Numerical control plasma flame cutting machine

A flame cutting machine, plasma technology, applied in digital control, gas flame welding equipment, electrical program control, etc., can solve the problems of affecting accuracy, low adjustment accuracy, wasting steel plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

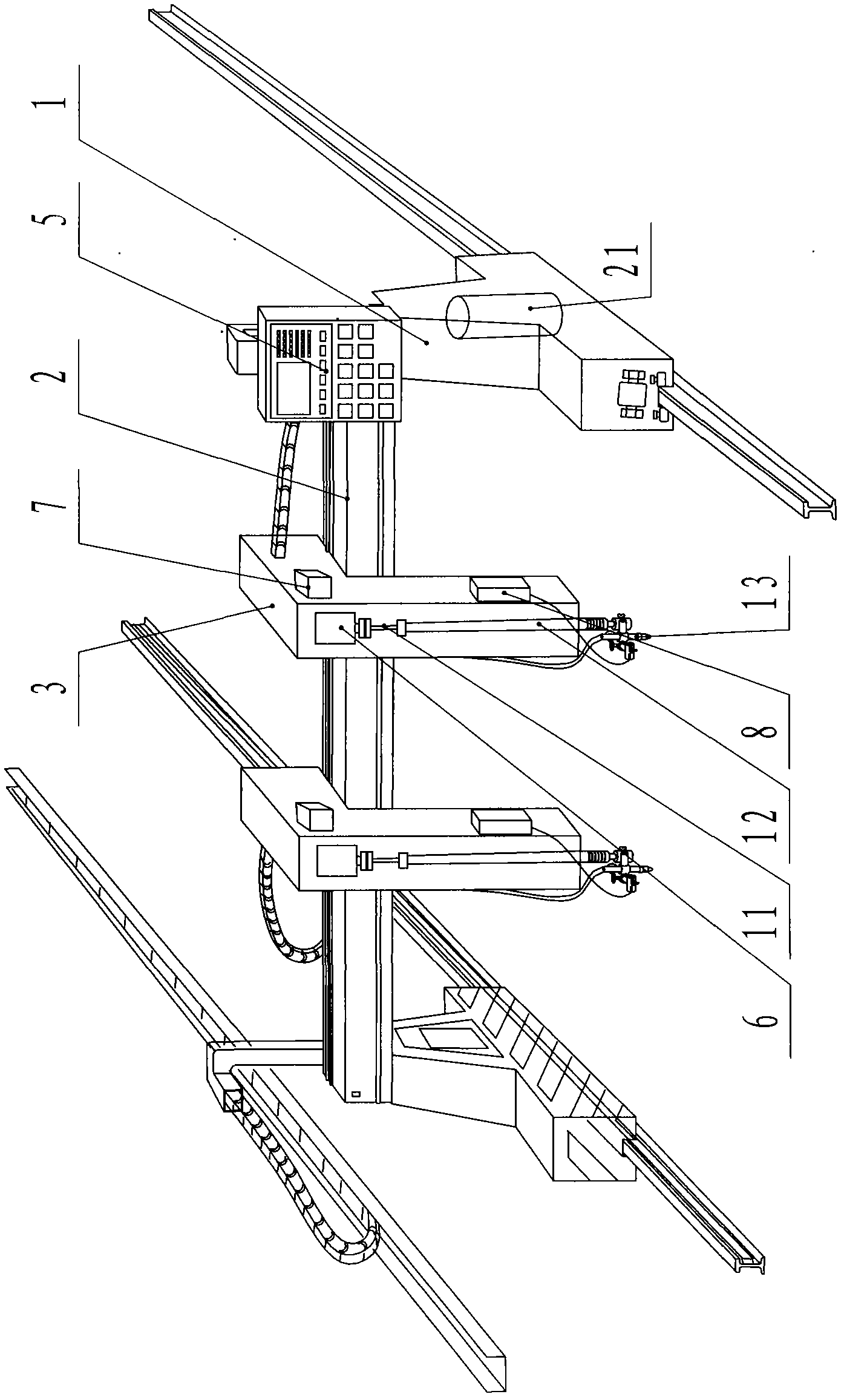

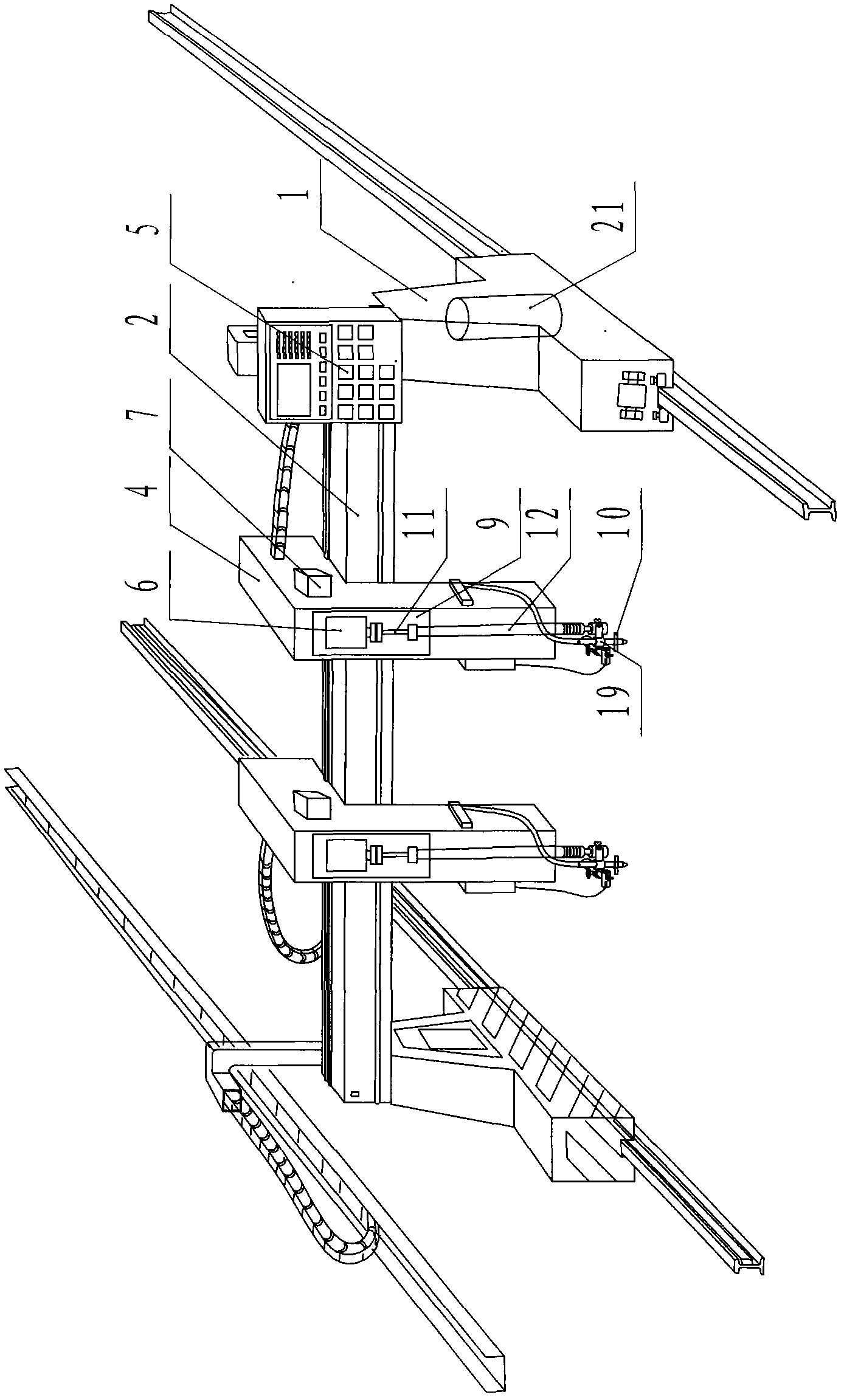

[0021] As shown in the figure, a numerically controlled plasma flame cutting machine includes a longitudinal support 1, a transverse support 2, a plasma follow-up mechanism 3 and a control system 5; the transverse support 2 is provided with two sets of plasma follow-up mechanisms 3, The plasma follow-up mechanism 3 is provided with a vertical stepping motor 6 and a horizontal stepping motor 7 that drive the vertical and lateral movement of the plasma torch 13. The vertical stepping motor 6 is connected with the screw mandrel 11, and the screw mandrel 11 is connected with the sliding rod 12. The gun 13 is arranged on the sliding rod 12 , and the plasma follower mechanism 3 is also provided with an arc voltage dividing module 8 .

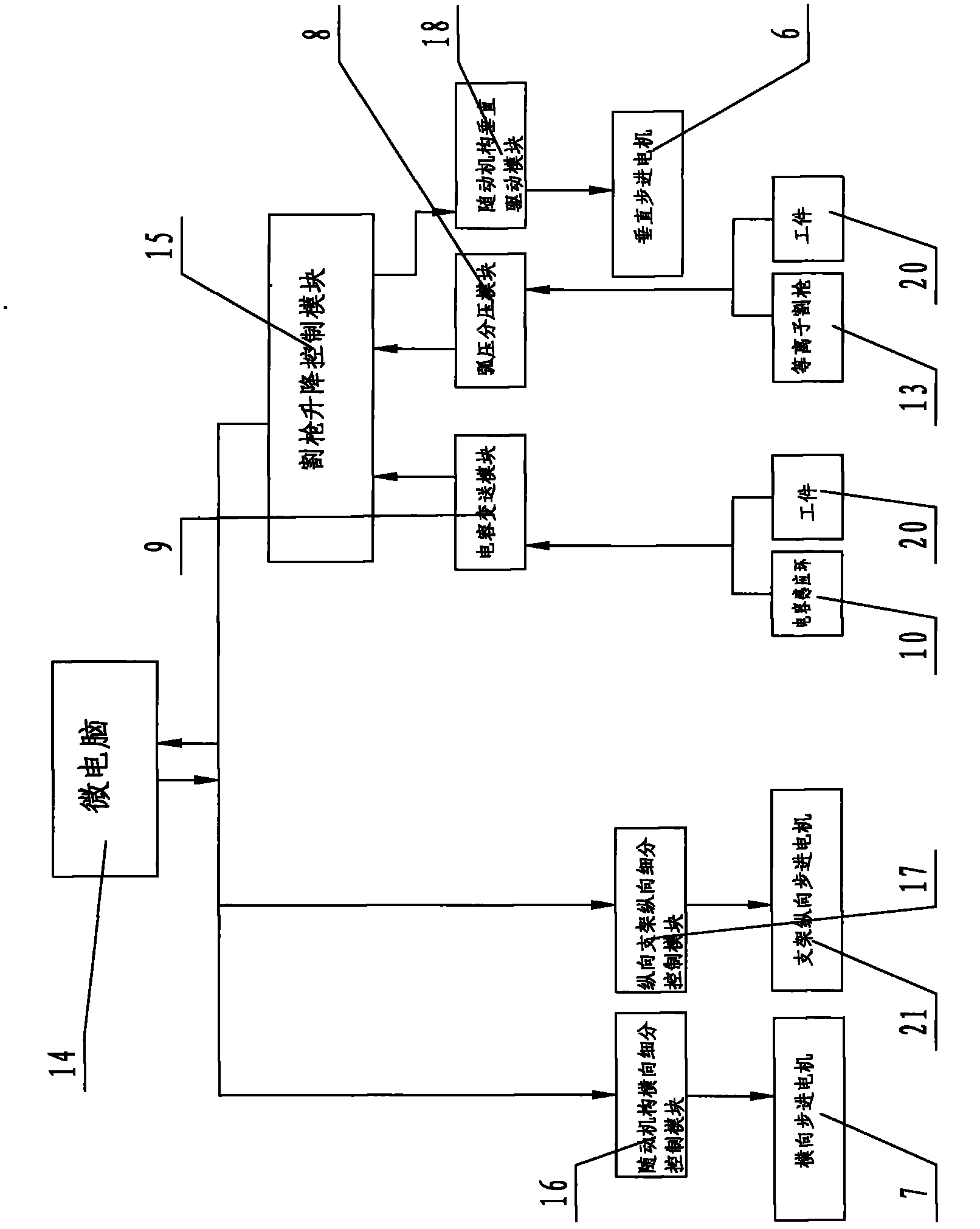

[0022] As shown in the figure, the control system 5 includes a microcomputer 14, a torch lifting control module 15, a follower mechanism horizontal subdivision control module 16, a longitudinal support vertical subdivision module 17, a capacitance tran...

Embodiment 2

[0027] As shown in the figure, a numerically controlled plasma flame cutting machine includes a longitudinal support 1, a transverse support 2, a flame follower mechanism 4 and a control system 5; the transverse support 2 is provided with two sets of flame follower mechanisms 4, Flame follow-up mechanism 4 is provided with vertical stepping motor 6 and horizontal stepping motor 7 that drive flame torch 19 vertical and lateral motions, and vertical stepping motor 6 is connected with screw mandrel 11, and screw mandrel 11 is connected with slide rod 12, and flame cutting The gun 19 is arranged on the sliding rod 12 , the flame follower mechanism 4 is also provided with a capacitance transmission module 9 , and the flame torch 19 of the flame follower mechanism 4 is provided with a capacitance induction ring 10 .

[0028] As shown in the figure, the control system 5 includes a microcomputer 14, a torch lifting control module 15, a follower mechanism horizontal subdivision control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com