Patents

Literature

57results about How to "Full dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

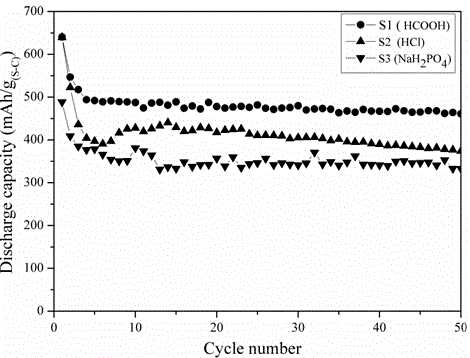

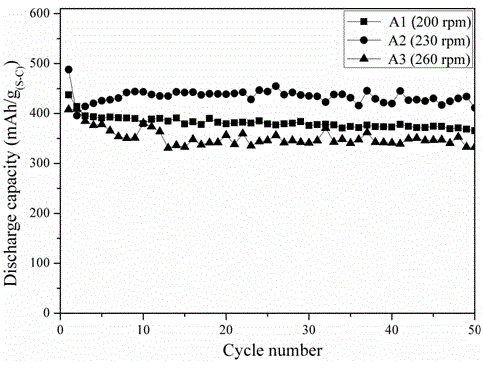

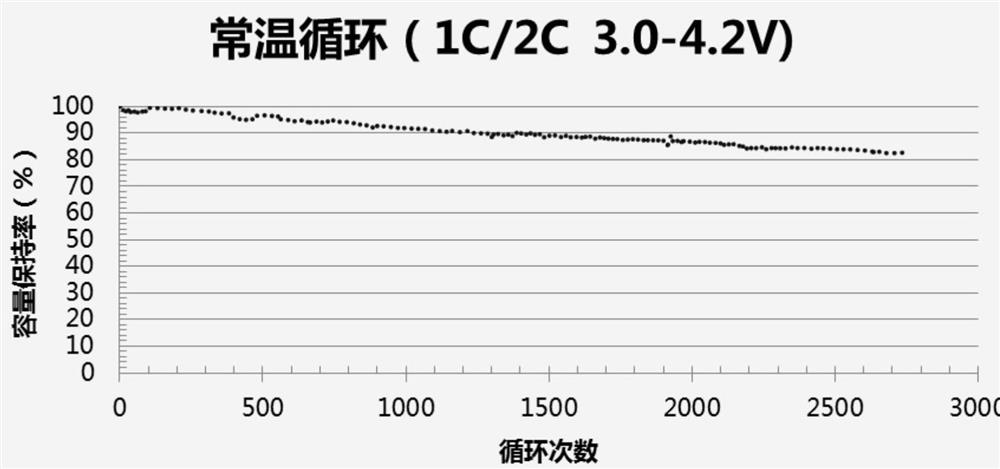

Sulfur-carbon composite positive electrode material for lithium-sulfur battery and preparation method of sulfur-carbon composite positive electrode material

ActiveCN104600247AIncrease contentImprove cycle stabilityNon-aqueous electrolyte accumulator electrodesLi-accumulatorsHigh concentrationCarbon composites

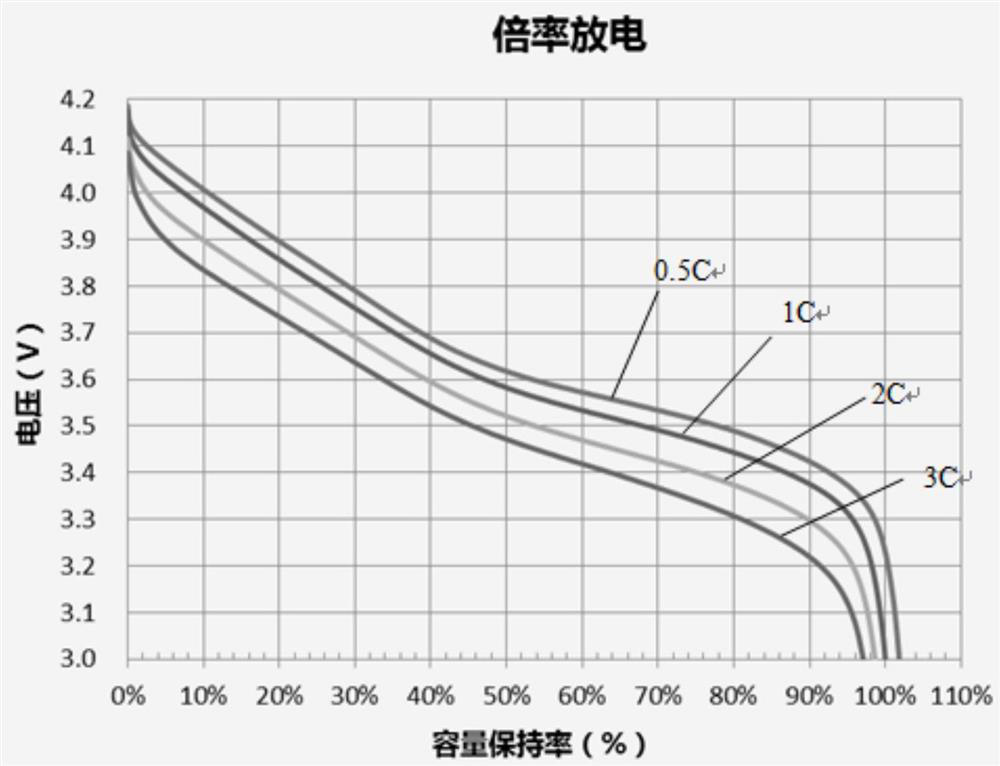

The invention particularly relates to a preparation method of a sulfur-carbon composite positive electrode material for a lithium-sulfur battery. Sodium polysulfide is taken as the raw material, and the nano-scale sulfur particles generated by use of a chemical reaction are promoted to be melted by virtue of high-speed ball milling and go into carbon pores of conductive carbon black, and finally, the sulfur-carbon composite positive electrode material is prepared. The high-performance sulfur-carbon composite material is prepared by use of an in-situ wet ball milling method. According to the preparation method, the operation is simple and easy, the energy consumption is low, the cost is low, an environment-friendly effect is achieved, and the industrial production is easy. The thorough dispersion and fixation of sulfur on a conductive substrate are realized; besides, a high-concentration lithium salt electrolyte is adopted to inhibit the solution of polysulfide, and therefore, the cyclic stability and the active substance utilization rate of the material are improved. As a result, the sulfur-carbon composite material prepared by use of the in-situ wet ball milling method is a positive electrode material which is high in specific capacity, long in cycle life and high in rate performance and can be applied to the field of lithium secondary batteries.

Owner:SHANDONG YUHUANG NEW ENERGY TECH +1

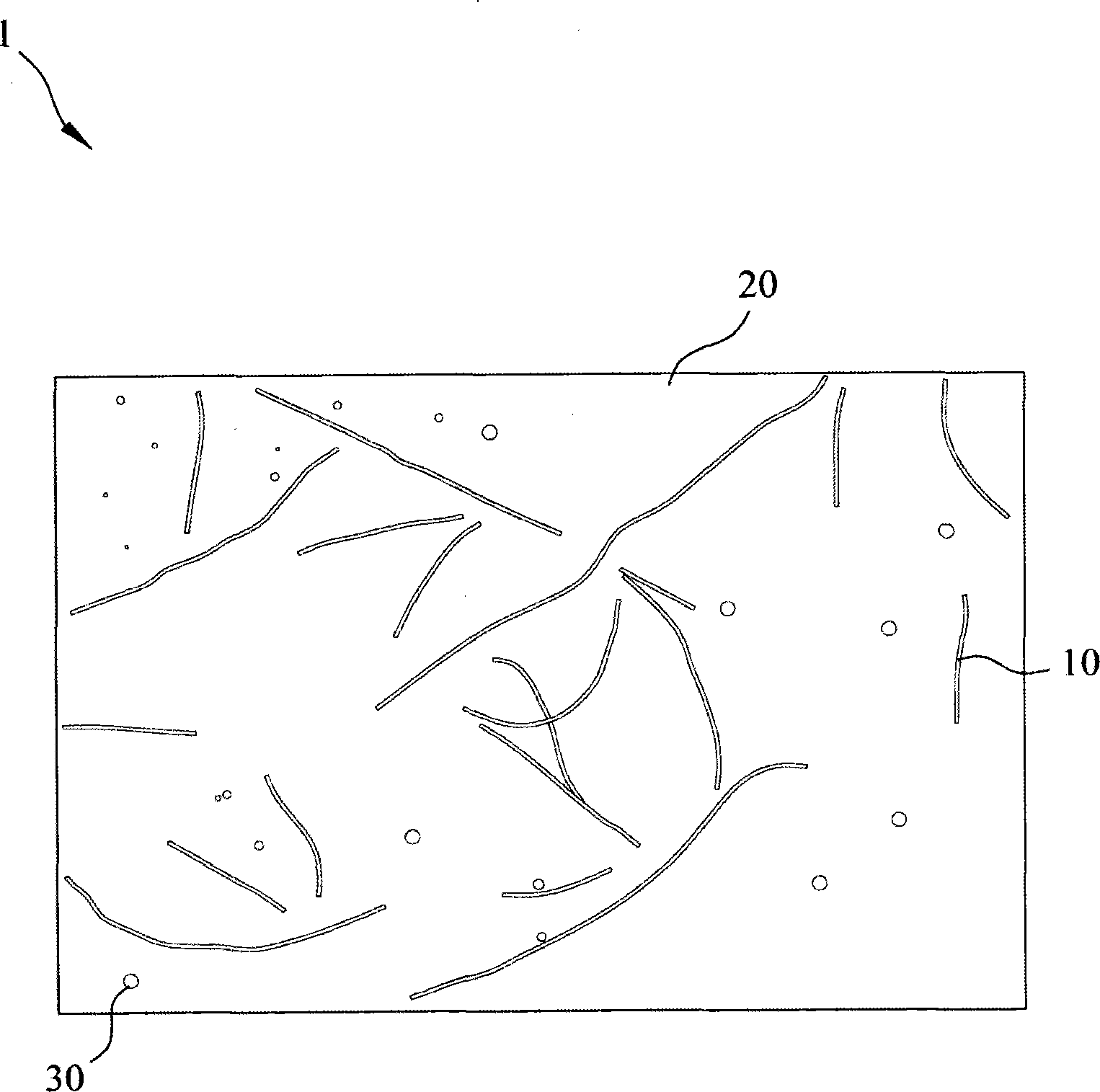

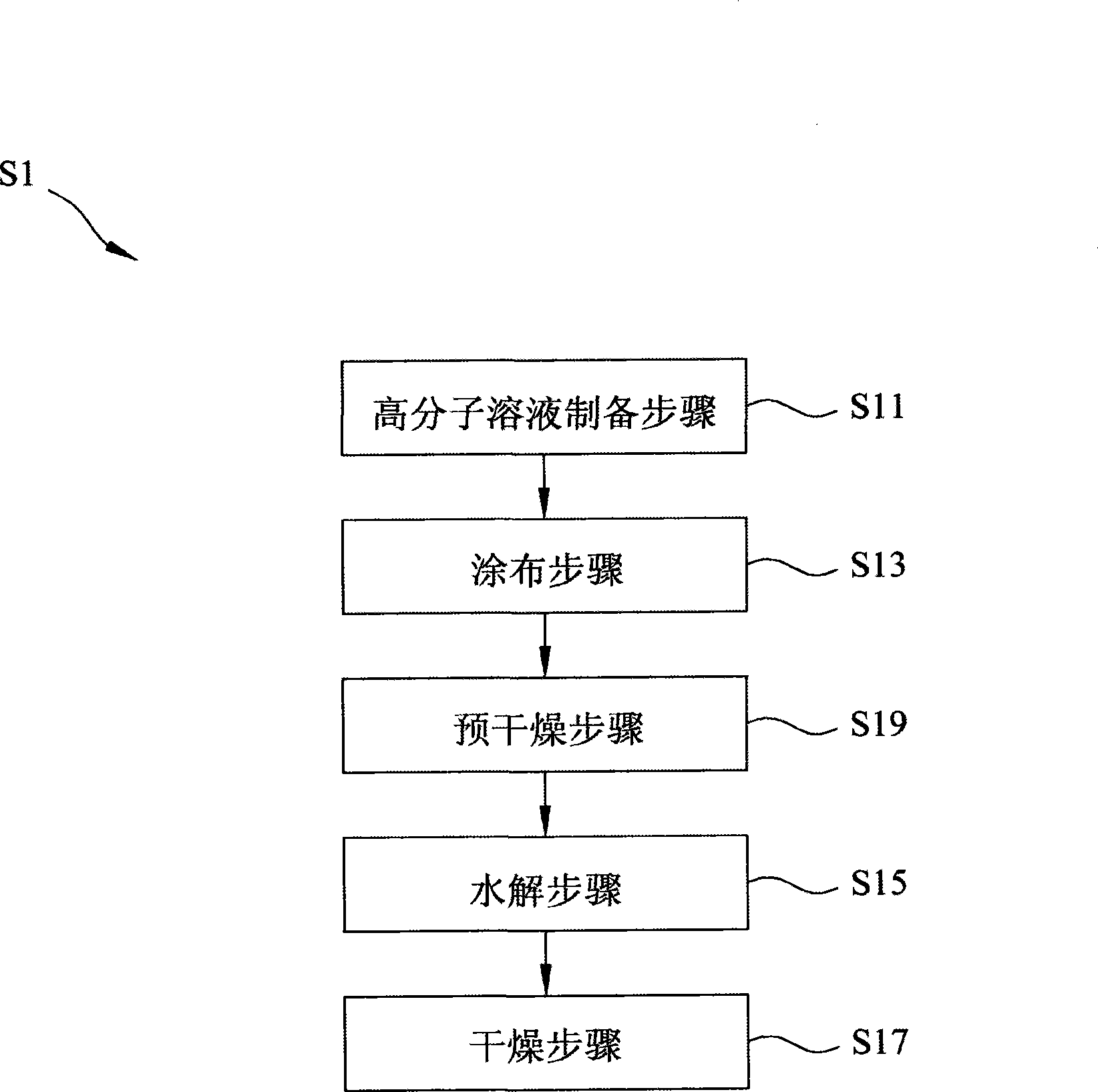

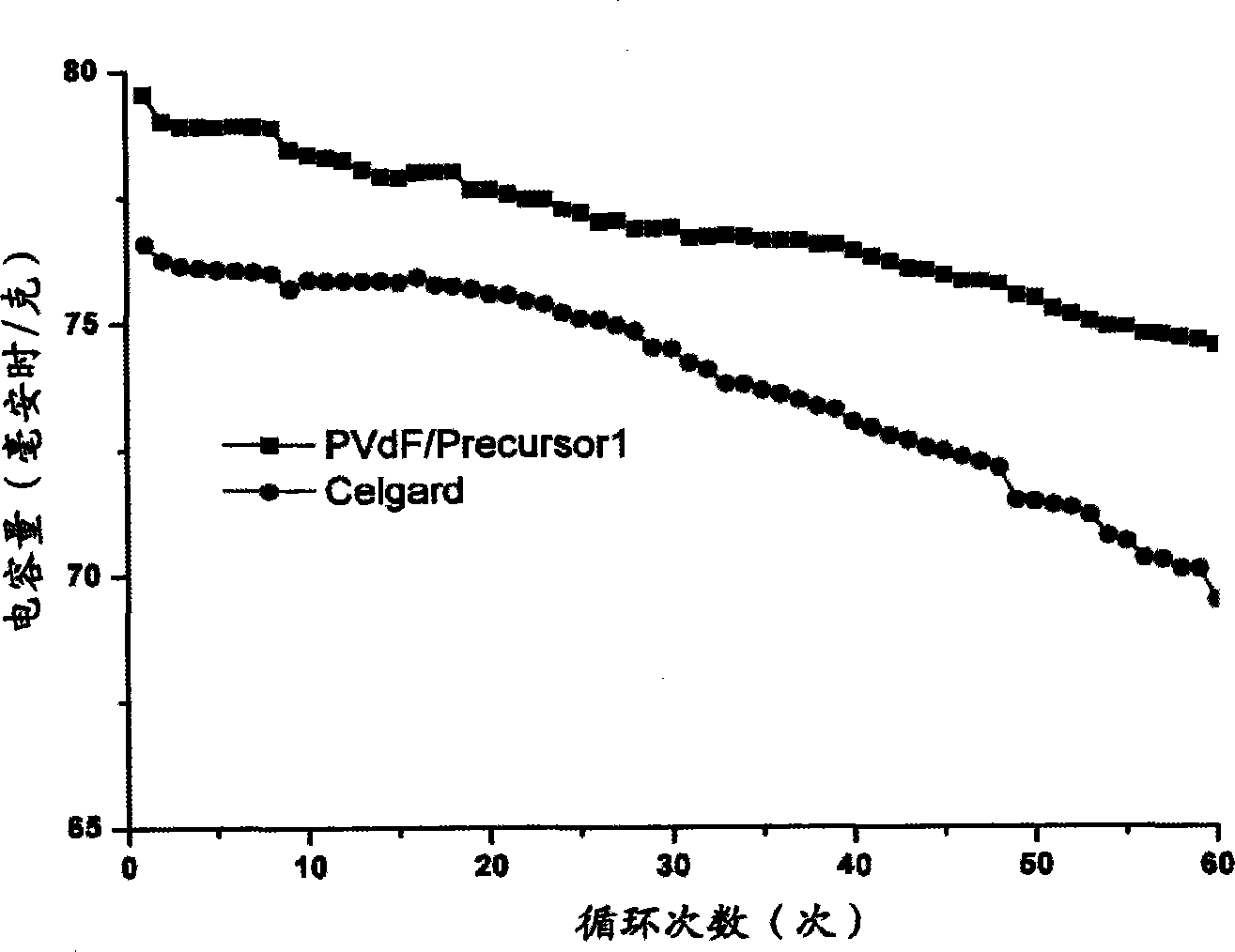

Isolating membrane of electrochemical device and preparation method of isolating membrane

ActiveCN103515561AImprove ionic conductivityImprove stabilityCell component detailsSolventElectrochemistry

The invention relates to an isolating membrane of an electrochemical device and a preparation method of the isolating membrane. The method comprises the following steps: preparing a macromolecular solution,namely completely mixing a macromolecular material, a solvent and a ceramic precursor to form the macromolecular solution, so that the macromolecular material and the ceramic precursor are dissolved into the solvent; coating: coating the macromolecular solution on a porous base material; hydrolyzing: contacting the porous base material, which is coated with the macromolecular solution, with an aqueous solution so as to hydrolyze the ceramic precursor in the macromolecular solution to form ceramic particles; drying: completely removing the solvent and the water from the hydrolyzed porous base material to obtain the isolating membrane of the electrochemical device. The ceramic precursor and the macromolecular material can be completely dispersed and mixed, so the prepared isolating membrane of the electrochemical device can effectively enhance ionic conductivity, interface stability and high-temperature stability by means of the ceramic particles.

Owner:ENERAGE INC

Aqueous graphene slurry and preparation method thereof

InactiveCN108455584AGood size controlRealize mass productionGrapheneConductive coatingSupercapacitor

The invention discloses aqueous graphene slurry and a preparation method thereof. The aqueous graphene slurry comprises aqueous dispersion liquid and a graphene material dispersed in the aqueous dispersion liquid, wherein the aqueous dispersion liquid contains a surfactant, and the mass content of graphene is 0.2 to 12%. The preparation method for the aqueous graphene slurry comprises the following steps: with a graphite oxide solid or an expandable graphite solid as a raw material, performing expansion treatment to prepare expanded graphite; immersing the expanded graphite in an aqueous stripping solution for infiltration treatment to obtain a mixture containing the expanded graphite; subjecting the mixture containing the expanded graphite to high-speed shearing or ultrasonic treatment toremove the aqueous stripping solution and obtain a wet graphene material; and adding the wet graphene material in aqueous dispersion liquid, and carrying out high-speed shearing to obtain aqueous graphene slurry. The aqueous graphene slurry prepared by using the method of the invention can be applied to the fields of electroconductive and heat-conductive coatings, anticorrosive coatings, batteries / supercapacitors and the like.

Owner:HAIMEN CITY RUITAI TEXTILE TECH CO LTD

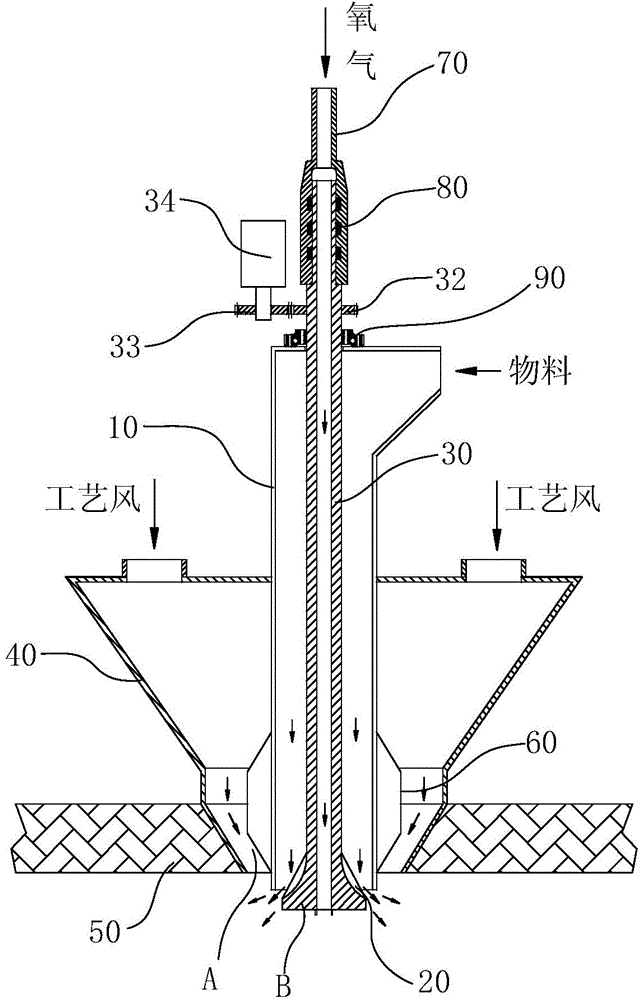

Jet nozzle of concentrate

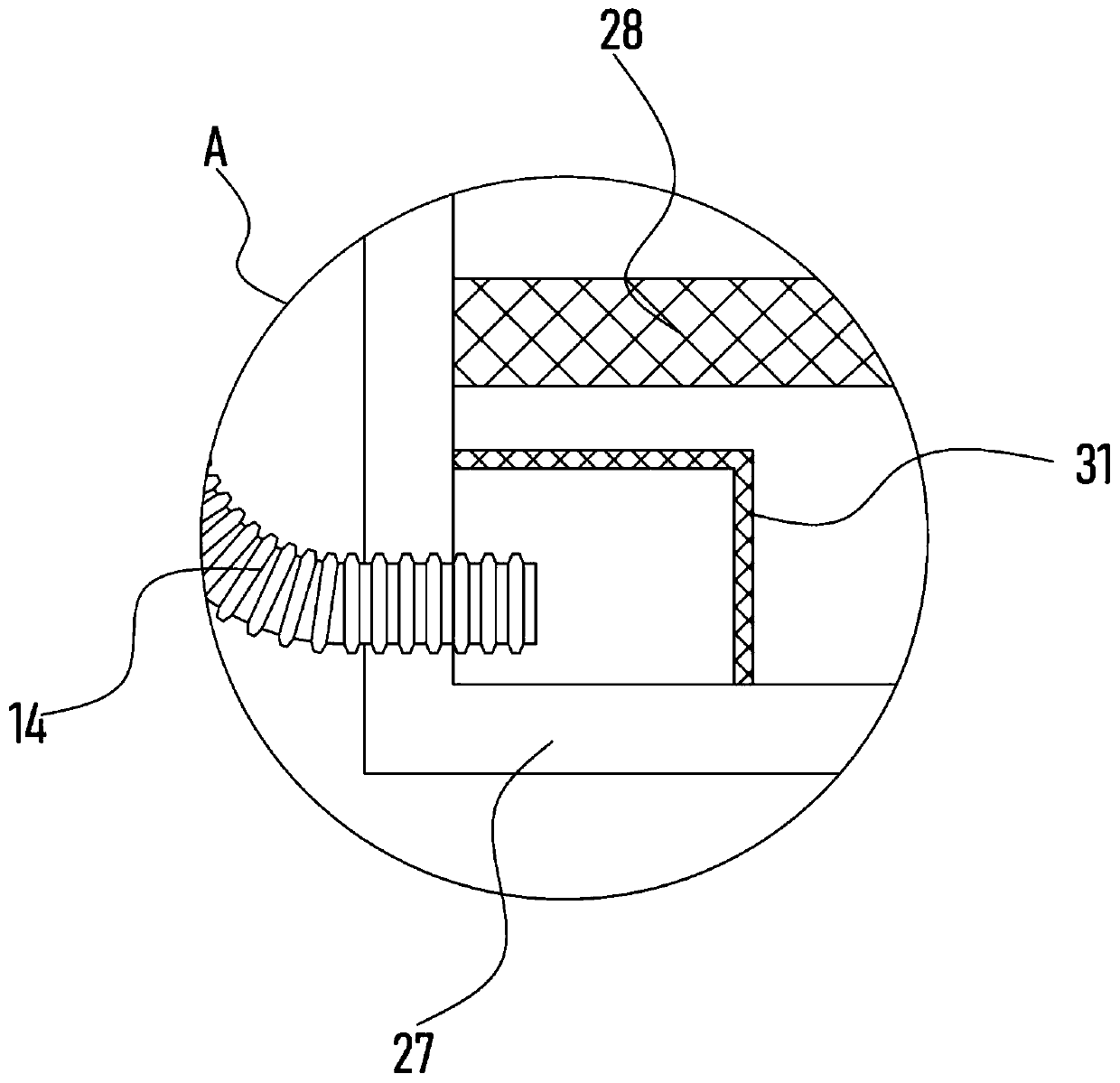

ActiveCN104388695ASufficient dispersion of kinetic energyGuaranteed responseCharge manipulationEngineeringTower

The invention discloses a jet nozzle of concentrate used in a copper smelting flash furnace. The jet nozzle comprises a distributor arranged inside a water-cooled sleeve, wherein rotary shifting sheets are arranged on the distributor located at the material-outlet end of a lower tube end of the water-cooled sleeve, and a driving mechanism drives the distributor to rotate to provide kinetic energy for dispersion to the passing material; when the concentrate material is delivered toward the jet nozzle of concentrate, the material enters a passage formed between the distributor and the water-cooled sleeve, falls under the action of gravity, acquires kinetic energy under the action of the rotary shifting sheets so that the concentrate material can evenly fall, be dispersed and be fully mixed with peripheral process air and the reaction effect of evenly mixed concentrate material in a reaction tower can be further ensured.

Owner:TONGLING NON FERROUS METAL GROUP CORP

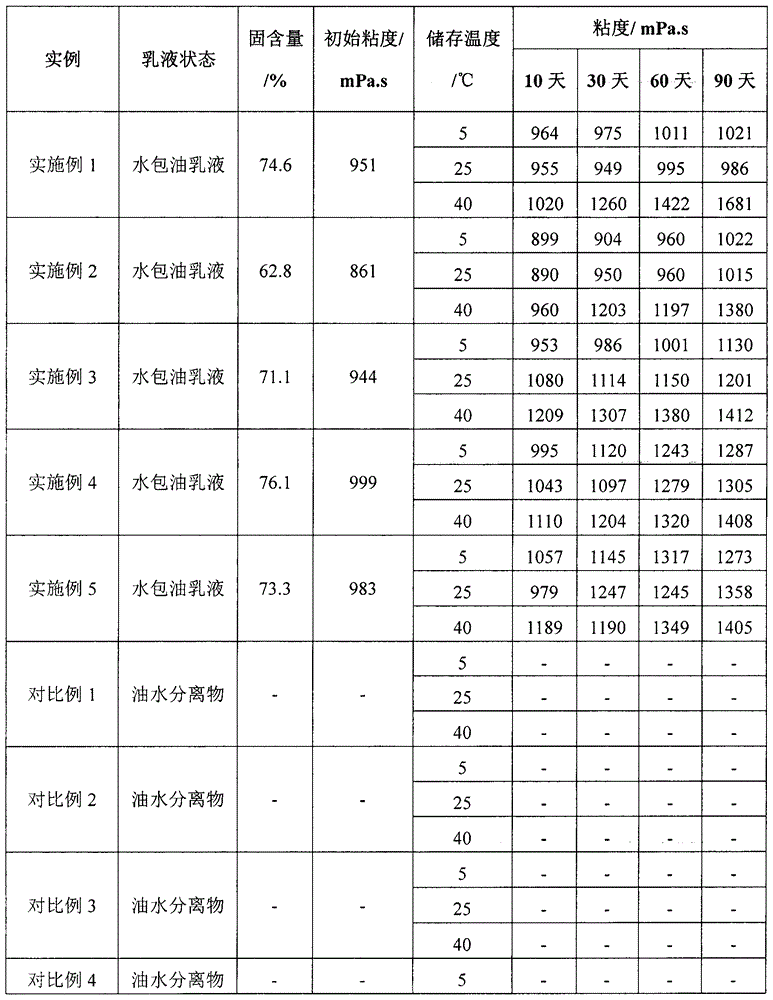

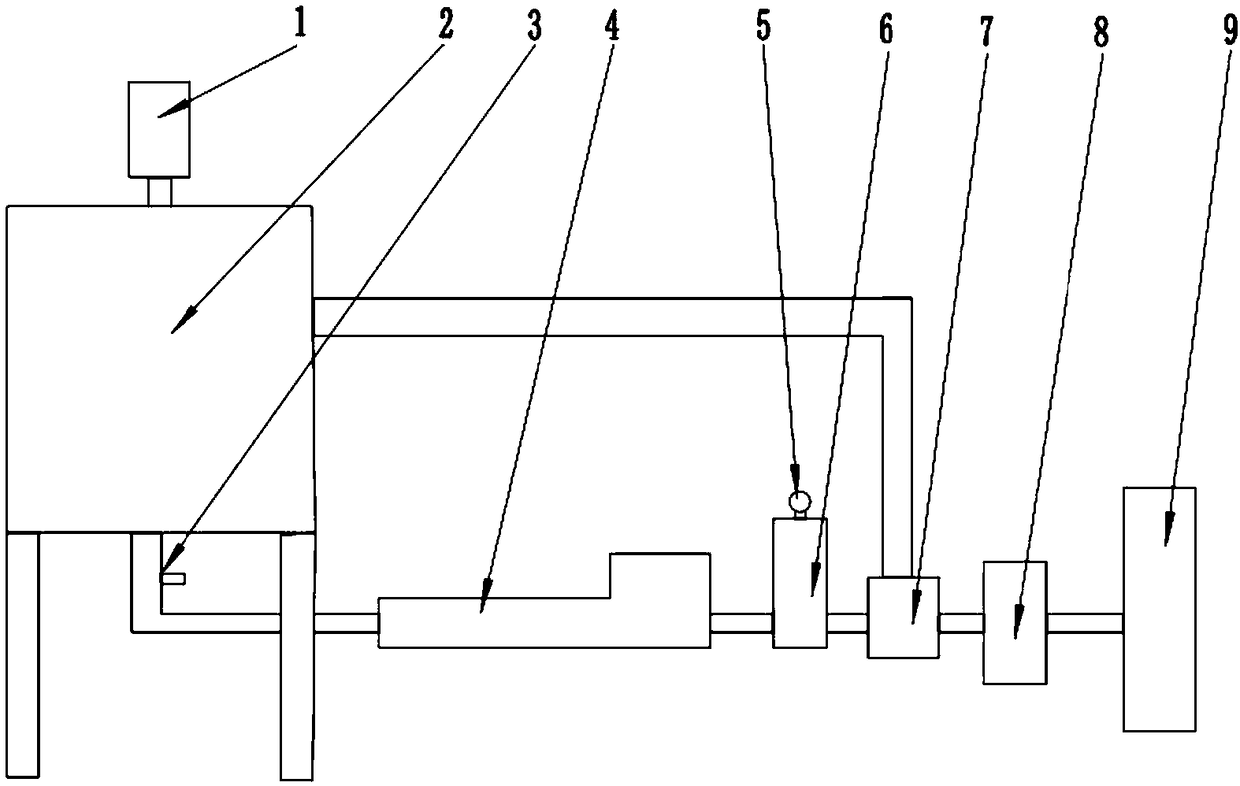

Preparation method of stable oil-in-water emulsion with high solid content

The invention relates to a special emulsification method. According to the method, stirring is stopped in the emulsification process, a mixture of W / O and little water or W / O / W is formed through standing, stirring is started, instantaneous inner shear force in unit area is increased, and formation of the O / W emulsion is facilitated; meanwhile, a hydrophilic emulsifier is dropwise added into the mixture during standing, the formation of the O / W emulsion is facilitated, and full wrapping and dispersing of droplets are facilitated to make the emulsion more stable; in the post-processing stage, the volume of the non-oil phase is increased by adding a stabilizer. By means of the preparation method, the problem that the viscosity of the emulsion with the high solid content is high is solved; meanwhile, the stability of the emulsion with the high solid content is improved, the preparation method is widely suitable for emulsification of hydrocarbons and oxygen-containing derivatives thereof, and the application range is wider.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

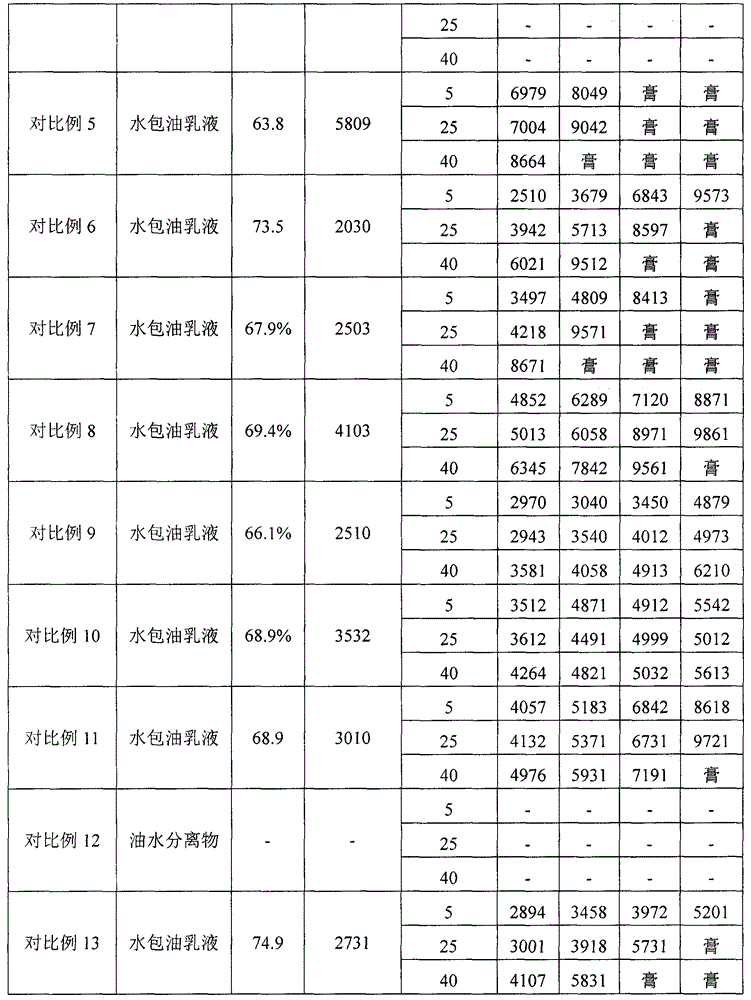

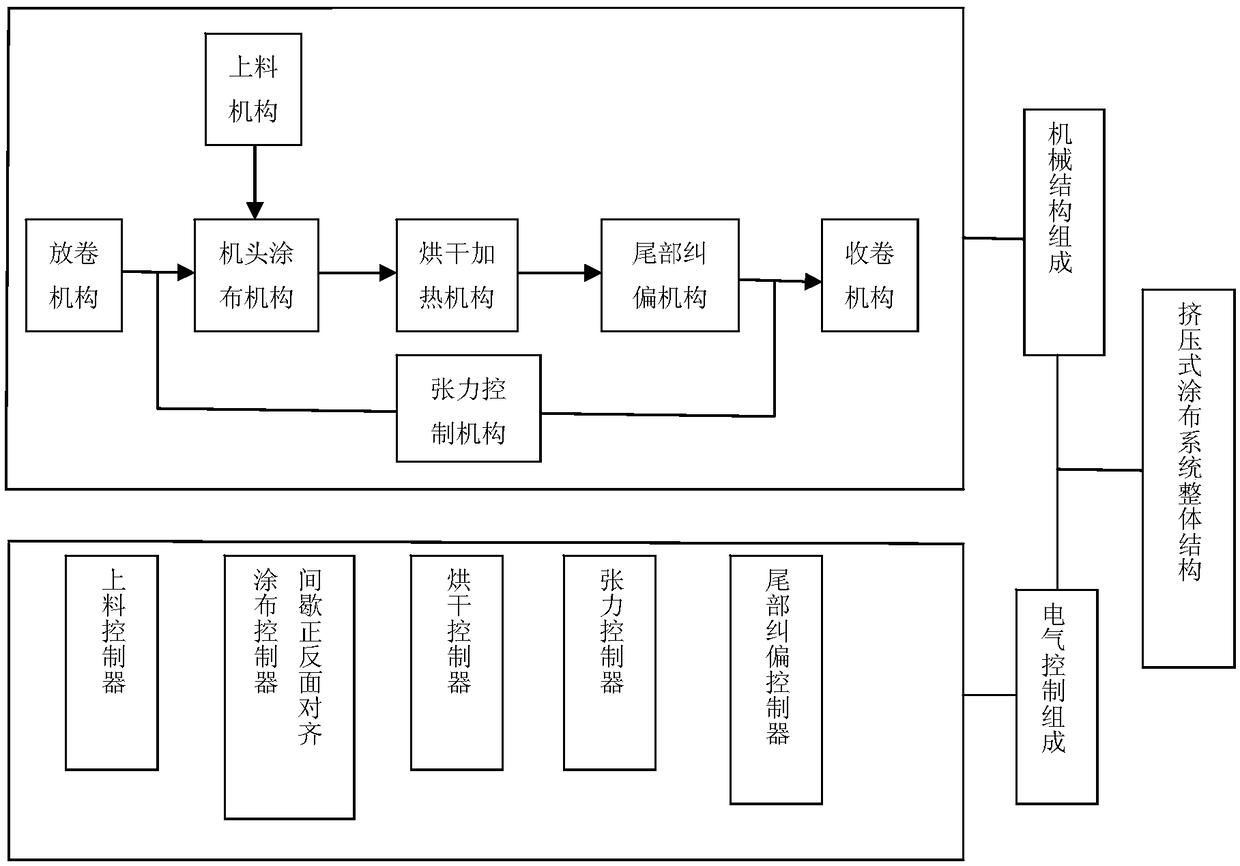

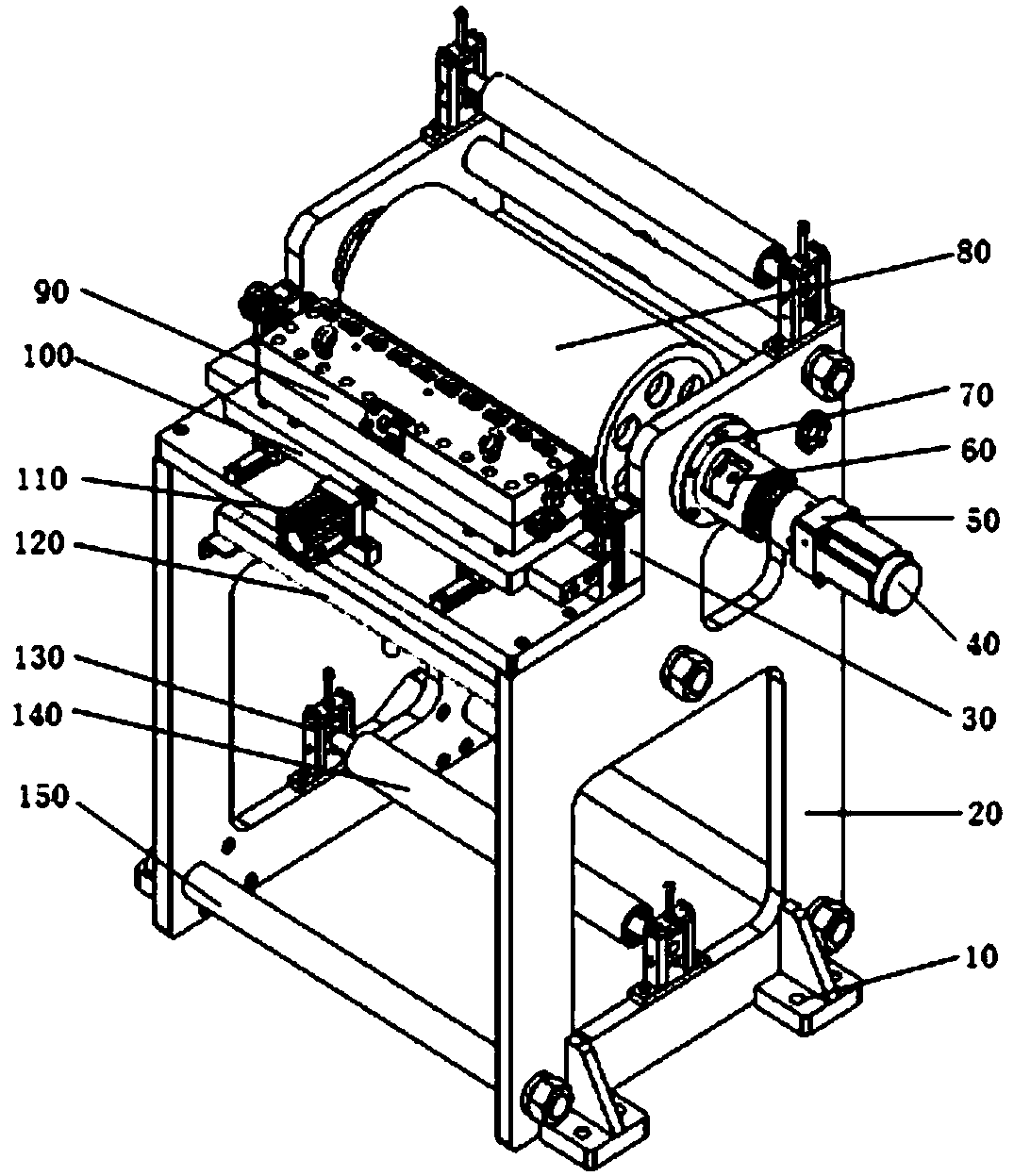

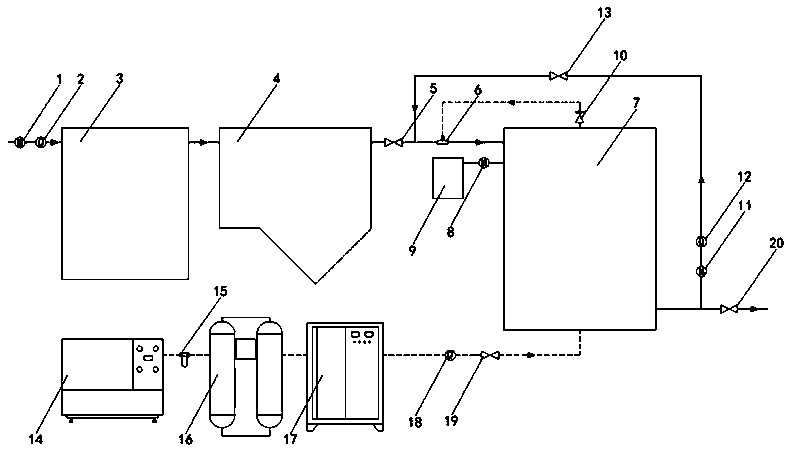

Extrusion type coating system of power lithium battery base band

ActiveCN108816645AFull dispersionFull homogenizationPretreated surfacesCoatingsCoating systemEngineering

The invention discloses an extrusion type coating system of a power lithium battery base band. The extrusion type coating system of the power lithium battery base band comprises an unwinding mechanism, a feeding device, a machine head coating device, a tension control device, a drying heating device, a tail deviation rectifying device and a winding mechanism. The unwinding mechanism releases the base band at a constant speed. The feeding device provides a stable sizing agent. The machine head coating device disperses the sizing agent to be uniform and discharges and coats the sizing agent to the base band along the position of a gap of an outlet of an extrusion mold head. The drying heating device dries the wet sizing agent coated to the base band. The winding mechanism winds the coated and dried base band. The tail deviation rectifying device can guarantee that the base band is tidy during taking up, operation of following working procedures is facilitated, and the tension control device can guarantee the best tension degree of the base band.

Owner:SOUTHEAST UNIV

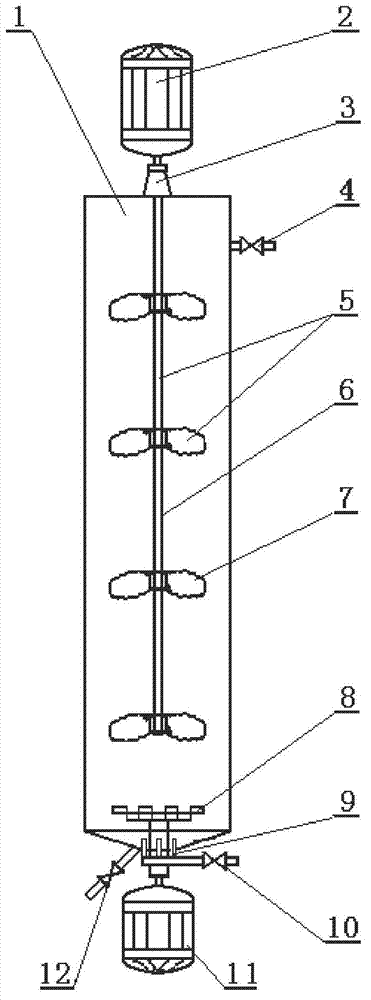

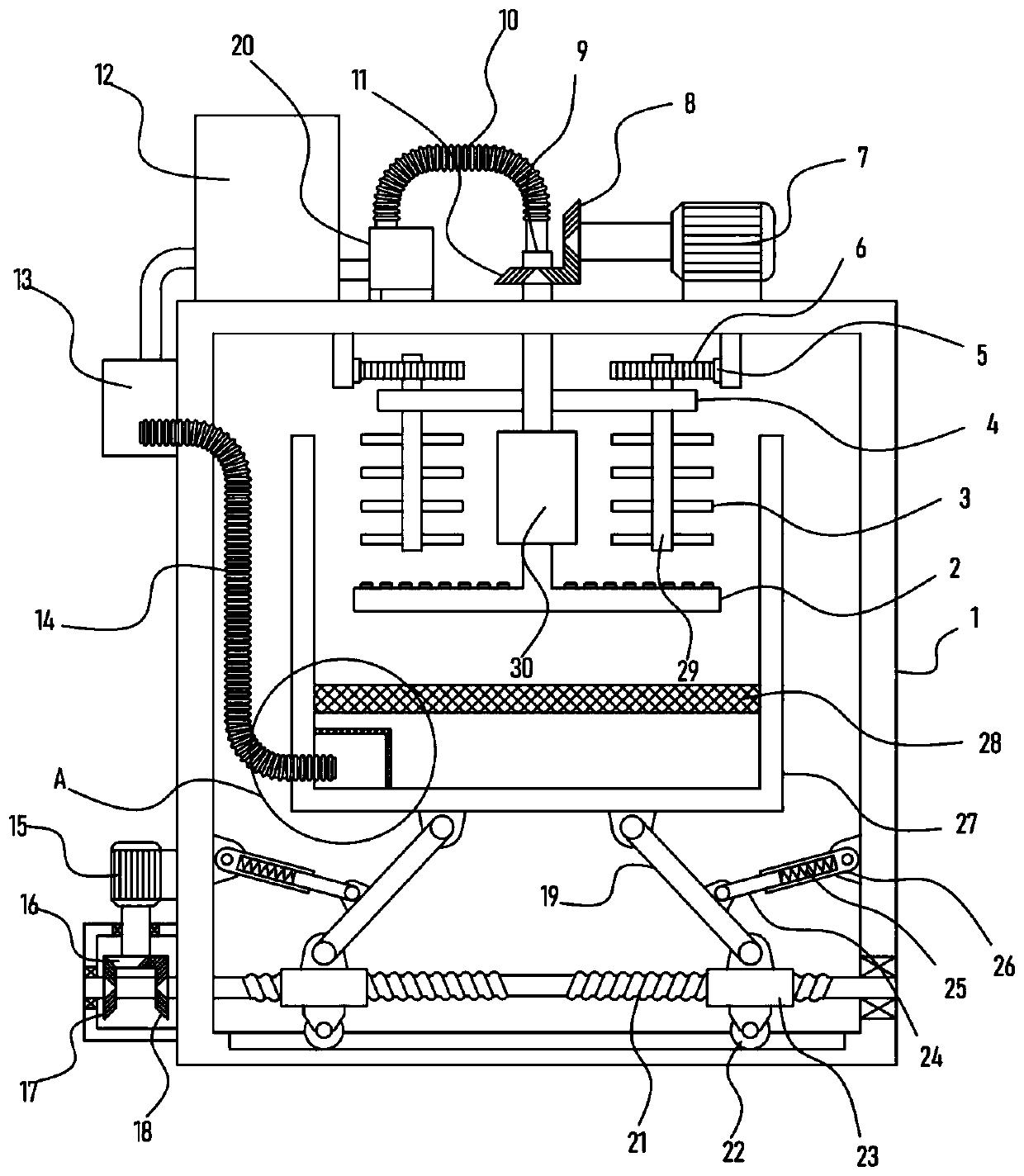

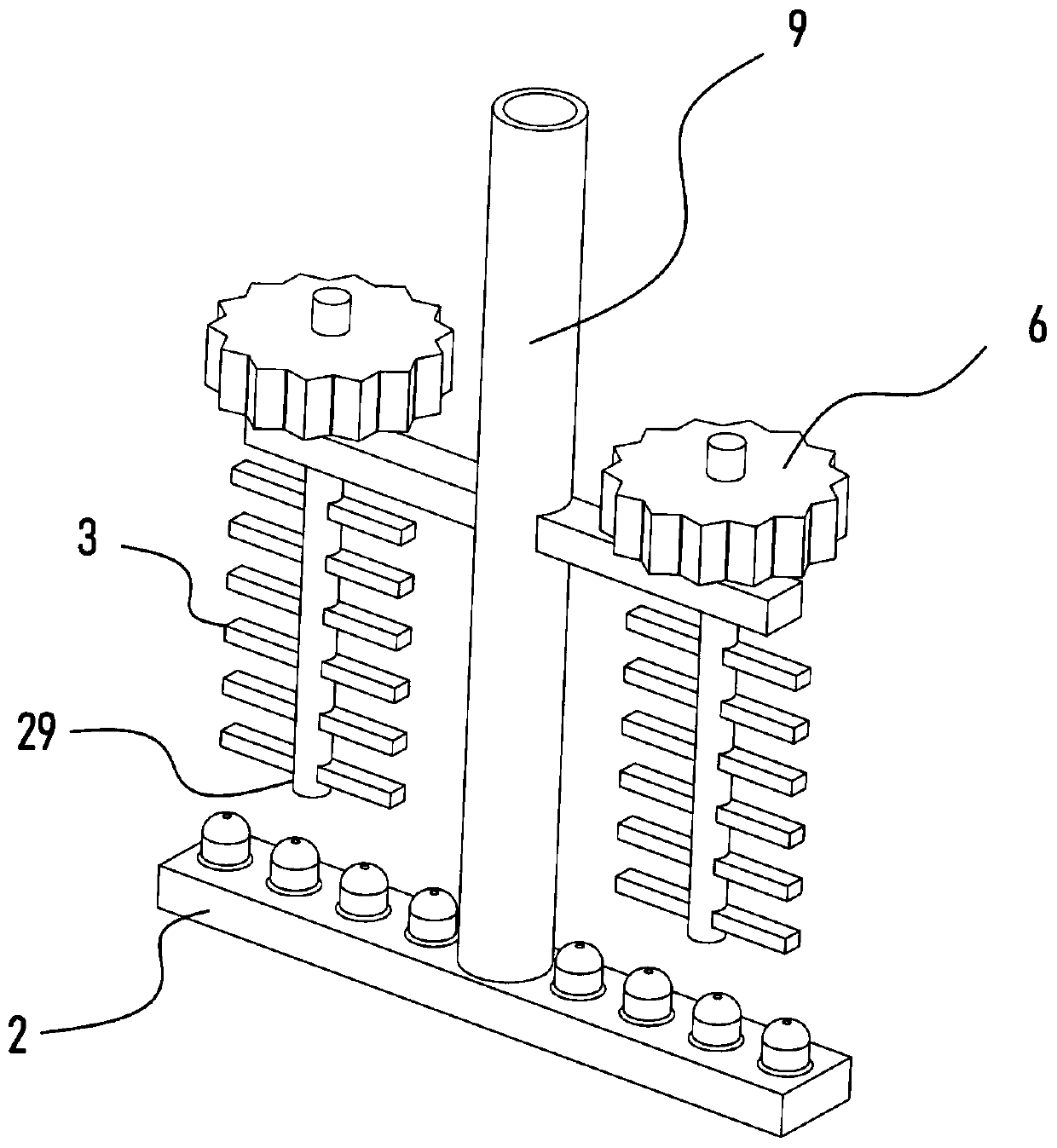

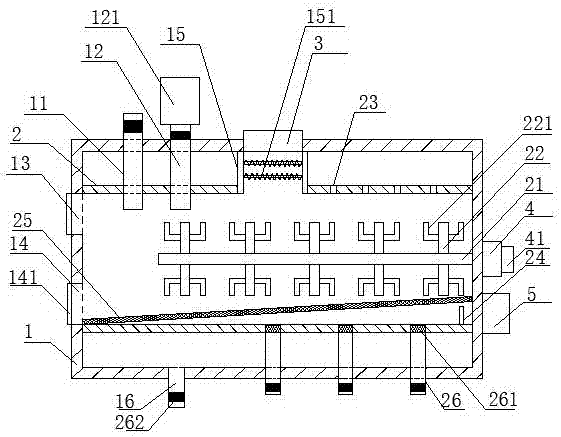

Nano-calcium carbonate carbonization reaction kettle

ActiveCN102897815AIncrease contact areaSmall diameterCalcium/strontium/barium carbonatesChemical industryImpellerControl engineering

The invention discloses a nano-calcium carbonate carbonization reaction kettle. The reaction kettle comprises a motor, a speed reducer, stirrers, a gas inlet pipe and valves, wherein the stirrer B8 is close to the bottom of a reaction kettle 1 and is connected with a variable frequency motor B11; the middle upper part of the reaction kettle 1 is provided with the stirrer A5 consisting of a stirring shaft 6 and a stirring impeller 7; the upper end of the stirring shaft 6 is sequentially connected with the speed reducer 3 on the top of the reaction kettle 1 and the motor A2; the reaction kettle 1 is provided with the valve A4; and the gas inlet pipe 9 and the valve C12 are arranged at the bottom of the reaction kettle 1. The round zigzag stirrers arranged in the reaction kettle are used for supplying high shearing force to slurry and gas in the reaction kettle, so that the effects of uniformly distributing gas, reducing bubble diameter, increasing gas-liquid contact area, sufficiently dispersing and strengthening mass transfer can be achieved, so that a macro-circulation is formed, and the utilization of carbon dioxide is improved; and the reaction kettle is simple in arrangement, small in investment, low in energy loss, easy in operation control and short in reaction time; and product quality is uniform and stable.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

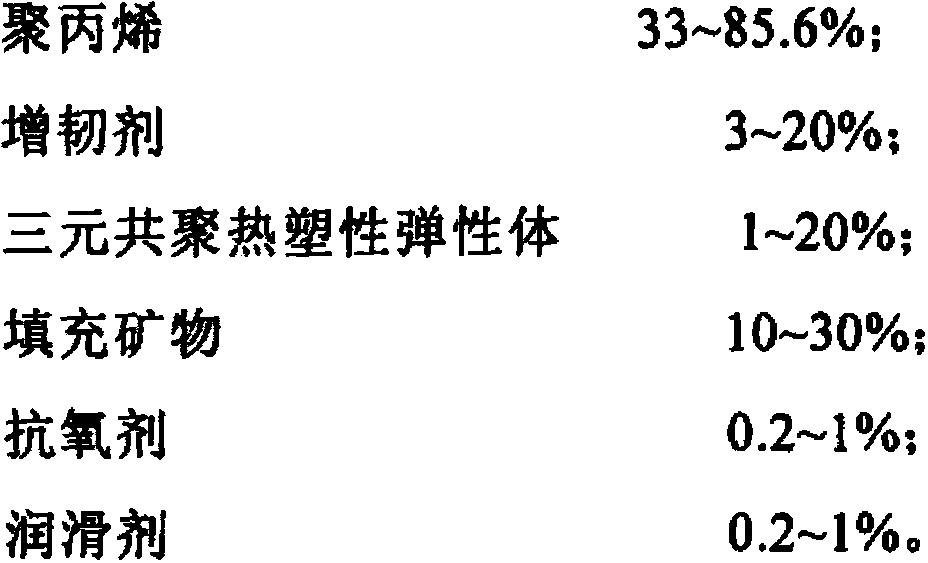

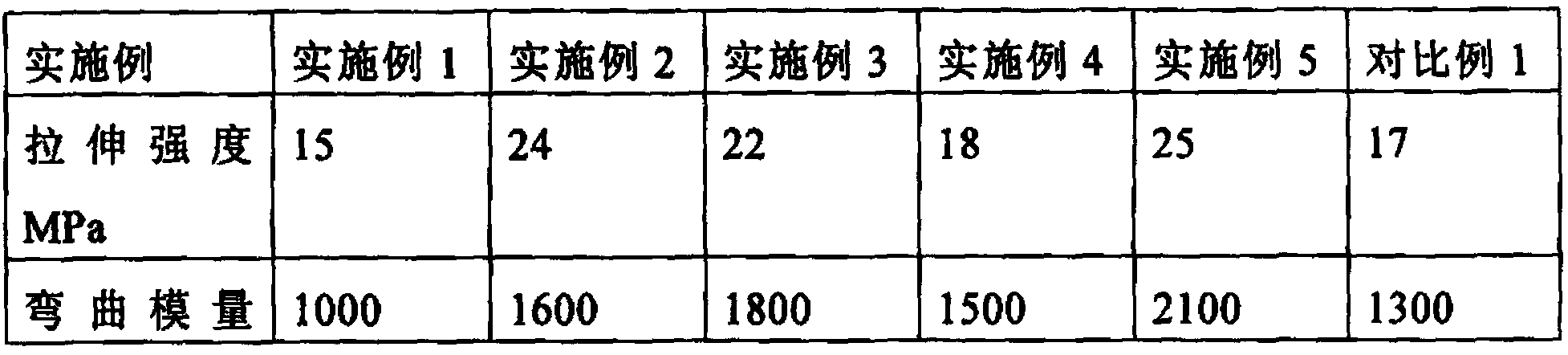

Polypropylene composite material with good appearance and preparation method thereof

The invention relates to a polypropylene composite material with good appearance and a preparation method thereof. The preparation method comprises the following steps: (1) weighing the following components by weight percent: 33%-85.6% of polypropylene, 3-20% of flexibilizer, 1-20% of ternary polymerization thermoplastic elastomer, 10-30% of filling mineral, 0.2-1% of antioxygen, and 0.2-1% of lubricant; (2) putting the raw materials of the step (1) into a high-speed mixer and mixing for 2-5 minutes, and discharging; (3) putting the materials mixed in the step (2) into a twin screw extruder and pelleting through extrusion so as to prepare the polypropylene composite material with good appearance, wherein the rotation speed of the twin screw extruder is 200-400 rpm (revolutions per minute), and the temperature is 180-220 DEG C. Compared with the prior art, the polypropylene composite material has good mechanical property, has no defects such as marks and tiger skin left on the surface, is environment-friendly, and can be widely used in the fields of automobiles, household appliances, sports goods and the like.

Owner:SHANGHAI SUNNY

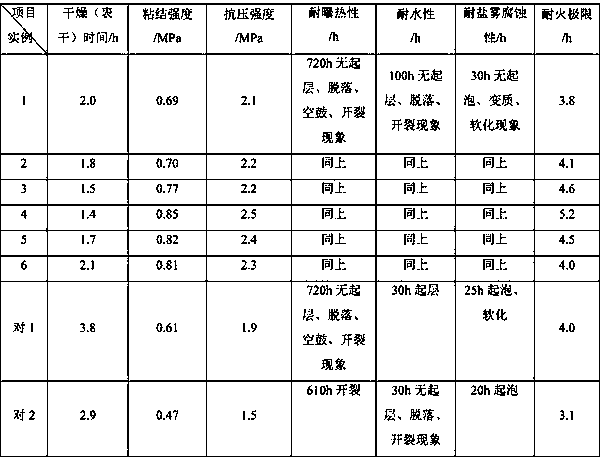

Fireproof coating and preparation method thereof

InactiveCN109294383AImprove stain resistanceHigh hardnessFireproof paintsAntifouling/underwater paintsDrying timeCorrosion

The invention discloses a fireproof coating and a preparation method thereof. The fireproof coating comprises, by weight, 30-40 parts of a fluorosilicone-modified acrylate emulsion, 20-35 parts of a waterborne polyurethane resin, 0.6-1.5 parts of sodium sulfosuccinate, 0.5-1.0 part of vinyl trimethoxysilane, 10-20 parts of ammonium polyphosphate, 12-17 parts of zinc borate, 5-10 parts of pentaerythritol, 10-20 parts of diatomite, 7-15 parts of expanded perlite, 0.5-1.5 parts of gamma-Al2O3, 5-10 parts of nano-titanium dioxide, 1-2 parts of a film-forming agent, 0.02-0.05 parts of a defoamer and 40-60 parts of water. The fireproof coating has the advantages of short drying time, good adhesion, high mechanical strength, excellent heat resistance, high temperature resistance, water resistanceand salt mist corrosion resistance.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

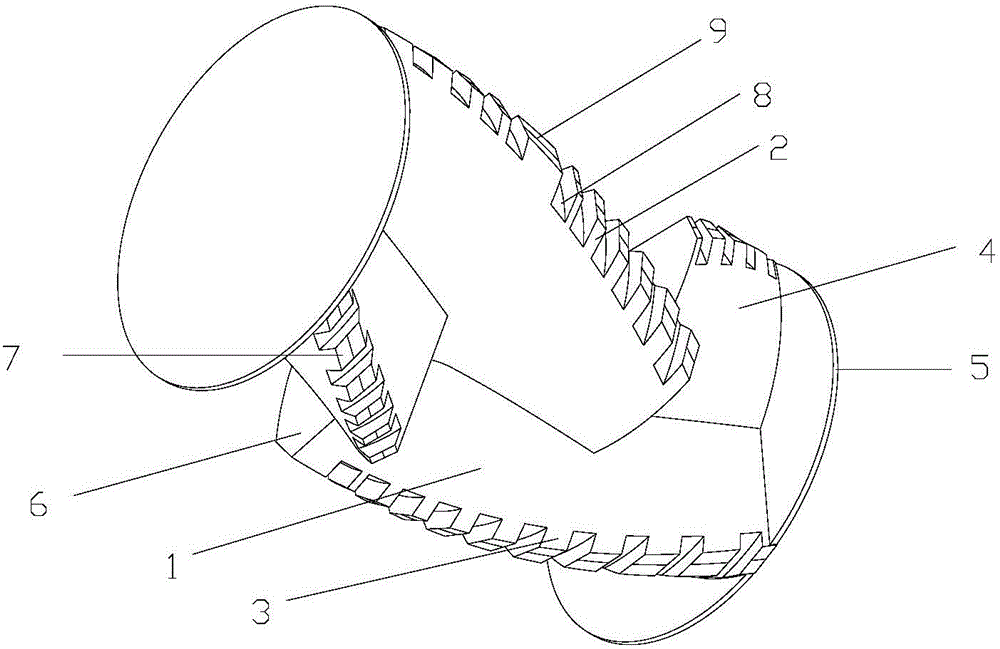

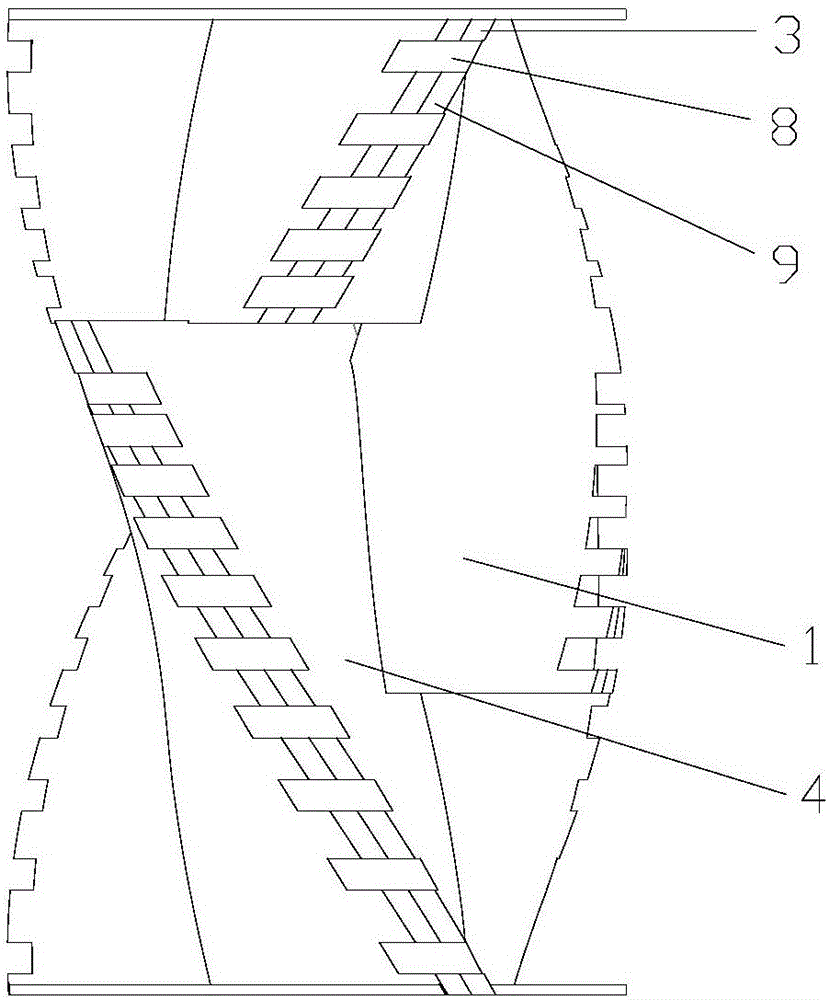

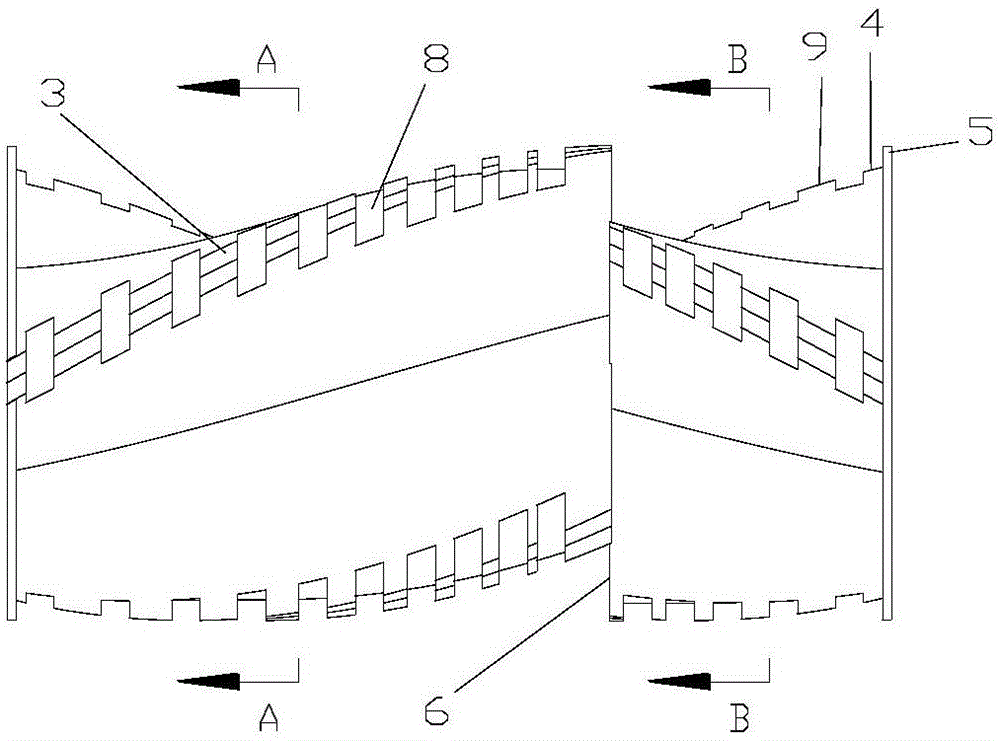

Six-ridge serrated dynamic variable-gap internal mixer rotor

The invention discloses a six-ridge serrated dynamic variable-gap internal mixer rotor which comprises a rotor body. Six protruded ridges are arranged on the rotor body, include three long ridges and three short ridges, spirally extend from two ends of the rotor body to the middle of the rotor body and comprise starting ends and finish ends; a plurality of tooth spaces are respectively arranged on ridge tops of the protruded ridges, the difference of the widths of the tooth spaces on each protruded ridge keeps unchanged in the direction from the starting end to the finish end of the protruded ridge, and the distances among the tooth spaces on each protruded ridge are gradually shortened in the direction from the starting end to the finish end of the protruded ridge. The six-ridge serrated dynamic variable-gap internal mixer rotor has the advantages that the tooth spaces are additionally arranged at the protruded ridges of the six-ridge serrated dynamic variable-gap internal mixer rotor, accordingly, peripheral flowing of rubber materials can be changed, and the six-ridge serrated dynamic variable-gap internal mixer rotor is favorable for distributing and dispersing various fillers and compounding ingredients; the quantities and the distribution density of the tooth spaces are increased along with increase of the peripheral flowing speeds of the rubber materials, accordingly, effects of masticating the lump-shaped rubber materials among the ridges can be enhanced, the rubber materials can flow in internal mixing chambers chaotically, and the rubber mastication quality and the rubber mastication efficiency can be improved.

Owner:QINGDAO UNIV OF SCI & TECH

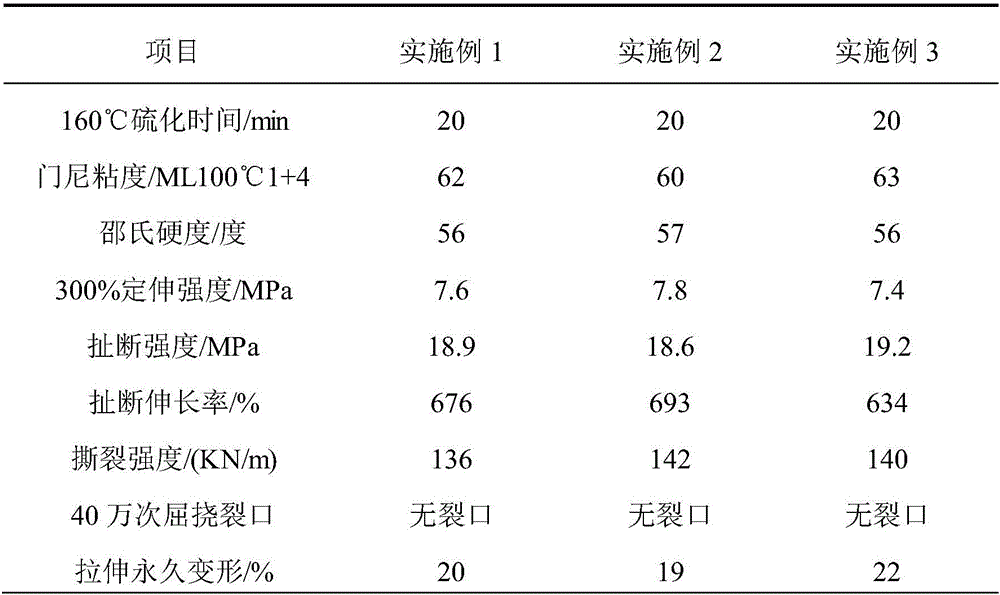

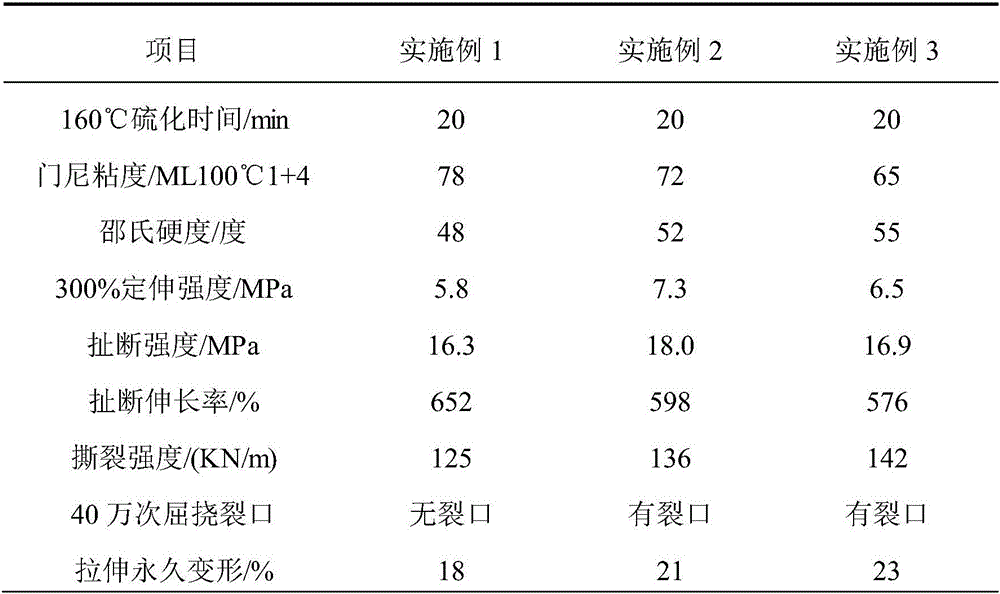

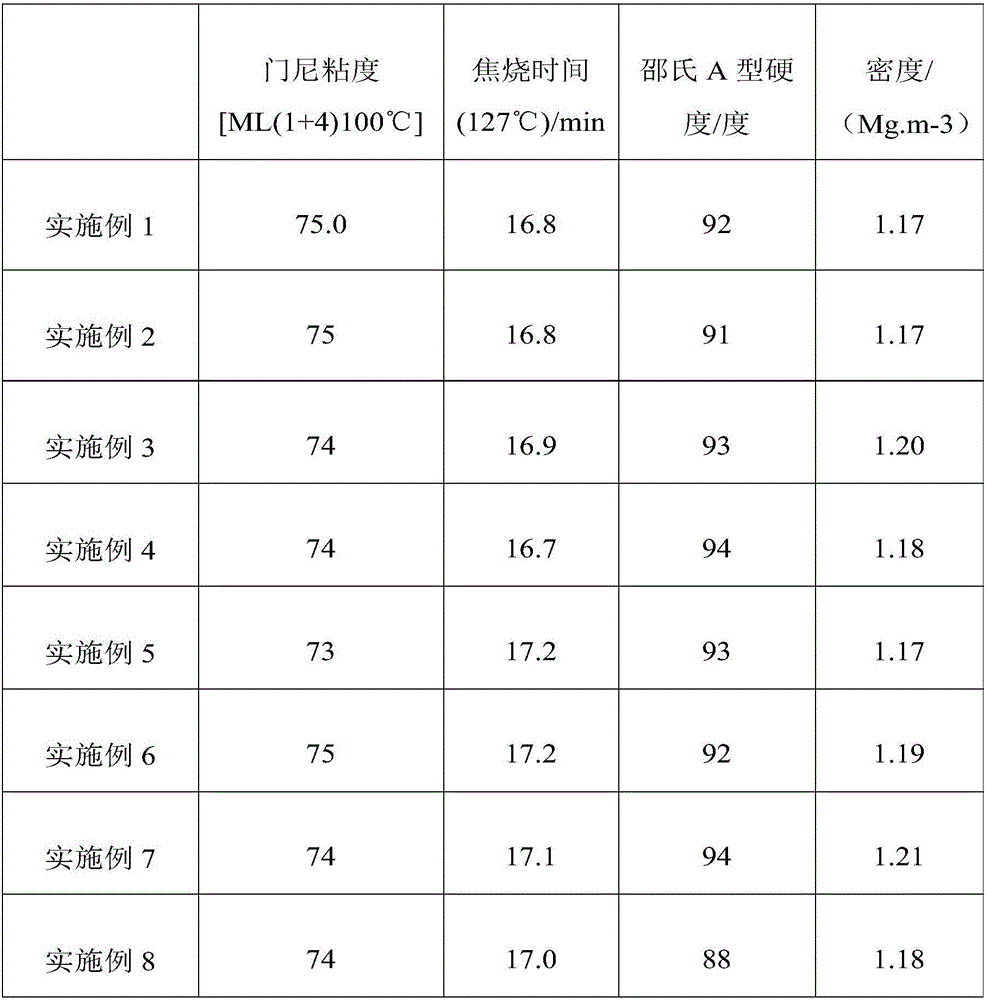

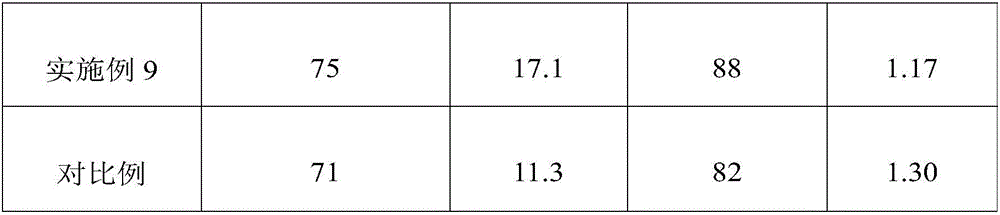

Semi-steel meridian tire sidewall rubber composition and preparation method thereof

InactiveCN106432830AHigh modulusIncrease stickinessSpecial tyresPolymer scienceManufacturing technology

The invention belongs to the technical field of rubber tires and chemical engineering manufacturing, and concretely relates to a liquid isoprene rubber-containing semi-steel meridian tire sidewall rubber composition and a preparation method thereof. The tire sidewall rubber composition comprises, by weight, 30-50 parts of natural rubber, 40-60 parts of butadiene rubber, 10-20 parts of liquid isoprene rubber, 52-56 parts of carbon black, 4.6-5.7 parts of an activator, 3.7-4.2 parts of an antioxidant, 1.8-2.5 parts of protection wax, 2-4 parts of a homogenizing agent, 0.7-1.0 part of a promoter and 1.76-1.8 parts of sulfur. The liquid isoprene rubber is used in semi-steel tire sidewalls, and rubber processing oil in traditional formulas is eliminated, so the problems of visual pollution and color change of tires, caused by migration and precipitation of the rubber processing oil from the surfaces of the tires in the late stage are solved, thereby the visual brightness of the tires is improved; and the use of the liquid isoprene rubber makes produced tires be better than tires produced by using the rubber processing oil in tire sidewall deflection heating reduction, tear resistance, cold resistance and ageing resistance.

Owner:山东新大陆橡胶科技有限公司

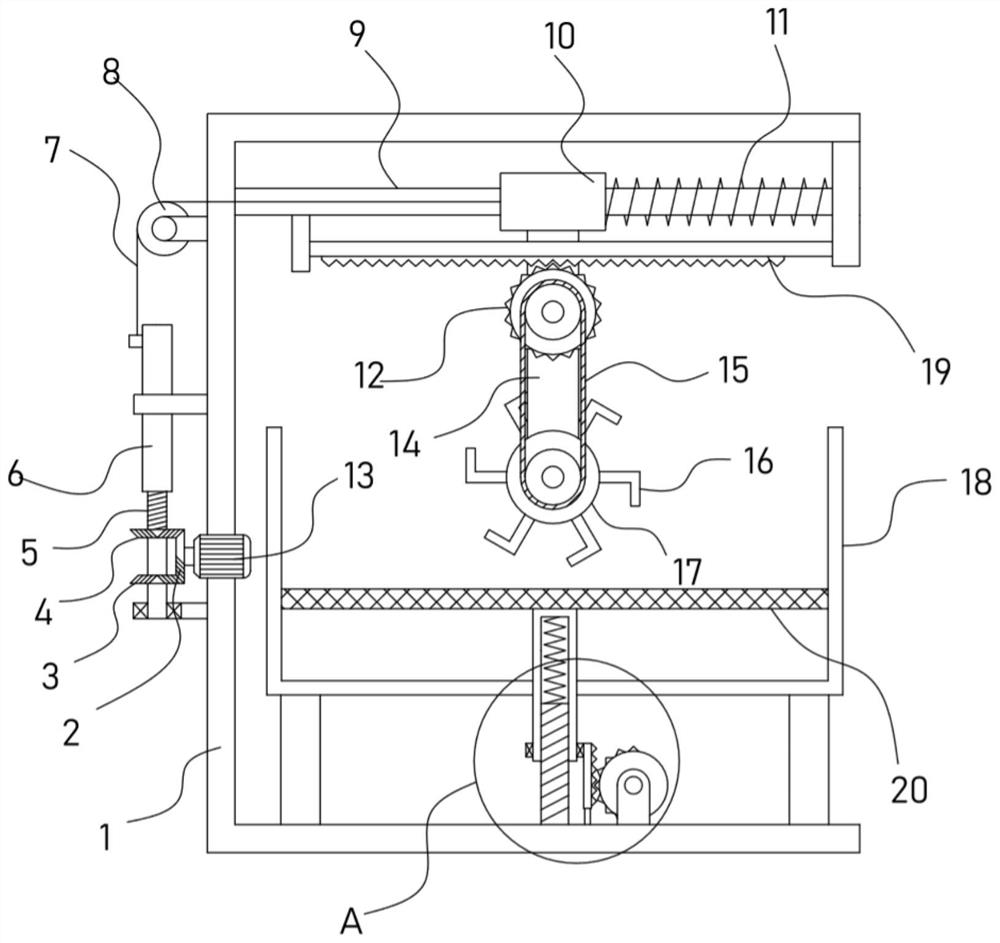

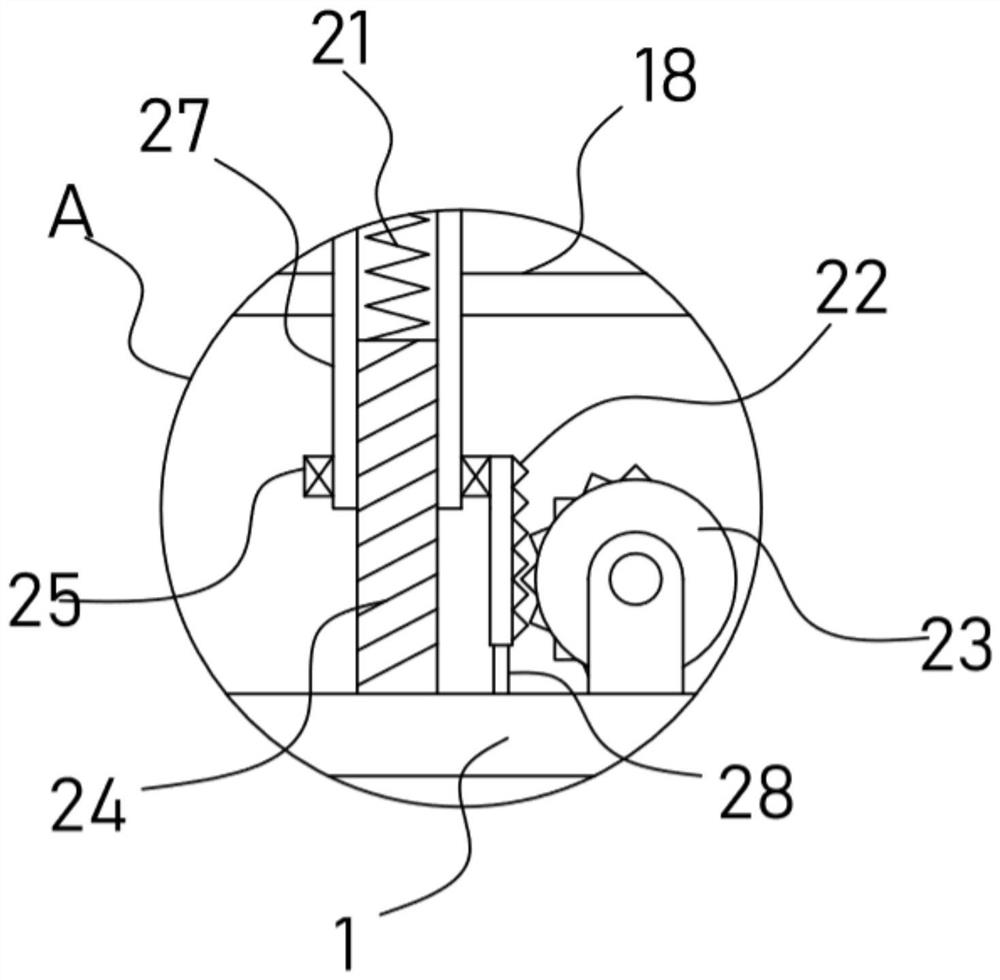

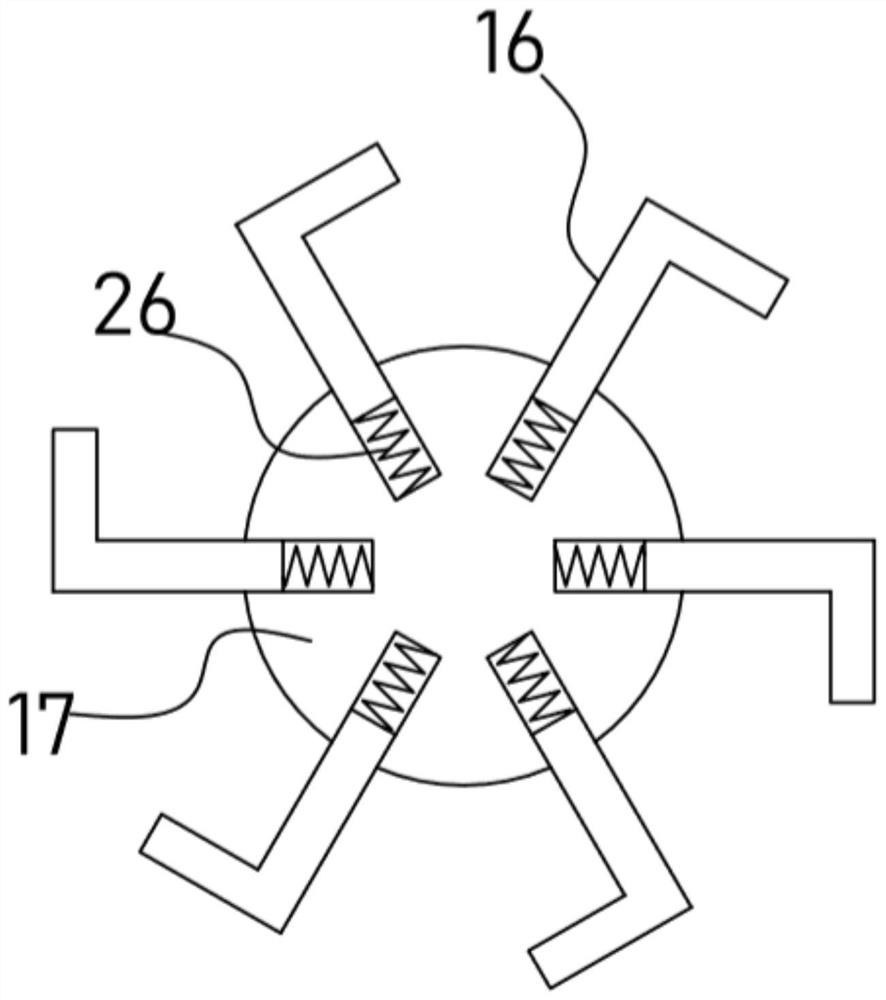

Building sand stone screening device

InactiveCN111774294ARealize flipping effectFully screenedSievingScreeningReciprocating motionGear wheel

The invention discloses a building sand stone screening device, and relates to the technical field of building construction machines. A fixing frame is included and fixedly provided with a screening groove. An incomplete gear is rotationally arranged on the fixing frame and is in driving connection with a reciprocating pushing mechanism for transmission of vertical lifting of a sieve plate. Through an arranged forward and reverse rotation mechanism, the vertical reciprocating type moving effect can be achieved on a threaded sleeve I, the threaded sleeve I achieves the purpose that a sliding block drives a vertical plate to transversely reciprocate through an arranged traction mechanism, accordingly, an overturning mechanism transversely reciprocates, the overturning effect on sand stone atdifferent positions in the screening groove is achieved, and the sieve plate is promoted to sufficiently screen sand stone. Through the arranged reciprocating pushing mechanism, a threaded sleeve IIcan be driven to vertically reciprocate, under the thread meshing action of a threaded rod, the sieve plate vertically ascends and descends in a reciprocating manner while the sieve plate rotates, sufficient rotating dispersing and vibrating of the sand stone on the sieve plate are promoted, and the sand stone screening efficiency is obviously improved.

Owner:屈洪先

Thin-layer graphene aqueous slurry and preparation method and application thereof

The invention discloses thin-layer graphene aqueous slurry and a preparation method and application thereof. The thin-layer graphene aqueous slurry comprises the following components in percentage bymass: 1-10% of thin-layer graphene, 1-20% of filler, 0.5-5% of functional auxiliary agent and the balance water. According to the thin-layer graphene aqueous slurry prepared by the preparation method,the graphene is uniformly dispersed in the filler, is stable in storage and good in compatibility with resin and the filler; in the process of mixing with the aqueous resin, emulsion or other fillers, the graphene is difficult to stack and agglomerate due to the blockage of the filler, so that the dispersion effect and efficiency of the thin-layer graphene in a coating is improved, the thin-layergraphene is fully dispersed and spread in the coating, the high-efficiency shielding effect is achieved with low content; and the process is simple, the efficiency is high, and the thin-layer graphene aqueous slurry plays an important role in improving the corrosion resistance of an existing coating based on an aqueous coating.

Owner:苏州格瑞丰纳米科技有限公司

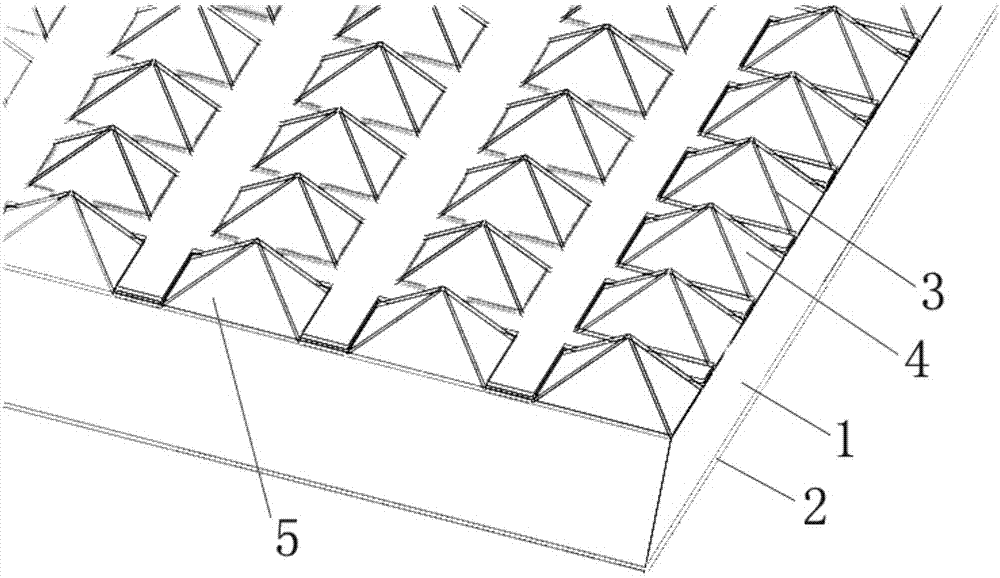

Bijection type reflecting solder strip

ActiveCN103681927AIncrease light intensity and areaReduce conversion efficiency lossPhotovoltaic energy generationSemiconductor devicesSurface fittingLight source

The invention belongs to the technical field of novel photovoltaic energy, and relates to a key component used in a solar cell assembly, in particular to a bijection type reflecting solder strip. The bijection type reflecting solder strip comprises a film substrate, wherein a film sticking layer is fixed on the bottom surface of the film substrate; the top surface of the film substrate is provided with a plurality of projections which are connected integrally with the film substrate and are formed uniformly; each projection has a regular rectangular pyramid structure; a metal layer is jointed to the upper surface of the film substrate. By adopting the reflecting solder strip, light sources are utilized to the maximum extent; meanwhile, power loss in a conversion process is reduced, the surface shading portion of a solar cell is reduced, and the power generation conversion efficiency is increased.

Owner:WUXI SVECK TECH

Preparation method of ternary positive electrode slurry

ActiveCN111933938AWell mixedFull dispersionSecondary cellsPositive electrodesLithium electrodeResidual solvent

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a preparation method of ternary positive electrode slurry. The preparation method of the ternary positive electrode slurry comprises the following steps: 1) adding a positive electrode active substance, a conductive agent and a binder into a VC efficient mixer, and carrying out mixing and sieving twice to obtain dry powder; 2) adding the dry powder into a stirrer, adding part of a solvent, standing for 20-30 minutes under the vacuum condition of -0.080 MPa to -0.085 MPa, and starting the stirrerfor stirring; 3) adding a carbon nanotube conductive paste, and carrying out stirring in vacuum; and 4) adding the residual solvent, and continuously stirring to obtain the positive electrode slurry.The VC efficient mixer is used for mixing and sieving twice, the mixing efficiency is effectively improved, moisture absorption of slurry in the slurry mixing process is inhibited through vacuum standing, agglomeration is reduced, mixing and dispersion of micron-sized particles in the slurry are facilitated, the internal resistance of the battery is reduced, and the rate capability, the cycle performance and the safety performance of the lithium ion battery are improved.

Owner:NINGBO XINSICHUANG AUTO PARTS +1

Triangle adhesive and preparation method thereof

The invention discloses a triangle adhesive and a preparation method thereof and relates to the field of tire processing. The triangle adhesive is prepared from the following raw materials in parts by weight: 50-70 parts of natural rubber, 30-50 parts of butadiene rubber, 2-3 parts of stearic acid, 64-80 parts of carbon black, 4-8 parts of zinc oxide, 5-8 parts of aromatic oil, 2-3 parts of an accelerant, 4-7 parts of insoluble sulfur and 0.05-0.2 part of a scorch retarder. The triangle adhesive is high in hardness and good in tenacity. The preparation method of the triangle adhesive comprises the steps of mixing the natural rubber and the butadiene rubber; adding the stearic acid, the zinc oxide and the carbon black and then adding the aromatic oil for mixing to generate an initial sizing material; mixing the initial sizing material, adding the remaining carbon black for mixing to generate a middle sizing material; and mixing the middle sizing material and then adding the insoluble sulfur, the scorch retarder and the accelerant for mixing to prepare the triangle adhesive. The triangle adhesive is simple and convenient in process, a rubber compound is good in dispersity, a green tire molding process is normal and the quality defects of glue starvation of a vulcanized product tire are avoided.

Owner:SICHUAN TYRE & RUBBER CO LTD

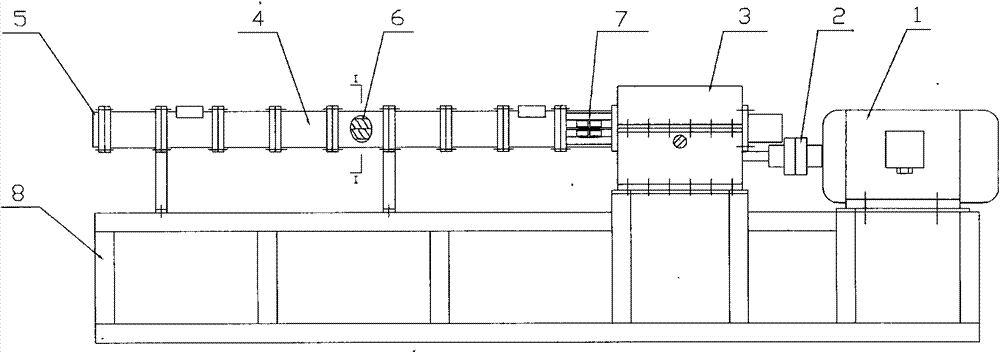

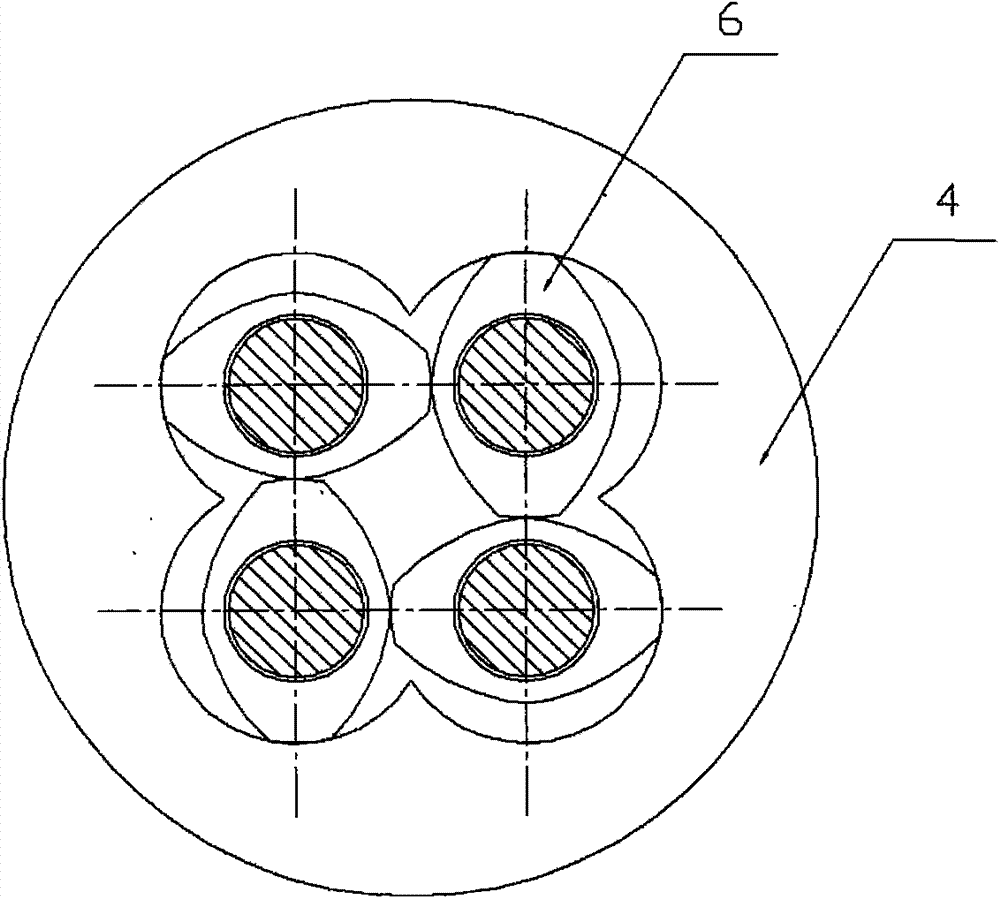

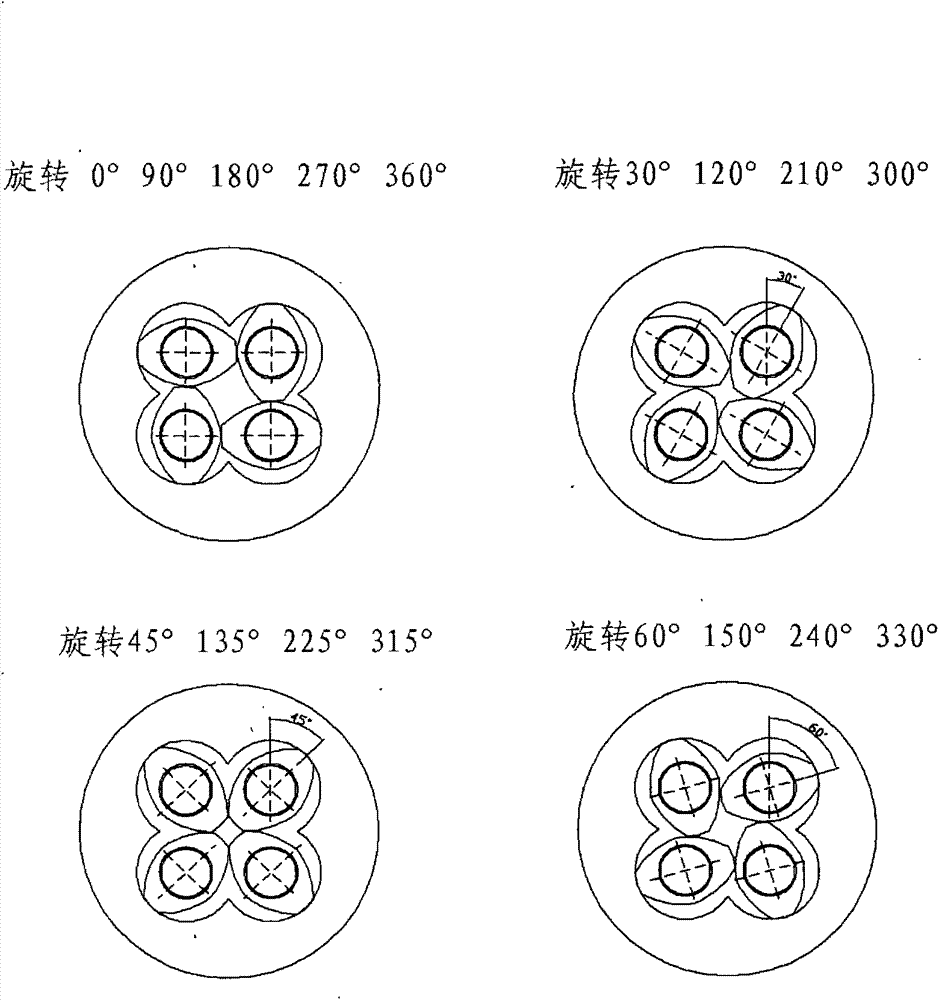

Four-screw mixing extruder

The invention relates to a novel plastic processing machine, in particular relates to a four-screw mixing extruder which is characterized in that a mixing device and an extruding device as well as a mixing working procedure and an extruding working procedure which are needed in the plastic processing process are respectively integrated. The four-screw mixing extruder consists of four screws, wherein the axes of the four screws are parallel to one another, the center distances of the four screws are equal, and a square shape is formed by connecting lines of four central points of the four screws in a vertical cross section. The four screws are respectively in a block combination type; all screw elements are meshed with one another, and a closed central area which is a mixing area can be formed. The four screws can rotate along the same direction, the area of the central area is changed for four times when the four screws turn a circle, and a period is defined by 90 degrees. The material is kneaded and extruded powerfully for tens of thousands of times every minute in the central area and is fully plastified, and all the components are evenly dispersed. The productivity of the four-screw mixing extruder is twice that of a common twin-screw extruder, and the energy consumption of the four-screw mixing extruder is reduced by 50%.

Owner:许汉辰 +2

Iron filing collection device for machining

InactiveCN111390634ARapid coolingImprove cooling effectMaintainance and safety accessoriesRotational axisCooling effect

The invention discloses an iron filing collection device for machining, and relates to the technical field of iron filing processing. The iron filing collection device includes a supporting frame, a cooling liquid tank is fixed to the supporting frame, a storage tank is arranged in the supporting frame, and a driving mechanism is arranged on the supporting frame; and the driving mechanism drives arotating tube extending into the storage tank to rotate, a drive motor II is connected with a reversing mechanism, and a lifting mechanism is connected between the reversing mechanism and the storagetank. Iron filings in the storage tank are adsorbed and collected through an electromagnet, and a spray disc in a cooling mechanism can spray cooling liquid to the iron filings in the storage tank topromote the cooling effect of the iron filings at higher temperature; and a stirring blade in a dispersing mechanism can rotate around a rotating shaft and revolve around the rotating tube, the fulldispersion of the iron filings is effectively improved, the rapid cooling of the iron filings is promoted, the centralized treatment of the iron filings after collection is facilitated, and the subsequent processing efficiency of the iron filings is improved.

Owner:陈思涵

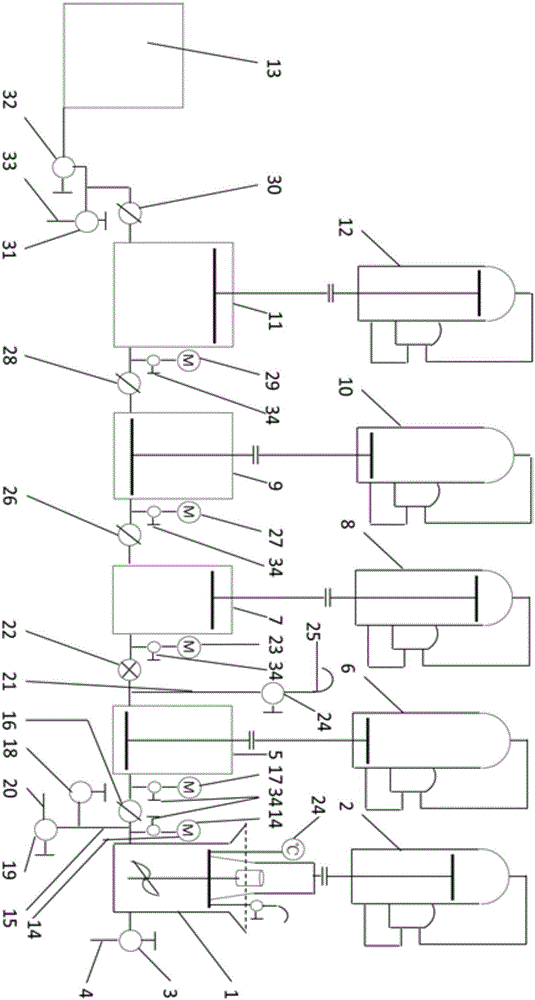

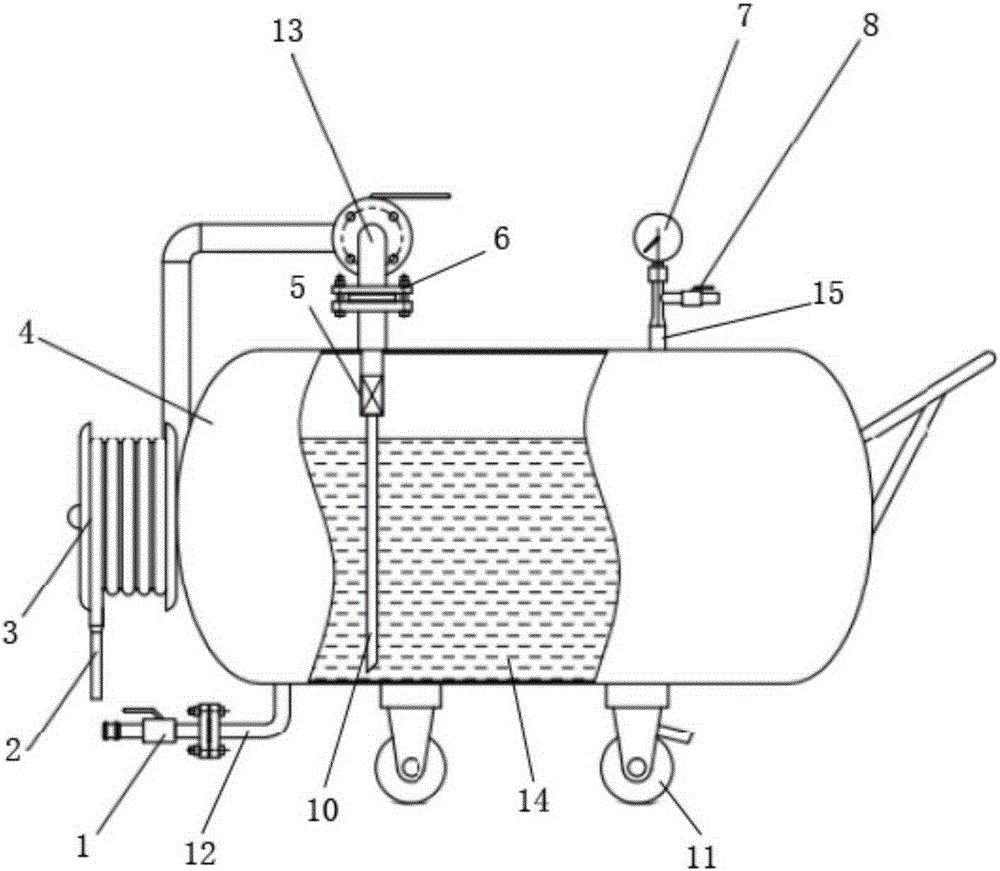

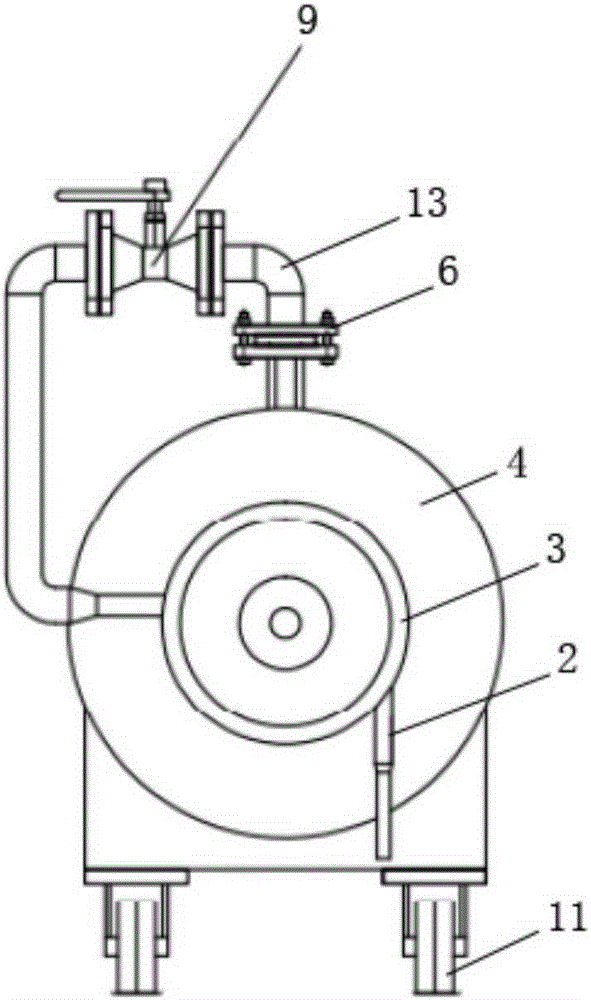

Preparation device of graphene composite dispersion liquid

The invention belongs to the technical field of machinery equipment, and relates to a preparation device of graphene composite dispersion liquid. A main body structure of the preparation device comprises a reaction kettle, a No.1 electrohydraulic servo mechanism, a No.1 sampling valve, a No.1 sampling opening, a No.1 pressurizing cylinder, a No.2 electrohydraulic servo mechanism, a No.2 pressurizing cylinder, a No.3 electrohydraulic servo mechanism, a No.1 pressure reduction cylinder, a No.4 electrohydraulic servo mechanism, a No.2 pressure reduction cylinder, a No.5 electrohydraulic servo mechanism, a storage container, a No.1 pressure meter, a No.1 branch pipeline, a No.1 one-way jet flow valve, a No.2 pressure meter, a safety valve, a liquid inflating valve, a liquid filling opening, a No.2 branch pipeline, a two-way jet flow valve, a No.3 pressure meter, a No.2 sampling valve, a No.2 sampling opening, a No.2 one-way jet flow valve, a No.4 pressure meter, a No.3 one-way jet flow valve, a No.5 pressure meter, a No.4 one-way jet flow valve, a No.3 sampling valve, a discharging valve, a No.3 sampling opening and a valve. The preparation device has the advantages that the structure is simple; safety and environment protection are realized; the preparation device can be widely used in the fields of chemical engineering, medicine, food processing and the like; the popularization and the use are easy.

Owner:QINGDAO HUAGAO GRAPHENE CORP LTD

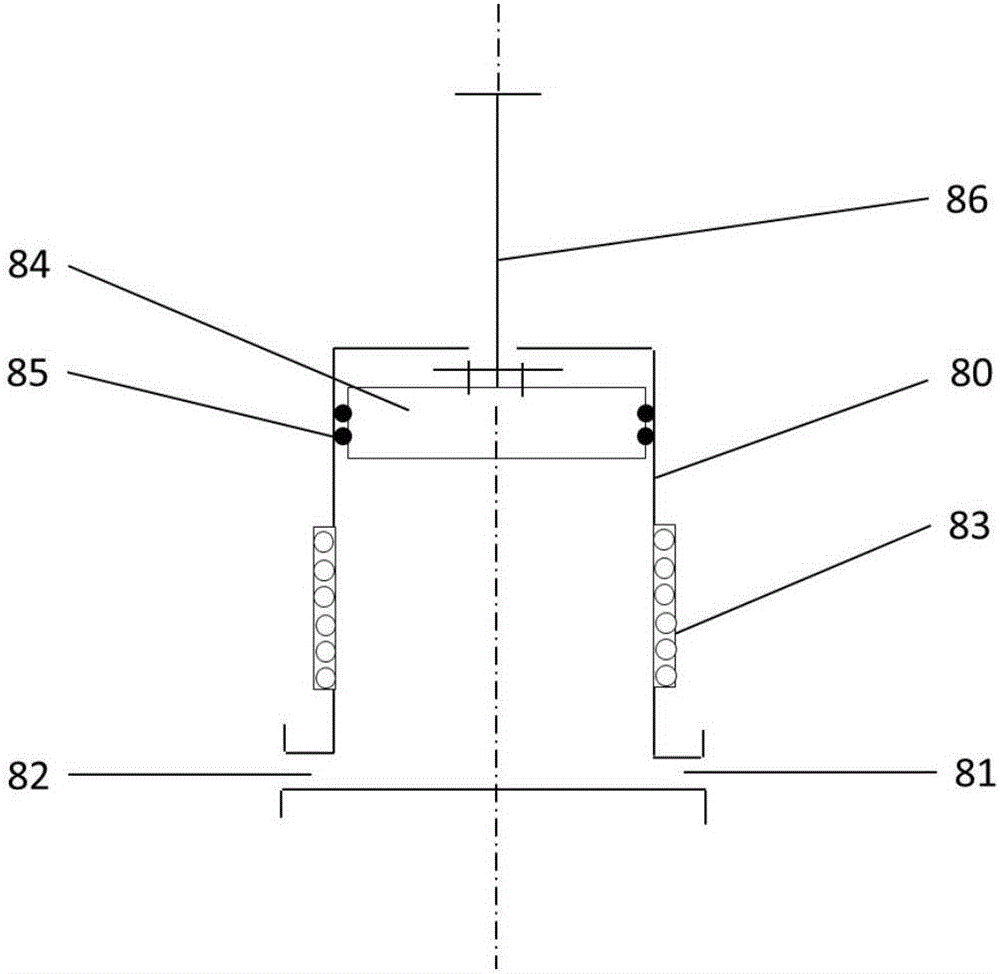

Batching device for uniformly and continuously measuring microscale solid powder and particles

InactiveCN105366382AGuaranteed accuracyGuaranteed continuityConveyorsLoading/unloadingCycle controlProgrammable logic controller

The invention discloses a batching device for uniformly and continuously measuring microscale solid powder and particles and relates to the continuous and uniform measuring and batching device for metallurgy, construction materials, foods and other manufacturing fields. The batching device is characterized in that the device structurally comprises a feeding box, a variable-speed spiral conveyor connected with a discharging pipe of the feeding box, and a weighting spiral conveyor connected with a discharging outlet of the variable-speed spiral conveyor; an electronic scale is arranged on the weighting spiral conveyor, and the data of the electronic scale are connected with the control end of a variable-frequency and variable-speed motor of the variable-speed spiral conveyor through a programmable logic controller (PLC). According to the batching device for uniformly and continuously measuring the microscale solid powder and the particles, close-cycle control, continuous operation and sealed operation in the batching process are achieved, sufficient mixing time and mixing space of the microscale solid powder, the particles and materials are ensured; the precision, the continuity and the stability of adding the microscale solid powder and the particles are ensured, and the microscale solid powder and the particles are sufficiently dispersed and mixed in the materials.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Light diffusion plate and preparation method thereof

InactiveCN108841079AHigh light transmittanceReduce black spots or failDiffusing elementsFluorescencePolypropylene

The invention discloses a light diffusion plate. The light diffusion plate is prepared from the following components in parts by mass: 100 parts of optical grade polypropylene, 0.4 to 0.96 part of light diffusion agent, 0.05 to 0.5 part of titanium dioxide, 0.008 to 0.02 part of white mineral oil, 3 to 9 parts of flexibilizer, 0.1 to 0.4 part of nucleating agent, and 0.00005 to 0.001 part of fluorescent whitening agent. The light diffusion plate disclosed by the invention is improved by adopting a screw rotary feeding, sealing and stirring mode; a formula in the light diffusion plate is directly and uniformly mixed, and then is extruded and molded through a mold without secondary granulation, so that the phenomenon of unstable optical performance caused by uneven master batch mixing of secondary granulation in the traditional production technological process is reduced; and in addition, the prepared product has the optical properties of low permeation, high haze and high luminance.

Owner:赖慎鹏

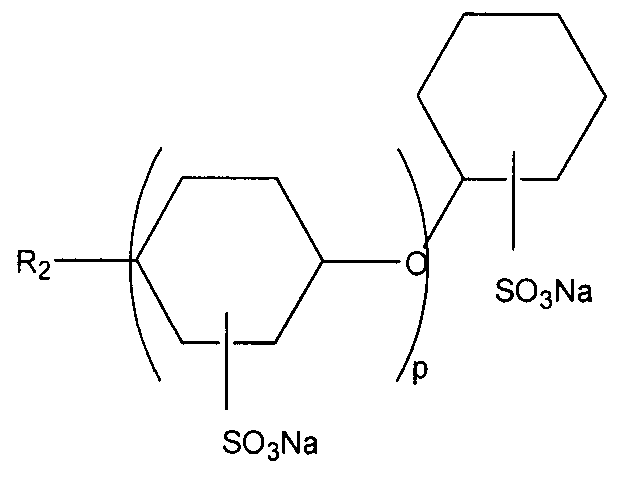

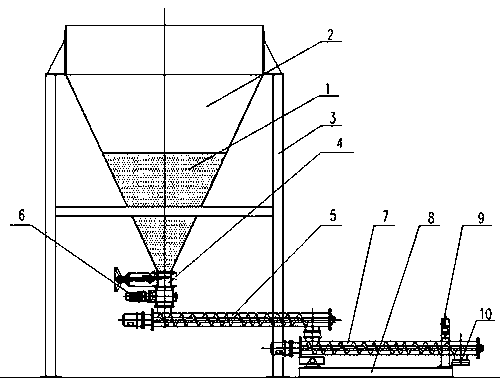

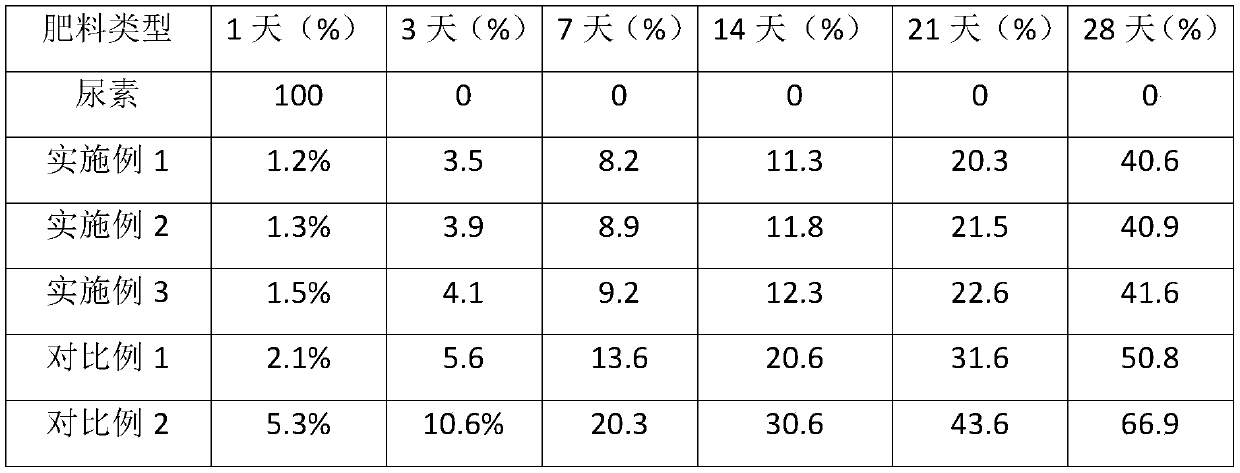

Slow release composite fertilizer for high-tower granulation and preparation method thereof

InactiveCN109776221AImprove disease resistancePromote crop growthClimate change adaptationAgriculture gas emission reductionPolyvinyl alcoholPhosphate

The invention discloses a slow release composite fertilizer for high-tower granulation and a preparation method thereof and belongs to the technical field of fertilizer. The fertilizer is prepared from, by weight, 100-150 parts of urea, 80-100 parts of monoammonium phosphate, 60-80 parts of potassium chloride, 20-40 parts of celestite powder, 10-20 parts of attapulgite powder, 10-20 parts of kieselguhr, 5-15 parts of a medium trace element mixture, 3-5 parts of a synergist and 5-10 parts of an outer-layer coating agent; the outer-layer coating agent is prepared in the mode that polyvinyl alcohol and polyvinylpyrrolidone are subjected to copolymerization, and then biomass charcoal is added. According to the slow release composite fertilizer, nanosilicon dioxide is added as the synergist, and through cooperation of the synergist and a coating material, an obvious slow release effect of the fertilizer is achieved. The prepared fertilizer is safe, environmentally friendly, has an obvious fertilizer efficiency, capable of achieving high tower granulation, low in cost and high in efficiency and has high market application potential.

Owner:GARSONI FERTILIZER MEISHAN

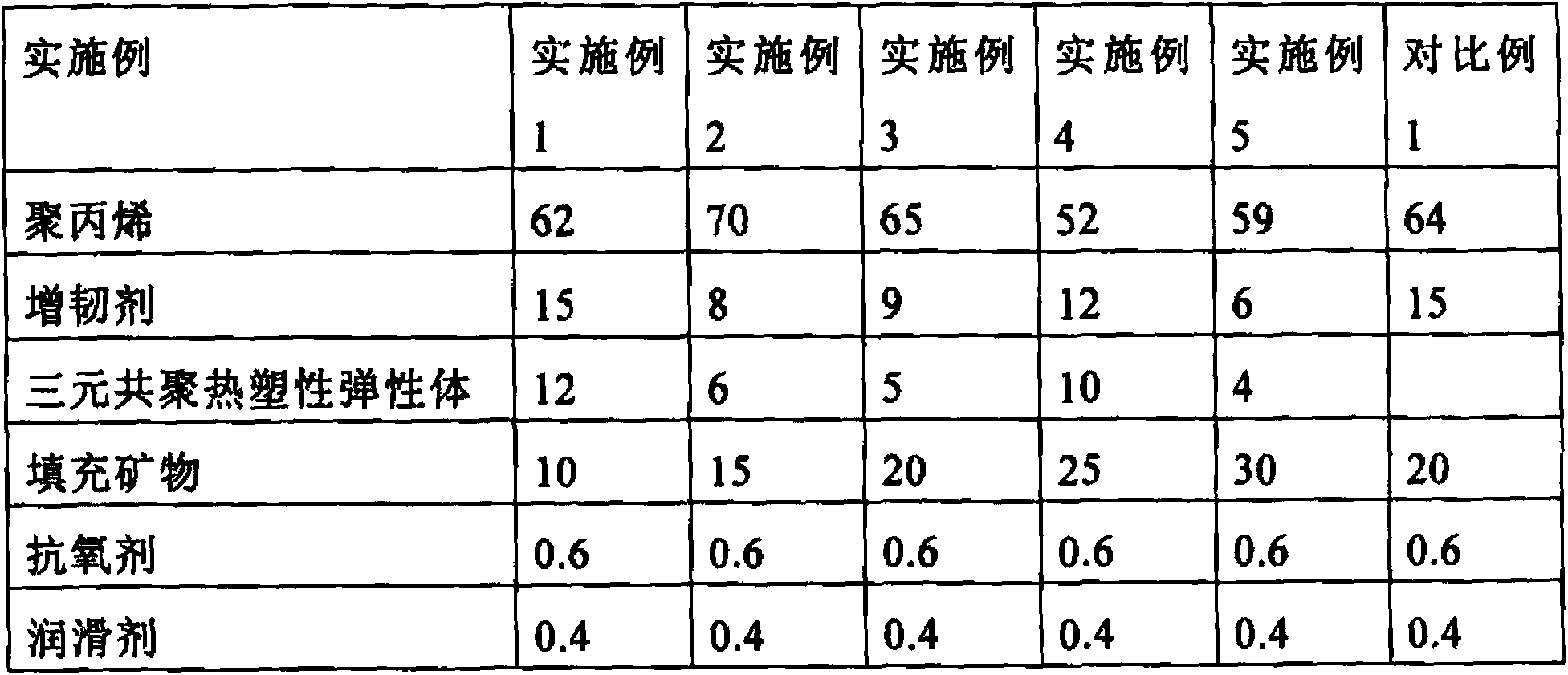

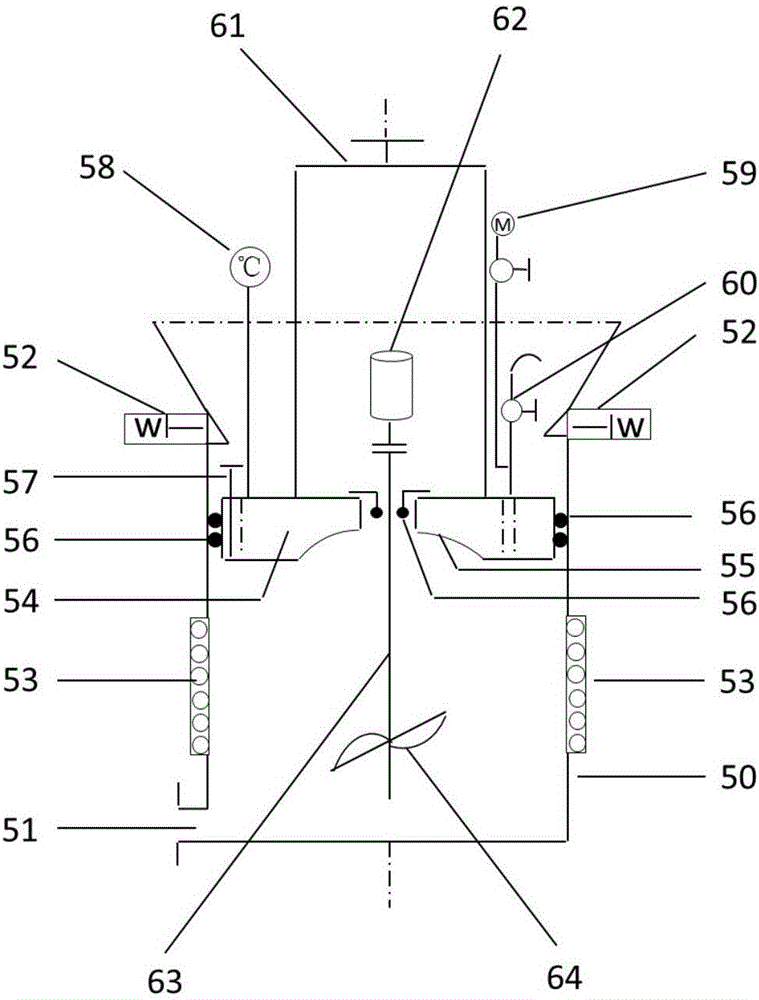

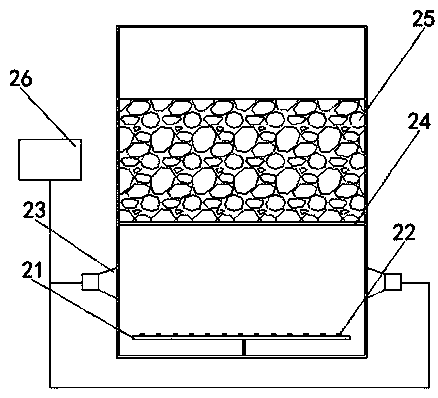

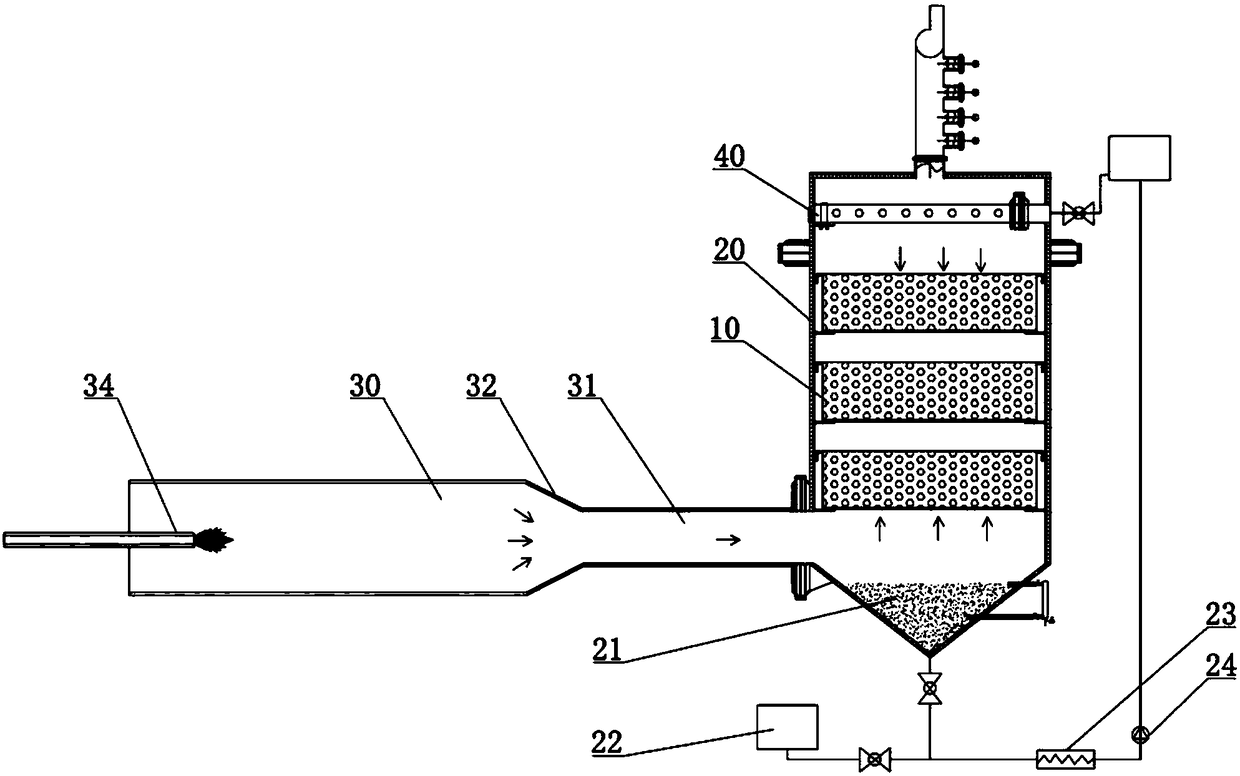

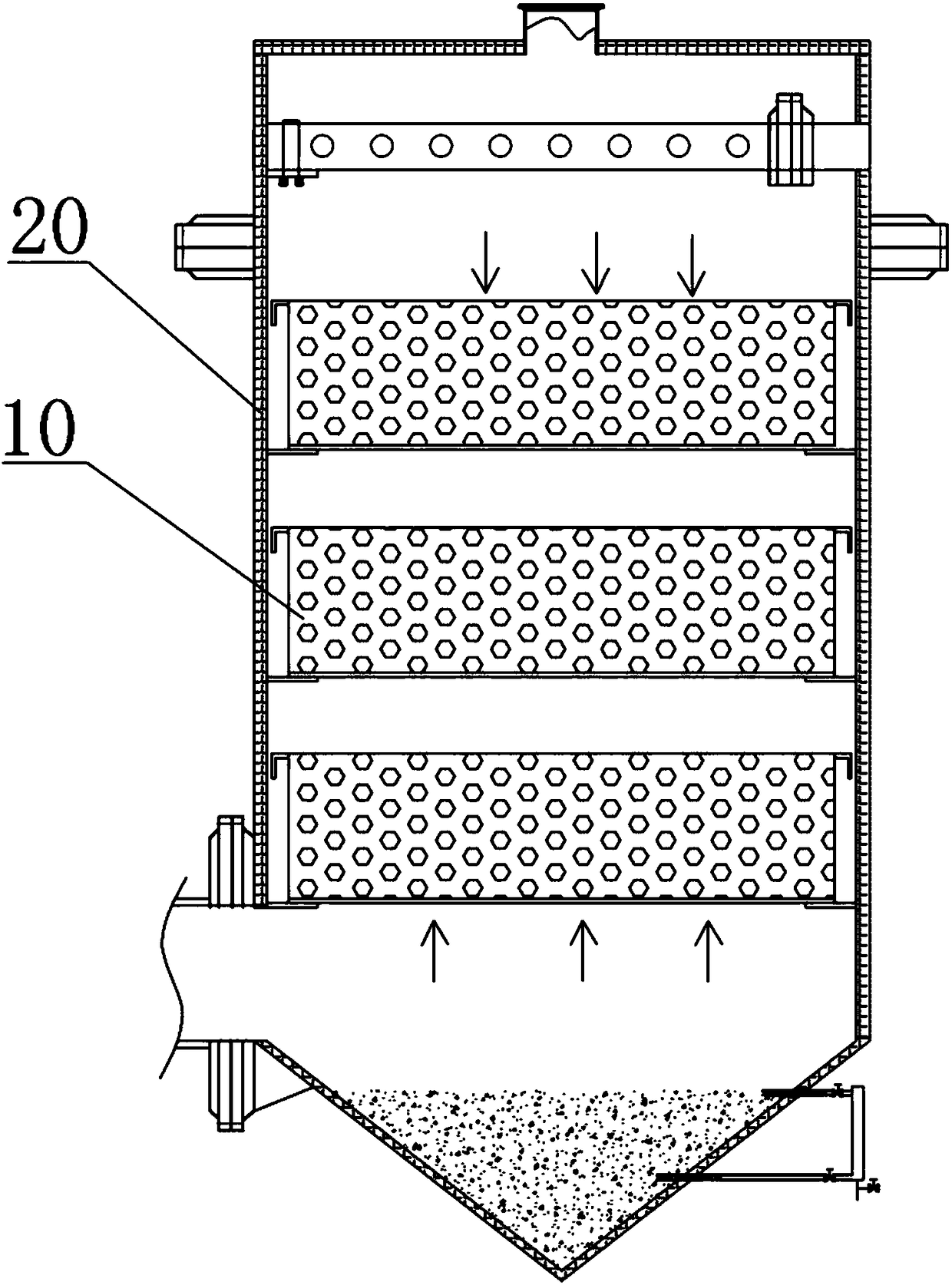

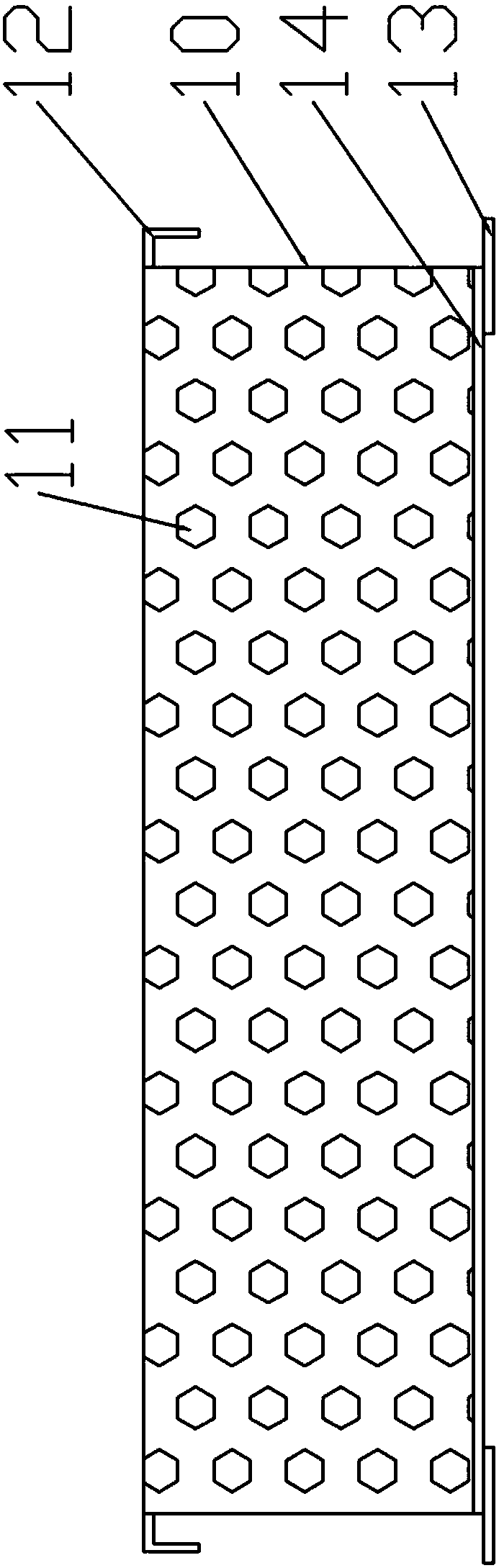

Device and method for treating high-concentration dye wastewater

PendingCN109626682AFull dispersionFull solubilityWater contaminantsWater/sewage treatment with mechanical oscillationsHigh concentrationOzone generator

The invention discloses a device and method for treating high-concentration dye wastewater. The device comprises a pH adjusting tank; a coagulation sedimentation, wherein a water inlet end of the coagulation sedimentation tank is connected with a water outlet end of the pH adjusting tank; a main reaction tank, wherein a water inlet end of the main reaction tank is connected with a water outlet endof the coagulation sedimentation tank; an oil-free air compressor; an adsorption dryer, wherein an air inlet end of the adsorption dryer is connected with an air outlet end of the oil-free air compressor; an ozone generator, wherein an air inlet end of the ozone generator is connected with an air outlet end of the adsorption dryer, and an air outlet end of the ozone generator is connected with anaeration pipe at the bottom of the main reaction tank through a pipeline. The device adopts a microelectrolysis-ozone-ultrasonic wave system, and the utilization rate of ozone can reach more than 95%through the synergistic effect of an iron-carbon filler and ultrasonic wave and the cyclic utilization of ozone tail gas. The device has the advantages of compact structure, high space utilization rate, good economy, high treatment efficiency and the like, and can be used for treating high-concentration dye wastewater.

Owner:辽宁拓启环保科技有限公司

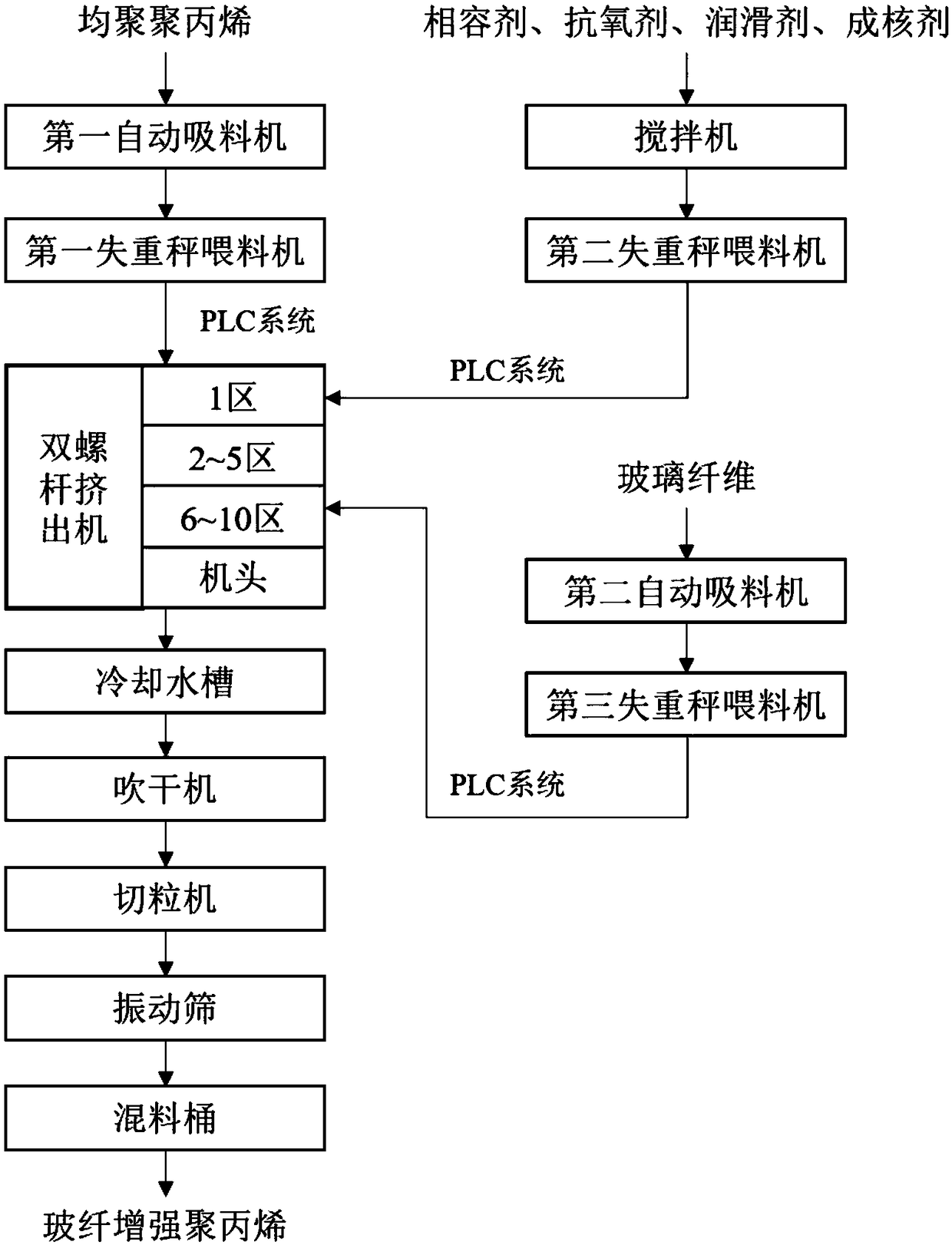

High-rigidity glass fiber reinforced polypropylene material and preparation equipment and preparation method thereof

The invention discloses a high-rigidity glass fiber reinforced polypropylene material and preparation equipment and a preparation method thereof. The high-rigidity glass fiber reinforced polypropylenematerial consists of the following raw materials: homo-polypropylene, a compatilizer, an antioxidant, a lubricating agent, a nucleating agent and glass fibers. Meanwhile, the invention discloses theequipment for preparing the polypropylene material and a method for preparing the high-rigidity glass fiber reinforced polypropylene material by using the equipment. In addition, the invention furtherdiscloses application of the high-rigidity glass fiber reinforced polypropylene material. The polypropylene material has high bending strength and modulus, is excellent in anti-impact property and good in thermal stability, resists hydrolysis, and can be widely applied to automotive panels, washing machine drums, handles of thermal jugs and the like.

Owner:GUANGDONG JUSHI CHEM CO LTD

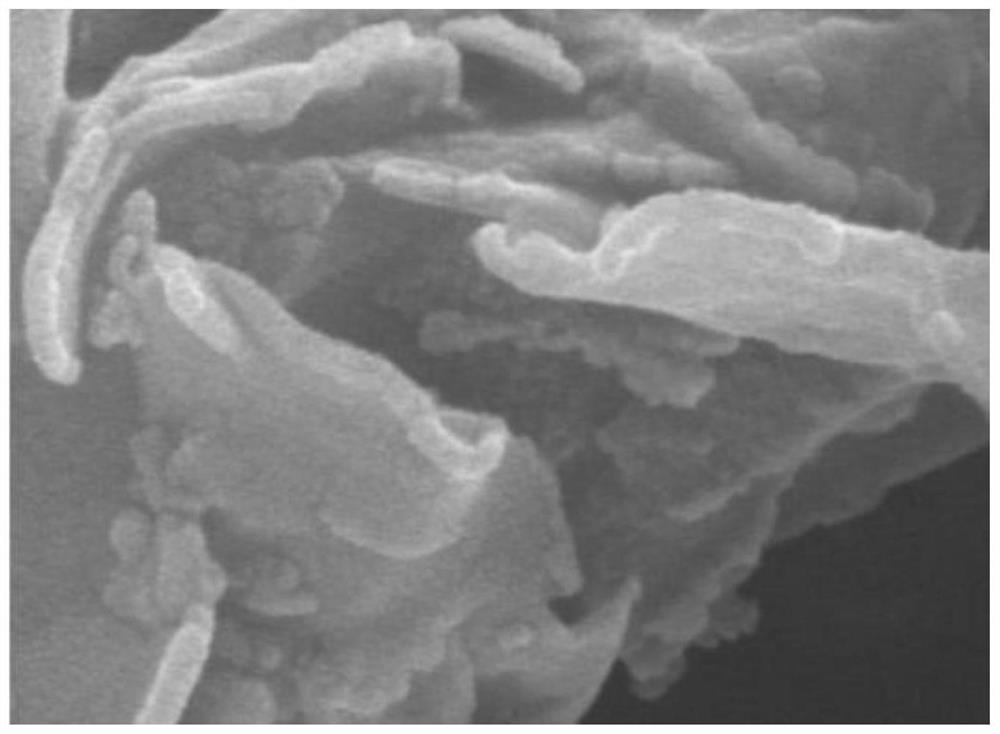

Preparation of high-specific surface area nanometer carbon tube

InactiveCN1613754ALarge specific surface areaSimple processOther chemical processesSorbentProduct gas

A production of high specific superficial area nanometer carbon tube is carried out by taking sodium hydroxide and potion as activating agent, mixing and dispersing nanometer carbon and activating agent by mechanical ball milling, and activating treating the ball milled nanometer tube mixture under high temperature. It achieves simple process and high specific superficial area for wide application.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

High-temperature flue gas quenching device

PendingCN108534564AGuaranteed to proceed normallyWon't accumulateWaste heat treatmentFlue gasElectromagnetic pump

The invention discloses a high-temperature flue gas quenching device which comprises a flue gas input mechanism and a quenching mechanism arranged in a heat exchange furnace; the flue gas input mechanism comprises a flue which is communicated with a flue gas source and the heat exchange furnace; the quenching mechanism comprises a dispersion disc, a filler unit, a hydrops pool and a circulation unit used for realizing quenching liquid circulation; the circulation unit comprises a heat exchanger which is communicated with the hydrops pool and an electromagnetic pump used for driving the quenching liquid to flow; one end of the electromagnetic pump is communicated with the heat exchanger, and the other end of the electromagnetic pump is communicated with the dispersion disc; the filler unitcomprises heat dissipation drums and heat exchange balls filled in the heat dissipation drums respectively, wherein the top surface and the bottom surface of each heat dissipation drum are arranged ina hollowed manner; the dispersion disc comprises a disc-shaped main body; the disc-shaped main body comprises a main pipe which is communicated with the electromagnetic pump and a plurality of branchpipes which are communicated with the main pipe; and the branch pipes are distributed on the two axial sides of the main pipe respectively. The invention is intended to provide the high-temperature flue gas quenching device capable of effectively lowering the energy consumption and the production cost.

Owner:北京宏帆态金节能科技有限公司

Pressure storage type compressed gas foam extinguishing system

The invention discloses a pressure storage type compressed gas foam extinguishing system which comprises a pressure liquid storage tank and a foam generator. The pressure liquid storage tank is filled with foam extinguishing agent mixed liquid and compressed gas. The foam generator is arranged in the pressure liquid storage tank and the foam generator is located above the foam extinguishing agent mixed liquid. A gas inflow hole, a liquid inlet and a turbulator are arranged on the foam generator. The liquid inlet is communicated with a liquid suction pipe arranged at the lower end of the foam generator. The bottom of the liquid suction pipe is located on the lower portion of the pressure liquid storage tank. A foam outlet pipe connected with the foam generator is arranged at the top end of the pressure liquid storage tank. A foam delivery pipe is arranged on one side of the pressure liquid storage tank and communicated with the foam outlet pipe. A foam gun is arranged at the tail end of the foam delivery pipe. The pressure storage type compressed gas foam extinguishing system can generate even, exquisite and stable kinetic energy foam without sucking air from the outside and is high in extinguishing speed, wide in covering range and large in jet distance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Regenerated waterproof putty powder and application method thereof

The invention provides regenerated waterproof putty powder and an application method thereof, which belong to the technical field of building materials. The regenerated waterproof putty powder is prepared from the following components in parts by weight: 220 to 350 parts of Portland cement, 400 to 680 parts of waste aerated concrete micro powder, 50 to 150 parts of ash calcium powder, 50 to 150 parts of heavy calcium carbonate powder, 50 to 120 parts of talcum powder, 2 to 7 parts of hydroxypropyl methyl cellulose, 3 to 8 parts of dispersible latex powder, 3 to 7 parts of magnesium aluminum silicate and 2 to 8 parts of dry powder polycarboxylate superplasticizer. Waste aerated concrete micro powder is used as a main filler, heavy calcium carbonate powder and talcum powder are used as secondary fillers, white cement and ash calcium powder are used as main film-forming substances, hydroxypropyl methyl cellulose, dispersible latex powder, magnesium aluminum silicate and a dry powder polycarboxylate superplasticizer are used as functional aids, and the putty powder has the characteristics of good crack resistance, high bonding strength, favorable water resistance and favorable decorative effects.

Owner:SHENZHEN HUAWEI ENVIRONMENTAL PROTECTION BUILDINGMATERIAL

Attapulgite purifying device

The invention discloses an attapulgite purifying device, and relates to the technical field of attapulgite processing. The device comprises an outer barrel and an inner barrel arranged in the outer barrel. The outer barrel and the inner barrel share a same axial lead and both have a horizontally arranged cylindrical structure. The inner barrel has a front opening and a rear opening. The front opening and the rear opening are fixedly connected to the internal wall of the outer barrel. The device can purify attapulgite, is applied to the primary processing of attapulgite, is convenient to use, is simple to operate, and is very practical and flexible.

Owner:MINGGUANG FEIZHOU NEW MATERIAL

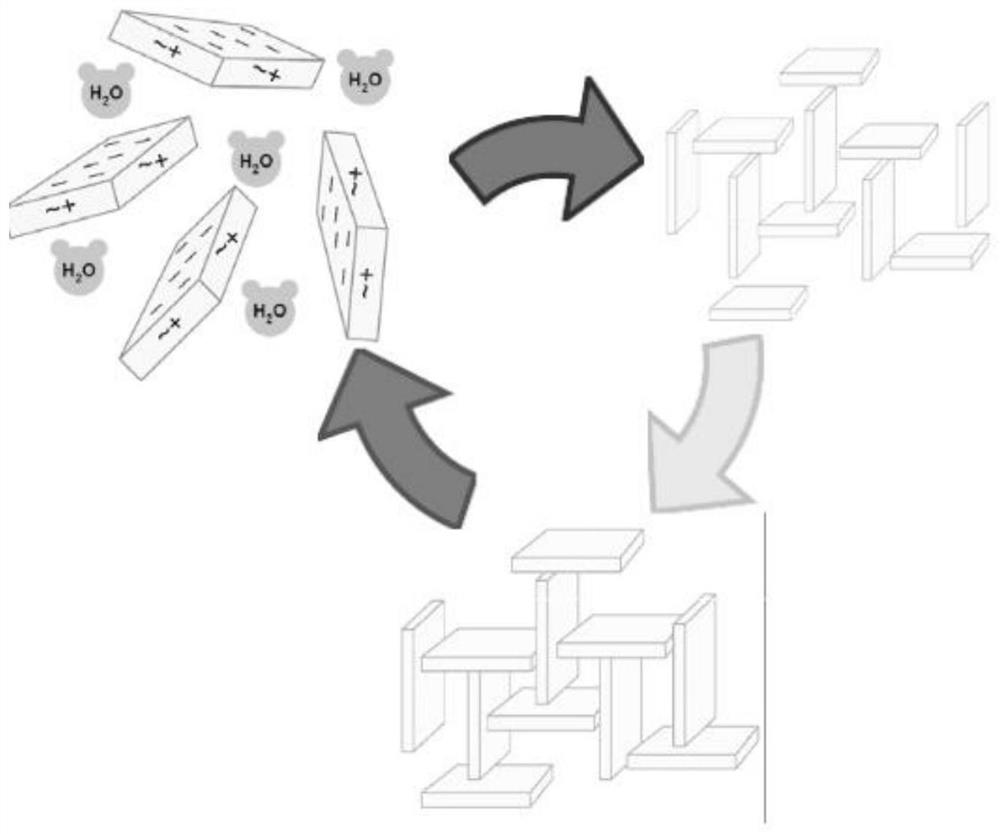

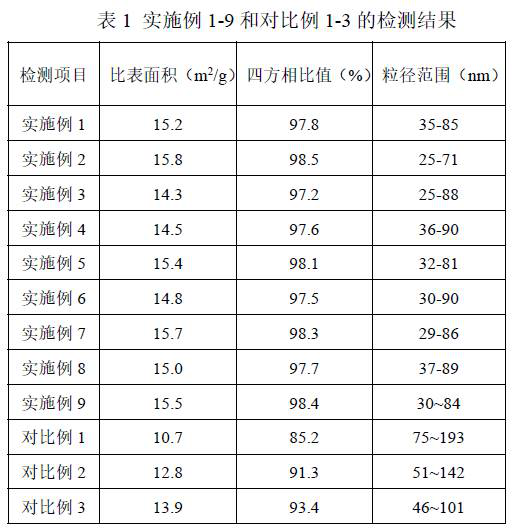

Nanoscale barium titanate powder and preparation process thereof

ActiveCN114105191AImprove hydrolytic stabilityGood dispersionAlkaline earth titanatesMaterial nanotechnologyAlcoholBarium titanate

The invention discloses nanoscale barium titanate powder and a preparation process thereof, and relates to the technical field of inorganic powder synthesis, and the preparation process of the nanoscale barium titanate powder comprises the following steps: uniformly mixing 280-320 parts by mass of deionized water, 20-30 parts by mass of monohydric alcohol and 78.85-80.85 parts by mass of titanium dioxide to obtain a mixed material, and keeping the pH value of the mixed material at 5-6, heating the mixed material to 45-60 DEG C, adding 0.5-1.5 parts of a chelating titanate coupling agent into the mixed material, carrying out heat preservation stirring for 6-9 h, and cooling to normal temperature to obtain a modified titanium dioxide material; 195.34-199.34 parts of barium carbonate and 0.1-0.3 part of a defoaming agent are taken and added into the modified titanium dioxide material, ball milling is conducted for 4-5 h, and ball-milled slurry is obtained; and carrying out spray drying on the ball-milled slurry, and calcining to obtain the nano-scale barium titanate powder. The nanoscale barium titanate powder prepared by the preparation process has the advantages of high tetragonal phase ratio value, small particle size and narrow particle size range.

Owner:GUANGDONG KANGRONG HIGH TECH NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com