Automatic indoor intelligent plastering machine capable of plastering uniformly and flatly

A plastering machine and uniform technology, which is applied in the direction of construction and building construction, can solve the problems of inability to improve the accuracy of plastering, the inability to fix the position of the top, the inability to accurately control the working position of the equipment, and the cumbersome and complicated operation, so as to improve the working efficiency , High operating precision, reducing the effect of manual adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

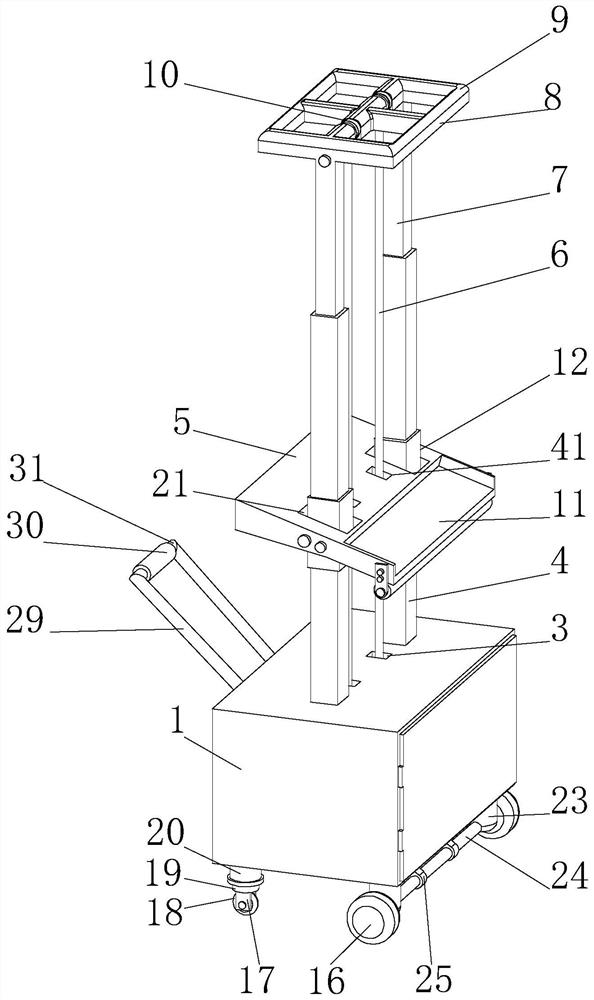

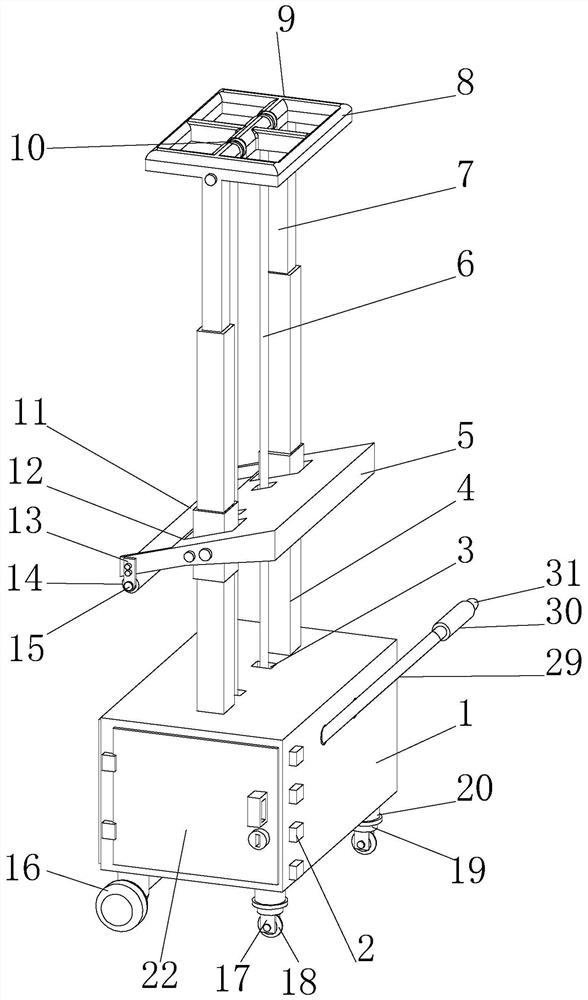

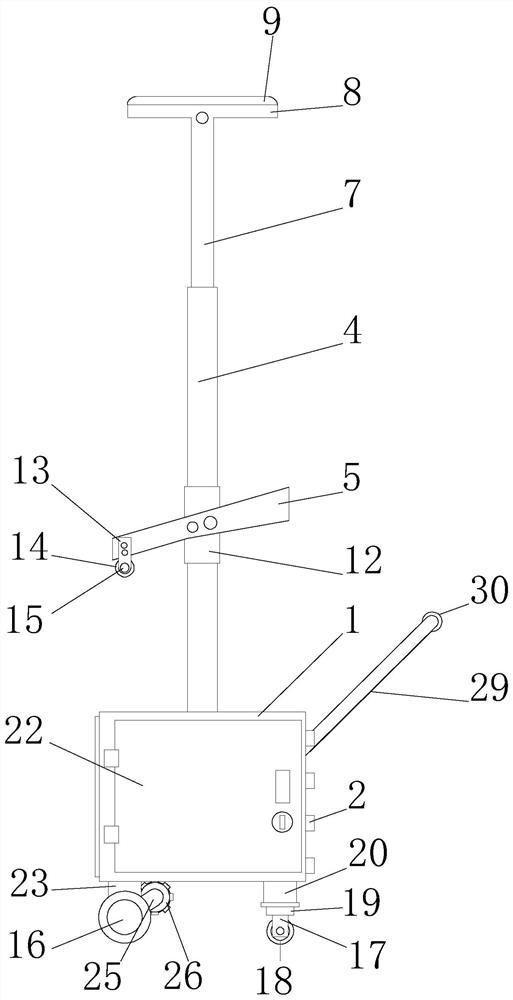

[0029] see Figure 1-7, the present invention provides a technical solution: an automatic indoor intelligent plastering machine with uniform plastering, comprising an equipment box 1, two telescopic outer rods 4 are fixedly installed on the top of the equipment box 1, and the outer sides of the two telescopic outer rods 4 Both are sleeved with sliders 12, and the activities of the sliders 12 are equipped with operation plastering boards 5, and the tops of the two telescopic outer rods 4 are sleeved with telescopic inner rods 7, and the tops of the telescopic inner rods 7 are fixedly installed with a top plate 8. Two steering wheel support columns 20 are installed on one side of the bottom of the equipment box 1, and the bottom of the two steering wheel support columns 20 is equipped with a steering axis column 19, and the bottom of the steering axis column 19 is fixedly equipped with two steering wheel axis column plates 17. Steering wheels 18 are installed on the opposite sid...

Embodiment 2

[0032] like Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: two first steering bearings 32 are installed on the bottom side of the equipment box 1, and the top of the steering wheel support column 20 is fixedly installed on the first steering bearing 32, the bottom of the steering wheel support column 20 is fixedly installed with the second steering bearing 33, the top of the steering shaft column 19 is fixedly installed inside the second steering bearing 33, and the transmission at both ends of the transmission shaft column 37 is connected with the power wheel 16. The outer side of the power wheel bearing 27 is fixedly installed on the inner wall of the power wheel hollow support shaft column 24, the two active power pulleys 28 are respectively located on the inner side of the two track guards 25, and the two power tracks 38 are respectively located on the inner sides of the two track guards. the inner side of the plate...

Embodiment 3

[0035] like Figure 1-7 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a rubber friction pad 9 is fixedly installed on the top of the top plate 8 , and two cable pulleys 10 are fixedly installed in the middle of the top plate 8 .

[0036] In this embodiment, after the equipment moves to the designated operation area, the telescopic inner rod 7 fixedly installed in the telescopic outer rod 4 is stretched to the top of the building, and the top plate 8 is pushed to the top of the building to fix its position. The rubber friction pad 9 fixedly installed on the top of 8 reaches the top of the building to increase the friction with the top of the building and fix the position, which effectively prevents the device from being displaced by the reaction force due to insufficient friction during the operation, resulting in When the plastering operation angle deviates and affects the operation quality, a cable pulley 10 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com