High-temperature flue gas quenching device

A high-temperature flue gas and flue gas technology, applied in the field of cooling for industrial production, can solve the problems of increased flue gas flow, acetylene quality impact, energy waste, etc., and achieve the effect of increasing the contact area and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Further detailed explanation through specific implementation mode below:

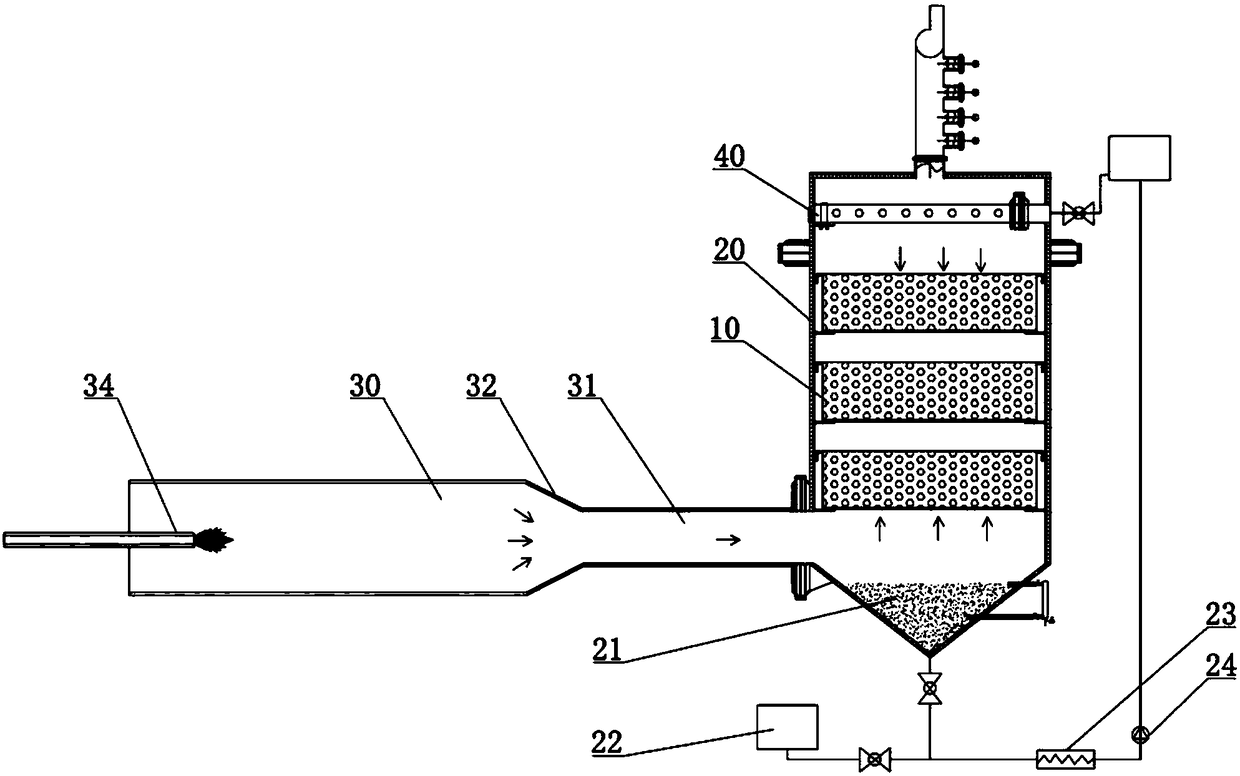

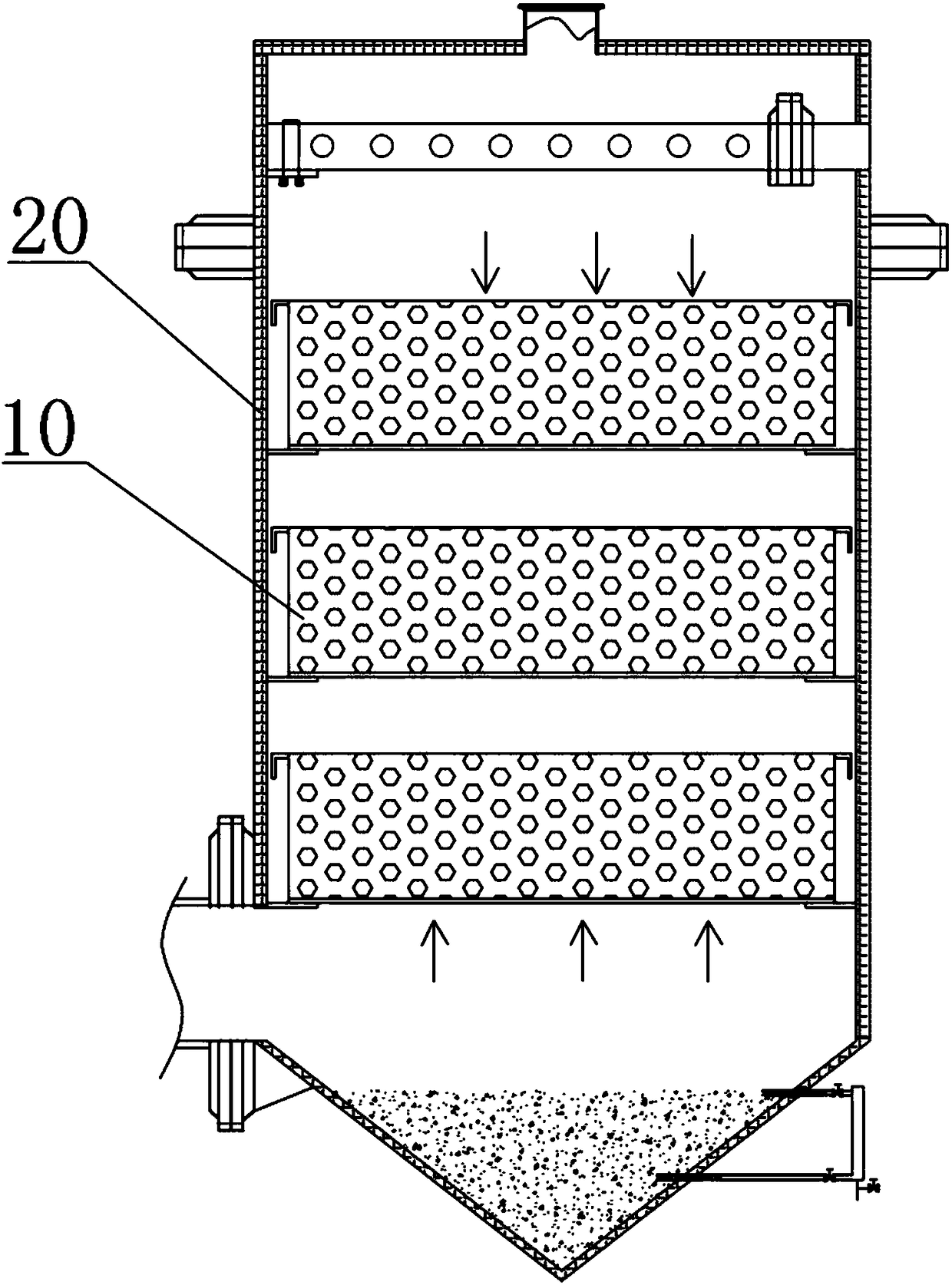

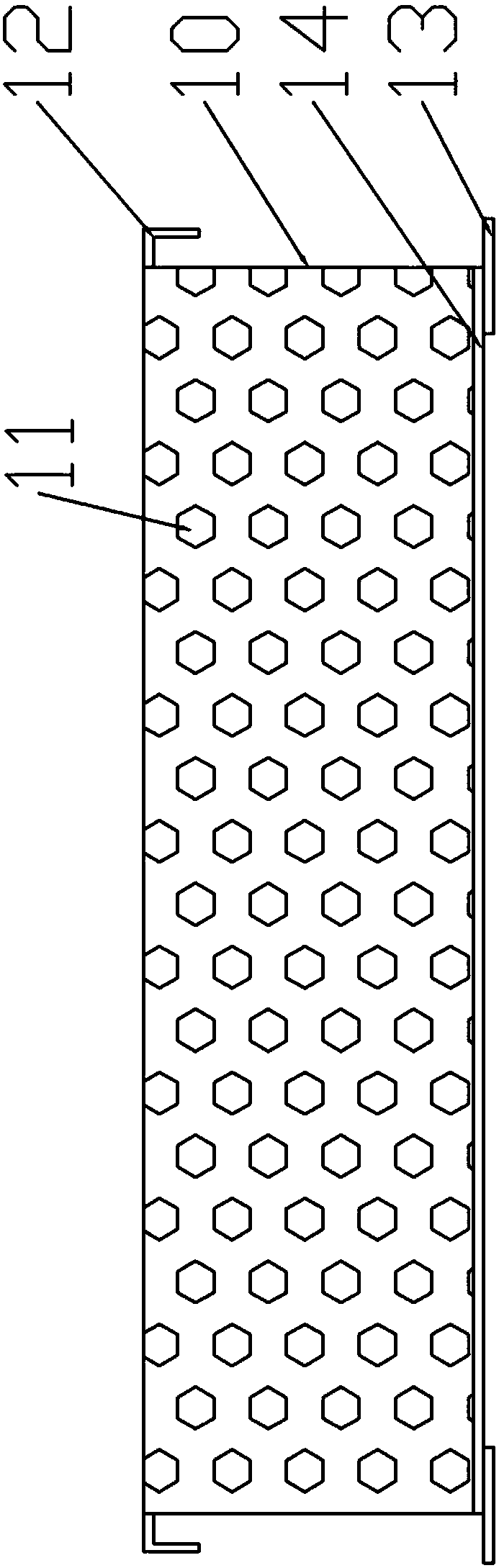

[0033] The reference signs in the accompanying drawings of the specification include: heat sink 10, heat exchange ball 11, outer edge 12, support sheet 13, bottom surface 14, heat exchange furnace 20, liquid accumulation pool 21, liquid storage tank 1 22, heat exchanger 23 , Electromagnetic pump 24, access section 30, contraction section 31, transition section 32, smoke source 34, dispersion disc 40, branch pipe 41, split hole 42, flange plate 43, bracket 44.

[0034] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com