEnhance degree of freedomCarrier coversRecord information storageIn vehicleMicrophone

An in-vehicle apparatus including: an apparatus body; a front surface of the apparatus body; and a lid configured to open and close the front surface. A microphone directed to the front side of the front surface in the condition where the lid is opened is provided at the front surface of the apparatus body. A gap for communication between the location, where the microphone is provided, of the front surface and the outside is secured between the front surface and the lid in the condition where the front surface of the apparatus body is closed with the lid.

Owner:SONY CORP

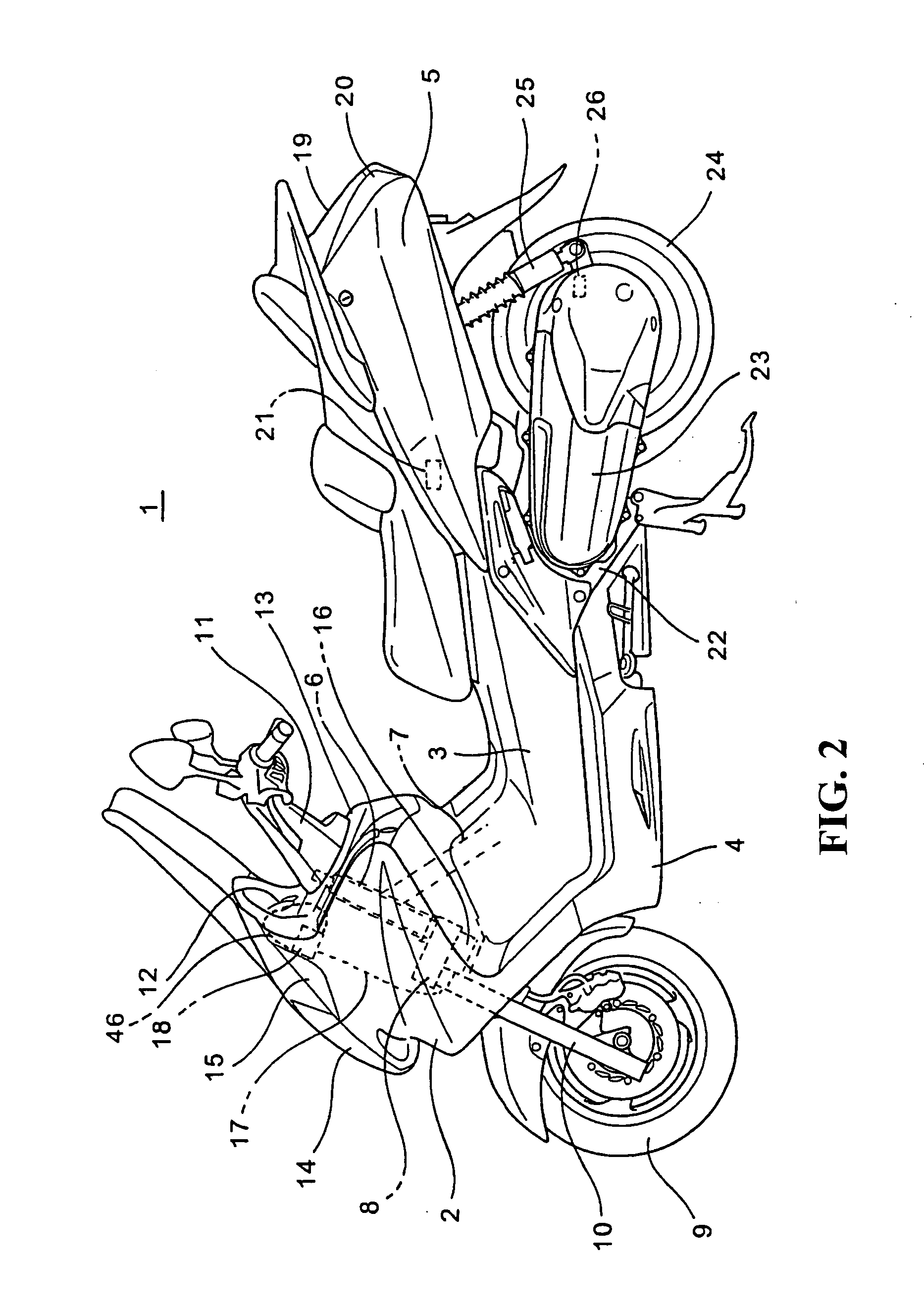

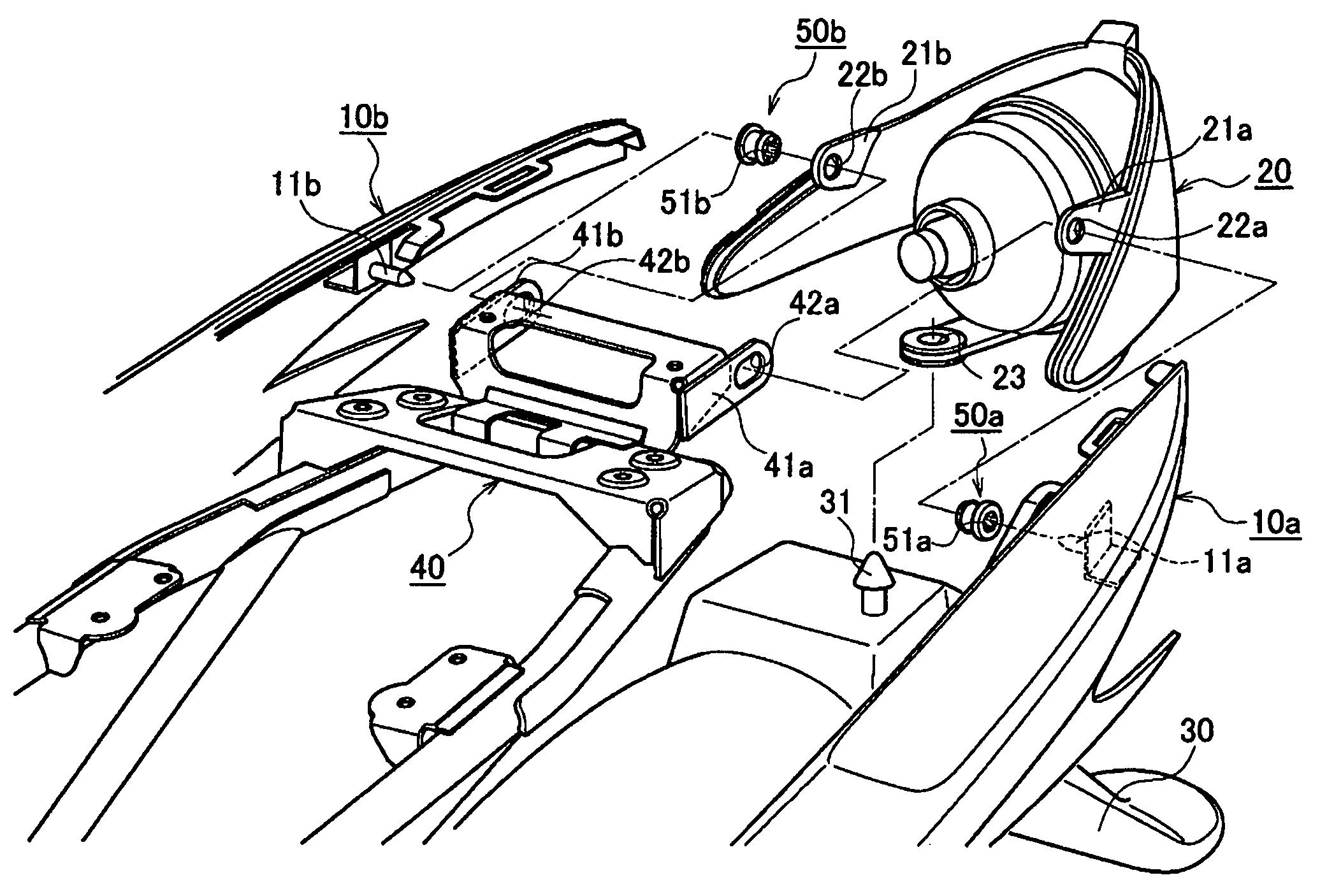

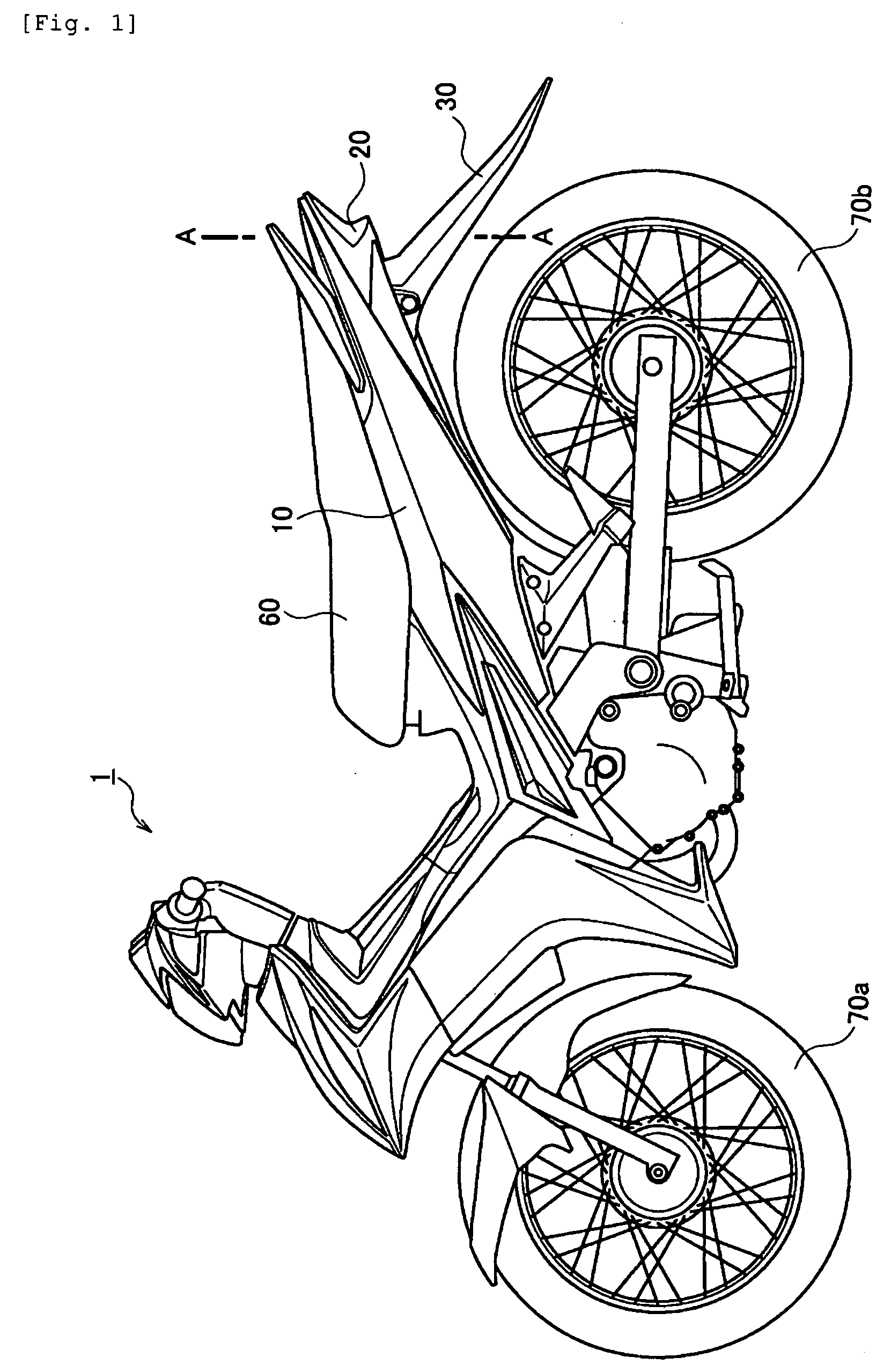

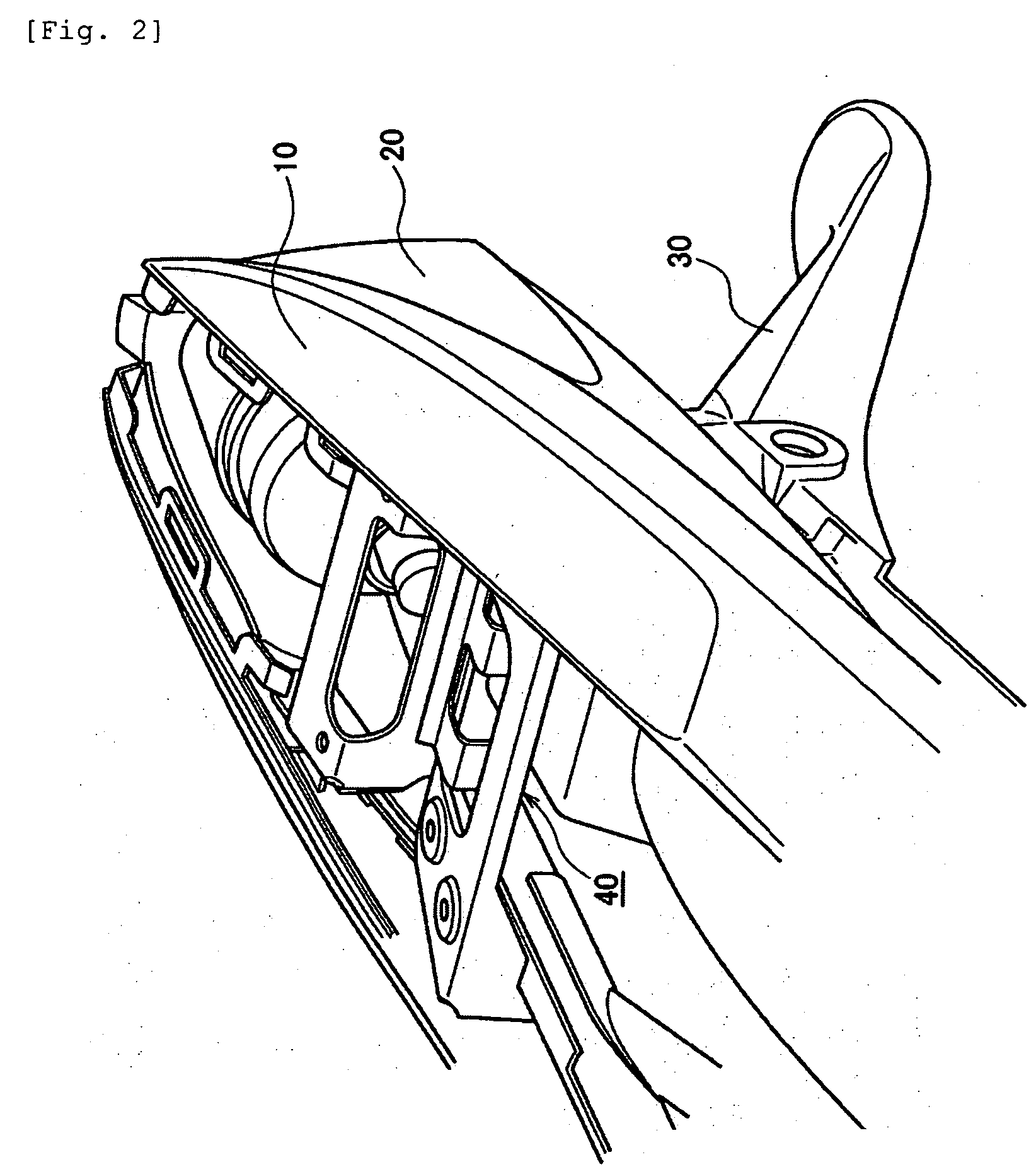

Saddle-ride type vehicle

InactiveUS20060077676A1Easy to workEasily insertNon-electric lightingOptical signalVehicle frameEngineering

A saddle-ride type vehicle is provided capable of making a mount construction of a lamp unit simple and lessening a possibility that a projection provided on a vehicle body cover is damaged. The saddle-ride type vehicle includes a vehicle body cover that covers a vehicle body of the saddle-ride type vehicle from outside the saddle-ride type vehicle. A protrusive projection is mounted to the vehicle body. A grommet having a cylinder holds the projection. A frame including a frame side mount is provided with a frame side mount hole. A rear lamp unit including a rear lamp side mount is provided with a rear lamp side mount hole. The grommet is inserted into the frame side mount hole and the rear lamp side mount hole. The cylinder is opened in a direction, in which the grommet is inserted into the frame side mount hole and the rear lamp side mount hole, and the projection is inserted into the cylinder.

Owner:YAMAHA MOTOR CO LTD

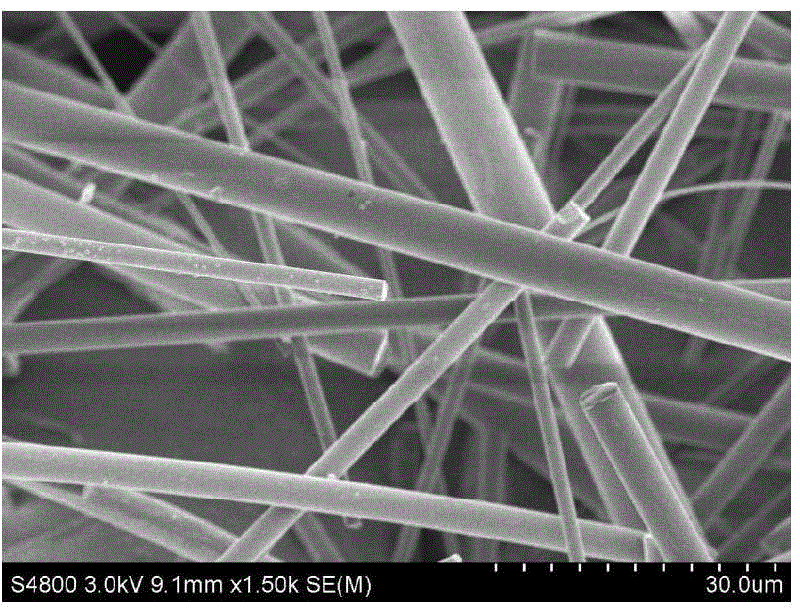

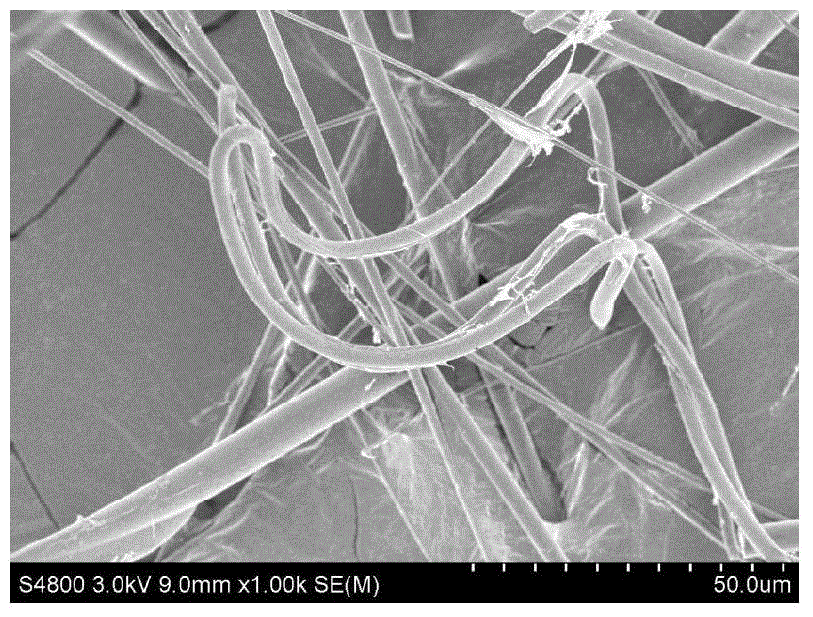

Modification method for enhancing strength of white mud fiber

ActiveCN103601373AHigh strengthEasy to workInorganic compound additionPolyvinyl alcoholFiber strength

The invention discloses a method for enhancing strength of white mud fiber. The modification method comprises the following steps of (1) weighing a certain amount of polyvinyl alcohol, water, H2O2 and sodium hydroxide, dissolving the weight polyvinyl alcohol into water, heating and stirring till the polyvinyl alcohol is dissolved, thus obtaining a transparent polyvinyl alcohol solution; adding H2O2 into the polyvinyl alcohol solution, then adding sodium hydroxide, and reacting fully to obtain a reactant; (2) weighing a certain amount of Al2(SO4)3, uniformly mixing Al2(SO4)3 with the reactant obtained in the step (1), reacting fully to obtain a mixed solution, then regulating the pH value of the mixed solution to 6-10, thus obtaining an agent for softening and enhancing the white mud fiber; and (3) weighing a certain amount of white mud fiber and water, adding the white mud fiber into water, then adding the organic fiber softening and enhancing agent obtained in step (2), mixing uniformly and steeping, thus obtaining the modified white mud fiber. The modified white mud fiber has large strength and good quality.

Owner:SHAANXI UNIV OF SCI & TECH

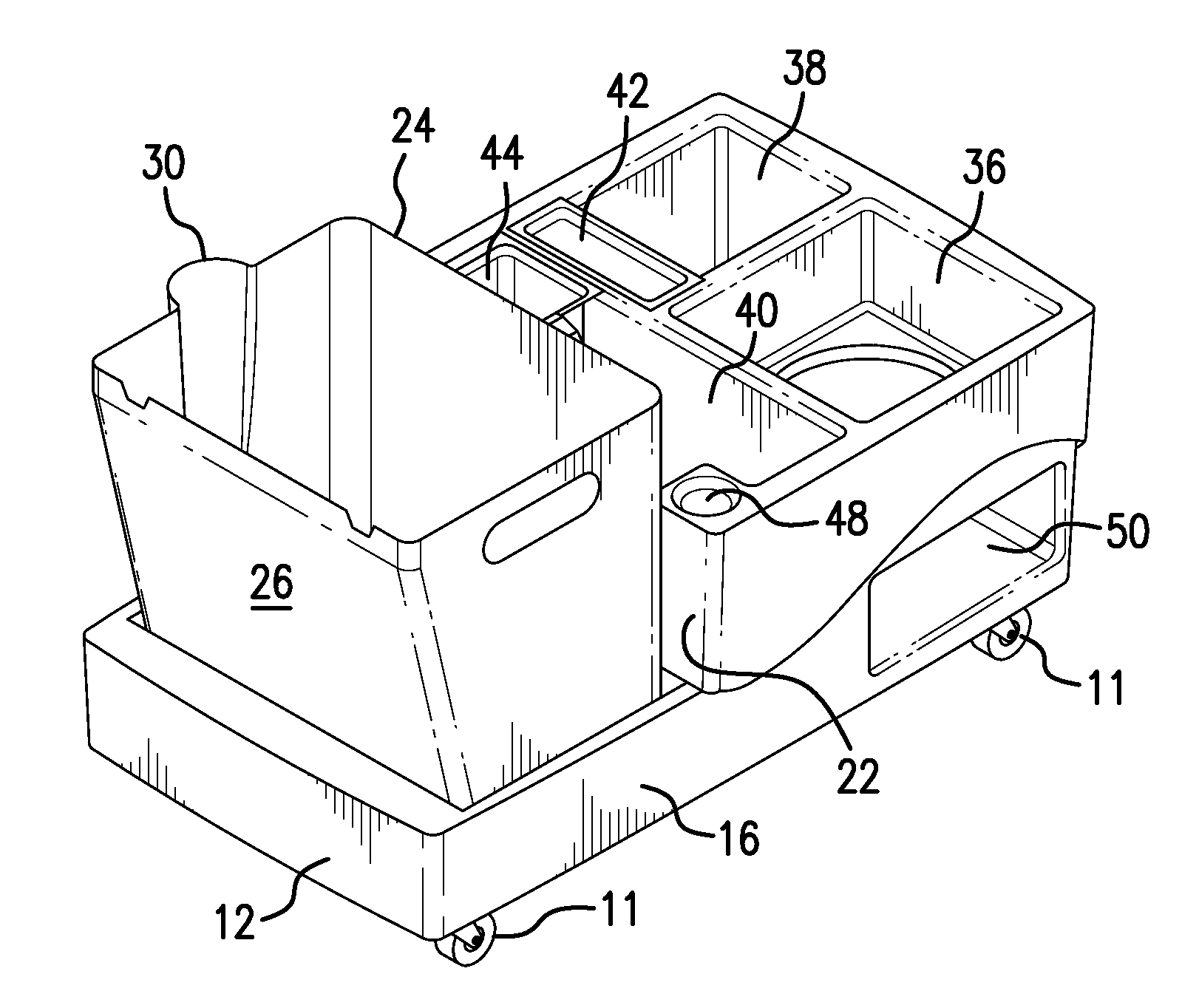

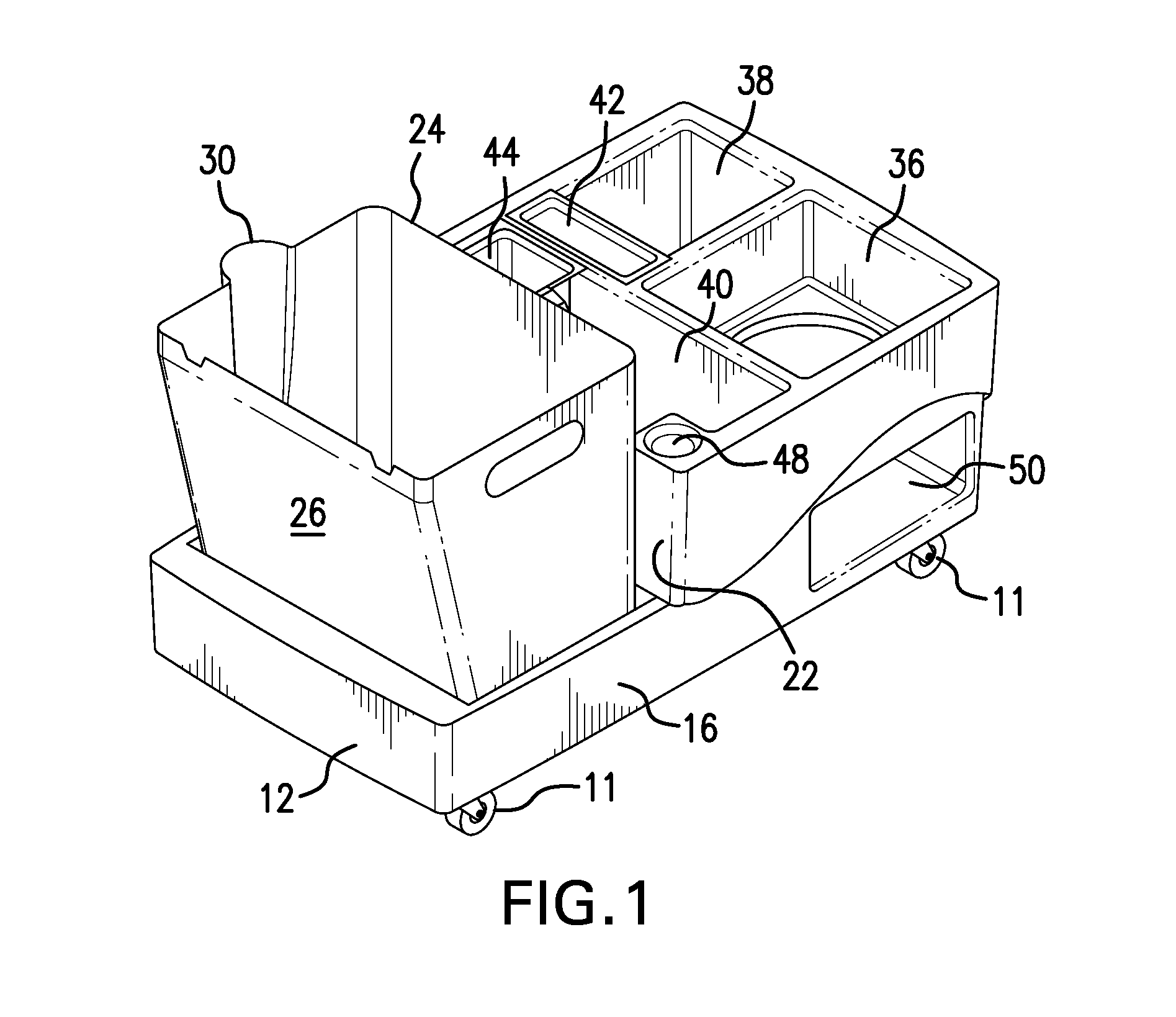

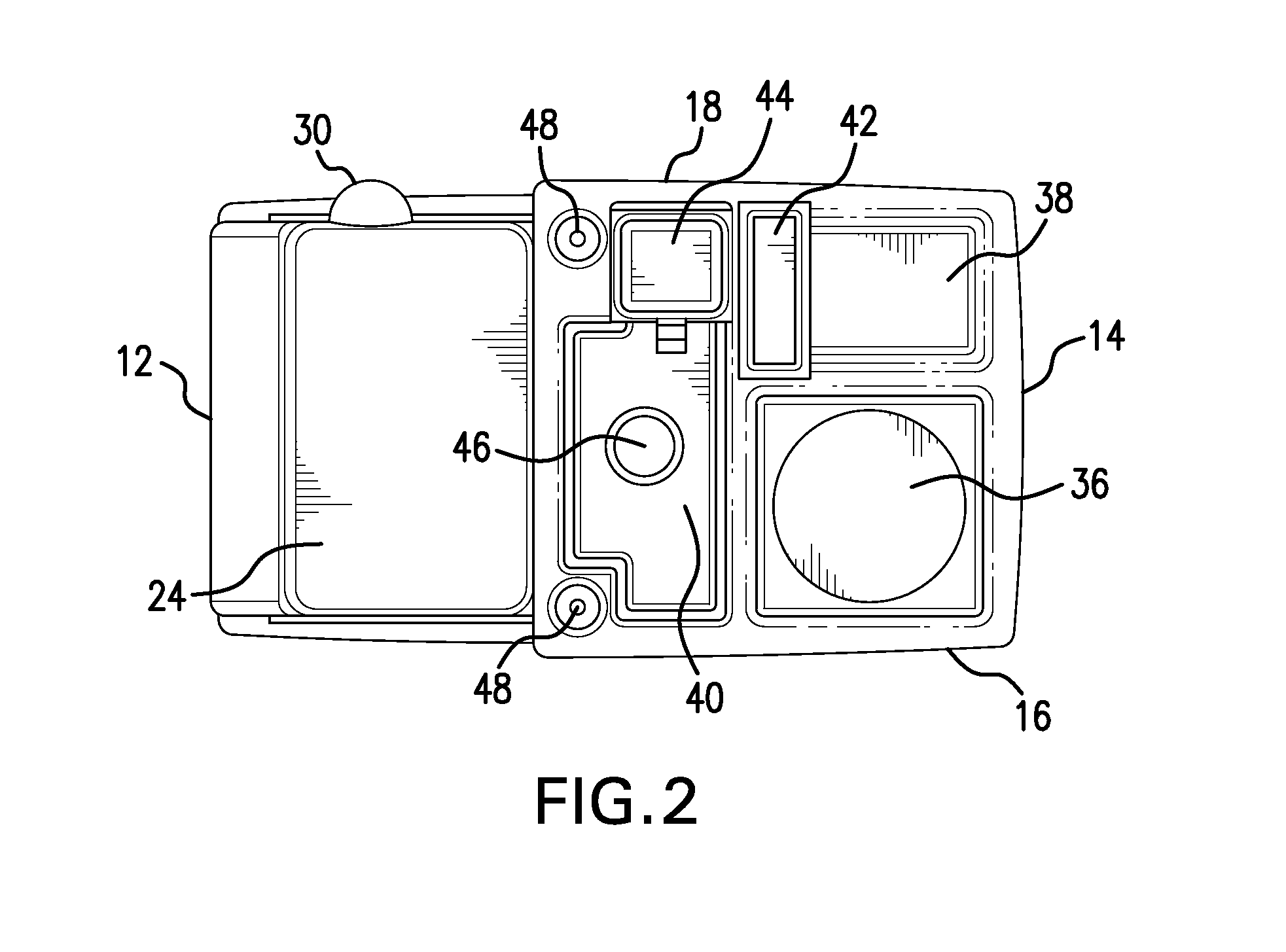

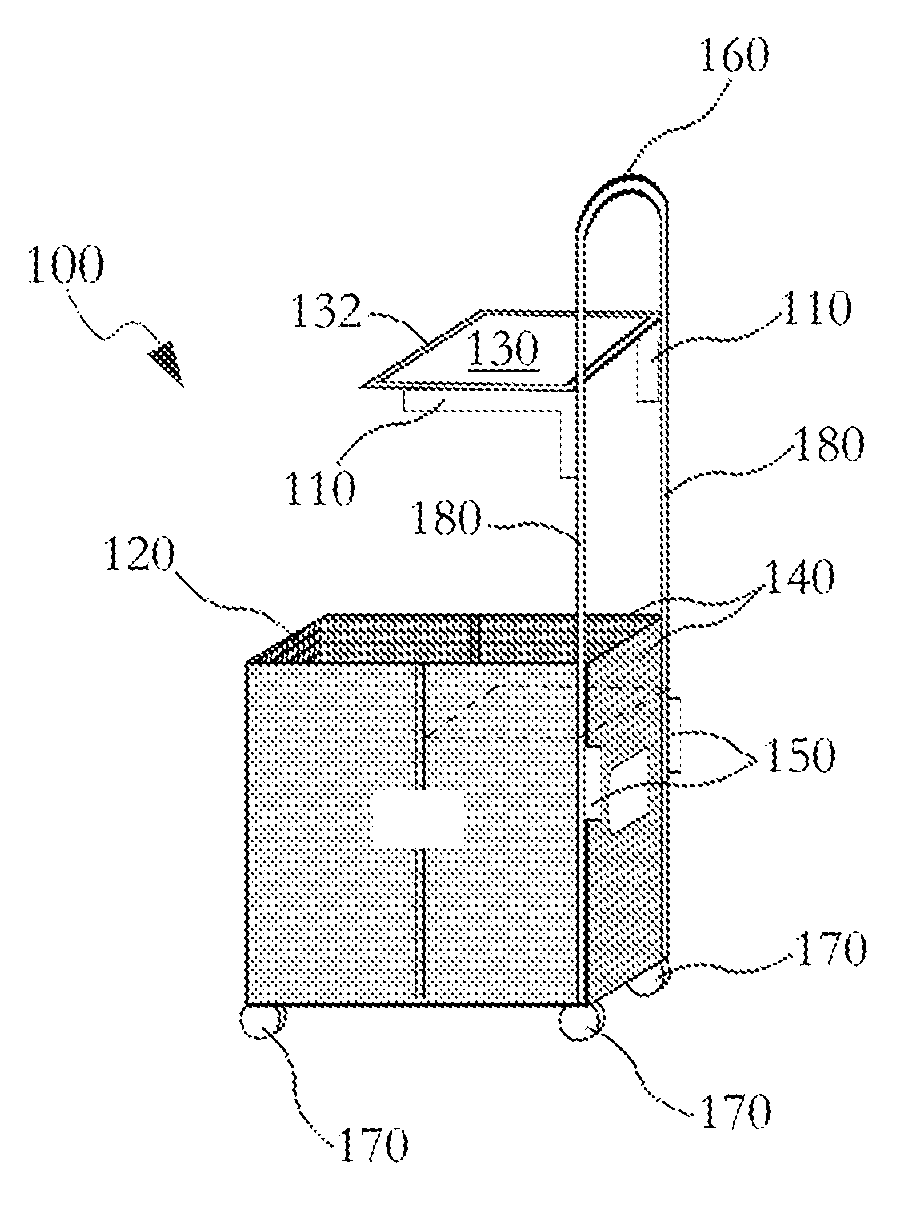

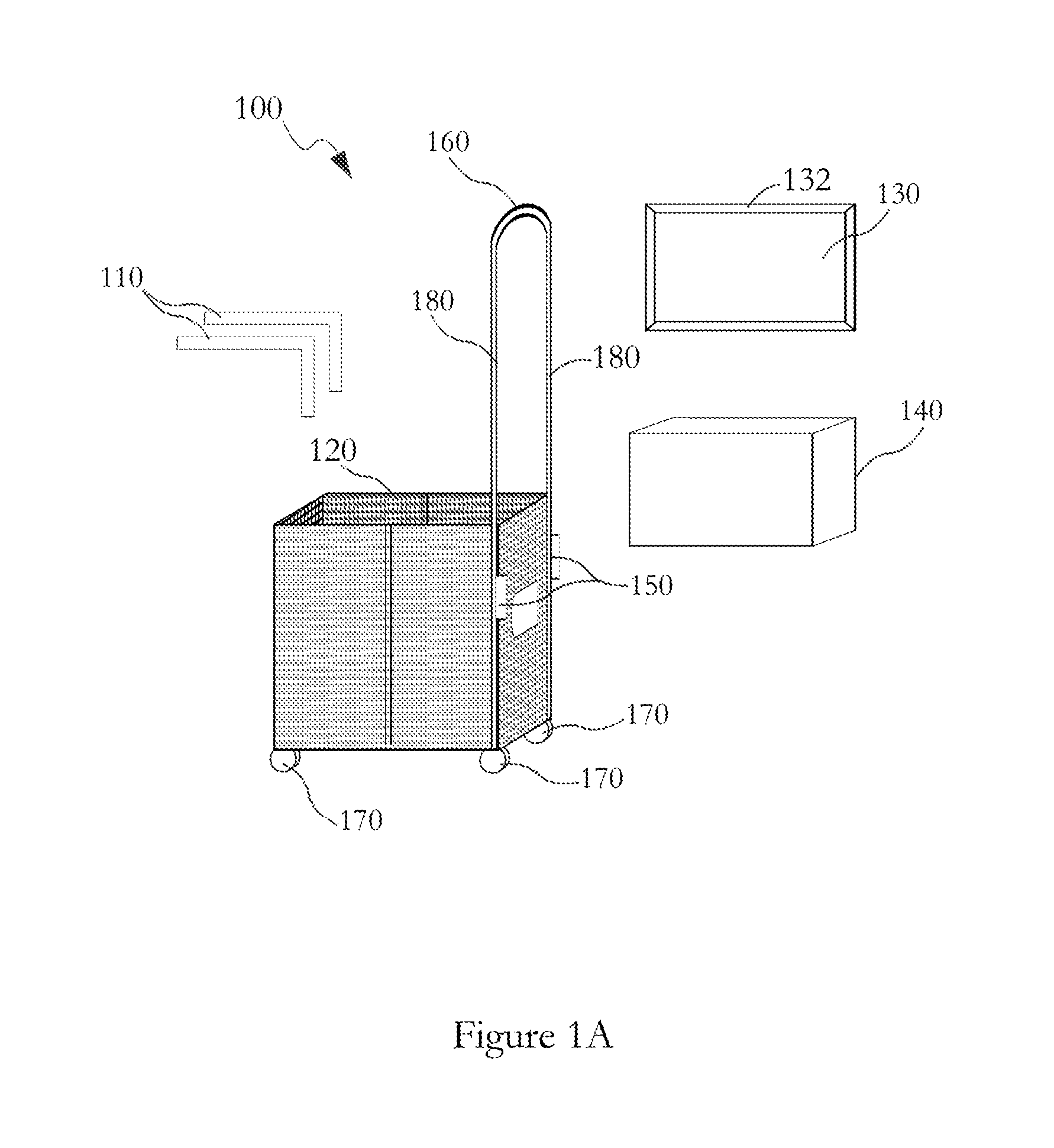

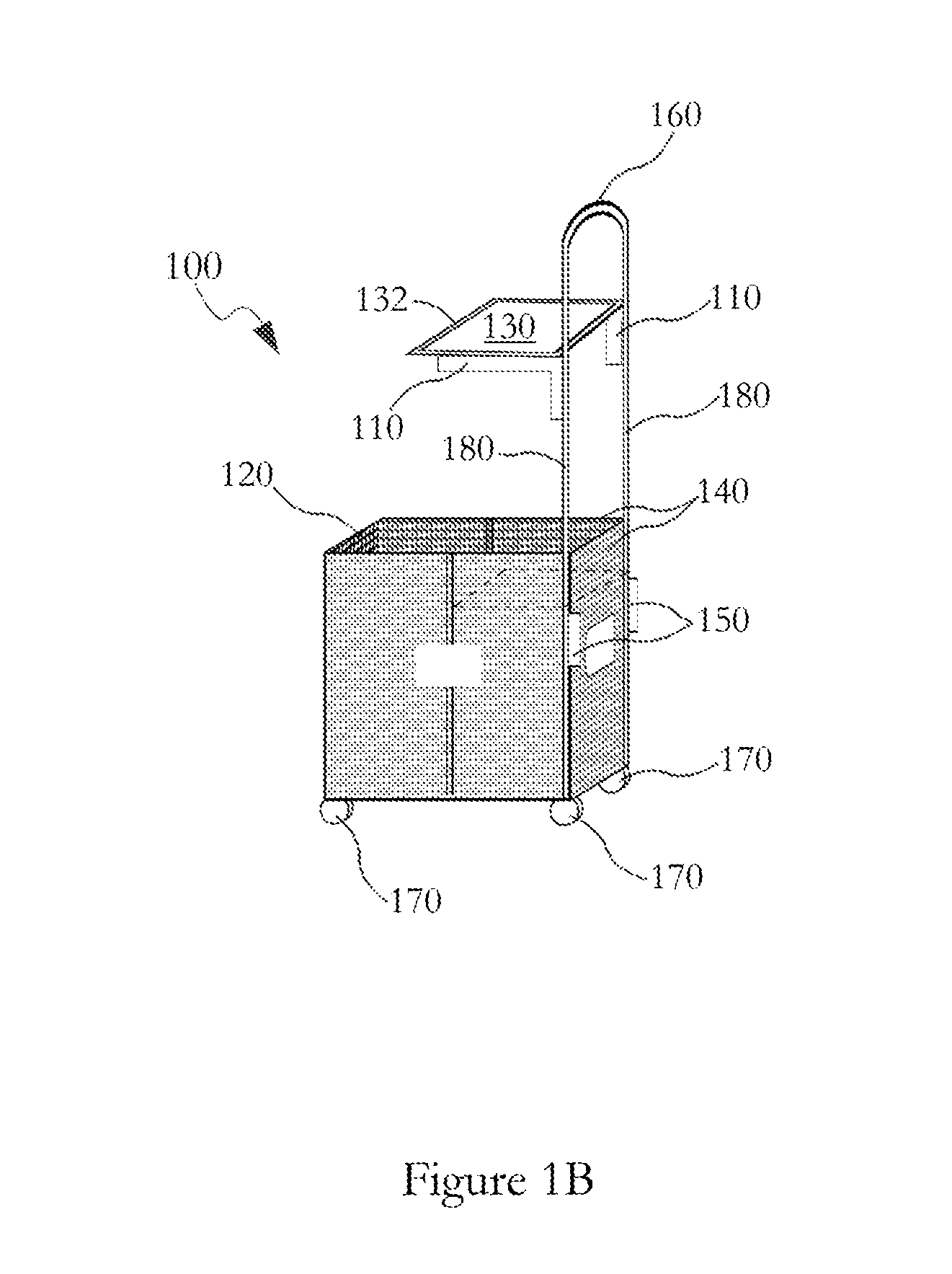

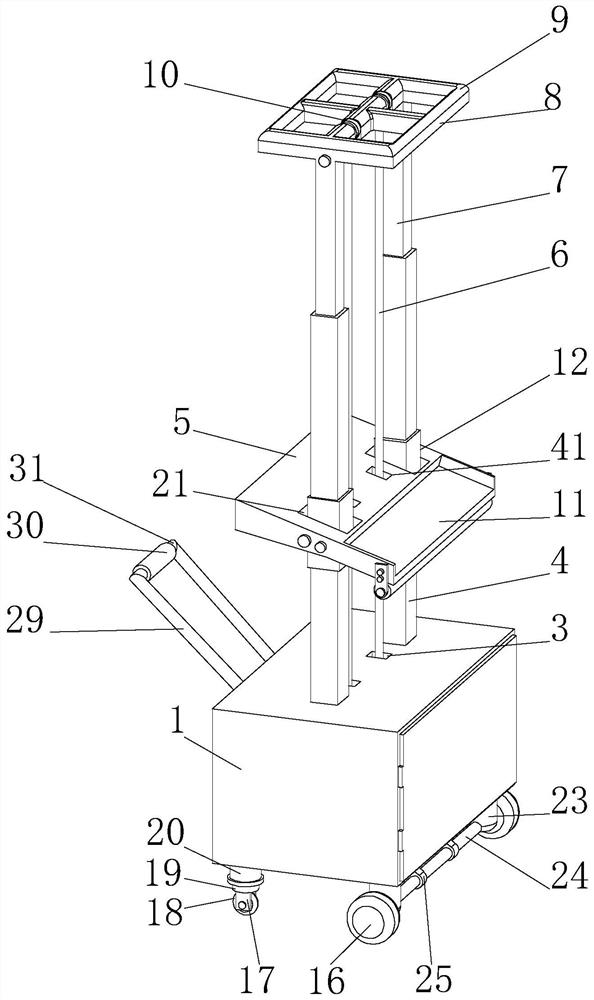

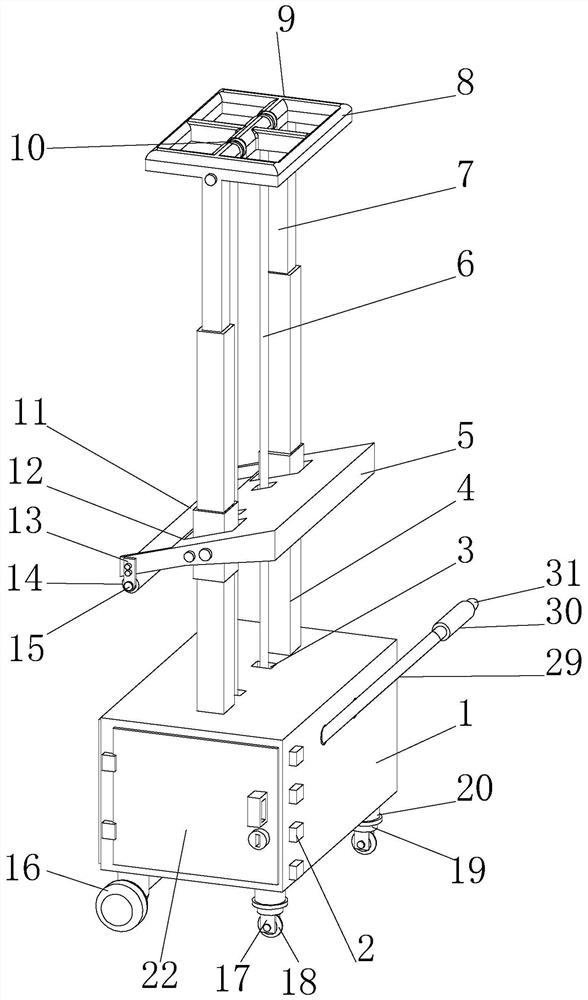

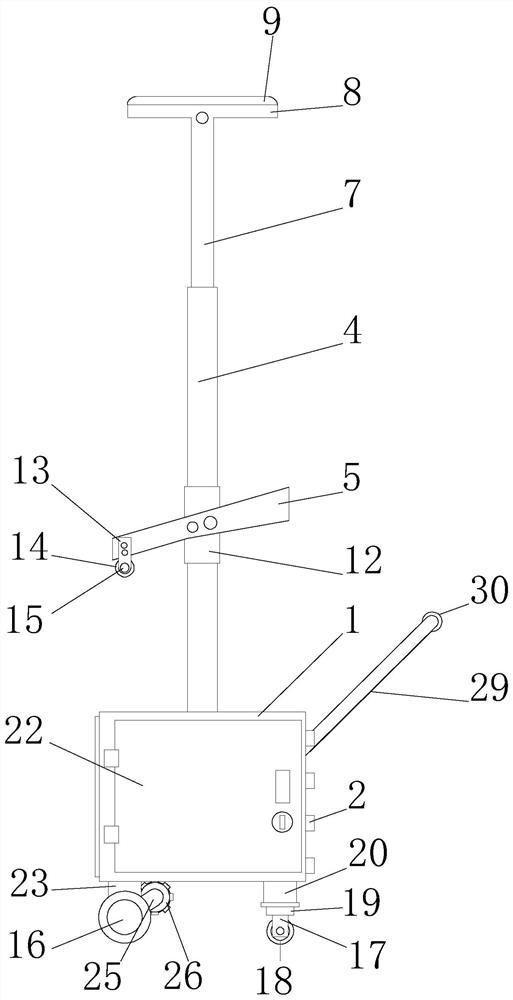

Multipurpose mobile caddy

ActiveUS9393979B1Efficient apparatusEasy to workWork benchesHand carts with multiple axesEngineeringMechanical engineering

Owner:MILTON DENEEN

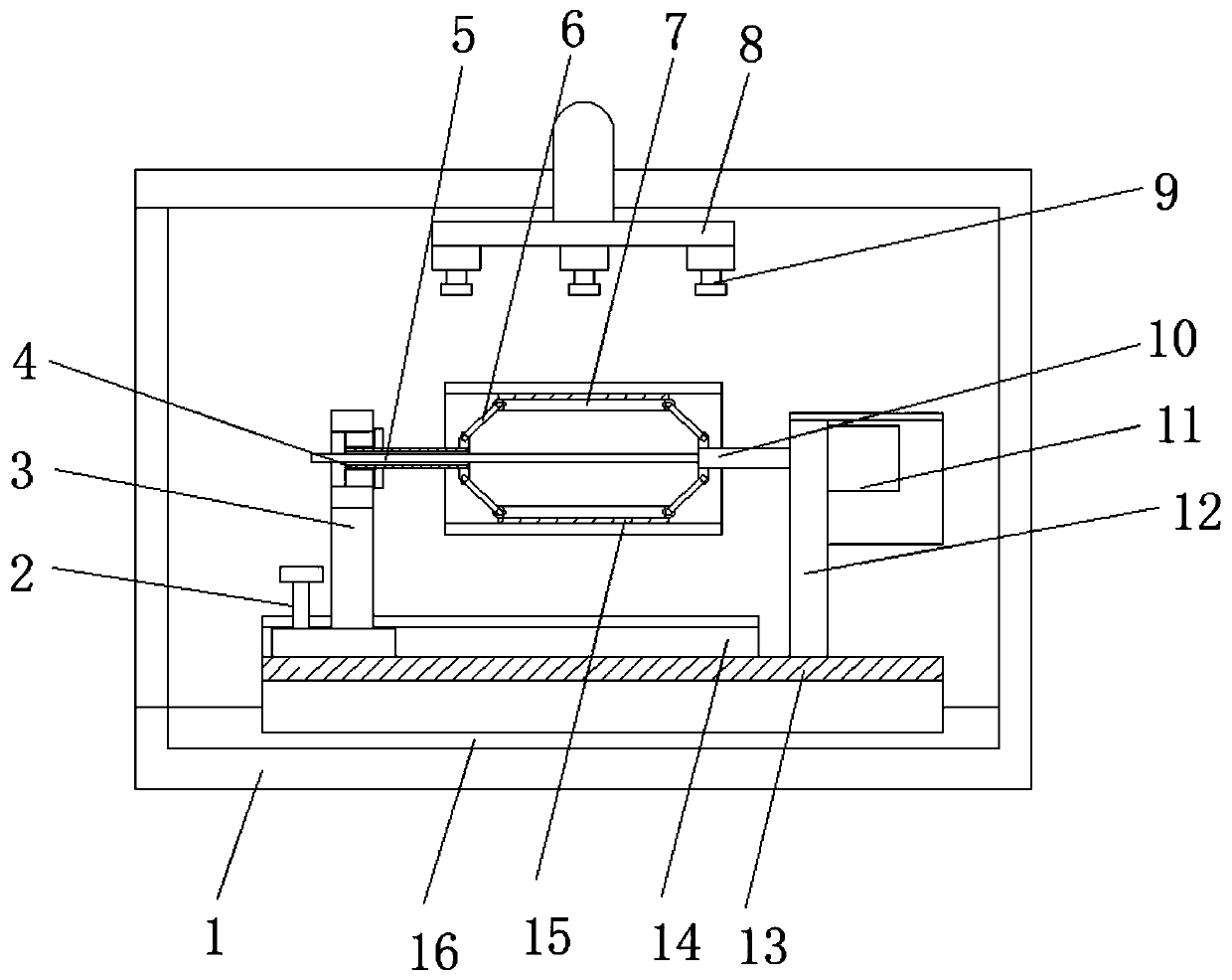

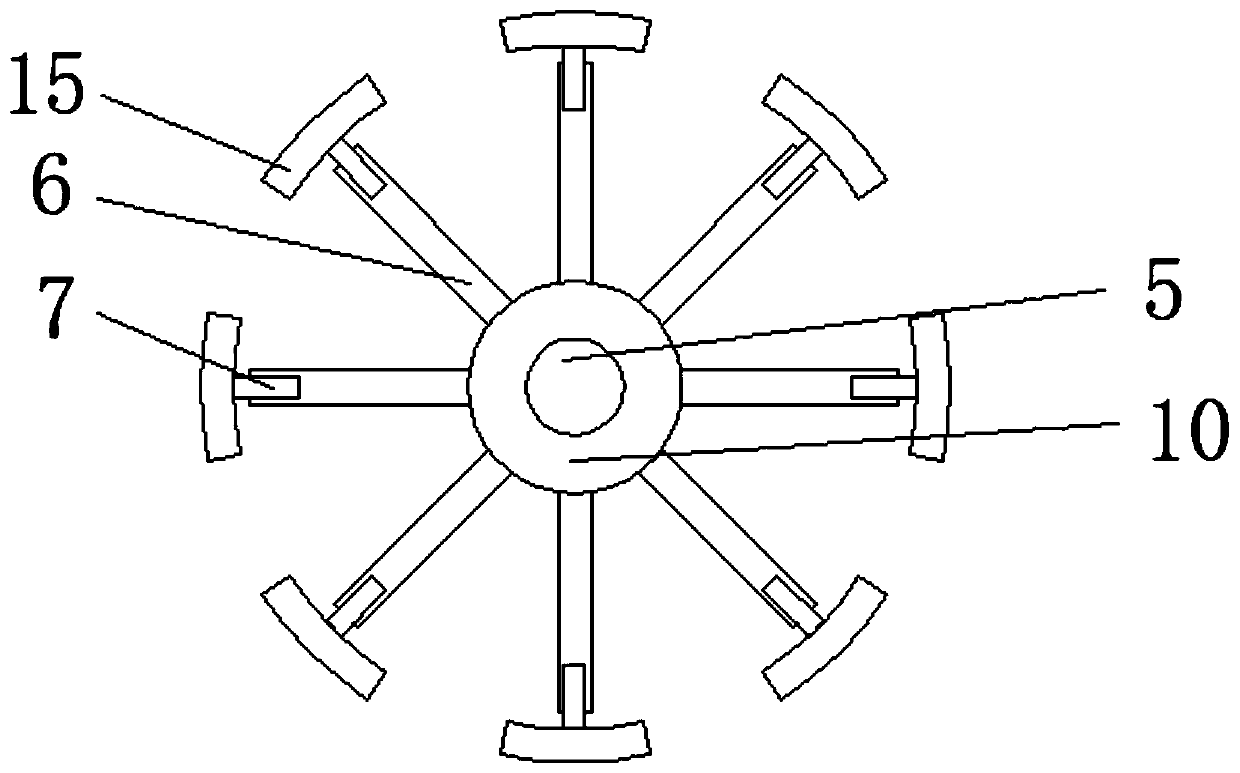

Paint spraying device for pump component machining

The invention discloses a paint spraying device for pump component machining. A box is included. A box door is hinged to the side face of the box door, and a paint pipe is connected to the inner wallof the top of the box through a bolt. The bottom end of the paint pipe is in screw joint with a plurality of spray guns. A sliding rail is connected to the inner wall of the bottom of the box throughbolts. The top end of the sliding rail is connected with a feeding rack through a sliding block. The top end of the feeding rack is connected with a main supporting rod through a bolt. The side face of the main supporting rod is connected with a stepping motor through bolts. An output shaft of the stepping motor is connected with a rotation shaft through a bolt. A limiting inserting rod is weldedto the end portion of the rotation shaft. In the paint spraying device, after the feeding rack is pushed into the box, the stepping motor is utilized for driving a pump shell to rotate, meanwhile, thespray guns start to conduct paint spraying operation on the outer surface of the pump shell, work is simple and convenient, the pump shell is subjected to paint spraying operation during rotation, distribution uniformity of a pump shell surface paint layer is improved, and the pump shell paint spraying quality is improved.

Owner:湖北鑫敏泵业有限公司

Mobile working station

InactiveUS20130234408A1Alleviate userEasy to workOffice tablesCarriage/perambulator with single axisTerrainEngineering

A mobile working station comprising a first container, where the first container includes an inner cavity; a pair of handlebars extending from the first container, where the pair of handlebars meet at a handle; a pair of brackets attached to the handlebars, where the pair of brackets support a platform; and a second container positioned within the inner cavity of the first container, where the second container receives a plurality of office supplies. The handle may include a comfort grip, and may be telescopic to enable the user to adjust the height. Finally, the mobile working station may include a set of all terrain wheels for greater transportability.

Owner:CHILDERS VICKIE

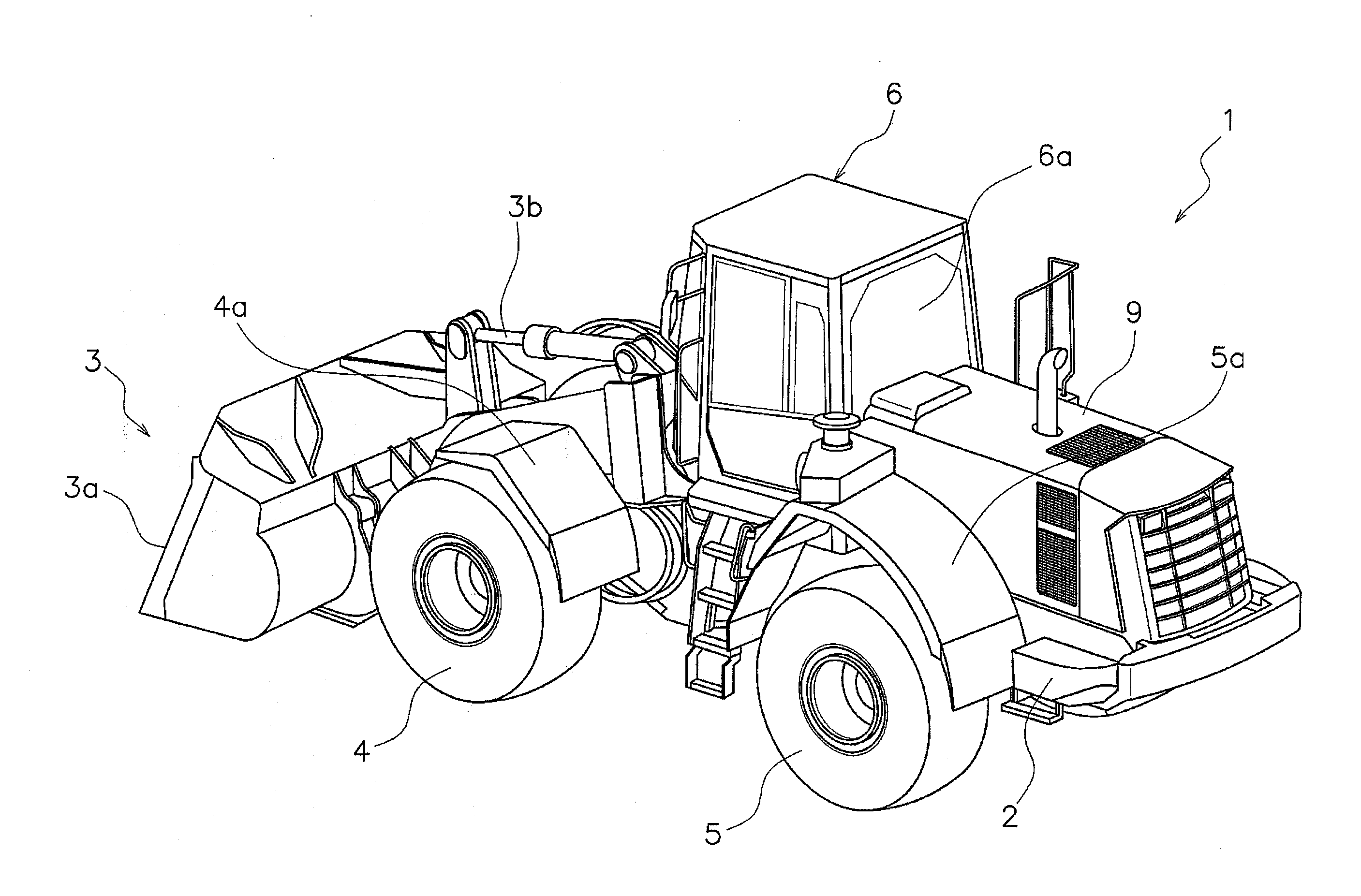

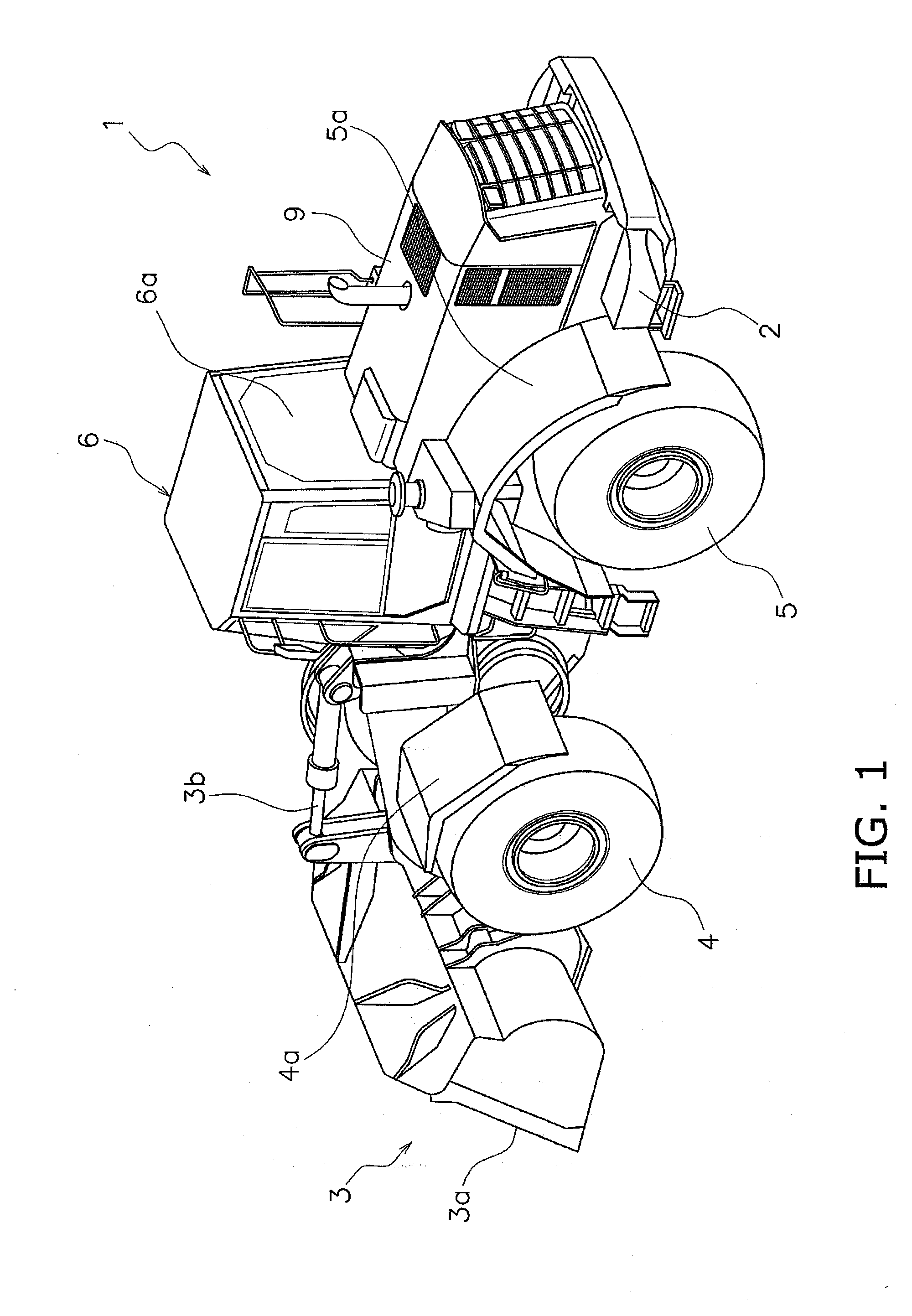

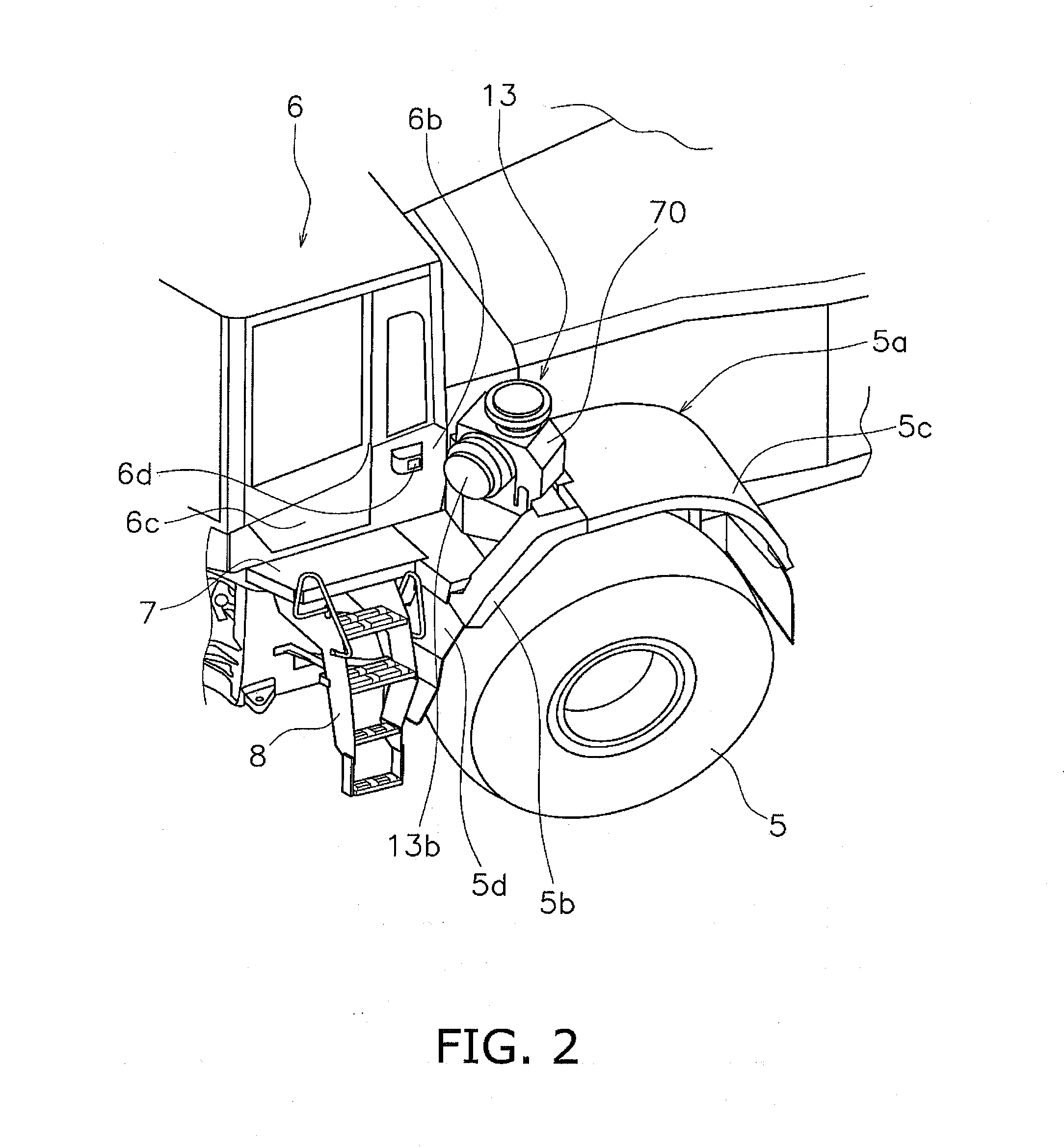

Wheel loader

ActiveUS20150184360A1Reduce visibilityEasy to workSoil-shifting machines/dredgersMachines/enginesAir cleanersEngineering

A wheel loader includes a cab, a ladder provided laterally of the cab, a vehicle body cover rear of the cab, an engine, an air cleaner and a platform disposed laterally of the cab. The engine is disposed inside an engine room defined by the cover. The air cleaner has an exchangeable filter to clean air supplied to the engine. The air cleaner is disposed outside of the cover and above / rear of the ladder. The ladder has a first top step projecting laterally relative to the platform, and steps below projecting laterally relative to the first step. Preferably at least one of the first and second steps has a larger projection amount than the step below. Preferably, a projection amount of a third step positioned at a bottom is smaller than a projection amount of at least one of the first and second steps.

Owner:KOMATSU LTD

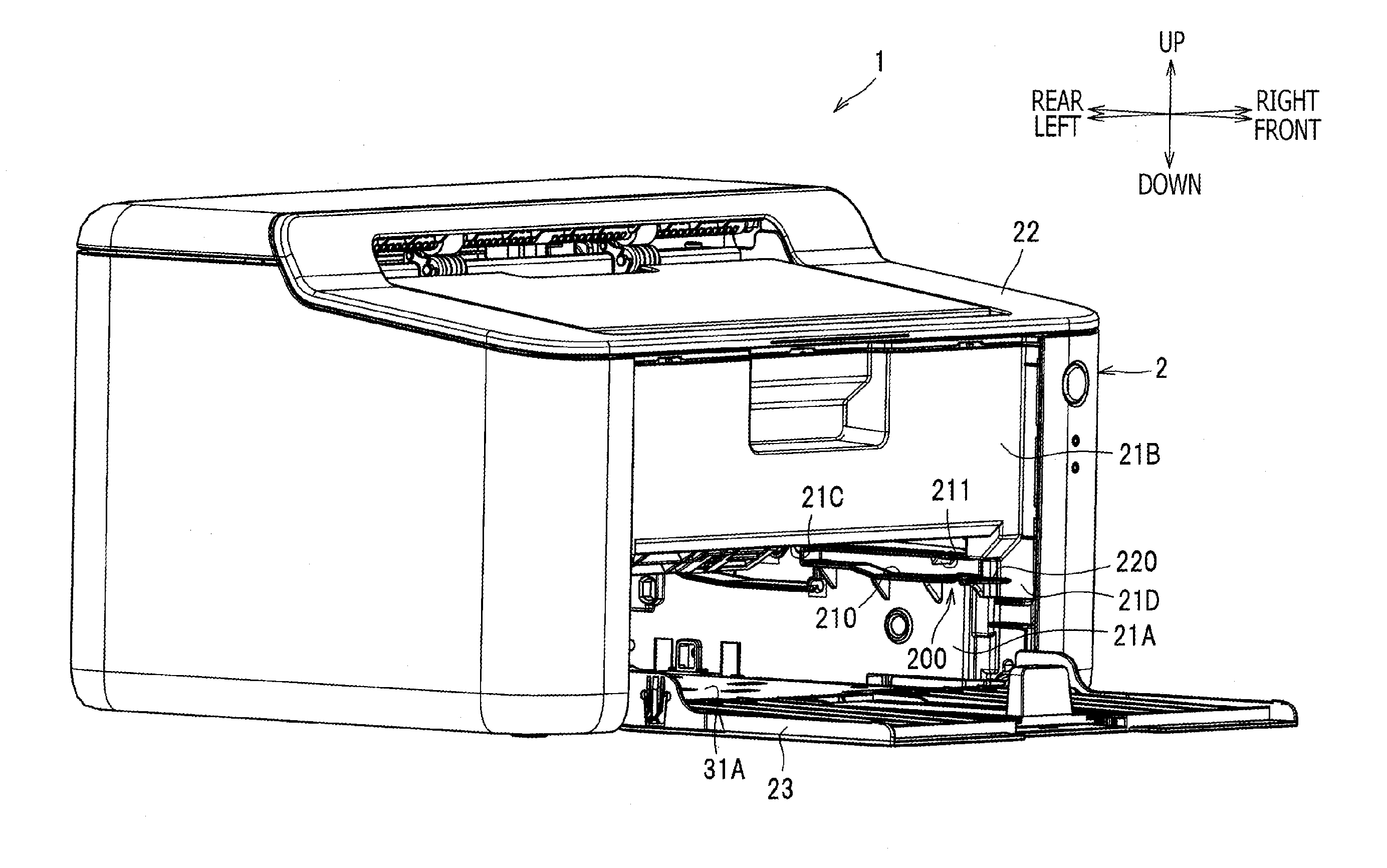

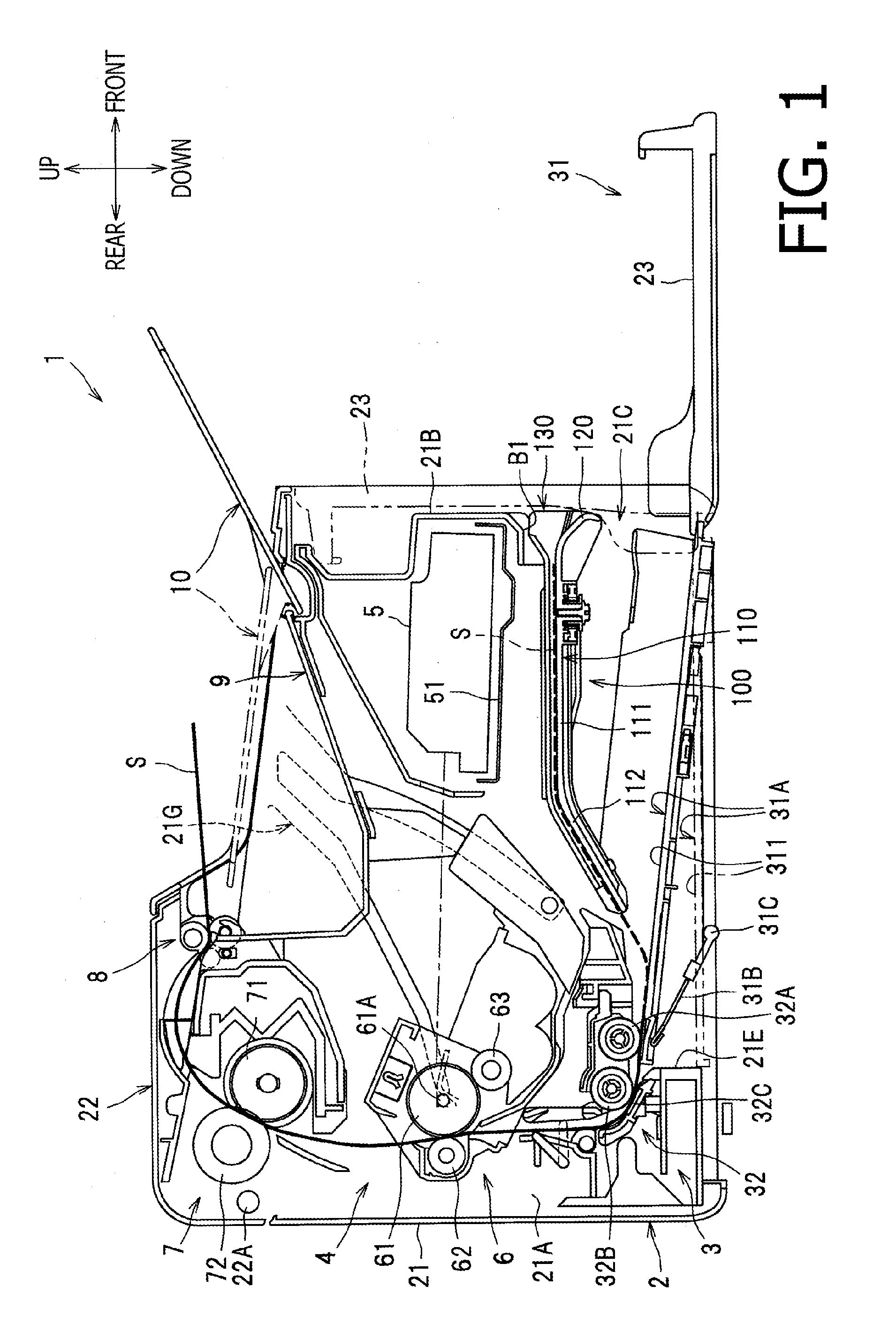

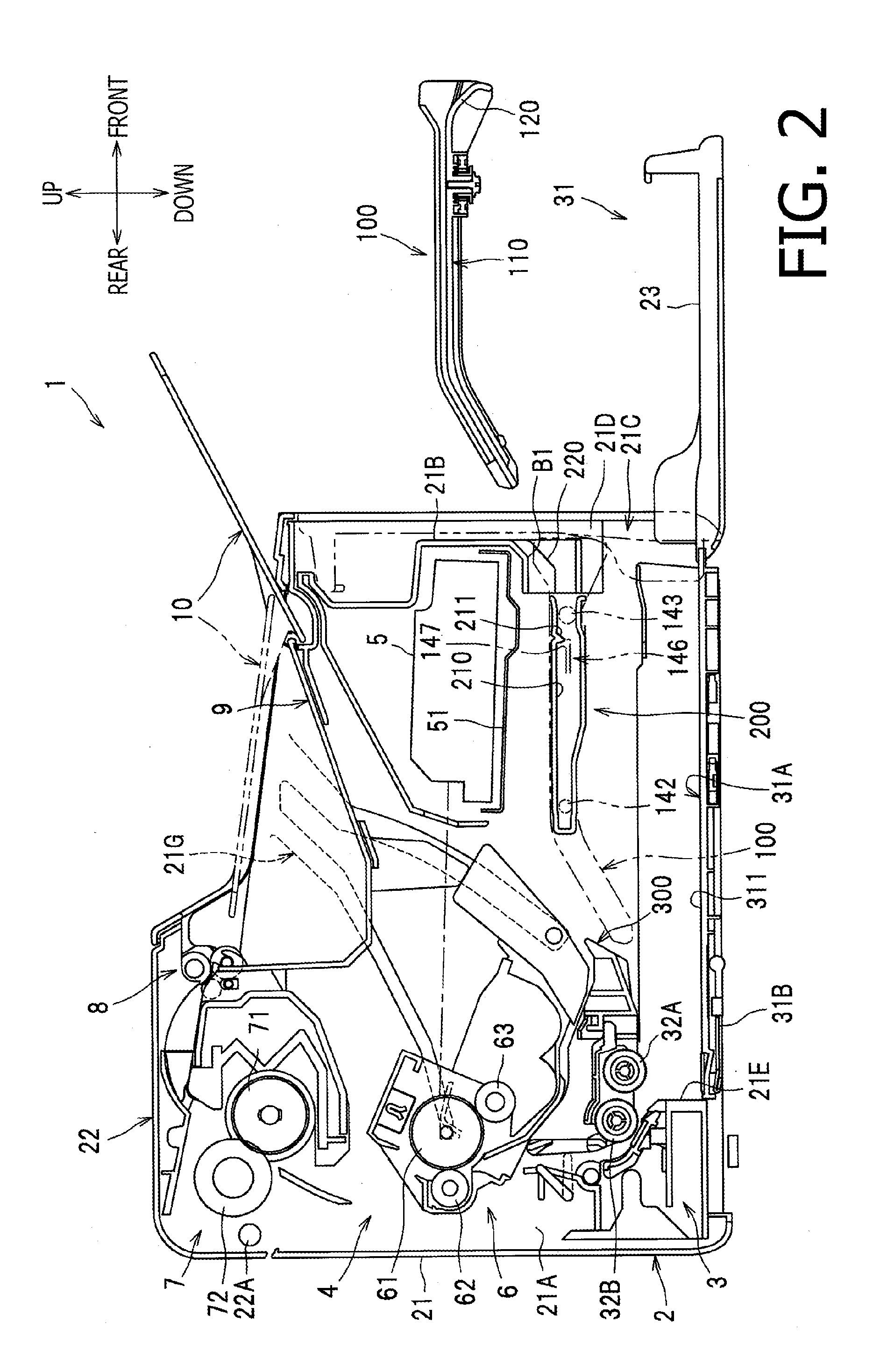

Image Forming Apparatus

ActiveUS20140252715A1Reduce volumeEasy to workRegistering devicesFunction indicatorsImage formationChassis

An image forming apparatus, including a chassis with an opening formed on one side thereof; a first placement section, on which a sheet inserted through the opening is placeable; a cover configured to be openable to expose and closable to cover the opening and configured to form, when in a position to expose the opening, an outer part of the first placement section outside the chassis; and a second placement section arranged in an upper position with respect to the first placement section, and on which a sheet inserted through the opening is placeable, is provided. The second placement section is detachably attached to the chassis through the opening.

Owner:BROTHER KOGYO KK

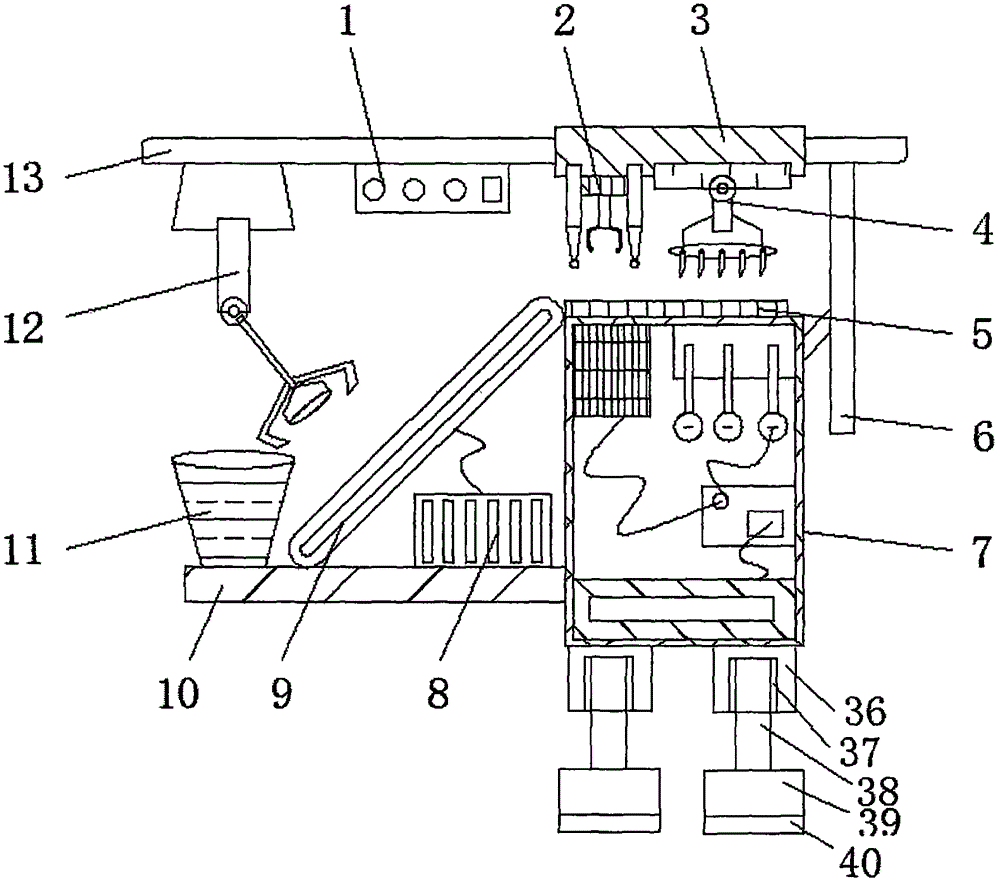

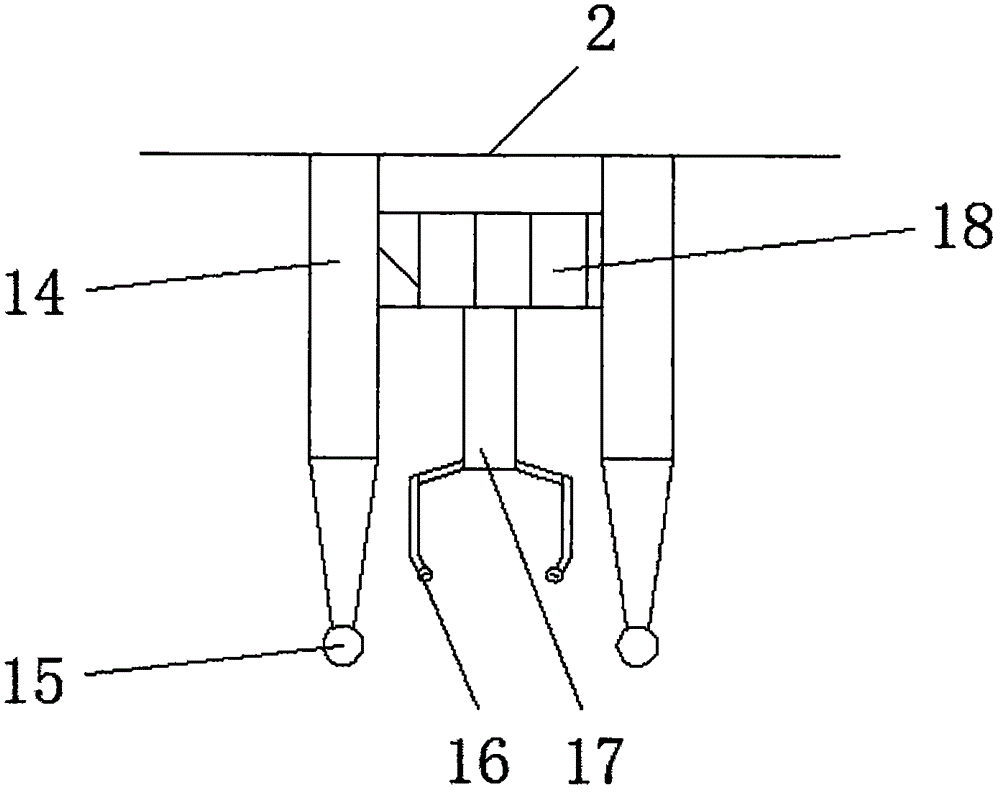

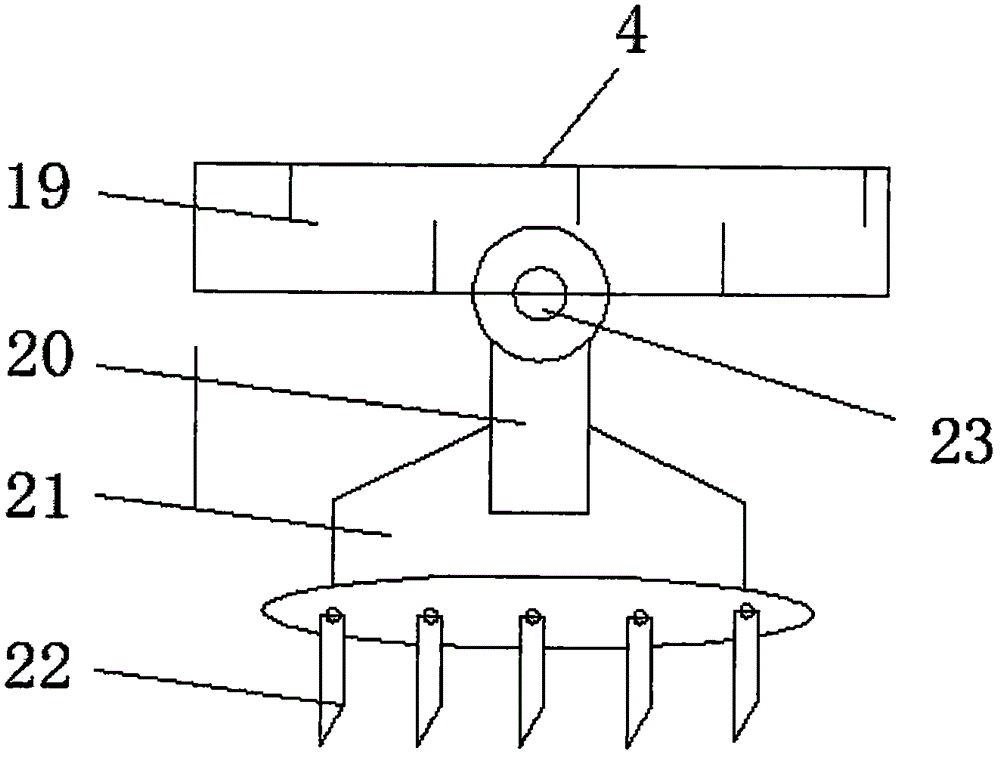

Automatic indoor intelligent plastering machine capable of plastering uniformly and flatly

InactiveCN112324102APrevent conditions that affect the quality of workIncrease frictionBuilding constructionsSteering wheelStructural engineering

The invention discloses an automatic indoor intelligent plastering machine capable of plastering uniformly and flatly. The plastering machine comprises an equipment box; two telescopic outer rods arefixedly mounted at the top of the equipment box; sliding blocks are connected to the outer sides of the two telescopic outer rods in a sleeving mode; operation plastering plates are hinged to two sides of each sliding block in a threaded mode; telescopic inner rods are fixedly mounted in the two telescopic outer rods; a top plate is fixedly mounted at the tops of the telescopic inner rods; and twosteering wheel supporting columns are fixedly mounted on one side of the bottom of the equipment box. A handle is manually pushed to move a box body, acting force acts on a steering shaft column to drive a steering wheel shaft column plate so as to control a steering wheel to rotate, steering is achieved, the box body is moved to a designated place, the telescopic inner rods fixedly installed inthe telescopic outer rods stretch to the top of a building, the top plate is jacked to the top of the building and is fixed, the inclination angles of the operation plastering plates are adjusted through threaded hinge at the joint of the operation plastering plates and the sliding blocks, and therefore plastering operation is achieved.

Owner:王立孟

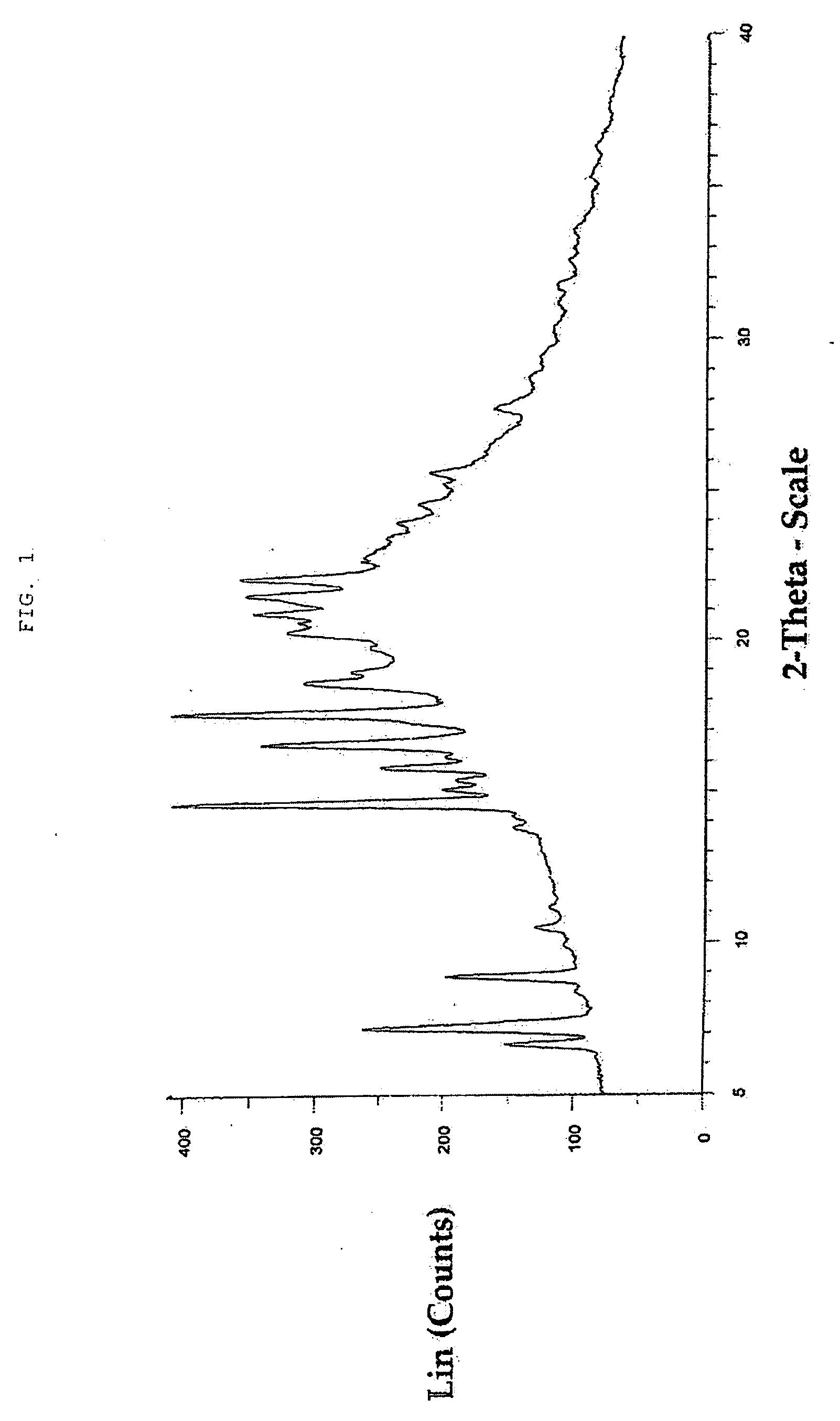

Macrolide compound in solid form, process for preparation thereof, and pharmaceutical composition containing the same

InactiveUS20080214564A1High purityEasy to workSilicon organic compoundsOrganic active ingredientsDrugChemical compound

The present invention provides the compound of formula (I) in a solid form which, as a bulk medicament for pharmaceutical manufacture, is uniform, has a high purity, and is easy to work with. The invention further provides a process for preparing this compound, and pharmaceutical compositions containing the same. A solid form of (8E,12E,14E)-7-{(4-cycloheptylpiperazin-1-yl)carbonyl}oxy-3,6,16,21-tetrahydroxy-6,10,12,16,20-pentamethyl-18,19-epoxytricosa-8,12,14-trien-11-olide which has uniform specifications and is easy to work with was developed.

Owner:EISIA R&D MANAGEMENT CO LTD +1

Tartrate salts of (R) -3-N,N- dicyclobutylamino-8-fluoro-3,4-dihydro-2H-1- benzopyran-5-carboxamide

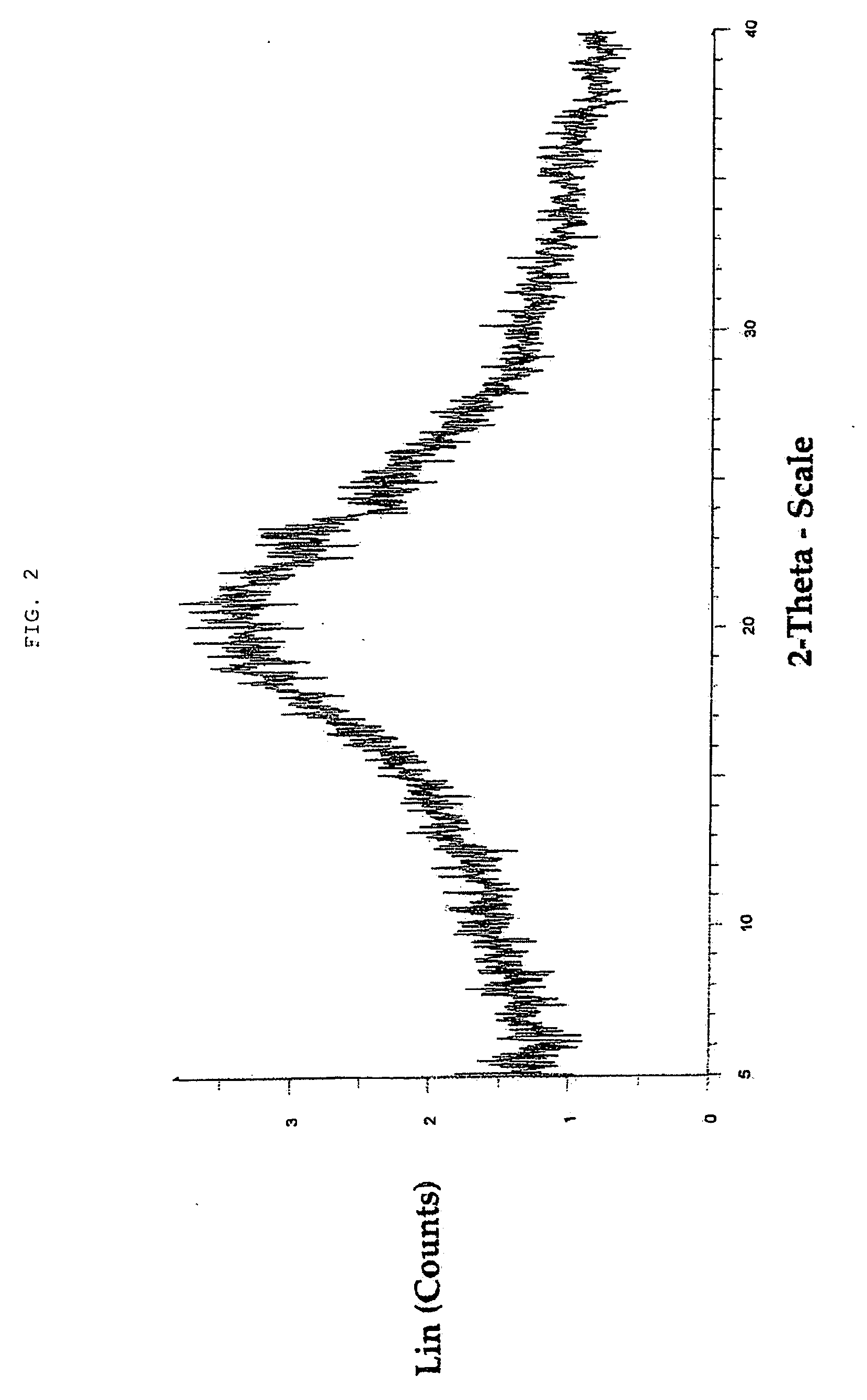

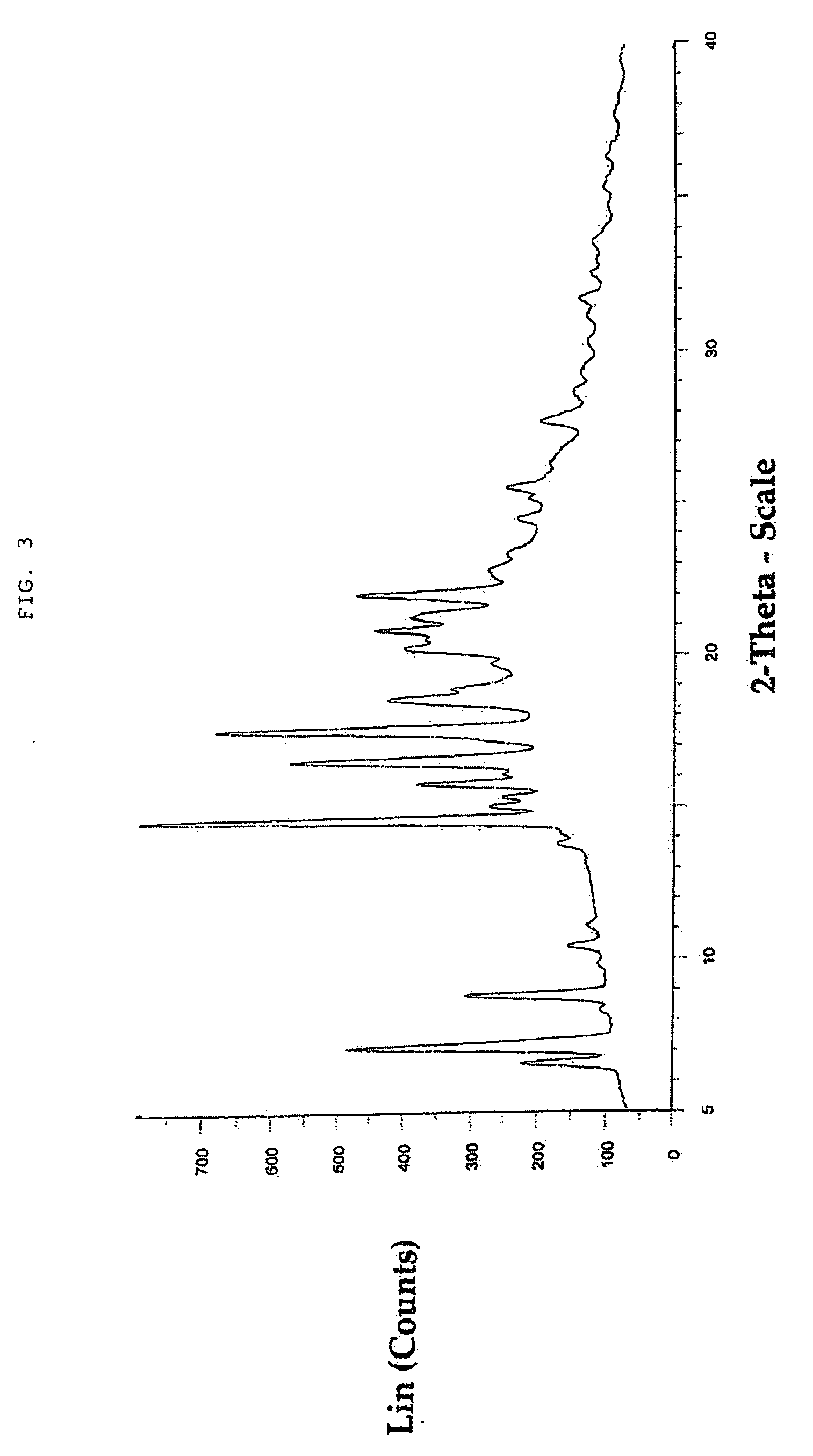

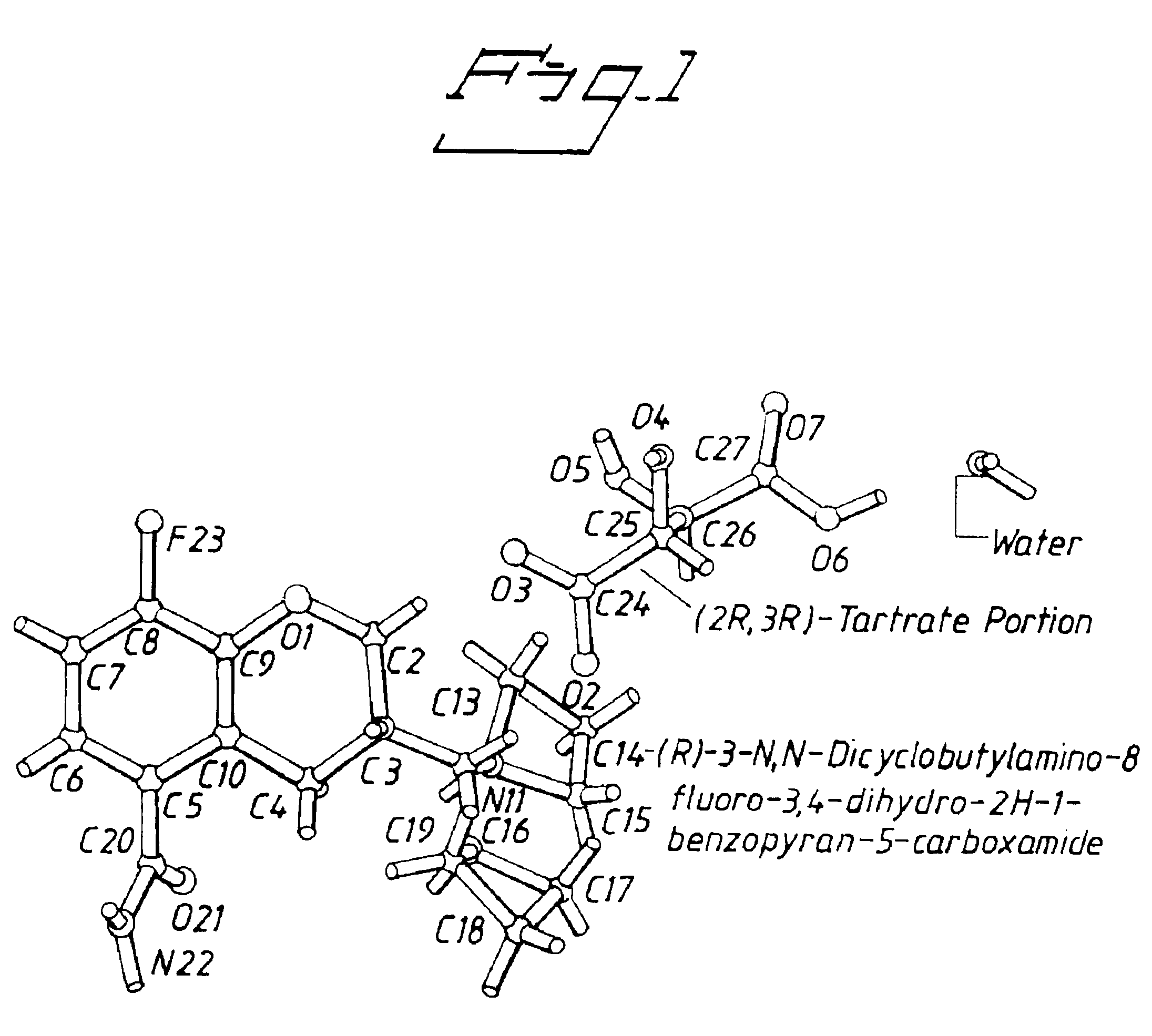

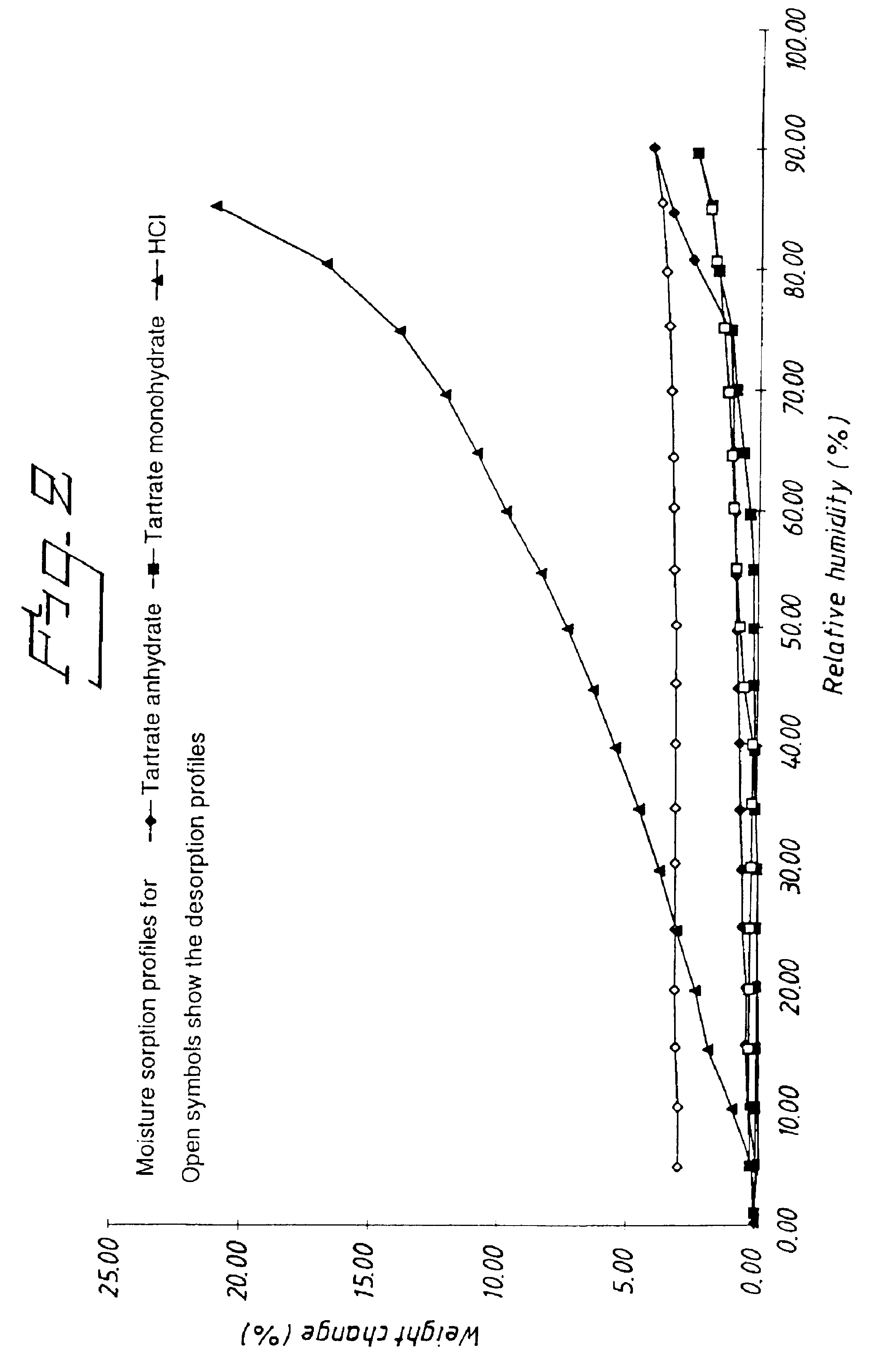

InactiveUS6858645B2Good solubility and dissolution propertyEasy to workBiocideNervous disorderPharmaceutical formulationTartrate

A new salt (R)-3-N,N-dicyclobutylamino-8-fluoro-3,4-dihydro-2H-1-benzopyran-5-carboxamide hydrogen tartrate, particularly the (2R,3R)-tartrate thereof, most particularly the (R)-3-N,N-dicyclobutylamino-8-fluoro-3,4-dihydro-2H-1-benzopyran-5-carboxamide hydrogen (2R,3R)-tartrate monohydrate, processes for the manufacture of said tartrate salt, the use of the salt in medicine, the use of the tartrate salt in the manufacture of pharmaceutical formulations, and a method for the treatment of CNS disorders by administration of the tartrate salt to a host in need of such treatment.

Owner:ASTRAZENECA AB

Pearl powder soft capsule

ActiveCN1682767AReduce viscosityImprove liquidityNervous disorderMetabolism disorderGlyceryl CaprateCarbon chain

The soft pearl powder capsule includes pearl powder and characterized glyceryl octyl caprate in the amount of 4-39 wt%. The addition of medium carbon chain glyceryl octyl caprate can lower the viscosity of the material and improve the flowability of material so as to facilitate the preparation of the soft capsule. The soft pearl powder capsule may have pearl powder content as high as 60 %, and this reduces the size of the soft capsule and is favorable to make best use of pearl powder.

Owner:FERGUSON WUHAN BIOTECH

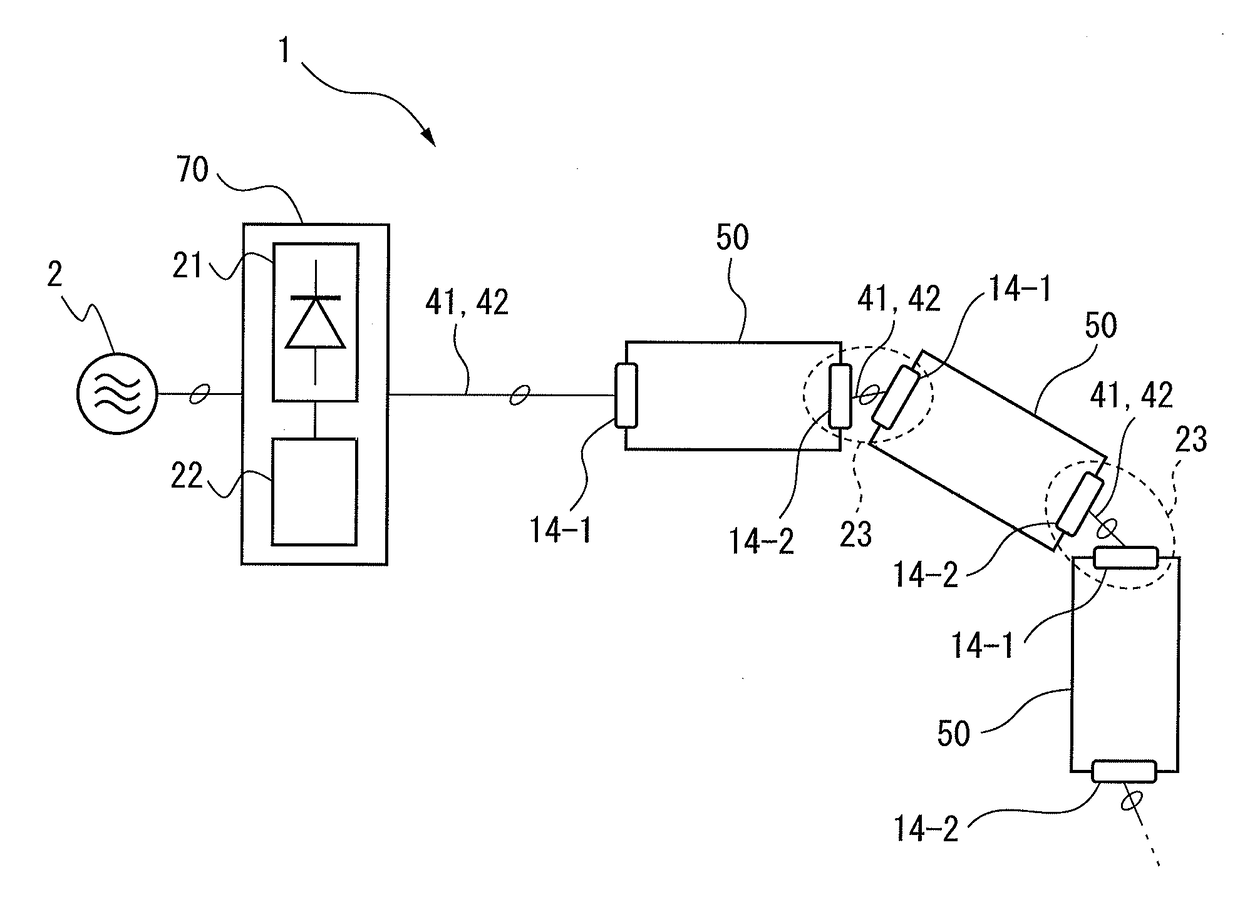

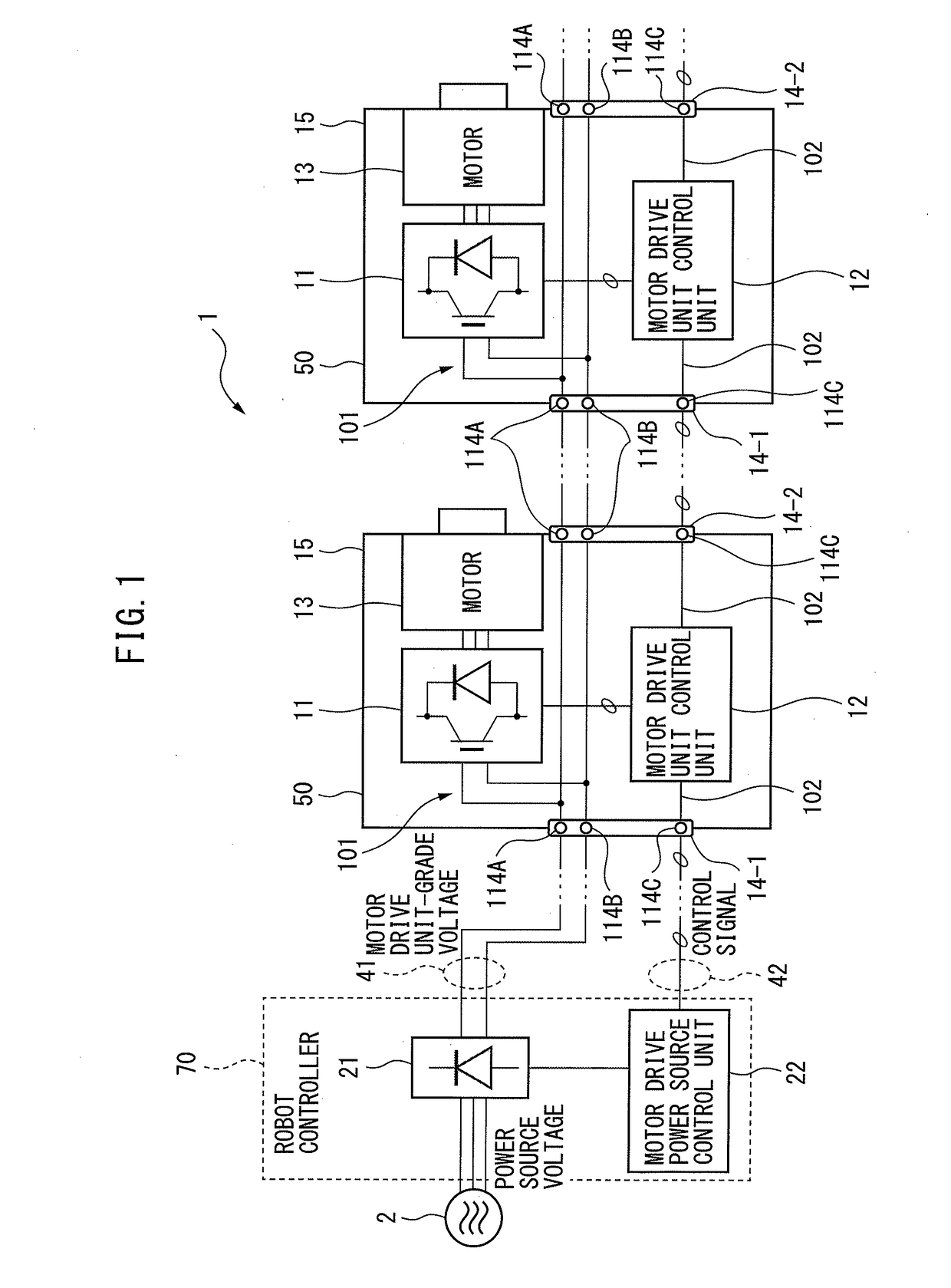

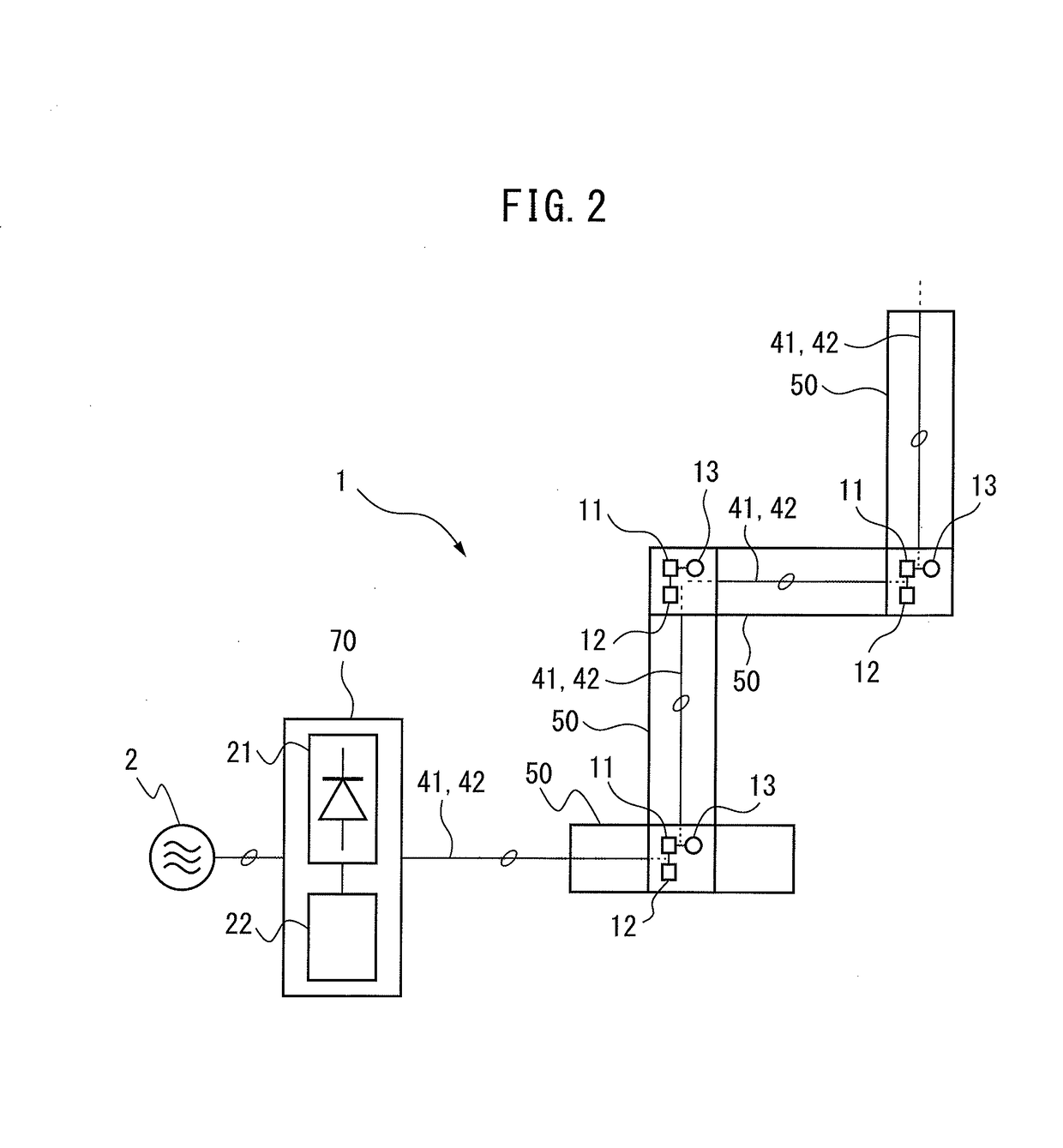

Robot with daisy-chainable robot arm

ActiveUS20170291298A1Reduce numberEasy to workProgramme controlProgramme-controlled manipulatorMotor Drive UnitVoltage

A robot includes a motor drive power source for converting a voltage supplied from a power source to a motor drive unit-grade voltage and outputting it, a motor drive unit for converting a motor drive unit-grade voltage output from the motor drive power source to a motor drive voltage and outputting it, a motor driven to be rotated by a motor drive voltage output by the motor drive unit, a robot arm on which the motor drive unit and the motor are arranged, and a robot controller which is provided independently of the robot arm and on which the motor drive power source is arranged.

Owner:FANUC LTD

Seismic sensing acousto-optic alarm device with anti-collision function

The invention discloses an earthquake sensing acousto-optic alarm with anti-collision function. There is an acousto-optic alarm, the positive terminal of the acousto-optic alarm is connected to the positive terminal of the storage battery through a third wire, a hook is provided on the left side of the upper end of the support, and a tapered piece is provided on the left middle of the support. The cone is suspended directly below the hook through the first wire, and the end of the first wire away from the cone is connected to the negative terminal of the sound and light alarm. One end is provided with a conductive ring. The earthquake sensing acousto-optic alarm with anti-collision function has a simple structure, is easy to install, can effectively prevent impact, and can function as an alarm, which is convenient for safe evacuation of personnel, reduces losses, and is convenient to use.

Owner:成都麟成科技有限公司

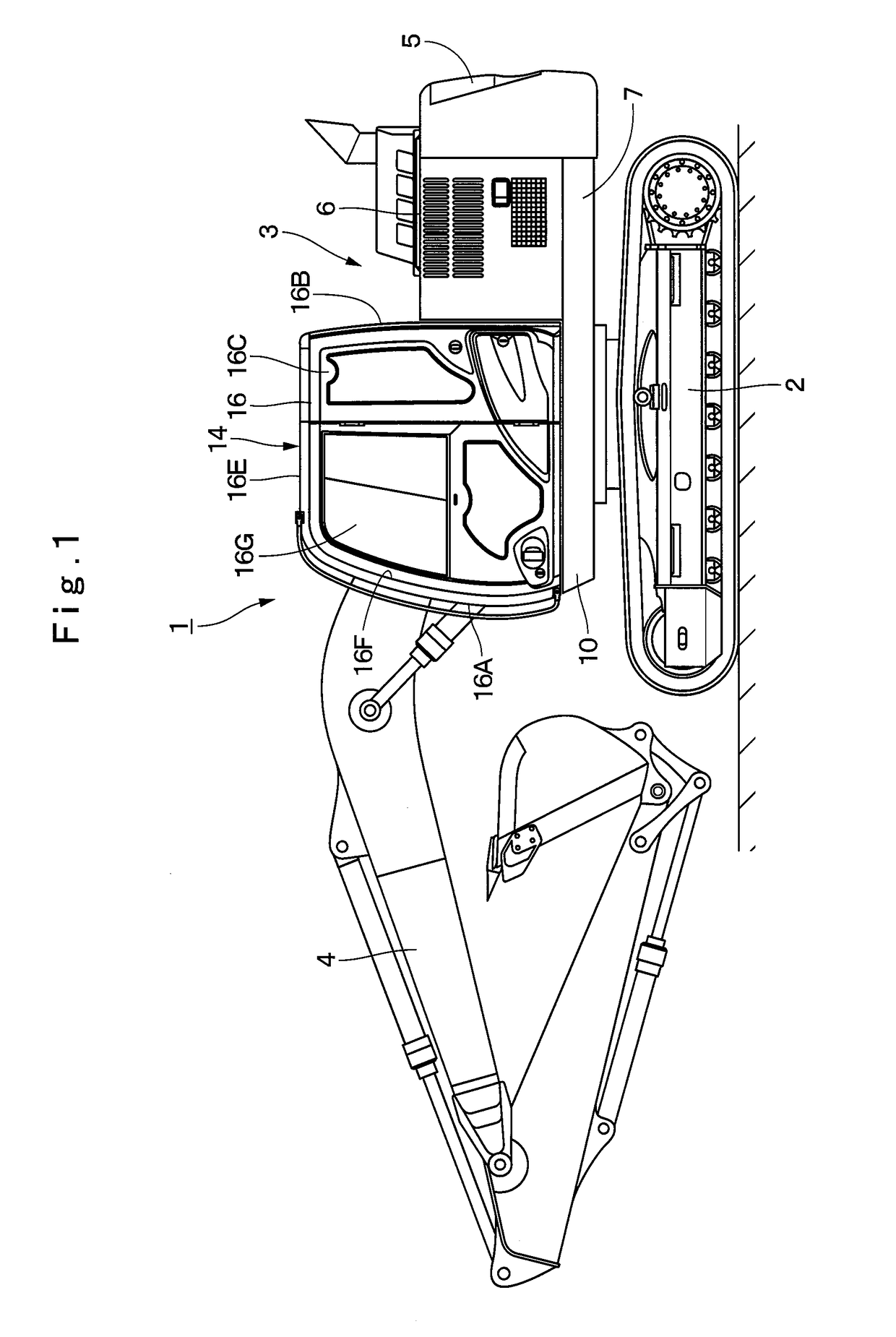

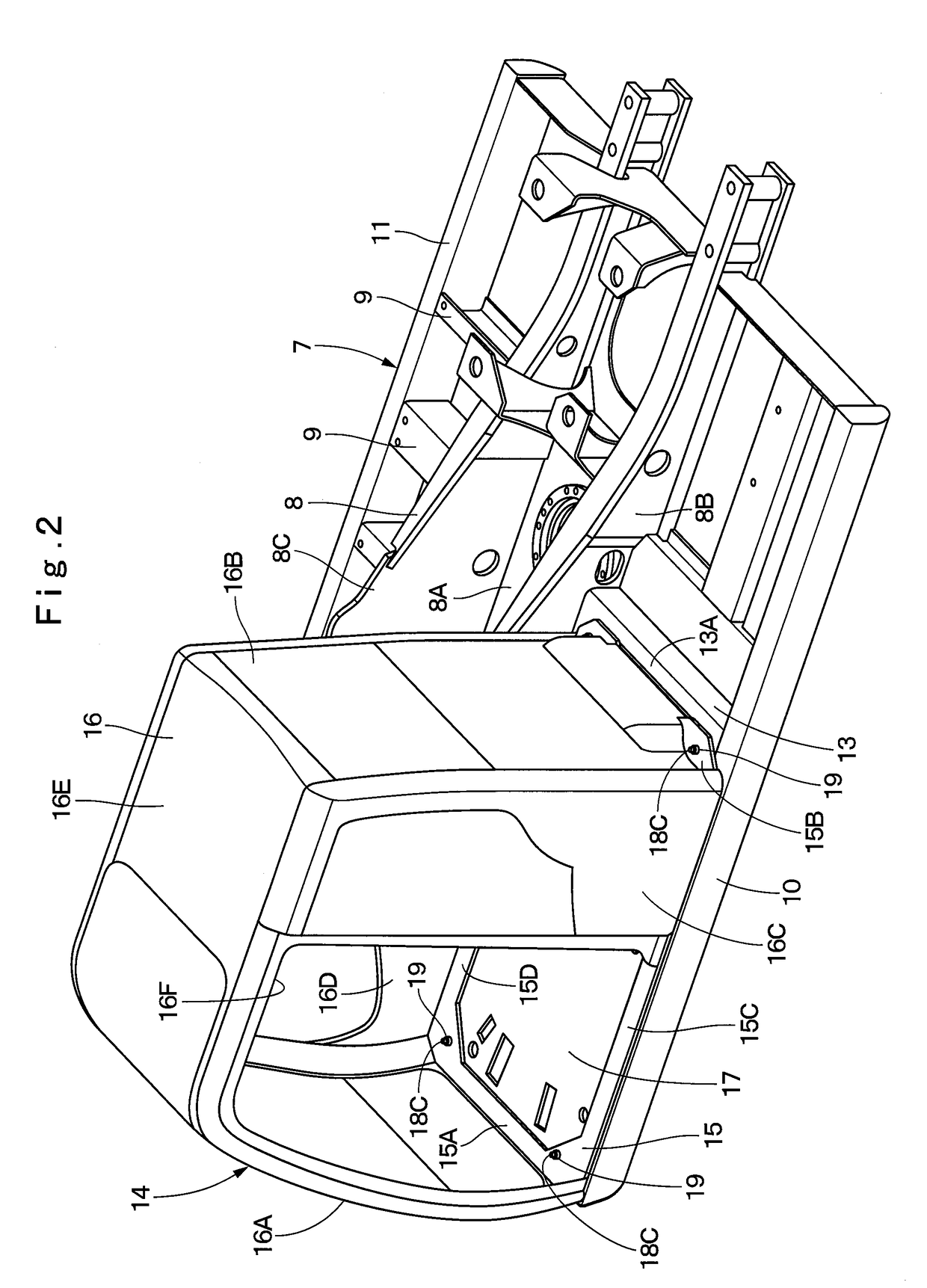

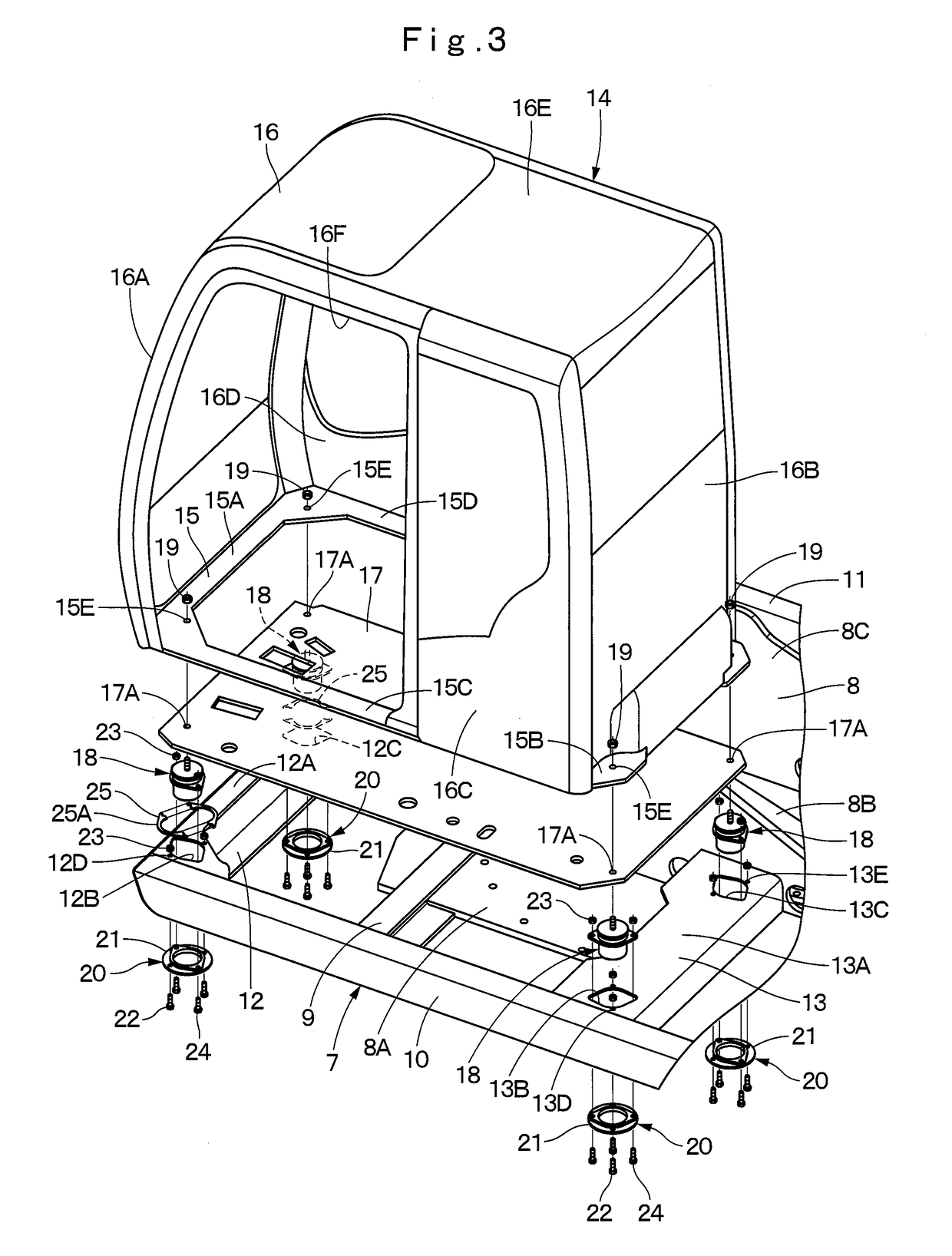

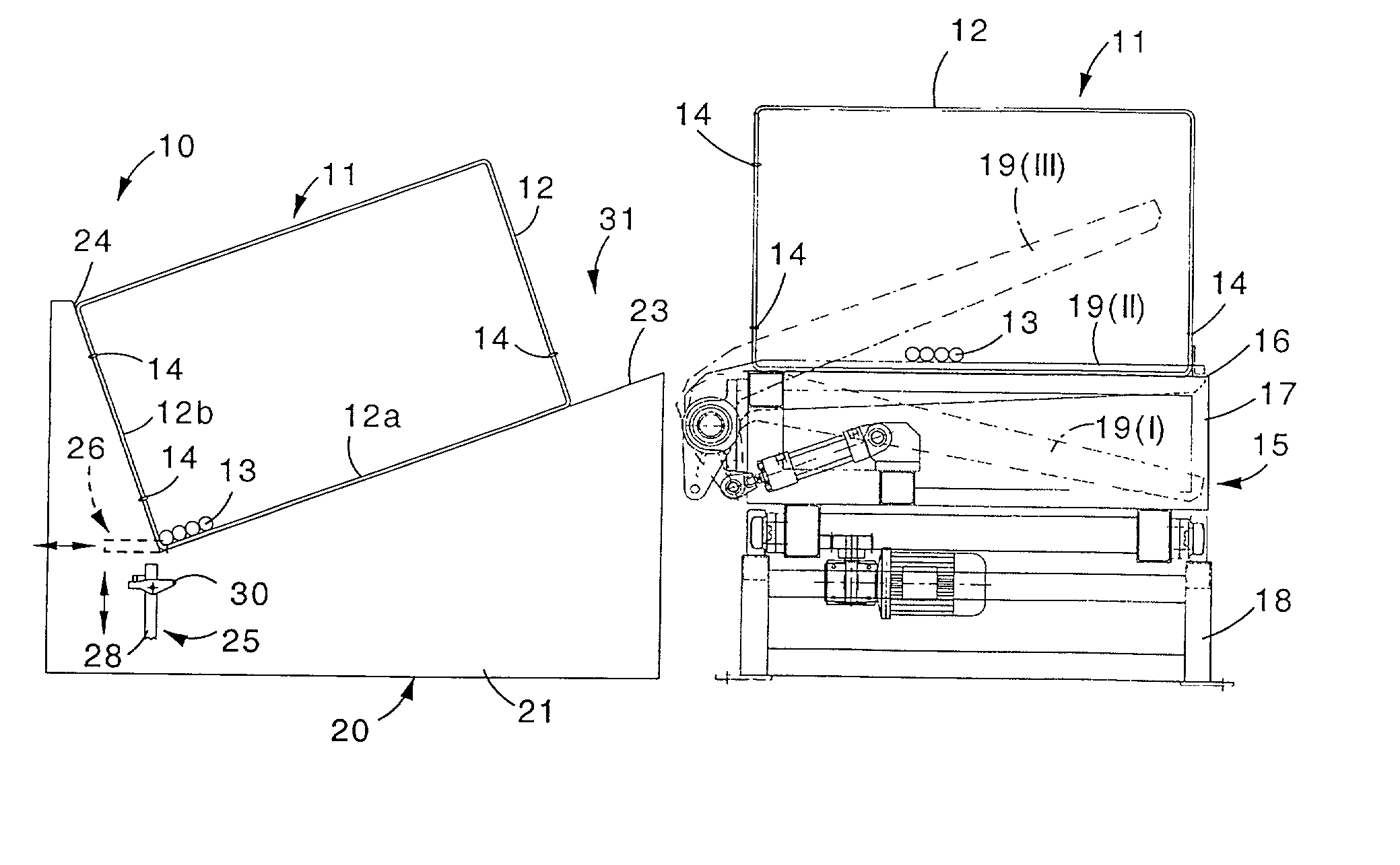

Construction Machine

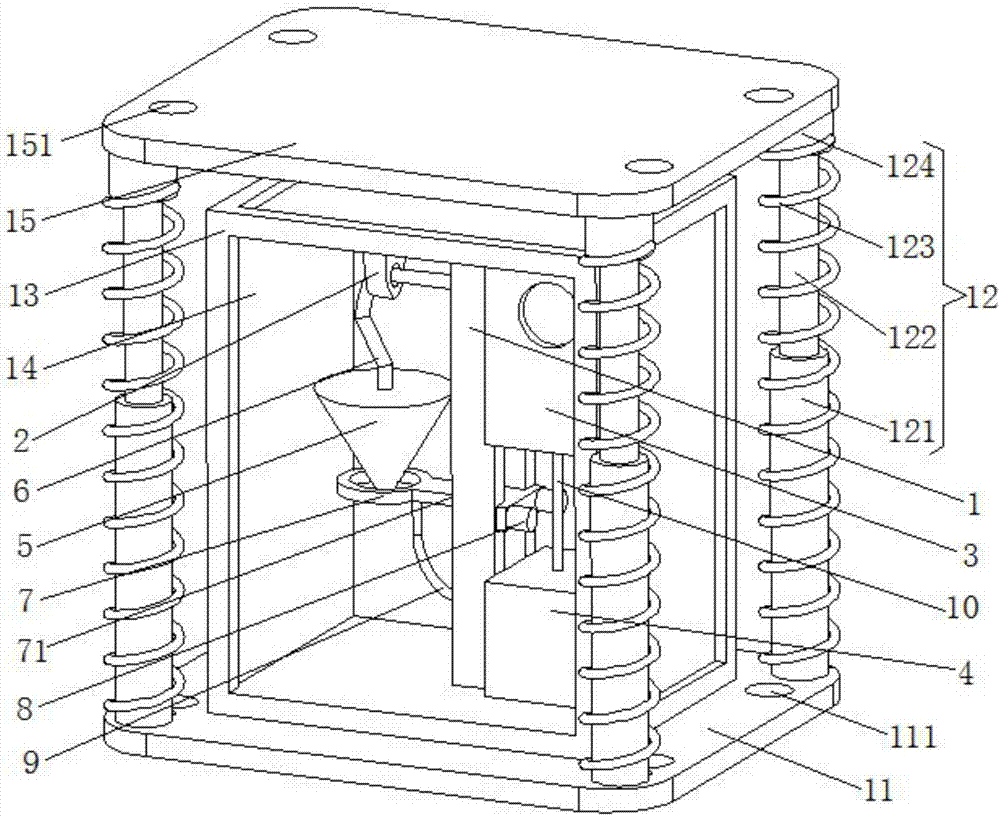

ActiveUS20190023328A1Easy to workAdjustment workSpringsSoil-shifting machines/dredgersEngineeringExcavator

A hydraulic excavator includes a revolving frame forming a support structure, a cab that is disposed to be positioned on a front side of the revolving frame and in which an operator gets, and a plurality of vibration isolating members that are disposed between the revolving frame and the cab to support the cab on the revolving frame in a vibration isolating state. Further, an intermediate connecting member is disposed for connection between the revolving frame and the vibration isolating member and for a height position adjustment of the cab to the revolving frame. The intermediate connecting member is fixed to the revolving frame from a lower side.

Owner:HITACHI CONSTR MASCH CO LTD

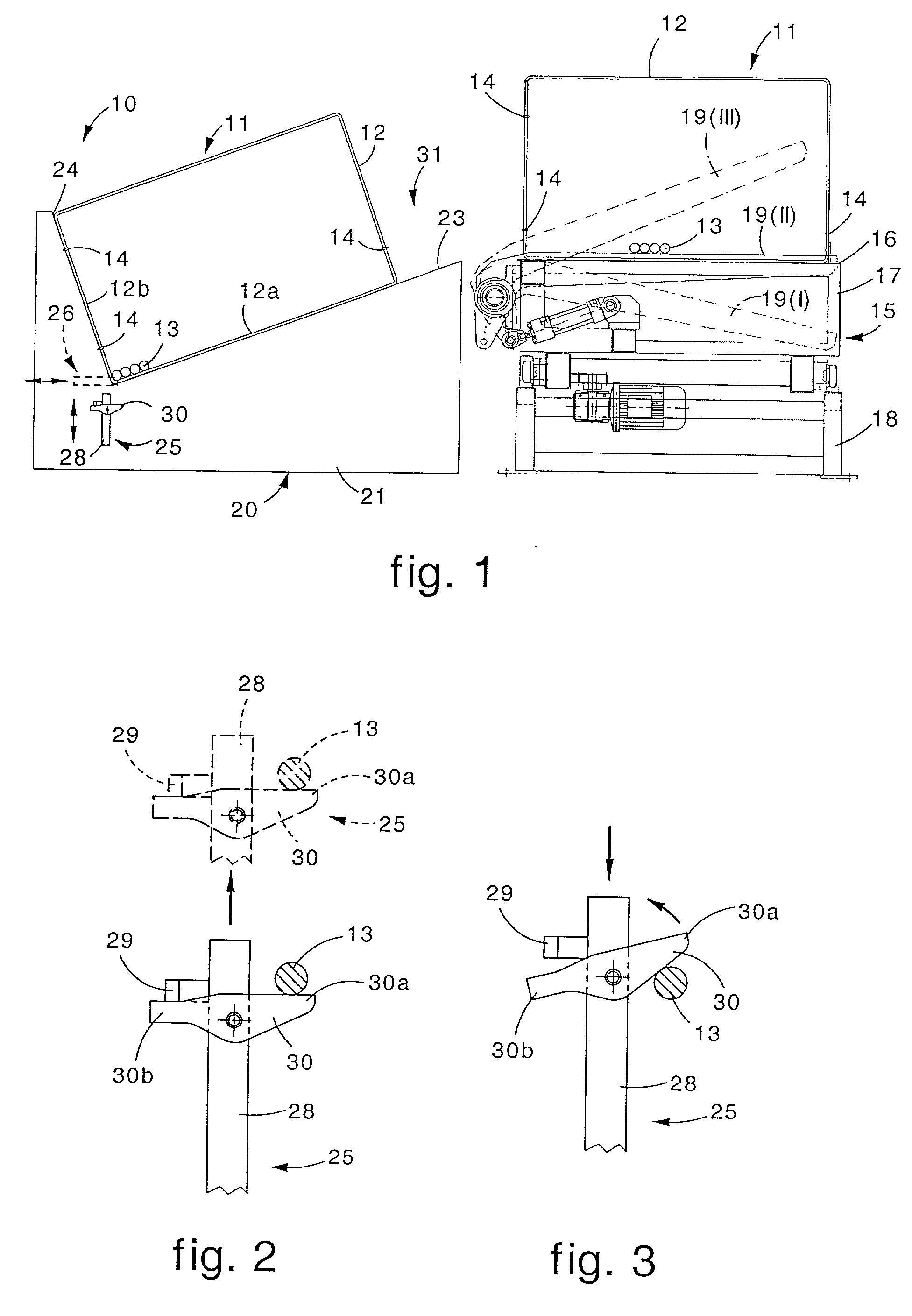

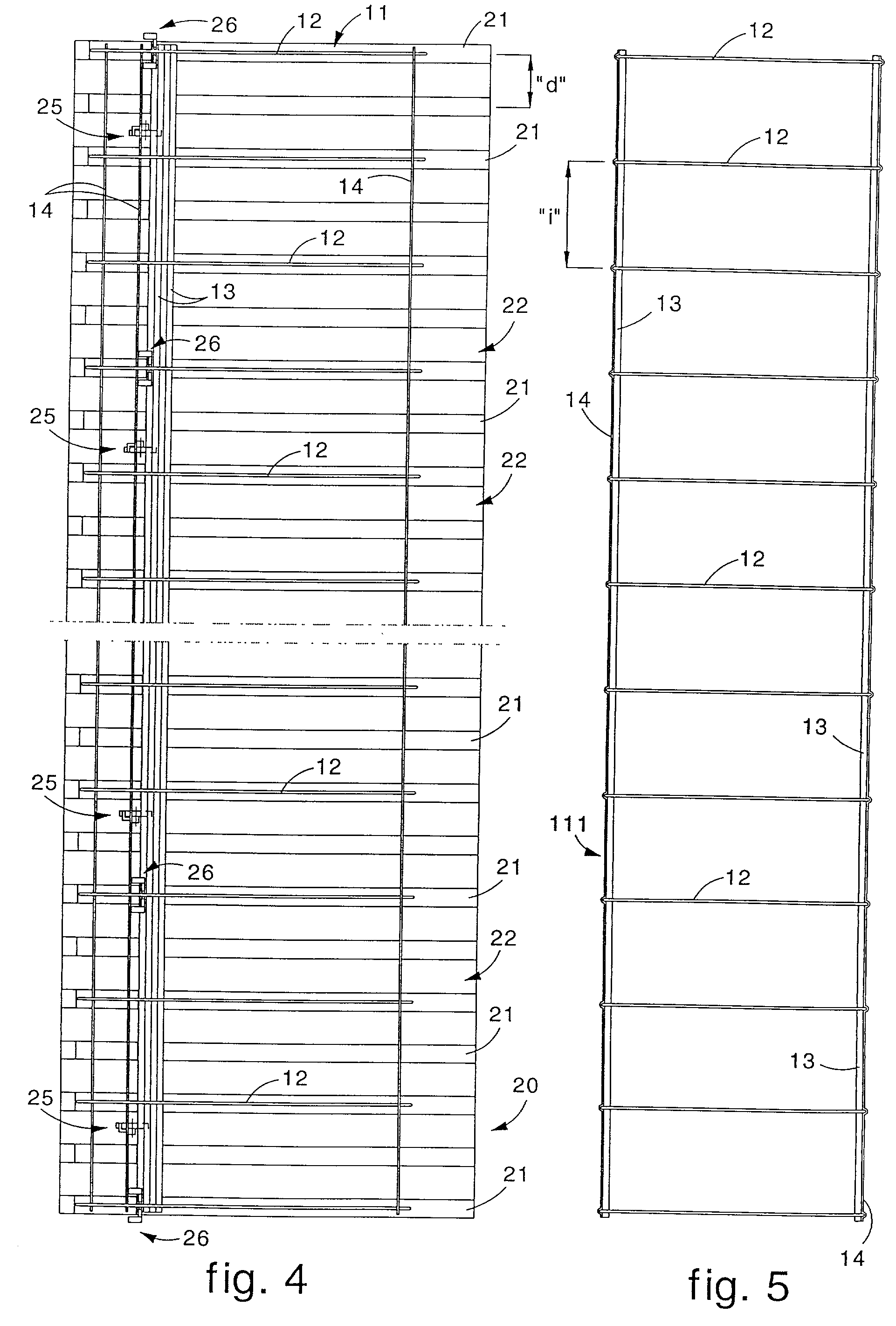

Device and method to complete reinforcement cages

Owner:M E P MASCH ELECTRONICS PIEGATRICI SPA

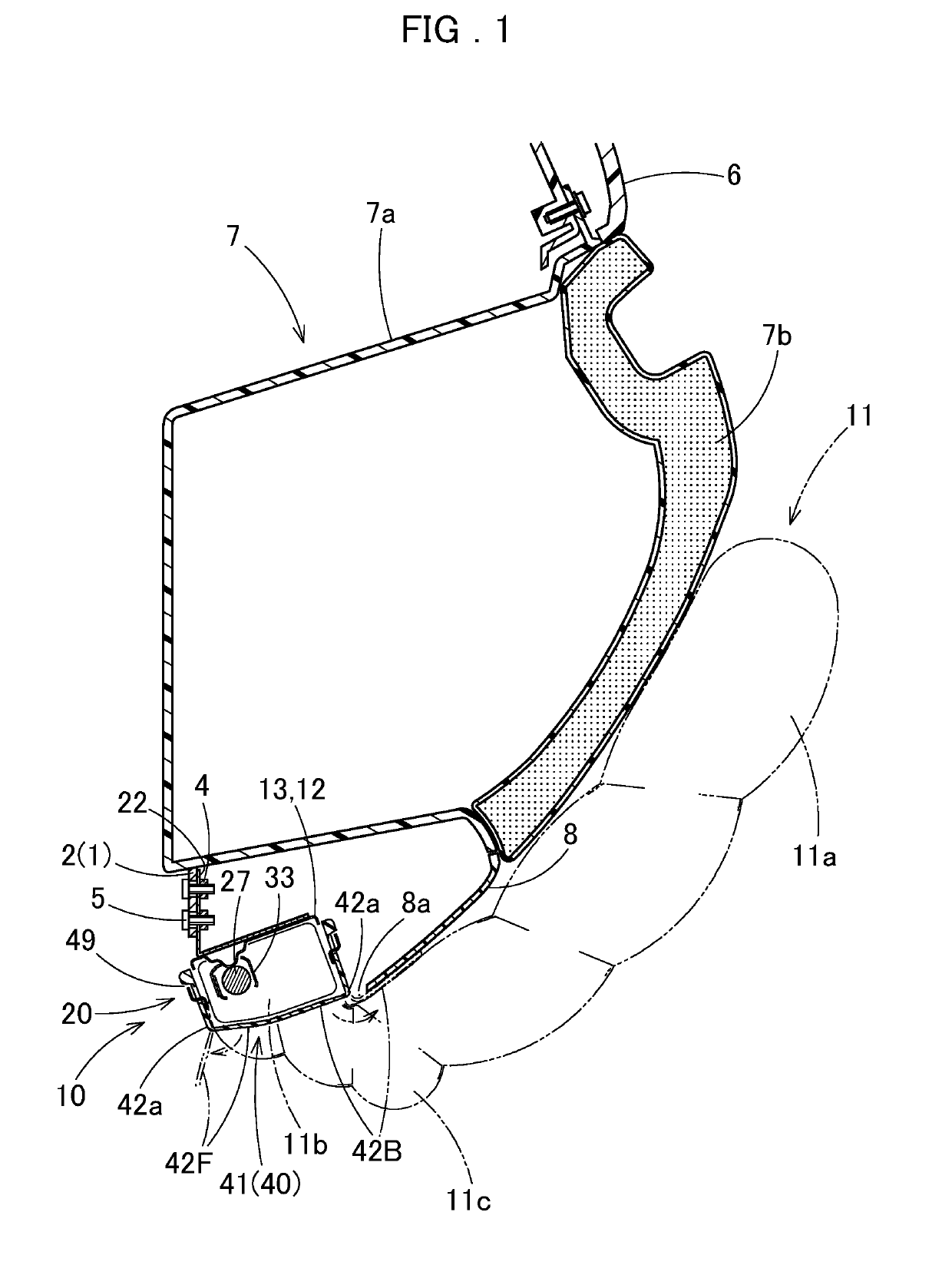

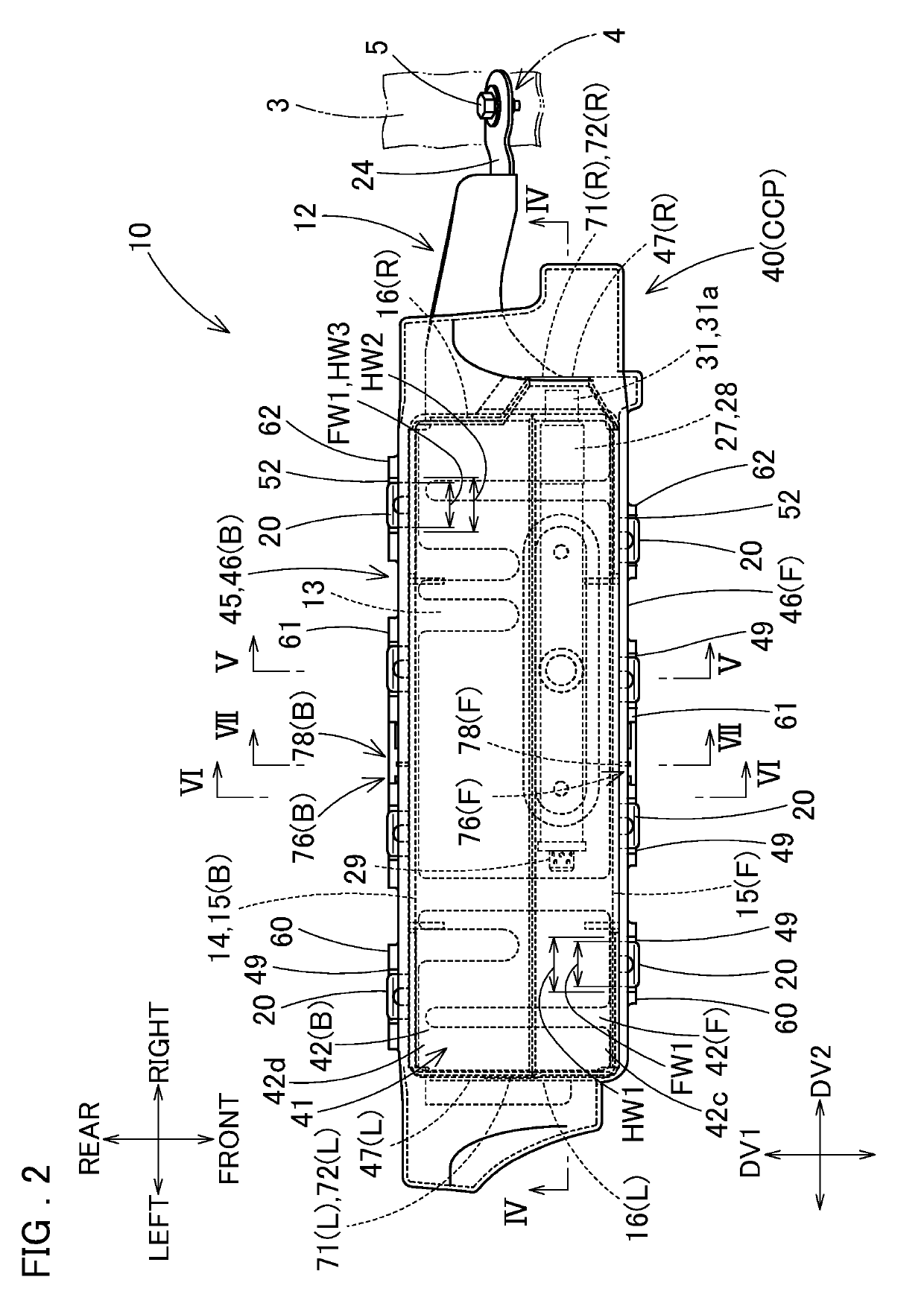

Airbag device

ActiveUS20190202392A1Easy to workDifficult to workPedestrian/occupant safety arrangementEngineeringAirbag

An airbag device includes an airbag, an airbag case that is made from metal and includes a base wall and a tubular wall, and an airbag cover that is made from synthetic resin and includes a covering wall and a joint wall. The case and cover are coupled together by insertion of hooks of the tubular wall of the case into joint holes of the joint wall of the cover. The device further includes an approximation-limiting region that suppresses the cover as coupled with the case from moving further towards the base wall of the case, and a separation-limiting region that suppresses the cover as coupled with the case from moving further away from the base wall of the case. The approximation-limiting region includes an abutment region and a receiving region engageable with the abutment region. The separation-limiting region includes a retaining hole and a projection engageable with an inner surface of the retaining hole.

Owner:TOYODA GOSEI CO LTD

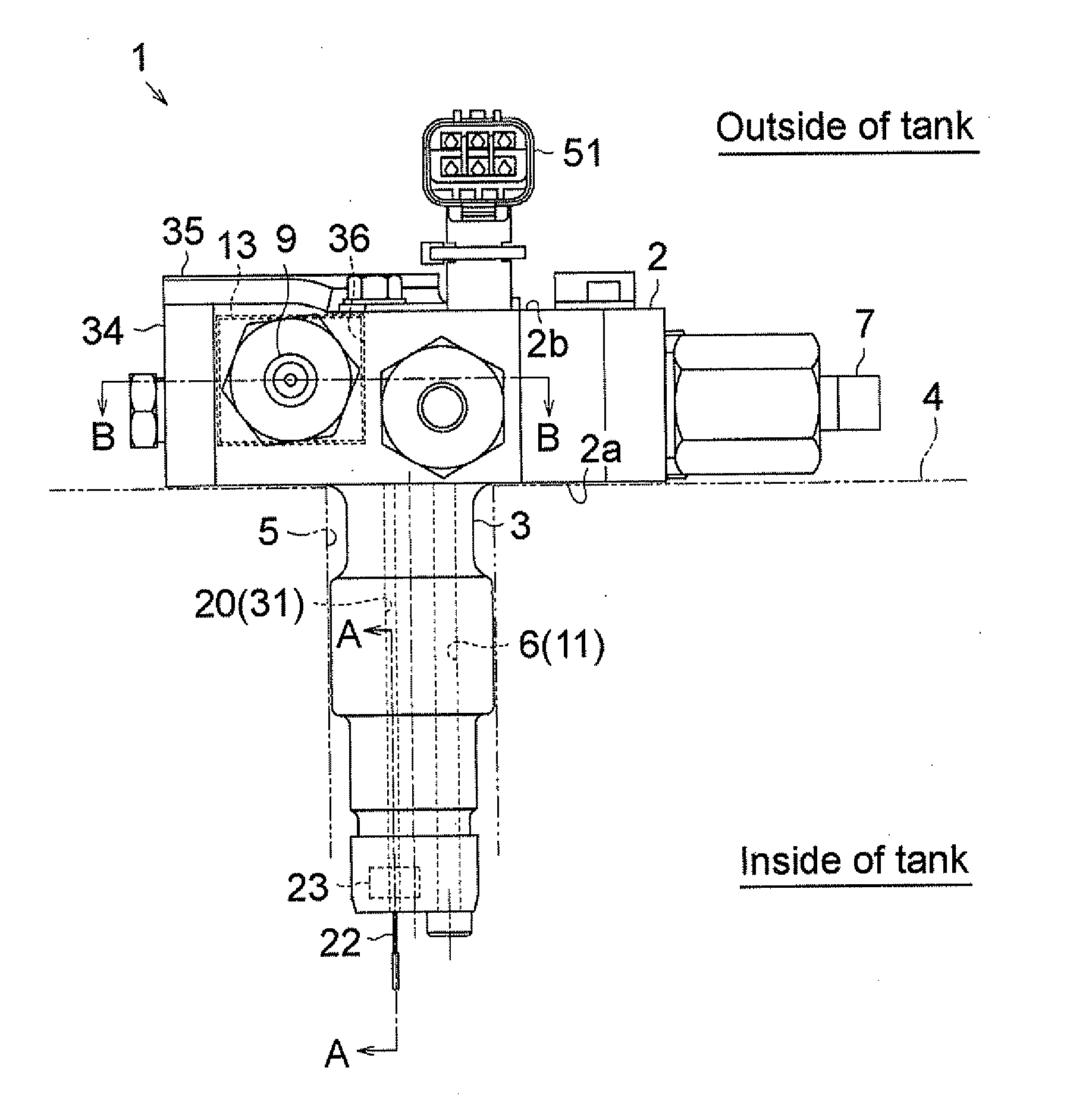

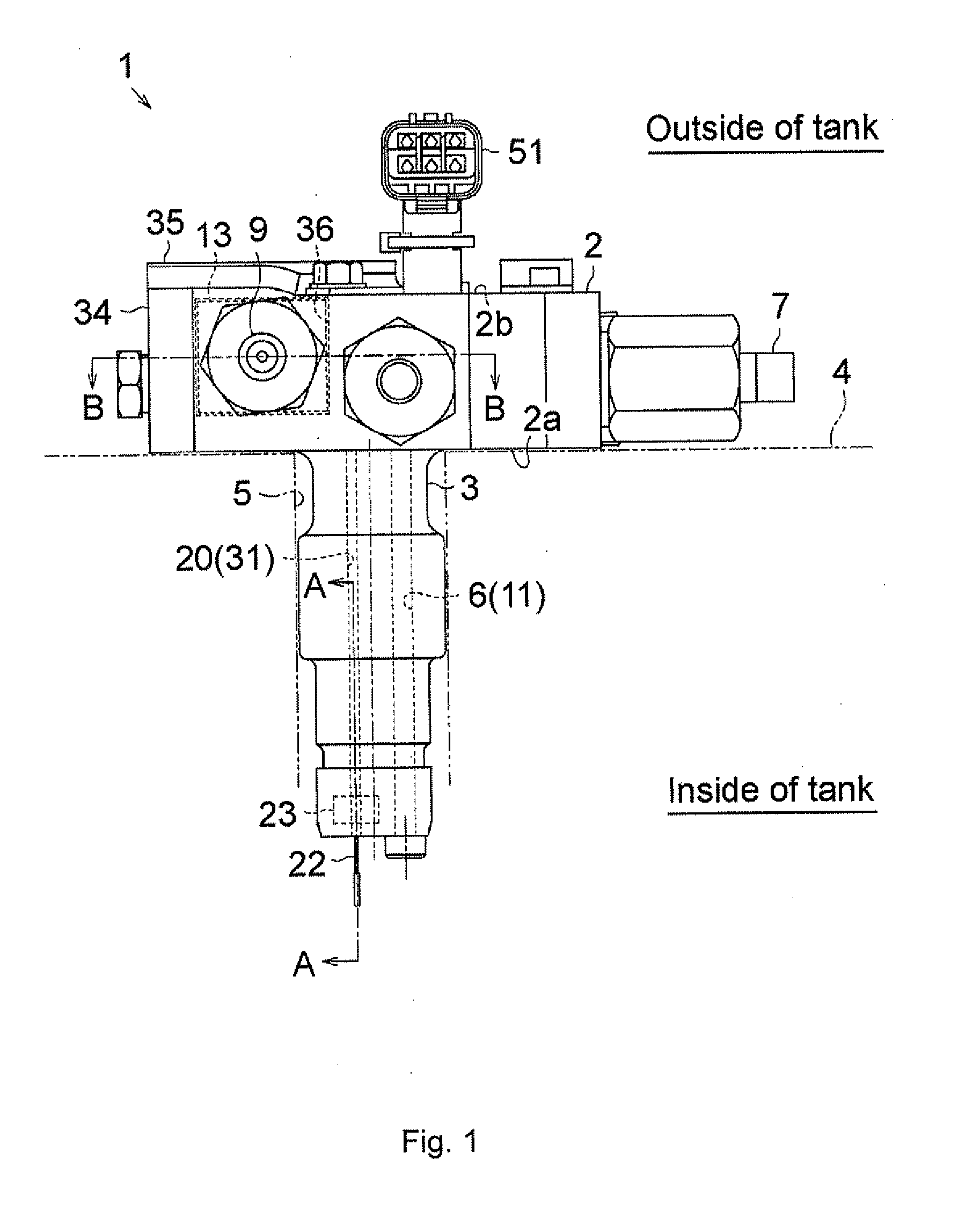

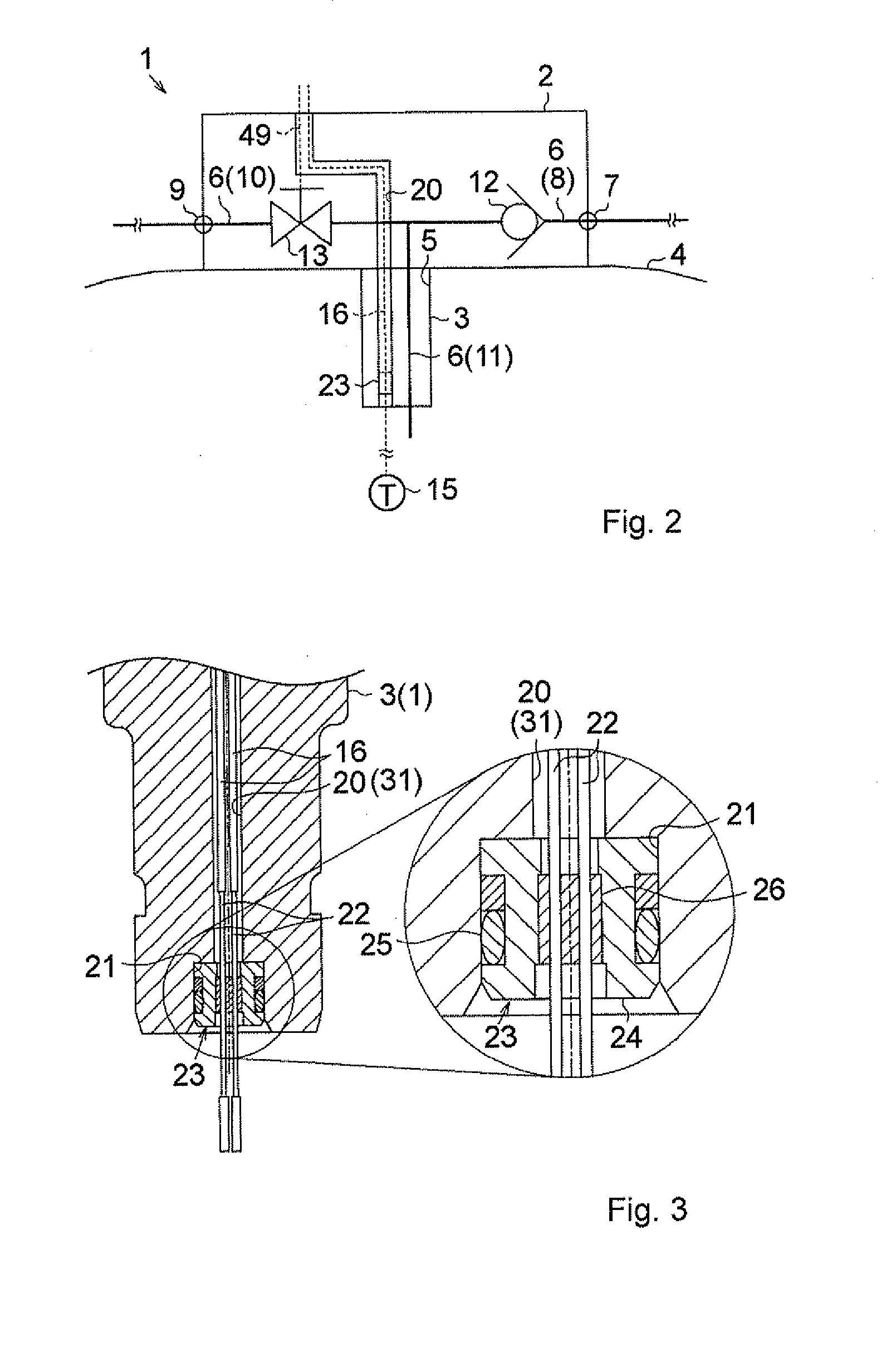

Valve device

ActiveUS20120273059A1Cost reductionEasy to workThermometer detailsServomotor componentsMechanical engineeringStress concentration

A valve device includes a wire channel through which wires are routed from the inside of a gas tank to the outside of the gas tank, and a hermetic connector in which a sealing member is provided around wire pins that constitute part of the wires is provided in the wire channel. In addition, the wire channel has multiple (two) bent portions formed on the outer side of the hermetic connector. When pulling force acts on the wires from the outside, stress concentration portions are formed in the wires at these bent portions.

Owner:JTEKT CORP

Lift type welded tube discharging device based on ZigBee technology

InactiveCN106354083AEasy to workSave time on manual transportTransmission systemsTube shearing machinesEngineeringSlide plate

The invention discloses a lift type welded tube discharging device based on a ZigBee technology. The lift type welded tube discharging device comprises a bottom working plate, a working support rod and a numerical control mainboard, wherein one end of the working support rod is connected with feeding equipment, an embedded sliding plate is embedded at the other end of the working support rod, a laser marker is connected below one end of the embedded sliding plate, die cutting equipment is mounted below the other end of the embedded sliding plate, a working case is arranged at the lower right part of the working support rod, the numerical control mainboard is arranged at the bottom end in the working case, an electronic speed regulator is arranged above one side of the numerical control mainboard, an equipment driver is mounted above the other side of the numerical control mainboard, one side of the outside of the working case is connected with the bottom working plate, a feed box is arranged above one end of the bottom working plate, a servo motor is fixed above the other end of the bottom working plate and a feeding conveying belt is connected above the servo motor. The lift type welded tube discharging device can realize automatic feeding and accurate cutting and is safe and convenient to use.

Owner:启成金属制品(江苏)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com