Easy-tear cap production line and manufacturing method

An easy-tear cover and production line technology, applied in other household appliances, household appliances, applications, etc., can solve the problems of slow production speed, high scrap rate, inability to achieve high-speed production, etc., and achieve the effect of convenient maintenance and pressure reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

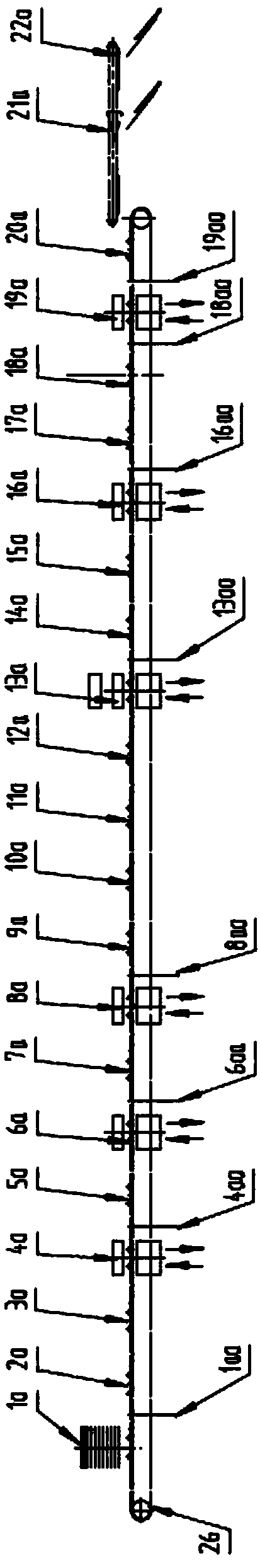

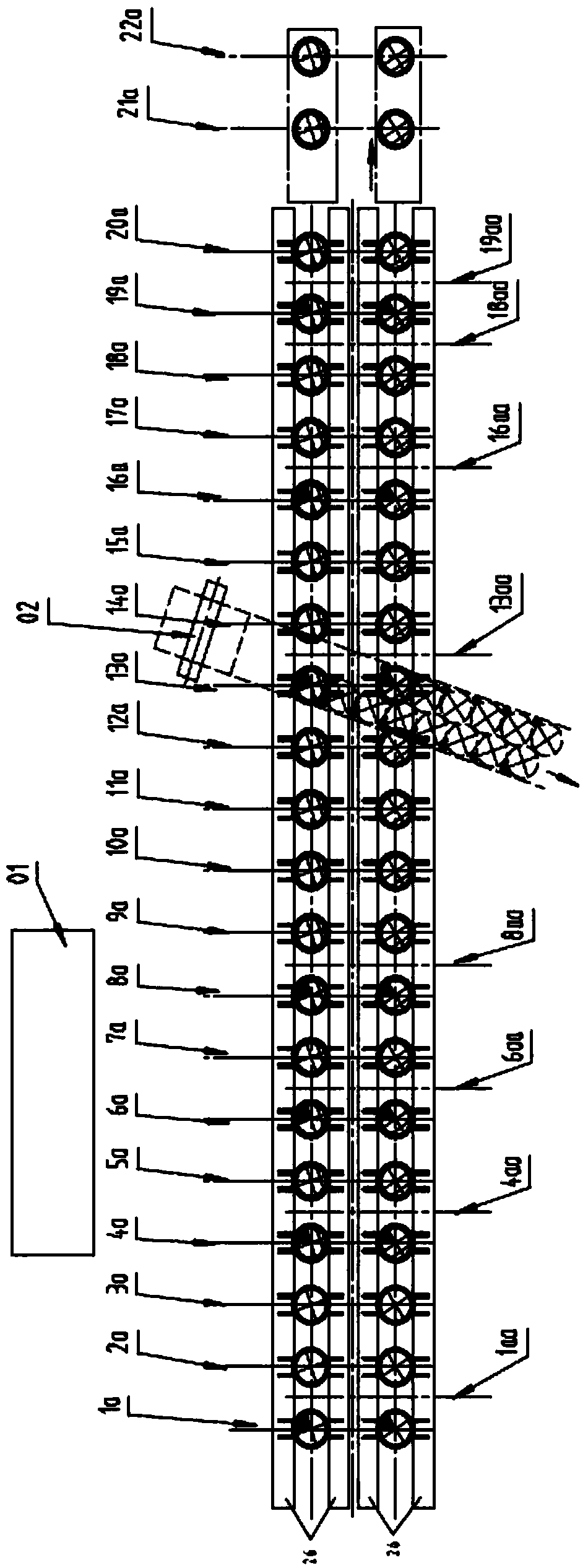

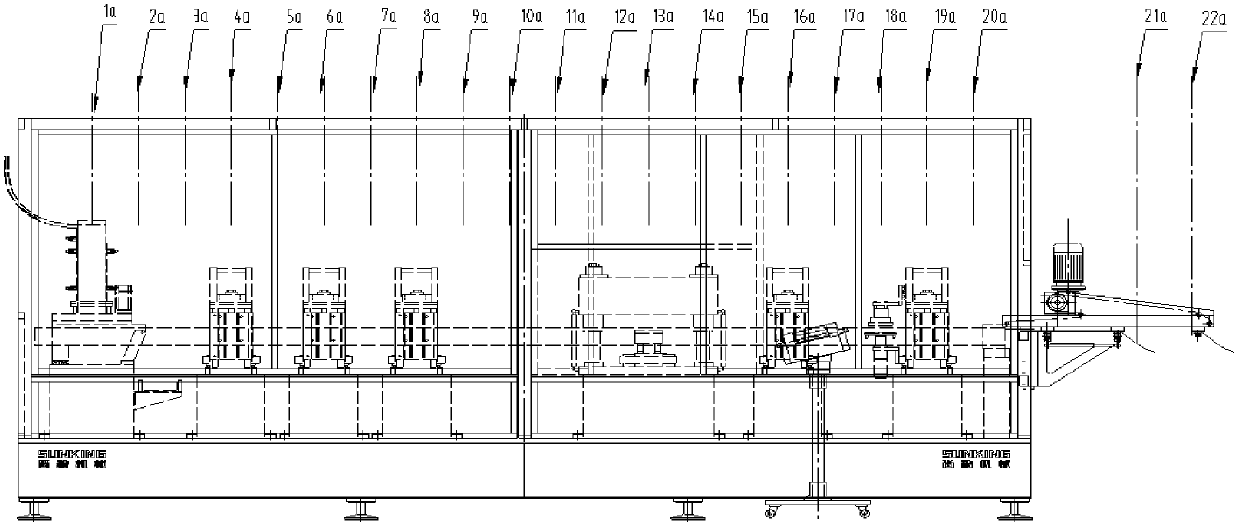

[0070] Embodiment 1: with reference to attached Figure 1-25 . An easy-tear cap production line 1, including an electric control box 01, an aluminum foil or film unwinding device 02, a synchronous belt conveying mechanism 26 (one or more groups of synchronous belt conveying mechanisms are arranged side by side), a sub-lid and a lower cap device 1a , middle hole forming device (4a, 6a, 8a), preheating device 10a-12a, punching aluminum foil or film and pre-sealing device 13a, heat sealing device 16a, cooling and handle alignment device 18a, folding handle device 18aa, pressing Flower or flattening device 19a, sealing defective product discharge device 21a, finished product output device 22a: in the sub-cover and lower cover device 1a: a. A turning cylinder 313 is added between the mounting plate 311 and the lower cover frame 312; b. The sub-cover screwdriver is composed of a body 31a, a cutter head 31b, and a gasket 31c. By adjusting the thickness of the gasket 31c, the height ...

Embodiment 2

[0077]Embodiment 2: On the basis of Embodiment 1, when manufacturing an easy-tear cover with a pull ring or a glued handle, the folding handle device 18aa is placed behind the embossing or flattening device 19a, and the handle fixing device 20a is added and the handle is fixed The device 20a is located behind the folding handle device 18aa.

Embodiment 3

[0078] Embodiment 3: On the basis of Embodiment 1, the lower aligning plate 83 can be made into a D-shaped groove to correspond to the D-shaped curling of the D-shaped cover.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com