Preparation process for graphene conductive film

A conductive film and preparation process technology, applied in cable/conductor manufacturing, conductive layers on insulating carriers, circuits, etc., can solve the problems of high cost, complex process, long process route, etc., to save costs, simplify process flow, The effect of improving the degree of structural orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

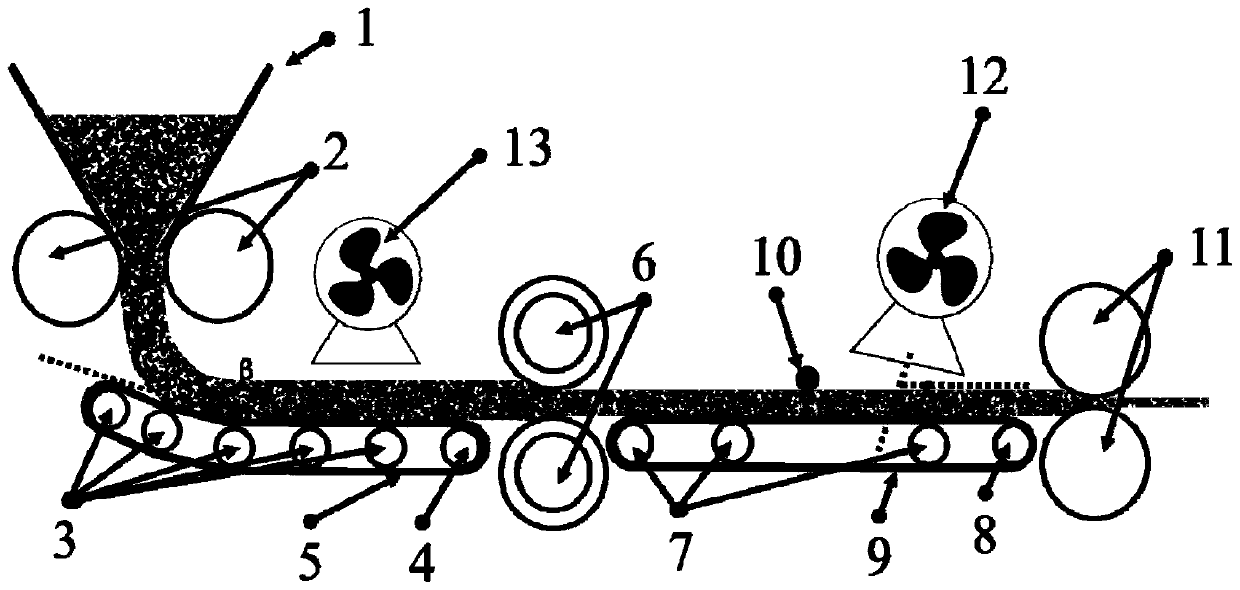

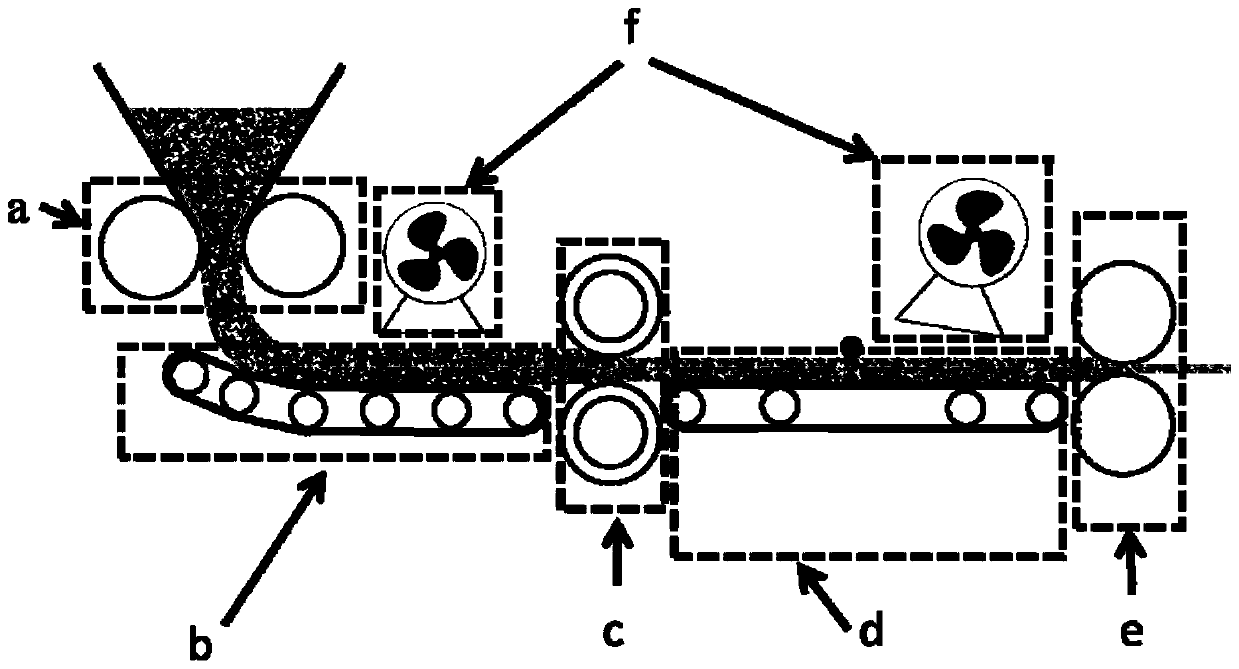

[0045] Fully mix the graphene-based conductive functional agent, binder dispersion, and additives to form a semi-dry slurry, and then pass it through the vertical rolling part a, the guiding traction part b, the hot rolling part c, and the conveying part d , the cold rolling part e and the purging part f are prepared into a graphene conductive film.

[0046] The weight composition of the graphene-based conductive functional agent, binder dispersion and auxiliary agent is: 20wt%, 60wt%, 1wt%, and the remaining components are water.

[0047] Described graphene-based conductive functional agent is the 0.1 micron graphene and 20wt% (relative to graphene-based conductive functional agent) of 0.1 micron graphene with redox method sheet diameter (relative to graphene-based conductive functional agent) A mixture of granular Ketjen Black solid-phase mixtures.

[0048] The binder dispersion is an aqueous dispersion with a solid content of 30 wt% formed by dispersing PTFE with a solid c...

Embodiment 2

[0059] Fully mix the graphene-based conductive functional agent, binder dispersion, and additives to form a semi-dry slurry, and then pass it through the vertical rolling part a, the guiding traction part b, the hot rolling part c, and the conveying part d , the cold rolling part e and the purging part f are prepared into a graphene conductive film.

[0060] The weight composition of the graphene-based conductive functional agent, binder dispersion and auxiliary agent is: 60wt%, 30wt%, 2wt%, and the remaining components are water.

[0061] Described graphene-based conductive functional agent is 50wt% (relative to graphene-based conductive functional agent) Graphene and 50wt% (relative to graphene-based conductive functional agent) high temperature pyrolysis method sheet diameter is 0.05 micron ) is a mixture of carbon nanotubes mixed in solid phase.

[0062] The binder dispersion liquid is a dispersion liquid formed by dispersing polyvinyl alcohol in water with a solid conten...

Embodiment 3

[0073] Fully mix the graphene-based conductive functional agent, binder dispersion, and additives to form a semi-dry slurry, and then pass it through the vertical rolling part a, the guiding traction part b, the hot rolling part c, and the conveying part d , the cold rolling part e and the purging part f are prepared into a graphene conductive film.

[0074] The weight composition of the graphene-based conductive functional agent, binder dispersion and auxiliary agent is: 40wt%, 40wt%, 3wt%, and the remaining components are water.

[0075] Described graphene-based conductive functional agent is that 10wt% (relative to graphene-based conductive functional agent) is 0.05 micron graphene and 90wt% (relative to graphene-based conductive functional agent) ) of silver nanosheets solid-phase mixed mixture.

[0076] The binder dispersion is a dispersion with a solid content of 40wt formed by dispersing nitrocellulose in ethyl acetate.

[0077] The auxiliary agent is 1 part of BYK163...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com