Extrusion type coating system of power lithium battery base band

A lithium battery, extrusion-type technology, applied in the direction of surface coating liquid devices, coatings, pre-treated surfaces, etc., can solve the problem of unguaranteed coating consistency, difficult coating process, coating scratches, etc. problems, to achieve the effect of uniform temperature in the oven space, optimized oven structure, and high flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

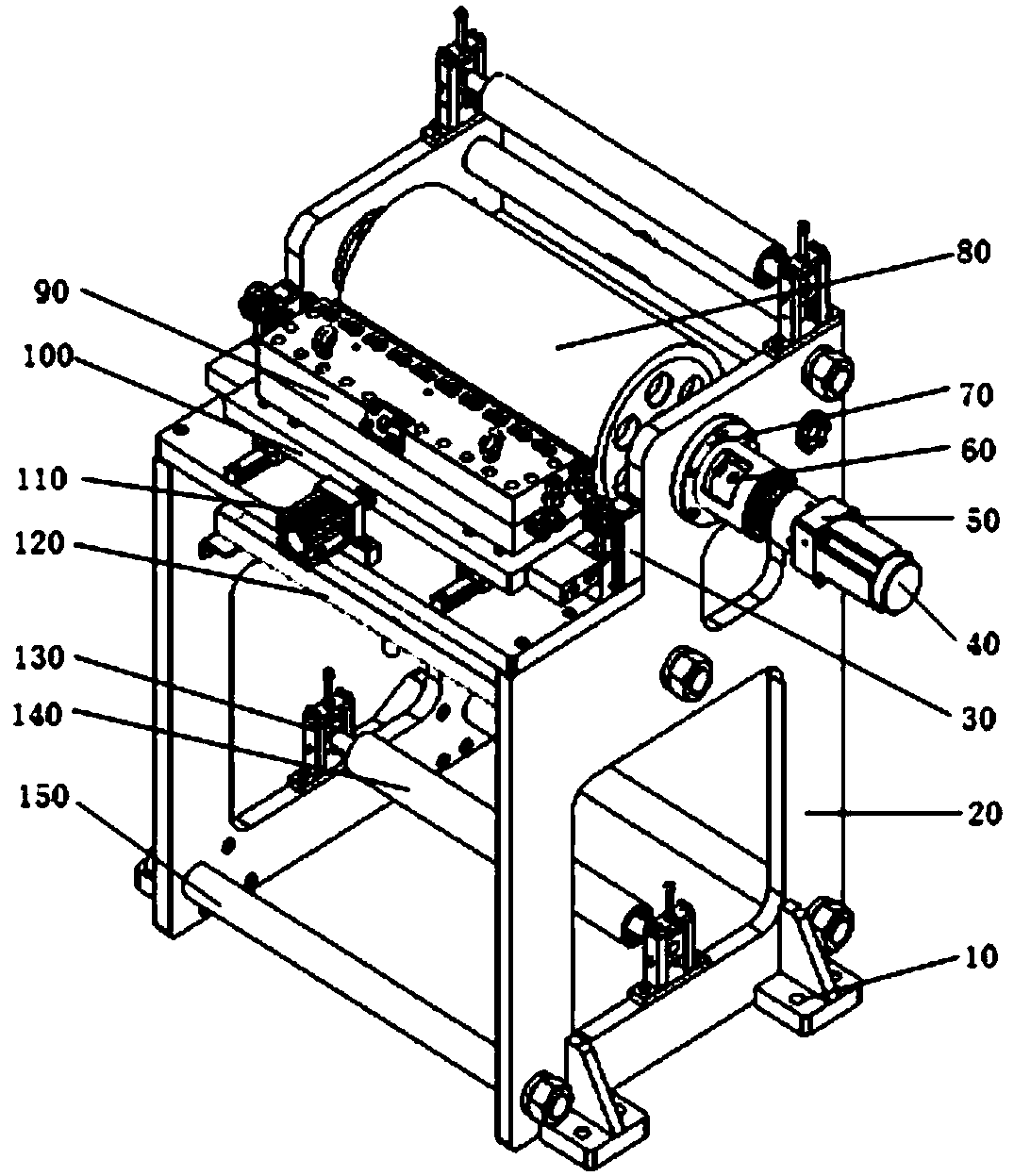

[0099] The technical solutions of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

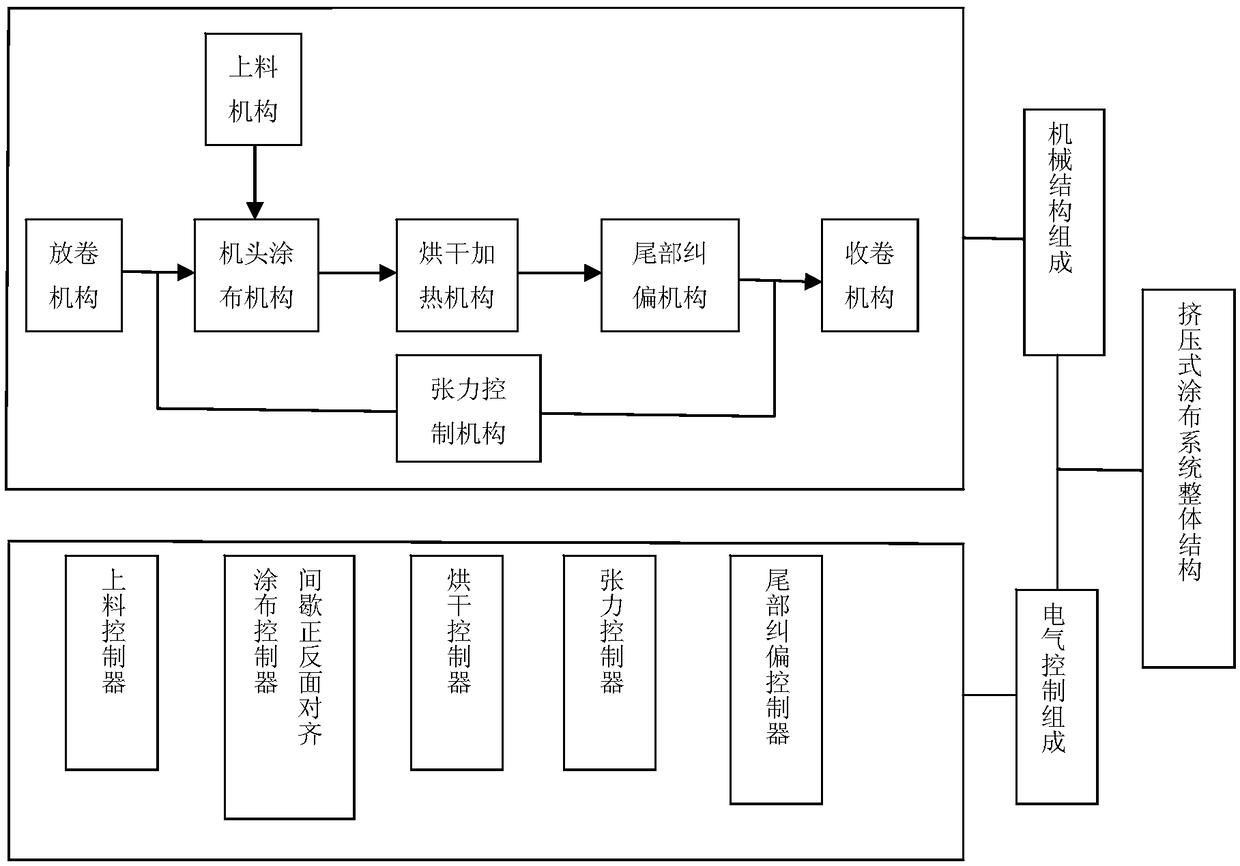

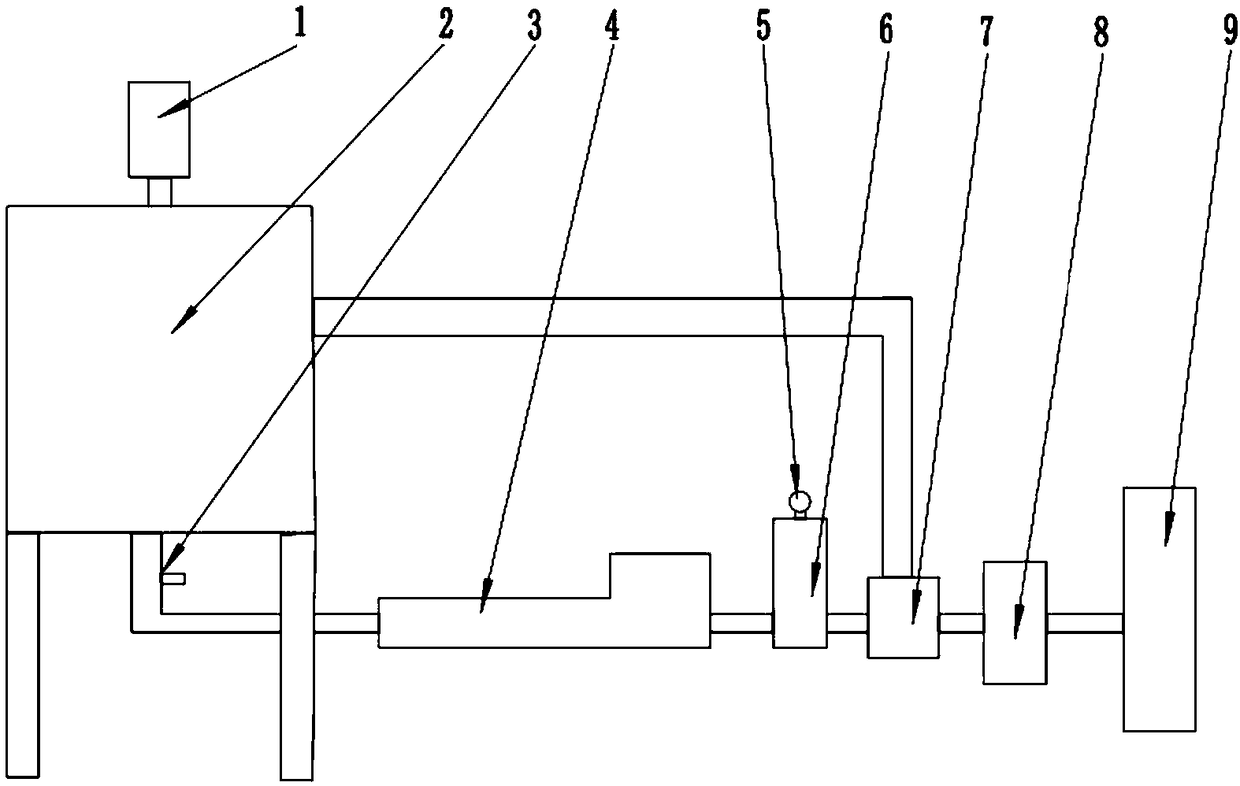

[0100] Such as figure 1 As shown, the present invention includes: an unwinding mechanism, which is used to release the base tape at a constant speed; a feeding mechanism, which is used to provide a slurry supply to the base tape; a head coating mechanism, which is used to evenly coat the slurry supplied by the feeding mechanism On the base belt; the drying heating mechanism is used to dry the wet slurry coated on the base belt; the base belt tension control mechanism includes a tension detector and a brake, wherein the tension detector is used to detect the tension of the base belt. The brake is used to provide tension resistance to the base belt; the tail correction mechanism is arranged between the drying heating mechanism and the winding mechanism, and is used for correcting the base belt before winding a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com