A feeding method and device for dropping funnel in an infusion set

The technology of an infusion set and a drip hopper is applied in the field of the feeding method of the drip hopper in the infusion set and the field of the device thereof, which can solve the problems of lower production efficiency of the assembly machine and unqualified assembly quality, etc., so as to improve the efficiency and quality, and improve the quality. and efficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

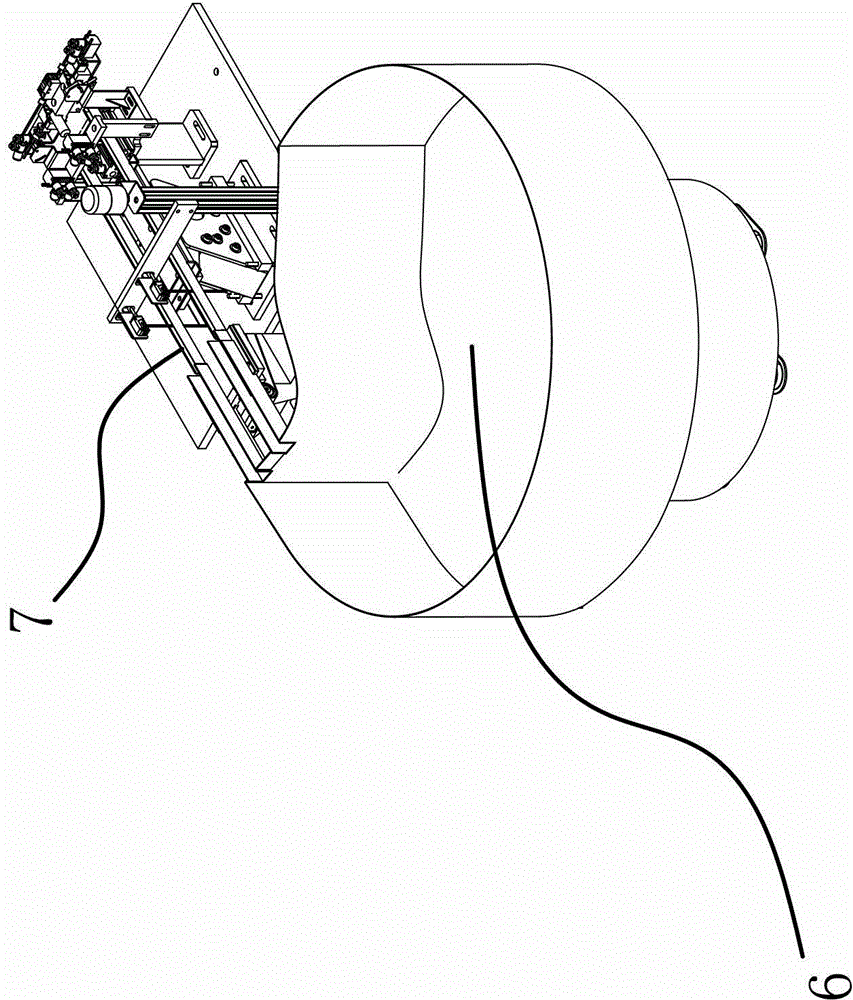

[0054] Such as Figure 7 As shown, the dripping funnel generally includes a dripping funnel body 11, a latex cap 10 and a tee joint 9, the two ends of the dripping funnel body 11 have ports, the tee joint 9 is connected to one of the ports, and the latex cap 10 is connected to the tee joint 9 on.

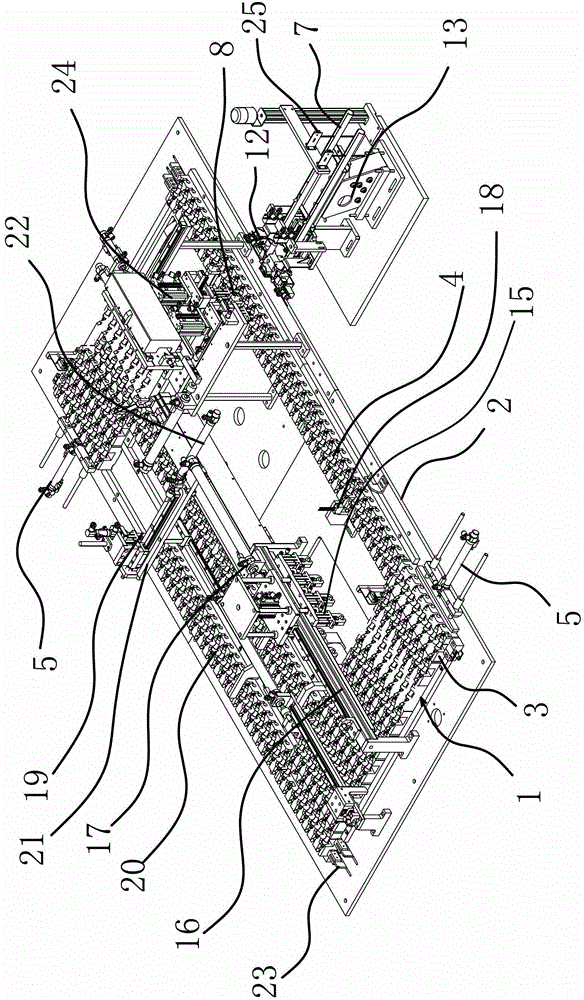

[0055] Such as figure 1 , figure 2 , image 3 As shown, the device mainly includes a frame 2, a loading manipulator 8, a rejecting manipulator 15 and a feeding manipulator 19, and the frame 2 is provided with a feeding channel 4 for the passage of the carrier 3.

[0056] The frame 2 is provided with a driving mechanism 5 that can drive the carrier 3 to move forward on the feeding channel 4. In this embodiment, the driving mechanism 5 is a combination of a cylinder and a push rod, but as another solution, its A combination of motor and drive chain is also possible.

[0057] One side of the frame 2 is provided with a hopper 6, the hopper 6 is connected with a feeding channel 7, ...

Embodiment 2

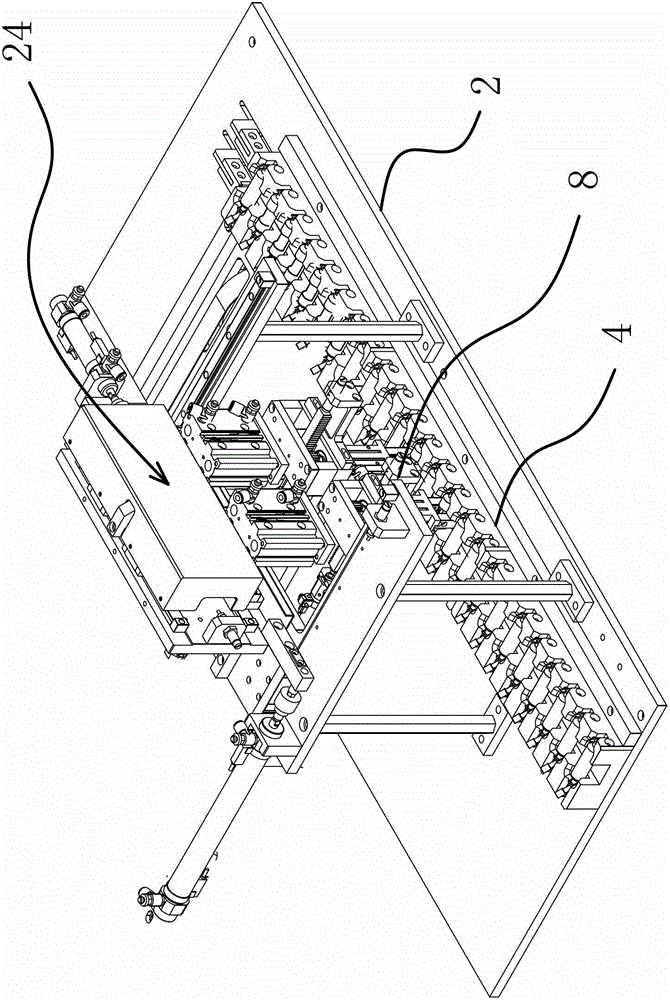

[0073] The general content of this embodiment is the same as that of Embodiment 1, the difference is that in this embodiment, as the above-mentioned side-by-side scheme, the device also includes a support, the feeding channel 7 is fixed on the support, and the loading manipulator 8 passes through a The translation and rotation power mechanism 24 is connected on the support. Adding an extra support structure can facilitate the adjustment of the position of the loading manipulator 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com