Tube supply and tube handling system

A supply device and bobbin technology, applied in thin material handling, transportation and packaging, and delivery of filamentous materials, etc., can solve problems such as complex structures and achieve the effect of simple structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, with reference to the accompanying drawings of embodiments of the present invention will be described. Further, the same description of the drawings elements denoted by the same reference numerals, duplicate description is omitted.

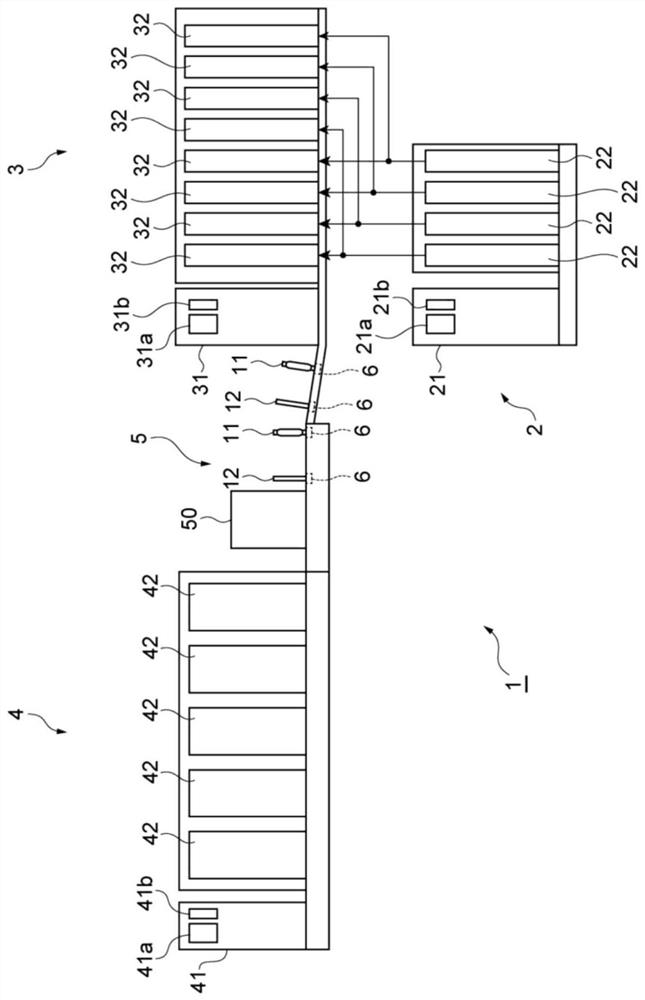

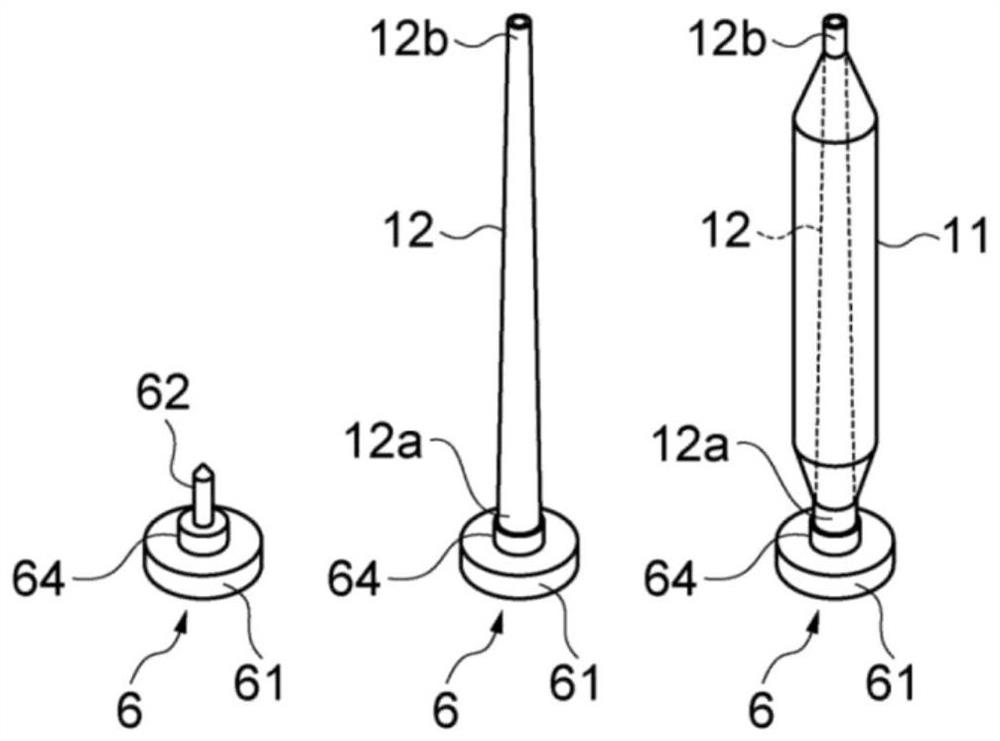

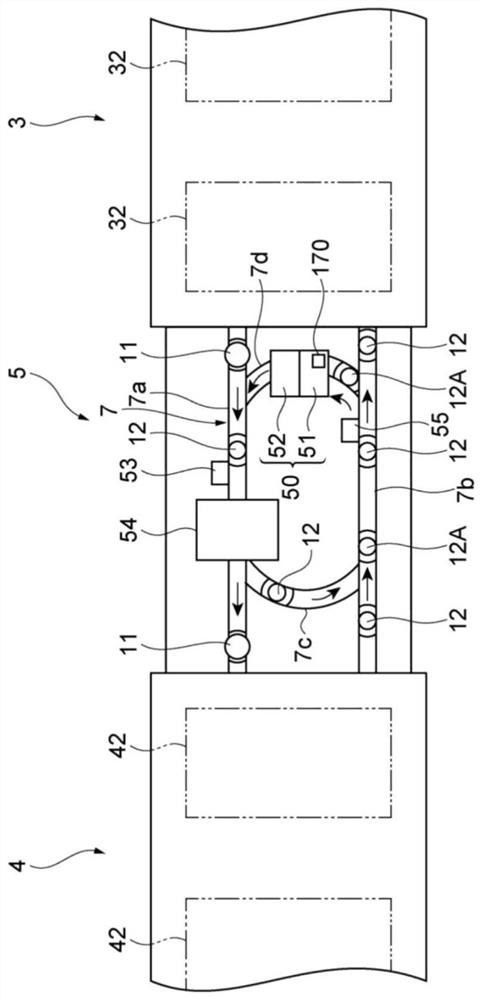

[0042] like figure 1 As shown, the system 1 includes a yarn winding: 2 roving machine, spinning frame 3, the automatic winder bobbin transfer device 4 and 5. To form a roving bobbins from the roving machine 2 generates a roving sliver, the wound roving. 3 generated from spinning the roving yarn, which yarn is wound to form a yarn feeding bobbin 11. Auto winder for yarn 4 from the yarn supplying bobbin 11 is wound to form a package. Bobbin transfer device 511, the automatic winder 43 is transferred (not wound yarn bobbins) spinning bobbin 3 from the tubular body 12 to an automatic winder 4 transfer the yarn feeding bobbin to the spinning machine. The bobbin of the bobbin transfer device 5 is provided with a processing system 50 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com