Patents

Literature

98results about How to "Moderate tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

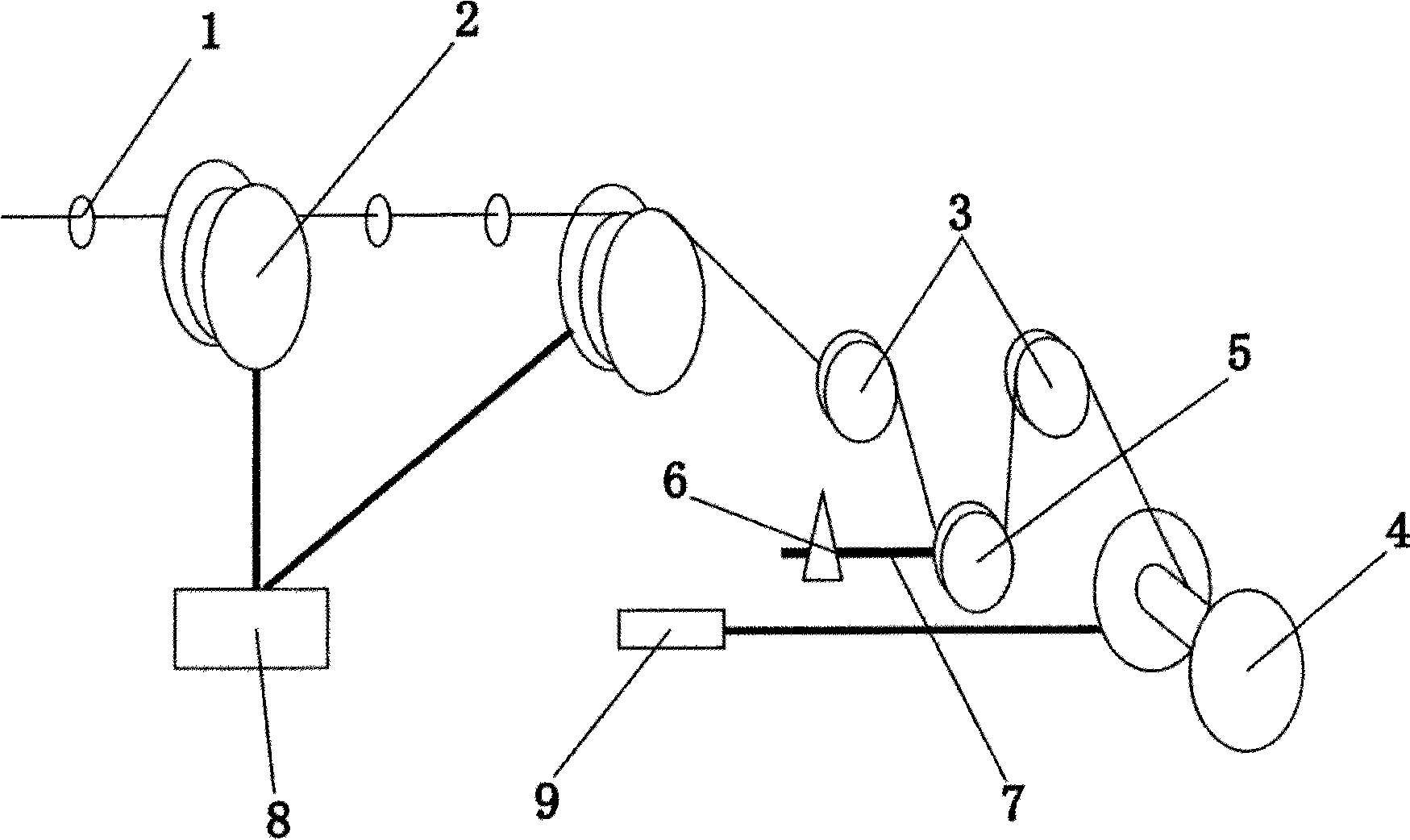

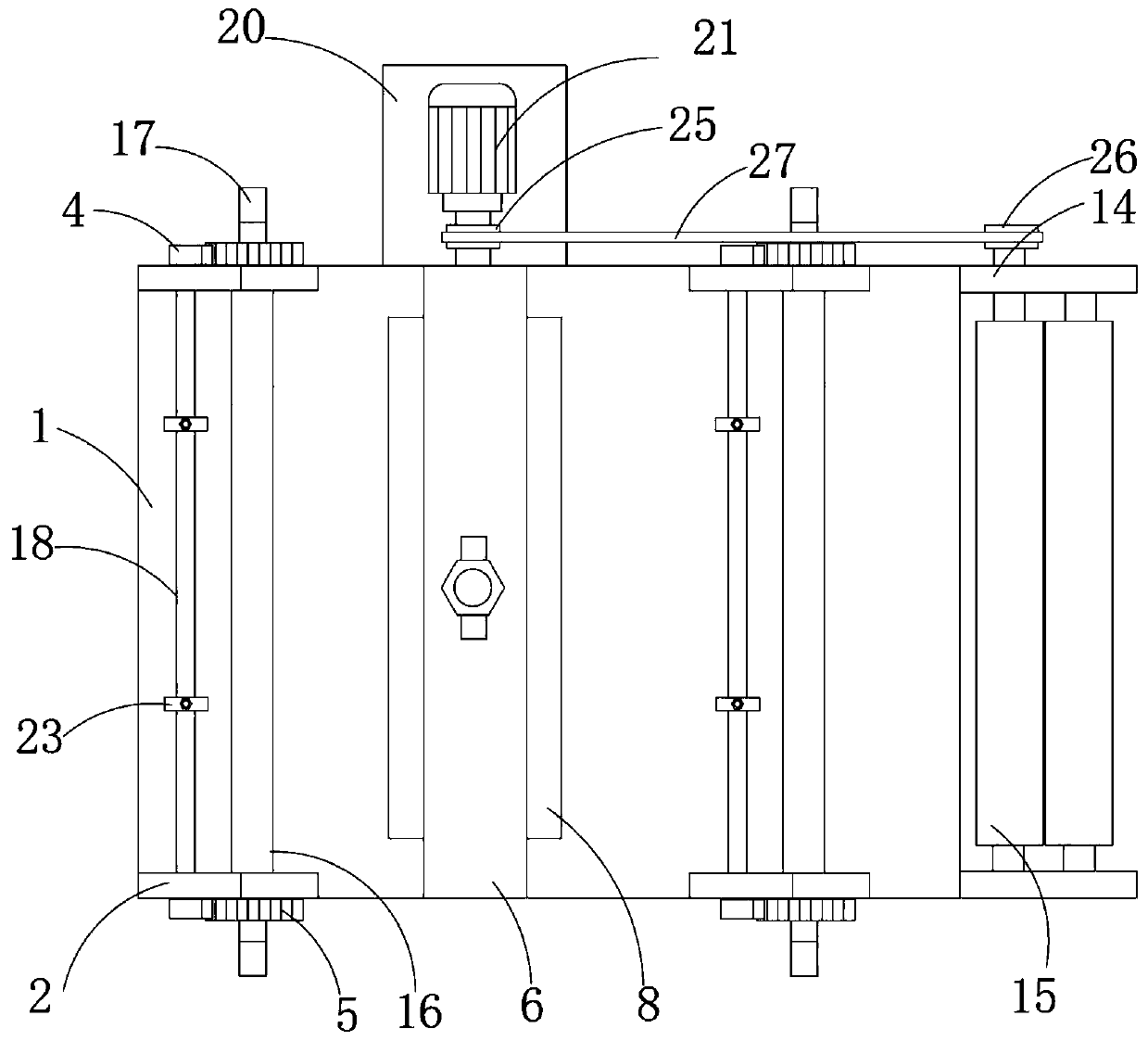

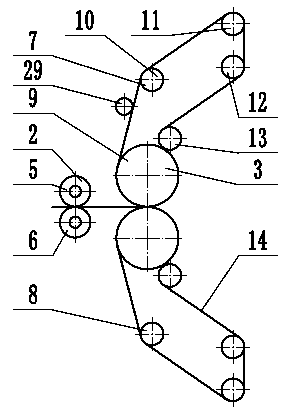

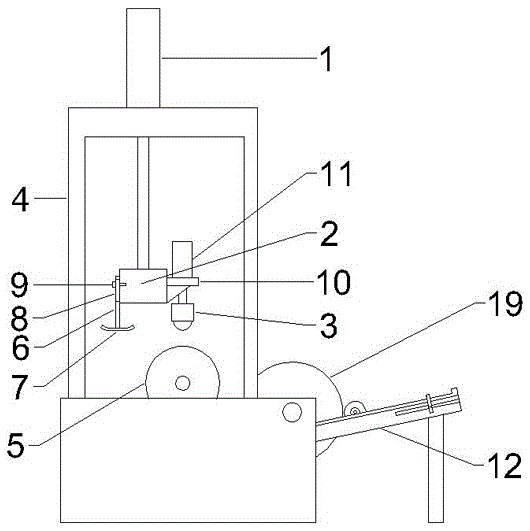

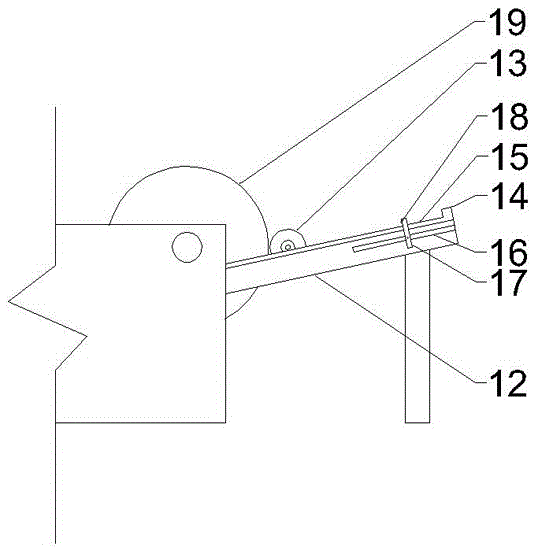

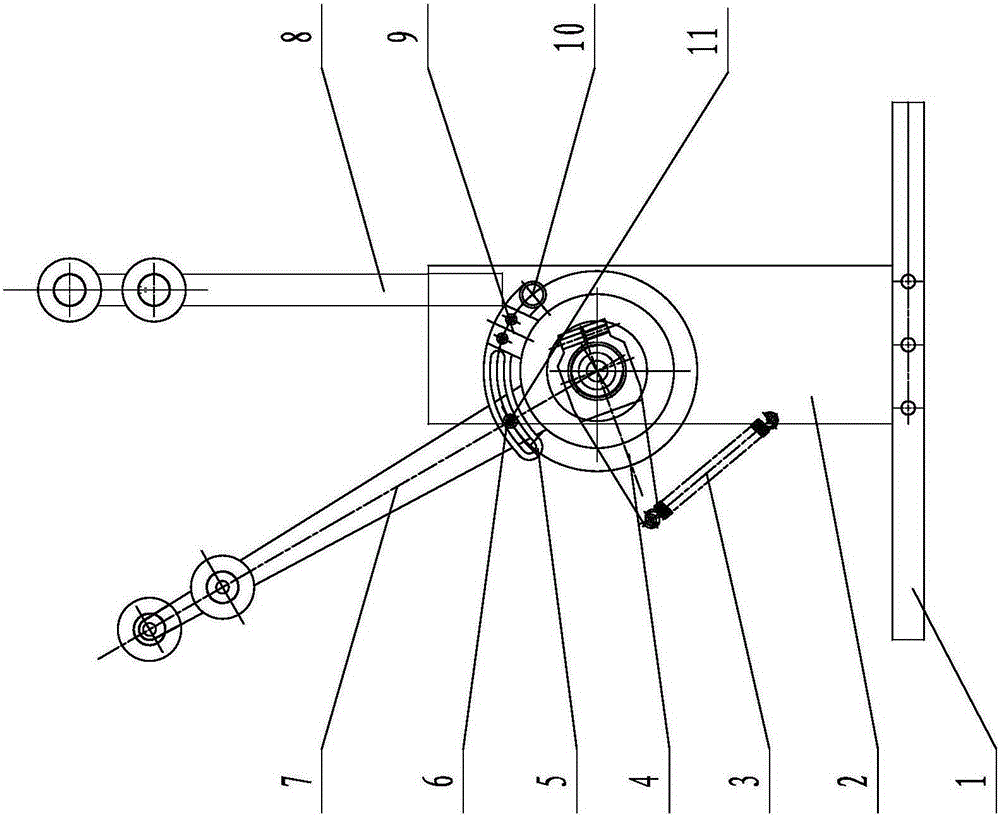

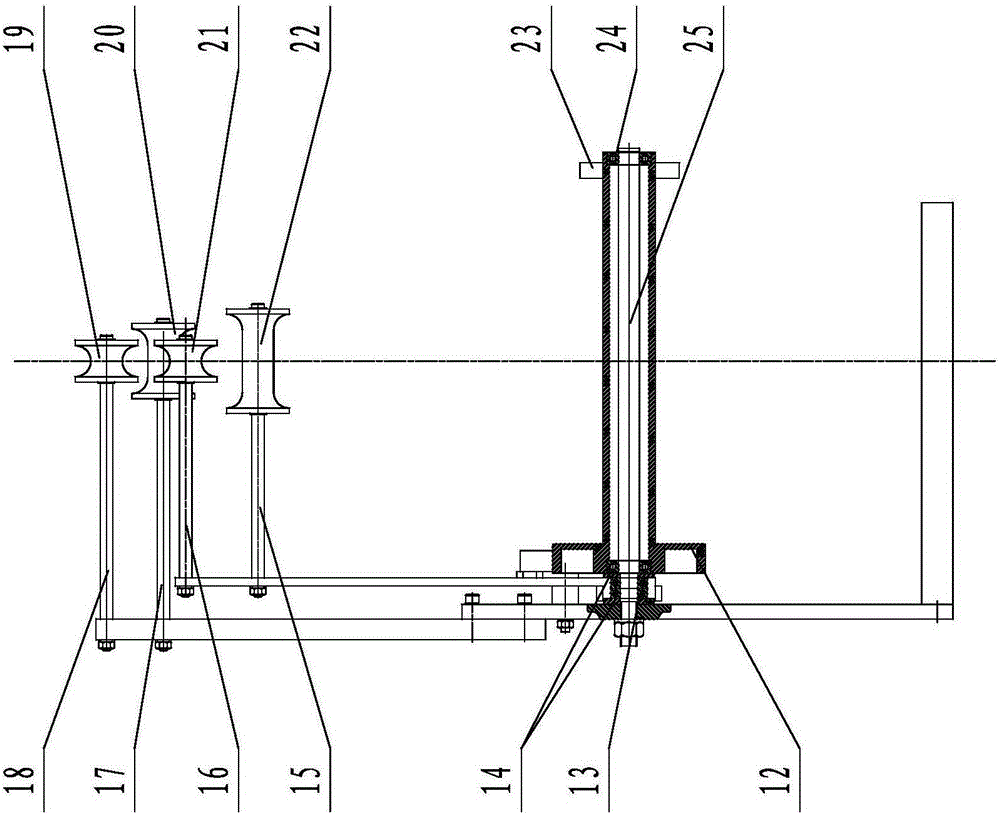

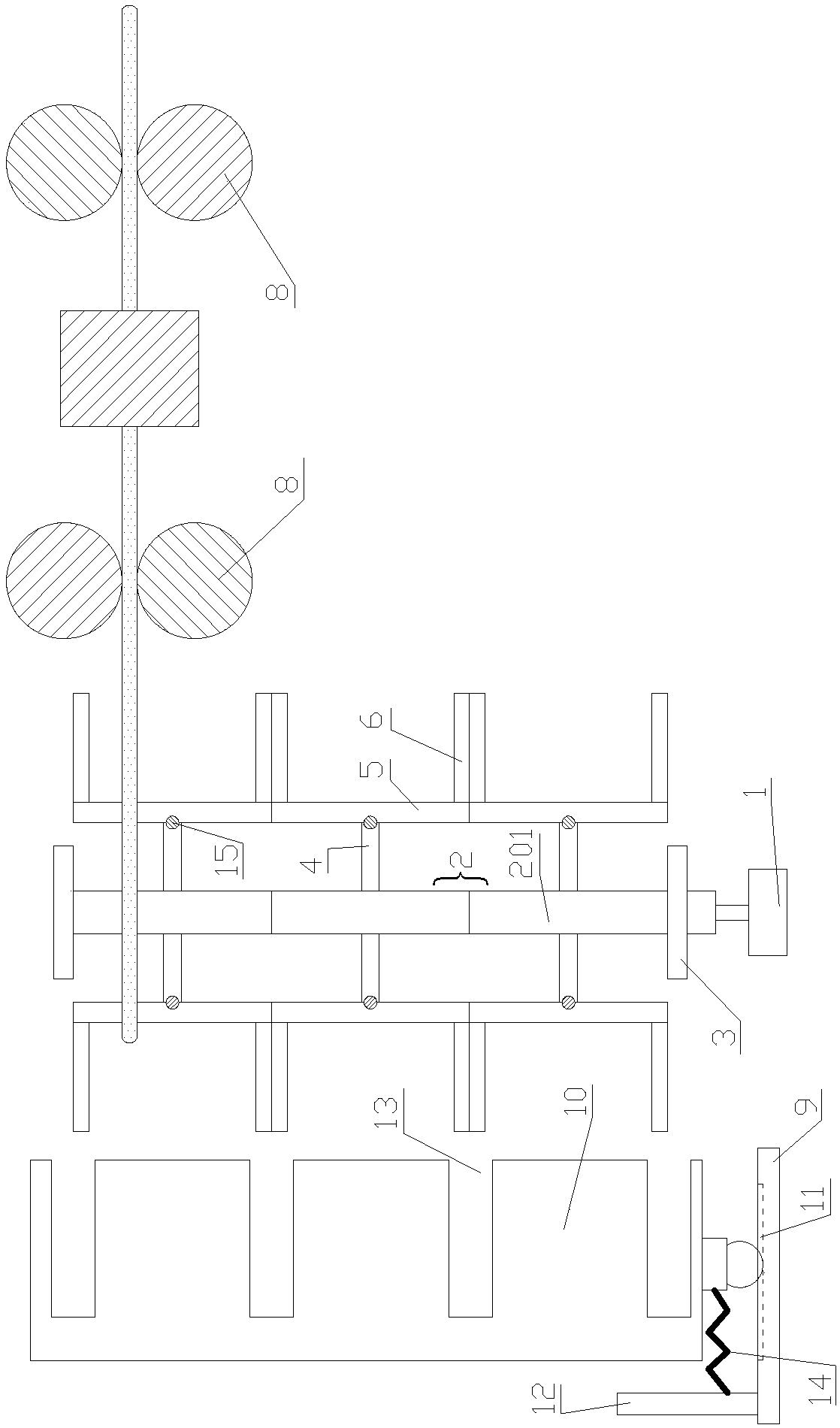

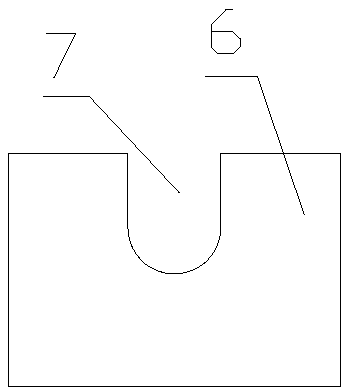

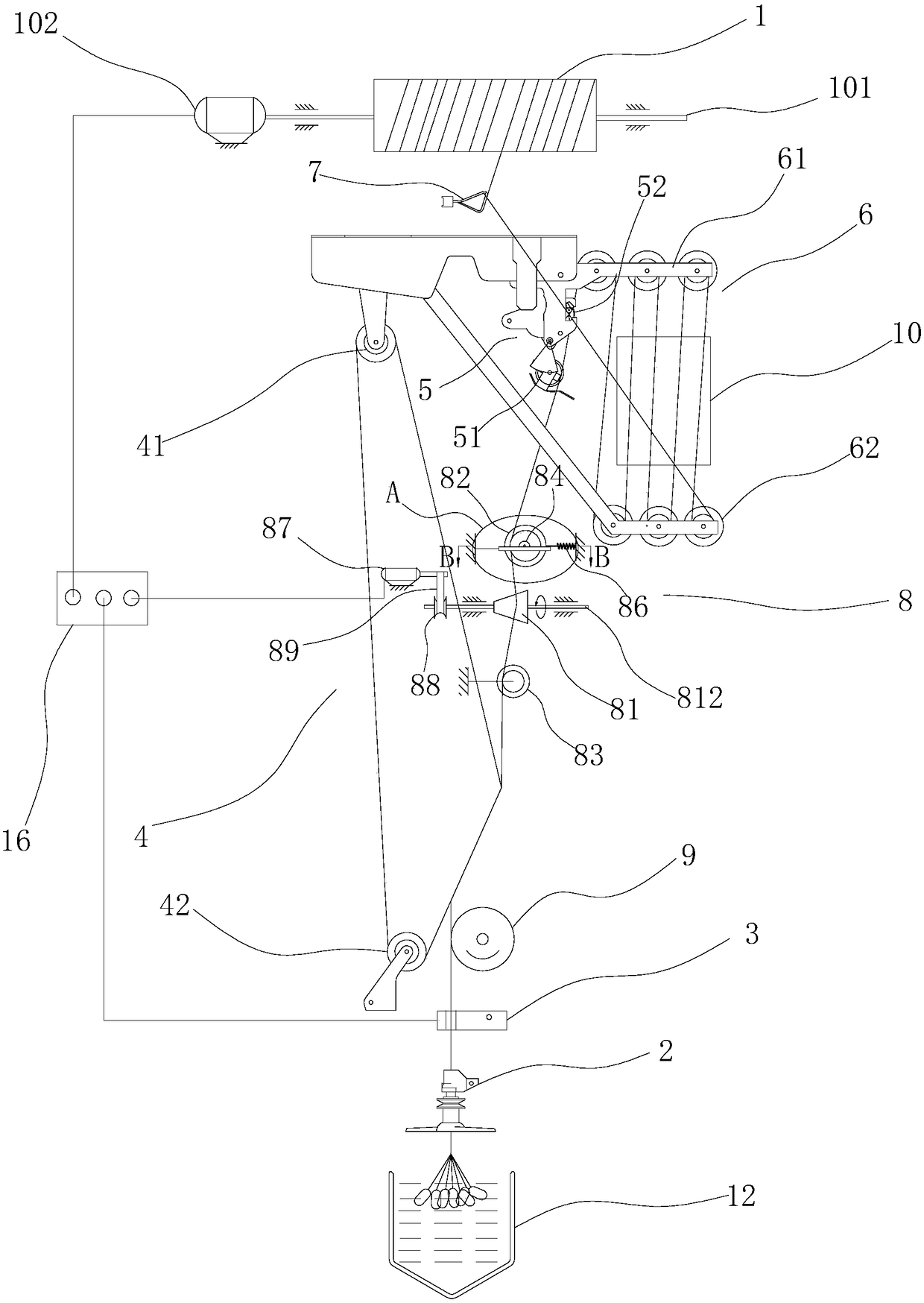

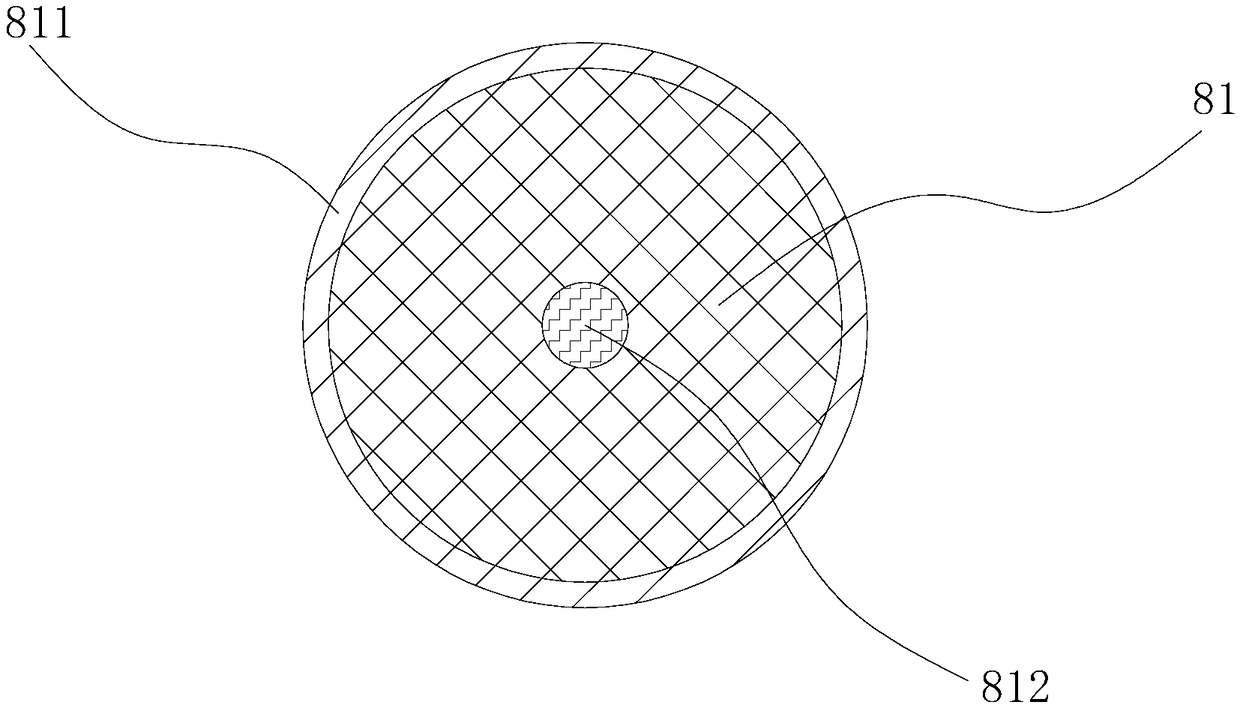

Small self-adapting wire drawing machine with variable disk diameter

The invention discloses a small self-adapting wire drawing machine with a variable disk diameter, which comprises multi-stage diameter-reducing wire drawing dies and multi-stage traction wheels, wherein each traction wheel is arranged between every two diameter-reducing dies; an annular groove is formed at the outer edge of each traction wheel; a plurality of pulleys and take-up pulleys are arranged behind the last-stage traction wheel; two brackets are arranged between two pulleys; a gap is formed between two brackets; each bracket is provided with a strip-shaped sliding groove; a wire passing wheel is positioned in the gap between two brackets; the central axis of each wire passing wheel slides up and down in each strip-shaped sliding groove; an annular groove is formed at the outer edgeof each wire passing wheel; a swinging rod seat is installed at one side of each bracket; a tension swinging rod is installed on each swinging rod seat through a rotation axis with a torsion spring;a rolling wheel is installed at the front end of each tension swinging rod; each rolling wheel is butted below the outer edge of each wire passing wheel; and an angle sensor is installed at the rotating connection point of each tension swinging rod and each rotation axis to sense the rotation angle of each tension swinging rod. The small self-adapting wire drawing machine with variable disk diameters overcomes the defects of prior wire drawing machines, ensures the consistency of the winding diameter of real-time computation and the practical winding diameter, completely solves the problems ofslow response of the large winding diameter and oscillation of the small winding diameter, shortens the production cycle and saves the cost.

Owner:ANHUI JIUHUA KIMRUN COPPER IND

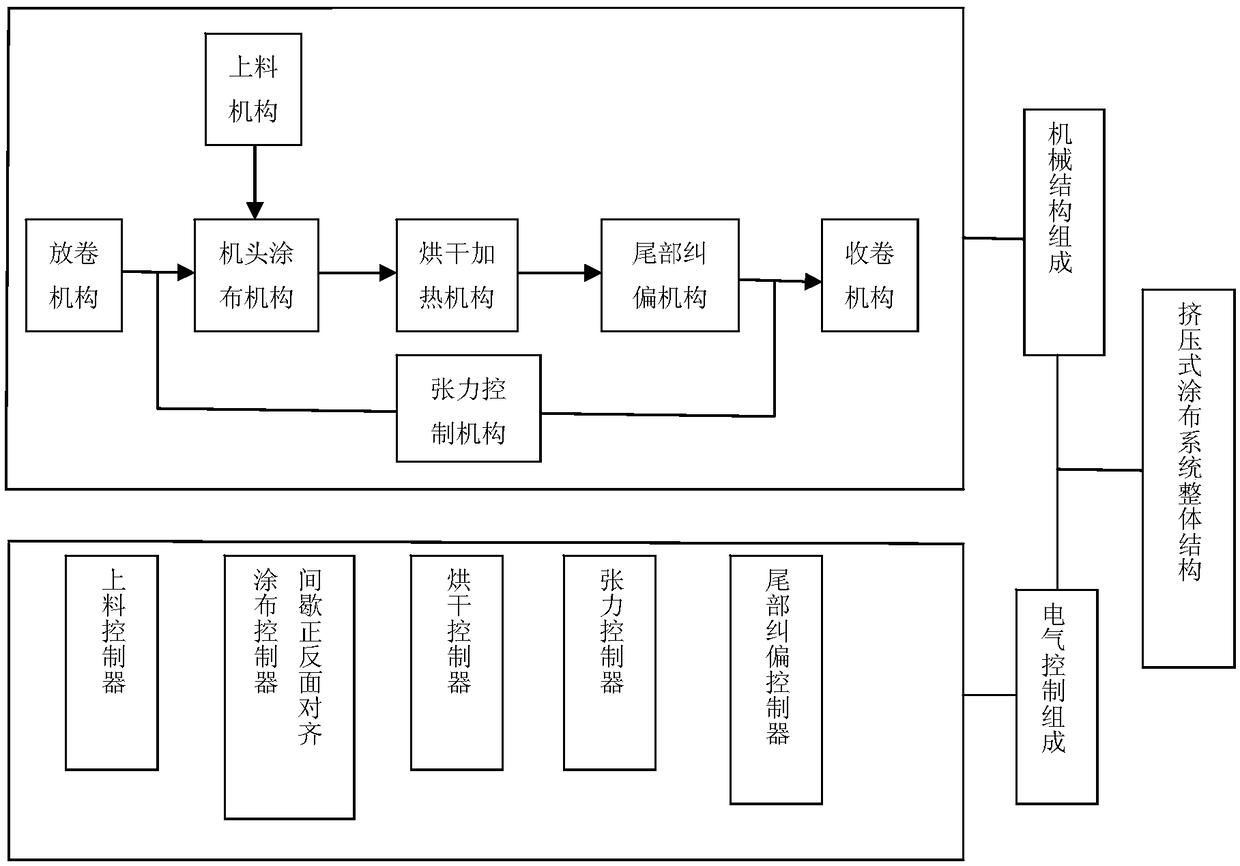

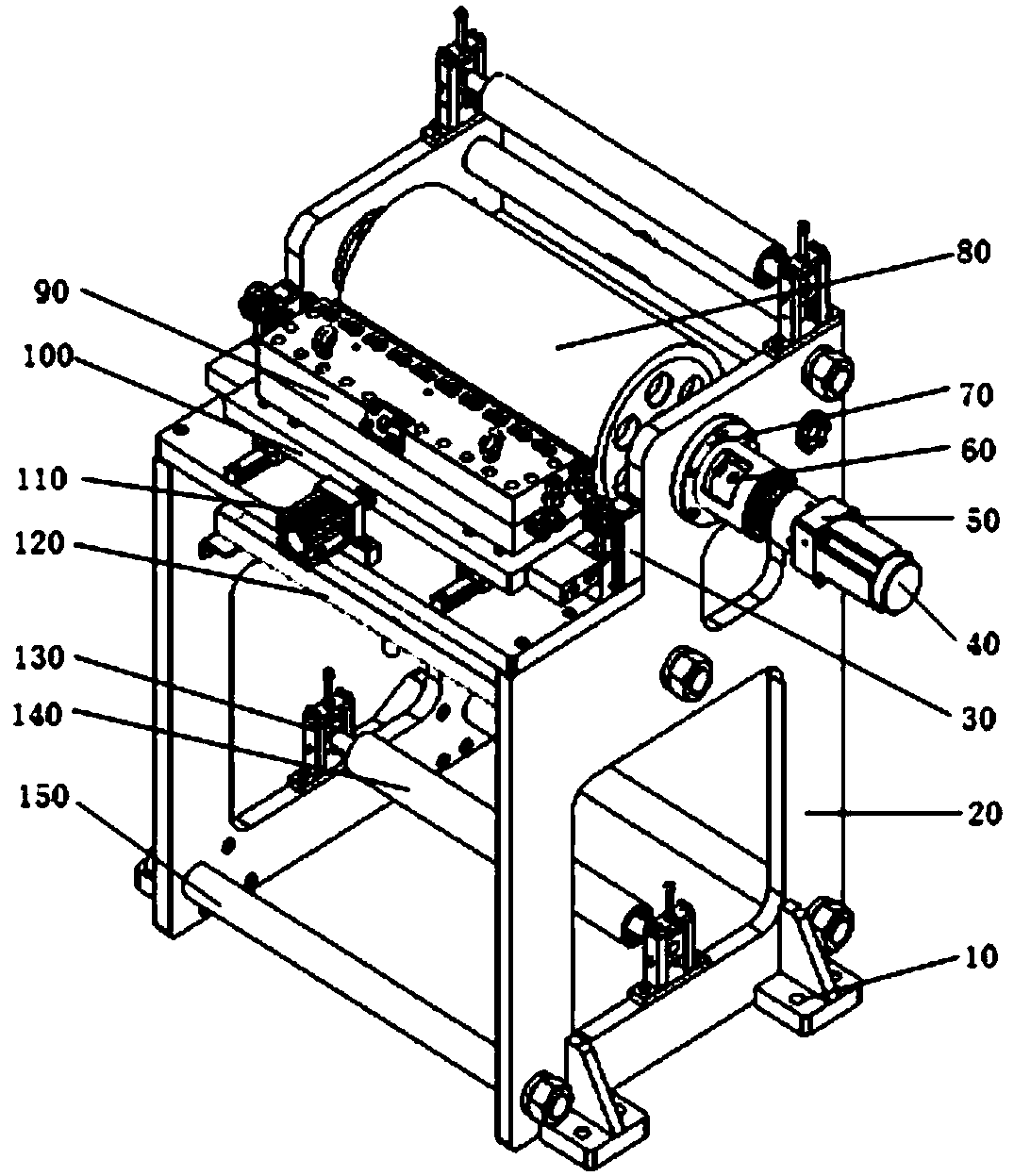

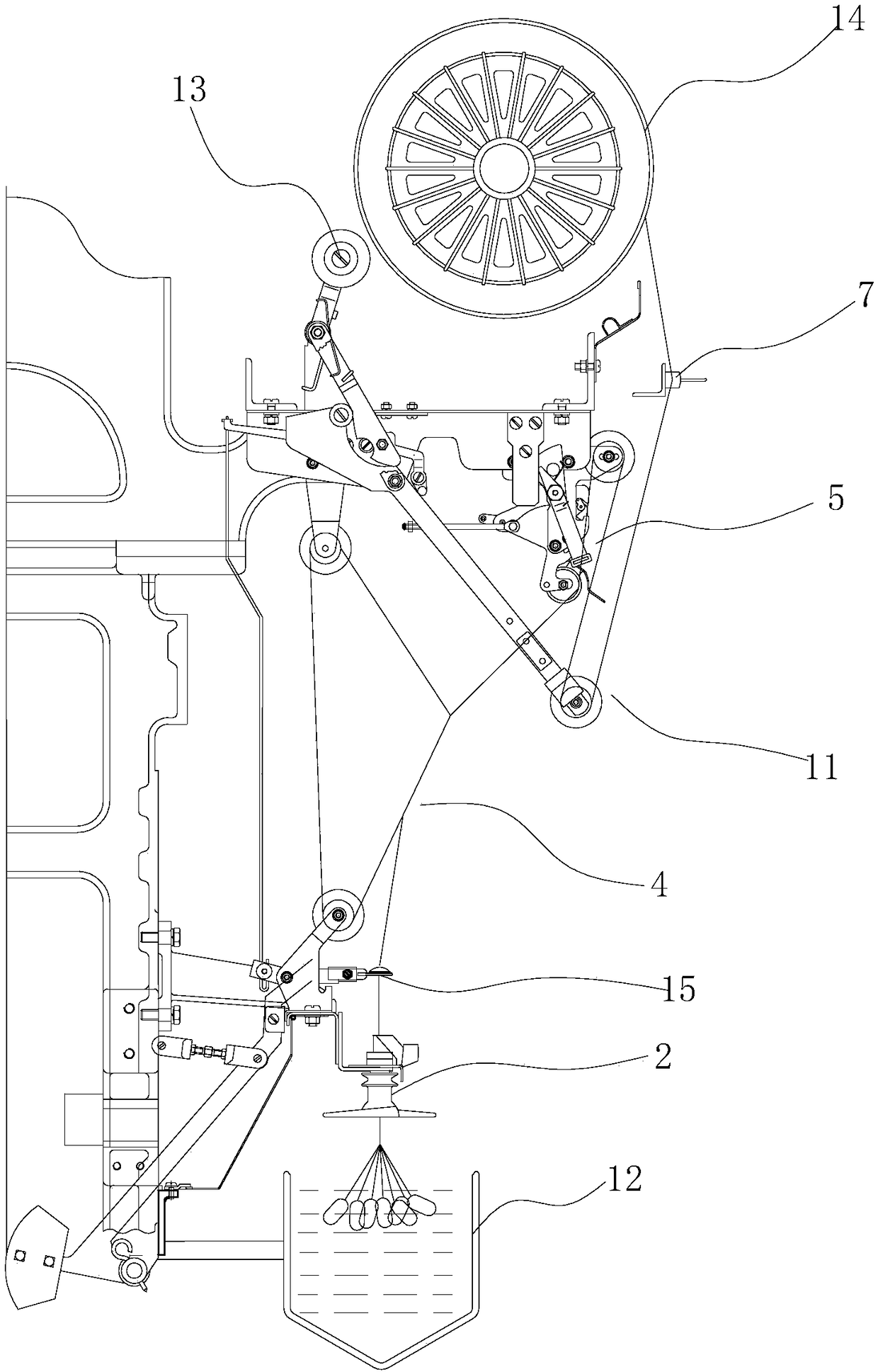

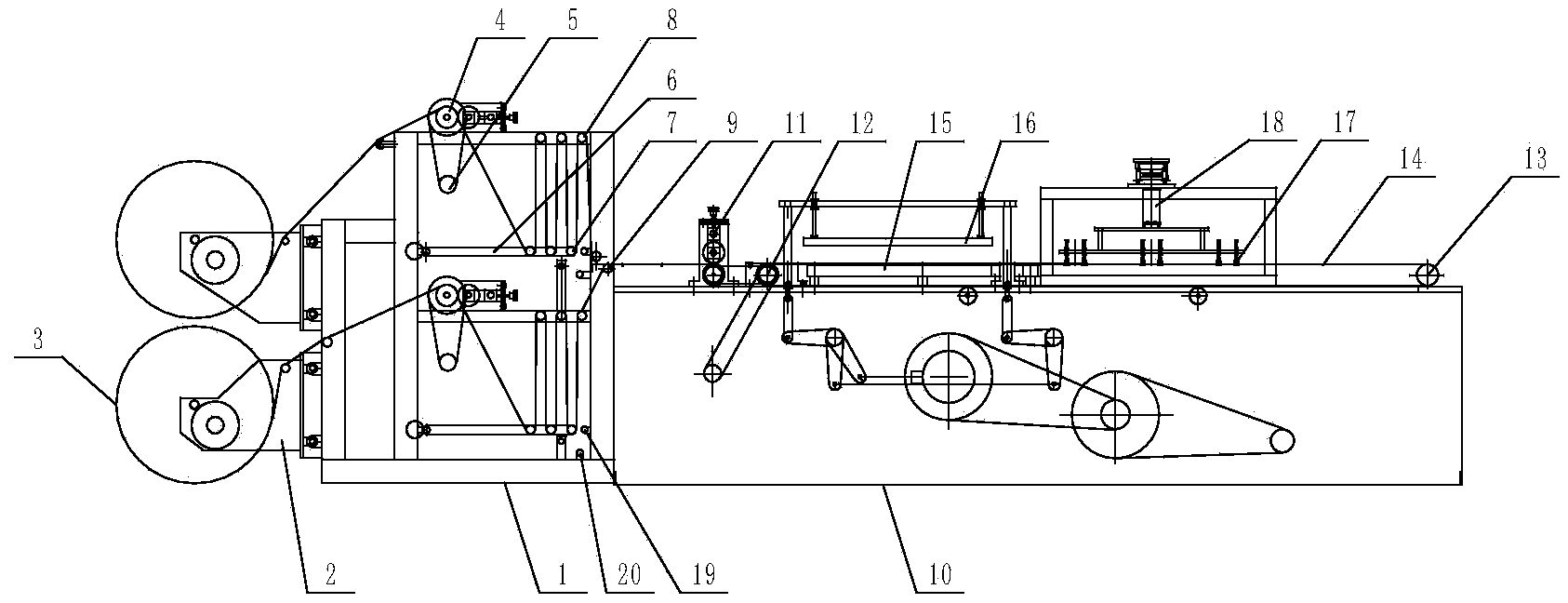

Extrusion type coating system of power lithium battery base band

ActiveCN108816645AFull dispersionFull homogenizationPretreated surfacesCoatingsCoating systemEngineering

The invention discloses an extrusion type coating system of a power lithium battery base band. The extrusion type coating system of the power lithium battery base band comprises an unwinding mechanism, a feeding device, a machine head coating device, a tension control device, a drying heating device, a tail deviation rectifying device and a winding mechanism. The unwinding mechanism releases the base band at a constant speed. The feeding device provides a stable sizing agent. The machine head coating device disperses the sizing agent to be uniform and discharges and coats the sizing agent to the base band along the position of a gap of an outlet of an extrusion mold head. The drying heating device dries the wet sizing agent coated to the base band. The winding mechanism winds the coated and dried base band. The tail deviation rectifying device can guarantee that the base band is tidy during taking up, operation of following working procedures is facilitated, and the tension control device can guarantee the best tension degree of the base band.

Owner:SOUTHEAST UNIV

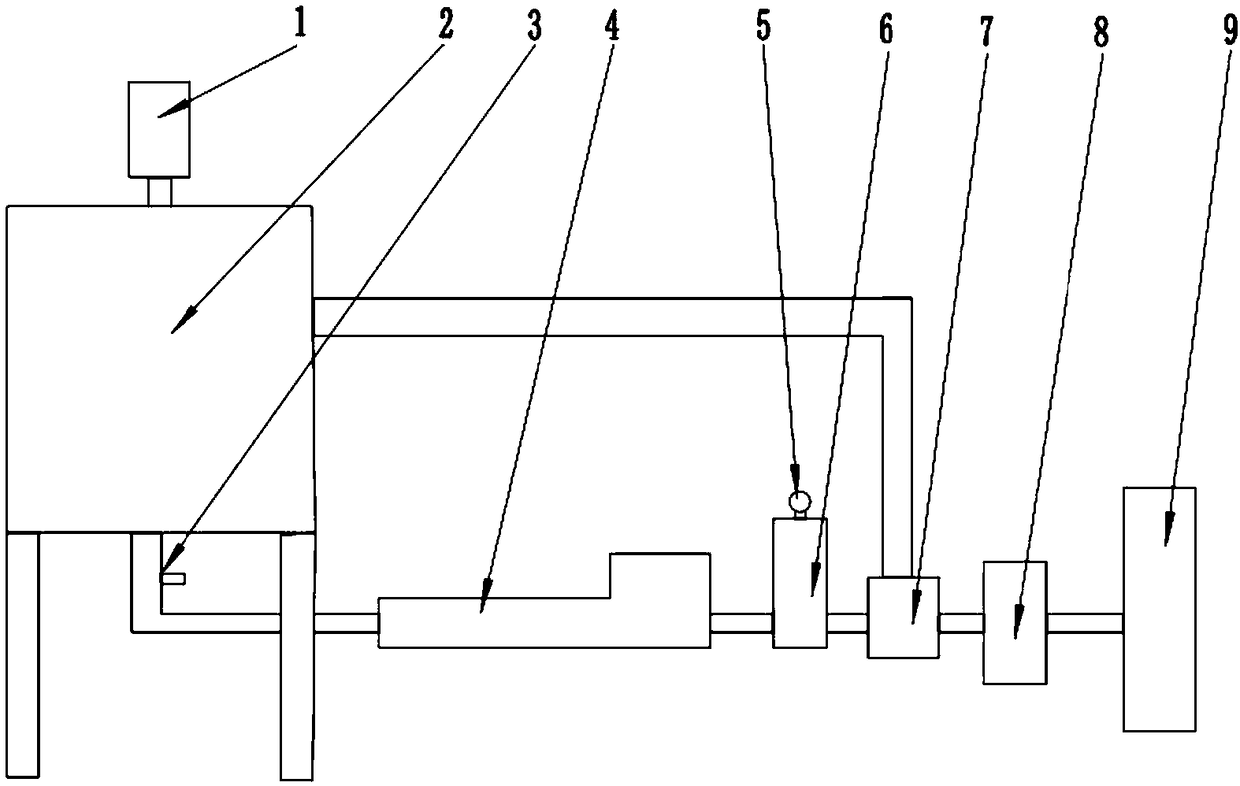

Preparation process for graphene conductive film

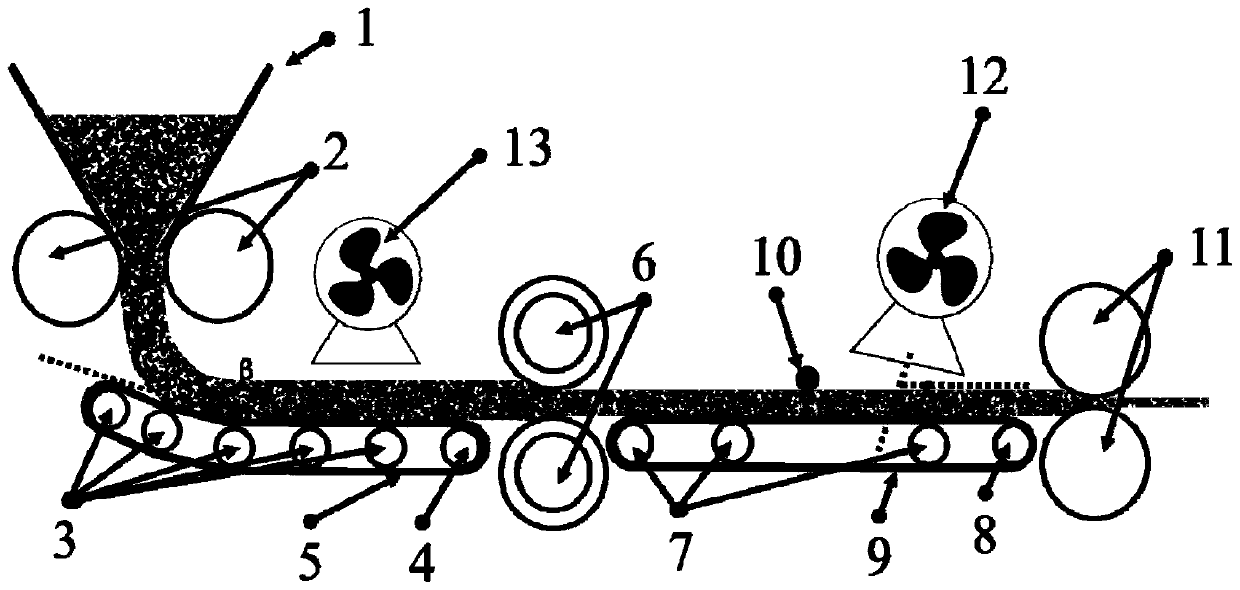

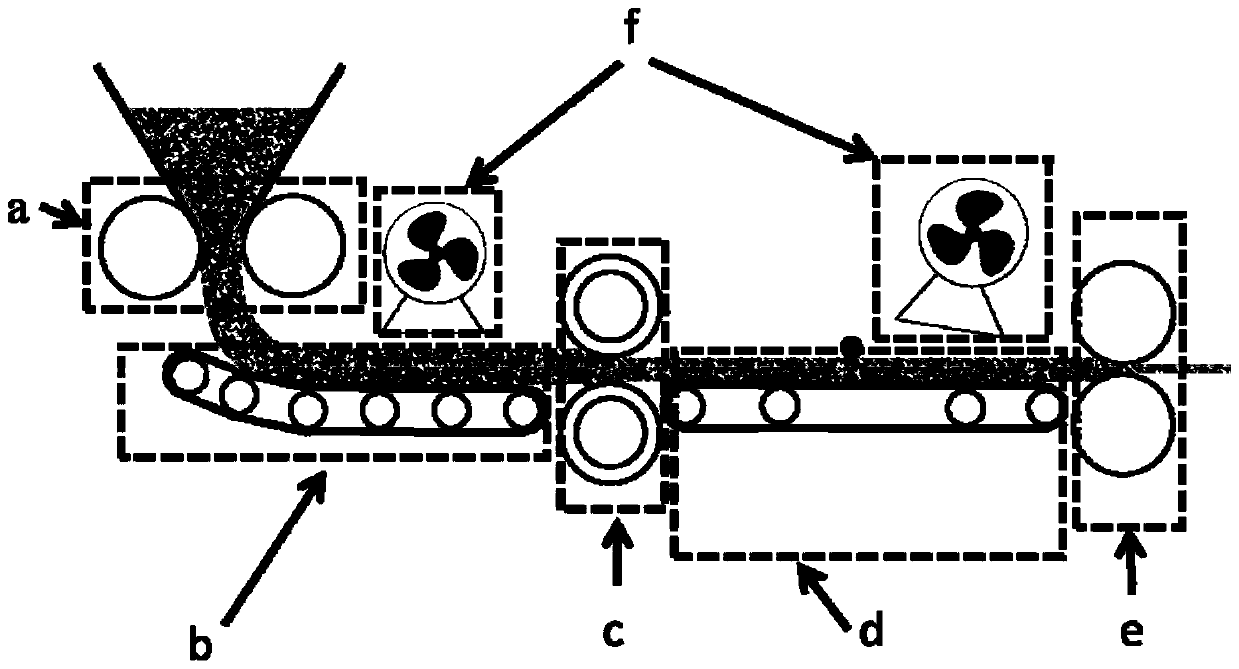

ActiveCN109801758AEnables continuous productionAvoid mixing disperse-pulp-coatConductive layers on insulating-supportsCable/conductor manufacturePolymer scienceTransfer procedure

The invention provides a preparation process of a graphene conductive film. The preparation process is of simplicity and has high efficiency. According to the preparation process, a dry preparation process is adopted. The dry preparation process includes the following steps that: a graphene-based conductive functional agent, a binder dispersion, and an auxiliary are thoroughly mixed so as to forma semi-dry slurry; and the semi-dry slurry is subjected to a vertical rolling procedure a, a guide traction procedure b, a thermal rolling procedure c, a transfer procedure d, a cold rolling proceduree and a blowing procedure f, so that a graphene conductive film is obtained. With the preparation process of the invention adopted, the continuous preparation of the graphene conductive film is realized, process steps such as mixing and dispersing, slurrying and coating are avoided; and the procedures are optimized, and efficiency can be improved, and therefore, costs can be saved, high-speed non-stop preparation is realized, and a process flow is simplified.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

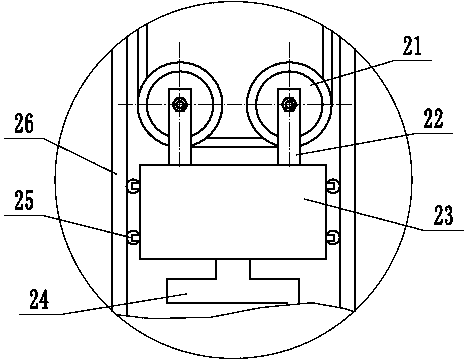

Film supply device

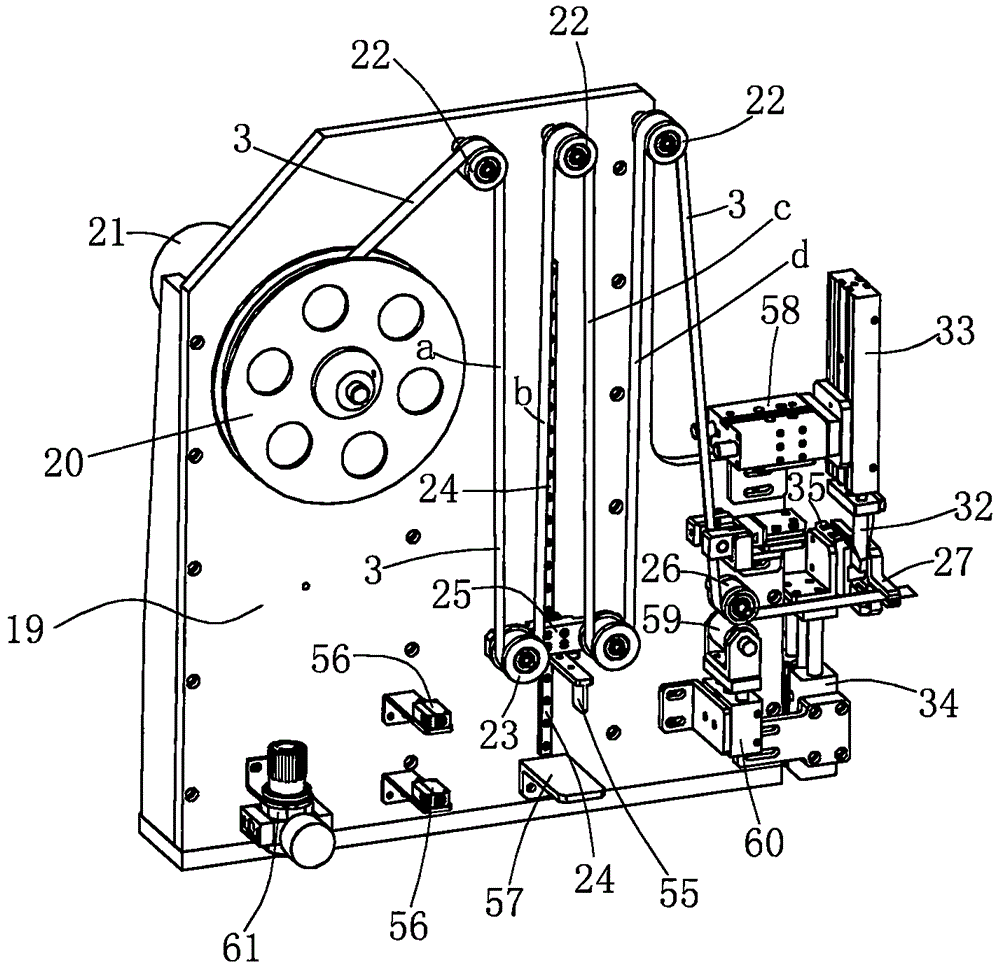

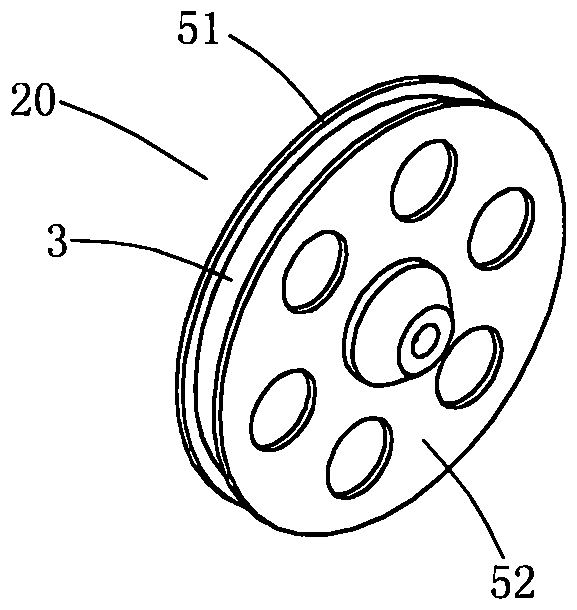

ActiveCN105731143AHigh degree of automationImprove work efficiencyArticle deliveryWebs handlingAutomation

The invention provides a film supply device used for providing a film belt with one face being a glued adhesive face for a film pasting device. The film supply device comprises a vertical plate (19). The vertical plate (19) is provided with an edged barrel (20) used for installing and rolling a film belt (3), and a wheel set tension mechanism used for enabling the film belt (3) to be wound and forming tension. The wheel set tension mechanism comprises three edgeless upper wheels (22) and two edged lower wheels (23), all of which are used for winding of the film belt (3). A vertical guide rail (24) and a sliding block (25) capable of vertically sliding along the vertical guide rail (24) are arranged below the upper wheel (22) arranged in the middle position. The two lower wheels (23) are symmetrically arranged on the sliding block (25) and located on the left side and the right side of the sliding block (25). The film supply mechanism further comprises a sixth wheel (26) for guiding the film belt (3) to the film pasting device, and a film clamping device (27). The film supply device is high in automation degree and operation efficiency, and the consistency of the supplied film belt is good.

Owner:NINGBO MINTH AUTOMOTIVE PARTS RES&DEV CO LTD

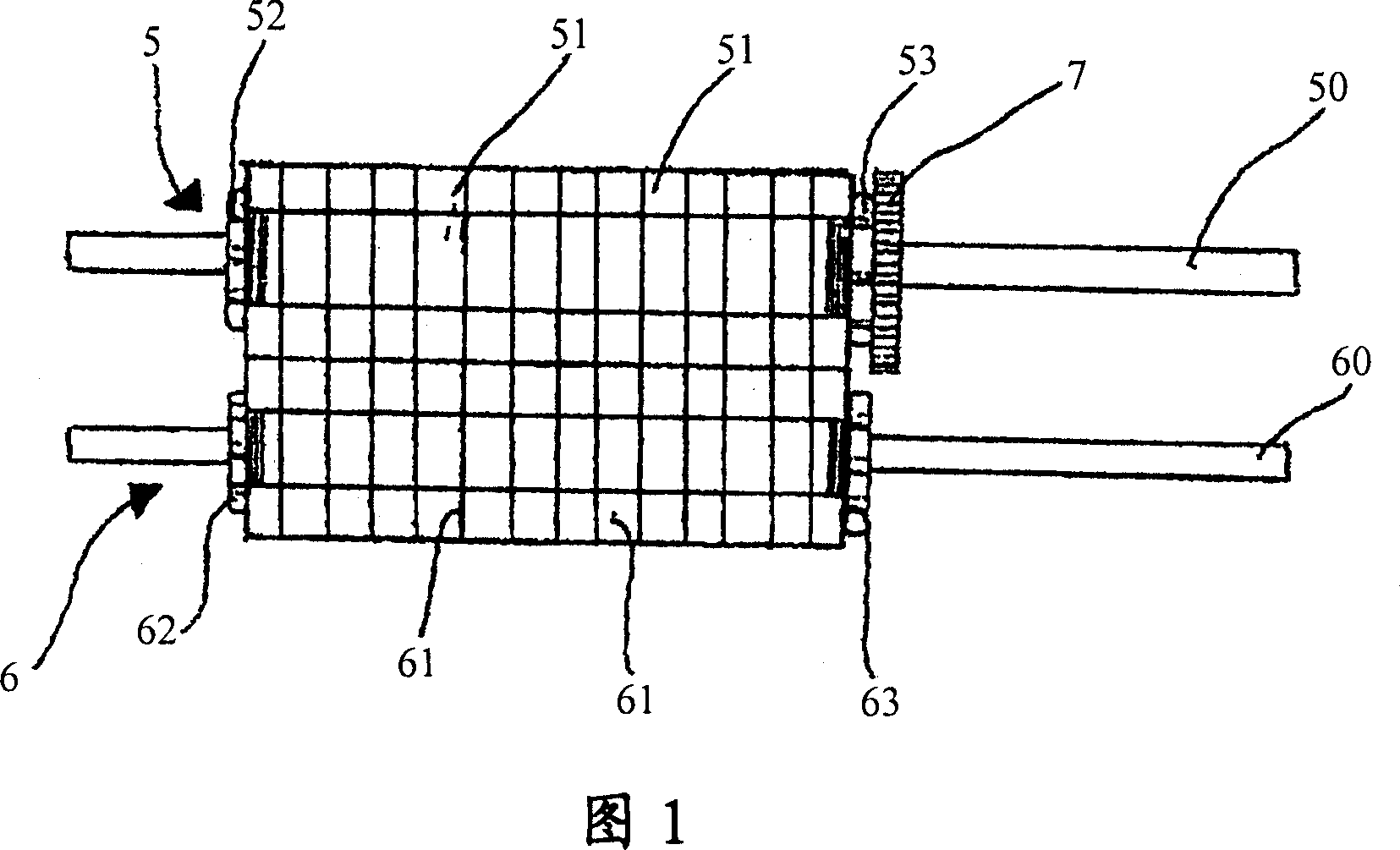

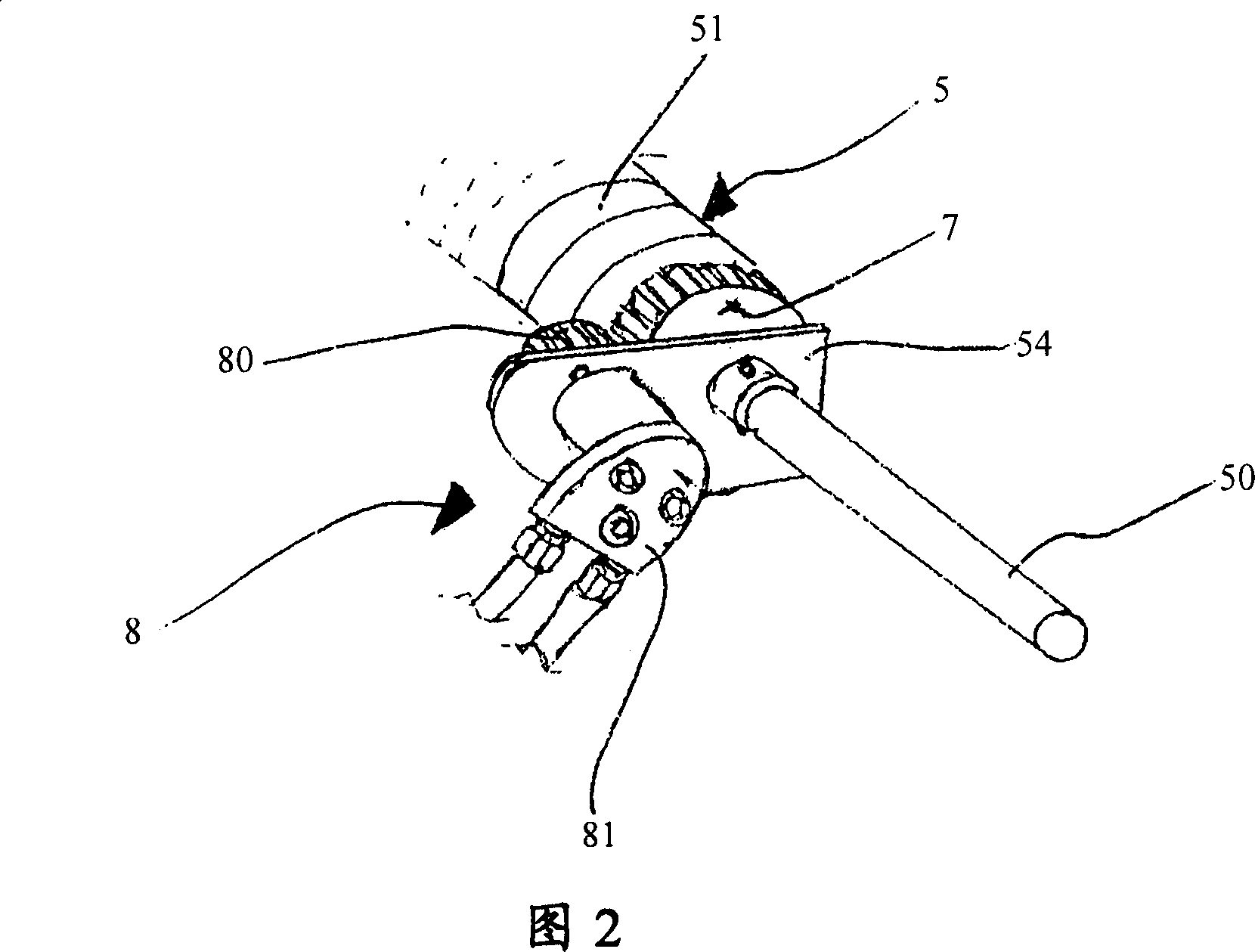

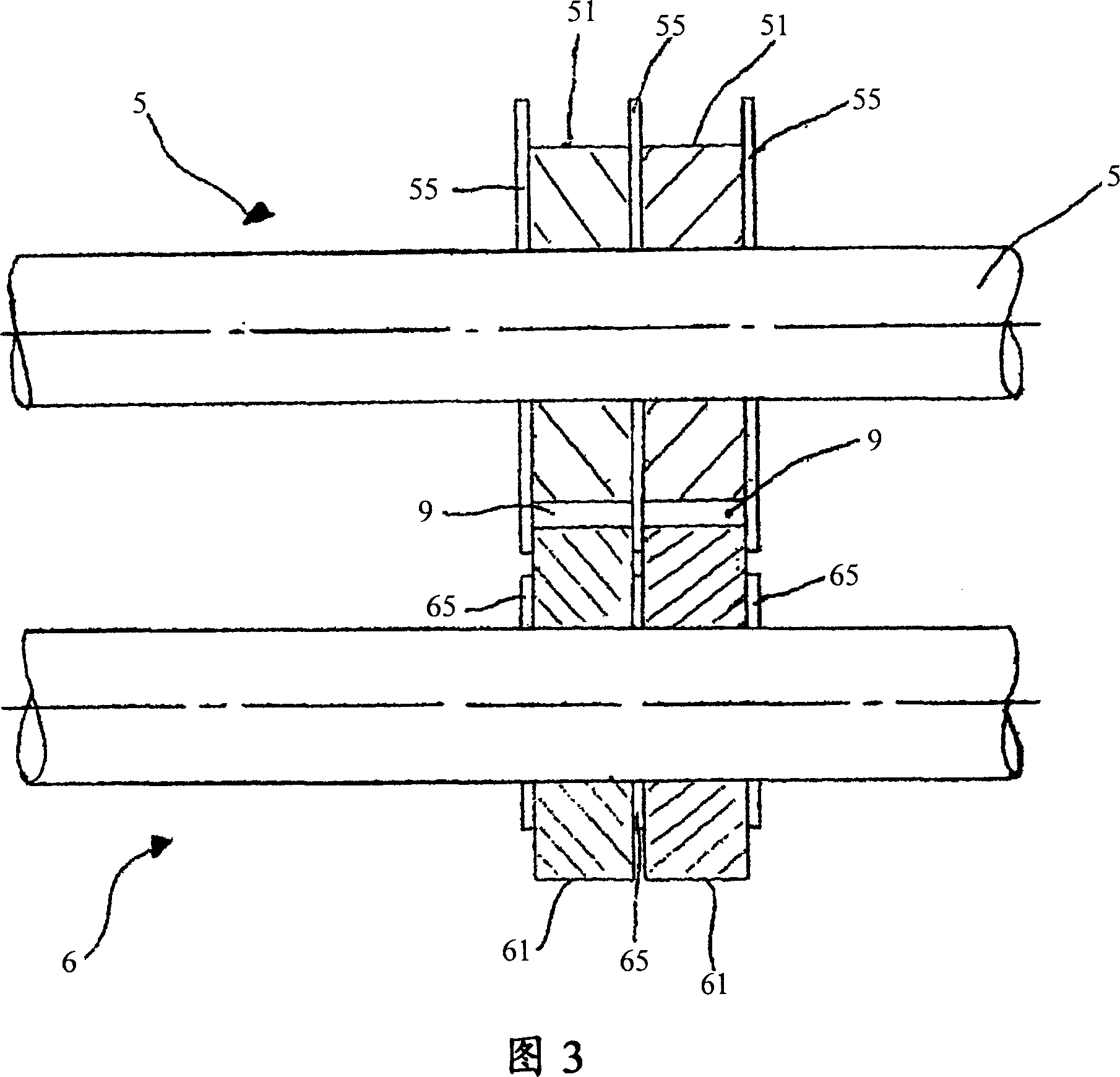

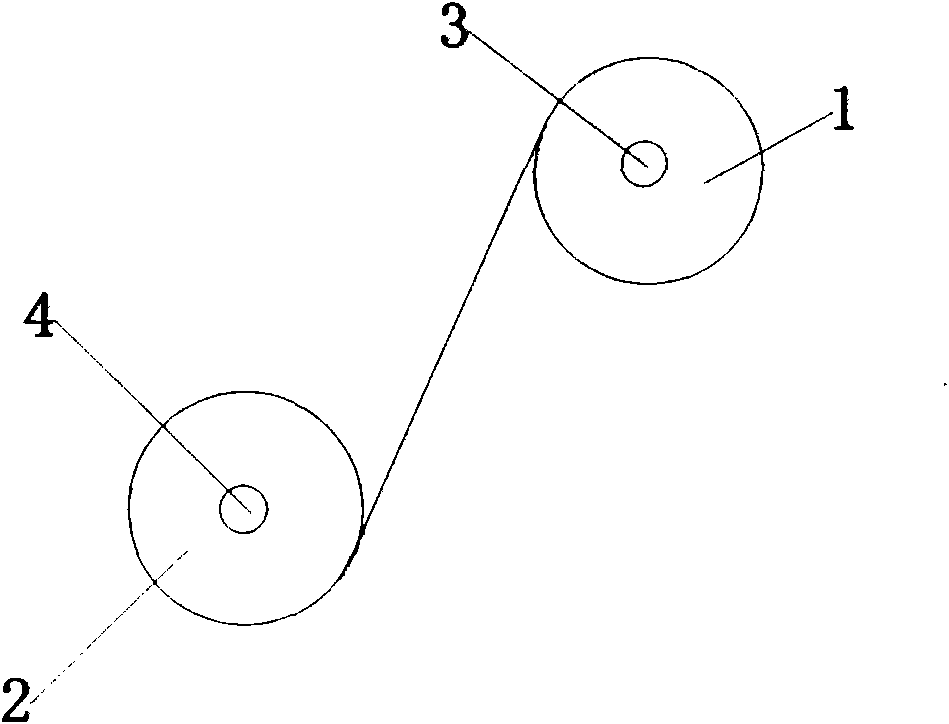

Traction device

The invention relates to a traction device (1) for straining at least a flat winding strip in a winding process. The traction device (1) comprises at least two rotary rollers (5, 6) connecting with each other through the circumference to guide the flat winding strip to pass through the rollers, wherein at least one roller (5) is connected to a motor driving system (8) for controlling roller speed, thus a predetermined tension is generated on the flat winding strip during the winding process.

Owner:NICO STEEL SOLUTION SINGAPORE

Matte glaze and production process thereof

The invention provides matte glaze and a production process thereof. The matte glaze comprises 25-30 parts of kaolin, 10-16 parts of clay, 8-12 parts of borax, 15-18 parts of matte frit, 5-8 parts ofbentonite, 3-5 parts of aluminum-magnesium hydrotalcite, 2-5 parts of kojic dipalmitate, 3-6 parts of calcium phosphate, 3-5 parts of calcium oxide and 9-12 parts of stannous chloride. The productionprocess includes: grinding, regulating glaze concentration, applying the glaze and performing oxidation firing to obtain a ceramic product with the matte glaze on the surface. The matte glaze producedaccording to the material proportion has the advantages that the glaze can be stably combined with a green body and be solidified into a polycrystalline structure during ceramic firing to achieve a matte effect, and the glaze is moderate in surface tension, smooth and mellow in surface and fine and smooth in texture. The production process is easy in temperature control, short in firing time andlow in production cost.

Owner:福建省德化县哈维陶瓷有限公司

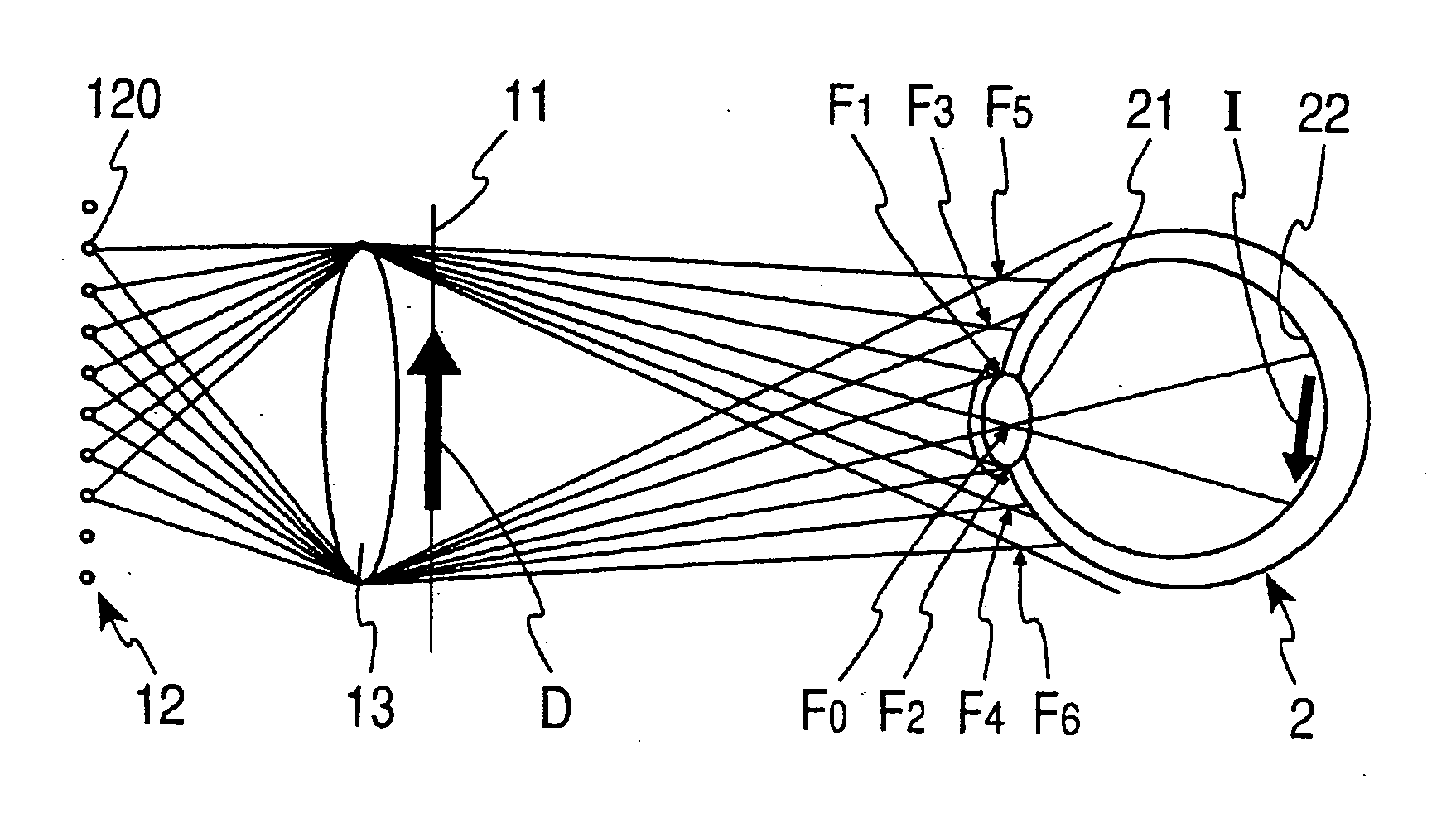

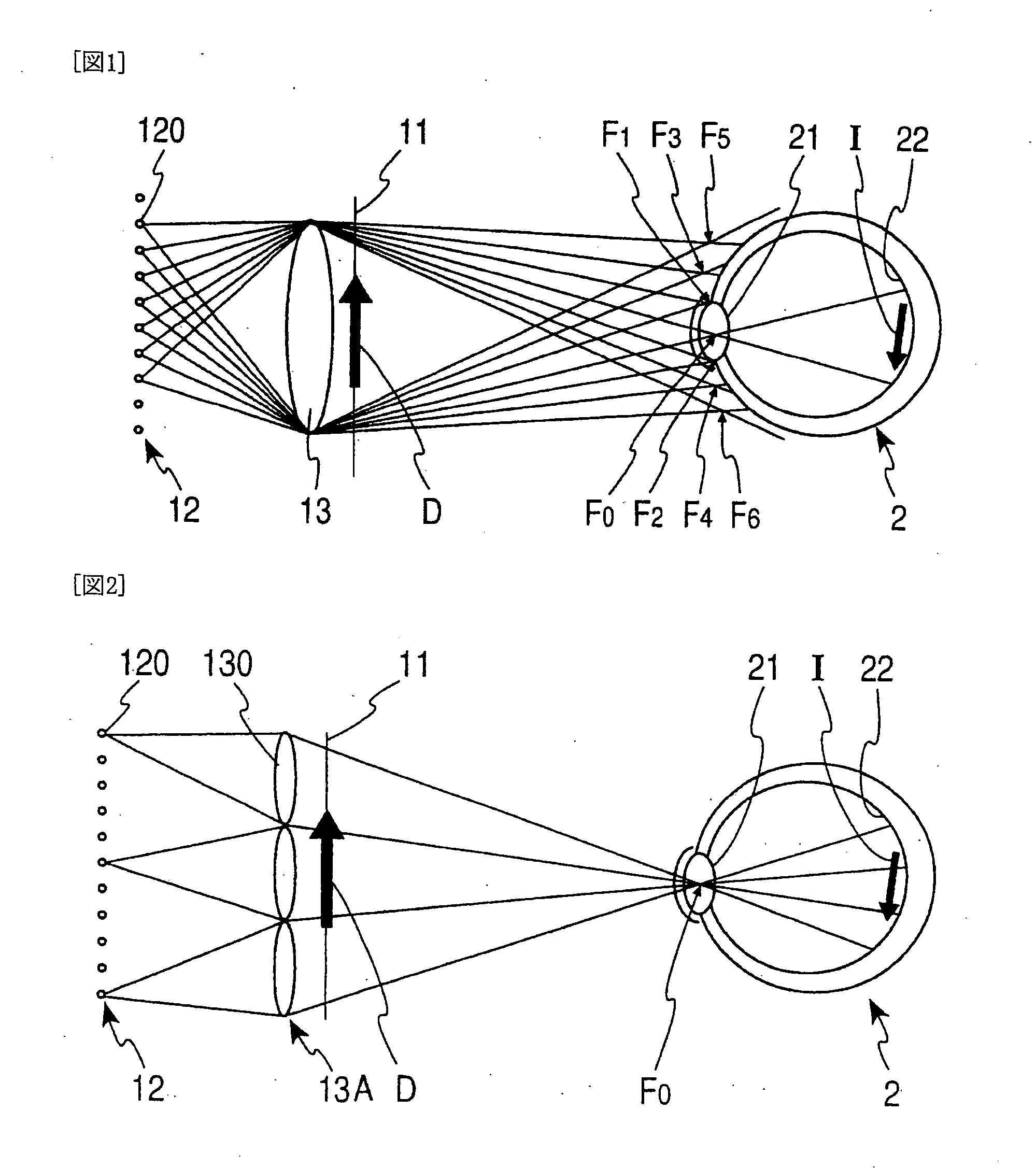

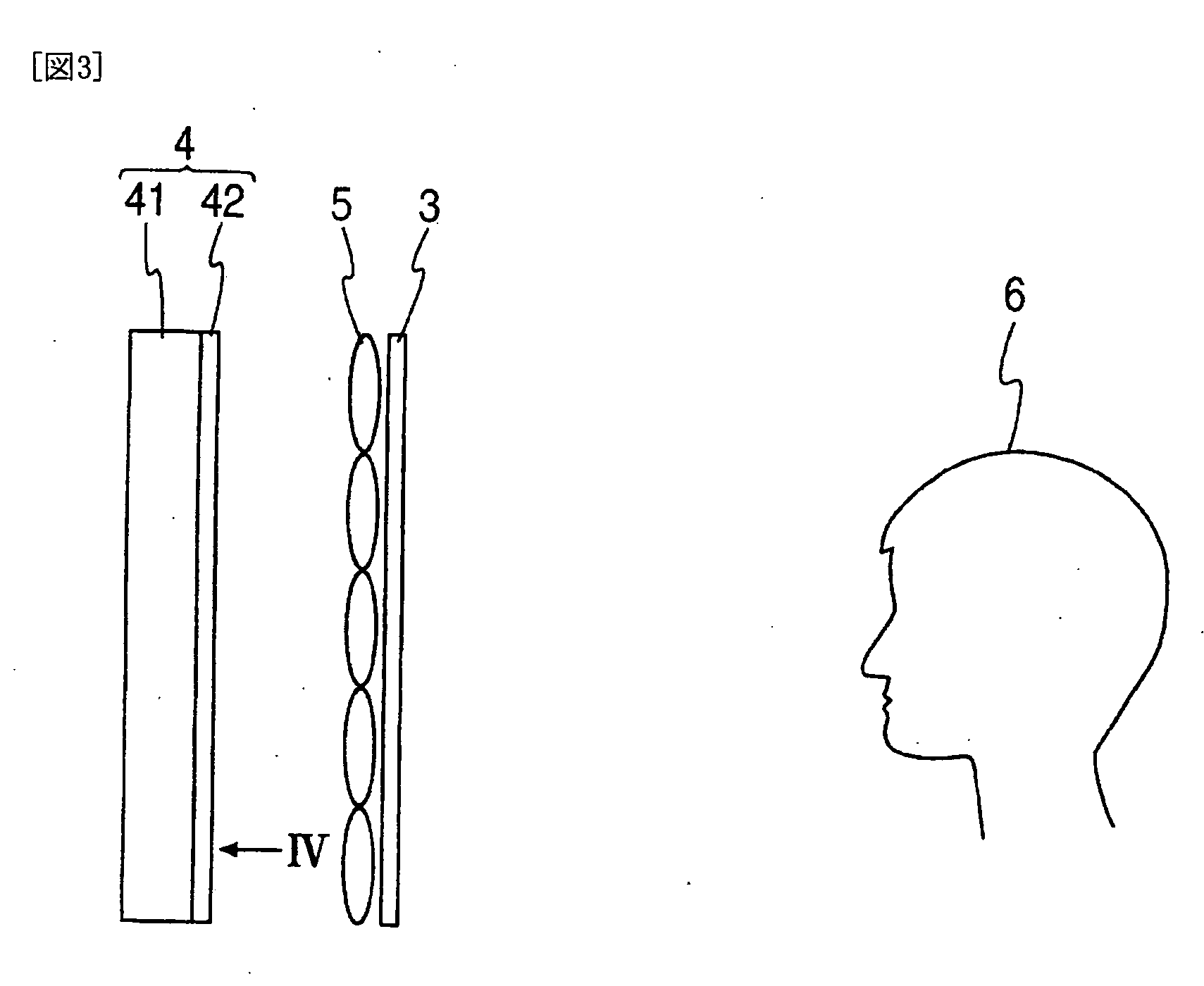

Image Display Unit

InactiveUS20070222954A1Improve observabilityImage can be preventedProjectorsOptical elementsPoint lightPupil

An image display unit provided with an image focusing member for focusing an image of a point light source on a pupil of an observer as means for projecting images displayed on a transmission type image display plate, which is capable of following the movement of the observer with a simple construction. A point light source array 12 composed of a large number of point light sources 120 which are arranged dispersedly in a plane direction in an array is provided such that the point light source 120 to be focused on the pupil shifts to its adjacent point light source 120 even when the observer moves. The ratio of the interval between adjacent point light sources 120 to the distance from the point light source array 12 to an image focusing member 13 is determined to become equal to the ratio of the diameter of a pupil of a person to the distance from the image focusing member 13 to the image focusing position of the point light source 120, thereby preventing the existence of an observation disabling area while avoiding the viewing of superimposed images.

Owner:SEA PHONE +1

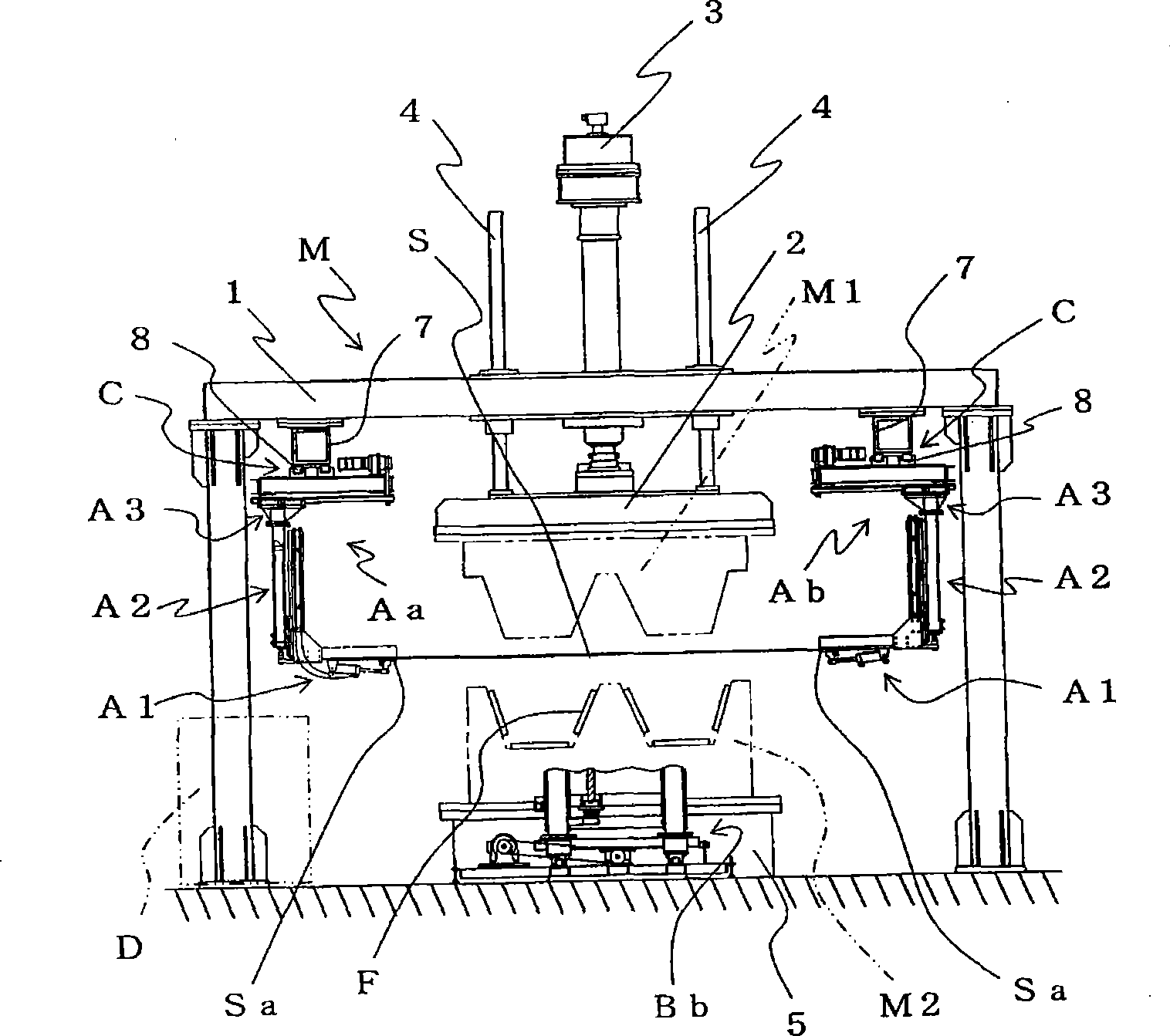

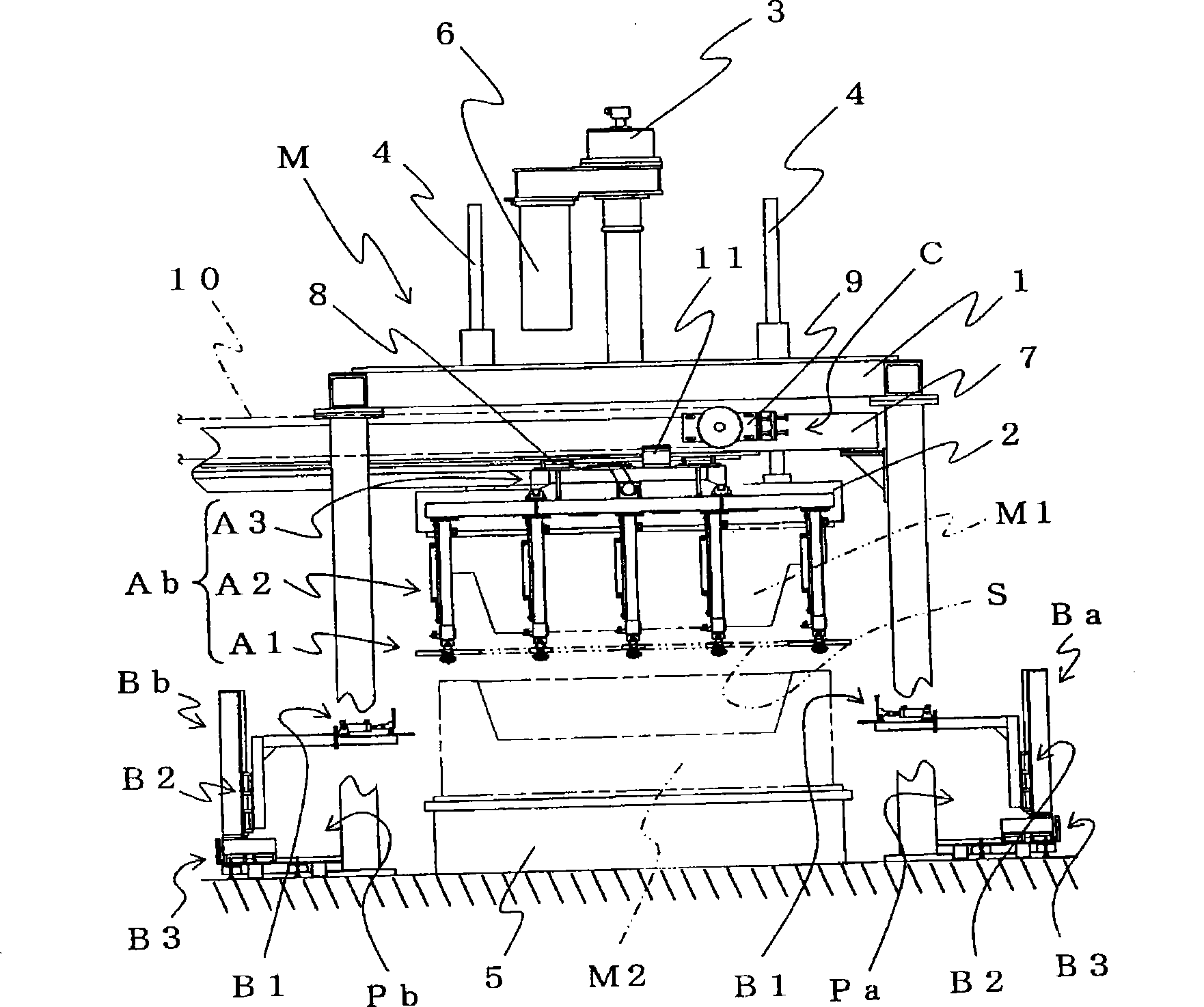

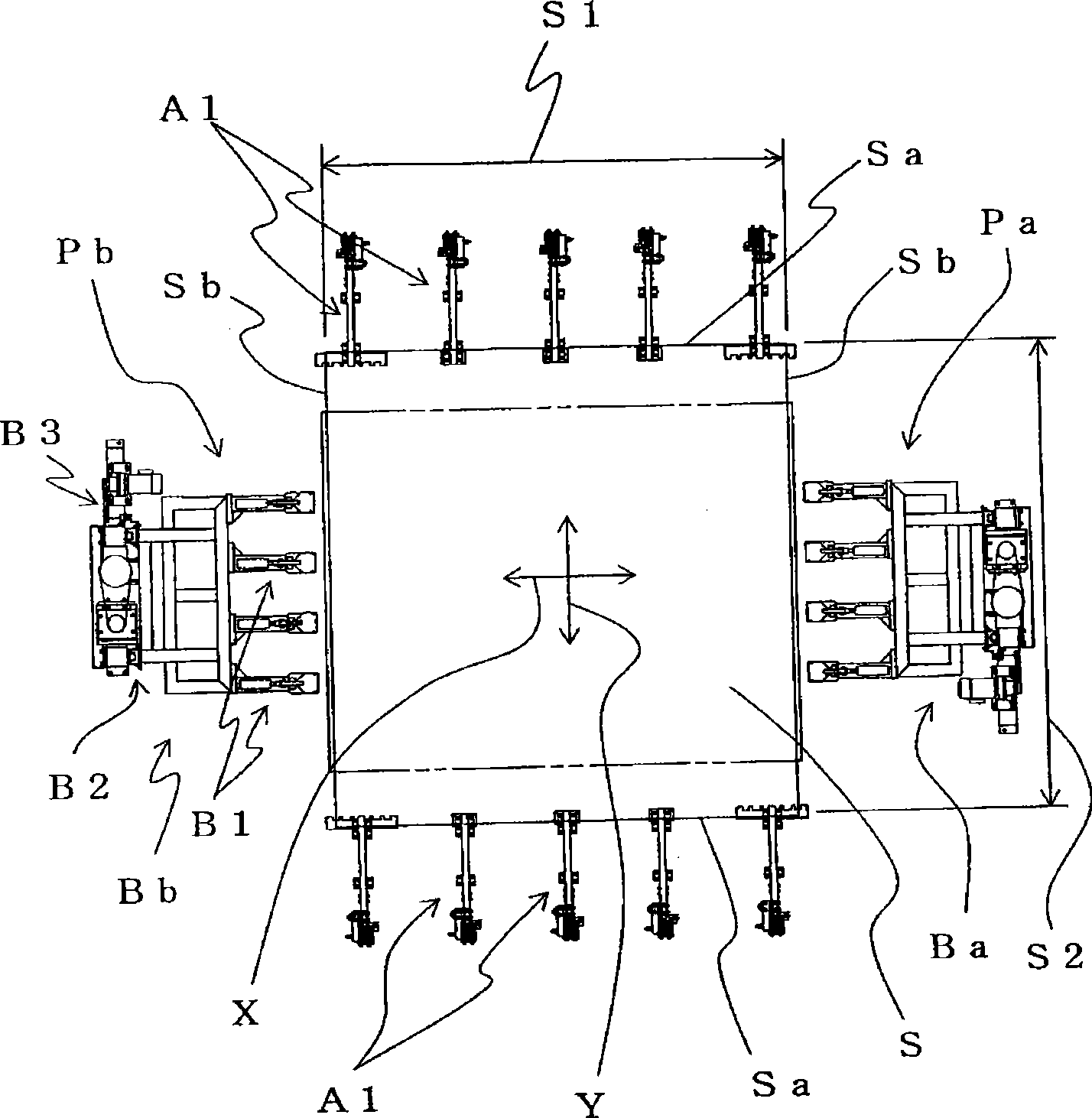

Method of clamping material and a material-clamping unit used therefor

This invention provides a method for clamping material, wherein a product that has no creases can be manufactured, even if the material has a complex shape, and the method can improve a yield of the product, and can reduce the cost of the dies. Also, the present invention provides a material-clamping unit used for the method. The method of clamping materials of the present invention is used for a forming machine that will form thermoplastic sheet material by an upper and a lower die, which sheet material is heated in advance to a predetermined temperature in heating furnace, and thus softened, comprising the steps of: holding both edges of the sides in the running direction of the thermoplastic sheet material, and then transferring the material between the upper die and the lower die of the forming machine; holding the rear and front edges of the sides of the thermoplastic sheet material, which sides are perpendicular to the running direction of the thermoplastic sheet material; and lowering the edges of the sides in the running direction of the thermoplastic sheet material and the rear and front edges of the sides of the thermoplastic sheet material, which sides are perpendicular to the running direction of the thermoplastic sheet material, so that the sheet material will fit in the upper die.

Owner:SINTOKOGIO LTD

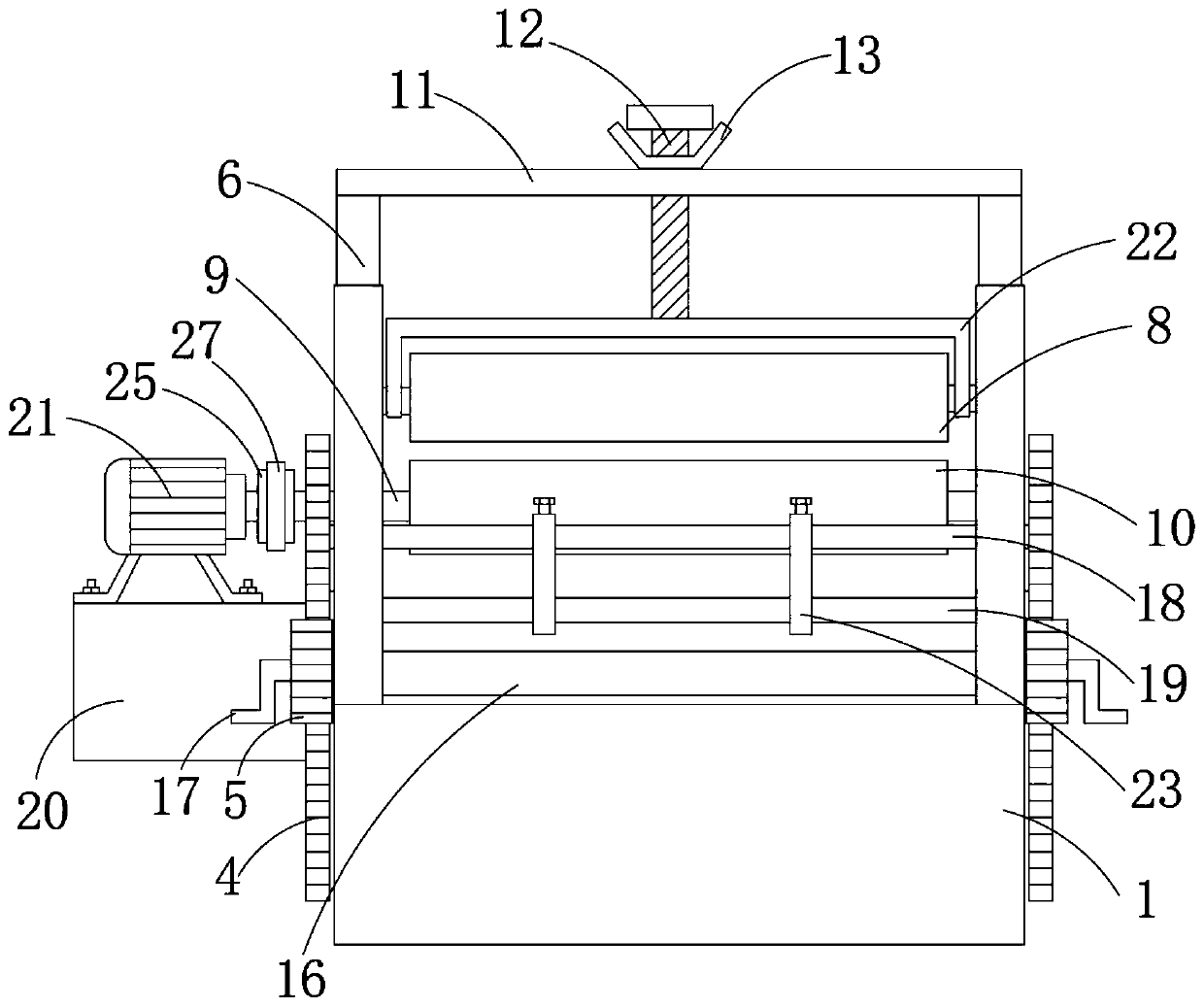

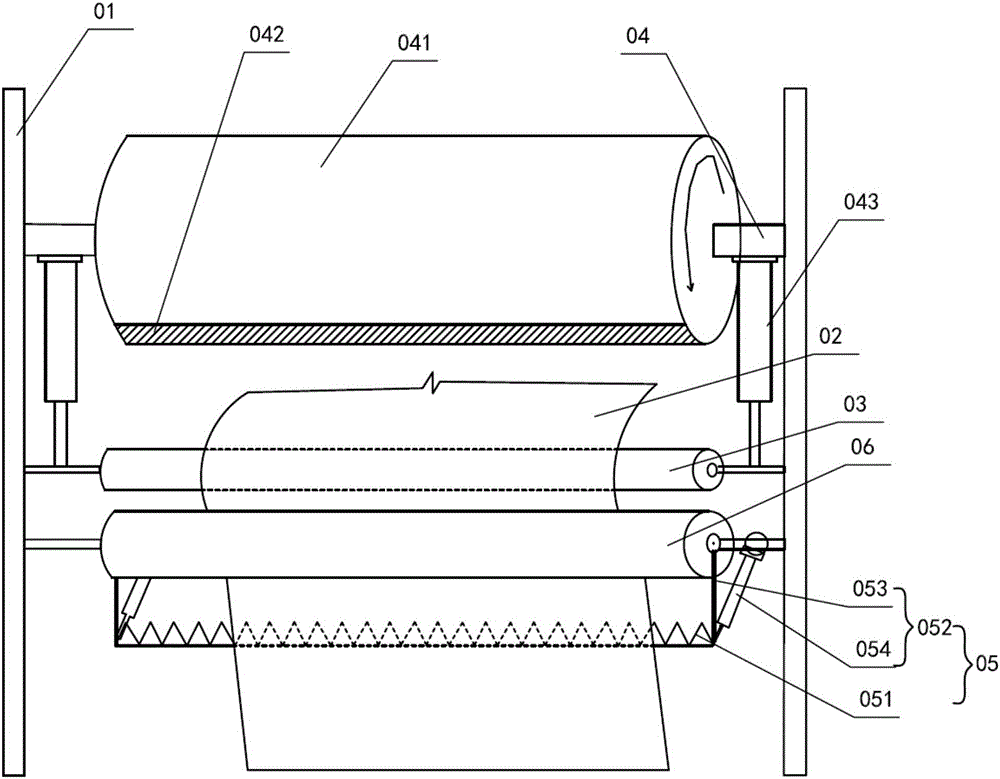

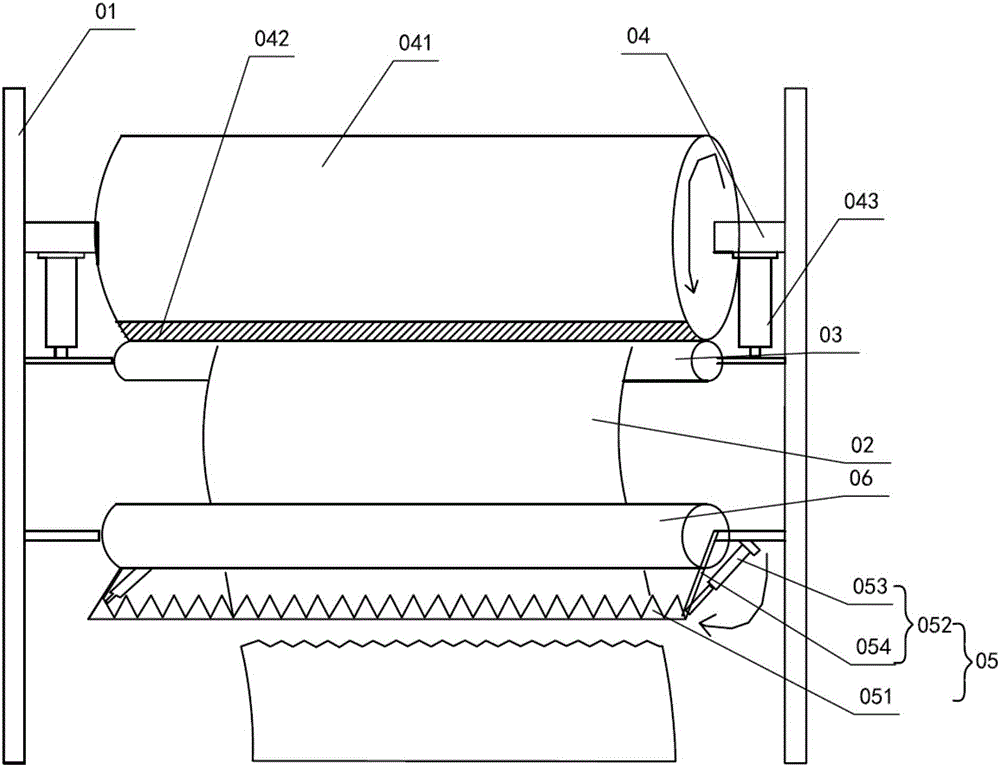

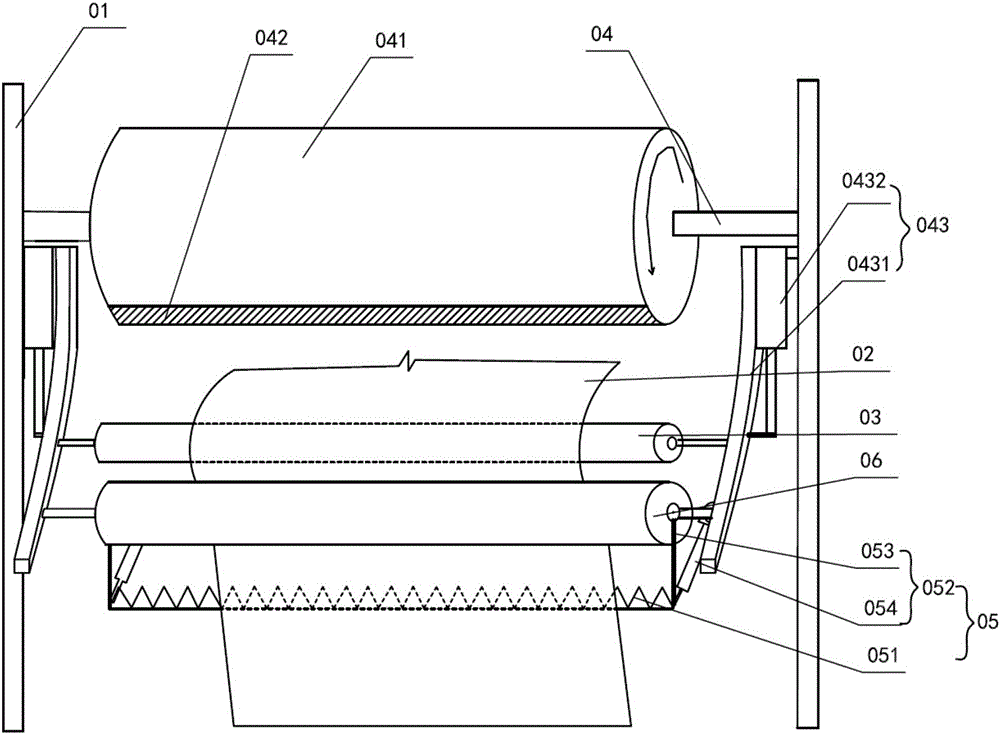

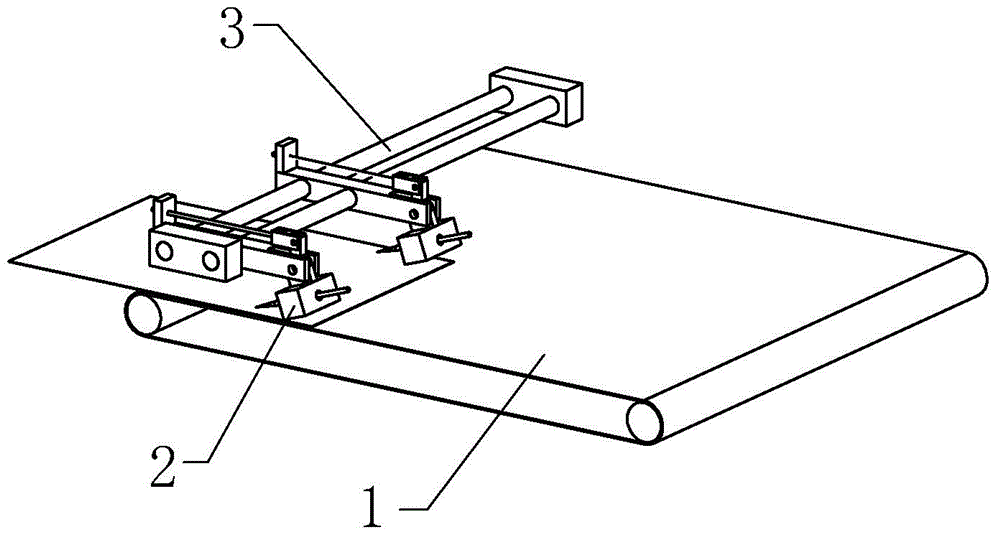

Cloth conveying and cutting integrated device used for clothes processing

InactiveCN108726235AModerate tensionReduce the risk of accidentsSevering textilesArticle deliveryDrive motorIntegrated devices

The invention discloses a cloth conveying and cutting integrated device used for clothes processing. The device comprises a workbench and a conveying assembly. The workbench comprises a workbench surface board, support columns, and two vertical boards fixed on two sides of the workbench surface board in a traverse direction. The conveying assembly comprises multiple conveying rollers and a drivingmotor used for driving all the conveying rollers to rotate. The conveying rollers are rotatably installed between the two vertical boards. The driving motor is fixed onto the bottom surface of the workbench surface board. Installation blocks used for rotatably cooperating with rolling shafts of the rollers are arranged on the vertical boards. The installation blocks are slidably installed into the vertical boards through an arc sliding which is coaxial to an output shaft of the driving motor. A first compression spring used for downwardly pressing the installation blocks is arranged in the arc groove. The cloth conveying and cutting integrated device can suitable for different thicknesses of cloth. During conveying, tension degree is moderate. There is no need for working staff to debug.The risk of accidents is reduced. Additionally, production efficiency is increased.

Owner:新诚达时装(安徽)有限公司

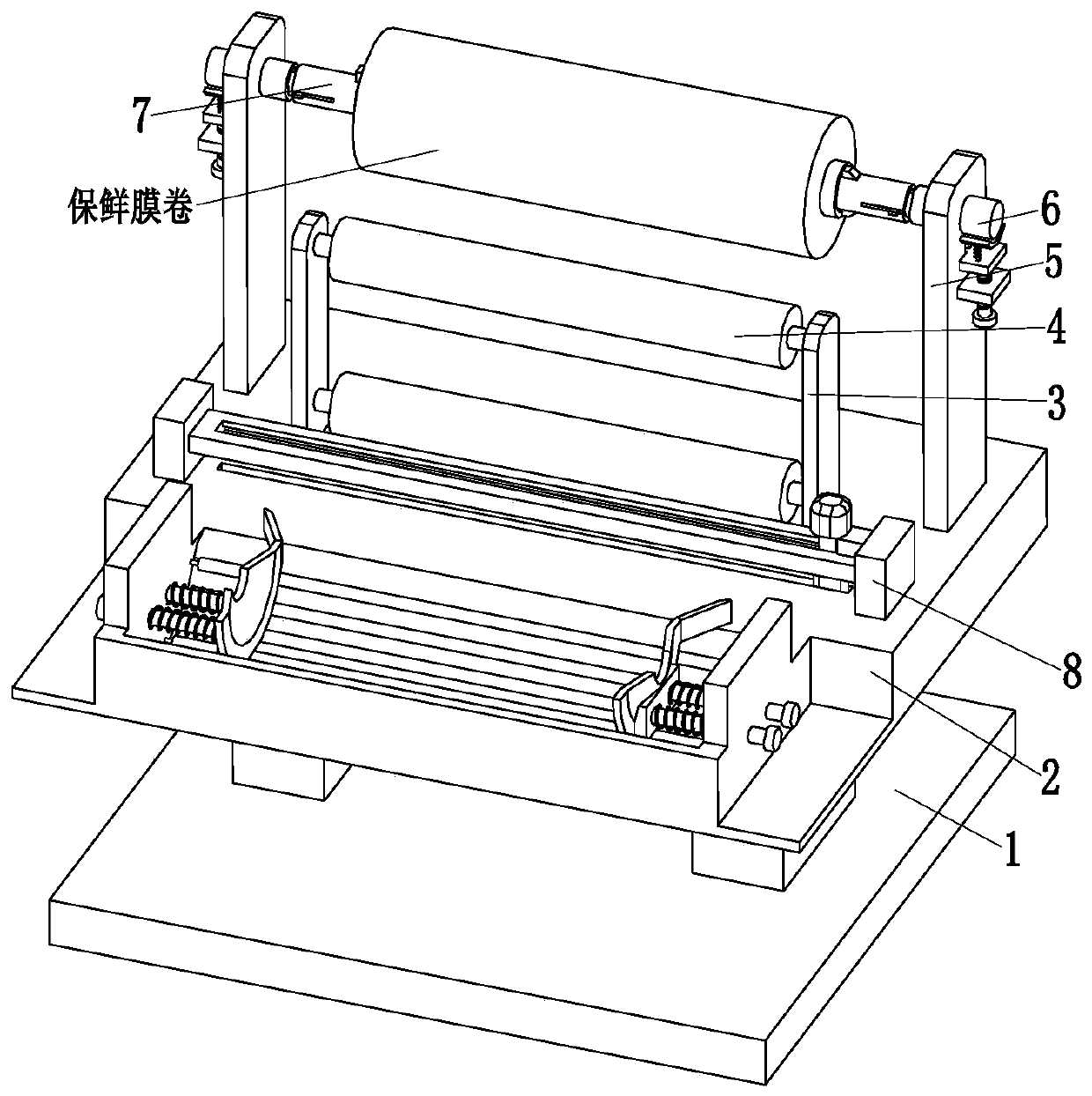

Fruit and vegetable transfer fresh-keeping packaging machine and packaging method thereof

ActiveCN111361797ATightly woundPacked tightlyWrapping material feeding apparatusPackaging fruits/vegetablesBiotechnologyEngineering

The invention relates to a fruit and vegetable transfer fresh-keeping packaging machine and a packaging method thereof. The machine comprise a base, a packaging plate, guide supporting plates, guide wheels, transmission supporting plates, speed reducing mechanisms, a connecting rod and a cutting mechanism, the packaging plate is installed on the top of the base, guide supporting plates are installed on the left side and the right side of the rear end of the packaging plate, the two guide wheels are installed between the guide supporting plates, the transmission supporting plate is distributedat the outer end of the rear side of each guide supporting plate, the speed reducing mechanism is installed on each transmission supporting plate, the connecting rod is installed between the two speedreducing mechanisms, and the cutting mechanism is installed on the top of the packaging plate. The machine and the method can solve the problems of existing fruit and vegetable packaging that when fruits and vegetables are packaged by a preservative film, the preservative film cannot be tensioned, the fruits and vegetables are not densely packaged, and the packaging effect is poor; and after thefruits and vegetables are packaged, a cutter needs to be manually taken to cut off the preservative film, and a cutting mode of the preservative film can influence the packaging efficiency of the fruits and vegetables.

Owner:山东公社联盟食品有限公司

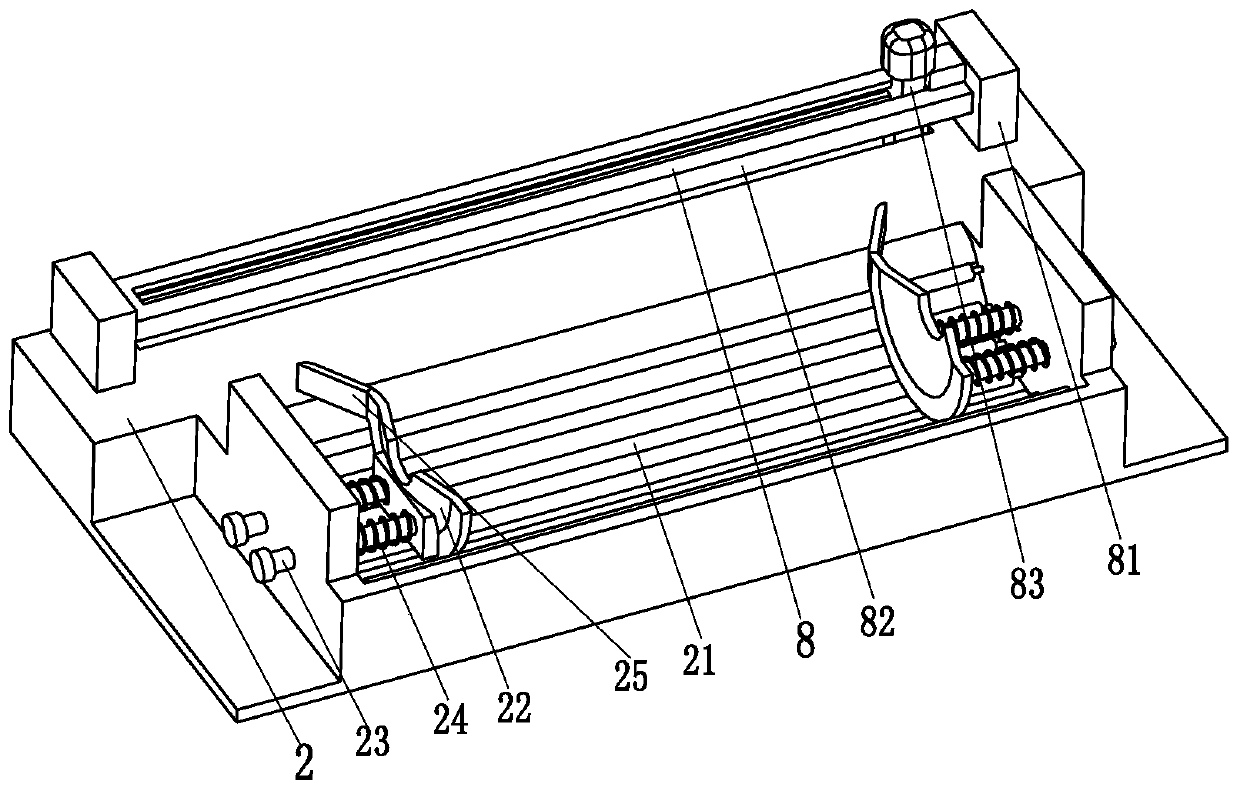

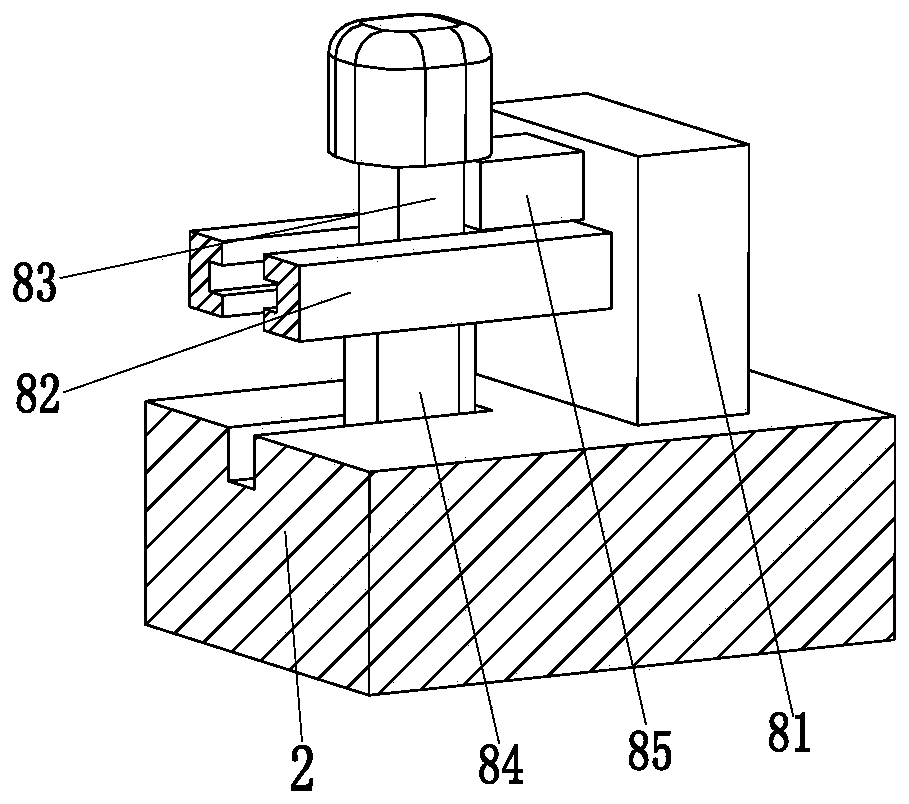

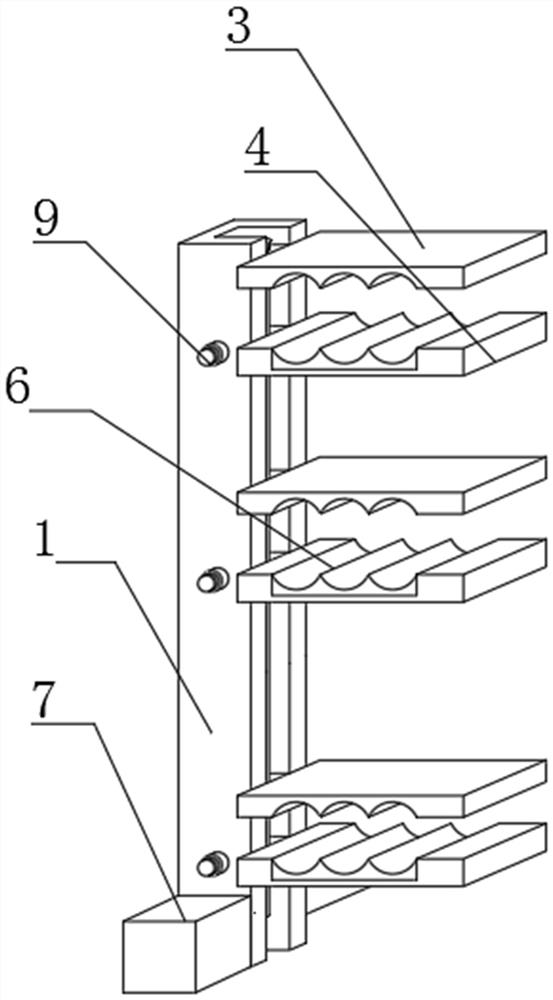

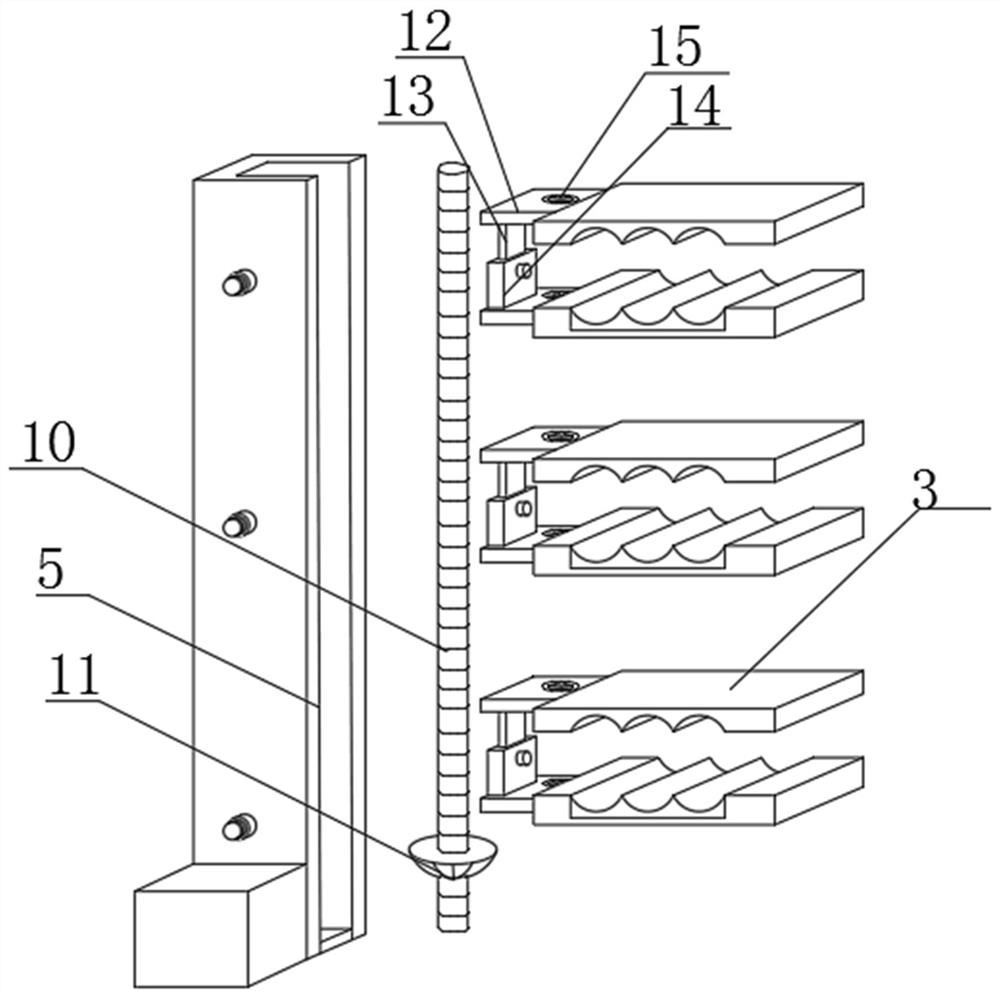

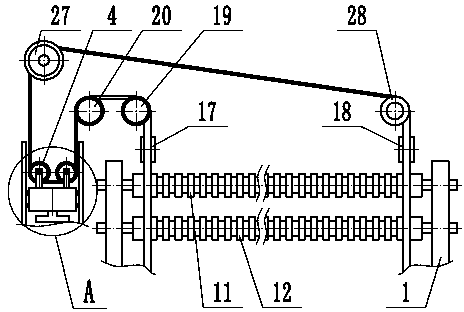

Tension-adjustable extruding and drawing device of drawing frame

The invention discloses a tension-adjustable extruding and drawing device of a drawing frame. The tension-adjustable extruding and drawing device of the drawing frame comprises a base, wherein four first fixing plates are symmetrically welded to the top end of the base; limiting grooves are separately formed in the middles of each two first fixing plates; a first connecting rod is embedded in eachlimiting groove, and toothed plates are separately welded to two ends of each first connecting rod; a second connecting rod is welded between the two toothed plates, and one end surfaces of the two toothed plates are connected with gears in an engaged manner; and a crank is welded to one end surface of each gear, and a rotating rod is arranged between the two gears. The gears, the toothed plates,the cranks, the first connecting rod and the second connecting rod are respectively arranged on the two sides of an extruding roller, so that slivers to be extruded on the two sides of the extrudingroller can be adjusted in different tensioning degrees, the tensioning degrees of the slivers to be extruded on the two sides of the extruding roller are conveniently kept moderate, the extruding effect is good, and the drawing efficiency is improved.

Owner:长兴超特纺织有限公司

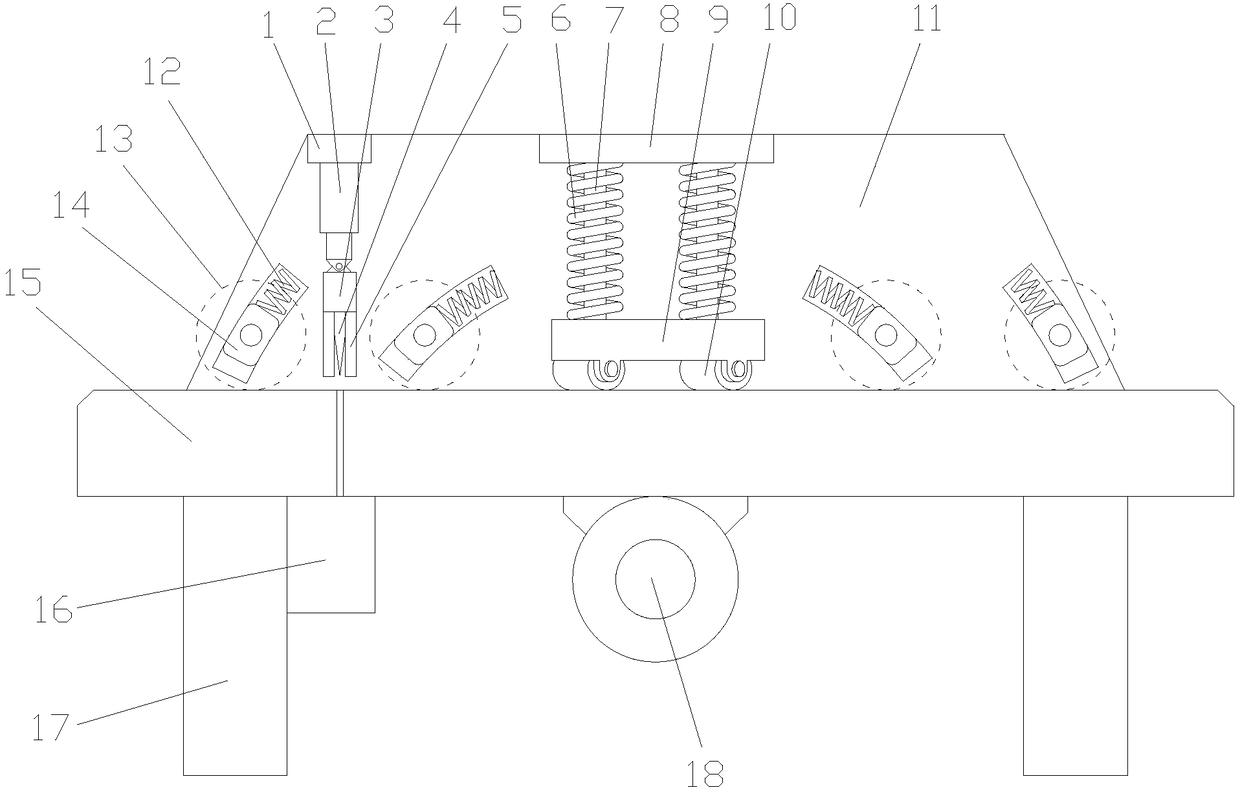

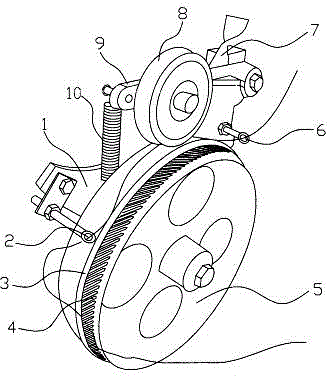

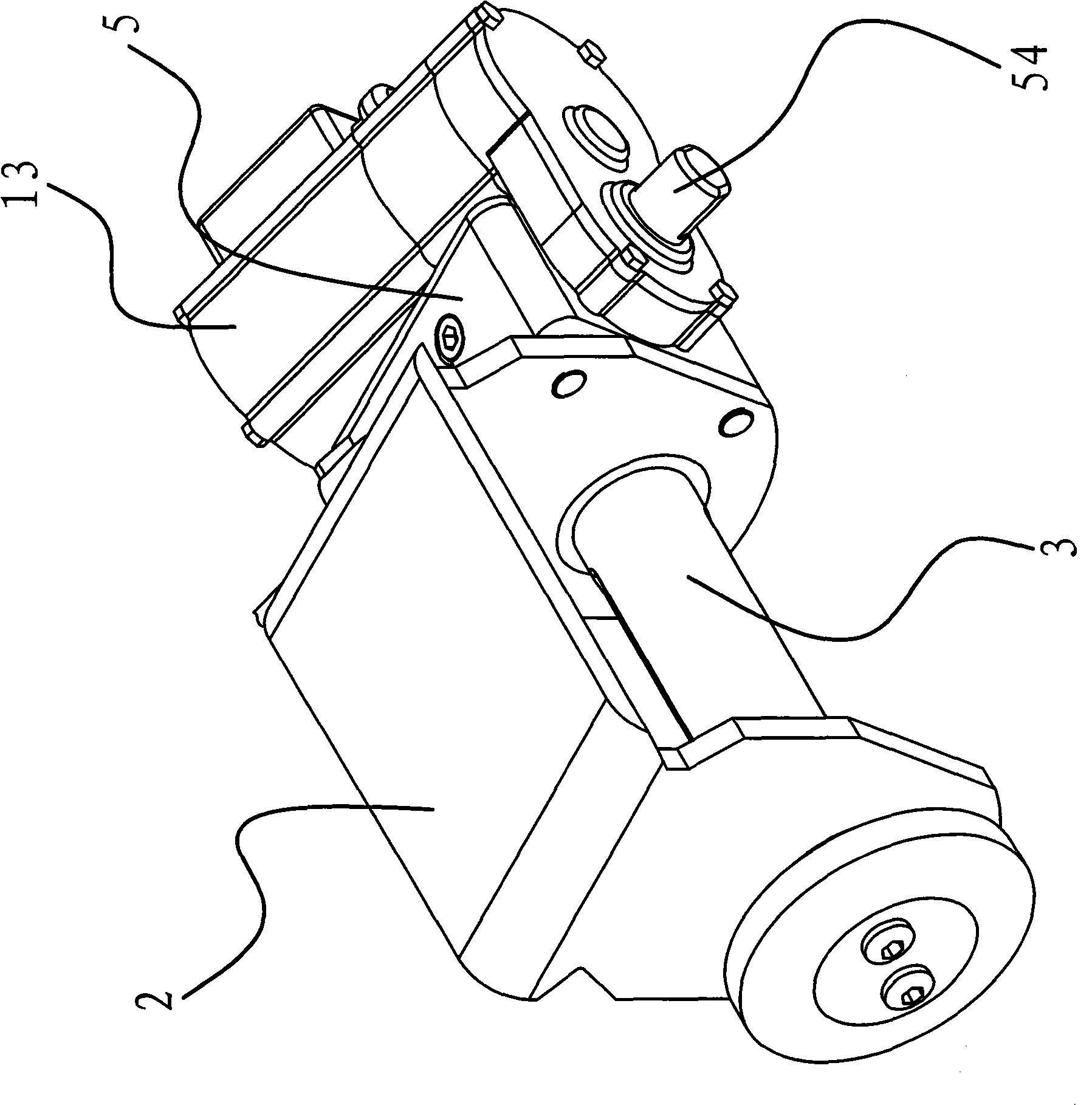

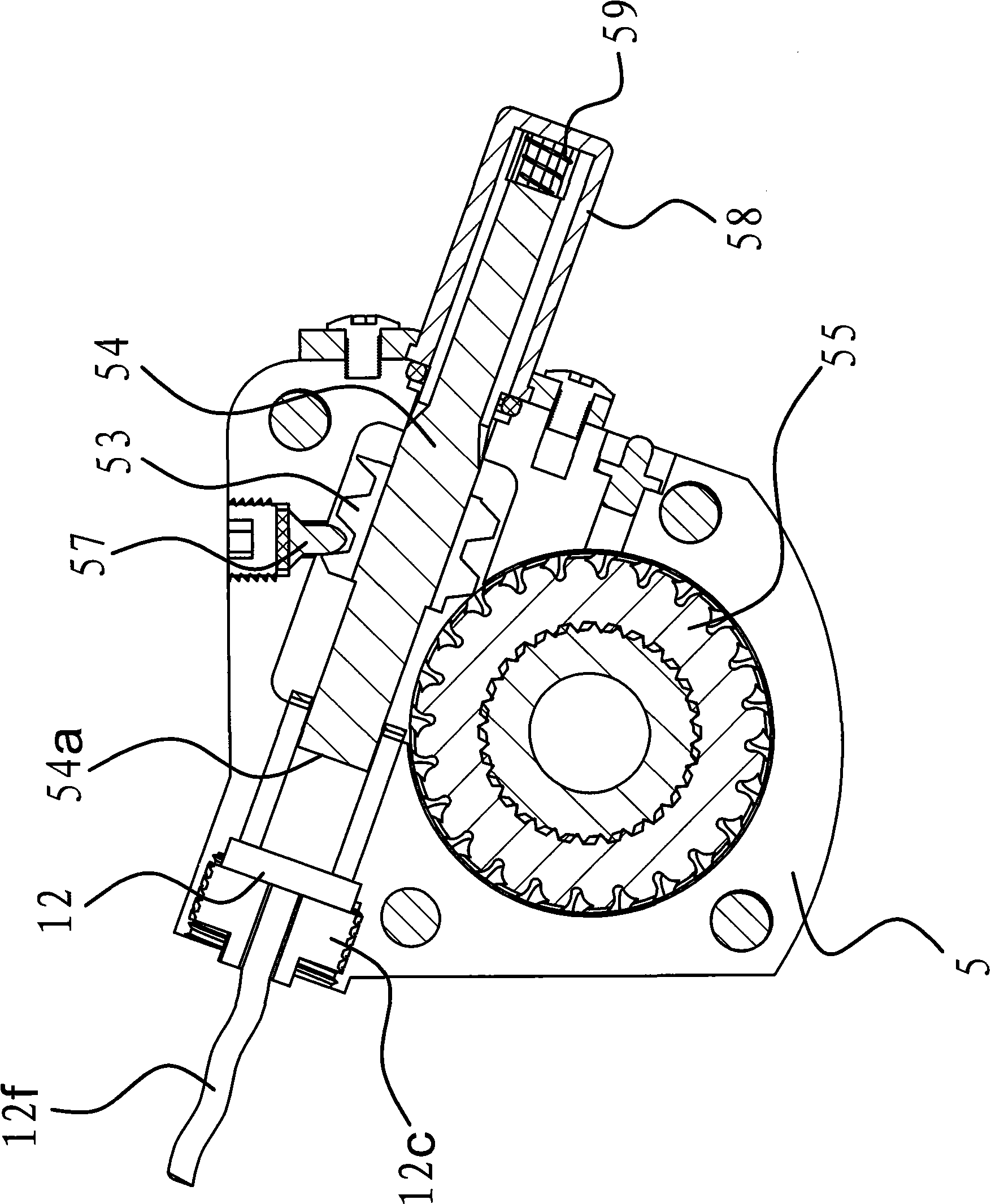

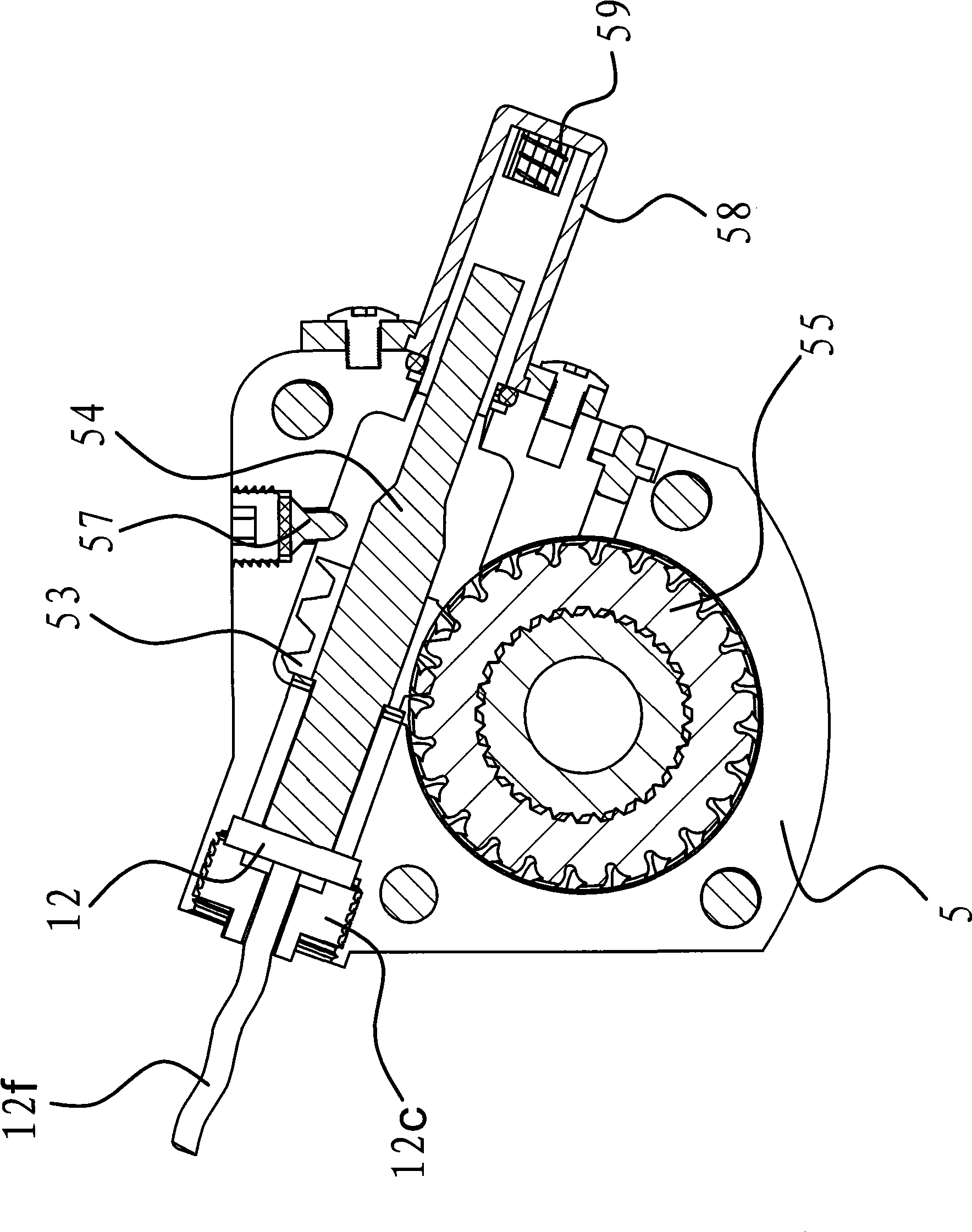

Yarn tension adjusting mechanism

The invention relates to a yarn tension adjusting mechanism. The yarn tension adjusting mechanism is characterized by comprising a body, a yarn outgoing guide hole, a yarn incoming guide hole, a yarn bearing wheel, a ratchet sleeve, an adjusting rod, an adjusting rotary arm, a compression wheel and a spring, wherein the yarn outgoing guide hole is fixedly formed in one side of the body, the yarn incoming guide hole is fixedly formed in the other side of the body, the yarn bearing wheel is rotationally installed on the body, the yarn bearing wheel is sleeved with the ratchet sleeve provided with a plurality of ratchets, the adjusting rod is rotationally installed on the body, the adjusting rotary arm is rotationally installed on the body, the compression wheel is rotationally installed at the free end of the adjusting rotary arm, the spring is tensioned between the body and the adjusting rotary arm, and the yarn breakage detection device is arranged on the yarn bearing wheel. The yarn tension adjusting mechanism is simple in structure and easy and convenient to use, the produced yarn is moderate in tension, the yarn can enter a weaving machine at gentle and stable speed, and the yarn tension adjusting mechanism well meets the requirement for textile industry production, and has the quite positive significance.

Owner:新昌县凯杰机械有限公司

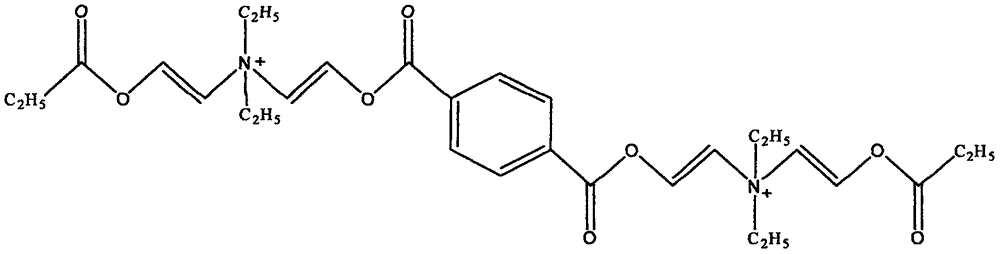

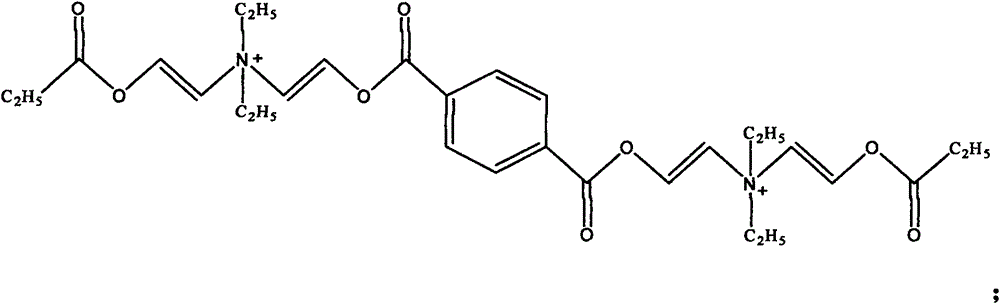

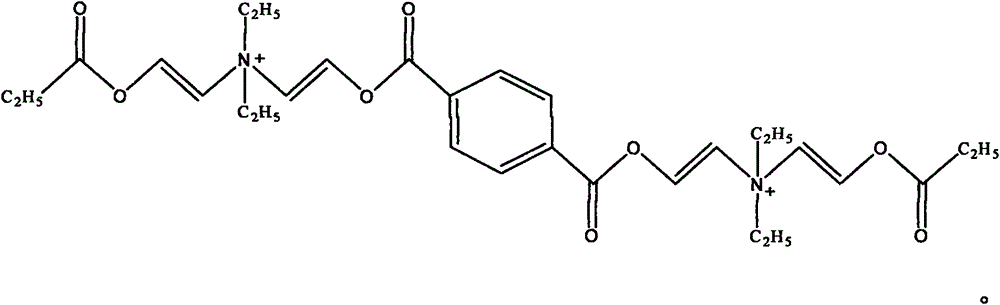

Splash-proof foam agent based on Gemini quaternary ammonium salt surfactant and preparation method for same

ActiveCN105903404AModerate surface tensionModerate tensionOrganic chemistryTransportation and packagingAnti bacterialSewage

The invention discloses a splash-proof foam agent based on a Gemini quaternary ammonium salt surfactant and a preparation method for the same. The splash-proof foam agent includes a surfactant, a foam stabilizer, a thickener, an emulsifier, a pushing agent, a sterilization cleaning agent and deionized water. The invention also discloses preparation methods for the Gemini quaternary ammonium salt surfactant and the splash-proof foam agent. The Gemini quaternary ammonium salt surfactant can stabilize foams and maintain a proper surface tension and certain strength of the foams, and also reduces the use amount of the foaming agent in the splash-proof foam agent without reduction on generation quantity of the foams. The splash-proof foam agent based on the Gemini quaternary ammonium salt surfactant can completely prevent water splashing generated when sewage falls into a collection container, and also has the effects of deodorization and is anti-bacterial. The splash-proof foam agent is suitable for large-scale promotion.

Owner:张放

Soft and elastic coat

InactiveCN102160691AModerate tensionNo burdenGarment special featuresWeft knittingPhysical medicine and rehabilitationExercise time

The invention discloses a soft and elastic coat. When the elastic coat is not worn with the naturally tensionless state, the part, more than 70% of body girth, consists of elastic weft-knitting fabric; when the elastic weft-knitting fabric is in the 30-80% extension range, the tight index is below 0.8, and the restoring stress is 0.3-1.3N. When the elastic coat is worn for exercise with the exercise intensity of being below 1Mets, the exercise time of being below 6 hours and the amount of body exercise of being below 25Mets. hr, the respiratory quotient is below 1.05. When the elastic coat is worn with the state of no action, the clothes pressure is below 0.6kPa, and when the elastic coat is worn with the state of motion, the clothes pressure is below 2.5kPa.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

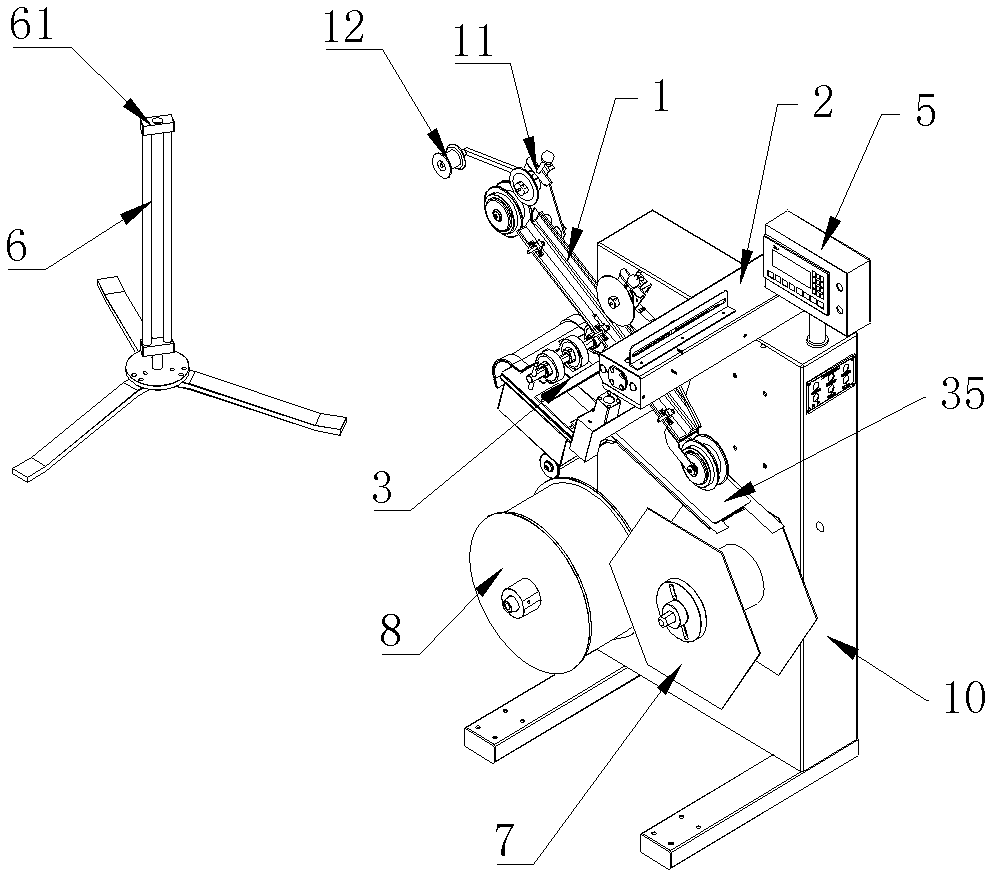

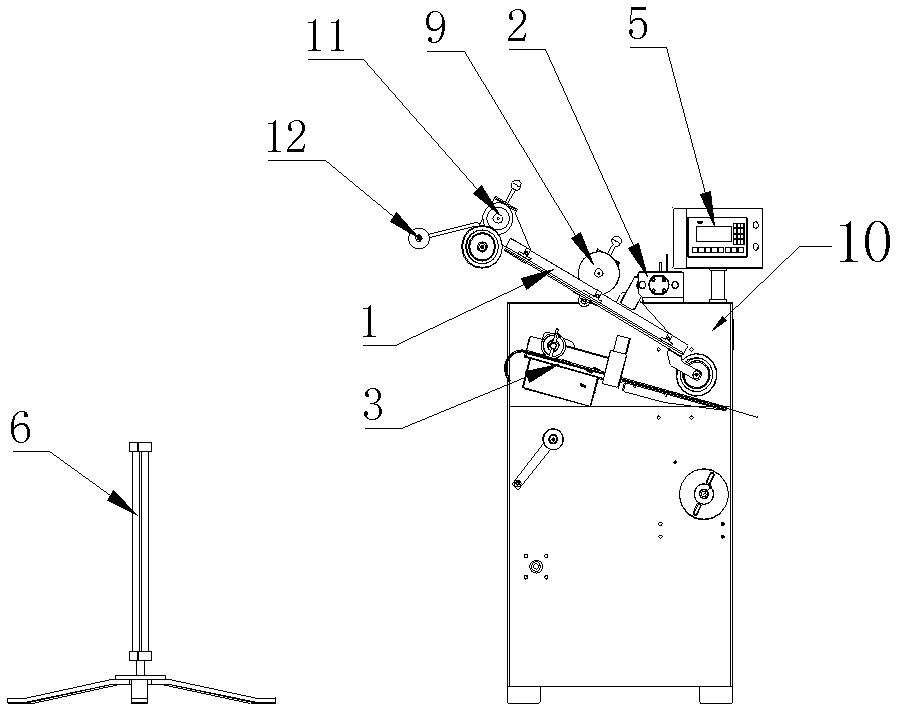

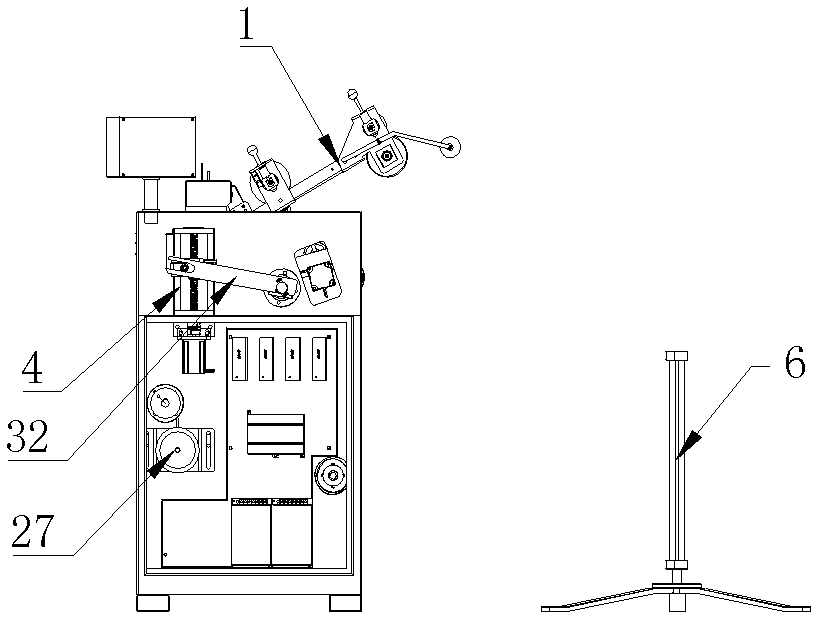

Metal terminal rolling and packaging machine

ActiveCN102431666AHigh control precisionEasy to operateConveyor wrappingPackaging automatic controlControl signalControl system

The invention discloses a metal terminal rolling and packaging machine, comprising a host machine. The host machine comprises a case, a material guiding device, a material discharging device, a packaging device and a control system, wherein a slipway for conveying a metal terminal string and a count detection device are arranged on the material guiding device; the material discharging device comprises a material discharging pedestal; a material discharging step motor is fixed on the material discharging pedestal; the material discharging step motor is connected with a material discharging ball screw; a material discharging slide block is screwed to the material discharging ball screw and fixed with the material guiding device; the packaging device consists of a paper releasing device, a paper conveying device and a rolling device arranged at the front side of the case respectively; a cutter device is arranged on the paper conveying device; the control system obtains the number of rolled metal terminals according to rotation turns of a counting wheel disc, and outputs a corresponding control signal according to the rolled number to control the operations of the material discharging device and the packaging device. with the adoption of the metal terminal rolling and packaging machine, the integration of packaging and rolling of the metal terminal is realized, the control precision is high, the operation is simple, discharging is uniform and tension is moderate, therefore, the production efficiency is improved and labor is saved.

Owner:浙江珠城科技股份有限公司

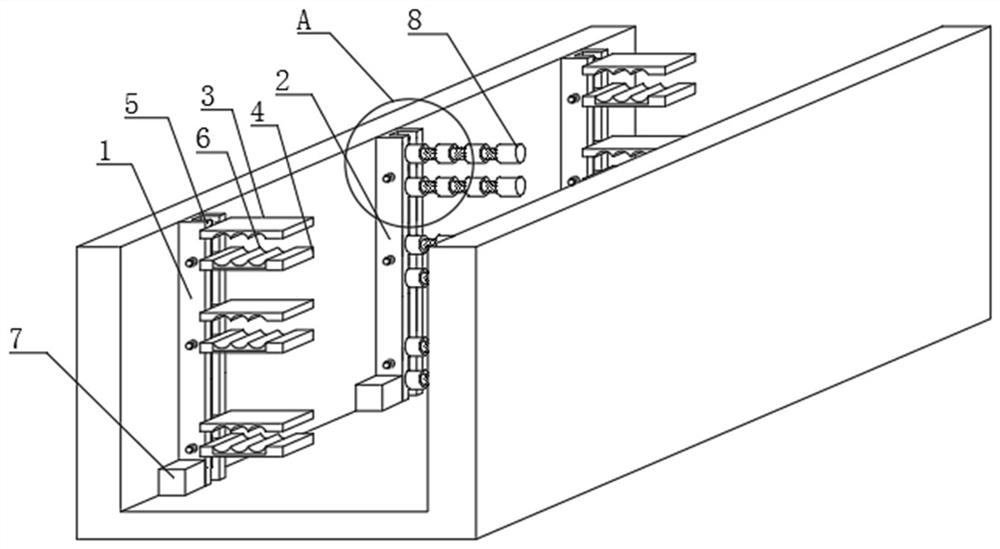

Cable laying frame for mining machinery and using method thereof

InactiveCN112653065ASave handling and installation timeGood practicalityCable installations on groundApparatus for laying cablesDrive motorEngineering

The invention discloses a cable laying frame for mining machinery and a using method thereof. The cable laying frame comprises a first supporting frame and a second supporting frame which are fixedly installed on the inner edge of a mine roadway, the first supporting frame and the second supporting frame are arranged in a crossed mode, and an upper clamping plate and a lower clamping plate are slidably connected to the outer surface of the first supporting frame; driving motors are fixedly mounted on the side faces of the first supporting frame and the second supporting frame correspondingly, and a flexible pad is fixedly mounted on the side, facing the upper clamping plate, of the lower clamping plate. According to the cable laying frame for the mining machinery and the using method thereof, the first supporting frame and the second supporting frame which are arranged on the side face of the mine roadway are used in cooperation, and the outer surfaces of multiple strands of cables are clamped in the clamping grooves between the upper clamping plate and the lower clamping plate; therefore, a plurality of layers and strands of cables can be quickly fixed on the laying frame from the upper side of the roadway, the cables do not need to be transported into the roadway and then lifted to the laying frame, and a large amount of carrying and mounting time is saved.

Owner:安徽宇艳智能机械科技有限公司

Slitting device of wool comber

The invention provides a slitting device of a wool comber and belongs to the technical field of textile machines. The slitting device of the wool comber comprises a web conveying mechanism, a slitting mechanism and a tension mechanism, wherein an upper web conveying roller and a lower web conveying roller of the web conveying mechanism are vertically adjacent but do not make contact with each other; a slitting roller of the slitting mechanism is provided with first slitting notches at equal intervals; a first guide roller, a second guide roller and a third guide roller are each provided with second slitting notches at equal intervals; an adjusting roller is a smooth roller; the tension mechanism comprises a tension wheel, an adjusting weight and a fixed sliding groove; a bracket is arranged in the fixed sliding groove in a vertically sliding mode through a pulley; the adjusting weight is arranged below the bracket; a belt is arranged among the slitting mechanism, a first supporting wheel, a second supporting wheel, the tension wheel, a left guide wheel and a right guide wheel in a closed slitting and surrounding mode. Only one belt is adopted for slitting, the uniformity of slitting a web into wool tops is greatly improved, and the quality of the wool tops is improved effectively.

Owner:JIANGSU ZHENGTAI PHARMA CHEM

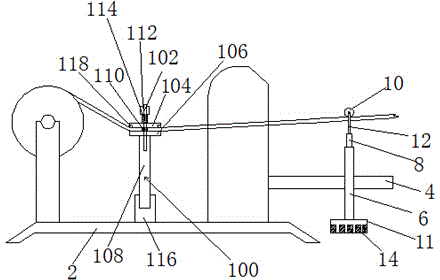

Braid production equipment

InactiveCN104805570AModerate tensionSimple structureSmallware loomsEngineeringMechanical engineering

The invention discloses braid production equipment. The equipment comprises a frame (2), wherein a horizontal supporting plate (4) is fixedly arranged on the frame (2); a straight rod (6) vertically penetrates through the supporting plate (4) and is capable of moving vertically; the top end of the straight rod (6) is connected with a tension spring (8); a rotatable pull rod (10) is arranged above the tension spring (8); the two ends of the pull rod (10) are respectively connected with the tension spring (8) by a pull rope (12); the bottom end of the straight rod (6) is fixedly connected with a box body (11); a plurality of weight blocks (14) are arranged in the box body (11). The braid production equipment disclosed by the invention can be used for enabling a braid to have a relatively suitable tensile force during production and is also simple and practical in structure and convenient to use.

Owner:SUZHOU SHENGDA RIBBON

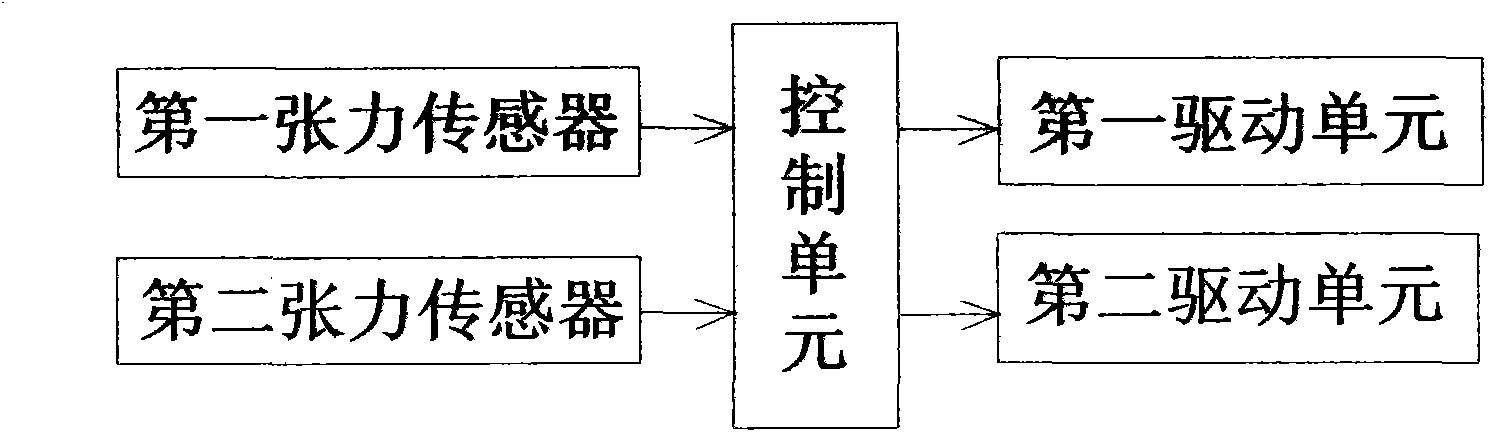

Cloth tension control device

The invention relates to a cloth tension control device. Cloth to be reeled bypasses a first roller and then is collected to a second roller. The cloth tension control device is characterized by comprising a control unit, a first tension sensor, a second tension sensor, a first driving unit and a second driving unit, wherein the first tension sensor and the second tension sensor are electrically connected with the control unit and are arranged on the first and second rollers respectively; the first and second driving units are used for driving the first roller and the second roller respectively; and the control unit is electrically connected with the first and second driving unit. In the tension control device, the first and second tension sensors are used for acquiring tension on the two rollers of a cloth collection device and transmitting the tension to the control unit, and the control unit is used for adjusting the rotating speed of a corresponding roller according to the magnitude of the tension on the two rollers, so that the cloth to be reeled keeps appropriate tension; therefore, process efficiency and the quality of finished cloth are improved.

Owner:JIANGSU SHENGFANG NANO MATERIAL TECH CO LTD

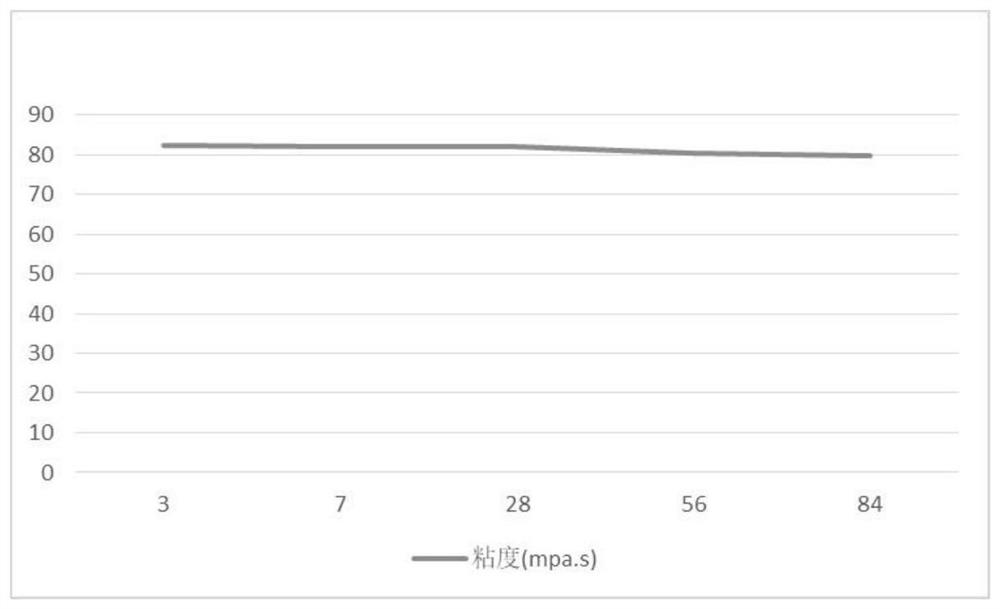

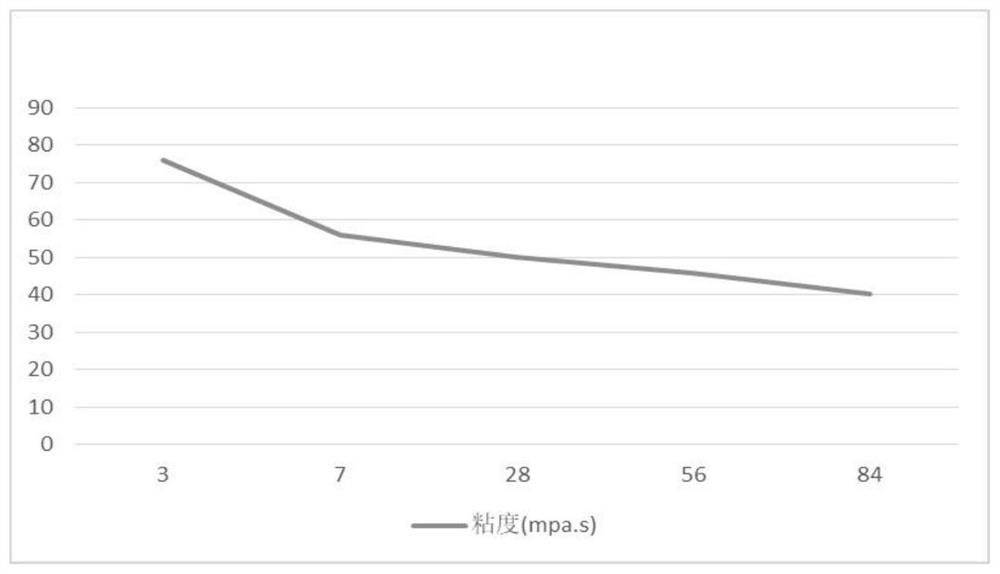

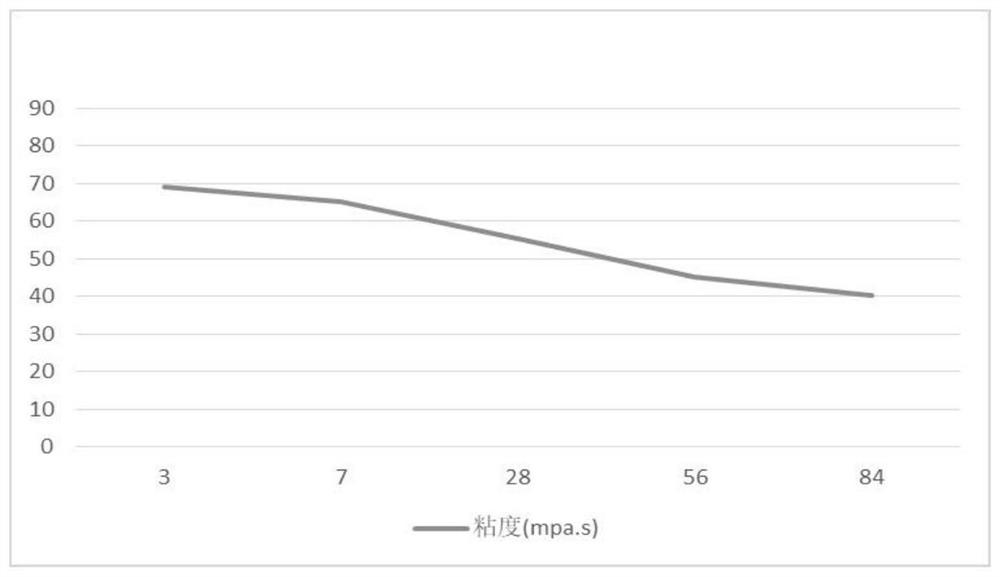

Pearlescent liquid eyeliner and preparation method thereof

ActiveCN111870563AImprove stabilityImprove permeabilityCosmetic preparationsMake-upInorganic saltsFilm-forming agent

The invention provides a pearlescent liquid eyeliner and a preparation method thereof, and belongs to the field of cosmetics. The raw materials of the pearlescent liquid eyeliner comprise the following components in parts by weight: 3-6 parts of a wetting agent, 2-30 parts of a solvent, 0.5-2 part of a dispersing agent, 20-45 parts of a thickening suspending agent, 1-8 parts of a pearling agent, 3-8 parts of a coloring agent, 0.5-1 part of a sterilizing agent, and 40-60 parts of a film forming agent, wherein the thickening suspending agent comprises an inorganic salt thickening agent and a polysaccharide thickening agent. The pearlescent liquid eyeliner provided by the invention has good centrifugal stability and high-temperature storage stability, and is moderate in viscosity and tension,relatively good in material permeability and smooth in liquid discharge, so that the pearlescent liquid eyeliner can be uniformly and continuously mixed with water in a liquid pen and is uniform in color saturation.

Owner:宁波爱诗化妆品有限公司

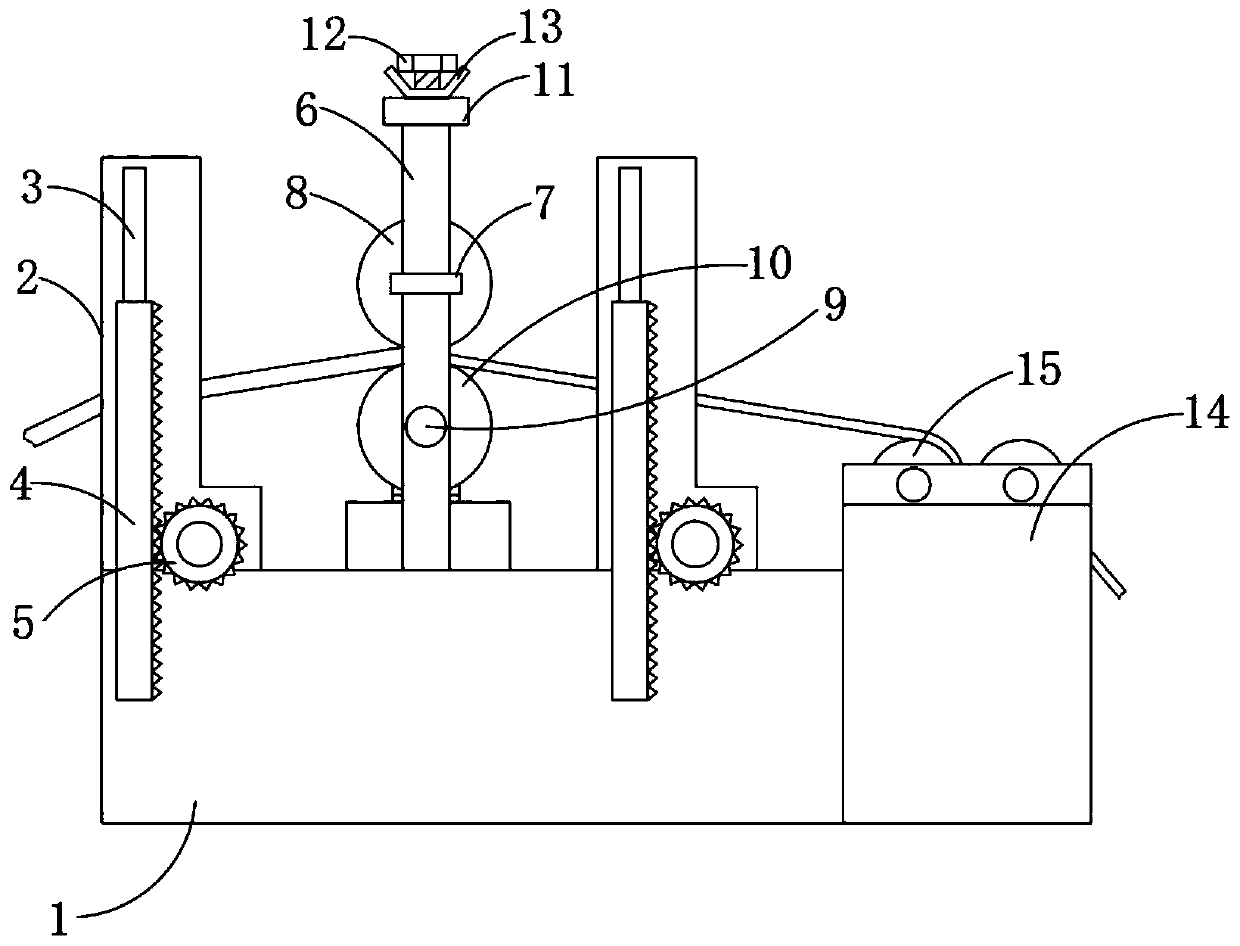

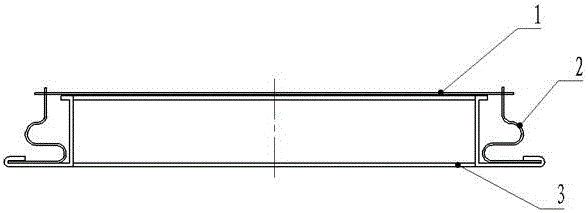

Paper cutting and winding device of extremely-thin glass fiber paper

The invention provides a paper cutting and winding device of extremely-thin glass fiber paper. The paper cutting and winding device comprises a lifting air cylinder, a slitting beam and slitting frames, wherein the two sets of slitting frames are mounted at the positions, at the two ends of a conveying roller, of a rack, the lifting air cylinder is mounted on the tops of the slitting frames, a piston rod of the lifting air cylinder is connected with the slitting beam in a perpendicularly-downward manner; the mounted slitting beam is located above the conveying roller and is parallel to the conveying roller; a slitting mechanism is arranged on one side of the slitting beam, and the other side of the slitting beam is provided with a paper pressing mechanism matched with the slitting mechanism; and a paper winding mechanism matched with the slitting mechanism is arranged at the output end of the rack. The paper cutting and winding device has the beneficial effects of being simple in structure, good in using effect and tight in wound paper.

Owner:ZHEJIANG LANDLONG IND

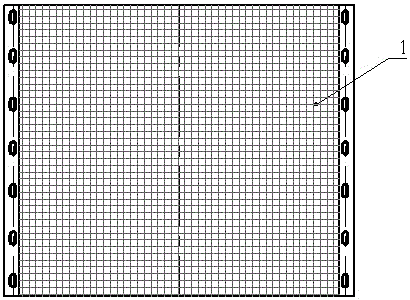

Screen cloth fixing structure for square swinging screen

The invention discloses a screen cloth fixing structure for a square swinging screen. The screen cloth fixing structure comprises a square screen cloth, an S-shaped spring clip and a screen frame, wherein a plurality of strip holes are uniformly distributed on a screen frame on both sides of the square screen cloth; both sides of the bottom plate of the screen frame respectively turn up to form U-shaped clamping grooves of which the openings are opposite; and the top end of the S-shaped spring clip extends vertically to form a vertical clamping edge in interference fit with the strip holes of the square screen cloth, and the bottom end of the S-shaped spring clip extends transversely to form a transverse clamping edge in interference fit with the U-shaped clamping grooves of the screen frame. According to the screen cloth fixing structure disclosed by the invention, the screen cloth can be conveniently and quickly replaced, the working time is saved, the tension of the screen cloth is moderate, the service life of the screen cloth is prolonged, and the screening efficiency is improved.

Owner:XINXIANG ZHEN YING MACHINERY EQUIP CO LTD

Laser film laminator reloading device and control method thereof

The invention provides a laser film laminator reloading device and a control method thereof. A conveying shaft is arranged between two supports. An unreeled material is located above the conveying shaft. A leading film shaft and a leading film shaft driving device are arranged at the position, above the conveying shaft, between the two supports. The leading film shaft is sleeved with a leading film. Double-sided adhesive tape is arranged on the surface, opposite to the conveying shaft, of the leading film. A conveying shaft driving mechanism is arranged on the conveying shaft. A reloading cut-off device is arranged between the two supports. The laser film laminator reloading device further comprises a control device which controls the leading film shaft driving device, the conveying shaft driving mechanism and the reloading cut-off device. When a laser film laminator needs reloading, the control device enables the unreeled material to get close to the leading film shaft and be bonded with the double-sided adhesive tape to form a leading film connector; when the leading film connector is conveyed to a predetermined position, rotation of the leading film shaft is stopped, and the whole reloading process is completed. The stay time of finished products in an oven between reeling and unreeling is saved, finished paper is convenient to operate, time and labor are saved, application and popularization are easy, and high practical value is achieved.

Owner:SICHUAN JINSHI TECH

Zipper discharging device for bag making machine

The invention relates to a zipper discharging device for a bag making machine. A side plate is fixed to a bottom plate. One end of a roller shaft is installed on the side plate. A roller is installed on the roller shaft through a third bearing in a supported manner. A blocking step is arranged at one end of the roller. A blocking ring is installed at the other end of the roller. One end of a swing rod is connected to the roller shaft through a second bearing. A first movable guide roller and a second movable guide roller are installed at the other end of the swing rod. One end of a swing arm is fixed to the swing rod, and the other end of the swing arm is connected with the side plate through a tension spring. The rear end of a locking base is hinged to the side plate, a long groove is formed in the front portion of the locking base, and the distance between the center of the long groove and the rotary center of the roller shaft is gradually increased from the back to the front. A brake block is fixedly installed in the middle of the locking base. A small shaft is installed on the swing rod and penetrates the interior of the long groove in the locking base. A fixed rod is fixedly installed on the side plate, and a first fixed guide roller and a second fixed guide roller are installed at the upper end of the fixed rod. Zippers can keep proper tension in the discharging process, the discharging effect is good, working efficiency is improved, and labor intensity is relieved.

Owner:WUXI KING MO MACHINERY

Belt-retracting device for tightener

InactiveCN101519131AEasy to useModerate tensionLoad securingBundling machine detailsInstabilityStrain gauge

The invention provides a belt-retracting device for a tightener, and relates to a tightener. The device solves the problems that the prior belt-retracting device for the tightener cannot detect the tension of a binding belt and has instability, troublesome operation, complicated structure, and the like. In the belt-retracting device, a bracket of the tightener is provided with a rotatable belt shaft of which one end extends out of the bracket. The device comprises a case body, a worm, a worm shaft and a worm wheel, wherein the worm is sleeved on and fixedly connected with the worm shaft. The device also comprises a sensor. When the worm shaft moves, the inner end face of the worm shaft can be supported against the sensor, and make the sensor generate signals which correspond to the tension of the binding belt. The sensor comprises a flaky compressed block. One end face of the compressed block faces towards the inner end face of the worm shaft, while the other end face faces towards the case body and is provided with a plurality of evenly-distributed resistance strain gages. The belt-retracting device has the advantages of simple structure, convenient operation, intelligence, safe use, and the like.

Owner:ZHEJIANG TOPSUN LOGISTIC CONTROL CO LTD

Automotive wire collection device

The invention discloses an automotive wire collection device which includes a motor, a rotating shaft and a bracket. Both ends of the rotating shaft are rotatably connected with the bracket. The rotating shaft is in transmission connection with the motor. The rotating shaft is provided with N supporting mechanisms in the circumferential direction thereof, and N>=2. Each supporting mechanism includes a plurality of supporting units which are arranged in the axial direction of the rotating shaft. Each supporting unit includes a sliding rod and winding plates. The sliding rod is detachably connected with the rotating shaft, the winding plates are mounted on the sliding rod, the two ends of each winding plate are provided with wire blocking plates for preventing cables from falling, and the wire blocking plates are provided with cable channels for the cables to pass. In the automotive wire collection device, the number of the winding plates is selected flexibly according to the number of the cables, the transportation is facilitated better, and the wound cables are ordered; through a design of a rubbing unit, the cables can be rubbed flexibly, the drooping of an insulating rubber layeris effectively avoided, the cable quality is effectively ensured, and a cable winding effect is better.

Owner:安徽奇祥汽车零部件有限公司

A silk making device

ActiveCN108166072AIncrease productivityReduce tensionSilk reelingAnimal materialElectric machineryEngineering

The invention relates to the technical field of silk making and in particular provides a silk making device comprising a plurality of independent silk making units. Each silk making unit is inside provided with a unit drum, a winding motor, a controller and an active adjustment mechanism, wherein the active adjustment mechanism comprises a variable-diameter silk guide roller, an upper drum wheel,a lower drum wheel, a rotating motor, a connecting rod and an telescopic spring; the upper drum wheel is provided with a central rotating shaft; the two sides of the upper drum wheel are provided witha guide wheel through which the central rotating shaft penetrates and a guide groove allowing the guide wheel to slide; one end of the connecting rod is connected with the central rotating shaft andthe other end is connected with the telescopic spring; the controller is connected with the winding motor and the rotating motor. When the tension of silk bars is excessive, the silk bars press the upper drum wheels forward and slide to the two ends of the variable-diameter silk guide rollers at the same time, so that the silk bar winding speed is increased; when the tension of silk bars is small,the telescopic springs are stretched and the silk bars slide to the rear ends of the variable-dimeter silk guide roller, so that the conveying and winding speeds of silk bars are reduced. The controllers coordinate operation of the winding motors and the rotating motors in the silk making units.

Owner:ZHEJIANG SCI-TECH UNIV

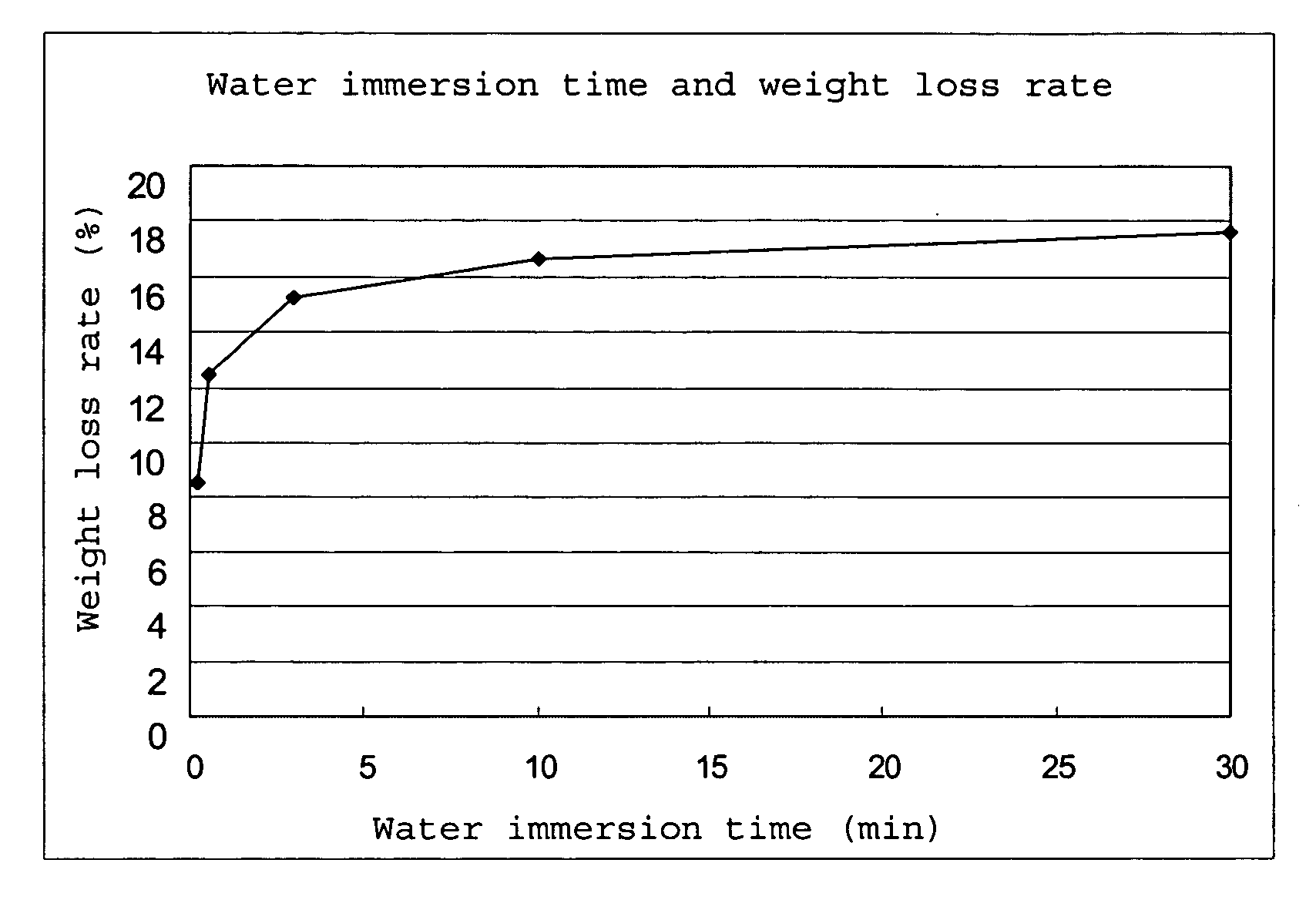

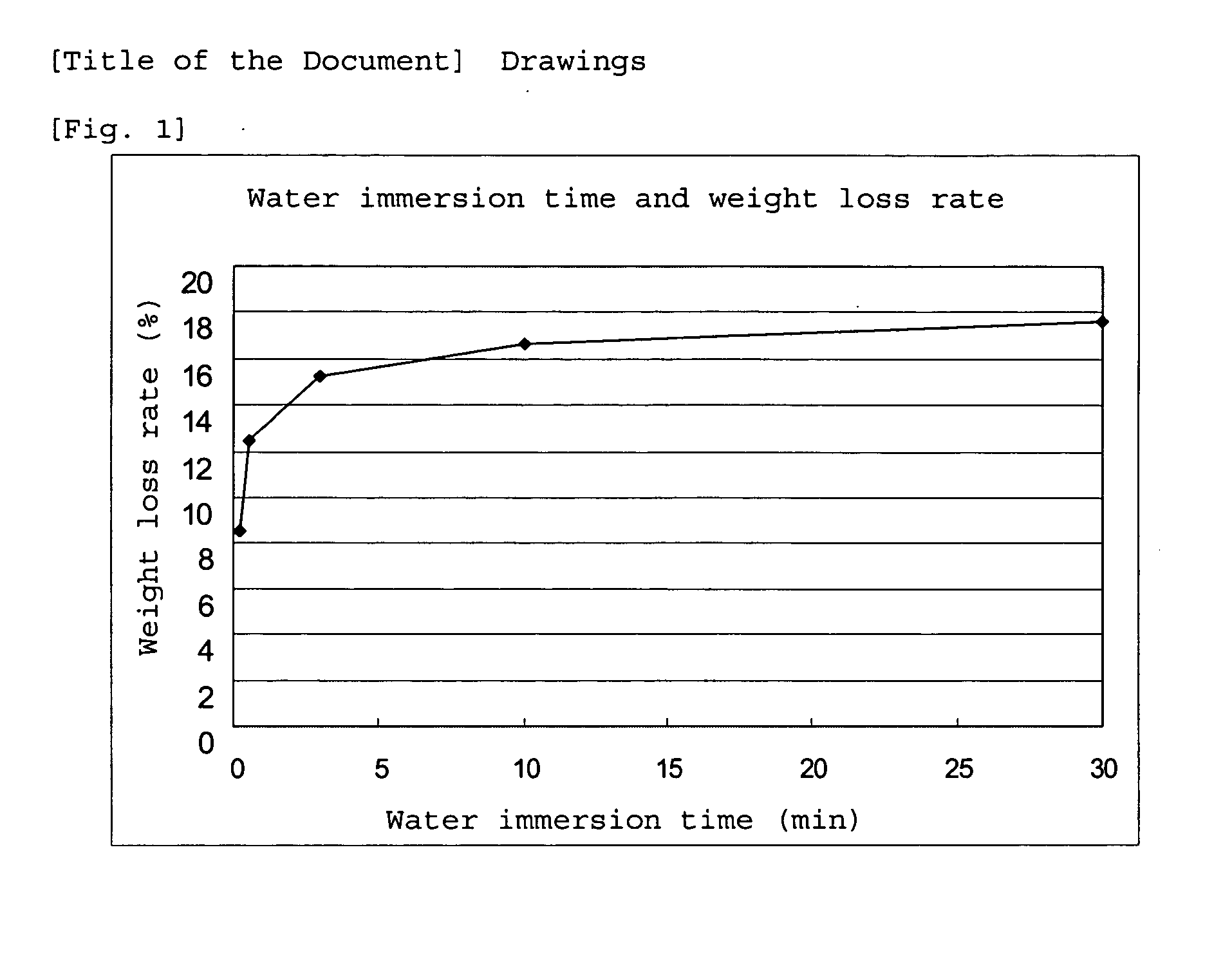

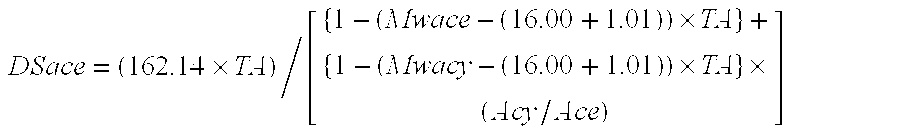

Fabric for Clothing and a Production Method Thereof

A fabric consisting of a cellulose mixed ester fiber having an appropriate strength, fiber diameter, uniformity of fineness, and Tg, is used. A fiber consisting of 80 to 95 wt % of said cellulose mixed ester and 5 to 20 wt % of one or more water-soluble plasticizers selected from the group of polyethylene glycol, polypropylene glycol, poly(ethylene-propylene) glycol, and end-capped polymers produced from them, is produced and said water-soluble plasticizers are removed by aqueous treatment to improve the heat resistance and strength, thereby providing a fabric having beautiful appearance achieved by color development properties and uniform fineness.

Owner:TORAY IND INC

Full-automatic precise film cutting machine

ActiveCN104890348AModerate tensionTo achieve a win-win goalLamination ancillary operationsLaminationTectorial membraneEngineering

The invention discloses a full-automatic precise film cutting machine. The full-automatic precise film cutting machine comprises an installation rack, wherein the installation rack is internally provided with a plate conveying belt and a plurality of paired film cutters arranged above the plate conveying belt in a suspending manner; the cutter distance of any group of film cutters is fixed and adjusted; the plate conveying belt also comprises constant-tension devices arranged at the two sides. The full-automatic precise film cutting machine disclosed by the invention has the advantages that when automatic precise film cutting is carried out, a protective film maintains proper tension by the constant-tension devices, edge-maintaining cutting is carried out on the protective film by the film cutters according to the fixed cutter distance, the procedures of downstream customers are solved in advance before a product is delivered, so that the two-win purpose of enterprises and the customers is realized, and the production efficiency and the industrial competitive advantage of a whole industrial chain are improved simultaneously.

Owner:ZHUHAI SPEEDBIRD NEW MATERIAL CO LTD

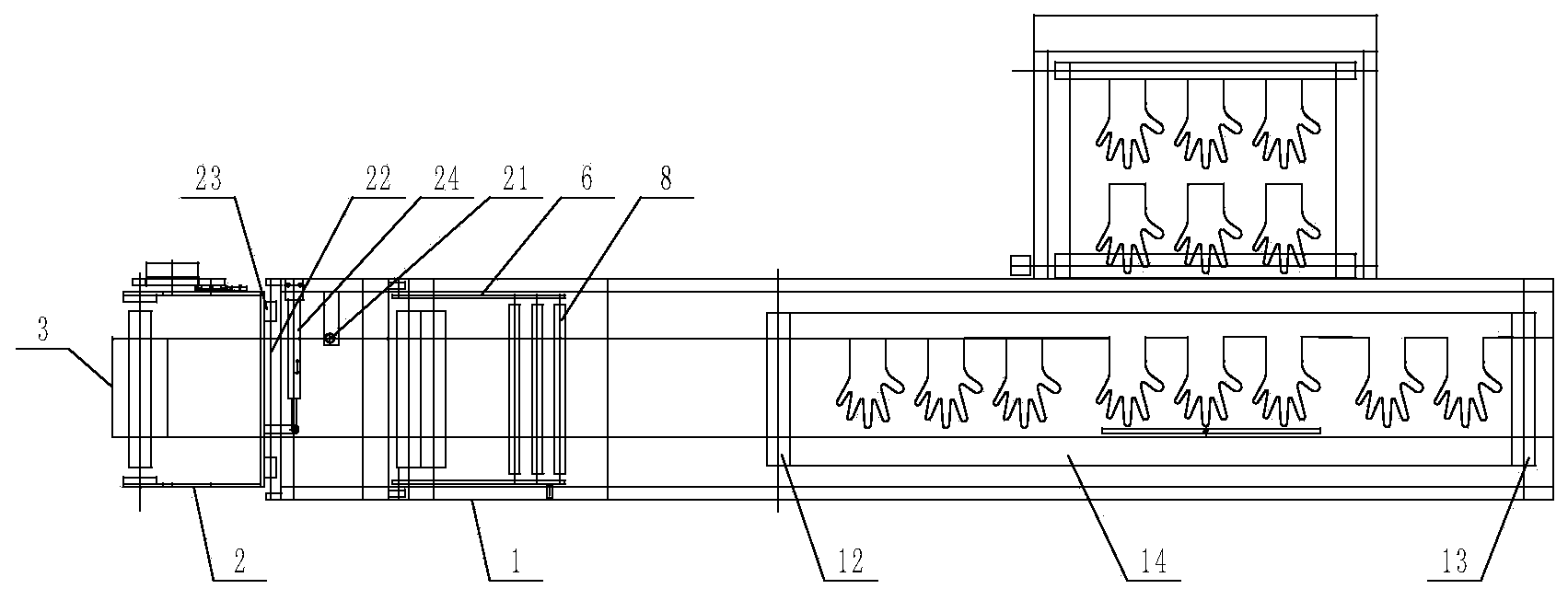

Glove making machine

The invention relates to a glove making machine. The glove making machine comprises an emptying device, a forming mold and a material receiving device which are sequentially arranged, wherein the emptying device comprises an emptying frame, two sets of emptying equipment, namely upper emptying equipment and low emptying equipment are arranged on the emptying frame, each set of emptying equipment comprises a material roll frame arranged at the front end of the emptying frame, and material rolls are arranged in the material roll frames; emptying glue rolls and driving devices are arranged on the emptying frame, and the driving devices are used for driving the emptying glue rolls; two oscillating bars on the same plane are further arranged on the emptying frame, one ends of the oscillating bars are hinged with the emptying frame, a plurality of lower support rods are arranged between the two oscillating bars, and a plurality of upper support rods are arranged at upper positions corresponding to the lower support rods in the emptying frame; transition wheels are arranged at the rear end of the emptying frame; after passing through the emptying glue rolls, plastic films in the material rolls are arranged in an S shape between the lower support rods and the upper support rods in an inserted manner and finally enter the forming mold through the transition wheels. According to the glove making machine, a forming procedure can be carried out continuously; proper tensions of the plastic films can be maintained and the quality of a product is improved.

Owner:ZHANGJIAGANG PIONEER AUTOMATION MACHINERY EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com