Layer paving device and layer paving method for main girder glass fiber cloth used for wind power blade production

A main beam glass fiber cloth and wind power blade technology, which is applied in the field of wind energy blade manufacturing, can solve the problems of difficulty in accurately laying glass fiber cloth into a mold, unfavorable large-scale production, and taking a long time, so as to ensure the laying quality. , Improve the laying efficiency, save time and manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

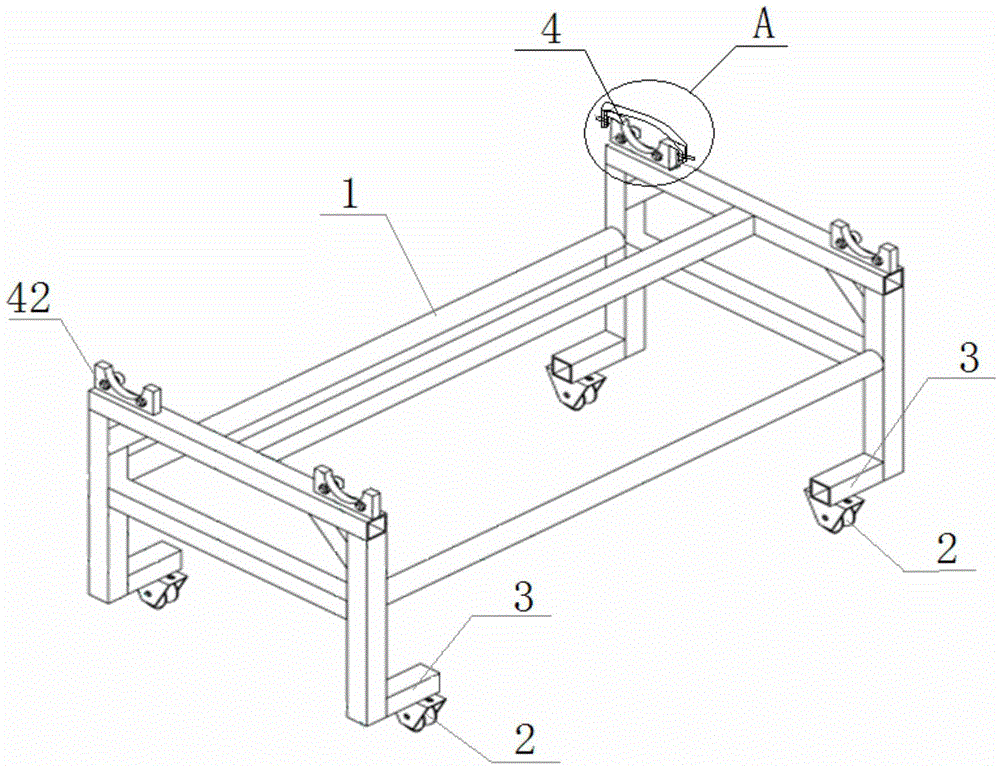

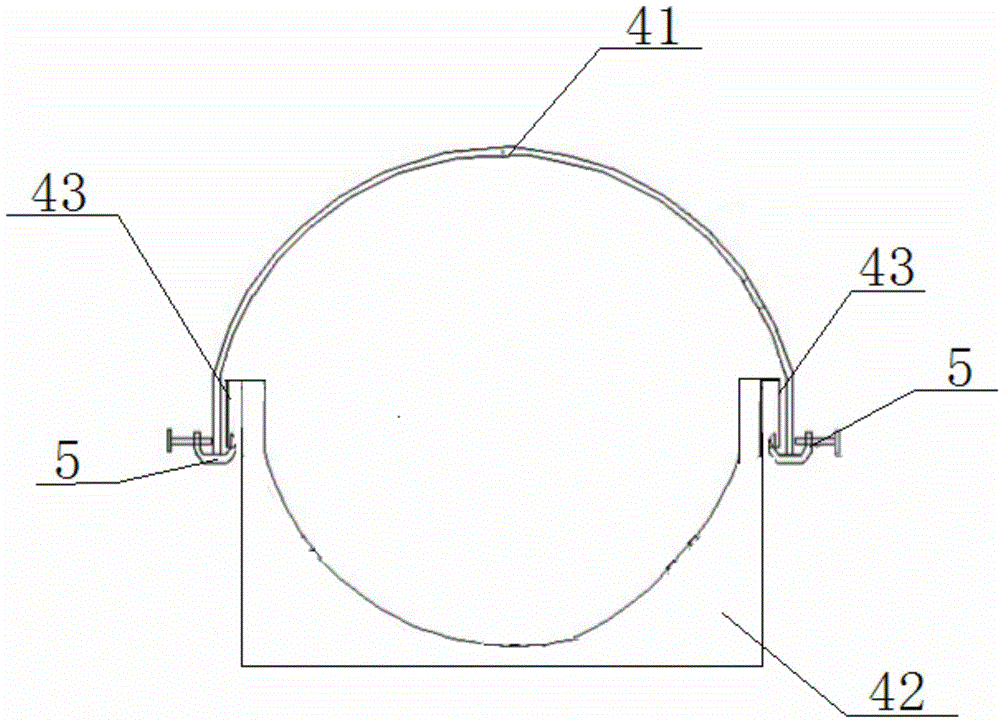

[0029] This embodiment provides a main girder glass fiber cloth laying device for the manufacture of wind power blades, the structure is as follows Figure 1-2 As shown, it is placed on the guide rail on the lower side of the mold, including the frame body 1 and the support structure set on the frame body 1 for placing glass fiber cloth rolls. The frame body 1 is a rectangular parallelepiped frame structure and its bottom four corners are all set There are wheels 2, and the frame body 1 is made of aluminum and steel structural parts through welding, wherein:

[0030] The four top corners of the bottom of the frame body 1 are equipped with L-shaped support rods 3, the lower ends of the support rods 3 are bent horizontally to form a bending part, and the wheels 2 are fixed on the lower surface of the horizontal bending part at the lower end of the support rods 3; the wheels 2 rotate along it There is a groove in the direction, and the groove matches the guide rail on the lower s...

Embodiment 2

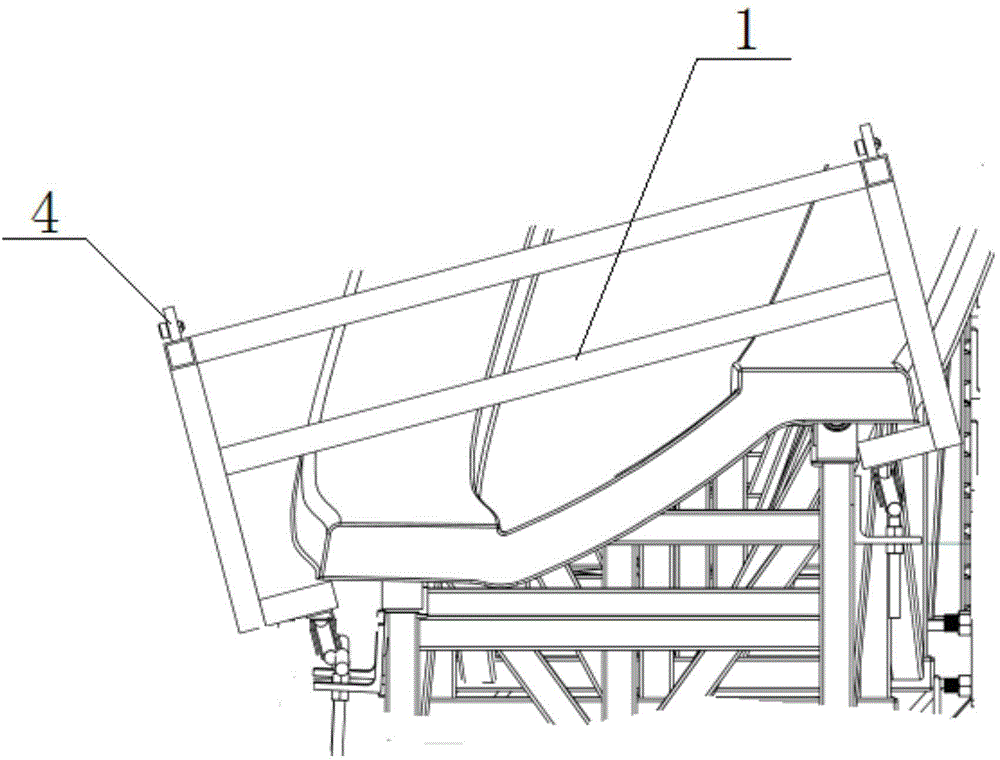

[0033] Such as image 3 As shown, this embodiment provides the laying method of the main beam glass fiber cloth laying device used in the manufacture of wind power blades in Example 1, which specifically includes the following steps:

[0034] A: Lift the glass fiber cloth layer moving device onto the guide rail located on the lower side of the mold, adjust the position of the wheel 2 on the support rod 3 according to the distance between the guide rails and use the wheel 2 to erect the glass fiber cloth layer moving device on the slide on the guide rail;

[0035] B: Push the glass fiber cloth layer moving device placed on the mold guide rail to one end of the mold, and then fix the glass fiber cloth roll wrapped with glass fiber cloth into the fixed frame 4 on the surface of the frame body 1 and place the glass fiber Pull out one end that is fixed to the mould, wherein, the fixed frame 4 fixes the glass fiber cloth roll, and when the glass fiber cloth roll is fixed by the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com