Patents

Literature

93results about How to "Reduce manual adjustments" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

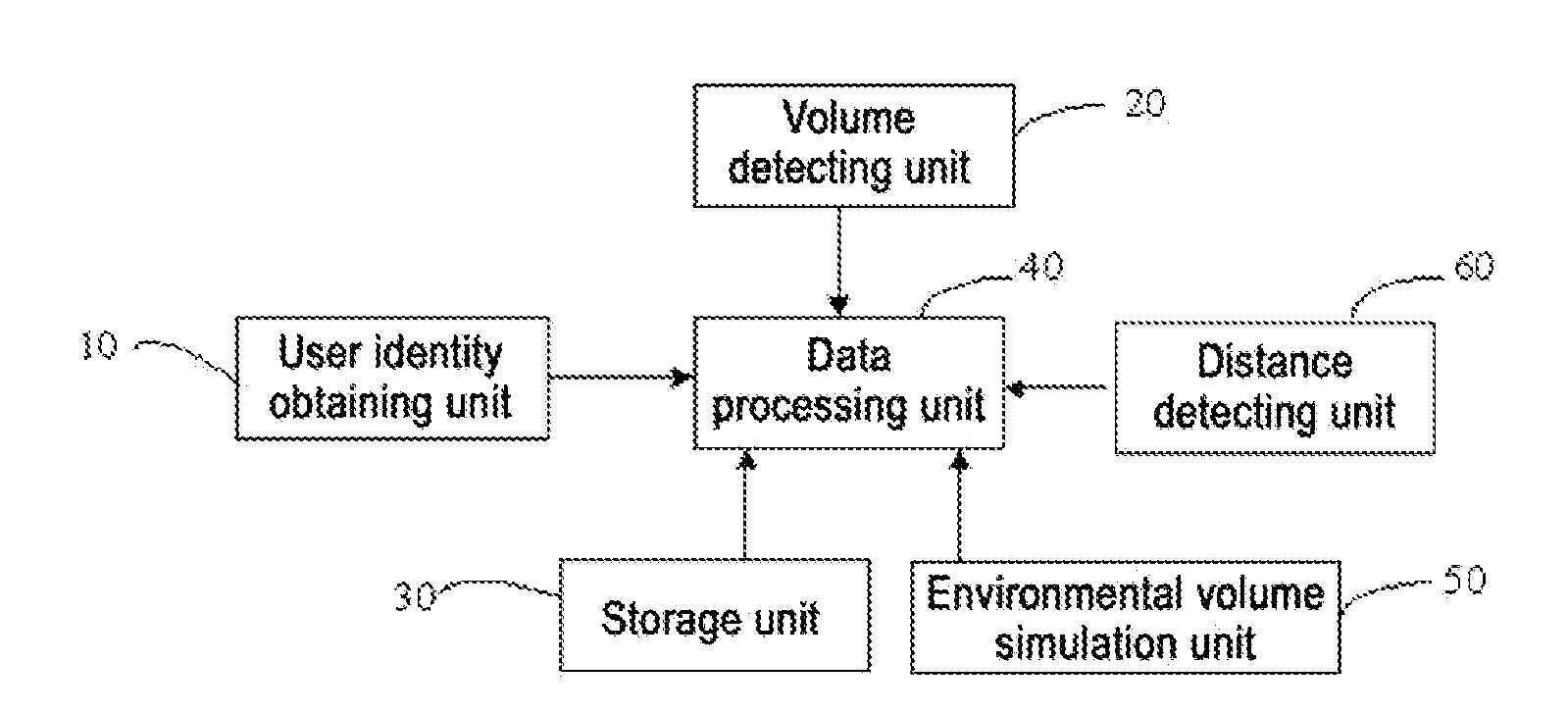

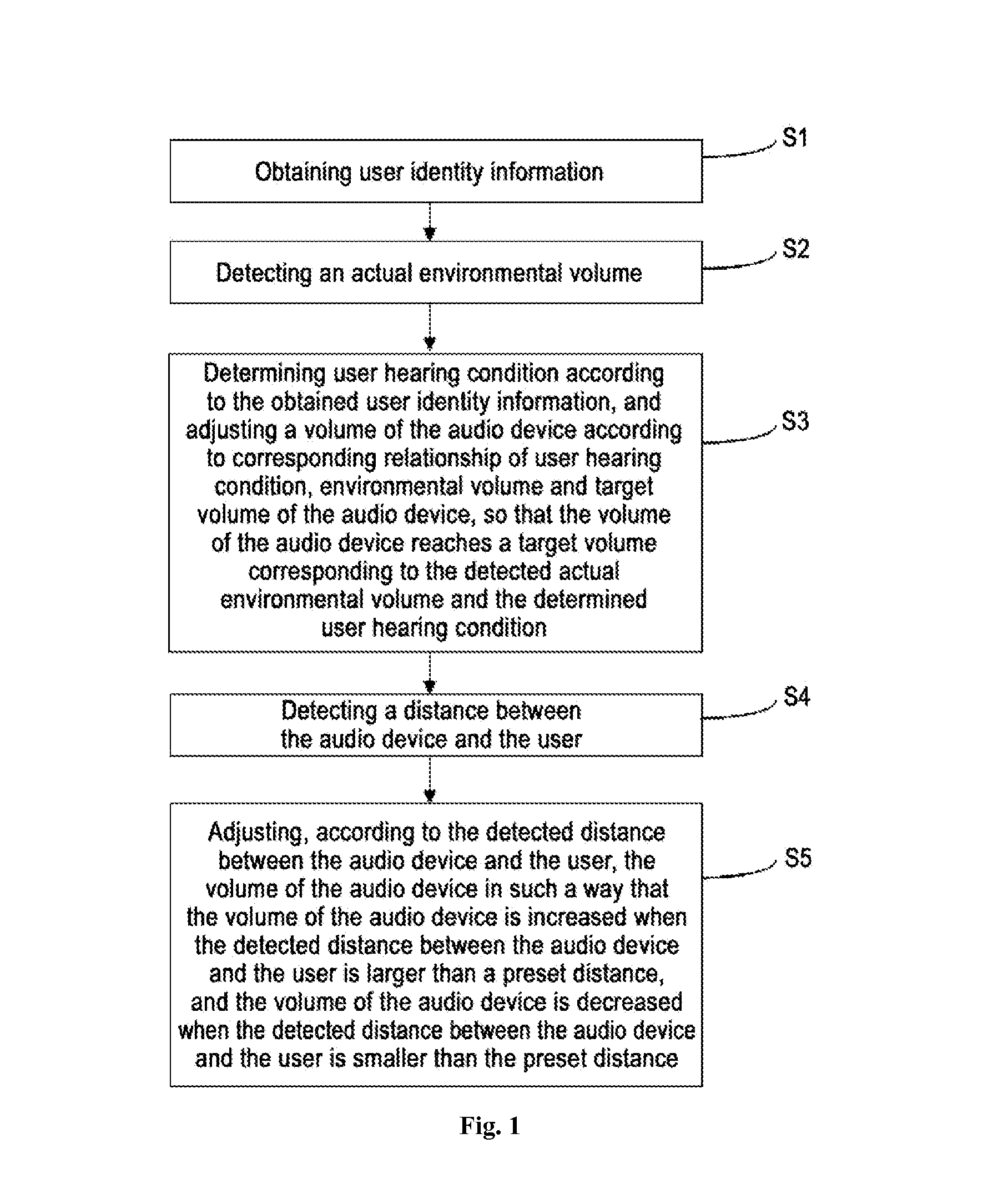

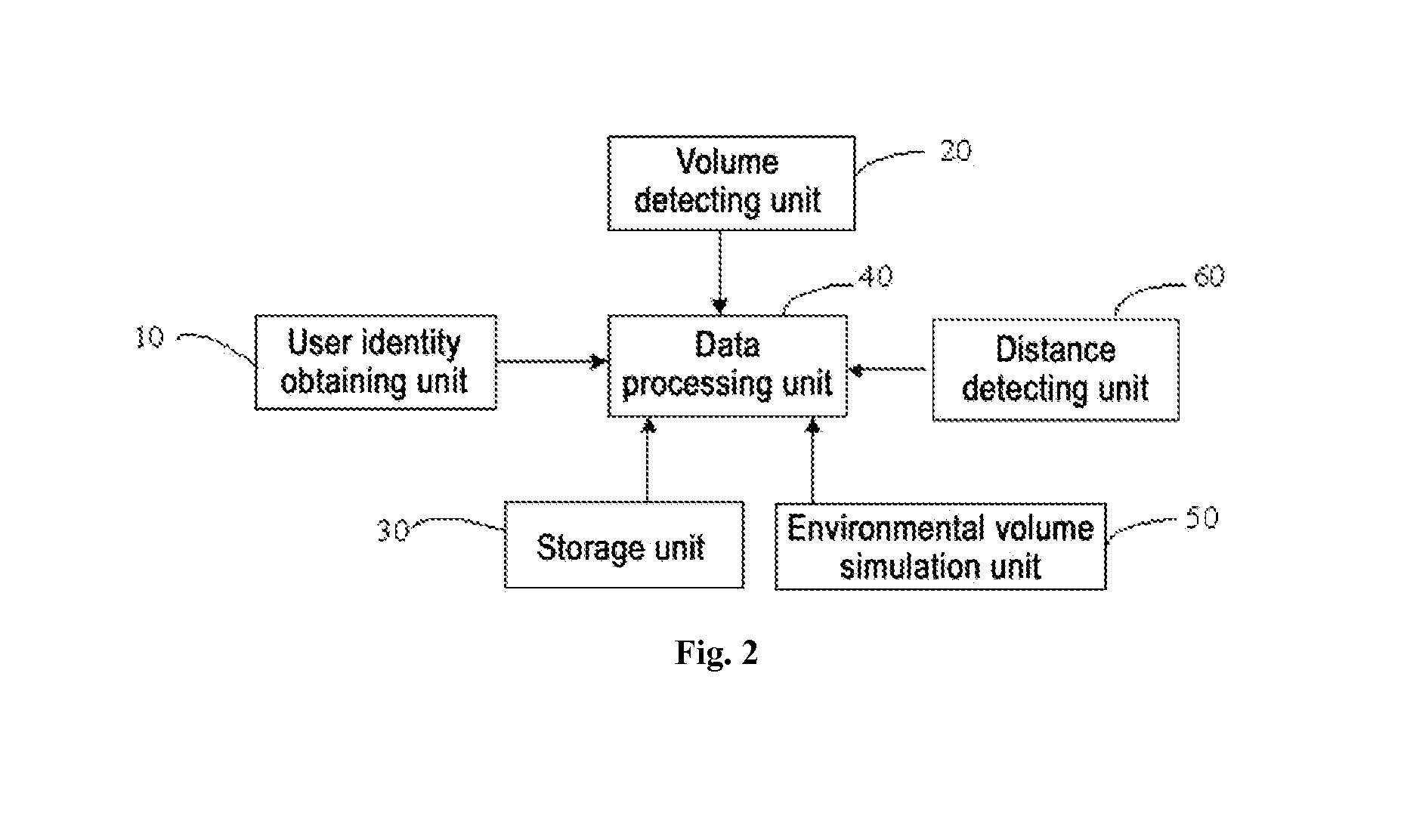

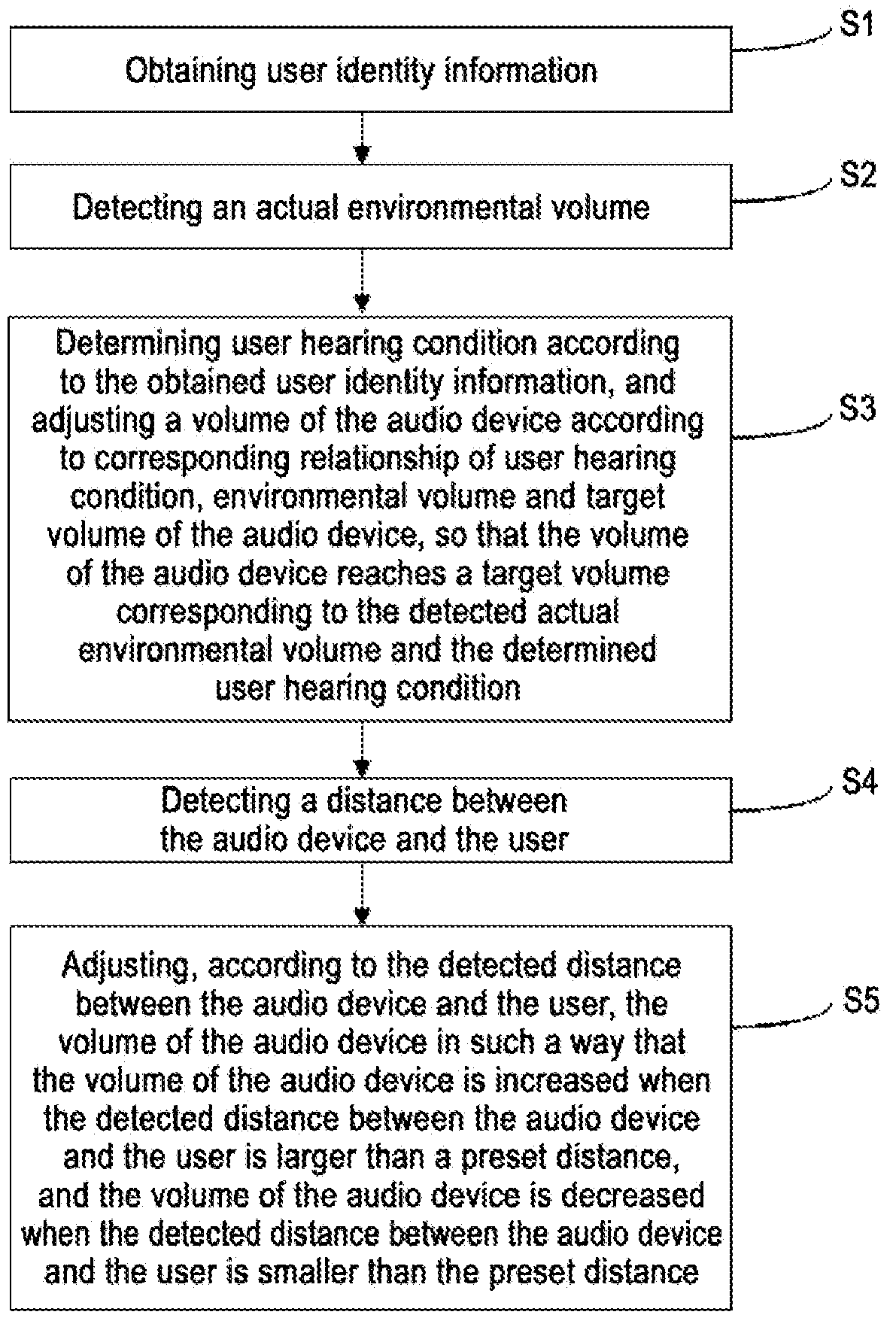

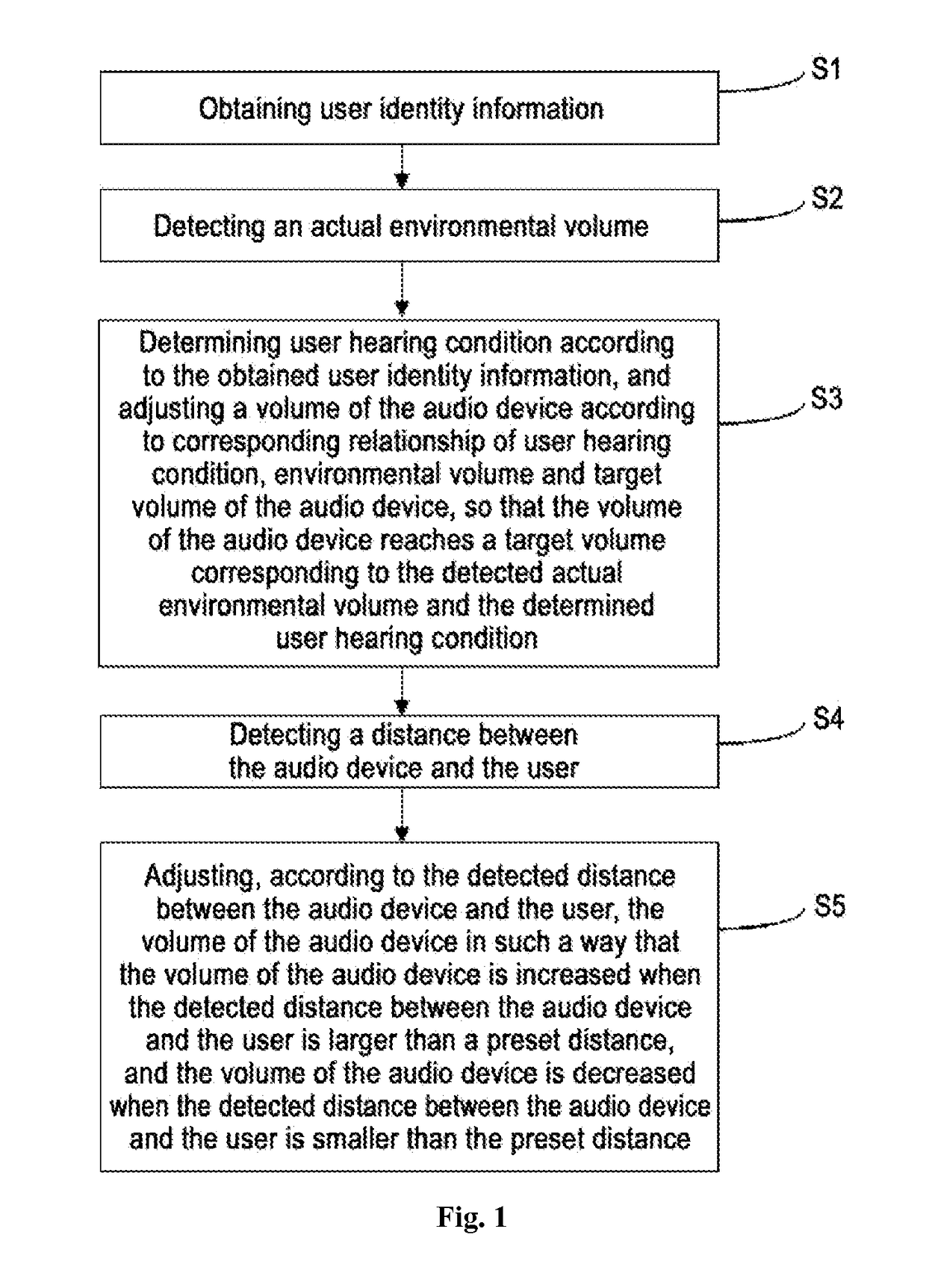

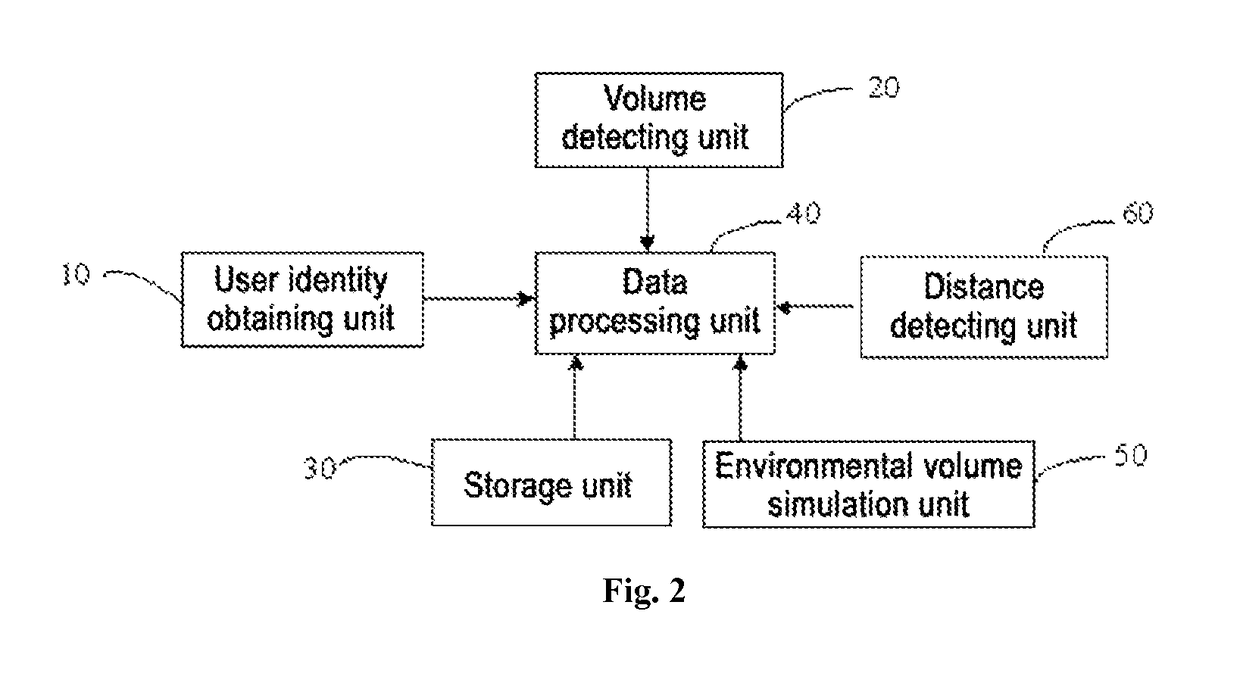

Audio device and method for automatically adjusting volume thereof

ActiveUS20160253146A1Reduce manual adjustmentsExtended service lifeTelevision system detailsSignal processingHearing perceptionComputer science

Owner:BOE TECH GRP CO LTD +1

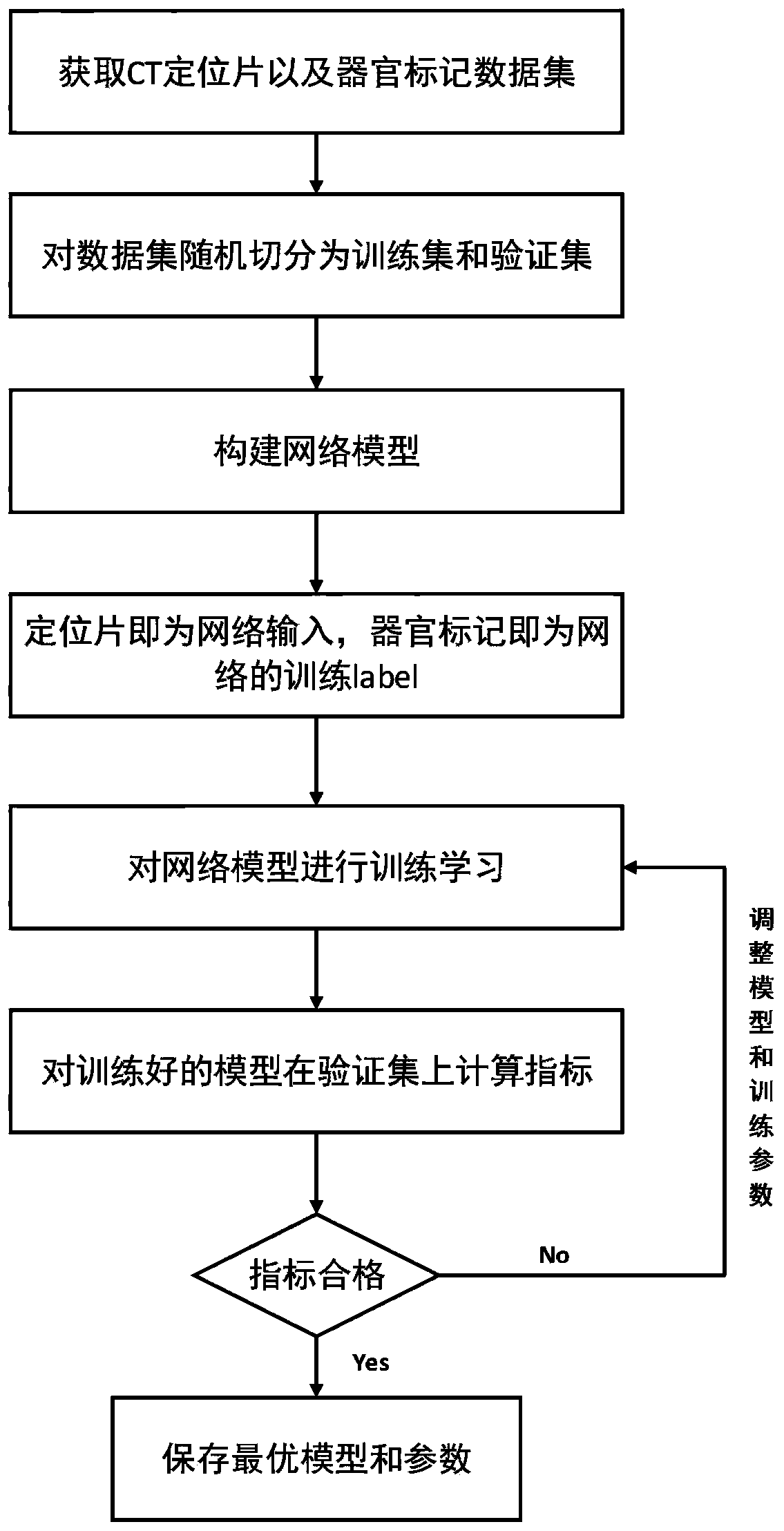

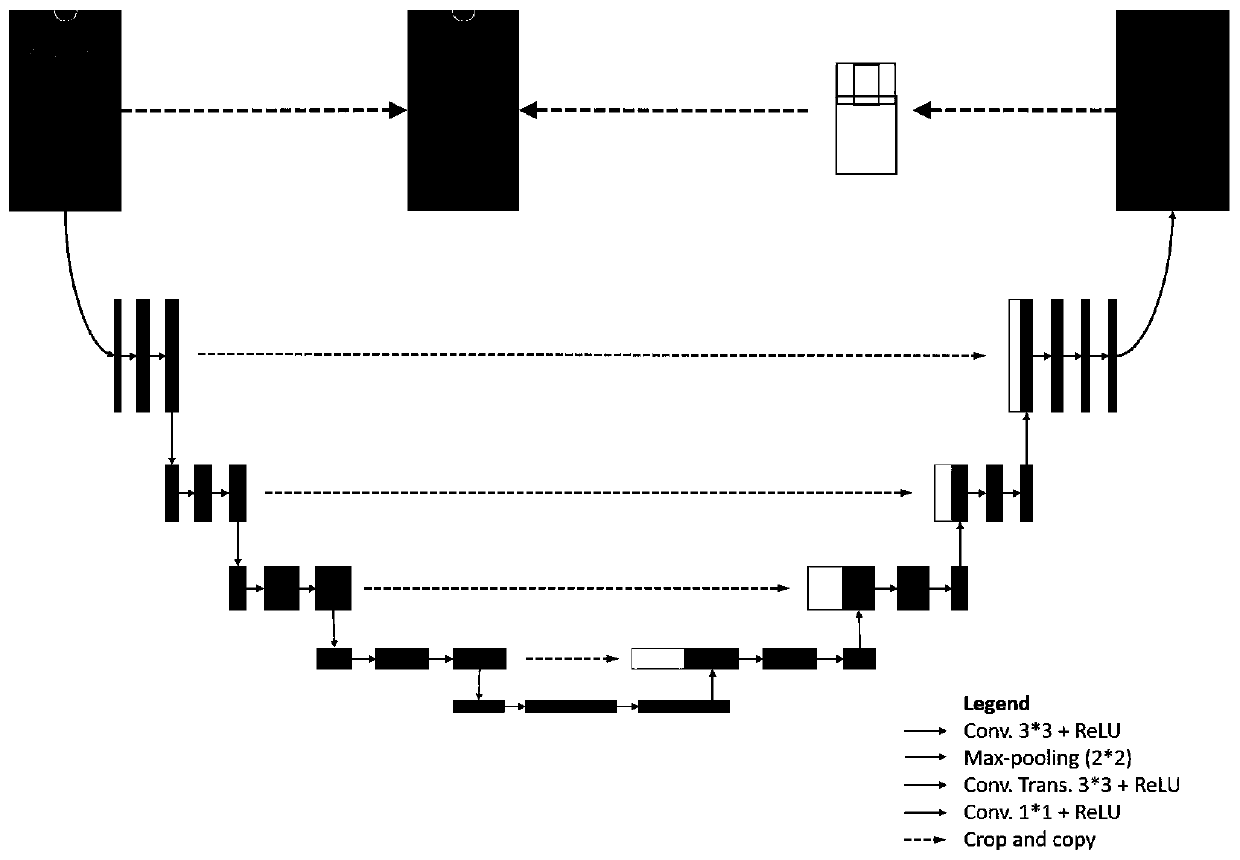

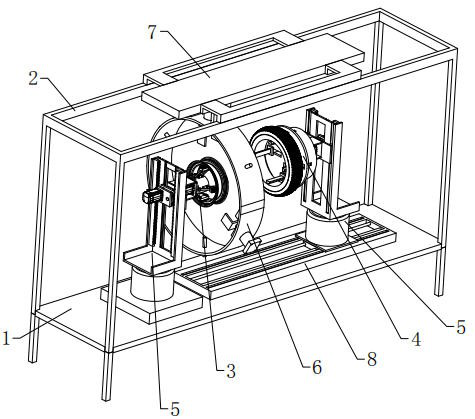

Medical image scanning automatic positioning method based on deep learning

ActiveCN110223352AReduce manual adjustmentsReduce radiationImage enhancementImage analysisHuman bodyNetwork model

The invention provides a medical image scanning automatic positioning method based on deep learning, and the method comprises the steps: obtaining a large number of positioning sheet images, and carrying out the random segmentation of the images into a training set, a verification set, and a test set; labeling each organ needing to be labeled in each positioning sheet image; constructing a deep learning network model, taking the training set and the verification set as input of the network model for training, and obtaining training parameters; operating the network model on the test set by using the training parameters; obtaining coordinates, width and height data and category data of a left upper point of a positioning frame of each organ needing to be examined, carrying out further post-processing on the obtained positioning frame data according to the requirements of CT and PET scanning parameters to obtain final positioning frame data of a human body part needing to be examined, and completing deep learning; and scanning the patient by using the network model which finishes deep learning, and finally obtaining an automatically positioned scanning image.

Owner:浙江明峰智能医疗科技有限公司

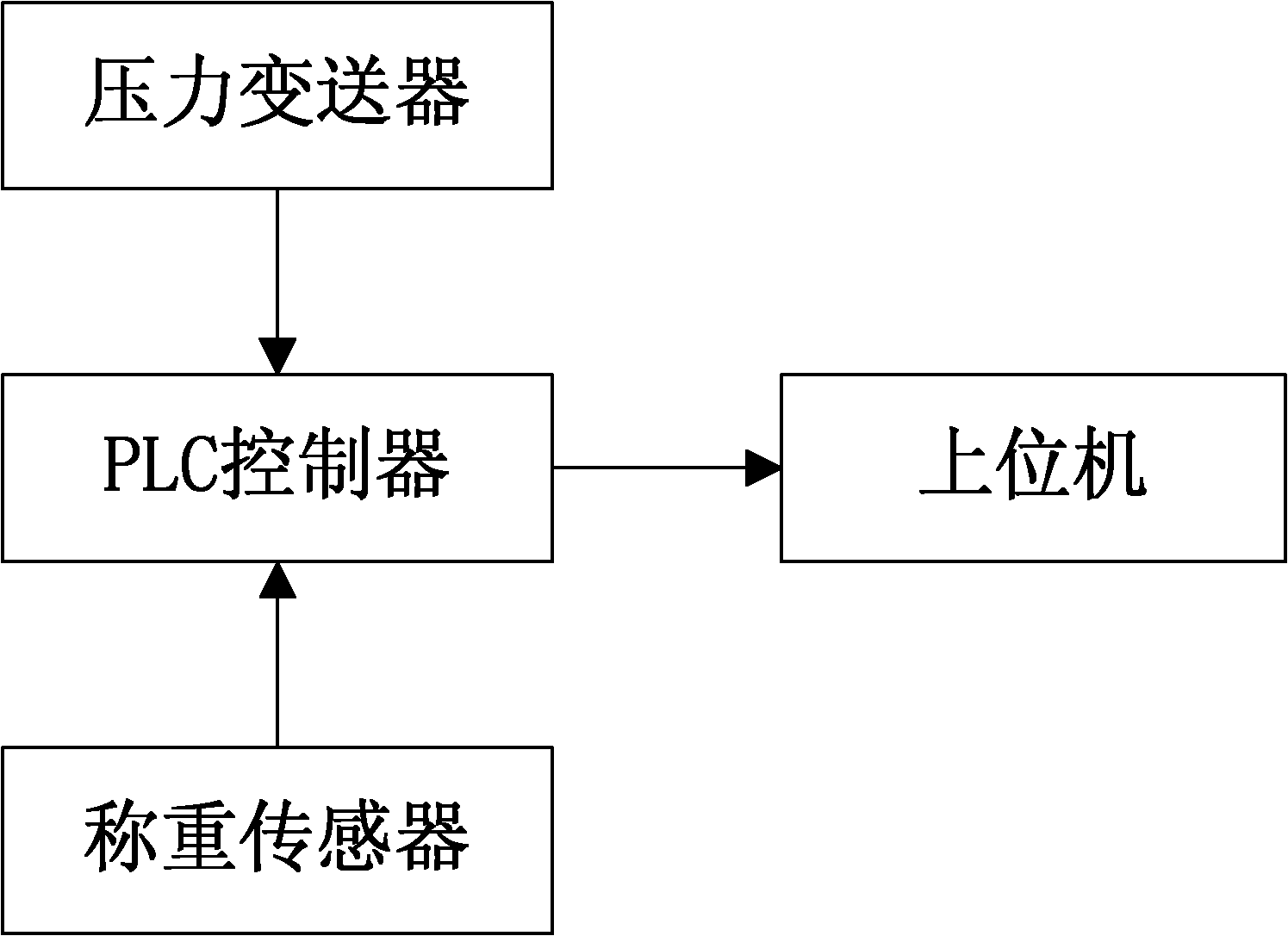

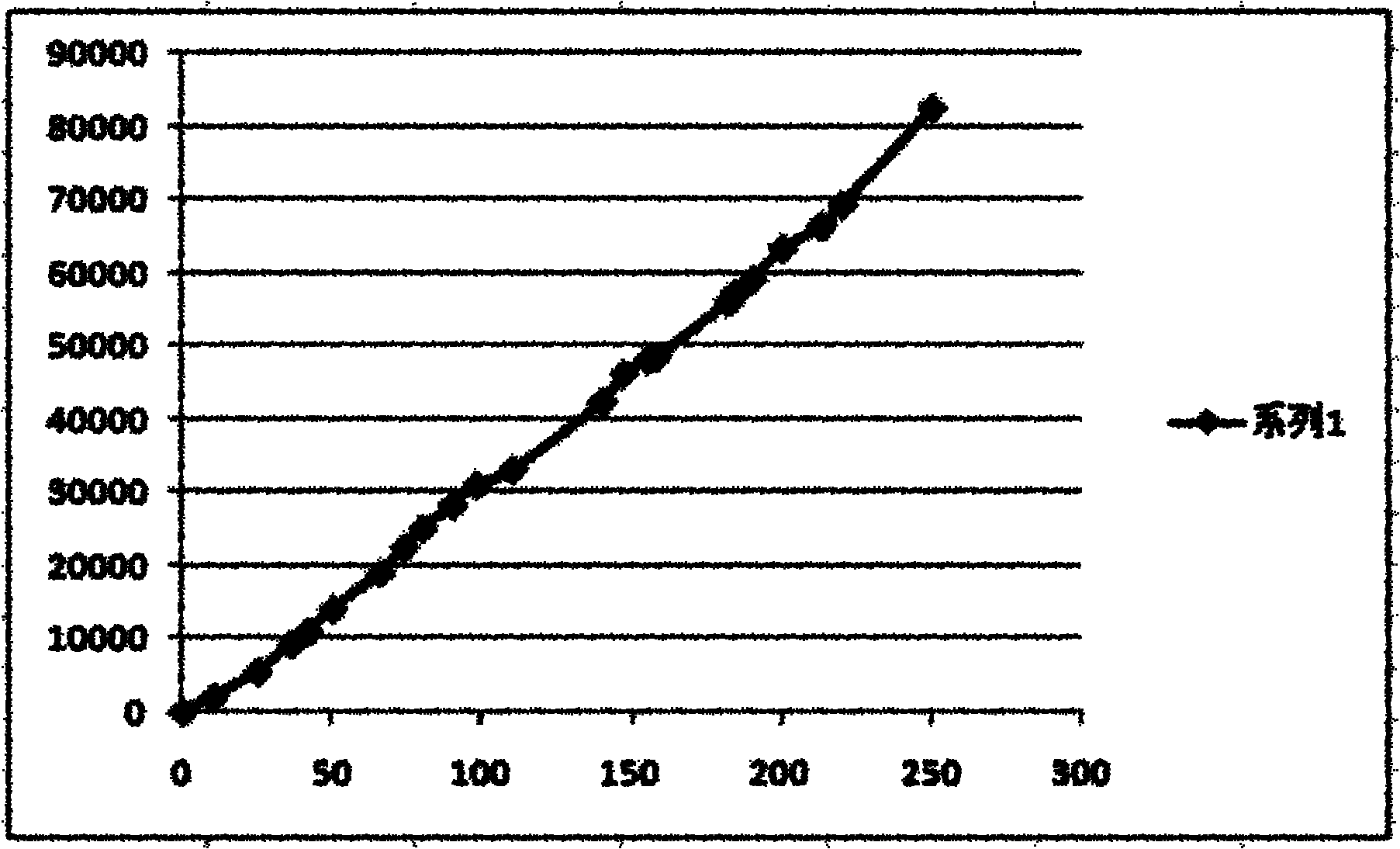

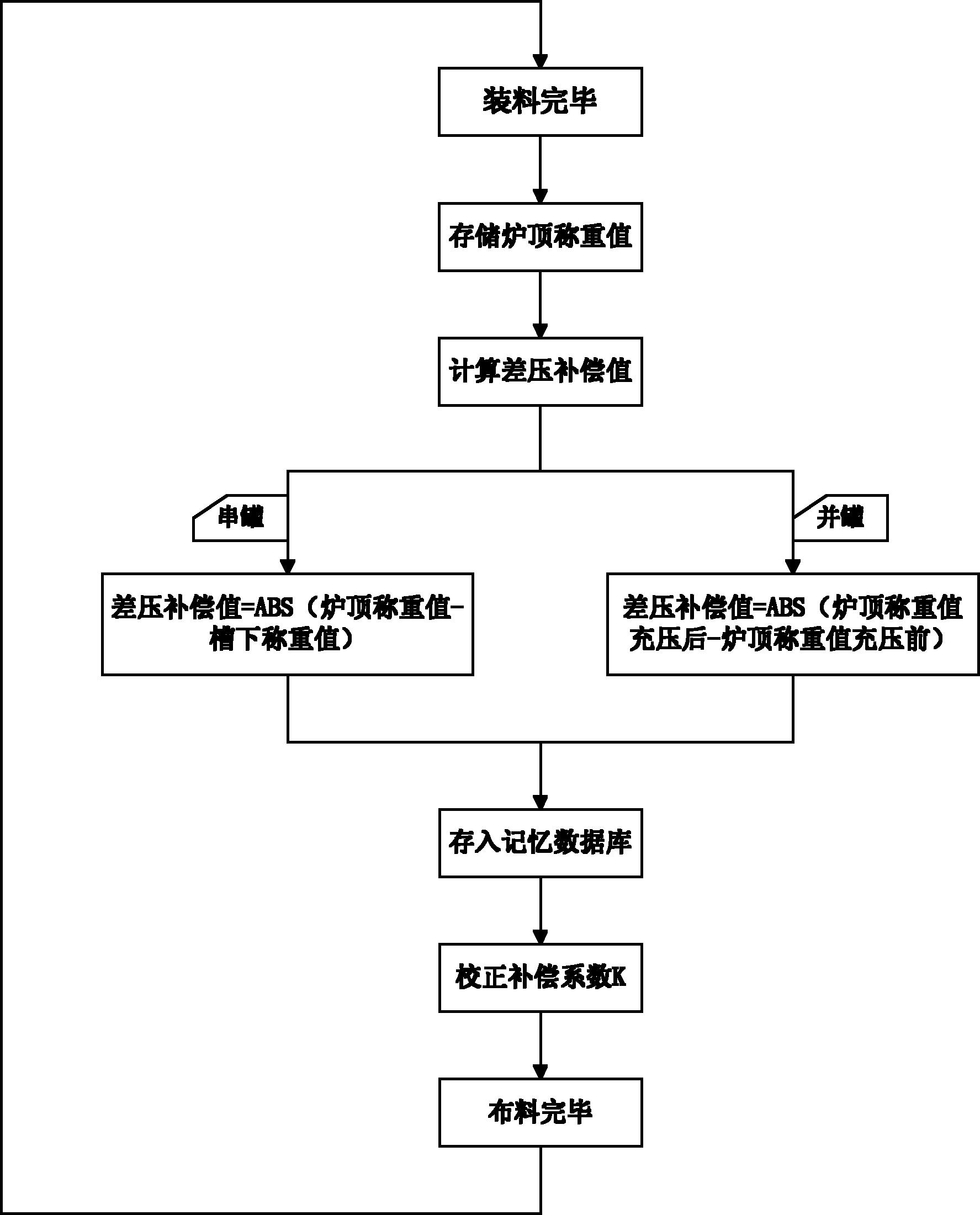

Method for automatically correcting differential-pressure compensation factors of weighing of top charging bucket

ActiveCN101985669AReduce distractionsReduce manual adjustmentsBlast furnace detailsChecking devicesWeight valueInterference factor

The invention relates to the technical field of bell-less top blast furnace, in particular to a method for automatically correcting the differential-pressure compensation factors of weighing of a top charging bucket. The invention comprises the following steps: determining the differential-pressure compensation factors of weighing in an ideal state; monitoring D-values between actual weight values and the weight values subjected to compensation so as to determine compensation values of weighing; correcting the compensation values according to the D-values of weighing, wherein the monitored data comprise the pressure and weight of a charging bucket, the pressure in a blast furnace, and the data obtained by the weighting measurement of the blast furnace; and carrying out periodical correction on the differential-pressure compensation factors of weighing based on differential values through comparing the weights of the charging bucket before and after pressurizing and the data obtained by the weighting measurement of the blast furnace. In the invention, because the differential-pressure compensation factors of weighing can be corrected periodically, the invention can effectively reduce the interference of external factors of blast furnaces on weighting measurement, improve the automation level, avoid the substantial fluctuation of weighing values caused by the influence of external interference factors, and create conditions for the stability and high yield of the blast furnace.

Owner:WISDRI ENG & RES INC LTD

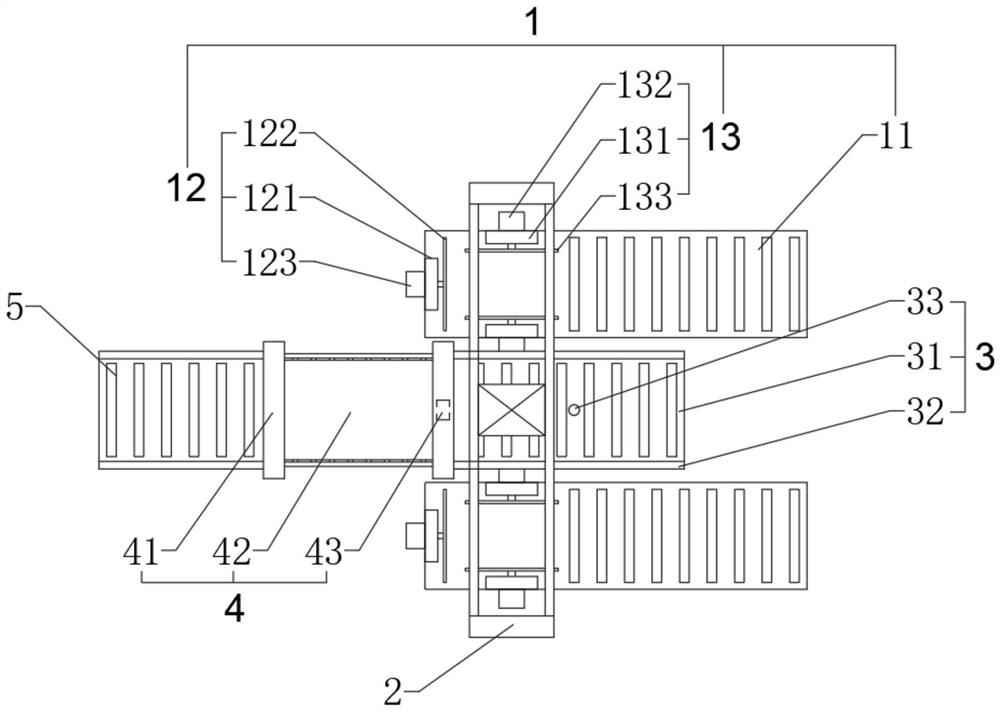

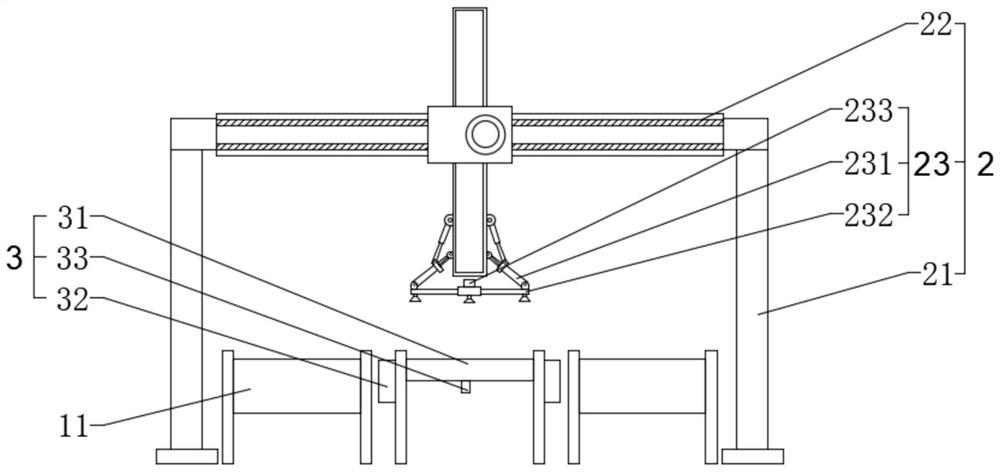

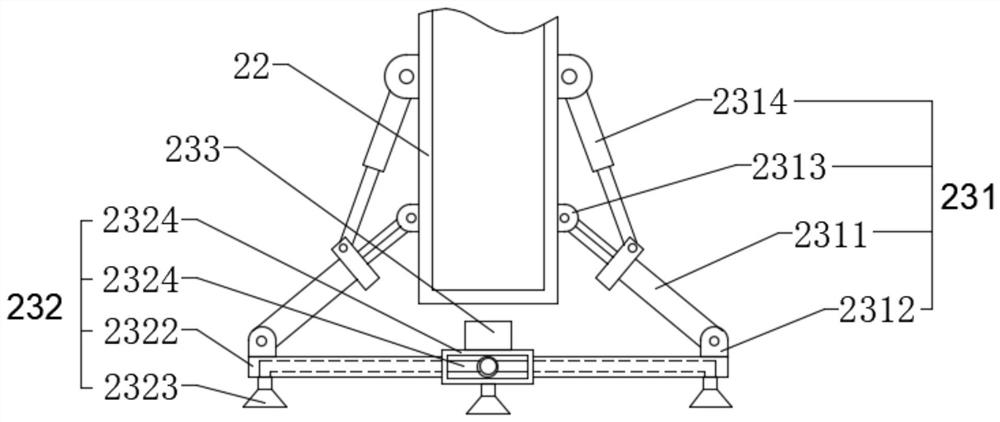

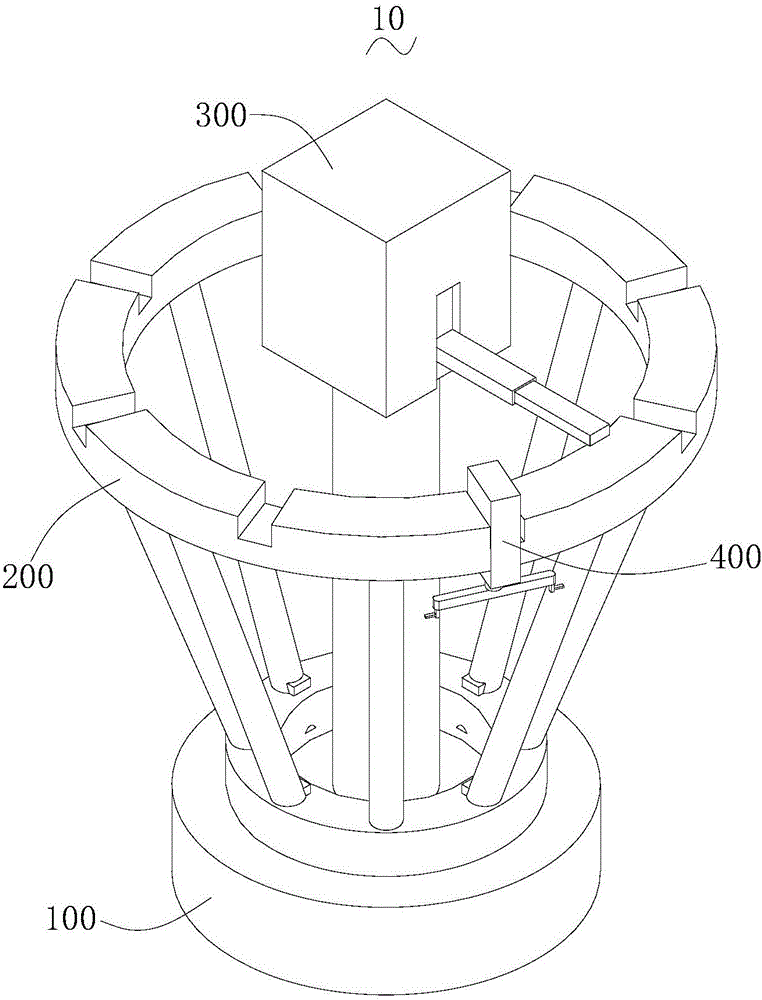

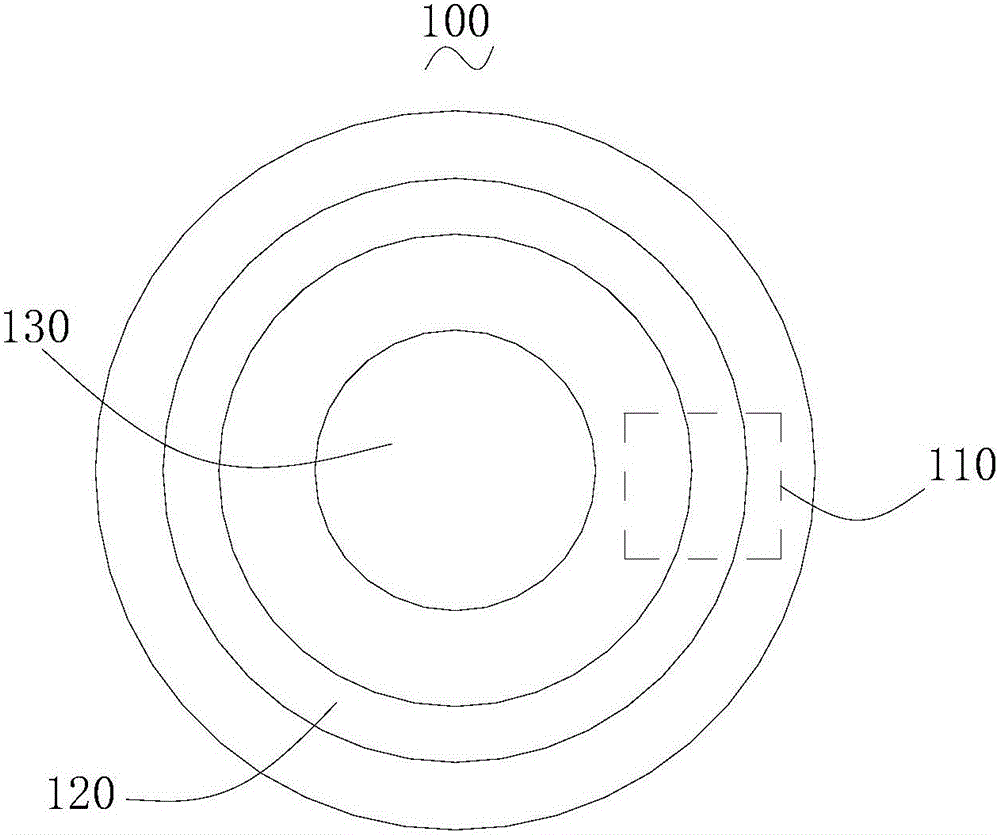

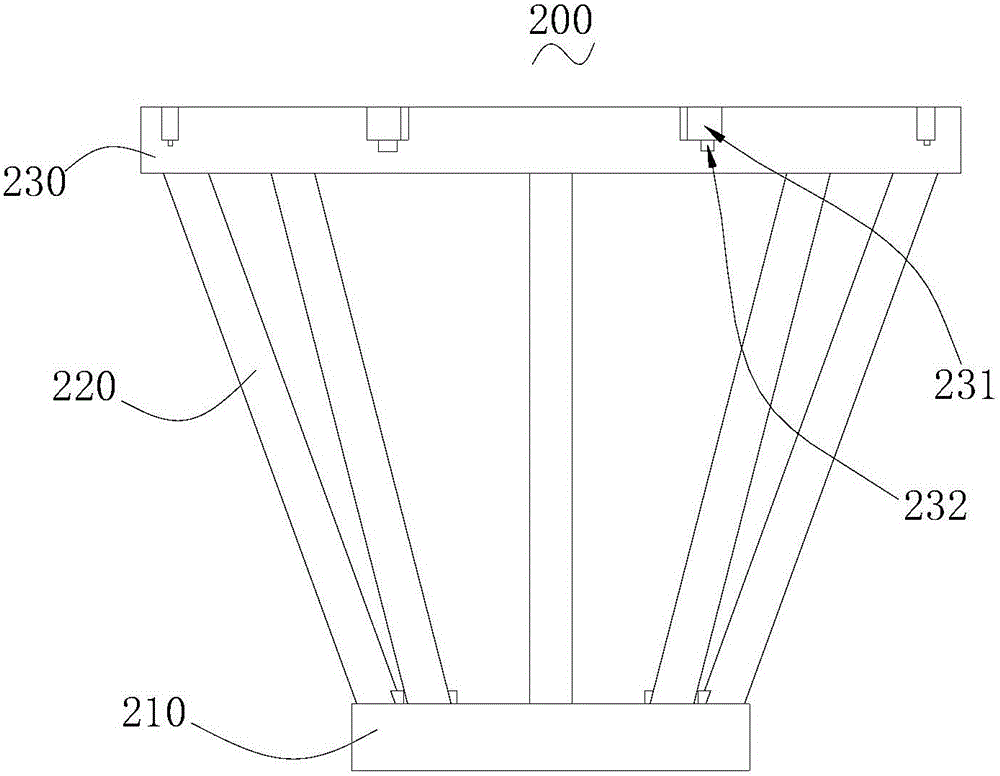

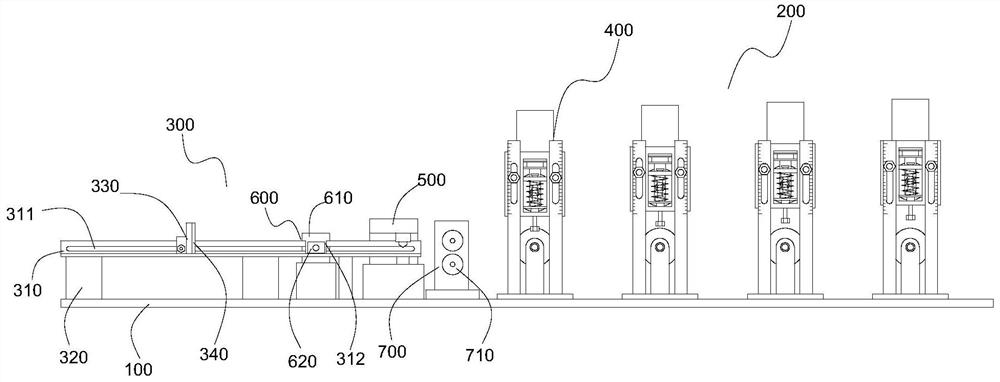

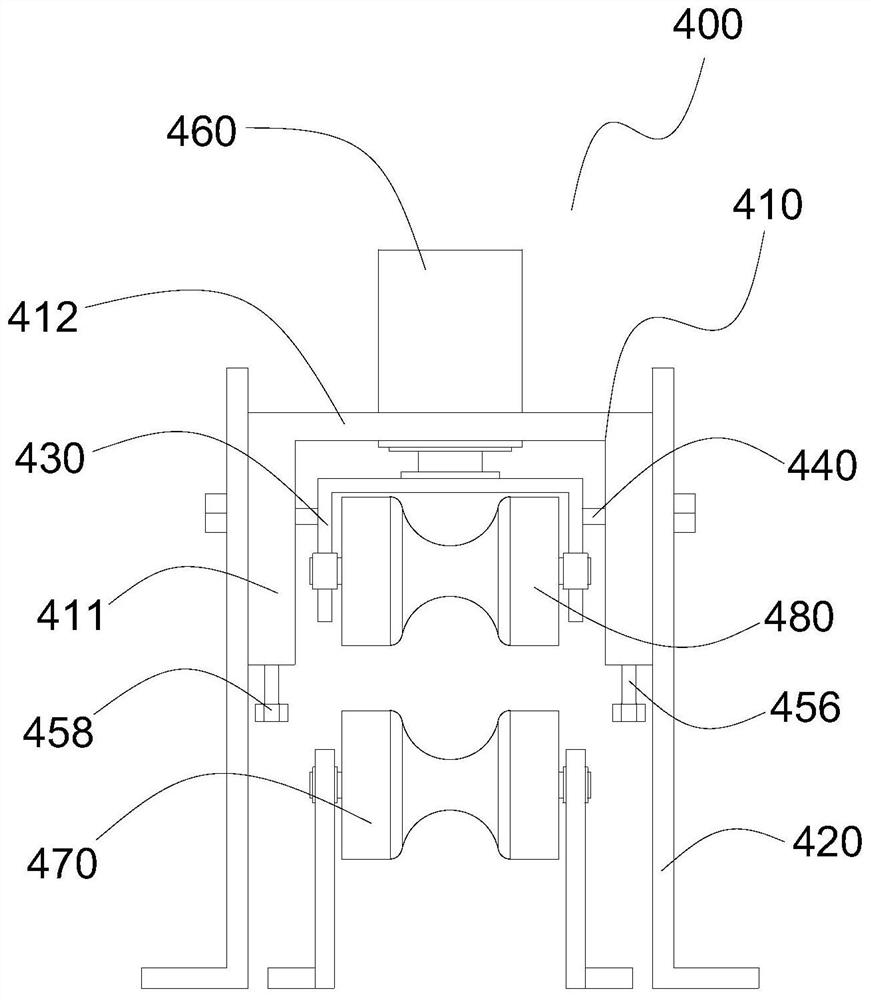

Intelligent feeding system and production control system

InactiveCN112978324AMaximize processing efficiencyImprove efficiencyControl devices for conveyorsRoller-waysProduction lineButt joint

The invention discloses an intelligent feeding system and a production control system. The intelligent feeding system comprises a left-right feeding roller way, a gantry suction cup mechanism, a plate feeding roller way, a plate turning device and an acceleration roller way which are sequentially arranged in a butt joint mode and used for conveying base plates. The left-right feeding roller way is used for correcting and conveying the base plates in batches through a left-right roller way structure, the gantry suction cup mechanism is matched with two sets of roller ways of the left-right feeding roller way to suck the base plates and conduct positioning and feeding on the plate feeding roller way in batches, the plate feeding roller way is in butt joint with the plate turning device and conveys the base plates at a low speed, the plate turning device turns over the base plates conveyed by the plate feeding roller way at intervals and conveys the base plates to the acceleration roller way, devices of all working sections on a gypsum plate production line are processed and controlled in a unified mode, so that it is guaranteed that the base plates are conveyed on all the working sections, the machining efficiency is maximized, and the devices of each working section are automatically switched to meet the processing and transporting specifications of the base plates of the corresponding specifications.

Owner:CHINA NAT BUILDING MATERIALS TECHCAL INNOVATION & RES INST LIMITED

BOB (BOB on Board) testing system and method for automatically calibrating BOB receiving power

ActiveCN104901738ARealize automatic calibrationAvoid problemsFibre transmissionTransmission monitoring/testing/fault-measurement systemsOn boardComputer module

The invention discloses a BOB (BOB on Board) testing system and a method for automatically calibrating BOB receiving power, and aims to solve the problems of complex operation, low accuracy and high labor cost in the calibration way of the BOB module receiving power. The BOB testing system comprises an upper computer, and an optical line terminal, a BOB module and an integrated authentication system integrated with an optical attenuator which are all connected with the upper computer, and an optical splitter which is synchronously connected with the optical line terminal and the optical attenuator through an optical fiber, wherein the optical splitter is connected with the BOB module through the optical fiber. The BOB testing system is reasonable in design and convenient to operate. Through effective combination of software and hardware, automatic calibration of the BOB receiving power is realized; the automatic degree and calibration accuracy are high; and unnecessary labor cost investment is effectively reduced. Thus, the BOB testing system and the method have very high application values.

Owner:江西网是科技有限公司

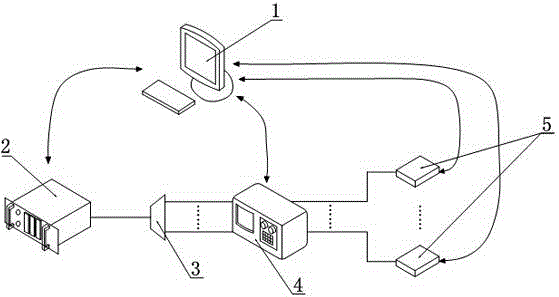

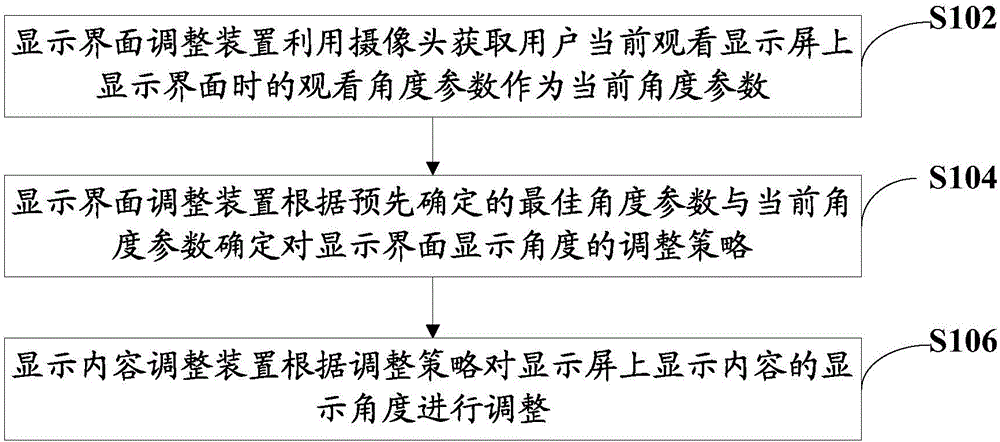

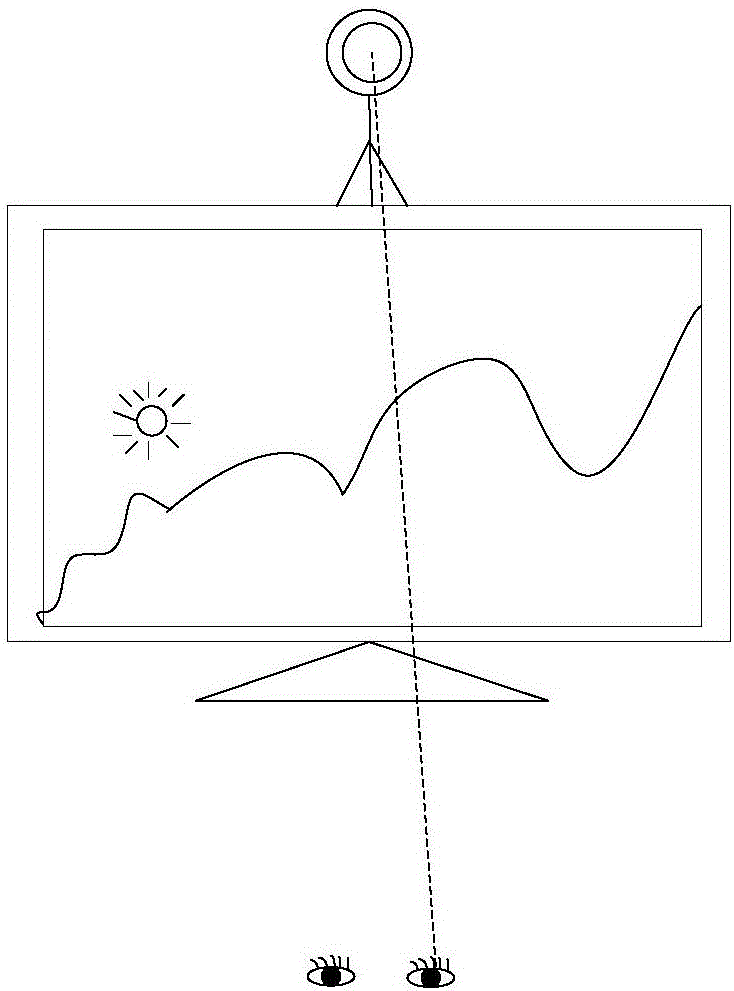

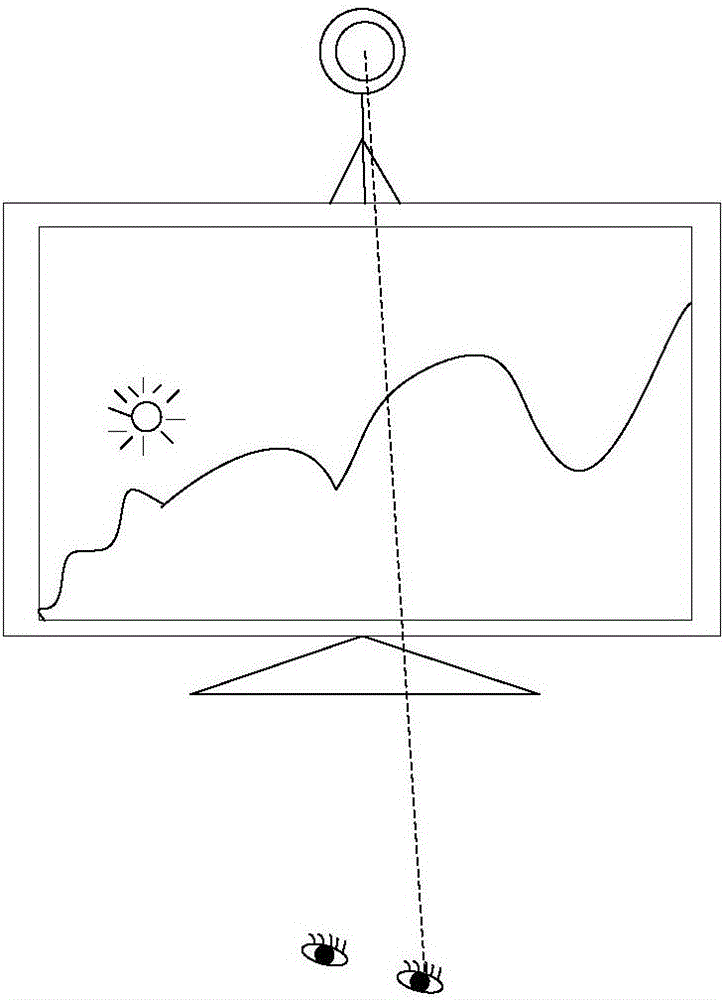

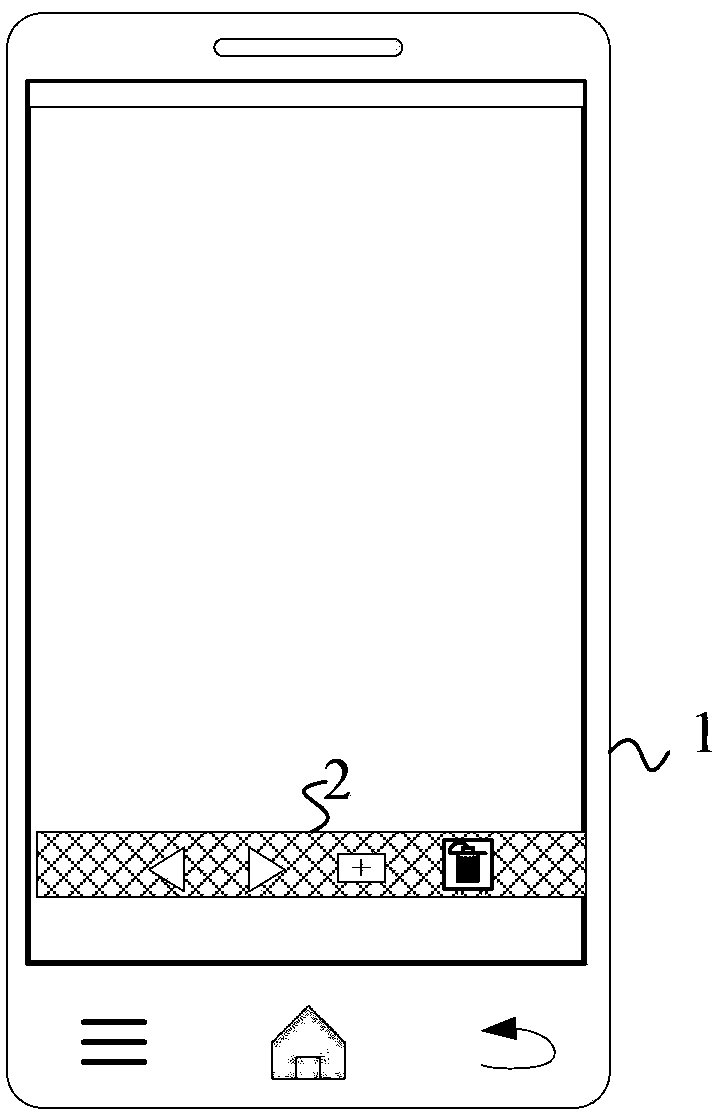

Apparatus and method for adjusting display interface, and terminal

InactiveCN106569611AReduce manual adjustmentsGuaranteed viewing qualityInput/output for user-computer interactionGraph readingComputer graphics (images)Visual angle

The invention discloses an apparatus and method for adjusting a display interface, and a terminal. A watching angle parameter of a user watching a display interface of a display screen currently is obtained by a camera and is used as a current angle parameter; according to the current angle parameter and a pre-determined optimal angle parameter, an adjusting strategy for the display angle of the display interface is determined; and on the basis of the adjusting strategy, the display angle of the display interface is adjusted, so that the adjusted display angle matches a current watching angle of the user. According to the adjusting method and apparatus, the adjusting apparatus adjusts the display angle of the display interface at the display screen automatically based on the preset optimal angle parameter and the current angle parameter obtained by the camera, so that the display angle of the display interface can adapt to the current watching angle of the user automatically. Therefore, the user can watch the display interface at an optimal watching visual angle all the time; and thus the hand-operated adjusting process of the use is reduced and the watching quality of the user is guaranteed.

Owner:NUBIA TECHNOLOGY CO LTD

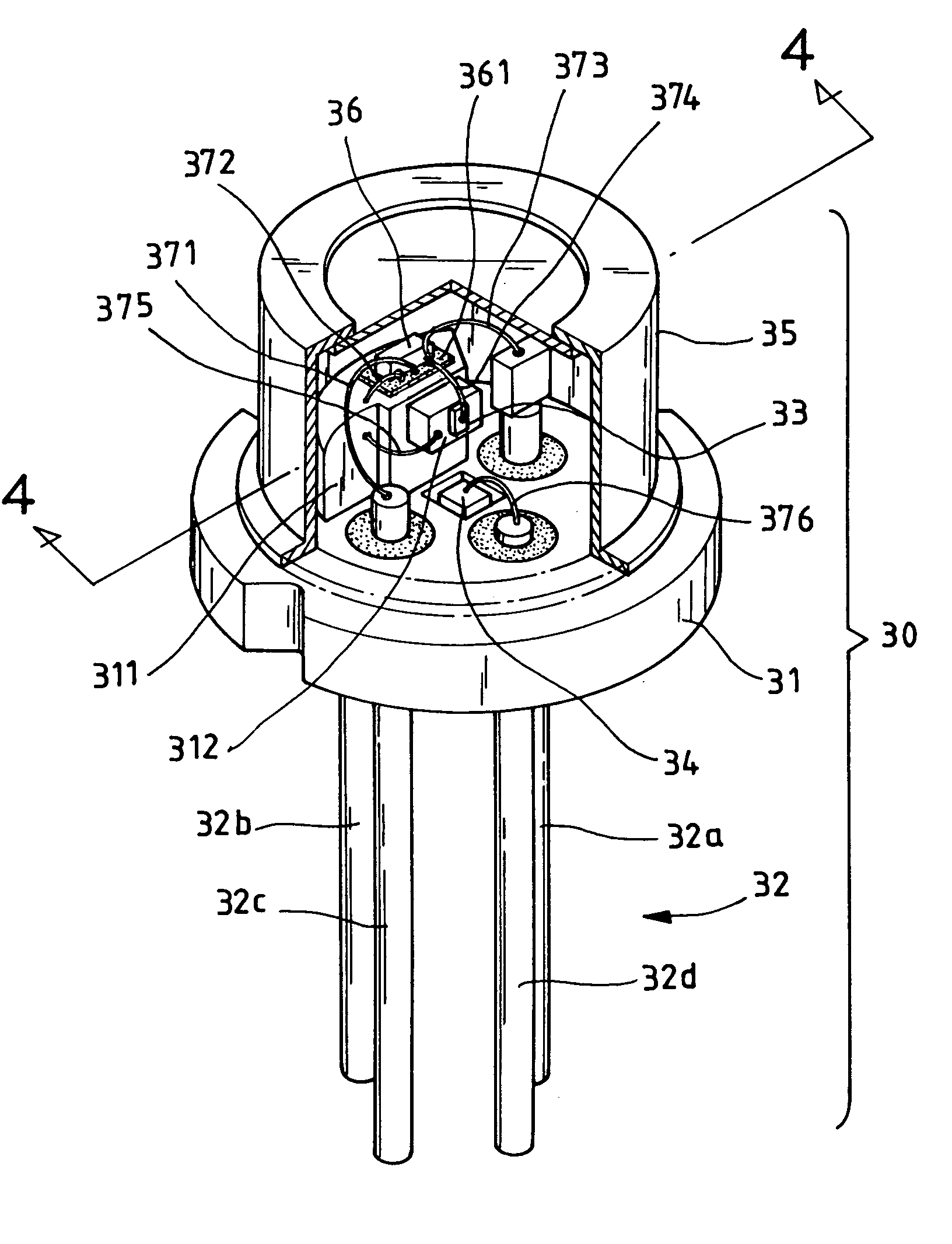

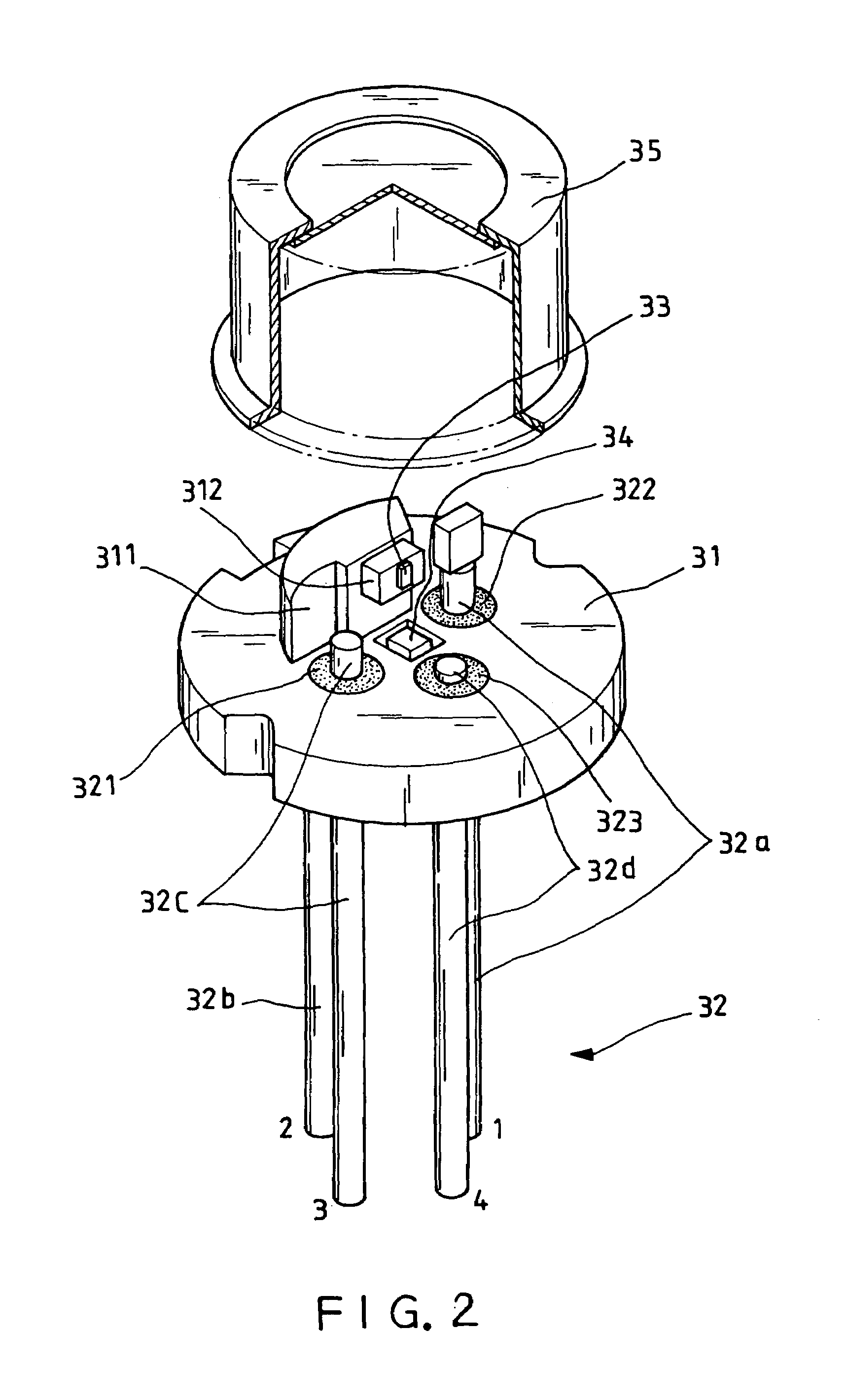

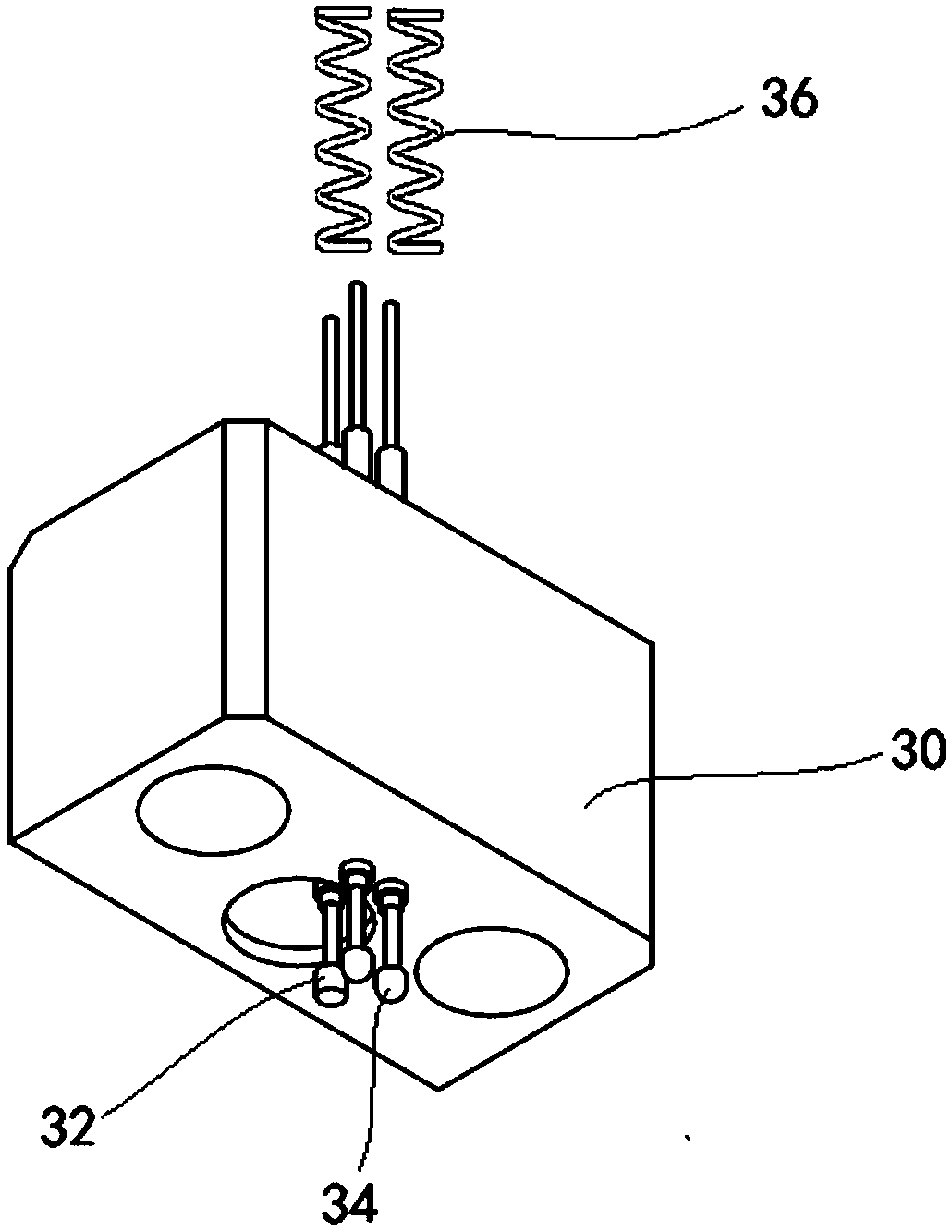

Laser diode module with a built-in high-frequency modulation IC

InactiveUS7177331B2Save the hassleRemove noiseSolid-state devicesSemiconductor lasersElectrical connectionPhotodiode

A laser diode module with a built-in high-frequency modulation IC used to remove the reflected noise generated as the laser beam reads the signal to be played back and directly packaged within a metal cap. The high-frequency modulation IC creates an electrical connection through wire bonding with several connection legs and the laser diode module. The packaged laser diode module has four connection legs. Two of these connection legs act as a positive and a negative terminal for supplying power to the built-in high-frequency modulation IC. The other two connection legs are electrically connected to an external automatic power control (APC) circuit and act as the positive terminal of the laser diode and the photo diode, respectively. In this way, the inconvenience of externally attaching a high-frequency current producing circuit board can be avoided, the productivity can be enhanced and the radiation of electromagnetic interference (EMI) can be reduced.

Owner:ARIMA LASERS CORP

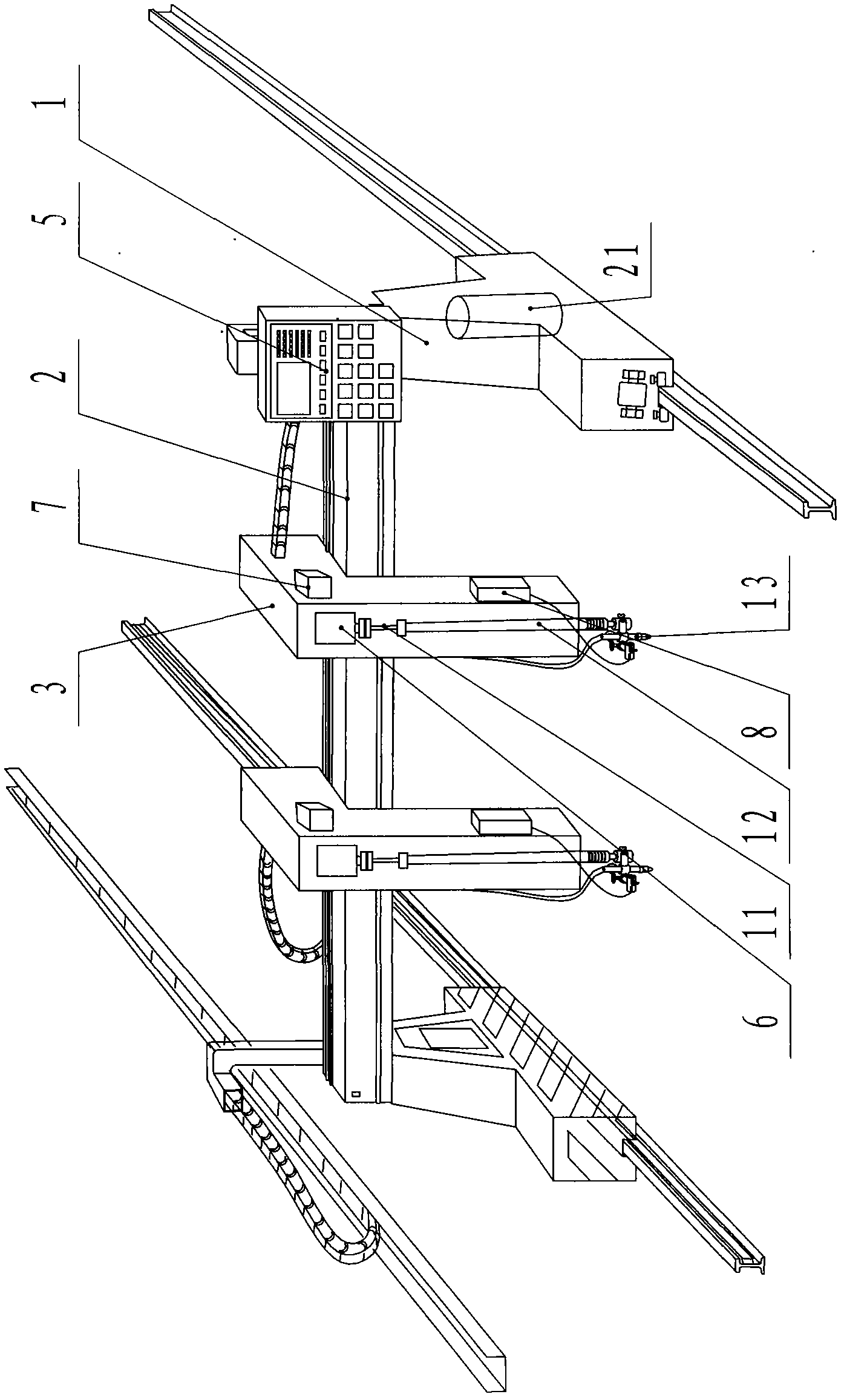

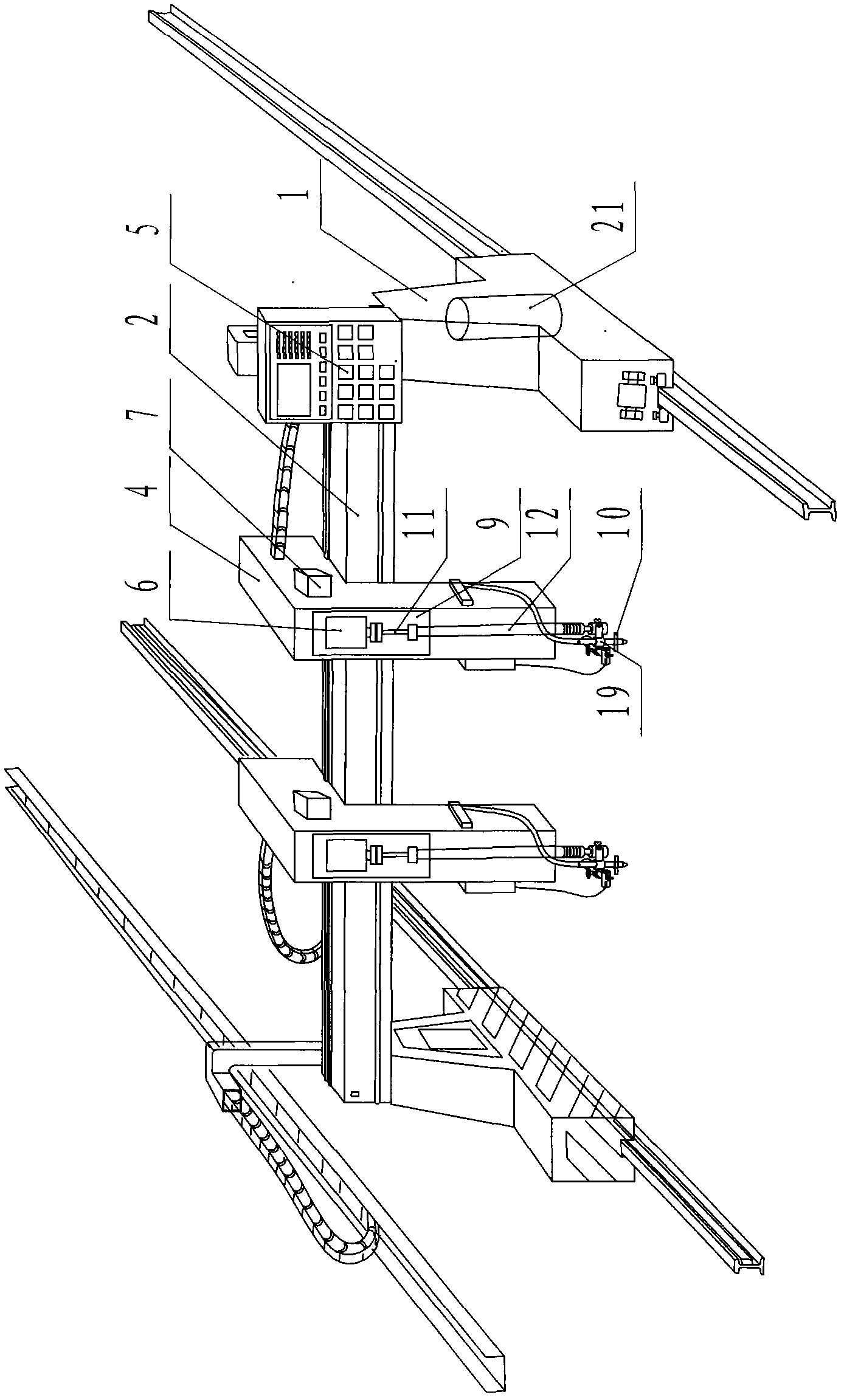

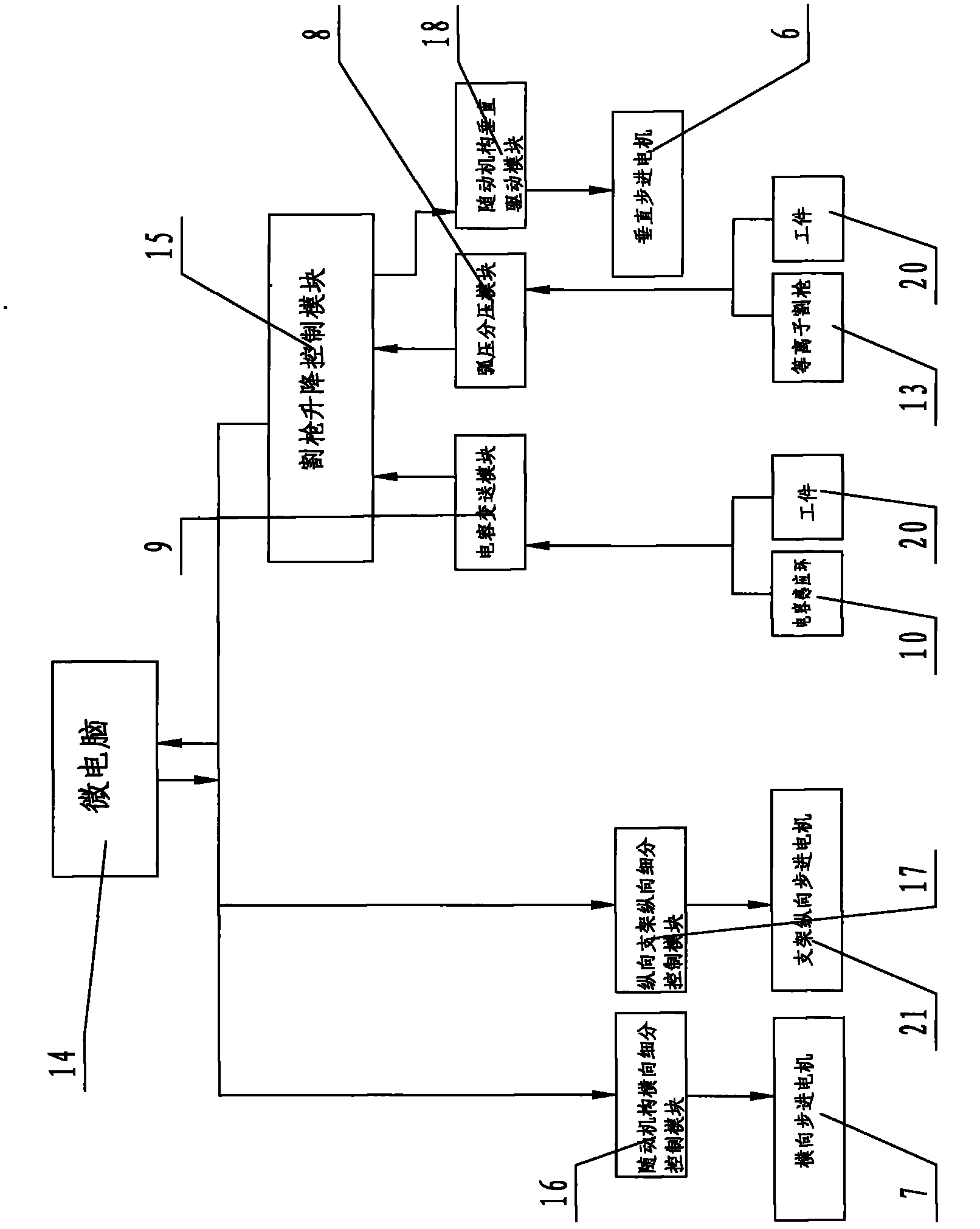

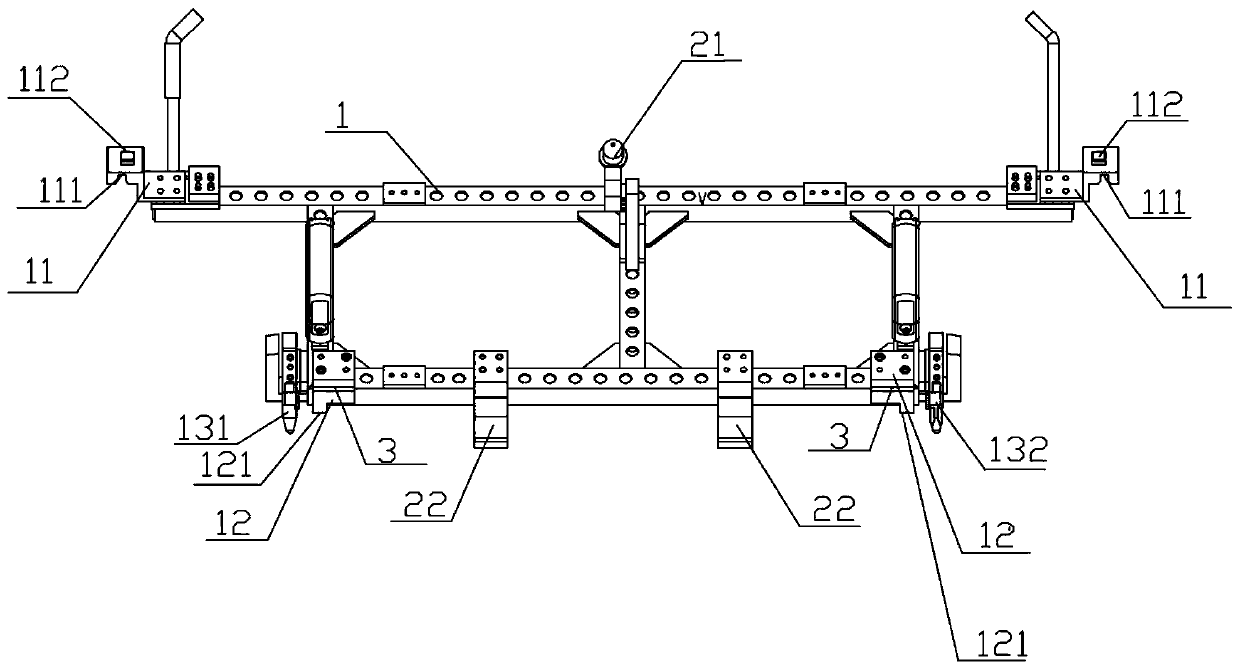

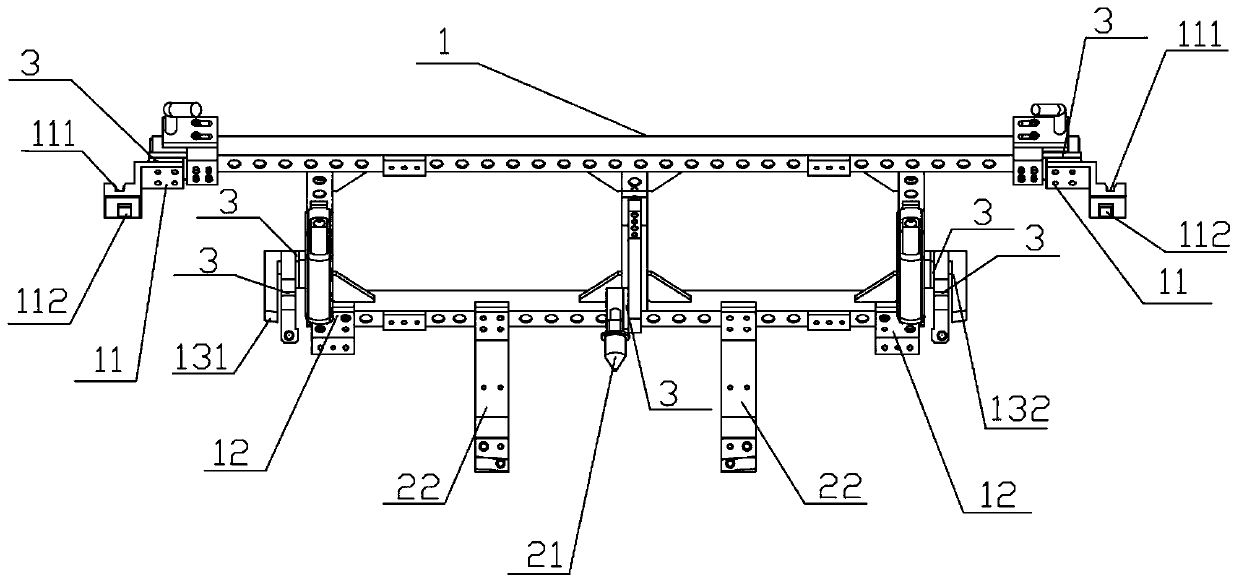

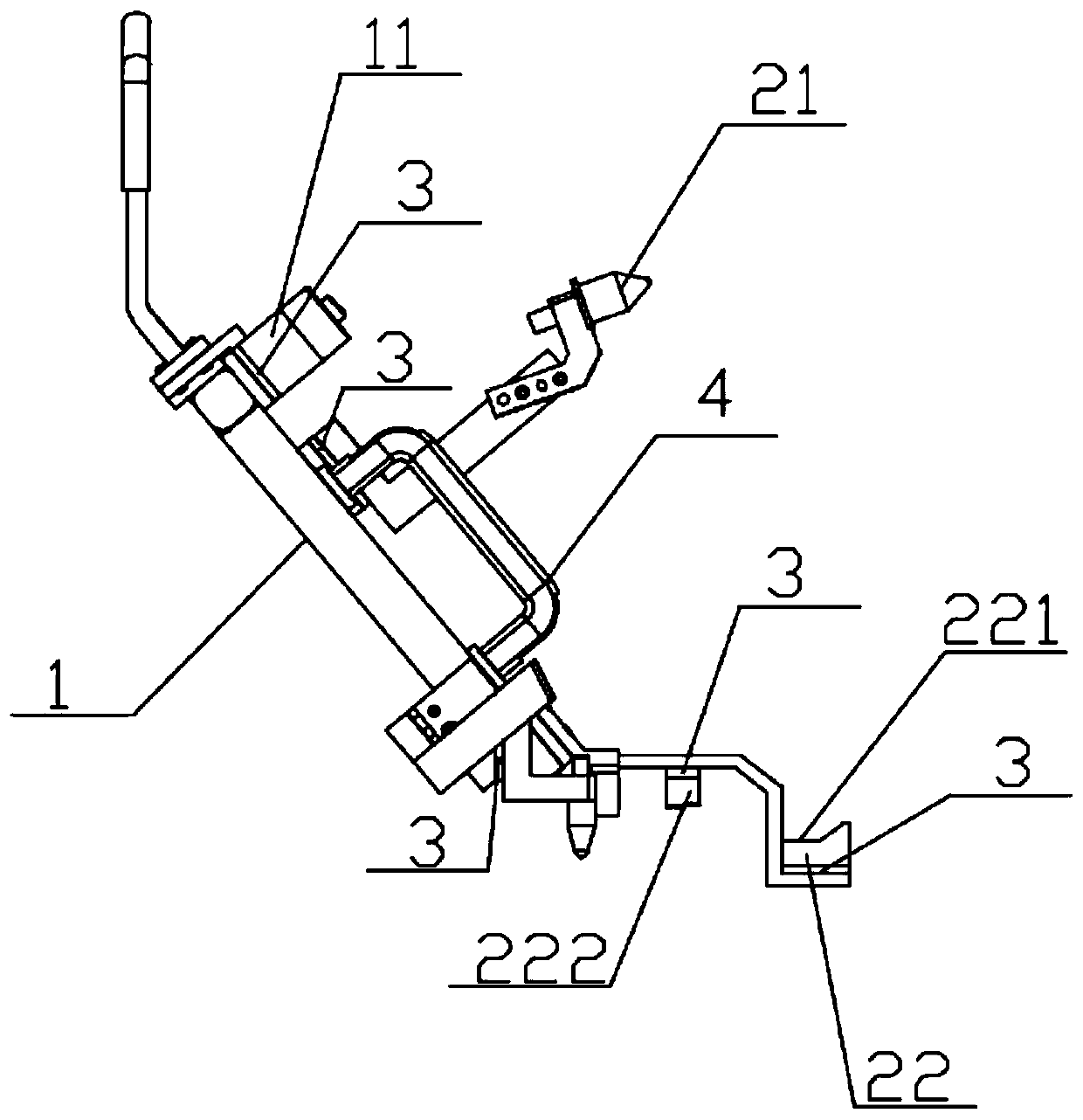

Numerical control plasma flame cutting machine

InactiveCN102319937AReduce distractionsCompact structureGas flame welding apparatusNumerical controlNumerical controlCapacitance

The invention discloses a numerical control plasma flame cutting machine, which comprises a longitudinal bracket, a transverse bracket, a follow-up mechanism and a control system. The follow-up mechanism comprises a plasma follow-up mechanism and a flame follow-up mechanism; the plasma follow-up mechanism and the flame follow-up mechanism are respectively provided with a vertical step motor and a transverse step motor which respectively drive a cutting gun to move vertically and transversely; the control system comprises a microcomputer, a cutting gun lifting control module, a follow-up mechanism transverse subdivision control module, a longitudinal bracket longitudinal subdivision module, a capacitance transmitting module, an arc-voltage voltage dividing module and a follow-up mechanism vertical driving module; the transverse bracket is provided with two sets of plasma follow-up mechanisms or two sets of flame follow-up mechanisms; the microcomputer is connected with the transverse step motor of the follow-up mechanism; the cutting gun lifting control module is connected with a capacitance inducting ring, a workpiece and the plasma cutting gun; and the follow-up mechanism vertical driving module is connected with the vertical step motor of the follow-up mechanism. The numerical control plasma flame cutting machine has strong interference resistance capability; a cutting power supply is economical; and the vertical displacement precision of the follow-up mechanism is high.

Owner:青岛利东机械有限公司

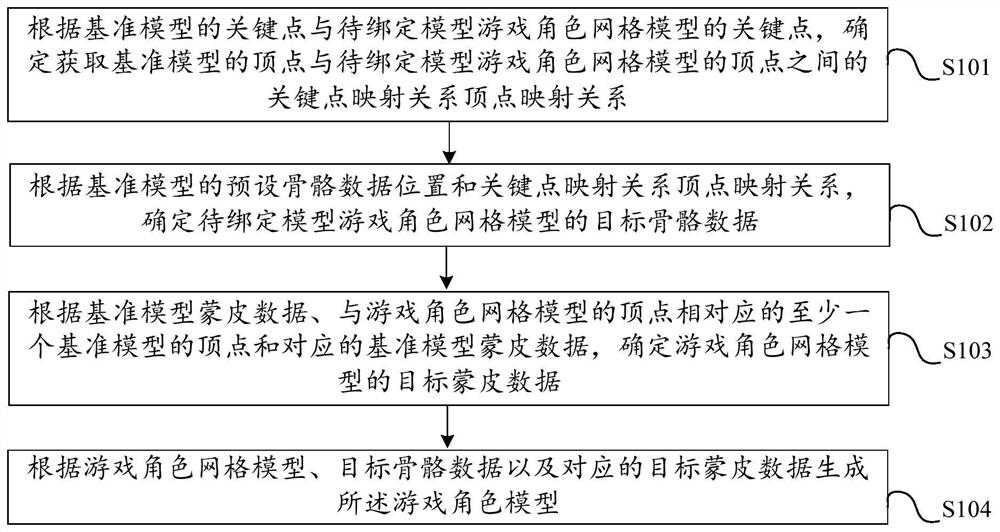

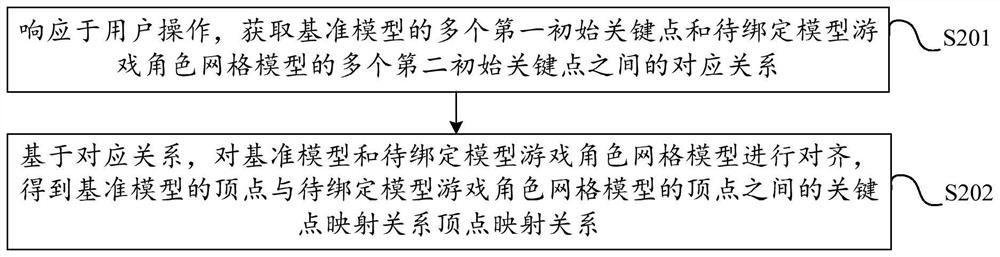

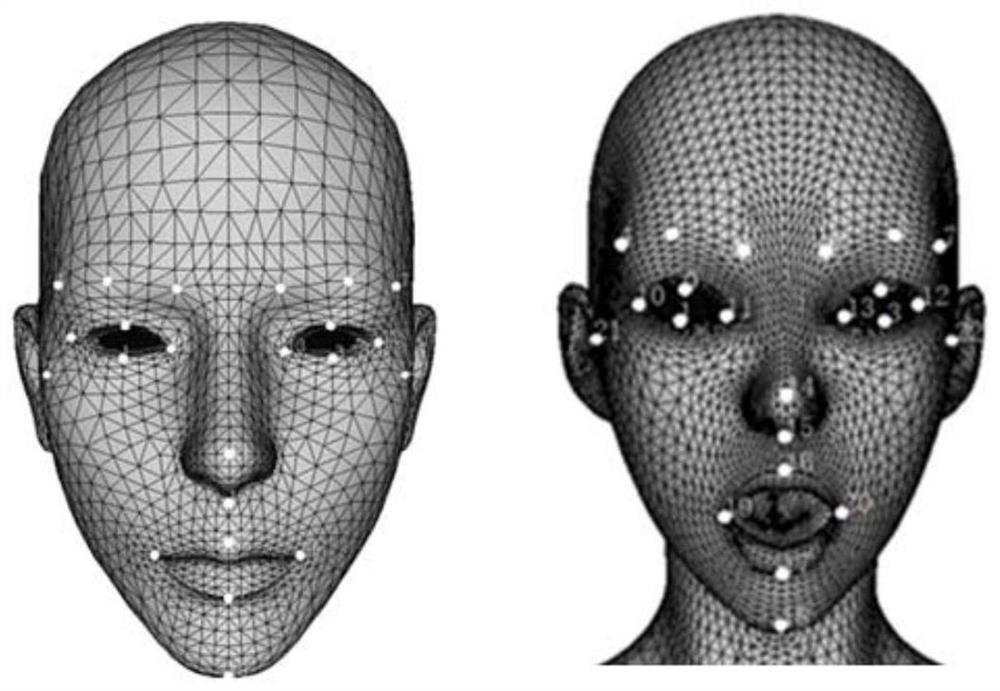

Game role model generation method and device, role adjustment method and device, equipment and medium

PendingCN111714885AImprove production efficiencyReduce manual adjustmentsAnimationVideo gamesReference modelSkin

The invention provides a game role model generation method and device, a role adjustment method and device, equipment and a medium, and relates to the technical field of games. The game role model generation method comprises the steps of determining a vertex mapping relationship between vertexes of a reference model and vertexes of a game role grid model according to key points of the reference model and key points of the game role grid model; determining target skeleton data of the game role grid model according to reference model skeleton data and the vertex mapping relationship; determiningtarget skin data of the game role grid model according to reference model skin data, the vertex of at least one reference model corresponding to the vertex of the game role grid model and corresponding reference model skin data; and generating the game role model according to the game role grid model, the target skeleton data and the corresponding target skin data. So, the fine manual adjustmentis greatly reduced, the automatic binding is realized, and the generation efficiency of the game role model is improved.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

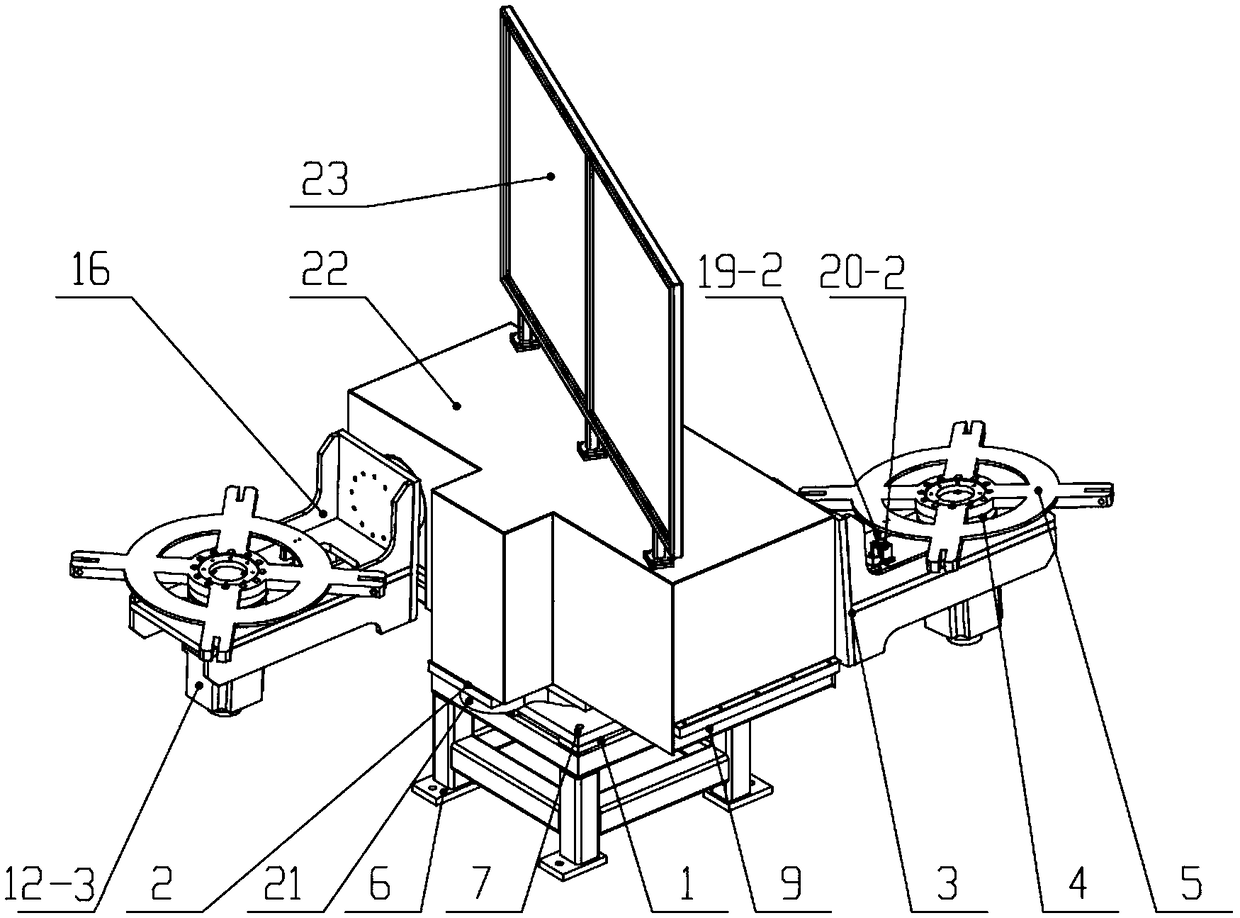

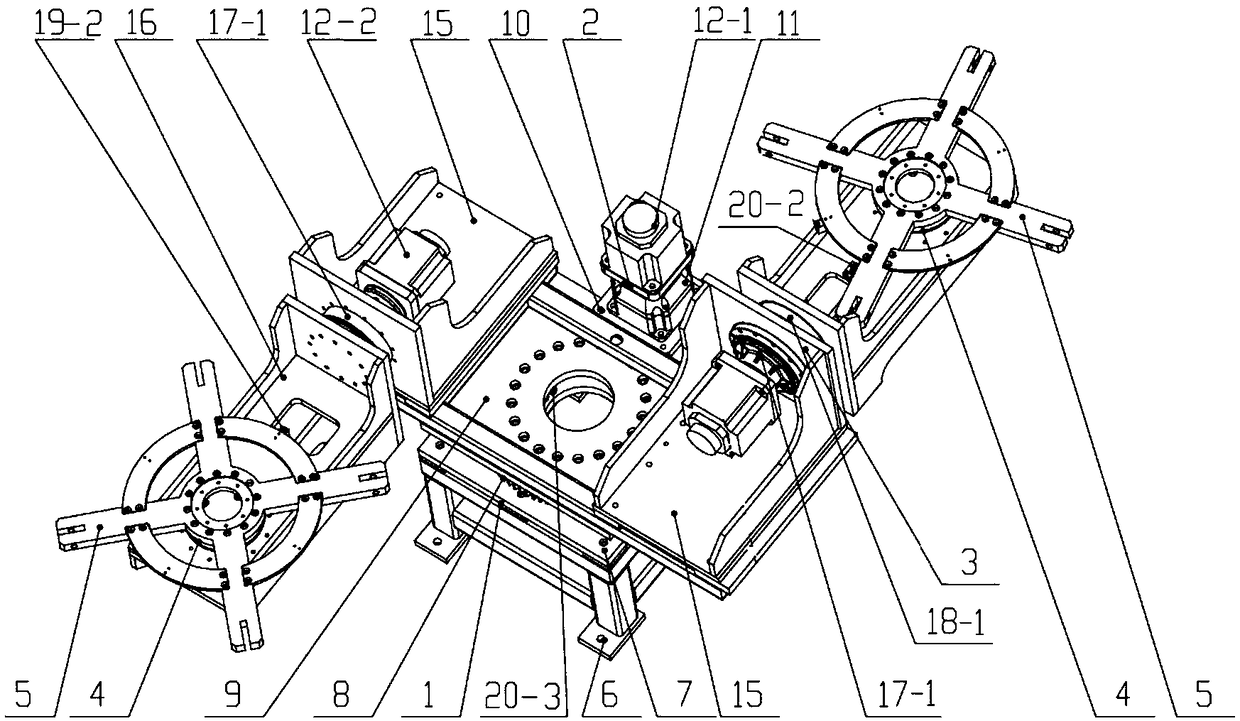

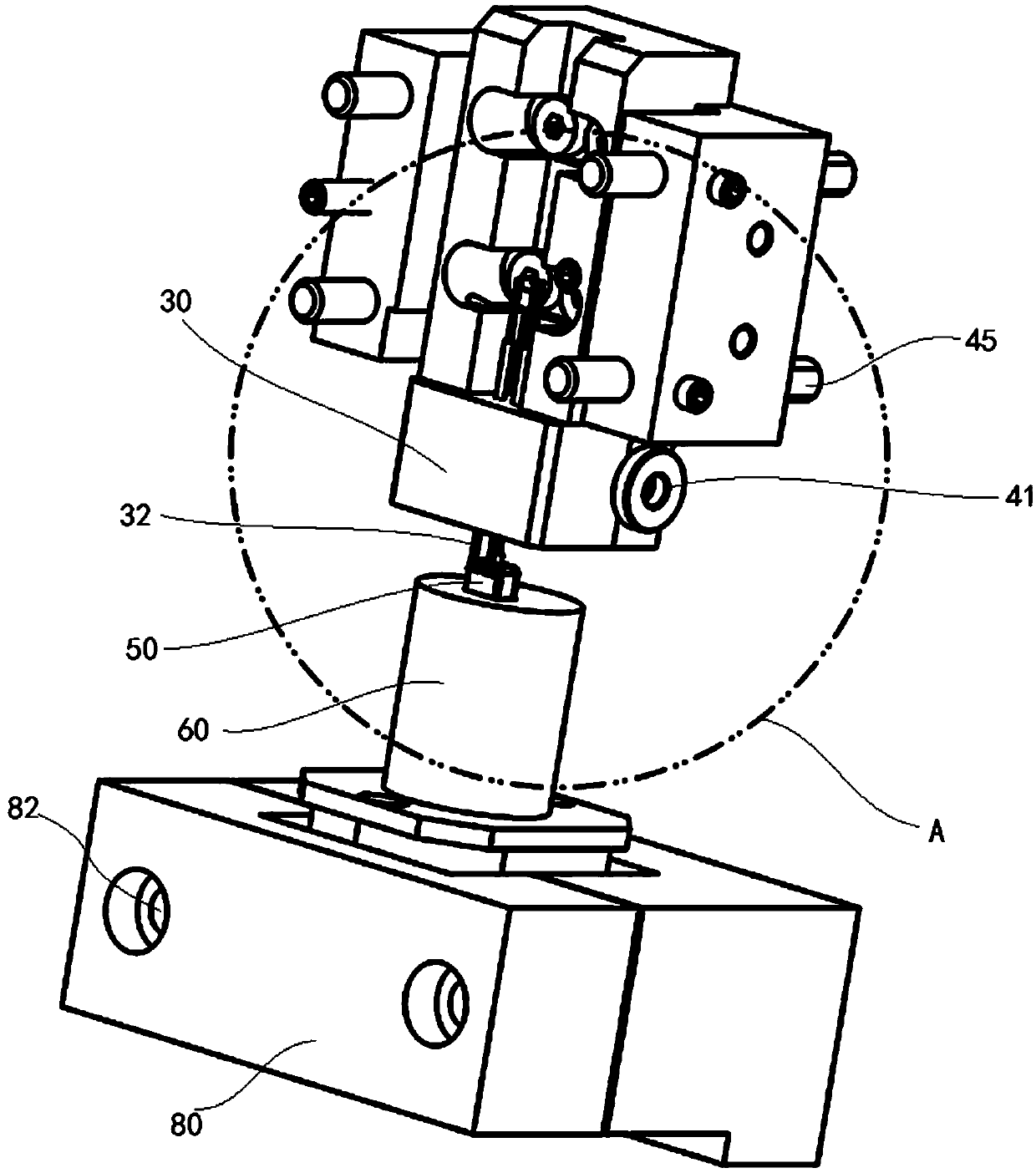

Intelligent hub assembling equipment for automobile production line

The invention relates to the technical field of automobile hub assembly, in particular to intelligent hub assembling equipment for an automobile production line, which comprises a machining table, a top bracket, a hub clamping jaw, a tire clamping jaw, rotary lifting mechanisms, a tire limiting mechanism, a first screw rod sliding table and a second screw rod sliding table, the top support is horizontally located over the machining table; the first screw rod sliding table is horizontally arranged on the top bracket; the tire limiting mechanism is arranged at the working end of the first lead screw sliding table; the second lead screw sliding table is horizontally arranged on the machining table; a pair of rotary lifting mechanims is arranged; one of the rotary lifting mechanisms is arranged on the machining table, and the other rotary lifting mechanism is arranged at the working end of the second lead screw sliding table; the hub clamping jaw is arranged at the working end of one of the rotary lifting mechanisms; the tire clamping jaw is arranged at the working end of the other rotary lifting mechanism; according to the automatic wheel hub butt-joint assembling equipment, butt-joint assembling can be automatically conducted on wheel hubs, the assembling precision is improved, manual adjustment is omitted, and the assembling efficiency is improved.

Owner:彭敬

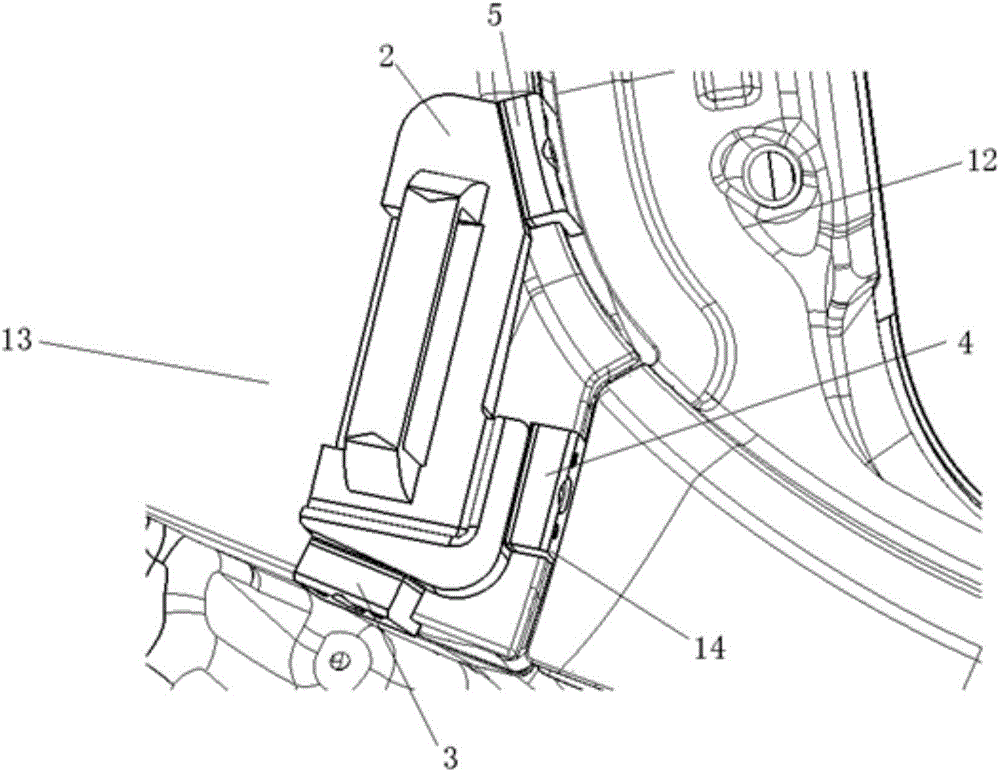

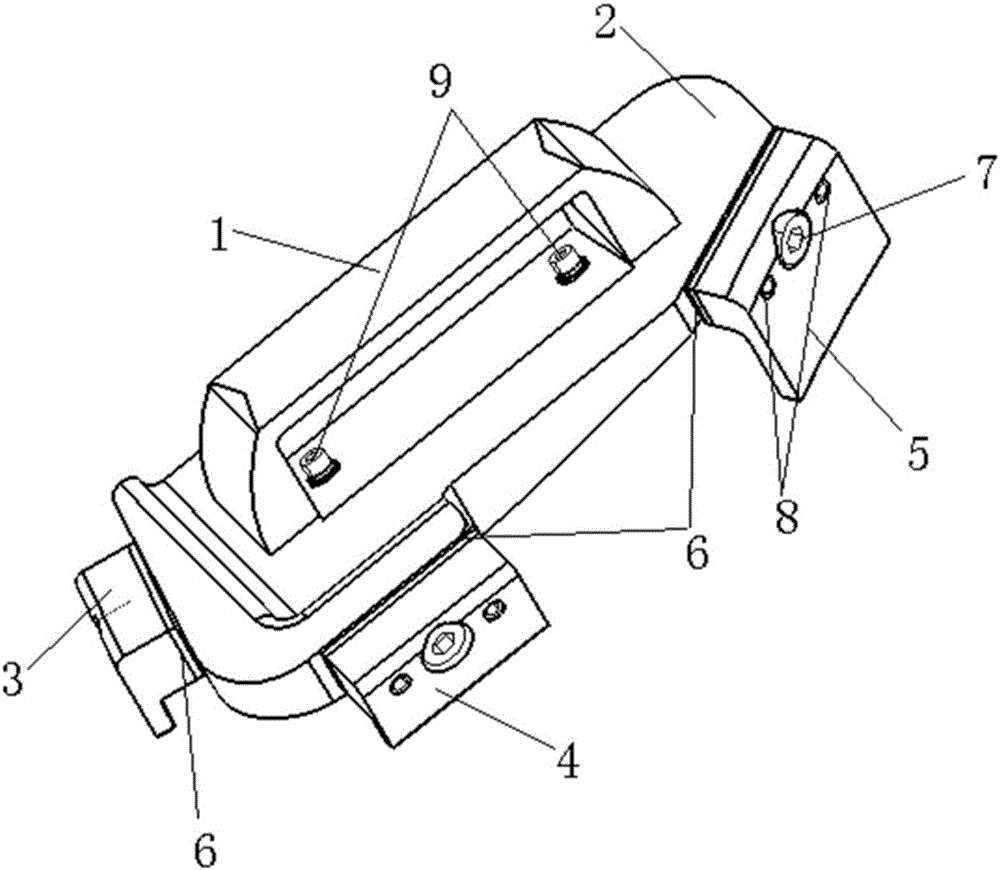

Backdoor assembling aid

The invention relates to a backdoor assembling aid. The backdoor assembling aid comprises two first auxiliary assembling modules and two second auxiliary assembling modules, wherein each first auxiliary assembling module comprises a handle, a side wall external plate imitation block, a first clamping block, a second clamping block, a third clamping block and a first magnet; each second auxiliary assembling module comprises a top cover imitation block, a fourth clamping block and a second magnet; and each fourth clamping block is fixed at an end of the corresponding top cover imitation block. According to the technical scheme, by the first auxiliary assembling modules and the second auxiliary assembling modules, the backdoor assembling aid is simple, convenient and flexible to operate, low in cost and small in occupied space; stability of quality of matching between an assembled backdoor and an automobile body is improved, manual adjustment amount is reduced, and labor intensity is also reduced; and when precision of the automobile body or a sub assembly fluctuates, the positions of the clamping blocks can be adjusted through adjustable gaskets on the first auxiliary assembling modules, and therefore, assembling alignment of the backdoor is ensured.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

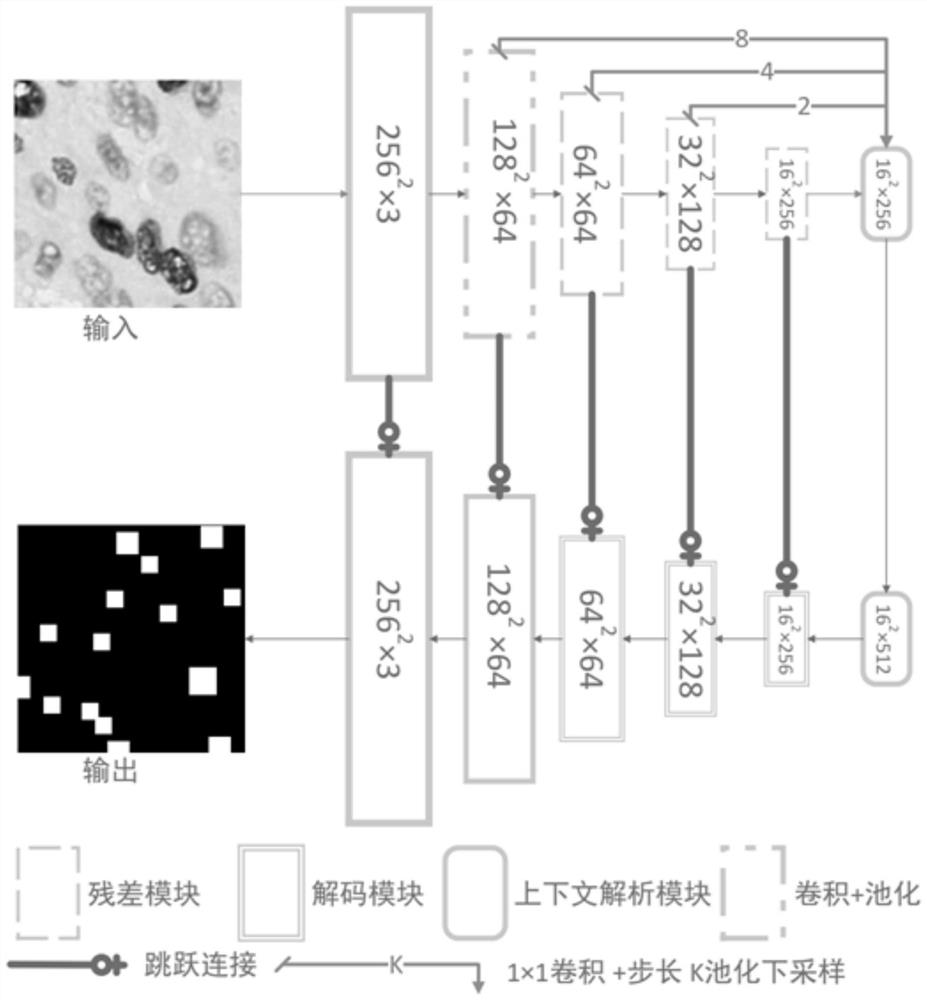

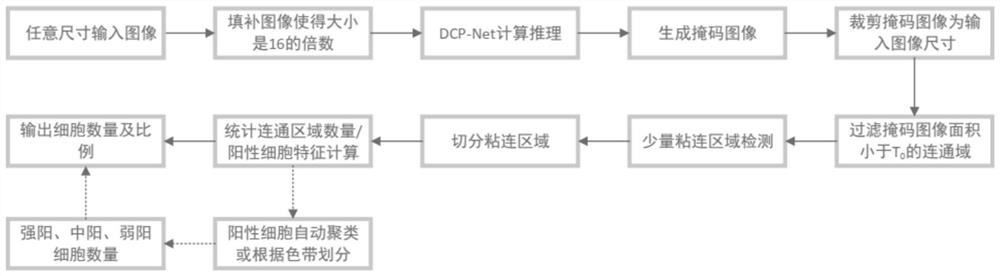

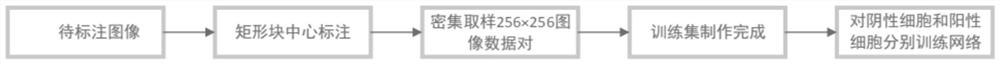

Nuclear staining cell counting method based on deep learning of incomplete marker, computer equipment and storage medium

ActiveCN112750106AImprove versatilityReduce manual adjustmentsImage enhancementImage analysisLabeled dataNuclear staining

The invention relates to a nuclear staining cell counting method based on deep learning of an incomplete label, computer equipment and a storage medium, and the method comprises the following steps: (1) making label data: loading a pathological image to label software, and obtaining sub-mask image data pairs of all sub-images and positive cells; (2) model training: training a convolutional neural network model to respectively obtain a trained positive cell convolutional neural network model and a trained negative cell convolutional neural network model; (3) reasoning stage: inputting pathological images to be detected into the trained convolutional neural network model to obtain real mask images; and (4) post-treatment stage: calculating the number of positive cells and negative cells, and calculating to obtain the proportion p of the positive cells in all the cells. The method does not need extra parameters, is high in universality, greatly reduces manual adjustment, and effectively improves the recognition accuracy and robustness. The method is faster, more accurate and more effective in data marking.

Owner:SHANDONG UNIV

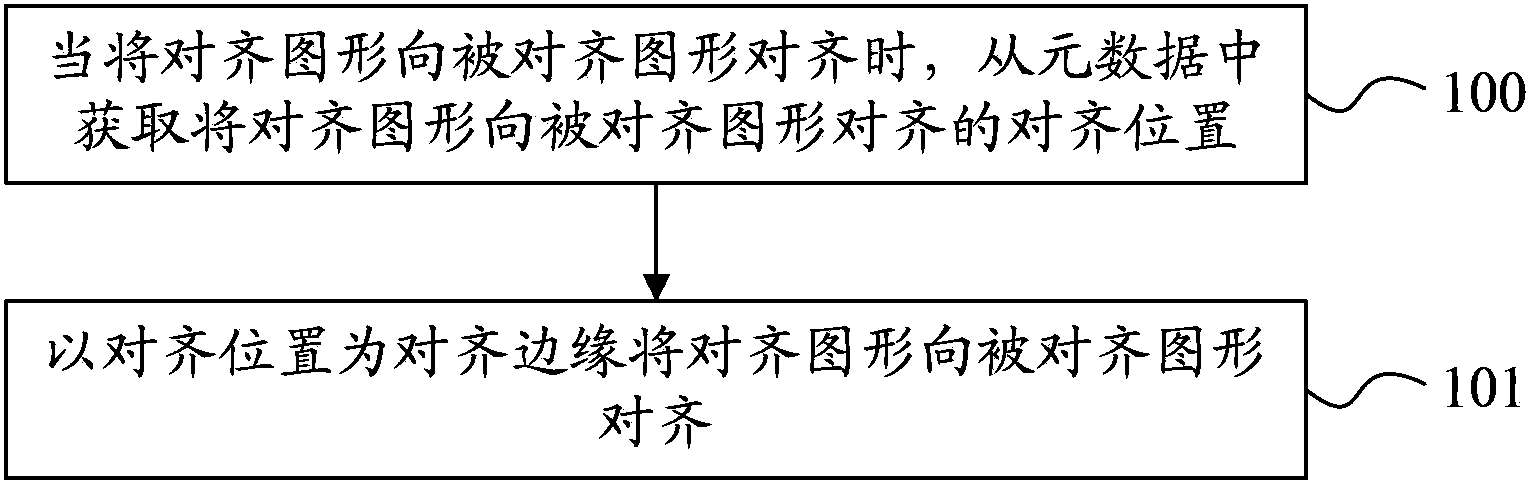

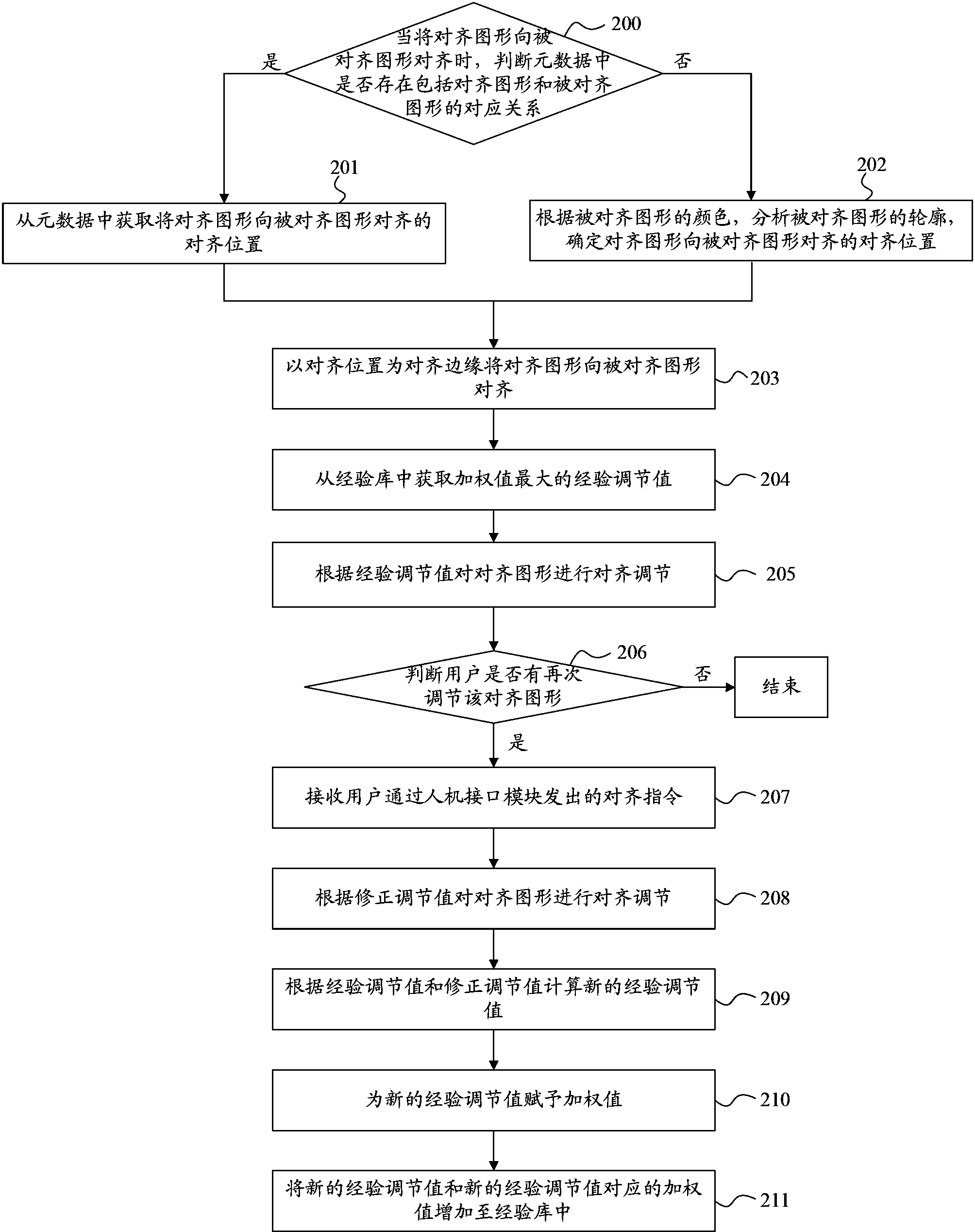

Graph alignment method and device

ActiveCN104239005AReduce manual adjustmentsImprove alignment efficiencySpecific program execution arrangementsGraphicsComputer science

The invention discloses a graph alignment method and device and belongs to the technical field of user interface design. The method includes that when aligning graphs are aligned to aligned graphs, aligning positions of aligning the aligning graphs to the aligned graphs are obtained from metadata; the metadata include corresponding relation of the aligning graphs, the aligned graphs and the aligning positions; the aligning positions serve as aligning edges to align the aligning graphs to the aligned graphs. By means of the technical scheme, the aligning positions sever as the aligning edges to align the aligning graphs to the aligned graphs according to the corresponding relation of the aligning graphs, the aligned graphs and the aligning positions in the metadata. Compared with technical schemes that aligning graphs are merely aligned to outer edges of the aligned graphs in the prior art, the technical scheme has the advantages that massive manual adjustments can be effectively reduced, and the aligning efficiency can be greatly increased.

Owner:TENCENT TECH (SHENZHEN) CO LTD

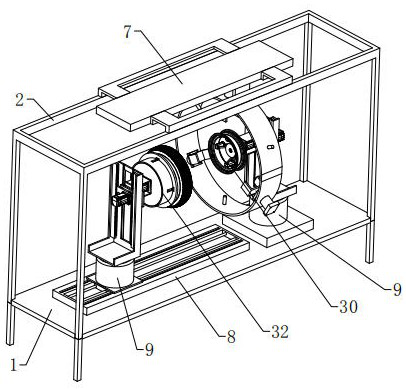

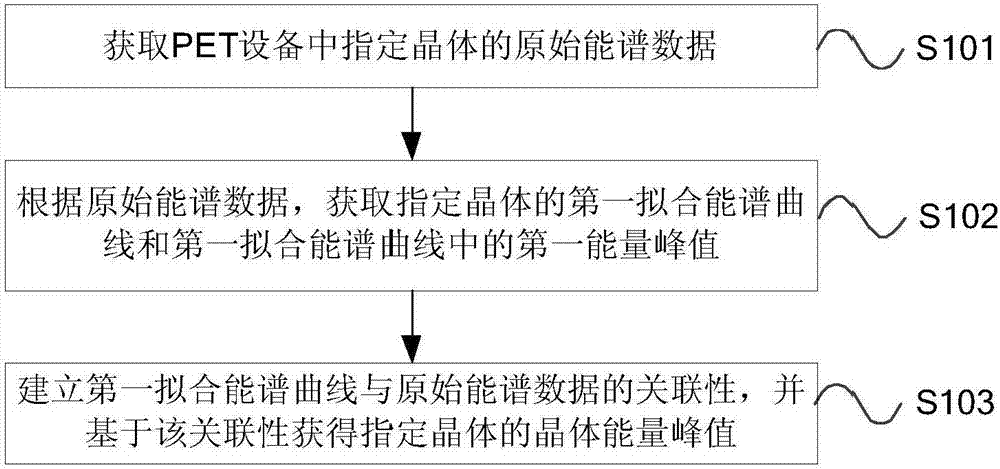

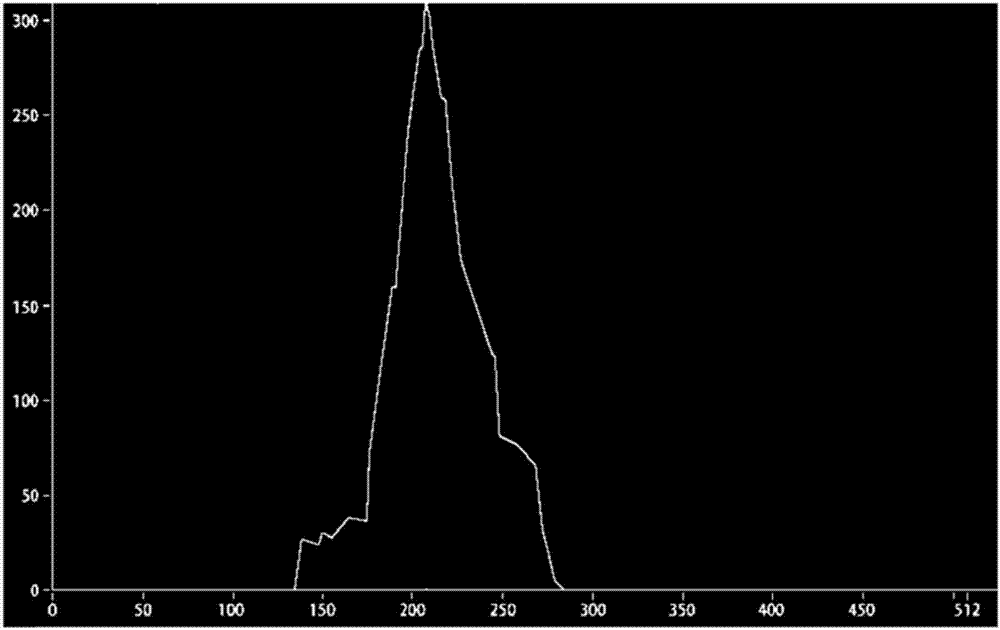

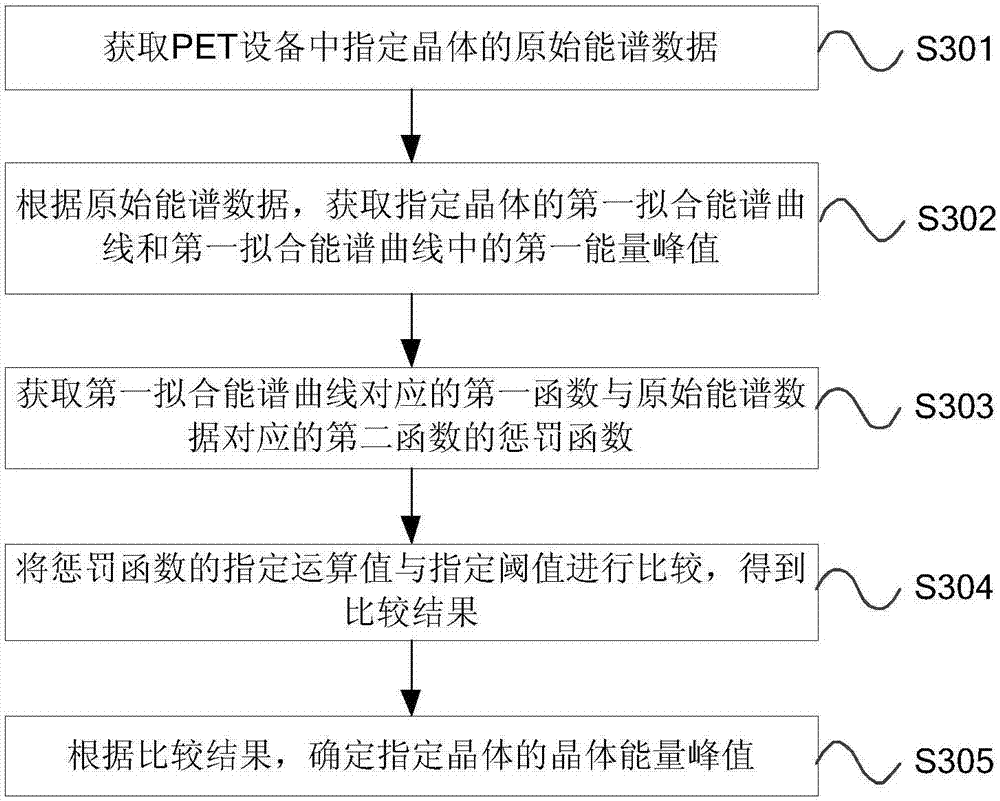

Data processing method, device and equipment

ActiveCN107133462AShorten the timeImprove processing efficiencyReconstruction from projectionInformaticsPeak valueCompanion animal

The embodiment of the invention provides a data processing method, device and equipment. The method comprises acquiring the original spectrometric data of a designated crystal in PET (positron emission tomography) equipment; according to the original spectrometric data, calculating to obtain the first fitted spectrometric curve and the first energy peak of the designated crystal; establishing correlation between the first fitted spectrometric curve and the original spectrometric data, and based on the correlation, calculating to obtain the crystal energy peak of the designated crystal, wherein, during the process, manual adjustment is reduced, so that the data processing time can be saved, the data processing efficiency can be improved, and the intelligent level during data processing can be enhanced. Further, the problems of much manual operation, low intelligence level and sequent low data processing efficiency in data processing processes on energy peak in the prior art can be solved to some extent.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

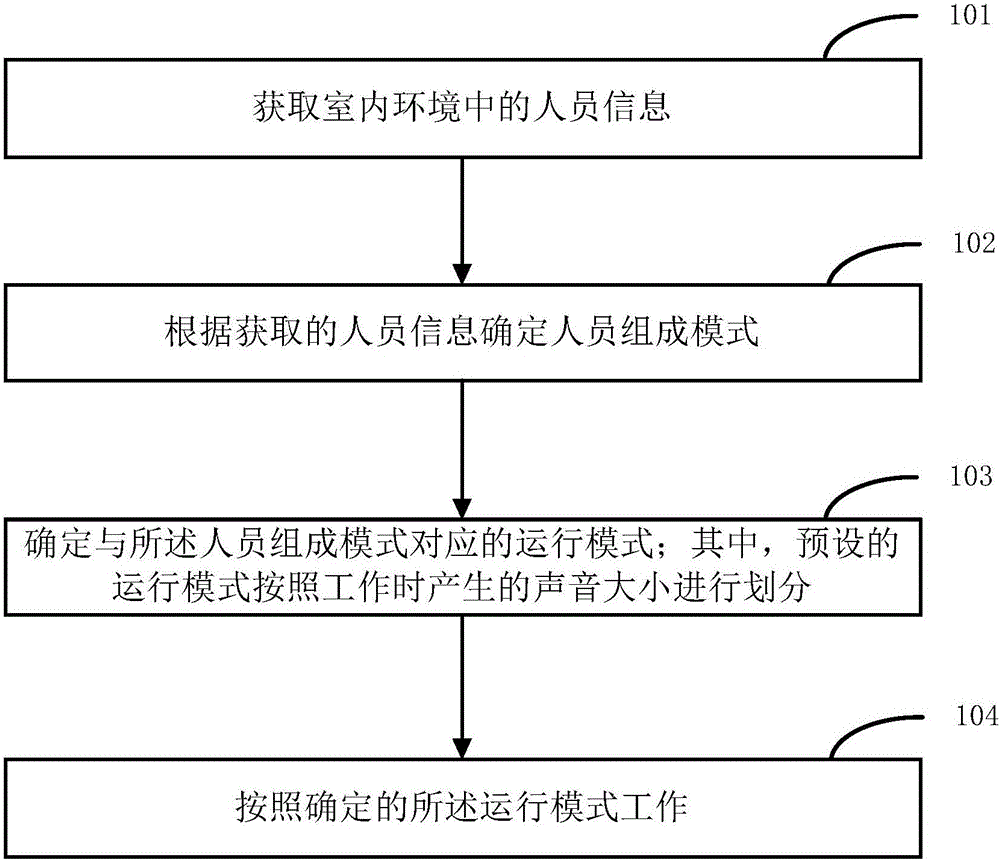

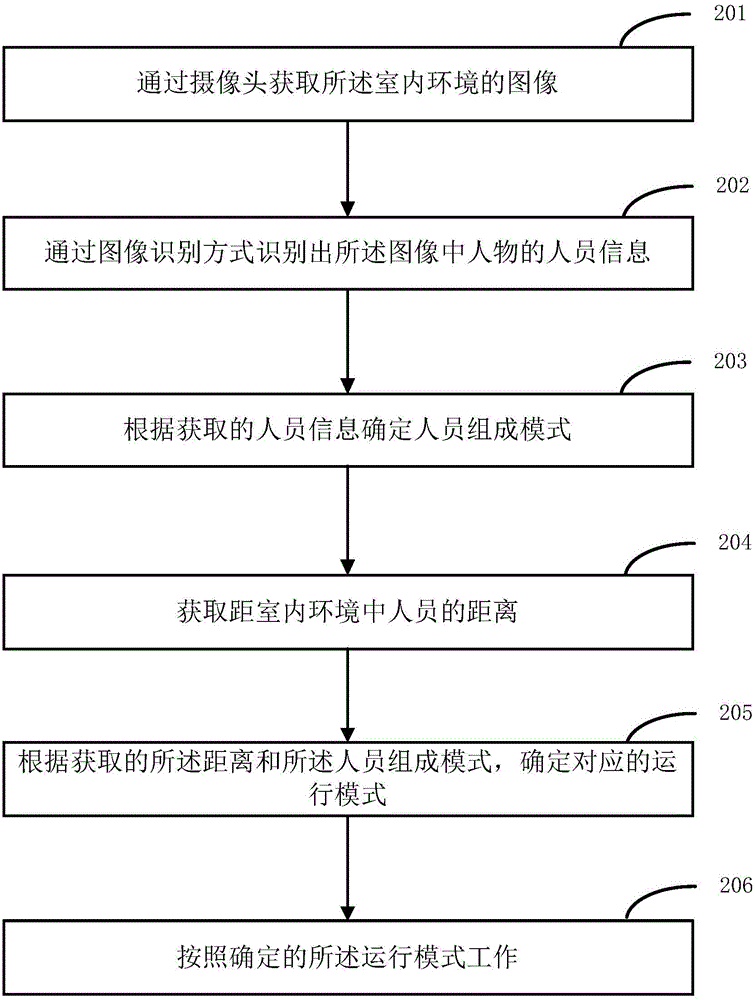

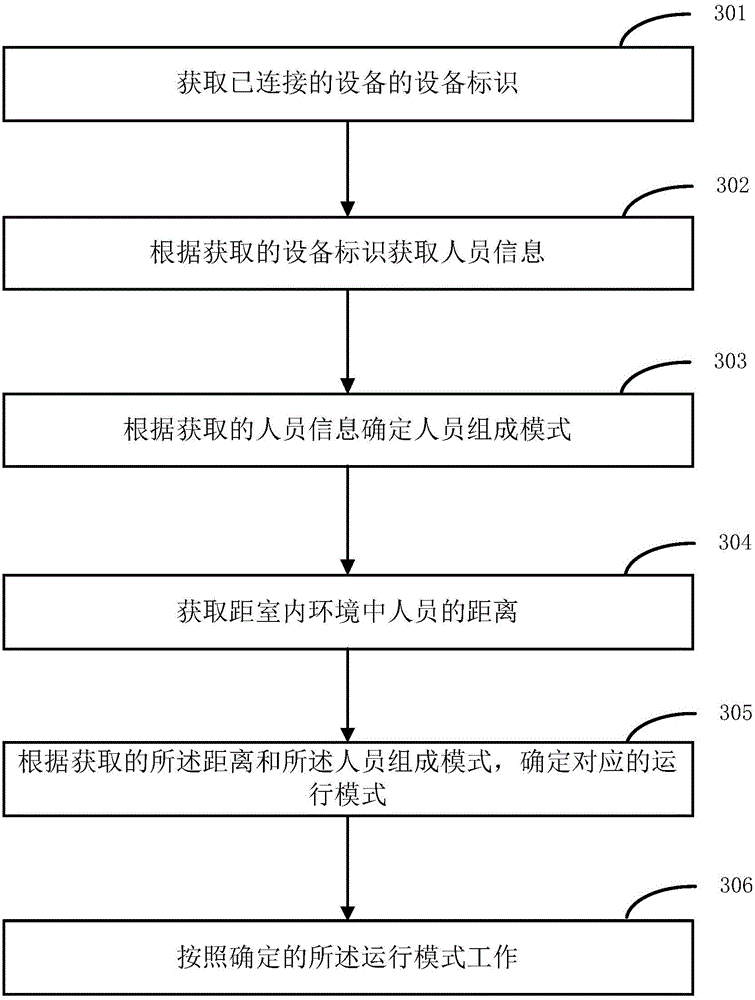

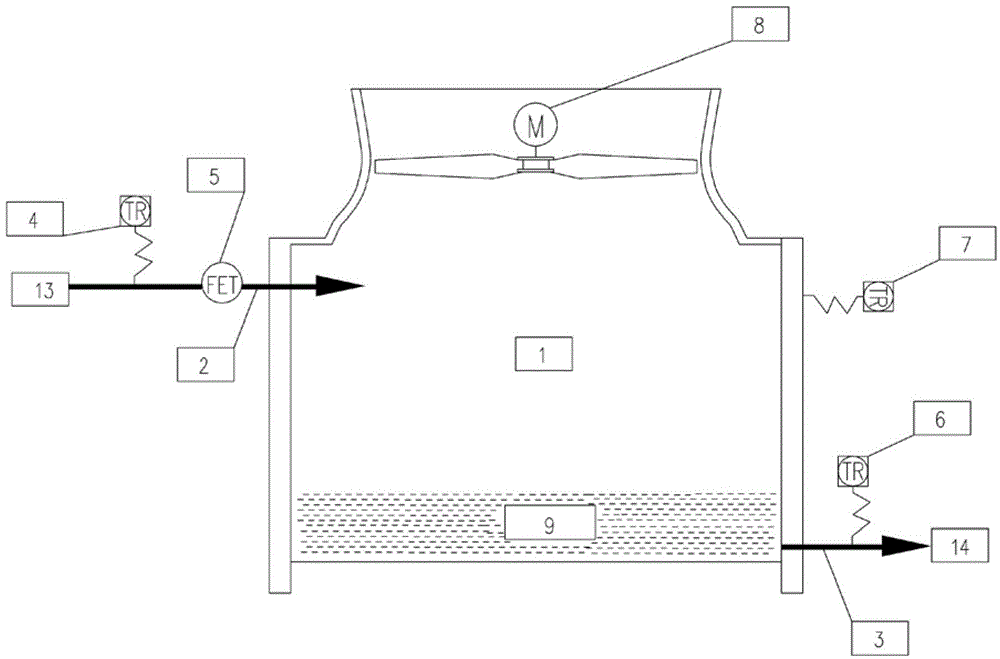

Method and device for controlling operation modes

ActiveCN105841297AImprove experienceReduce manual adjustmentsMechanical apparatusSpace heating and ventilation safety systemsOperation modeComputer science

The invention relates to a method and device for controlling operation modes. The method and device are used for automatically adjusting the operation modes and reducing disturbance on users. The method includes the steps of acquiring personnel information in indoor environment, determining a personnel compositional pattern according to the acquired personnel information, determining the operation mode corresponding to the personnel compositional pattern and working according to the determined operation mode. The preset operation modes are classified according to the magnitude of sounds generated during work.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

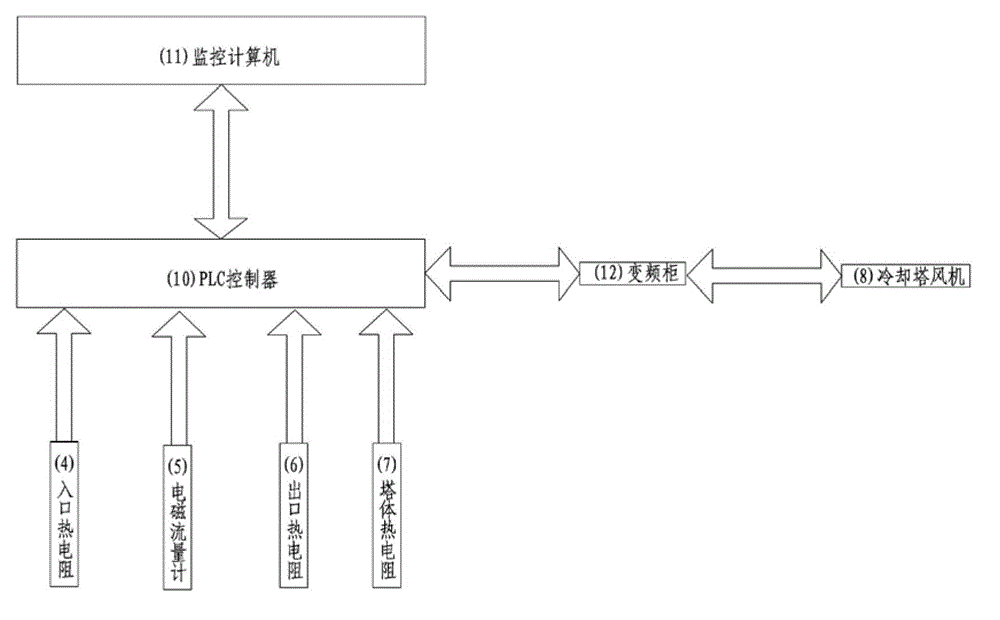

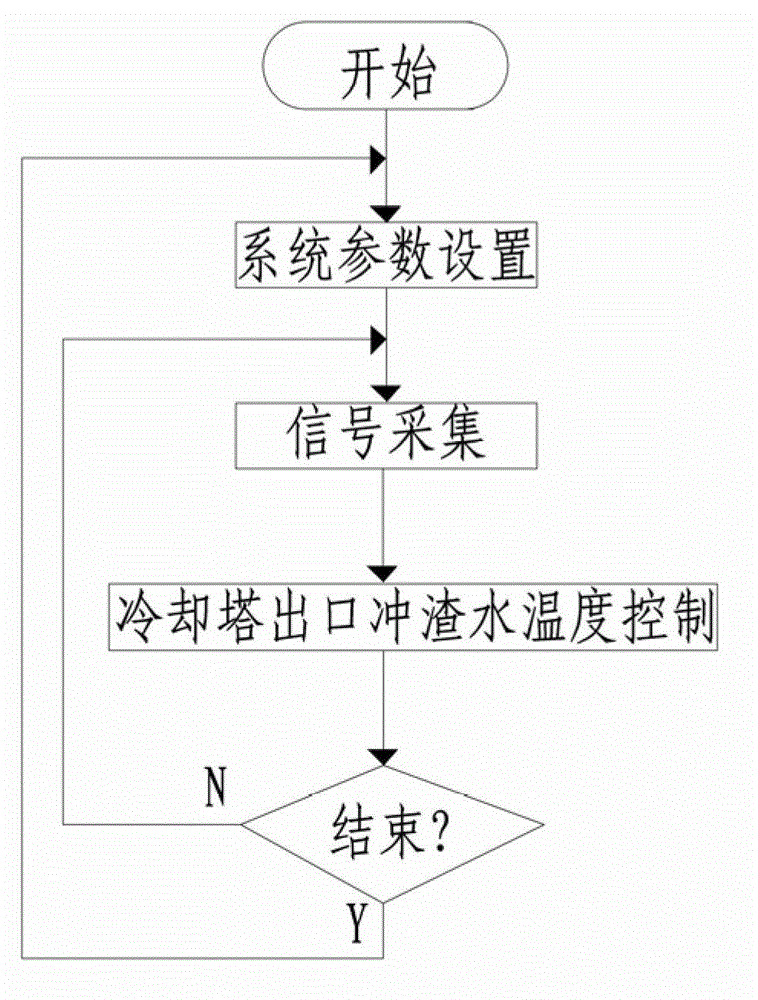

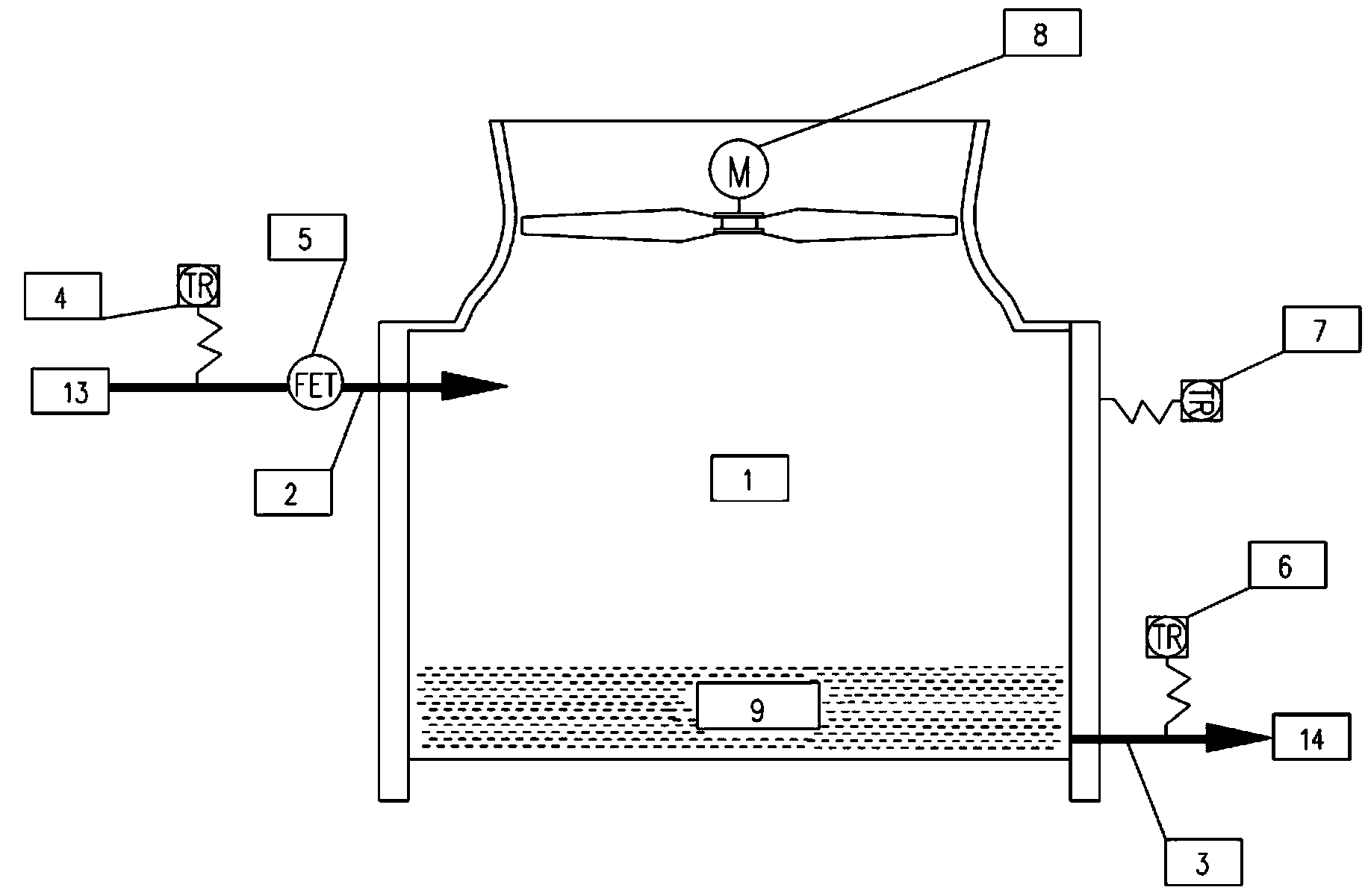

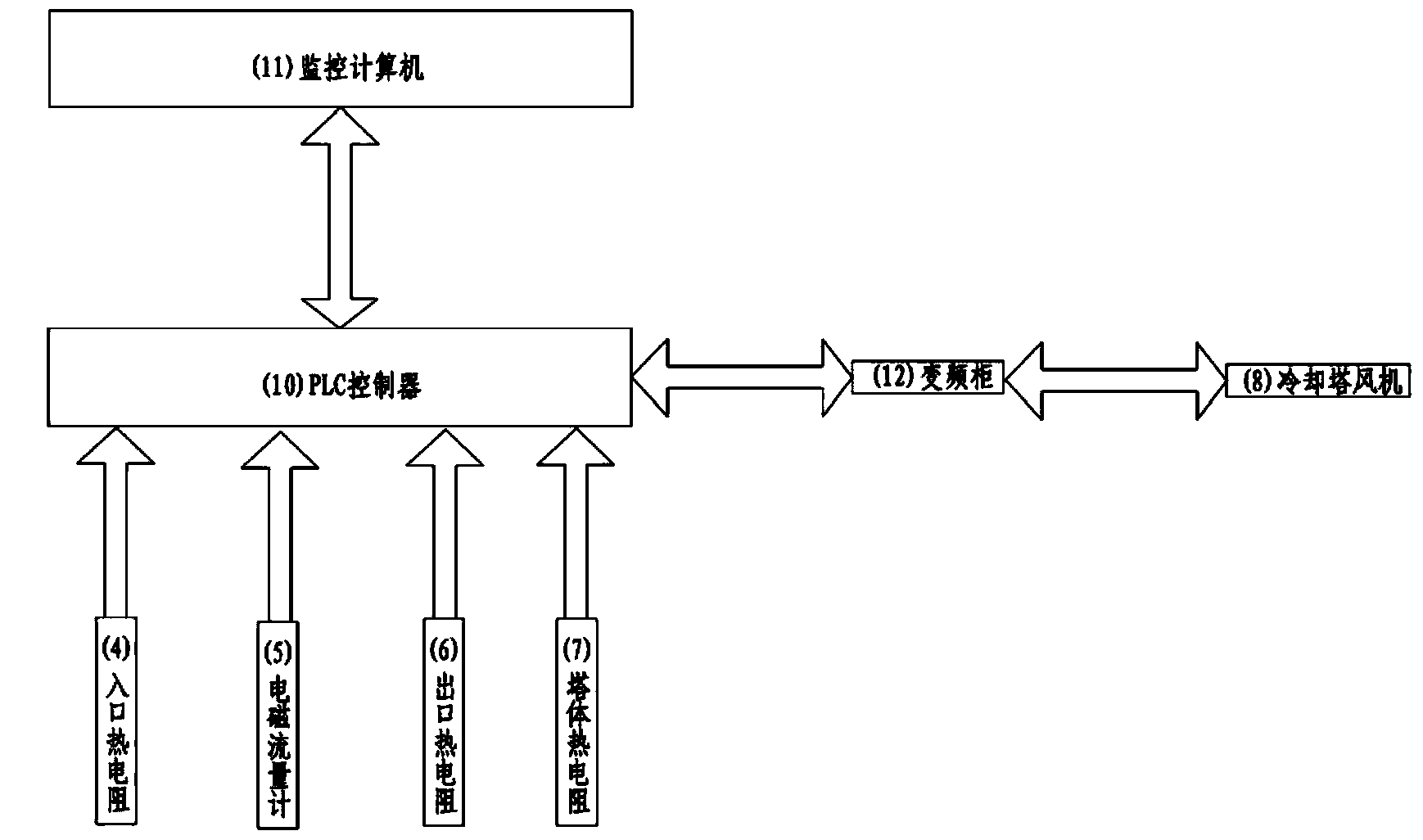

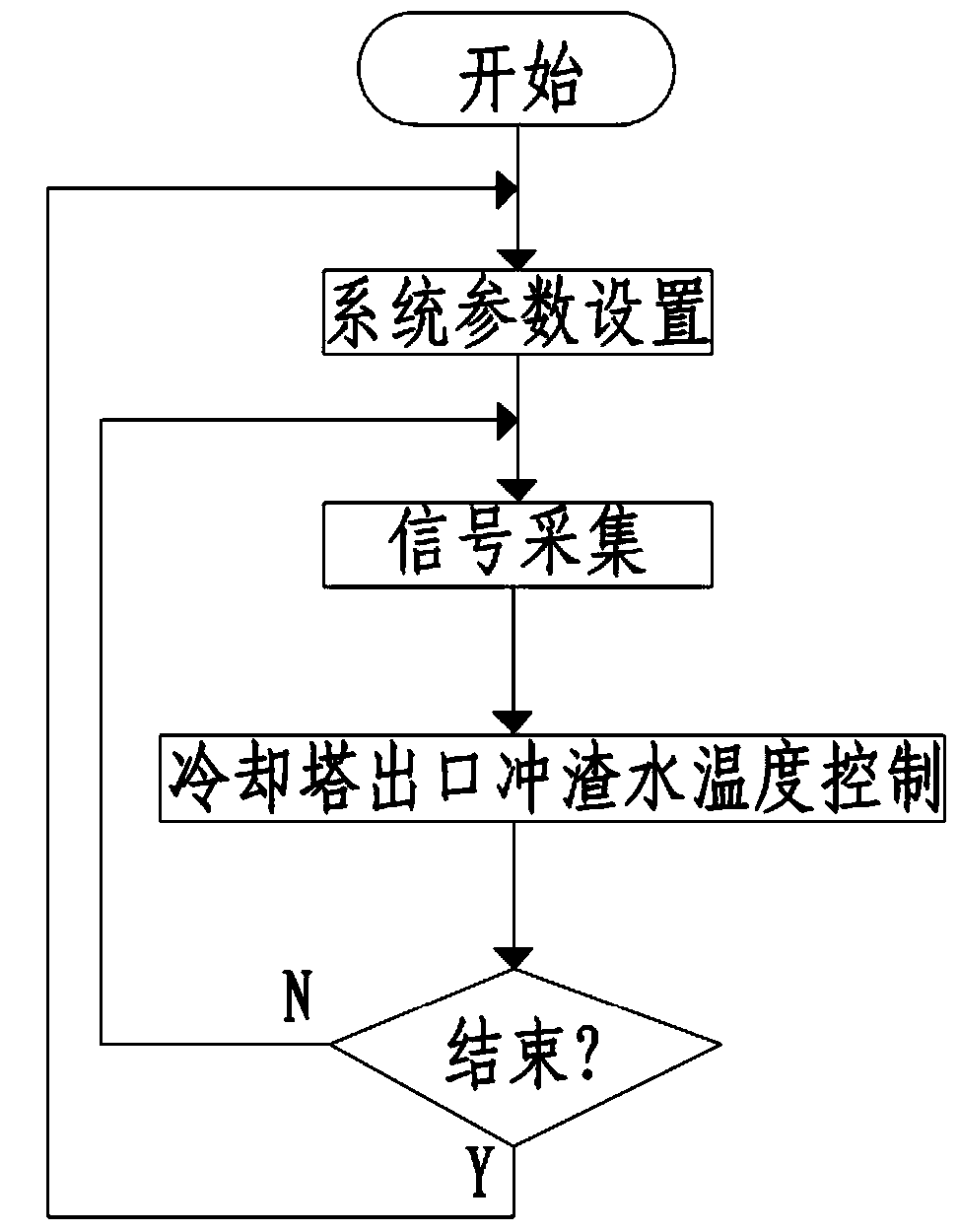

Temperature control method of cinder-flushing water of cooling tower outlet of blast furnace slag processing system

InactiveCN103063080AReduce manual adjustmentsReduce work intensityHeat exchange apparatusTemperature controlCooling tower

The invention provides a temperature control method of cinder-flushing water of a cooling tower outlet of a blast furnace slag processing system. The temperature control method of the cinder-flushing water of the cooling tower outlet of the blast furnace slag processing system comprises step (1) setting a system parameter of a temperature of the cinder-flushing water; step (2) performing real-time collection on all signal parameters of a cooling tower of a blast furnace; step (3) controlling the temperature of the cinder-flushing water of the cooling tower outlet by adjusting rotation speed of a cooling tower fan according to setup of the system parameter and all obtained signal parameters from real-time signal collection; step (4) changing an operation state of the cooling tower fan into a stop state and step (5) returning back to step (1) and performing control on the temperature of the cinder-flushing water of next production cycle. The temperature control method of the cinder-flushing water of the cooling tower outlet of the blast furnace slag processing system has the advantages of being capable of controlling the temperature of the cinder-flushing water of the cooling tower outlet accurately, rapidly and automatically, improving the precision, rapidity and automation-level of the control and creating conditions for the stability and high-yield of the blast furnace.

Owner:WISDRI ENG & RES INC LTD

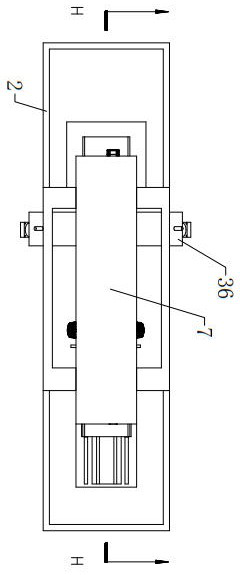

Self-adjusting display

ActiveCN111006103AAchieve angle adjustmentAchieve fixationStands/trestlesIdentification meansComputer hardwareDisplay device

Owner:ONYX INT

Audio device and method for automatically adjusting volume thereof

ActiveUS9990171B2Increase volumeLower the volumeTelevision system detailsSignal processingAuto regulationComputer science

Owner:BOE TECH GRP CO LTD +1

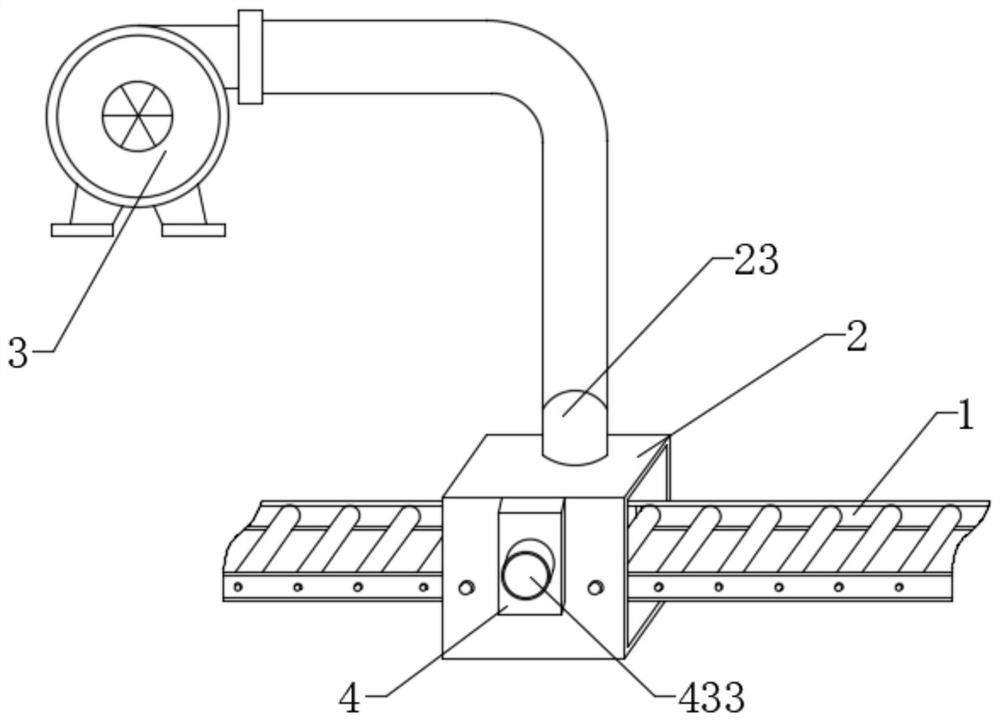

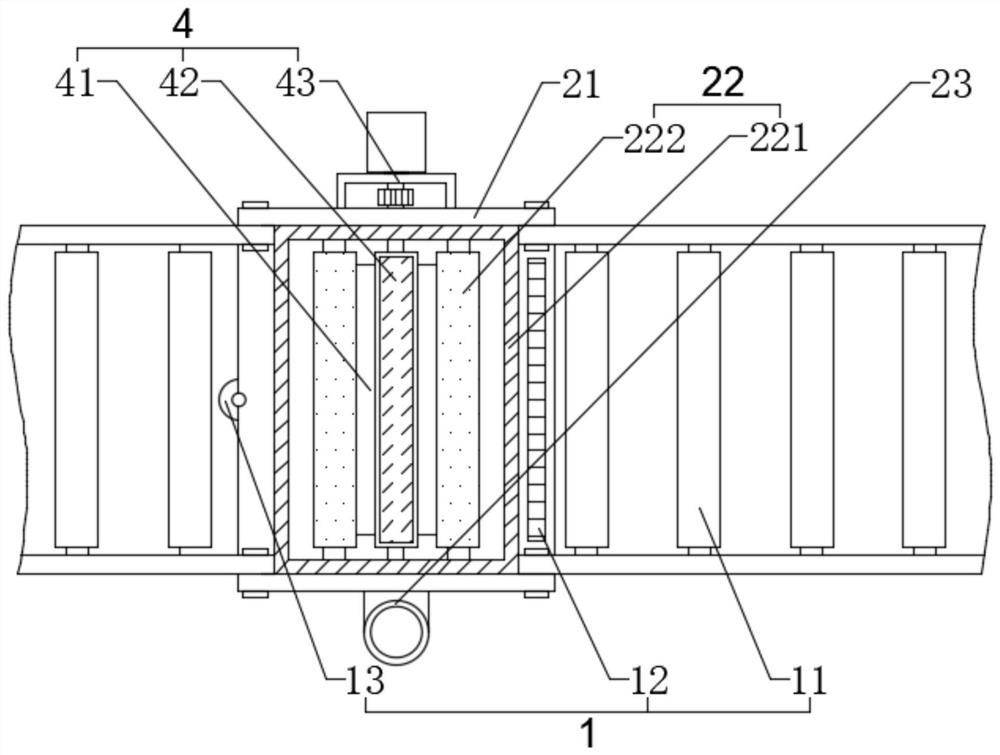

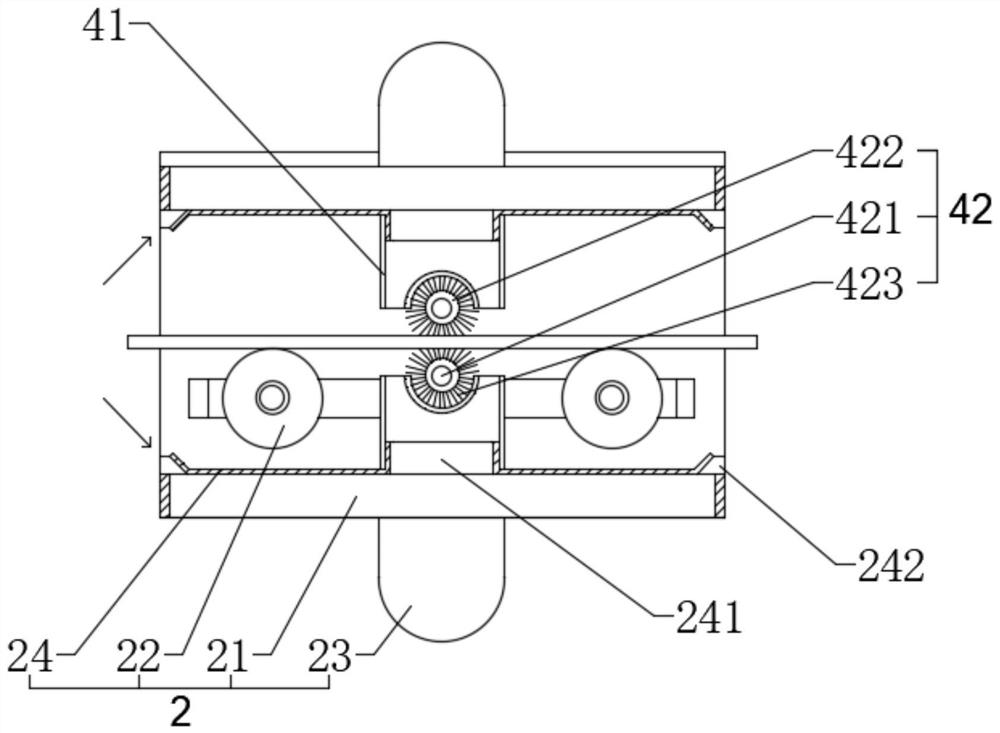

Finish machining system and control system for gypsum base material

ActiveCN113083755ATransport maximizationMaximize processing efficiencyDirt cleaningCleaning using toolsMining engineeringControl system

The invention discloses a finish machining system and a control system for a gypsum base material. The finish machining system comprises a limiting roller way mechanism, a dual dust collection mechanism, a dust collection fan and a base plate dust removal mechanism, wherein the dual dust collection mechanism is matched with the dust collection fan through an internal structure to form a middle large-area suction area; opposite-angle air curtains used for sucking flying dust are formed at the two ends of the dual dust collection mechanism, and the dual dust collection mechanism is matched with the base plate dust removal mechanism to conduct powerful dust removal on the upper surface and the lower surface of a base plate and suck the base plate in real time; and the control system comprises a control module and a substrate detection device arranged on the rear half section of the conveying roller way, as well as a lifting blocking device and a proximity switch sensor which are arranged on the front half section of the conveying roller way; the base plate dust collecting system is arranged between a feeding mechanism and a film covering mechanism to collect dust of a base plate conveyed to a film covering system; and the base plate dust removal mechanism is arranged in the dust collection system and can be matched with the dual dust collection mechanism to form powerful dust collection combining adsorption and sweeping.

Owner:CHINA NAT BUILDING MATERIALS TECHCAL INNOVATION & RES INST LIMITED

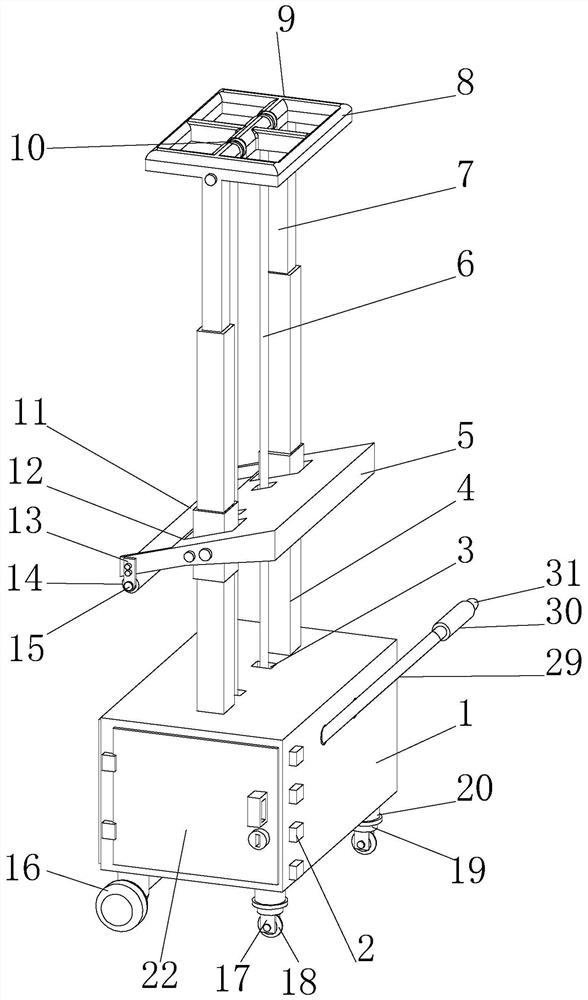

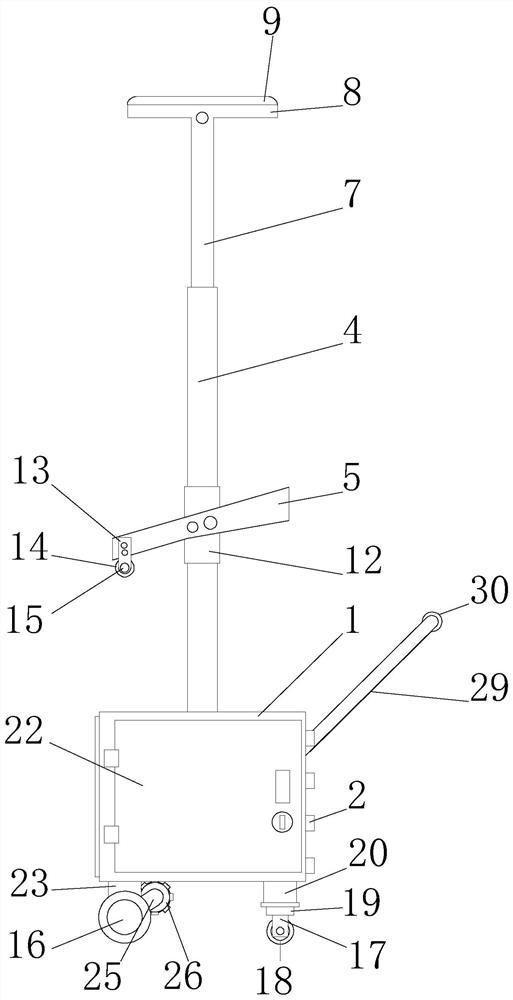

Automatic indoor intelligent plastering machine capable of plastering uniformly and flatly

InactiveCN112324102APrevent conditions that affect the quality of workIncrease frictionBuilding constructionsSteering wheelStructural engineering

The invention discloses an automatic indoor intelligent plastering machine capable of plastering uniformly and flatly. The plastering machine comprises an equipment box; two telescopic outer rods arefixedly mounted at the top of the equipment box; sliding blocks are connected to the outer sides of the two telescopic outer rods in a sleeving mode; operation plastering plates are hinged to two sides of each sliding block in a threaded mode; telescopic inner rods are fixedly mounted in the two telescopic outer rods; a top plate is fixedly mounted at the tops of the telescopic inner rods; and twosteering wheel supporting columns are fixedly mounted on one side of the bottom of the equipment box. A handle is manually pushed to move a box body, acting force acts on a steering shaft column to drive a steering wheel shaft column plate so as to control a steering wheel to rotate, steering is achieved, the box body is moved to a designated place, the telescopic inner rods fixedly installed inthe telescopic outer rods stretch to the top of a building, the top plate is jacked to the top of the building and is fixed, the inclination angles of the operation plastering plates are adjusted through threaded hinge at the joint of the operation plastering plates and the sliding blocks, and therefore plastering operation is achieved.

Owner:王立孟

Fan impeller rotation type double-station eight-axis linkage robot welding apparatus and method

PendingCN109366025AQuality improvementReduce in quantityWelding/cutting auxillary devicesAuxillary welding devicesWeld seamImpeller

The invention discloses a fan impeller rotation type double-station eight-axis linkage robot welding apparatus and method. For a workpiece which is provided with a circular seam or space welding seamsin other structural forms, a linkage positioner cooperates with a welding robot for linkage so that welding can be conducted more accurately and conveniently. A rotation mechanism of the fan impellerrotation type double-station eight-axis linkage robot welding apparatus can simultaneously drive two turnover mechanisms to rotate around the center of a rotation plate; each turnover mechanism drives the corresponding rotation mechanism to turn over; each rotation mechanism drives a welding platform to rotate; a fan impeller fixture is fixed to each welding platform; and a PLC controller controls rotary mechanisms, the turnover mechanisms, the rotation mechanisms and a six-axis joint type welding robot, two axes of the turnover mechanisms and two axes of the rotation mechanisms as well as the six-axis joint type welding robot form eight-axis linkage, accordingly, fillet welding in the flat position or flat position welding is achieved, and continuous welding of the narrow complex space trajectory is ensured. According to the fan impeller rotation type double-station eight-axis linkage robot welding apparatus and method, manual welding seam position adjusting is omitted, the welding quality is improved, and the welding efficiency is improved through the double-station design.

Owner:浙江理工大学上虞工业技术研究院有限公司 +1

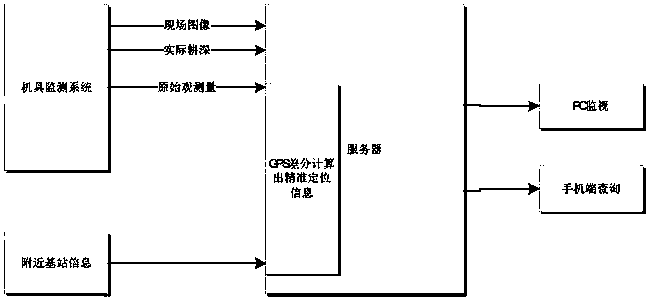

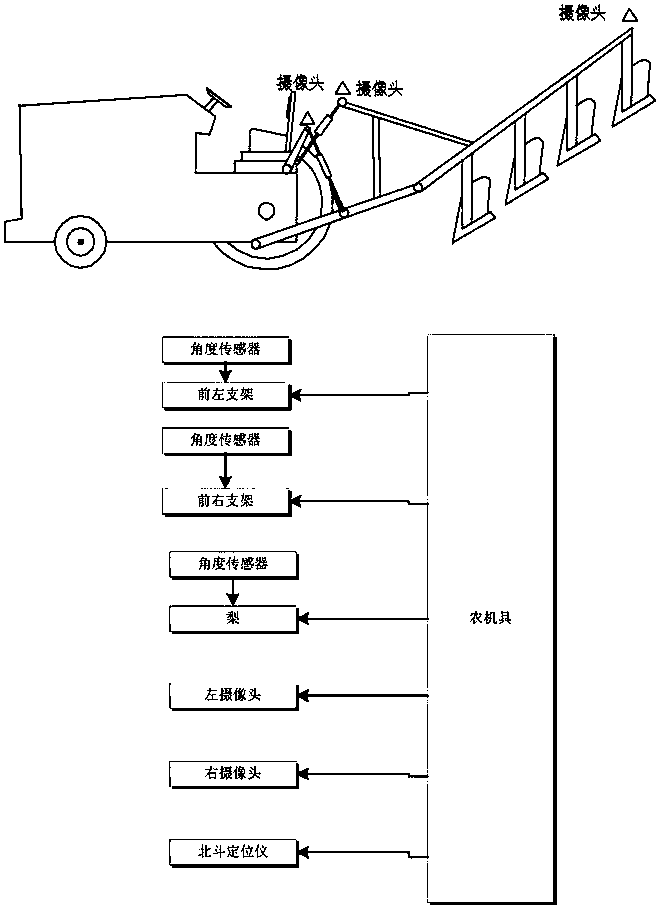

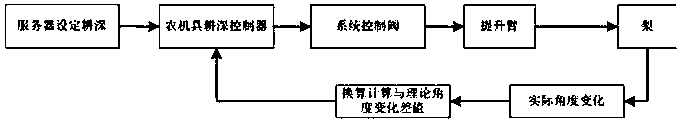

Automatic control system and method based on Beidou positioning and ploughing depth measurement

InactiveCN110275550AEasy to adjustReduce manual adjustmentsControl using feedbackPosition/course control in two dimensionsAutomatic controlAutomated control system

An automatic control system based on Beidou positioning and ploughing depth measurement data is composed of a machine detection system, a nearby base station, a cloud server, a PC monitoring terminal and a mobile phone client. The machine detection system obtains Beidou original observation amount by using a Beidou positioner. An angle sensor obtains an angle change of a machine sensing part and calculates actual ploughing depth of a plough. A shooting camera captures an on-site image and transmits the image to the cloud server through a communication module. Meanwhile, the cloud server obtains information of the nearby base station and calculates precise positioning information by a decoding algorithm. The cloud server transmits the image information captured by the camera to the PC monitoring terminal in real time and transmits a final calculation result to the mobile phone client. The automatic control system and method based on the Beidou positioning and the ploughing depth measurement effectively reduce manpower action and improve the automation and standardization of agricultural machinery operation.

Owner:SENSOR ELECTRONICS CO LTD

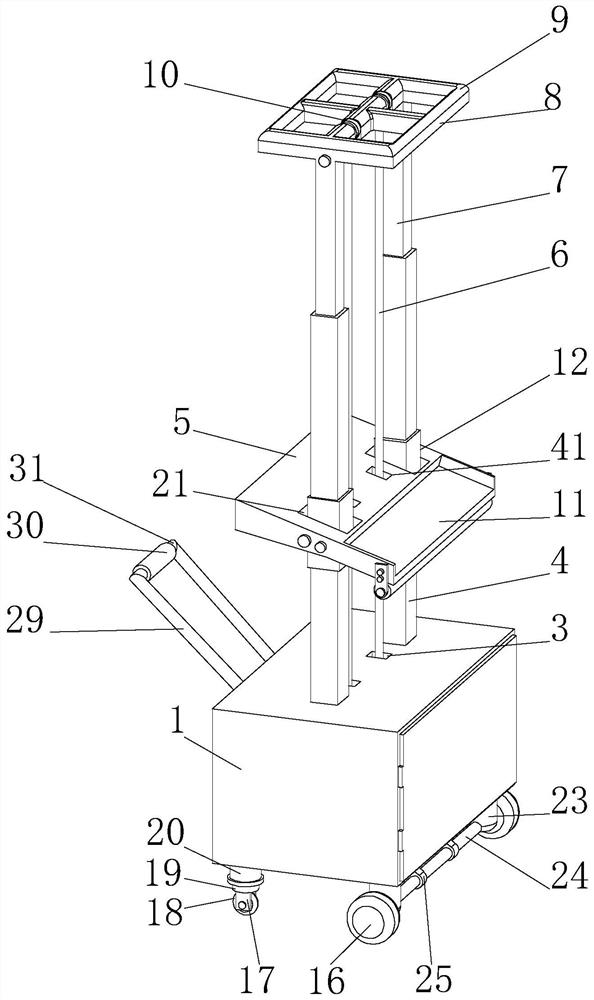

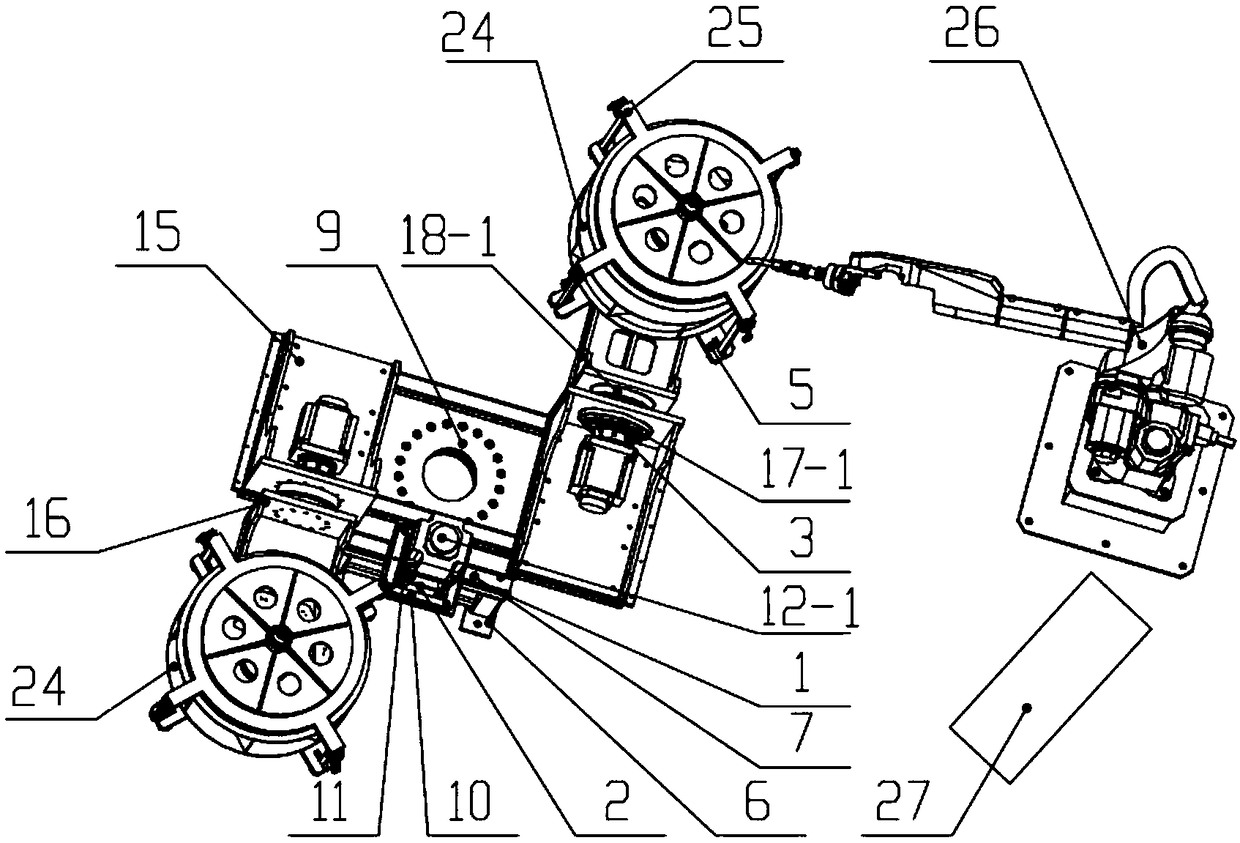

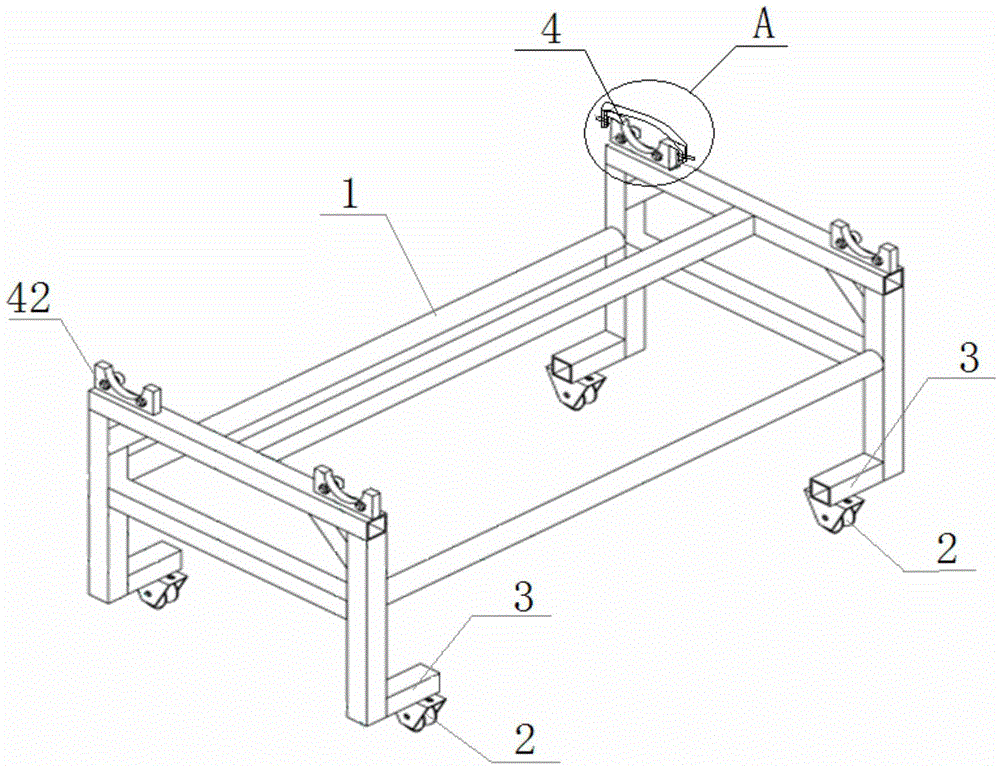

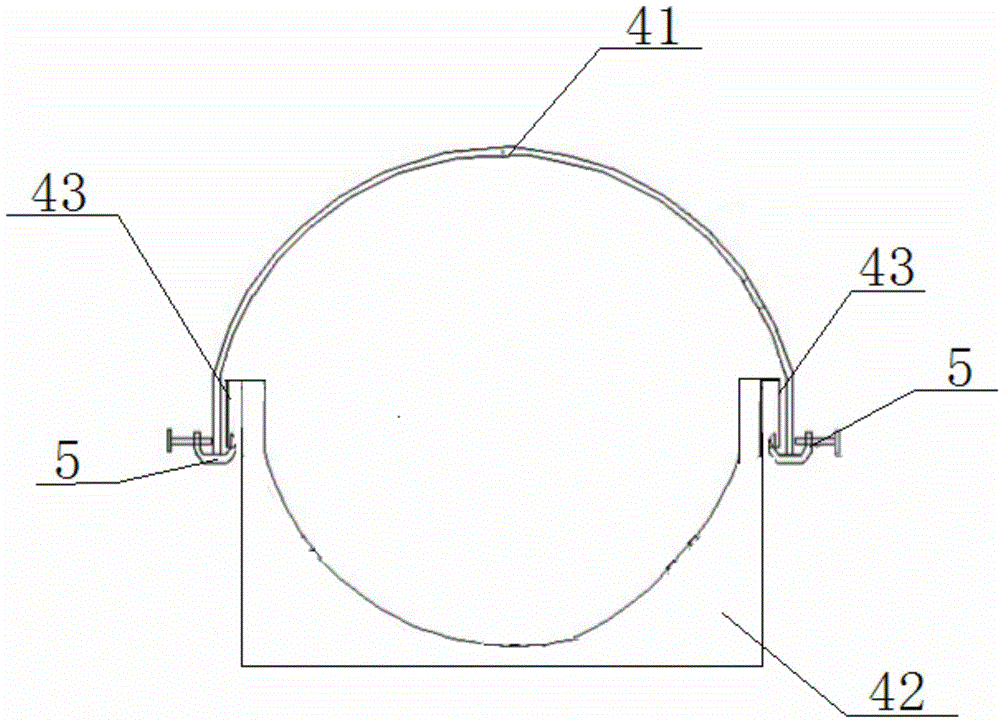

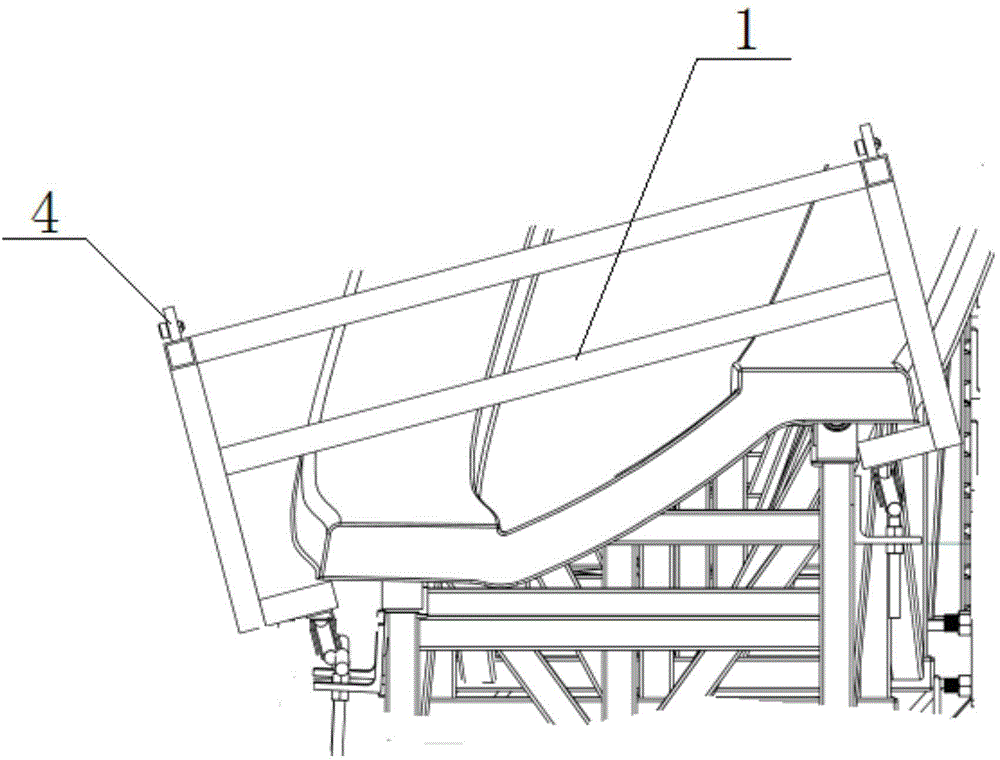

Layer paving device and layer paving method for main girder glass fiber cloth used for wind power blade production

The invention discloses a layer paving device for main girder glass fiber cloth used for wind power blade production. The layer paving device comprises a frame body and a supporting structure, wherein wheels are arranged at the bottom of the frame body, the supporting structure consists of four sets of fixing frames, each set of fixing frame comprises an upper fixing frame and a lower fixing frame, two sides of the lower fixing frame extend outwards to form right-angled folding ears, G-shaped clamping devices are arranged at parts corresponding to the right-angled folding ears on two sides of the upper fixing frame; the invention also discloses a layer paving method of the layer paving device for main girder glass fiber cloth used for wind power blade production, by placing the layer paving device on a guide rail and moving the layer paving device to one end of a mould, a glass fiber cloth roll is placed, and then glass fiber cloth is pulled out and fixed at one end of the mould, the layer paving device for main girder glass fiber cloth is pushed to the other end of the mould, and the operation is repeated until all layer paving is completed; and the layer paving device and the layer paving method which are disclosed by the invention can pave glass fiber cloth into the mould rapidly, accurately and smoothly, so that the subsequent manual adjustment is reduced, the time and manpower for adjustment of glass fiber cloth after laying are saved, and the laying efficiency is improved while guaranteeing the laying quality.

Owner:迪皮埃风电叶片大丰有限公司

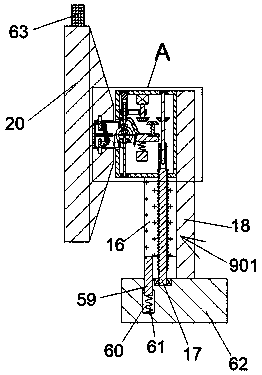

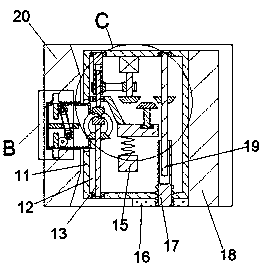

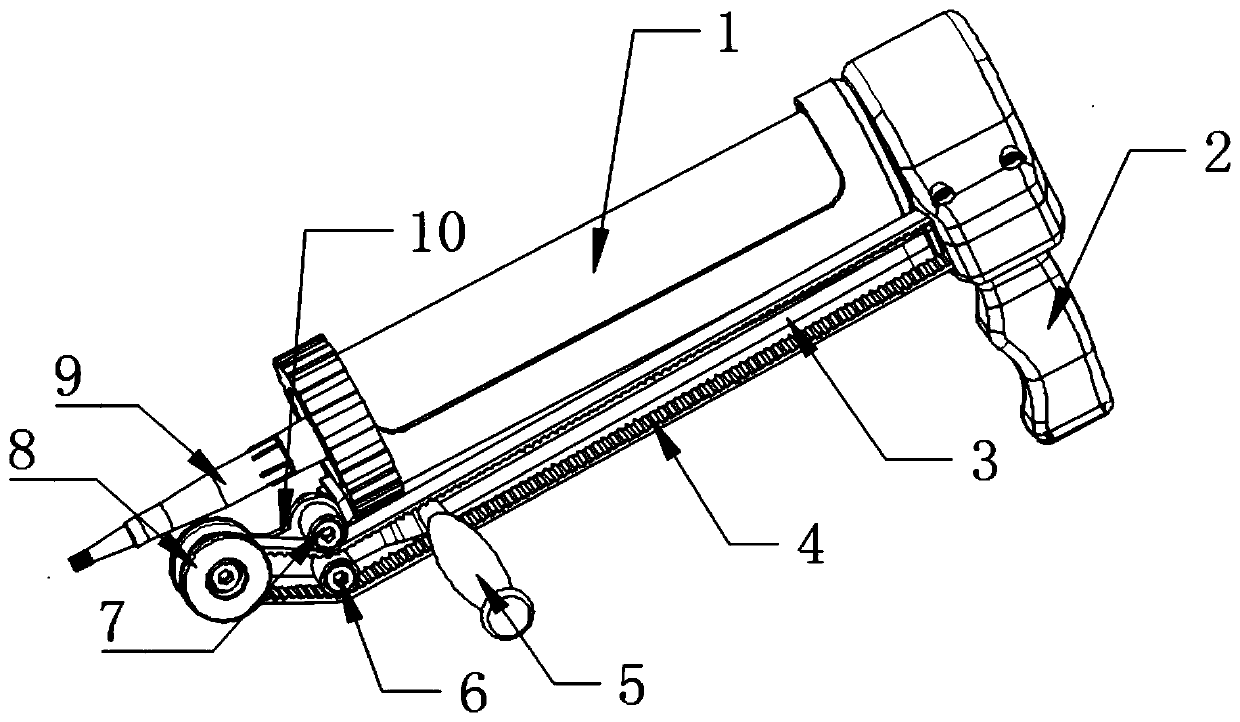

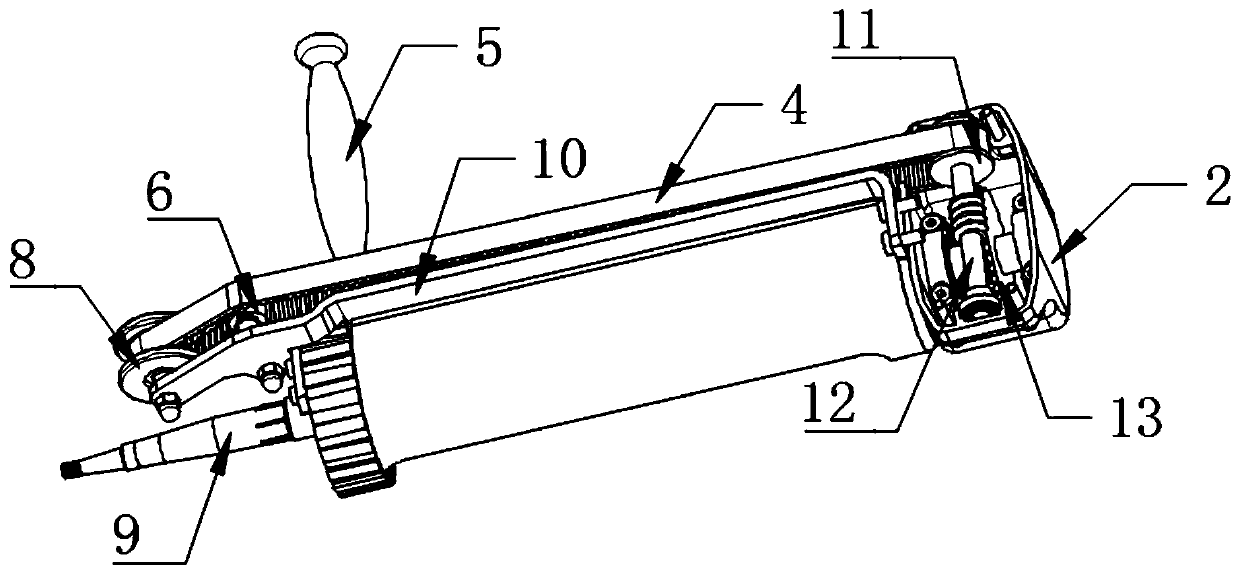

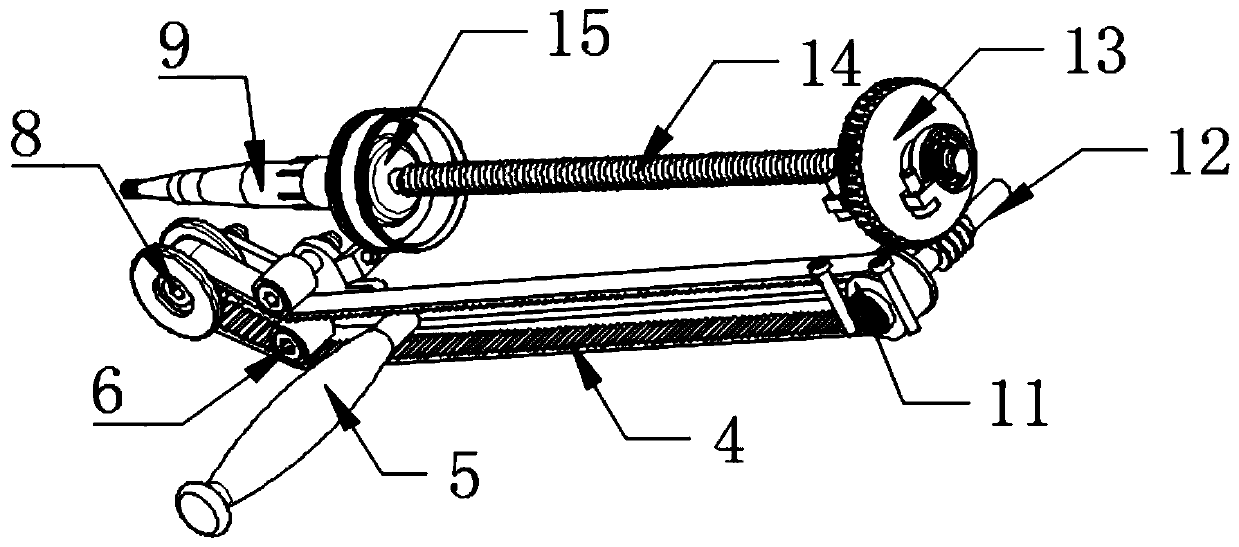

Pneumatic glue gun with quantitative glue discharging function for packaging rubber pipe and using method

PendingCN110787969ARealize quantitative glue outSimple structureLiquid surface applicatorsCoatingsThreaded rodElectrical and Electronics engineering

The invention discloses a pneumatic glue gun with a quantitative glue discharging function for a packaging rubber pipe. The pneumatic glue gun comprises a glue gun barrel, a glue gun handle, a limiting rod, a driving belt wheel, a fixing plate, a driven belt wheel, a pushing block, a limiting plate, an adjusting block, a fixing column, a winding drum, a limiting column, a limiting block, a baffle,a connecting rod and a supporting rod, wherein a glue gun head is mounted at one end of the glue gun barrel, and the glue gun handle is fixed to the other end of the glue gun barrel; a storing grooveis formed in the side, close to the glue gun barrel, of the glue gun handle; and the fixing plate is fixed to one side of the glue gun barrel. According to the pneumatic glue gun, the limiting rod drives the adjusting block and the limiting block to be matched with each other, thus the moving position of the limiting rod is fixed, a belt drives a worm gear and a worm to be matched with each other, a threaded rod drives the pushing block to extrude liquid glue to move, and thus quantitative glue discharging of the liquid glue is achieved; and the structure is simple, operation is convenient and fast, the glue discharging amount is fixed, and the working efficiency is improved.

Owner:上海欧堪电子科技有限公司

Method for controlling temperature of slag flushing water at cooling tower outlet in blast furnace slag treating system

The invention provides a method for controlling temperature of slag flushing water at a cooling tower outlet in a blast furnace slag treating system, comprising: (S1) setting system parameters of the slag flushing water temperature; (S2) real-time acquiring each signal parameter of a blast furnace cooling tower; (S3) based on each parameter obtained by system parameter arrangement and signal real time acquisition, by regulating a rotation speed of a cooling tower blower fan, controlling the temperature of the slag flushing water at the cooling tower outlet; (S4) changing the cooling tower blower fan from an operation state to a stop state; and (S5) returning to the step S1, and carrying out temperature control of the slag flushing water in a next production period. The method can accurately, rapidly and automatically control the temperature of the slag flushing water at the cooling tower outlet, raises control precision, rapidity and automation level, and creates conditions for stable high yield of the blast furnace.

Owner:WISDRI ENG & RES INC LTD

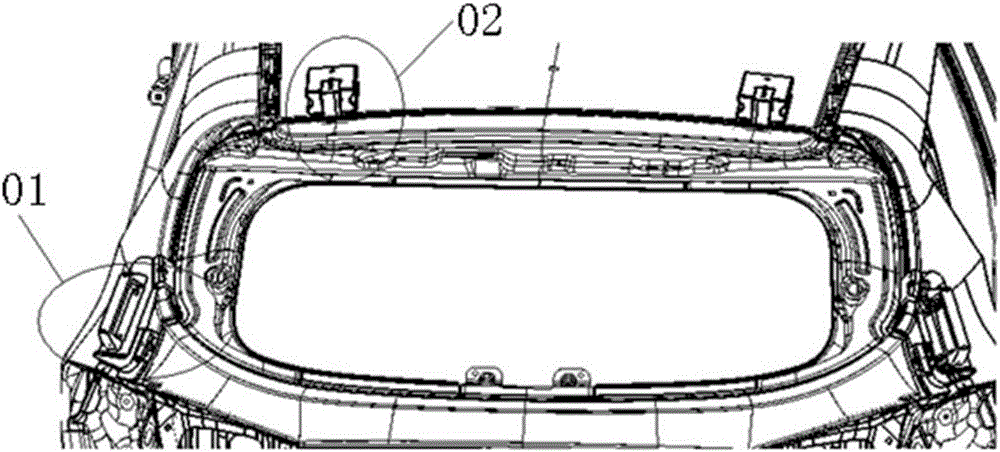

Automobile back door built-in tooling structure

PendingCN109940357AGuaranteed to be assembled in place at one timeImprove stabilityMetal working apparatusBack doorReference surface

The invention discloses an automobile back door built-in tooling structure. The tooling structure comprises a tooling framework. The tooling framework is provided with a first positioning assembly matched with an automobile body for positioning and a second positioning assembly matched with a back door for positioning. The second positioning assembly comprises a back door Y-direction positioning pin fixed to the width direction of the tooling framework and back door Z-direction positioning blocks fixed to the length direction of the tooling framework. The back door Y-direction positioning pinis connected with a corresponding Y-direction positioning hole corresponding in the back door. Each back door Z-direction positioning block comprises a back door Z-direction positioning surface attached to a corresponding reference surface of the back door, wherein the Y-direction is perpendicular to the Z-direction. Through the automobile back door built-in tooling structure, the back door and the automobile door are assembled. The automobile back door built-in tooling structure ensures that the gap surface differences between the back door and a sidewall and between a tail lamp and the sideface are good. Meanwhile, the part accuracy of a back door assembly can be reduced, the part machining cost can be reduced, and the online manual assembly and adjustment time is shortened.

Owner:DFSK MOTOR LTD CHONGQING BRANCH CO

Floor type clothes hanger

ActiveCN105662085AImprove the efficiency of finishing clothesReduce manual adjustmentsApparel holdersClothes hangerIndustrial engineering

The invention relates to the field of living supplies, in particular to a floor type clothes hanger. The floor type clothe hanger comprises a base, a support, a regulating part and clothes hanging parts; the base is provided with a motor and a first installation position and a second installation position which are rotatably connected with the motor; the support is arranged at the first installation position and provided with a plurality of clothes hanging positions; the regulating part is arranged at the second installation position and used for being driven by the regulating part to rotate when the motor works; the clothes hanging parts are hung at the clothes hanging positions; the regulating part is provided with a mechanical arm, the clothes hanging parts are provided with regulating positions, the clothes hanging parts are transferred to the non-occupied clothes hanging positions through the mechanical arm when the regulating part works. According to the floor type clothes hanger, the base and the support are connected, the regulating part regulates the clothes hanging parts arranged on the support, therefore, the phenomenon that clothes arranged on the clothes hanging parts in a sleeving mode are distributed on the support too densely is avoided, manual regulating is reduced, and the clothes sorting efficiency is improved.

Owner:希格玛智家(重庆)科技有限公司

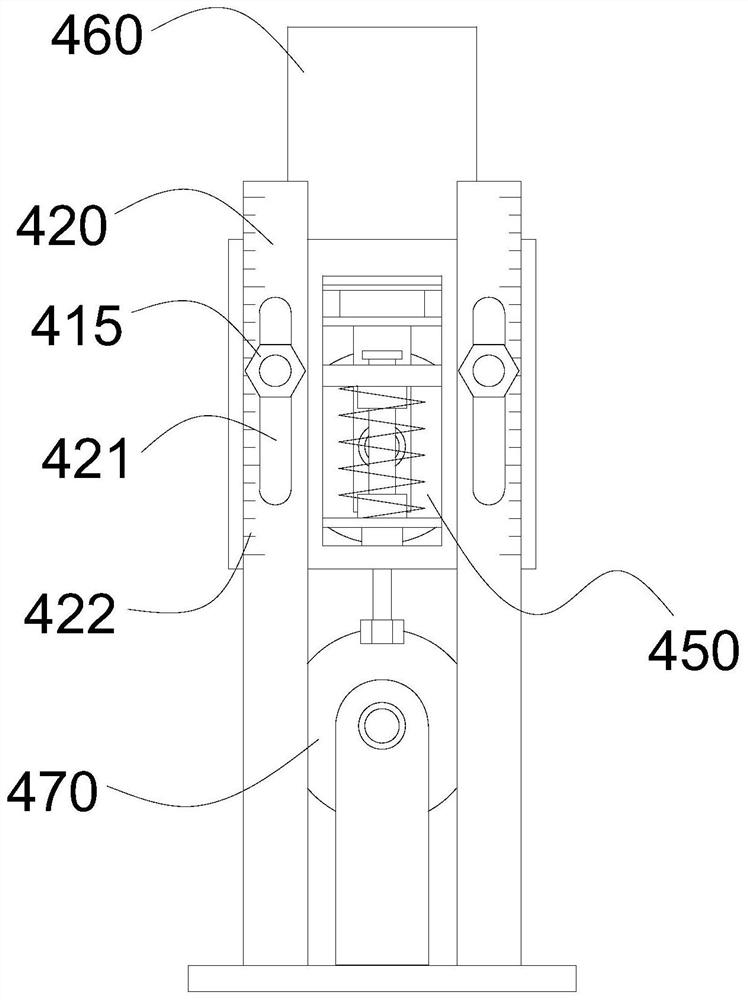

Rapid straightening cutting equipment

The invention discloses rapid straightening cutting equipment. The equipment comprises a straightening part and a cutting part, wherein the straightening part comprises a plurality of guide compression roller structures arranged in sequence, a first roller body and a hydraulic cylinder for driving the first roller body to move are arranged on each guide compression roller structure, and the firstroller bodies are secondarily supported through a pressure regulating structure; the cutting part comprises a bearing groove, a cutting machine is arranged at the end, close to the straightening part,of the bearing groove, a pushing structure is arranged on the side, away from the straightening part, of the cutting machine, and the pushing structure is used for pushing cut steel bars away from the bearing groove; a double-roller pressing and conveying mechanism is arranged on one side, close to the straightening part, of the cutting machine; according to the equipment, the steel bars can be rapidly pressed, straightened and cut, the straightening distance of a pressed and straightened portion can be driven and adjusted by a driving piece, manual operation is reduced, and the adjusting efficiency is improved; and the pressing and straightening portion has a certain buffering effect, so that the bent steel bar can be prevented from being in hard fit with a pressing piece, the pressing piece is prevented from being damaged, and the service life of the equipment is prolonged.

Owner:QINGYUAN DINGXINGTAI MASCH EQUIP CO LTD

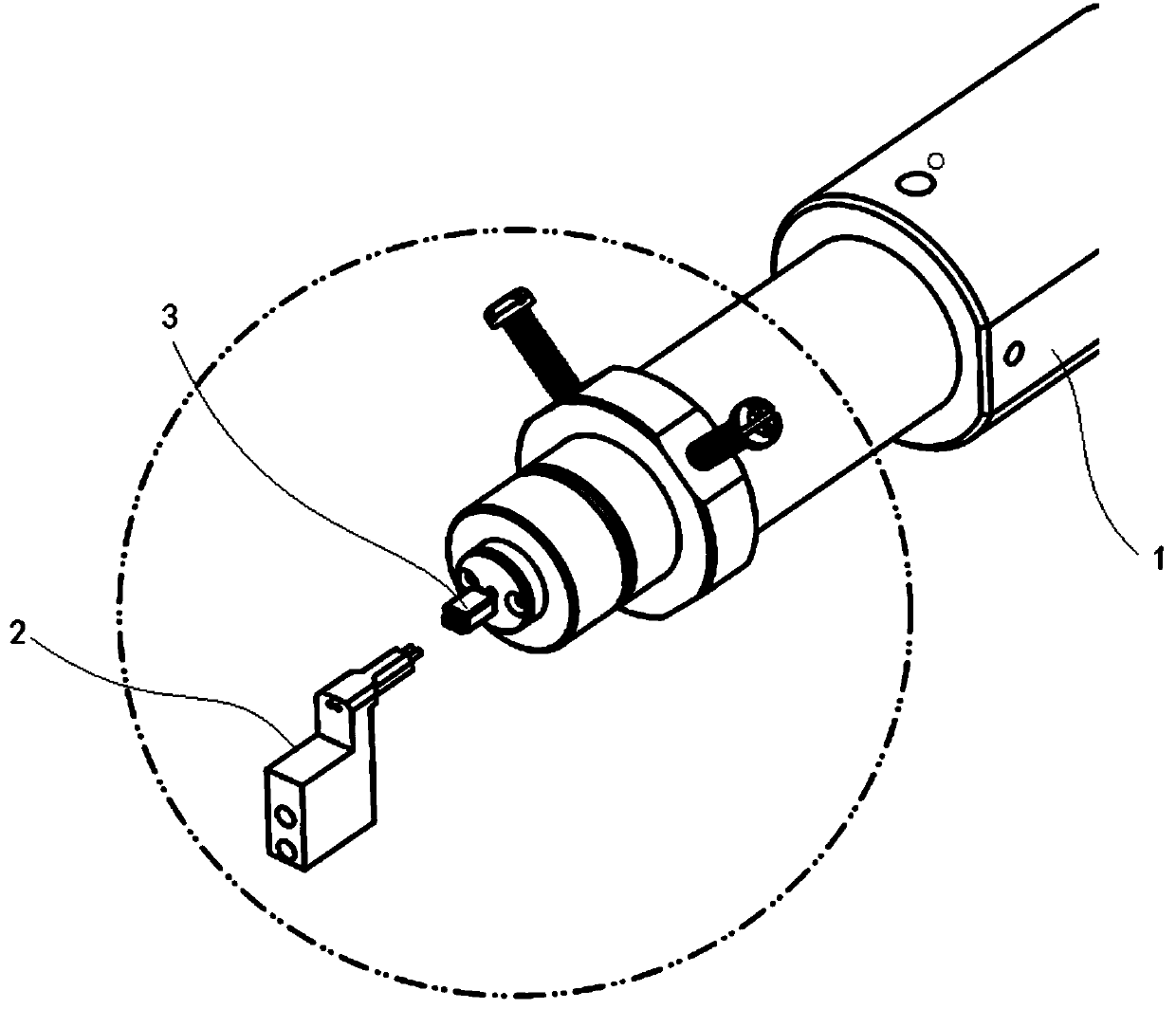

Telephone receiver acoustic testing device and telephone receiver acoustic testing system

ActiveCN107659884AAccurate and efficient dockingAvoid scratching hidden quality risksElectrical apparatusTest efficiencyCoupling

The invention discloses a telephone receiver acoustic testing device and a telephone receiver acoustic testing system. The device comprises a driving device and an output device, the driving device comprises a bracket, a guide rail, a pressing component and a testing adjustment device, the guide rail is installed on the bracket, the pressing component used for inputting testing signals is fixed tothe guide rail, and the pressing component adjusts the abut joint position with a tested telephone receiver via the testing adjustment device; the output device comprises a testing seat, a locating cavity and a coupling cavity are formed in the testing seat, and a sealing ring is arranged between the locating cavity and the coupling cavity of the tested telephone receiver. The telephone receiveracoustic testing device and system can achieve automatic acoustic testing, the testing efficiency is higher, the test result is more accurate, and the product yield is improved.

Owner:SHENZHEN EVERWIN PRECISION TECH

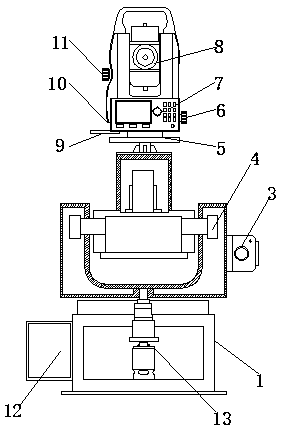

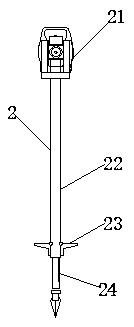

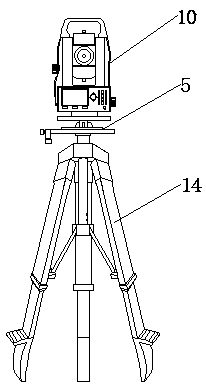

Building displacement monitoring device

InactiveCN111307127AEasy to monitorGood monitoring resultsSurveying instrumentsHeight/levelling measurementElectric machineryStructural engineering

The invention discloses a building displacement monitoring device. The device comprises a real-time monitoring seat and a total station head, the outer wall of the bottom end of the total station headis connected with a detachable base through a thread, and fixing buckles are arranged at the four corners of the detachable base; and the real-time monitoring seat comprises a base, an adjusting baseand a height adjusting structure, a fine adjustment motor is fixed to the inner wall of the base through bolts, an output shaft of the fine adjustment motor is connected with a rotating shaft, and the outer wall of the bottom end of the adjusting base is connected to the outer wall of the top end of the rotating shaft in a clamped mode. The method is based on a total station, two forms of auxiliary operation of the total station are used, one form is that the total station is set at a fixed-point observation receiving marker post, real-time monitoring and image acquisition of a building are conducted, the other form is mobile operation, a receiving marker post needs to be observed manually at a fixed point, the building is intermittently monitored through different positions, two groups of data are summarized and supplemented, a specific staged database is formed, and the monitoring effect is better than that of a traditional monitoring result.

Owner:JINLING INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com