Cap arranging device for automatic bottom cap feeding machine

A bottom cover machine and cover unscrambling technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problem that the efficiency of equipment cover cannot be effectively improved, the efficiency of cover cannot be greatly improved, and the labor of workers is increased. Problems such as volume and labor intensity, etc., to achieve the effect of good unpacking effect, low manufacturing cost, and low solution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

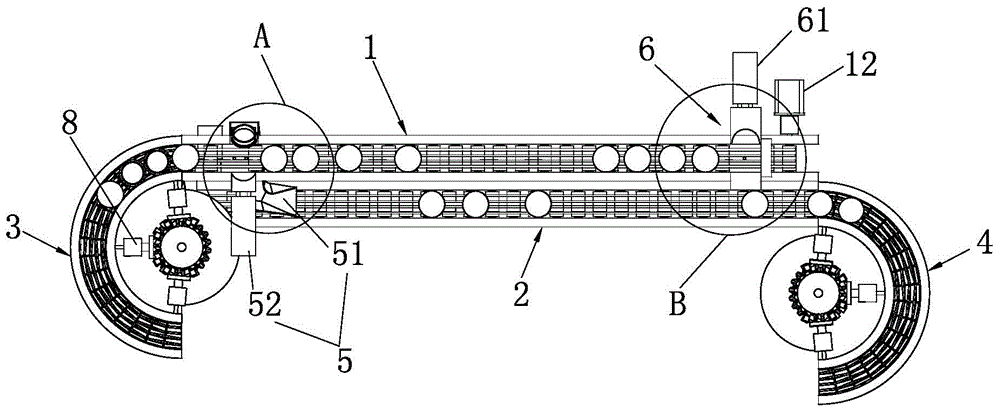

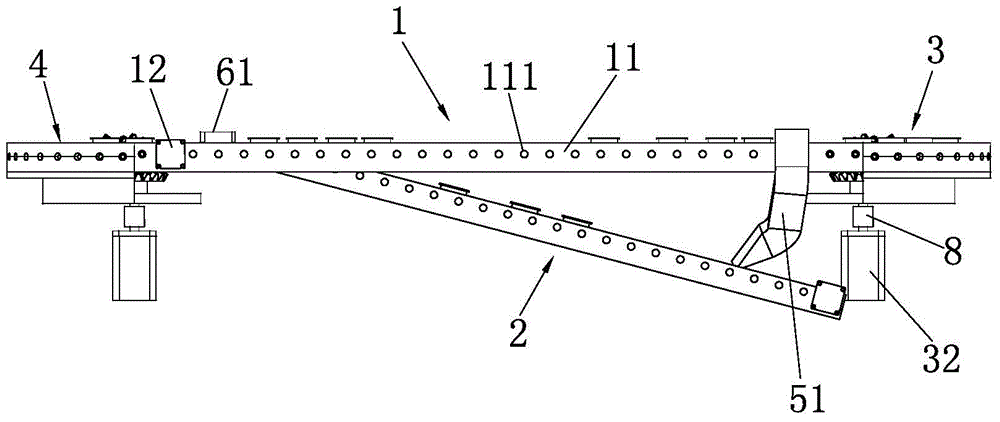

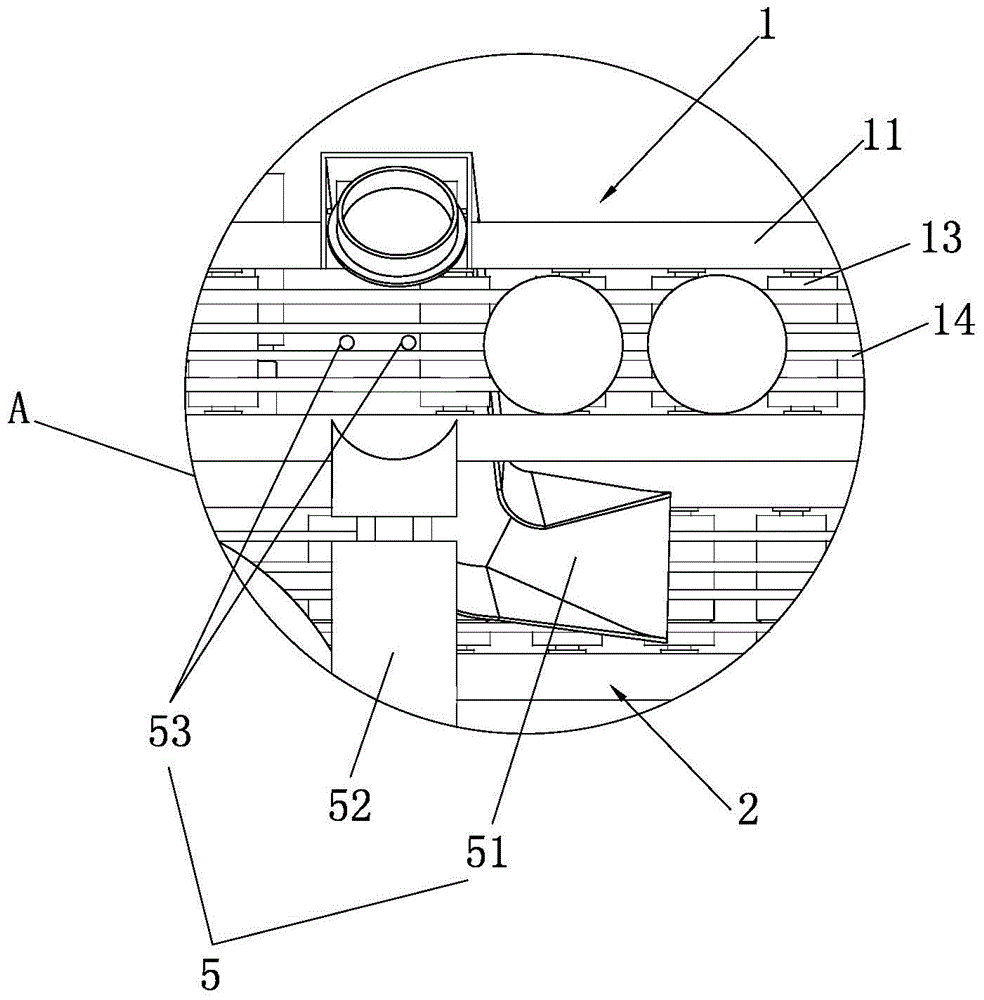

[0023] Such as Figure 1 to Figure 8 As shown, a cover sorting device for an automatic bottom cover machine includes a first feeding track 1, a second feeding track 2, a first arc-shaped delivery track 3, a second arc-shaped delivery track 4 and a control mechanism. The left and right ends of a feeding track 1 are arranged horizontally, and the second feeding track 2 is arranged on the side of the first feeding track 1 with one end low and the other end high, and the right end of the second feeding track 2 is connected with the right end of the first feeding track 1 flush with height; figure 1 As shown, the high end of the second feeding track 2 and the right end of the first feeding track 1 are arranged close to each other and a connecting groove 21 for conveying bottle caps is provided at the abutting part of the two, and the first arc-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com