Patents

Literature

49results about How to "Reduce travel speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Industrial truck with an electrical control unit

InactiveUS20070007080A1Reduce travel speedOperational securityLifting devicesEmbedded systemElectrical control

An industrial truck includes at least one electronic control unit for traction functions and / or lifting functions of the industrial truck and at least one communications device for data transfer with object identification means, such as with RFID transponders. Connections can be provided for the transmission of data between the communications device and the electronic control system for traction functions and / or lifting functions of the industrial truck.

Owner:STILL GMBH

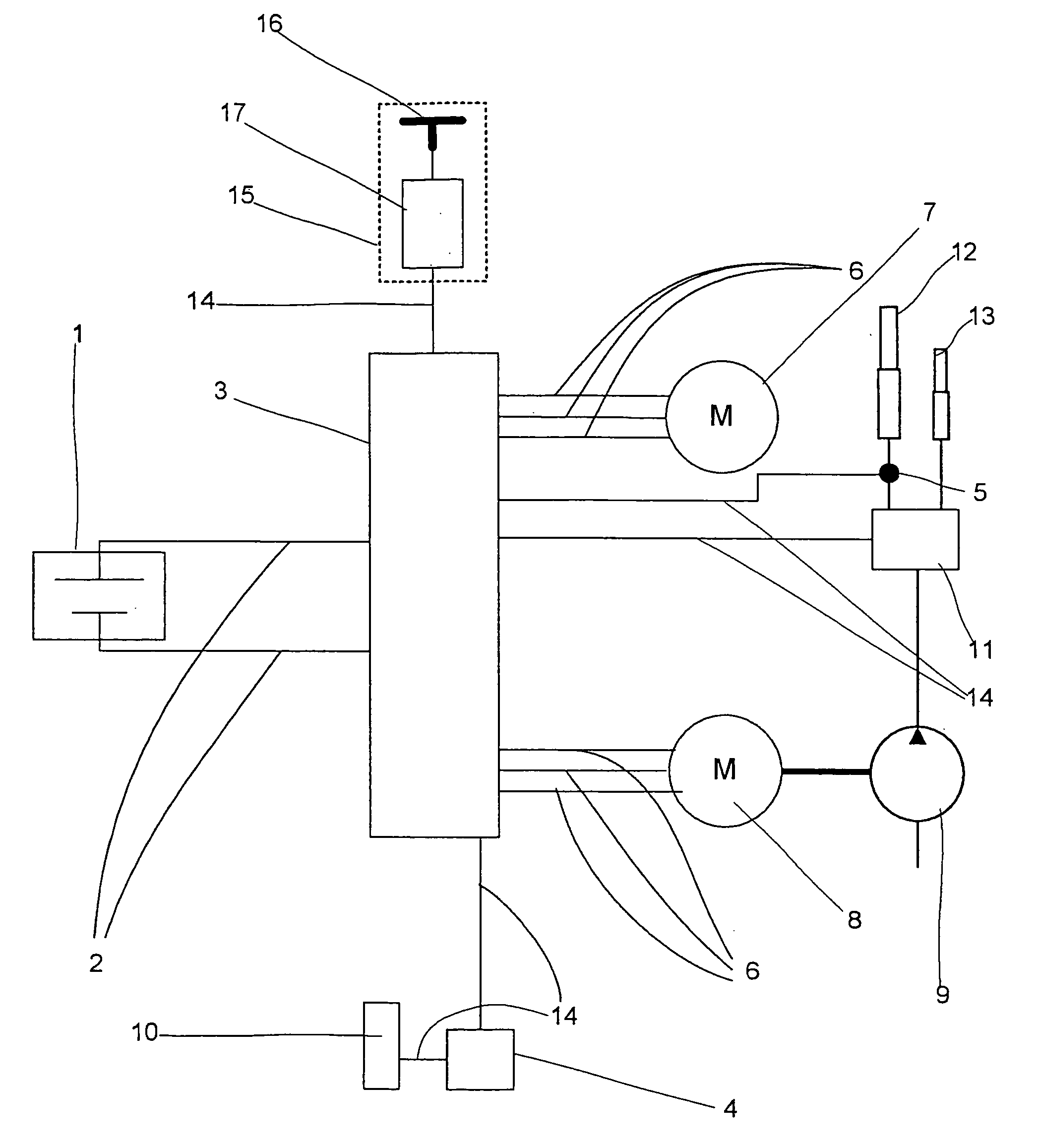

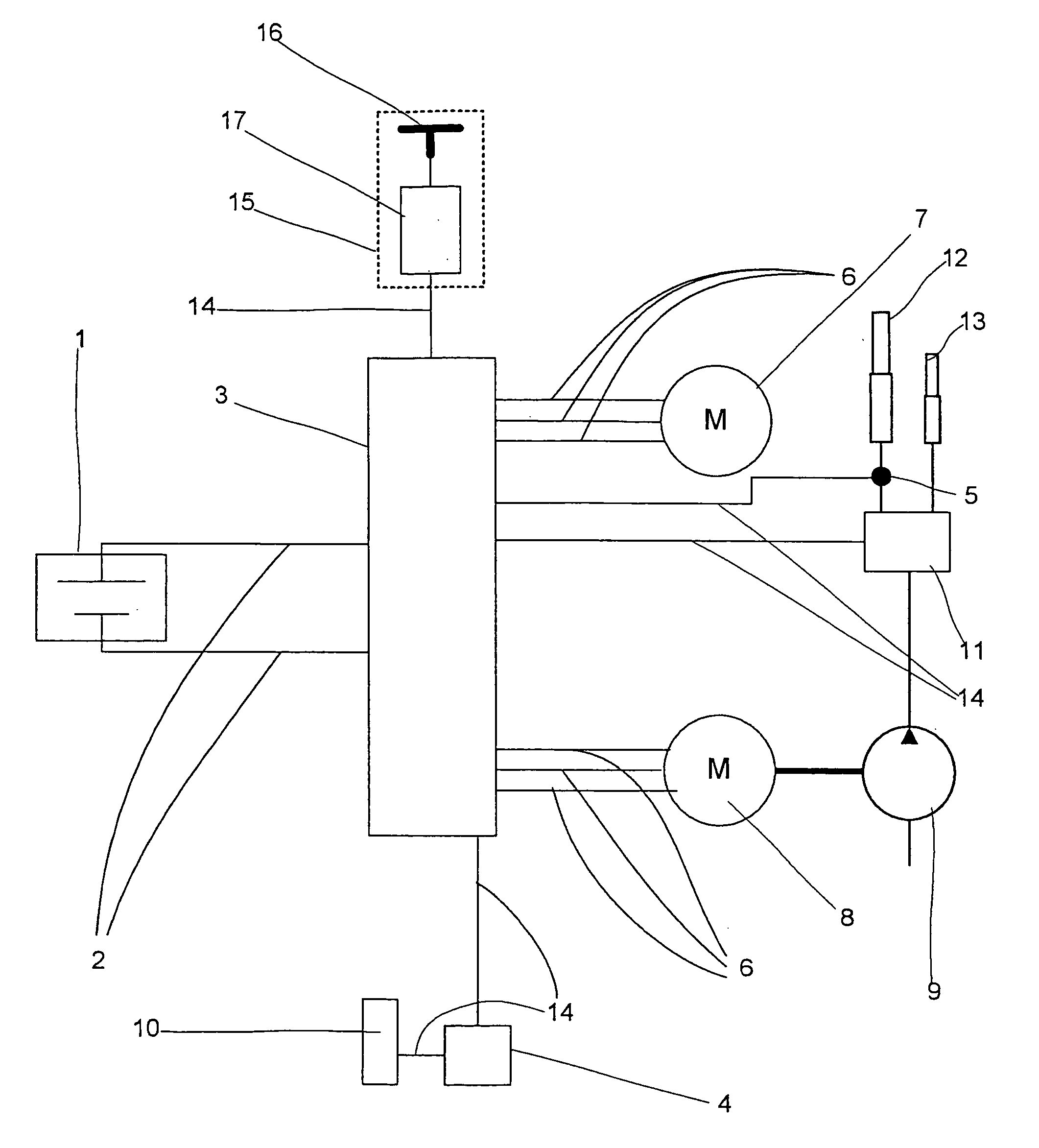

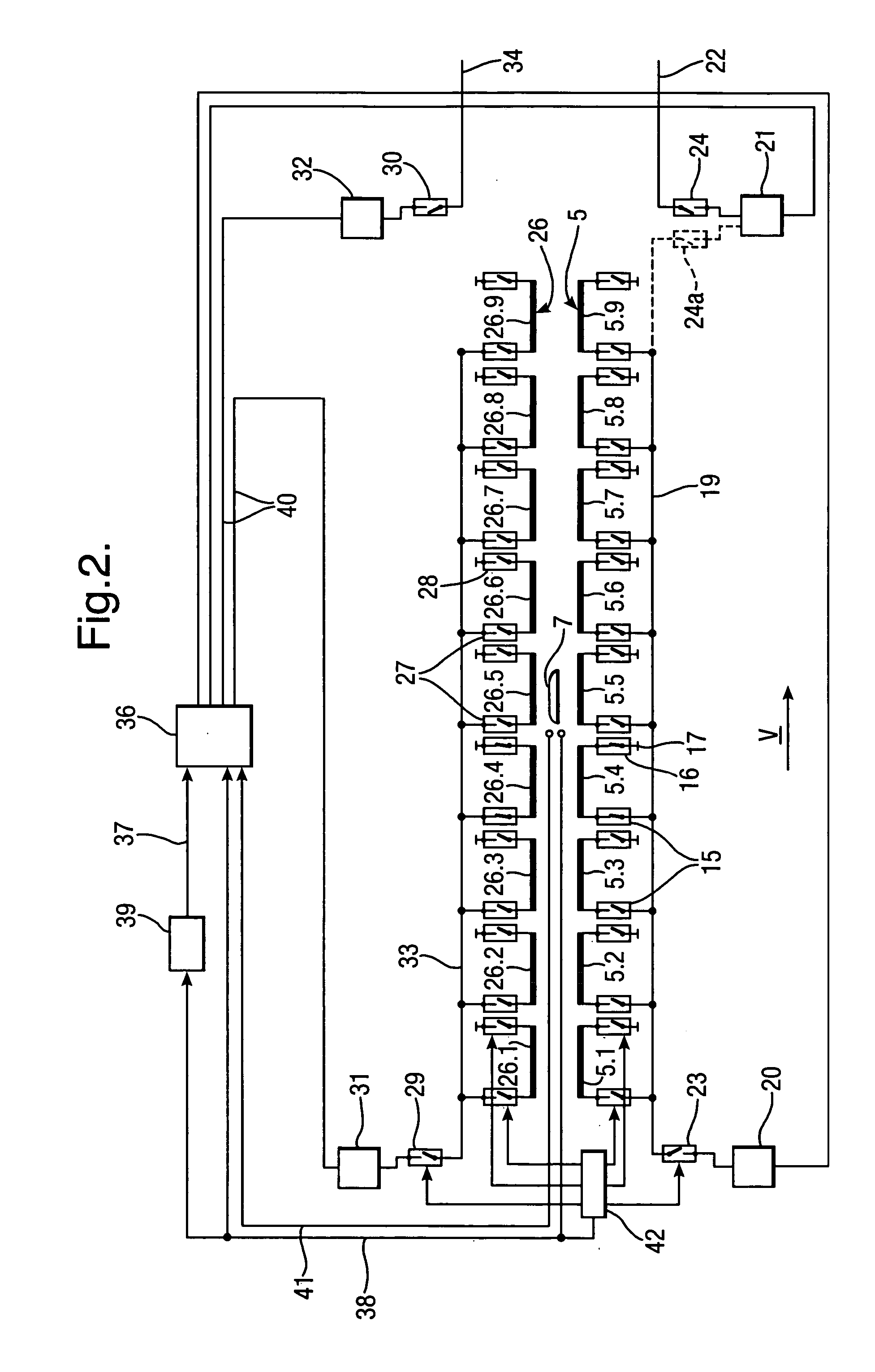

Method and arrangement for operating a magnetically levitated vehicle

InactiveUS20060097116A1Reduce travel speedAccelerated trainingMotor/generator/converter stoppersDC motor speed/torque controlLinear motorMagnetic levitation

The invention relates to a method and an arrangement for operating a magnetically levitated vehicle by means of an arrangement having at least one long-stator linear motor. The linear motors are sub-divided longitudinally of a track into individual motor regions (A3, A4) in which only one vehicle (7e, 7f) at a time can normally travel. To increase the vehicle concentration along the track, provision is made in accordance with the invention for selected motor regions (A4) to be divided into at least two mutually independent motor region sections (A4a, A4b) and for one vehicle (7f, 7g) to be operated in each motor region section (A4a, A4b) at a part of that power which is preset for each motor region (A4).

Owner:SIEMENS AG

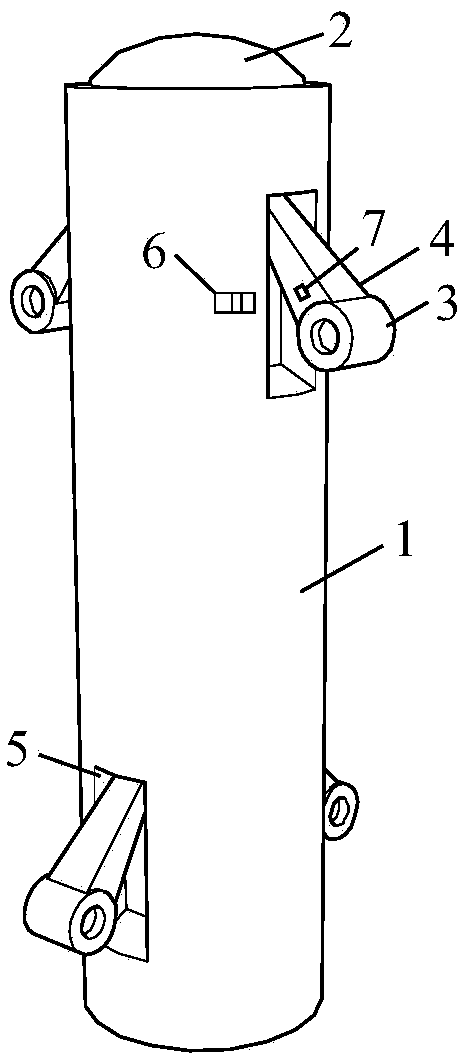

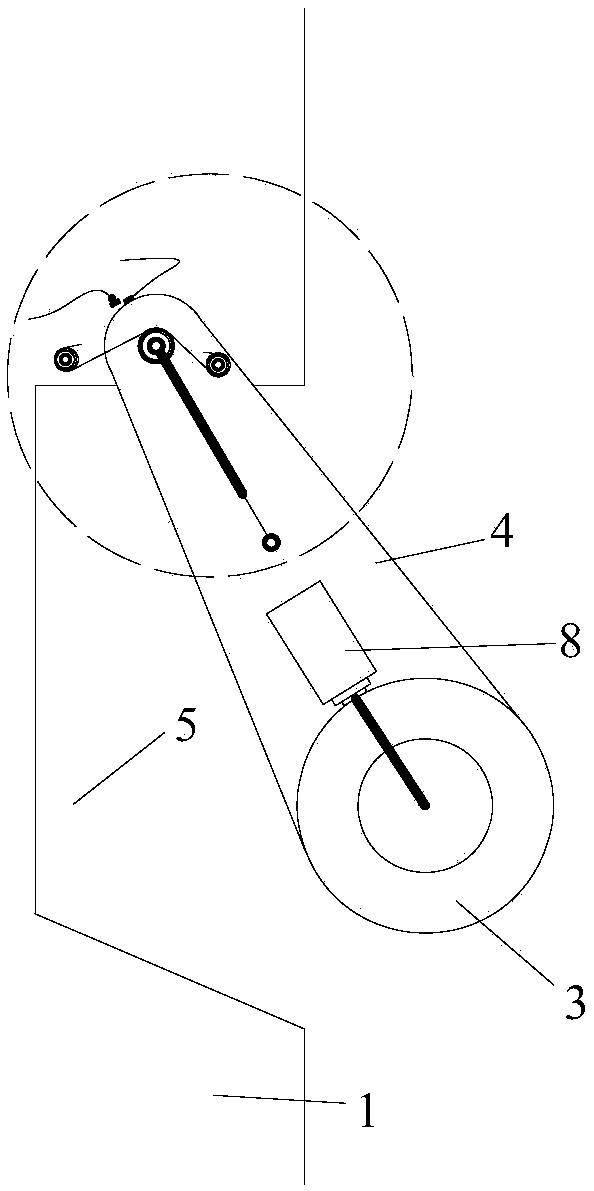

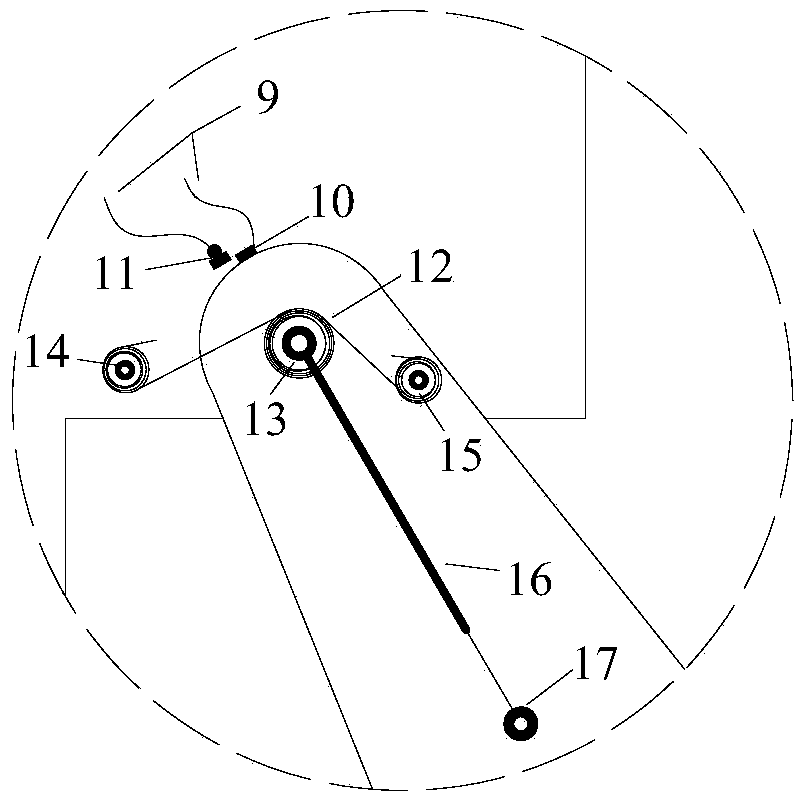

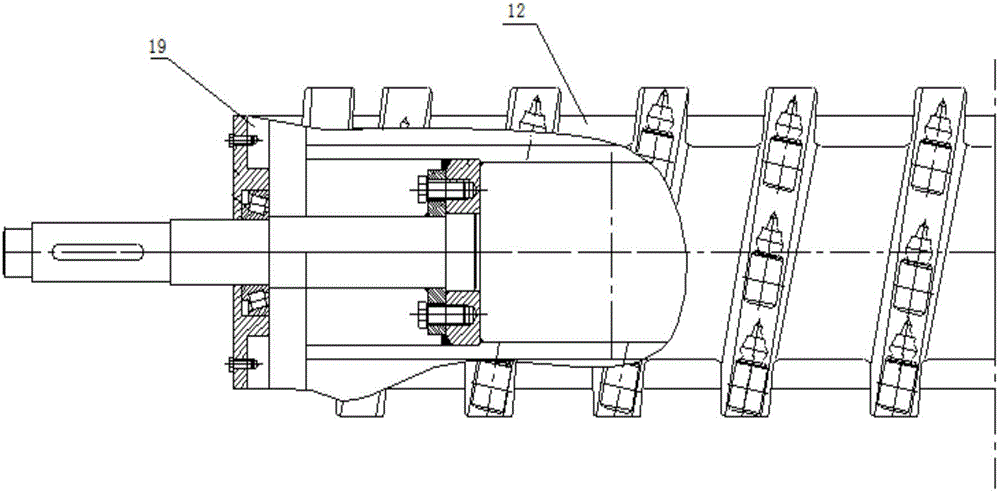

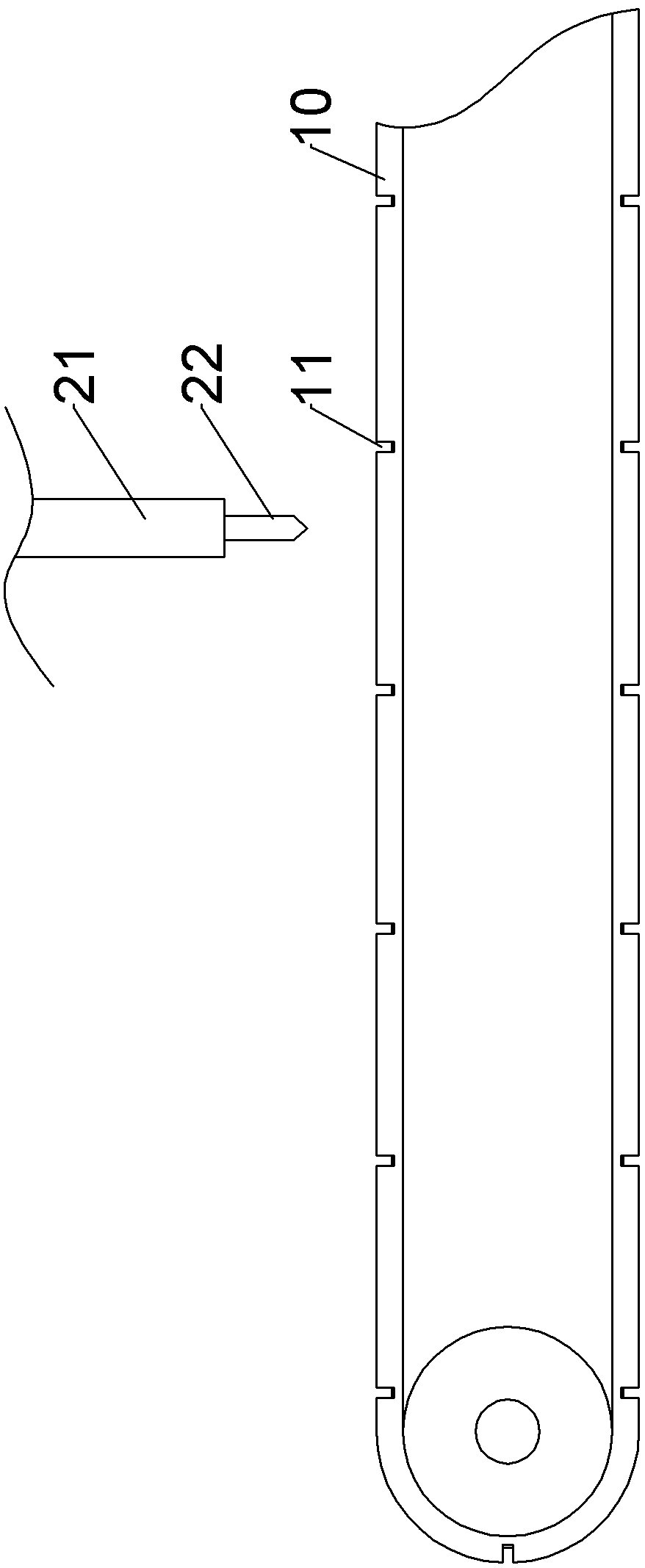

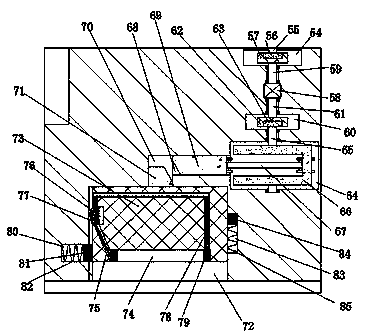

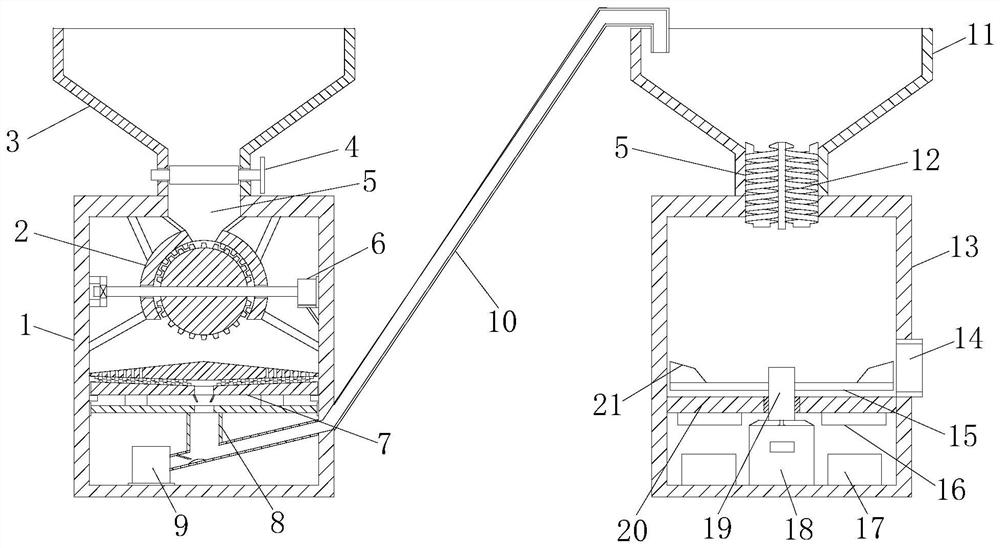

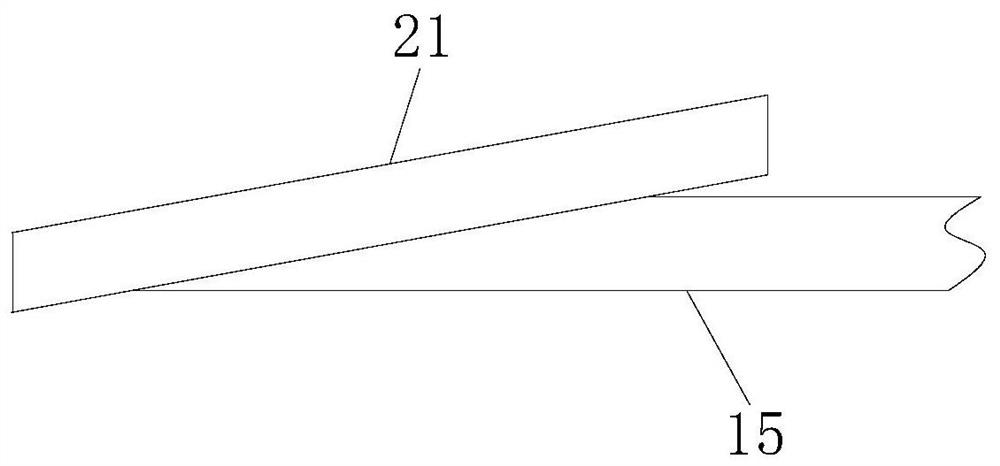

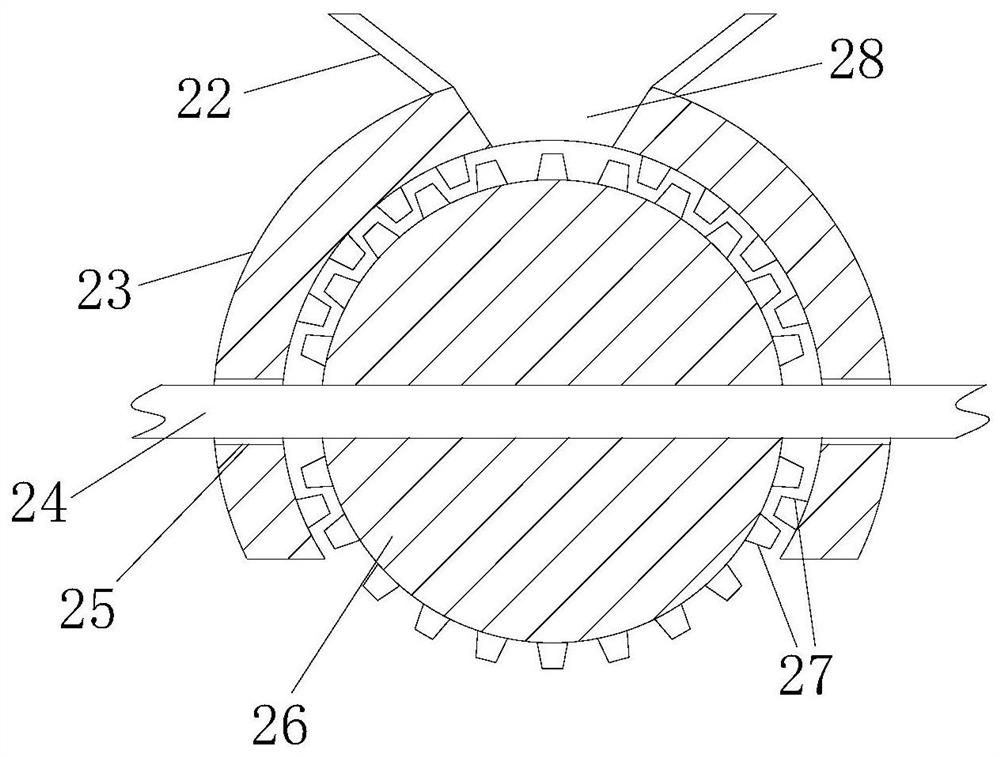

Self-propelled peeping probe adapted to different diameters of drill holes and peeping method thereof

The invention discloses a self-propelled peeping probe adapted to different diameters of drill holes and a peeping method thereof. The probe comprises a peeping probe body, a camera, walking wheels, rocker arms connected to the walking wheels, and an operating host. The rock arms can achieve a certain angle of damping opening and closing under the effects of internal torsion springs and gas springs and have alarm functions, and the rocker arms can be fixed in grooves of a peeping probe side through locking holes and locking blocks. The self-propelled function of the peeping probe in a drill hole can be achieved through an internal power supply, a driving motor, a video processing module, a control module, a WIFI module and the external operating host. The peeping probe has the advantages of centered drill hole, self-propelling and less workers in operation in a drilling peeping operation process, the complexity in a conventional drilling peeping operation is reduced, a push rod and a video transmission line are removed, auxiliary accessories are greatly reduced, and a new solution is provided for determining the fracture of a rock mass through drilling peeping in underground engineering.

Owner:CHINA UNIV OF MINING & TECH

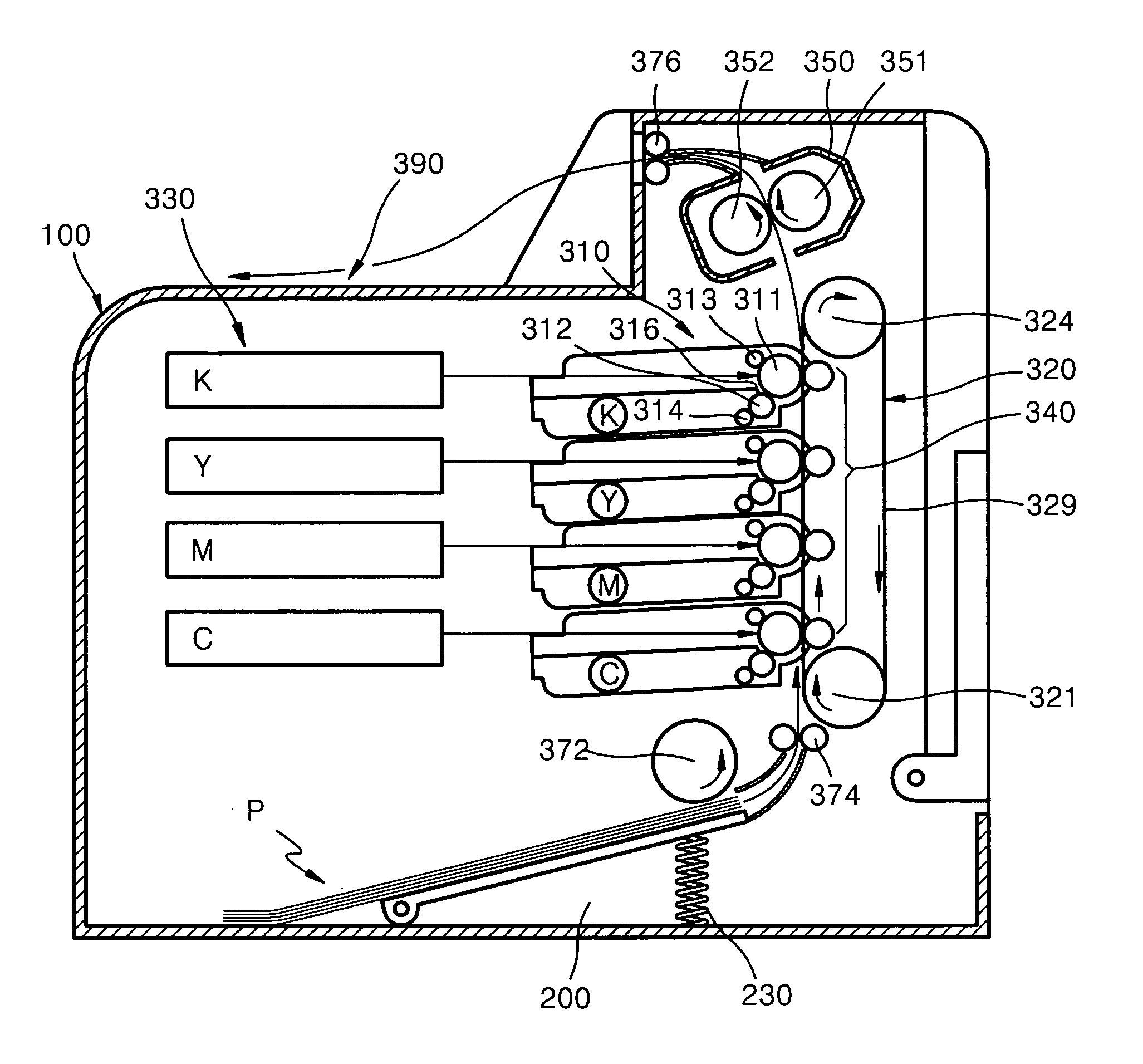

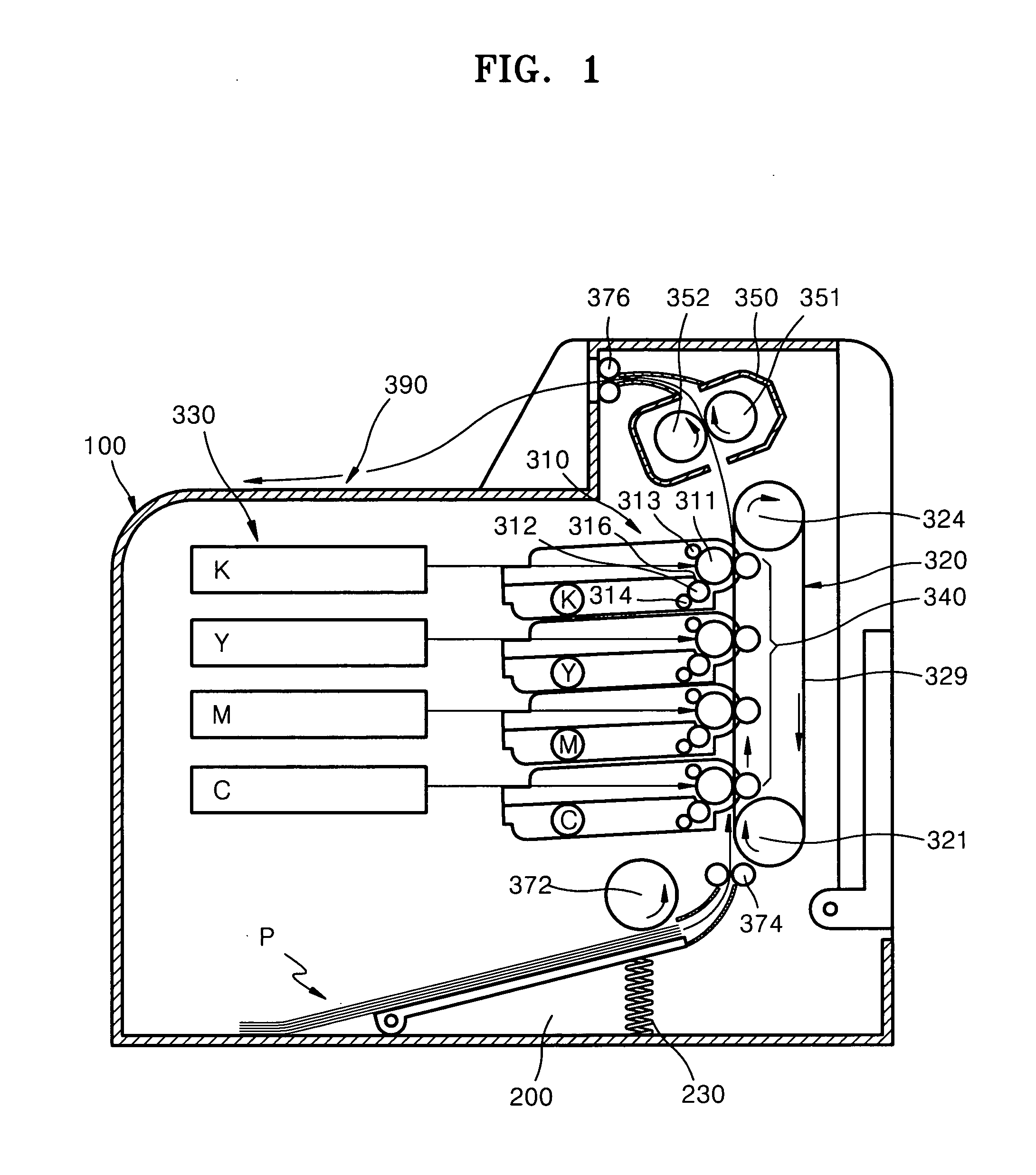

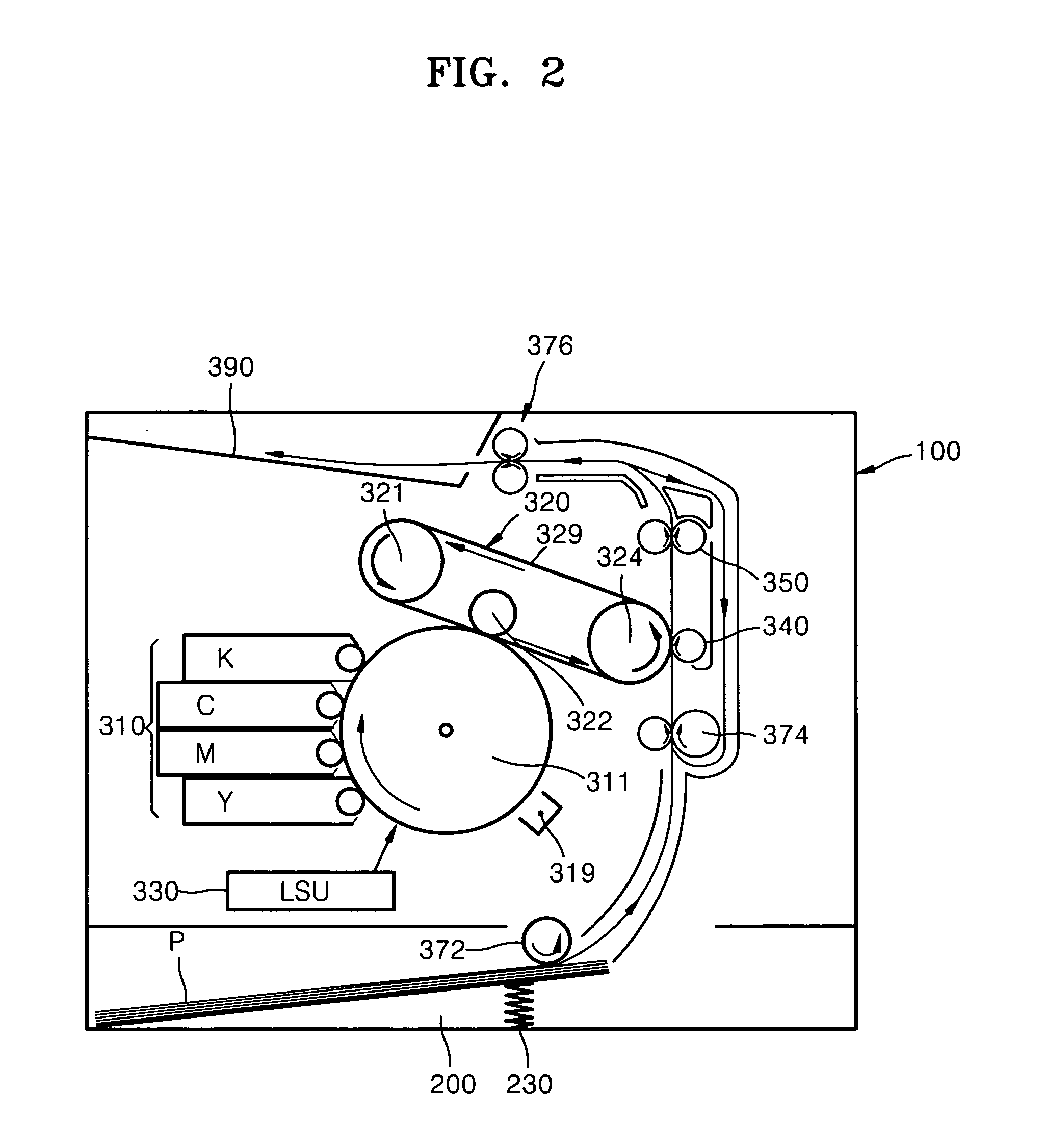

Transfer belt unit and image forming apparatus having the same

InactiveUS20070151829A1Meandering be substantially preventReduce travel speedConveyorsElectrographic process apparatusMechanical engineeringImage formation

Owner:S PRINTING SOLUTION CO LTD

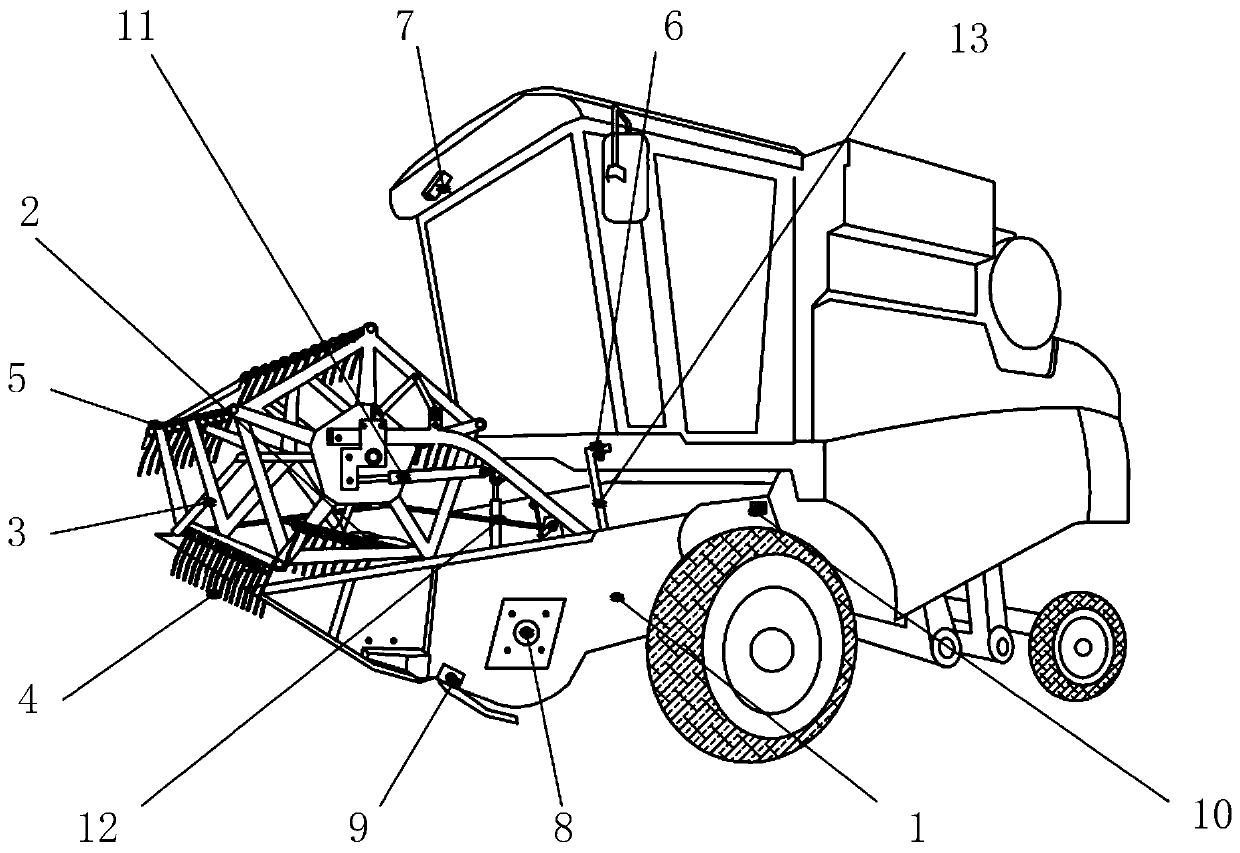

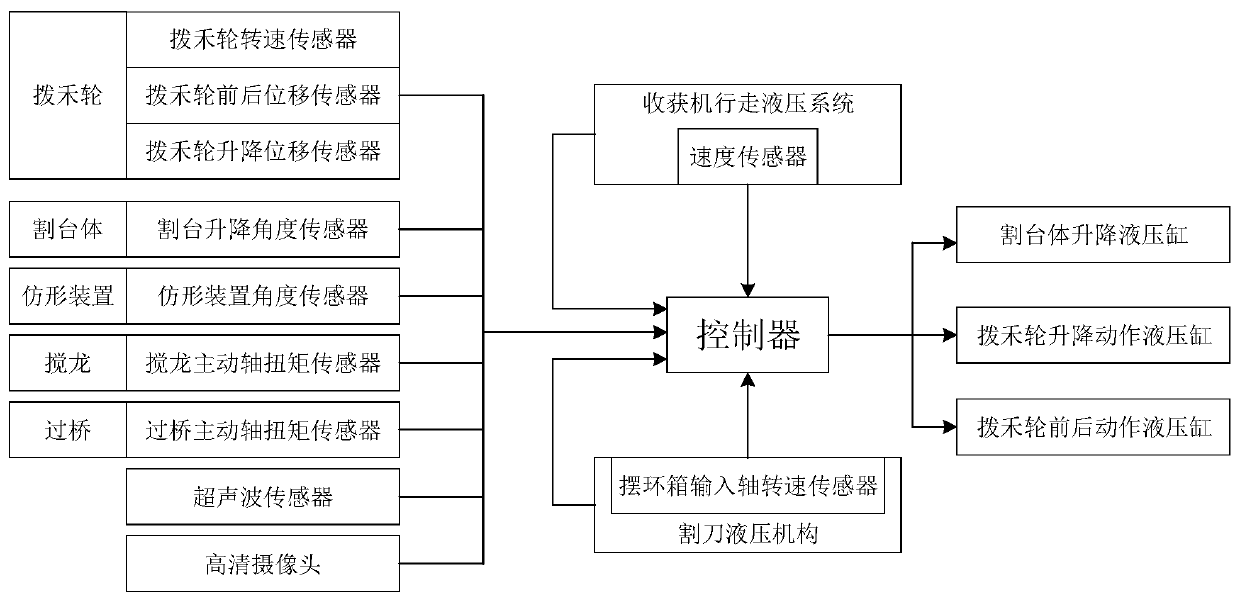

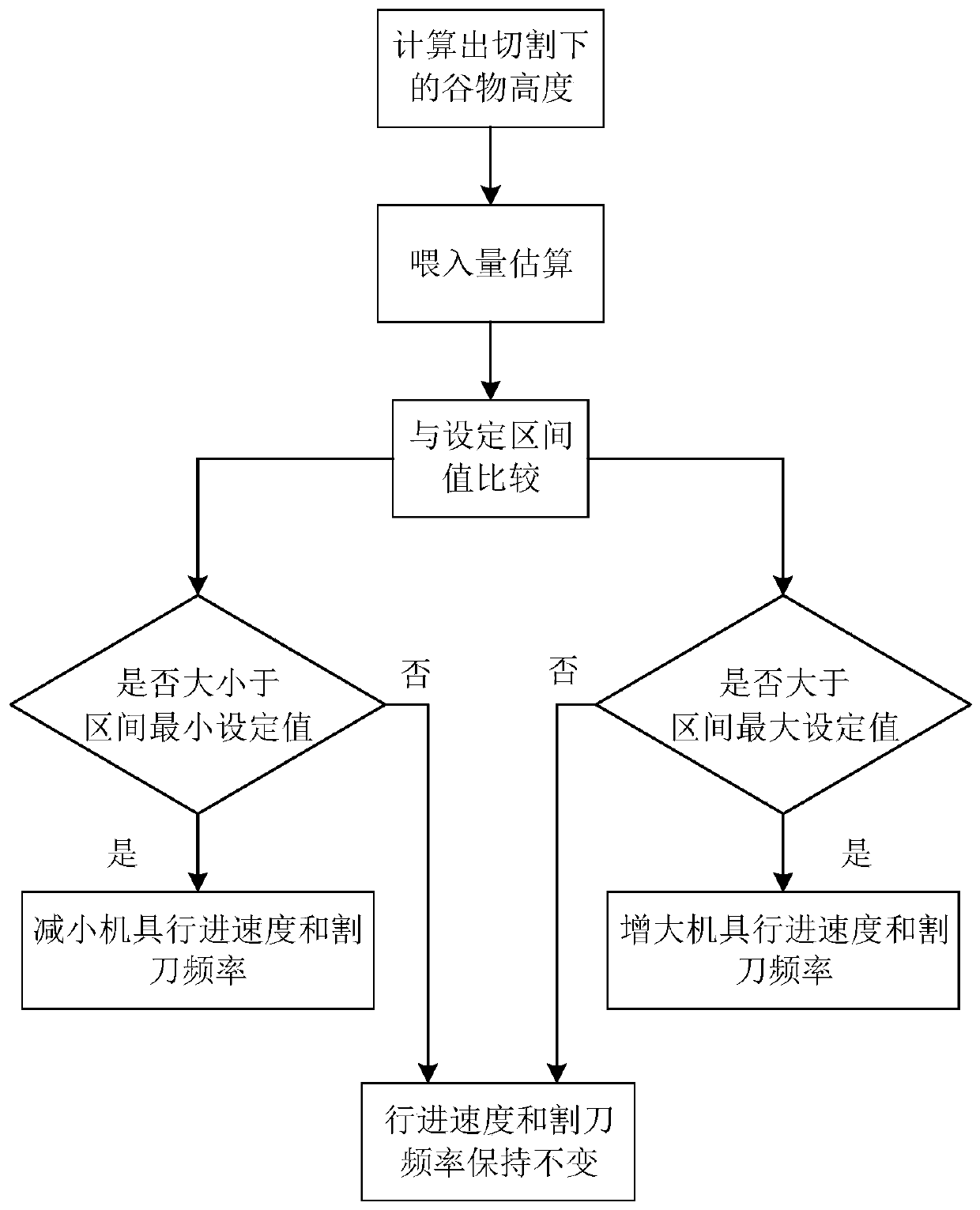

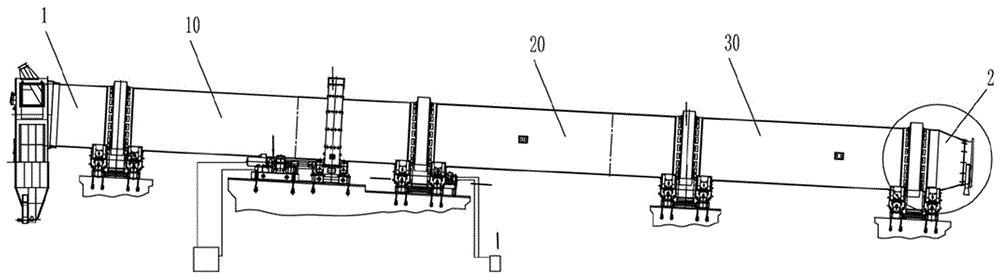

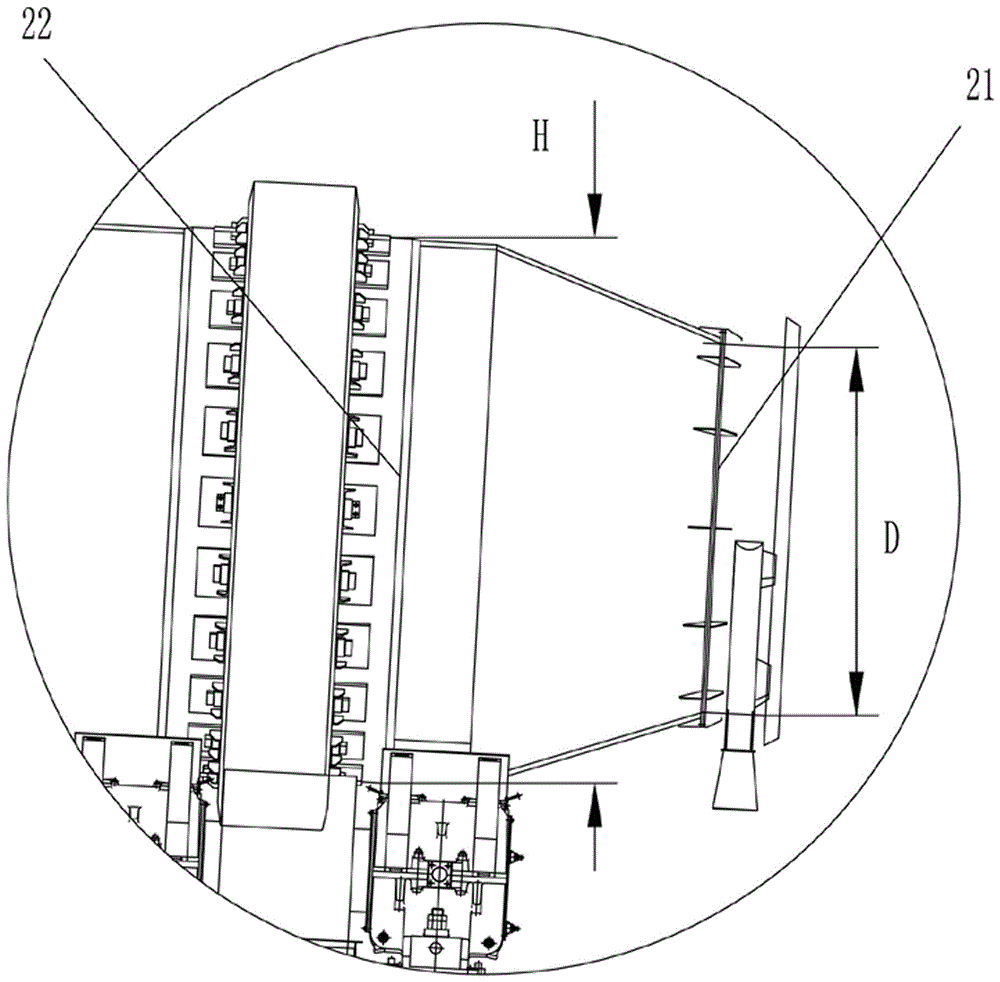

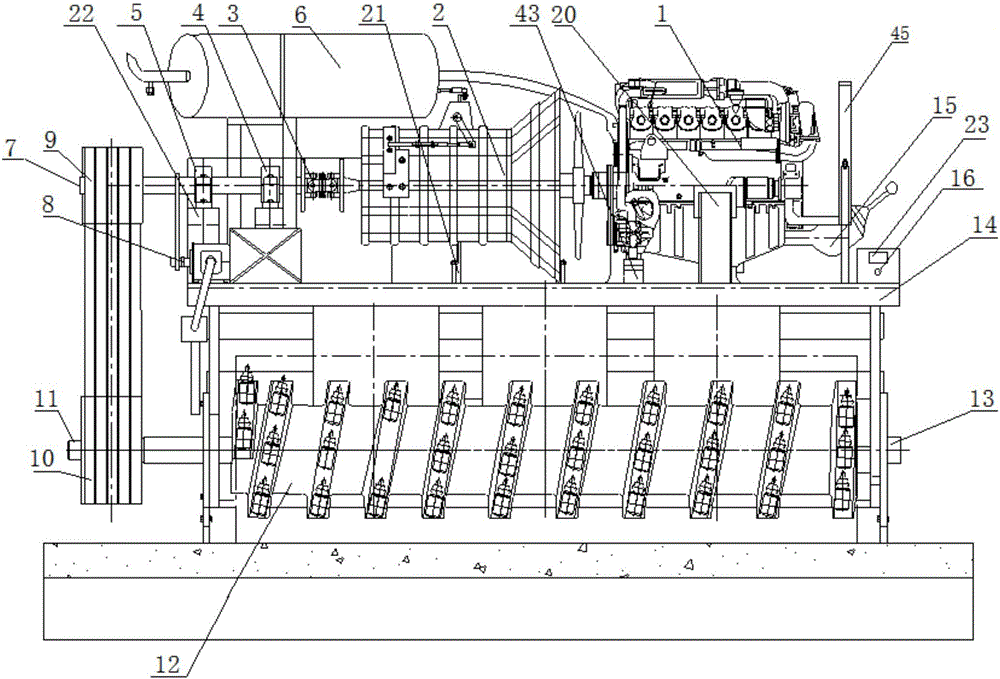

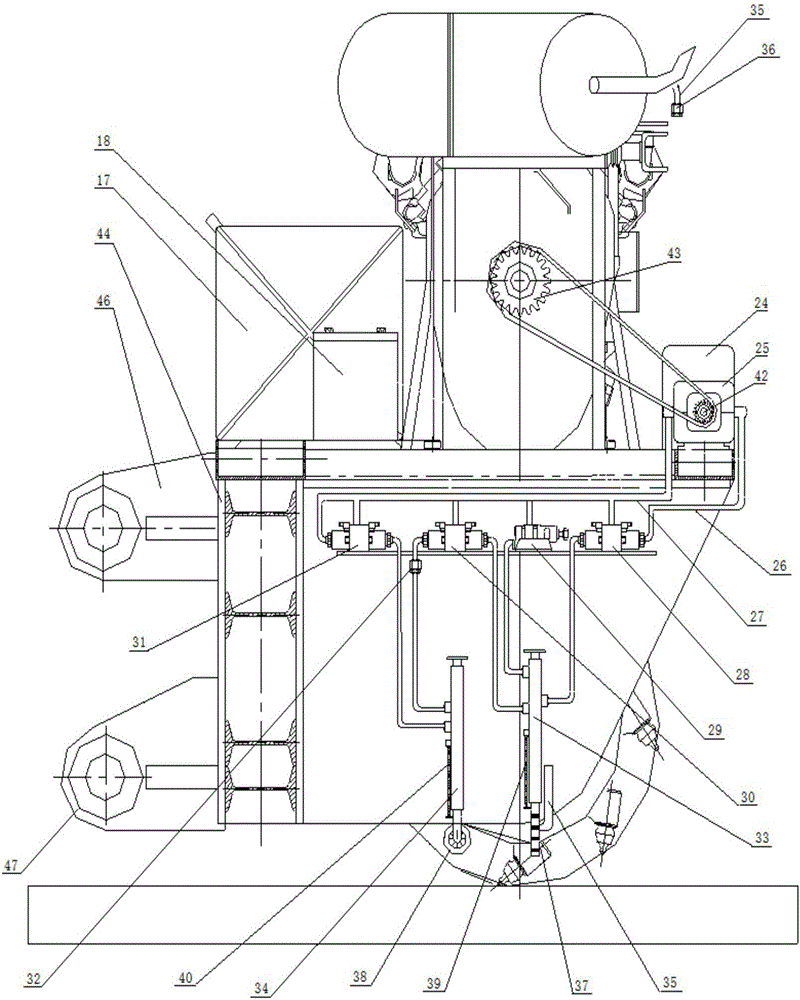

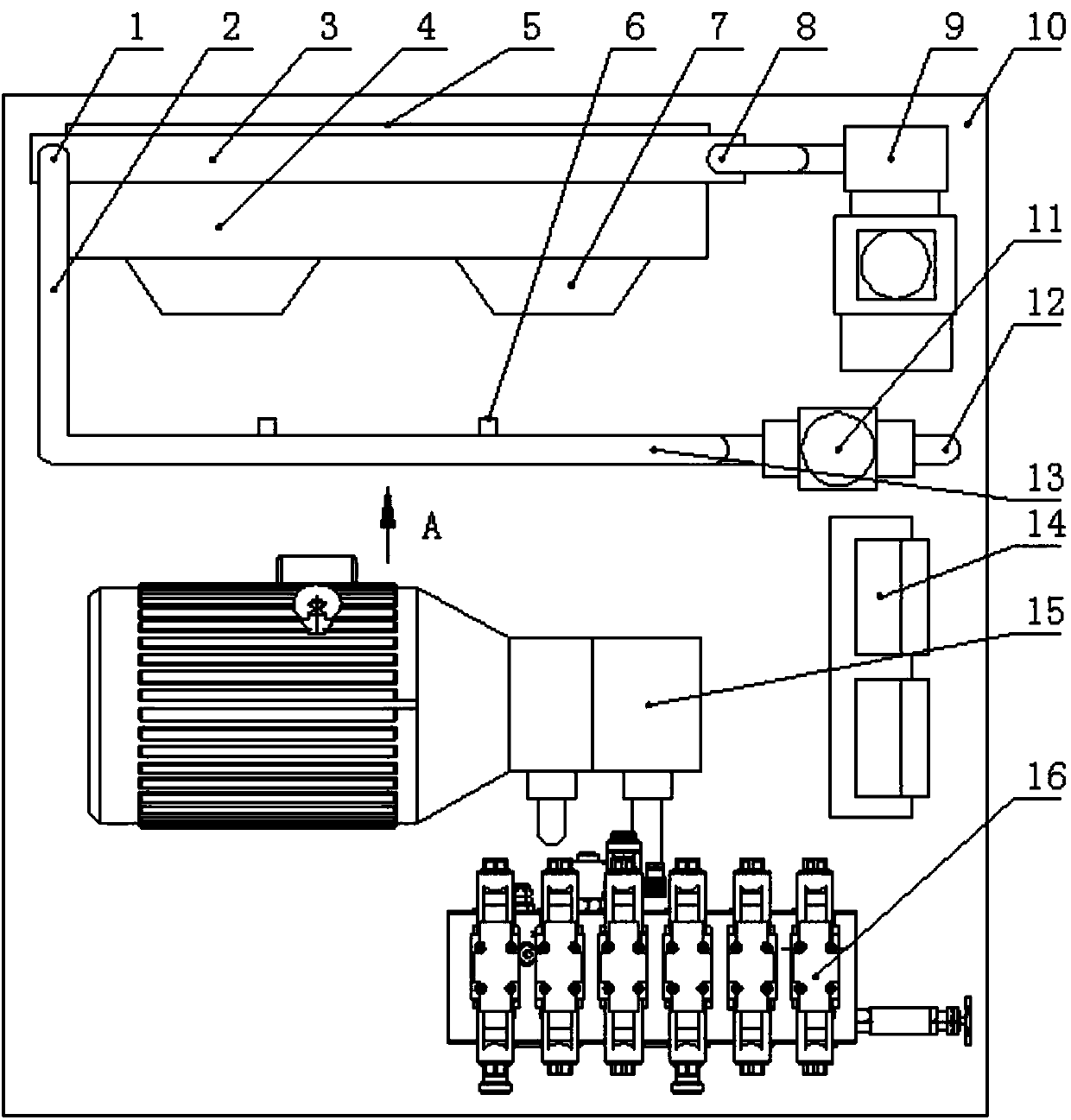

Self-adaptation control device and method of grain harvesting machine header

The invention discloses a self-adaptation control device of a grain harvesting machine header. A header body is connected with a vehicle body axle of a harvesting machine; one end of a reel bracket isconnected with the header body, and a reel is installed at the other end of the reel bracket; spring tooth shafts are installed on the reel, and spring teeth are installed on the spring tooth shafts;a cutter pendulum ring box is installed below the reel; shaft heads at the two ends of an auger are fixed to the two side walls of the header body through bearings; a cutter is installed on a pendulum rod of the cutter pendulum ring box; by utilizing an information collection device, the work state of the harvesting machine is acquired, and adjustment is conducted. The invention discloses the self-adaptation control device and method of the grain harvesting machine header. For matching of the operation state of the harvesting machine header and the operation speed and feeding quantity of theharvesting machine header, the problems are solved that in order to adapt to different operation conditions, an operator needs to adjust the operation state of the harvesting machine header frequently, and otherwise the harvesting machine cannot work stably; the work efficiency is greatly improved, and the failure rate of the harvesting machine is reduced.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

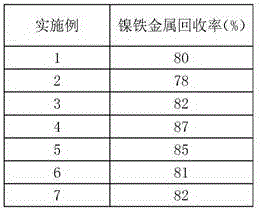

Technology of direct reduction of nickel-iron particles from laterite-nickel ores in rotary kiln

The invention discloses a technology of direct reduction of nickel-iron particles from laterite-nickel ores in a rotary kiln, comprising the steps of mixing the laterite-nickel ores, carbon reductant and limestone, then briquetting the mixtures into mixed pellets on a briquetting machine; sintering the mixed pellets through a preheating section and removing crystal water in the rotary kiln, reducing nickel elements at a transition section, and then entering into a sintering section to reduce iron elements and the nickel elements and metal particles grow up. Wherein, the temperature of the sintering section near the transition section is controlled within such scope that the materials are kept in solid state, and the kiln ringing can be prevented while keeping the metal reduction temperature; the temperature of the sintering section located at a kilneye is controlled within such scope that the materials are kept in half-molten state. Since the kilneye of the rotary kiln is in a throat structure, heat is uneasy to dissipate, in favor of reduction and enrichment of metal; even sometimes minor ringing occurs, the previous ringing can also be easily removed under the rolling effect of subsequent materials, so that the technology disclosed by the invention plays a foundation for continuous production of direct reduction, and the reduction efficiency of the rotary kiln is improved.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

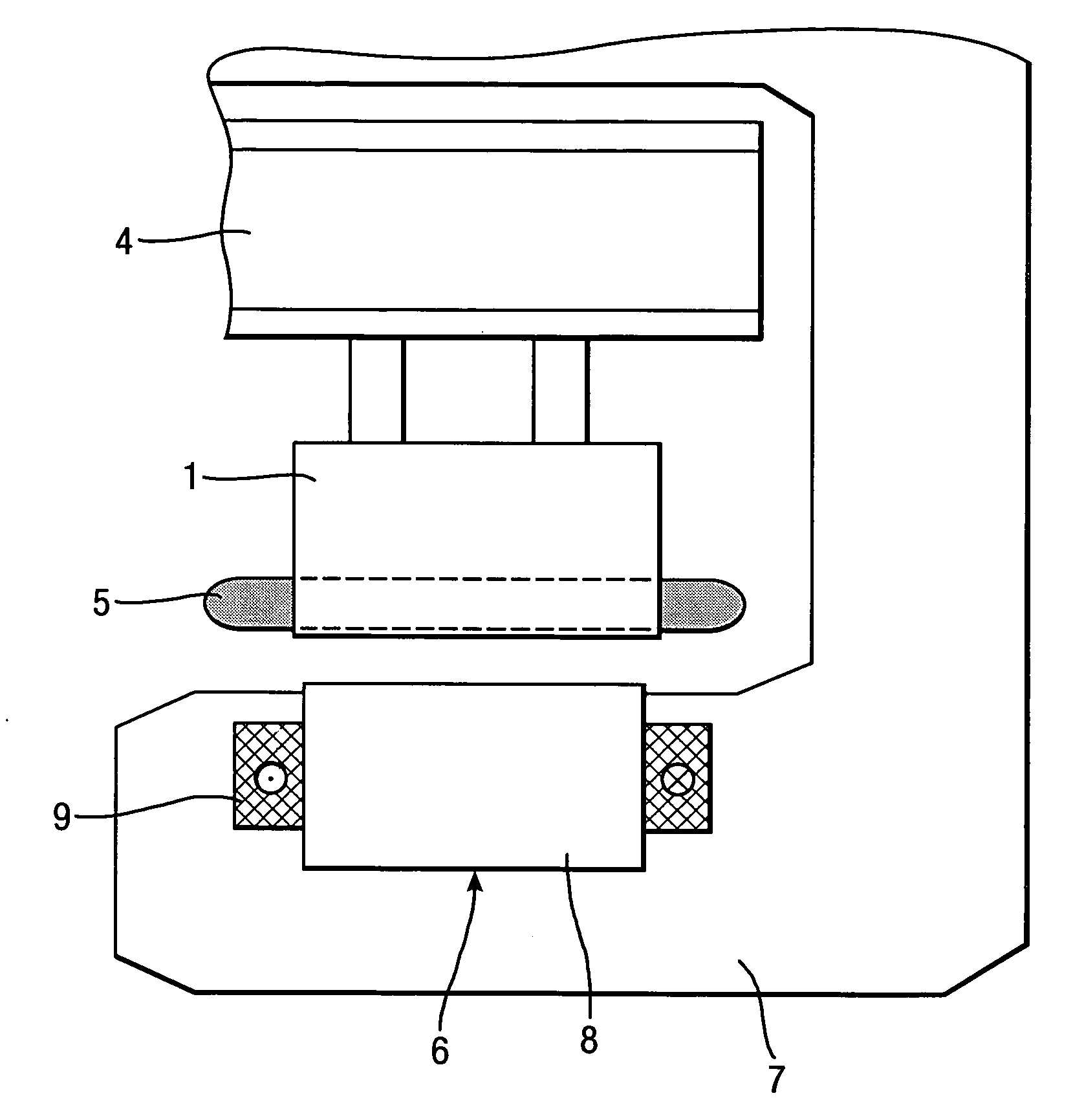

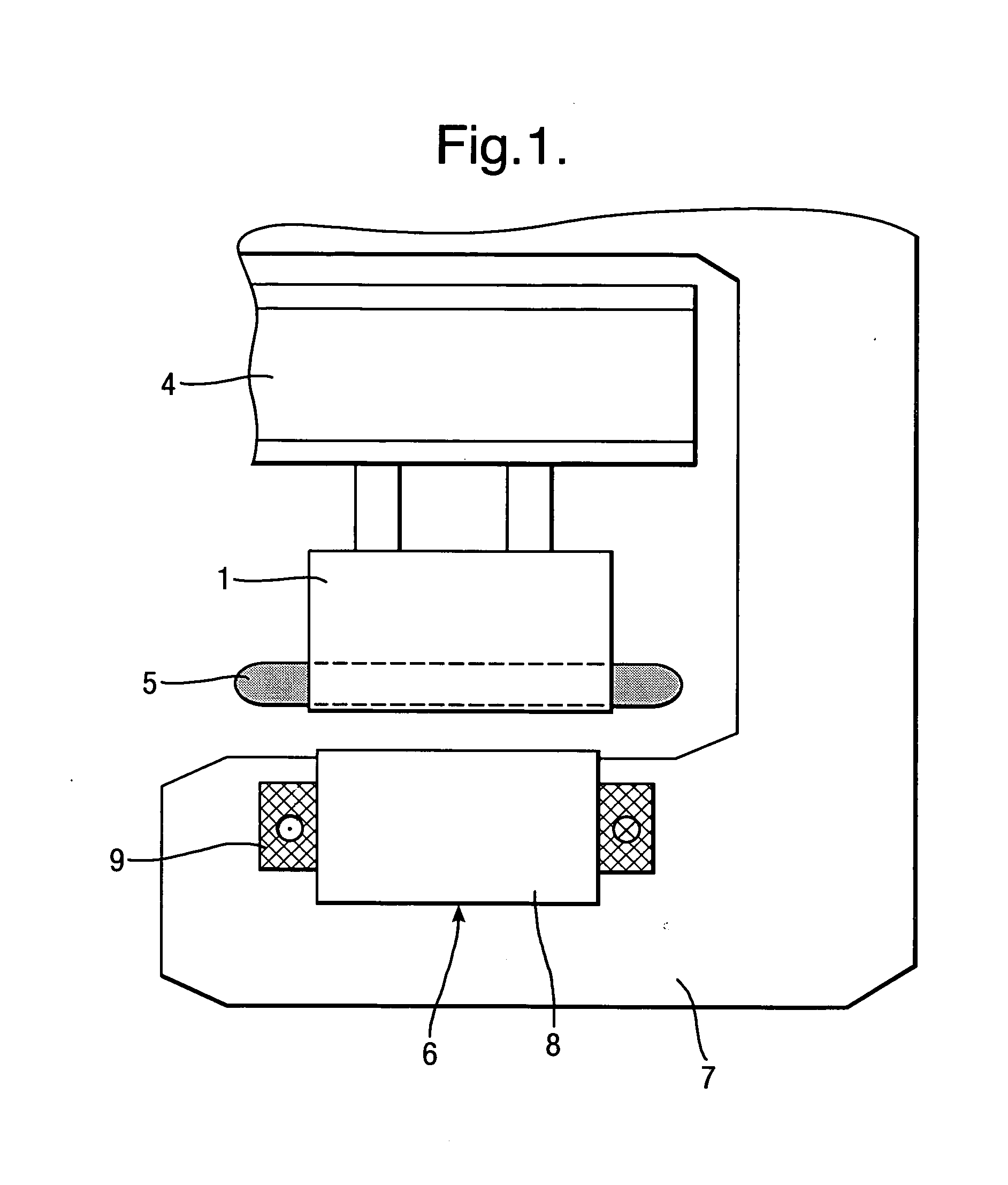

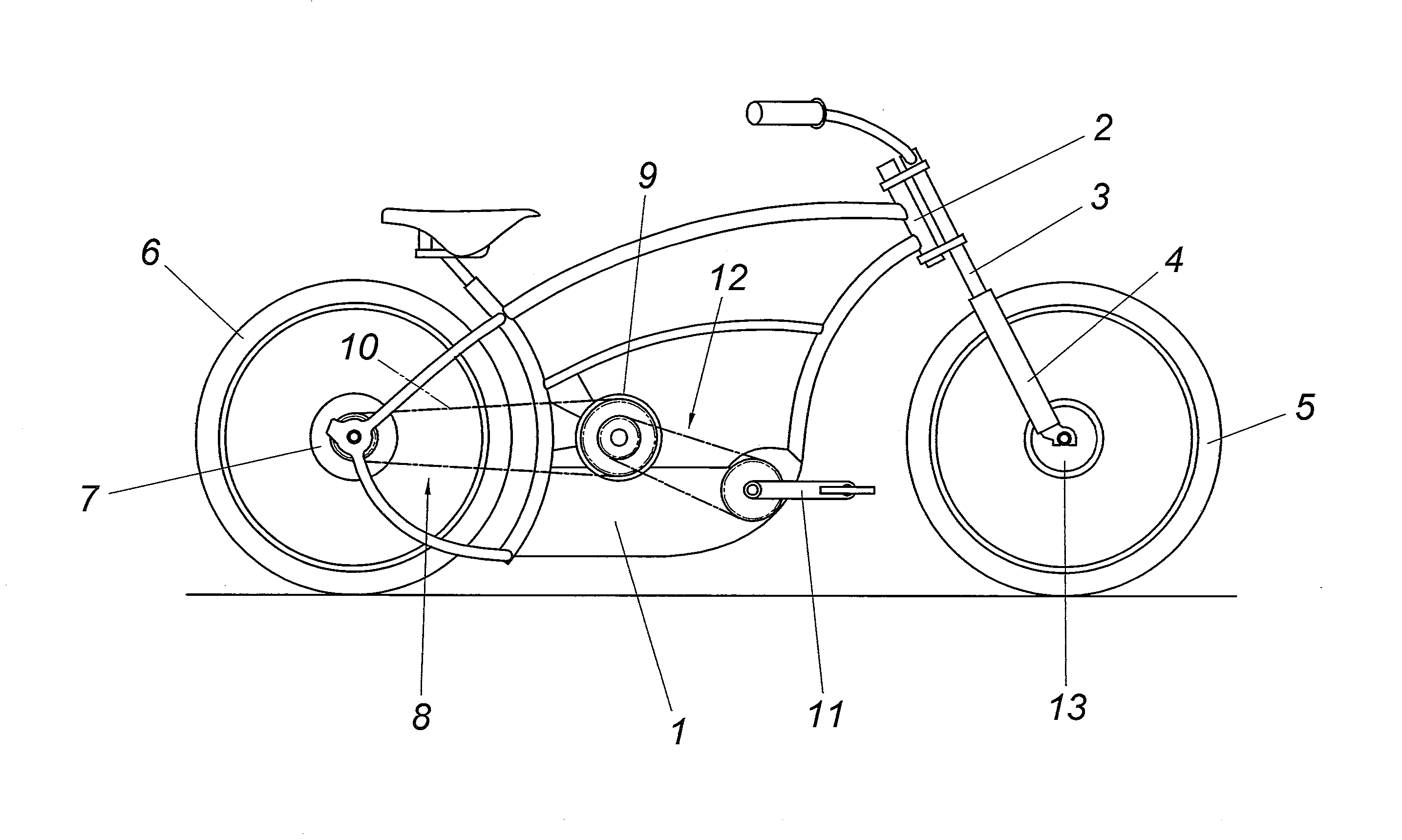

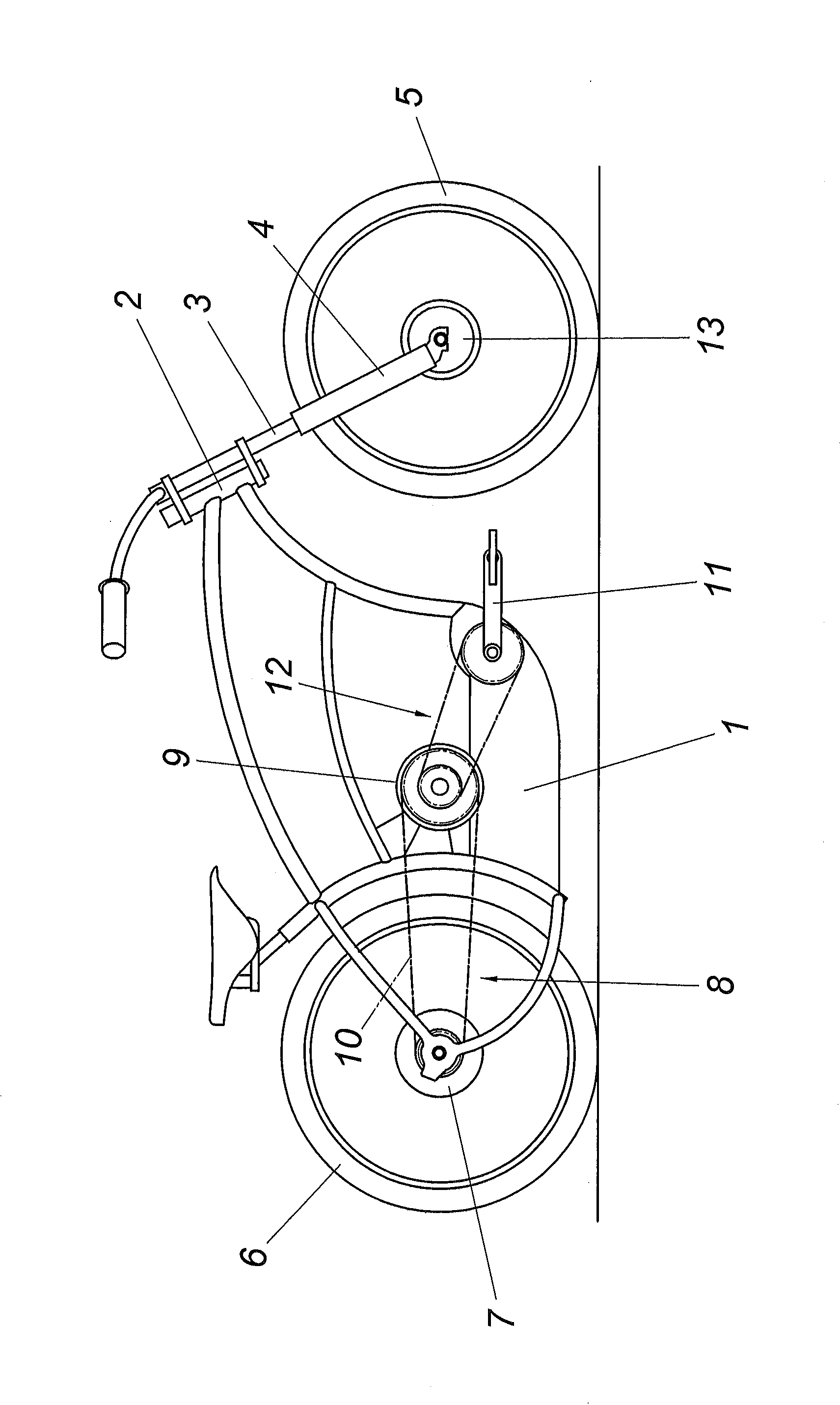

Bicycle having an electrical auiliary drive

InactiveUS9079634B2Maintenance frequencySmall sizeElectric devicesElectric propulsion mountingFreewheelElectricity

A bicycle having a pedal crank drive (12) and having an electrical auxiliary drive, which is connected to the pedal crank drive (12), is described, which has a wheel hub motor (7) having a freewheel hub for the rear wheel (6). To provide advantageous drive conditions, it is proposed that the wheel hub motor (7) for the rear wheel (6) have a drive connection via a transmission gearing (8) to an electrical auxiliary motor (9) of identical size.

Owner:INTERHOLZ HANDELS

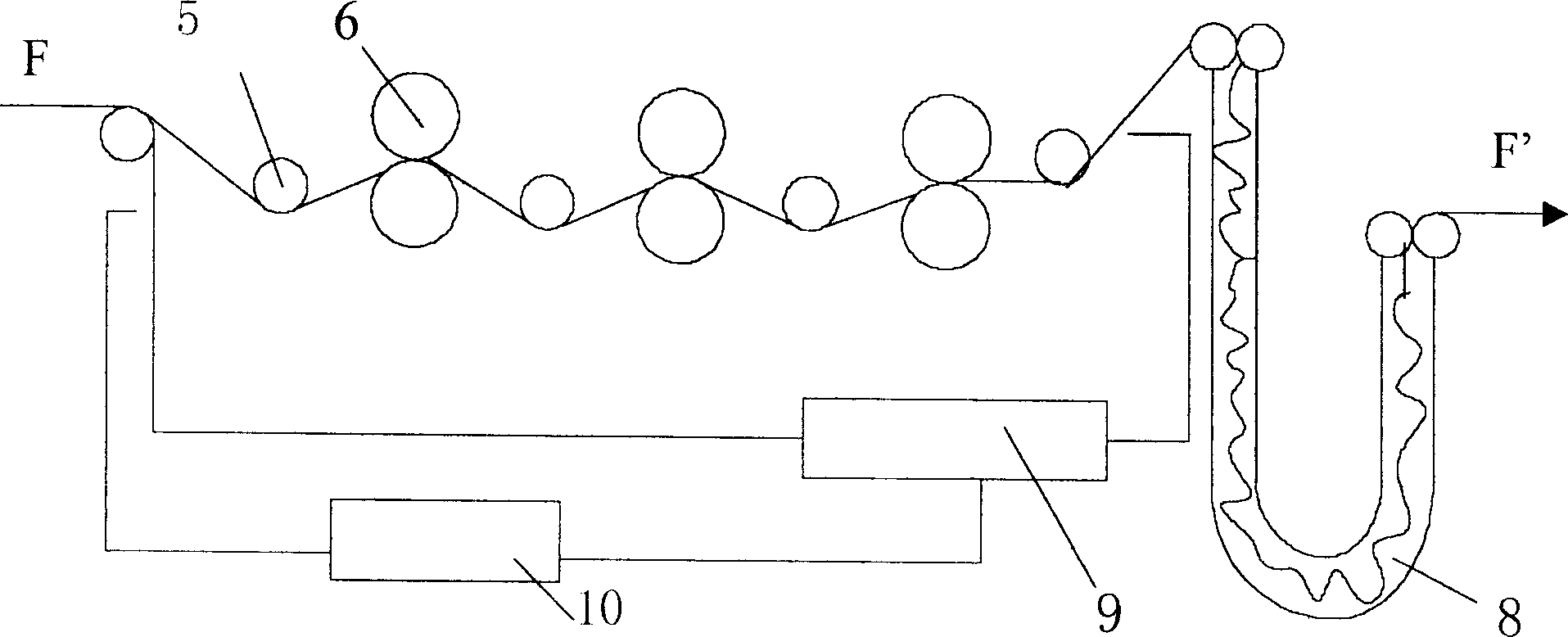

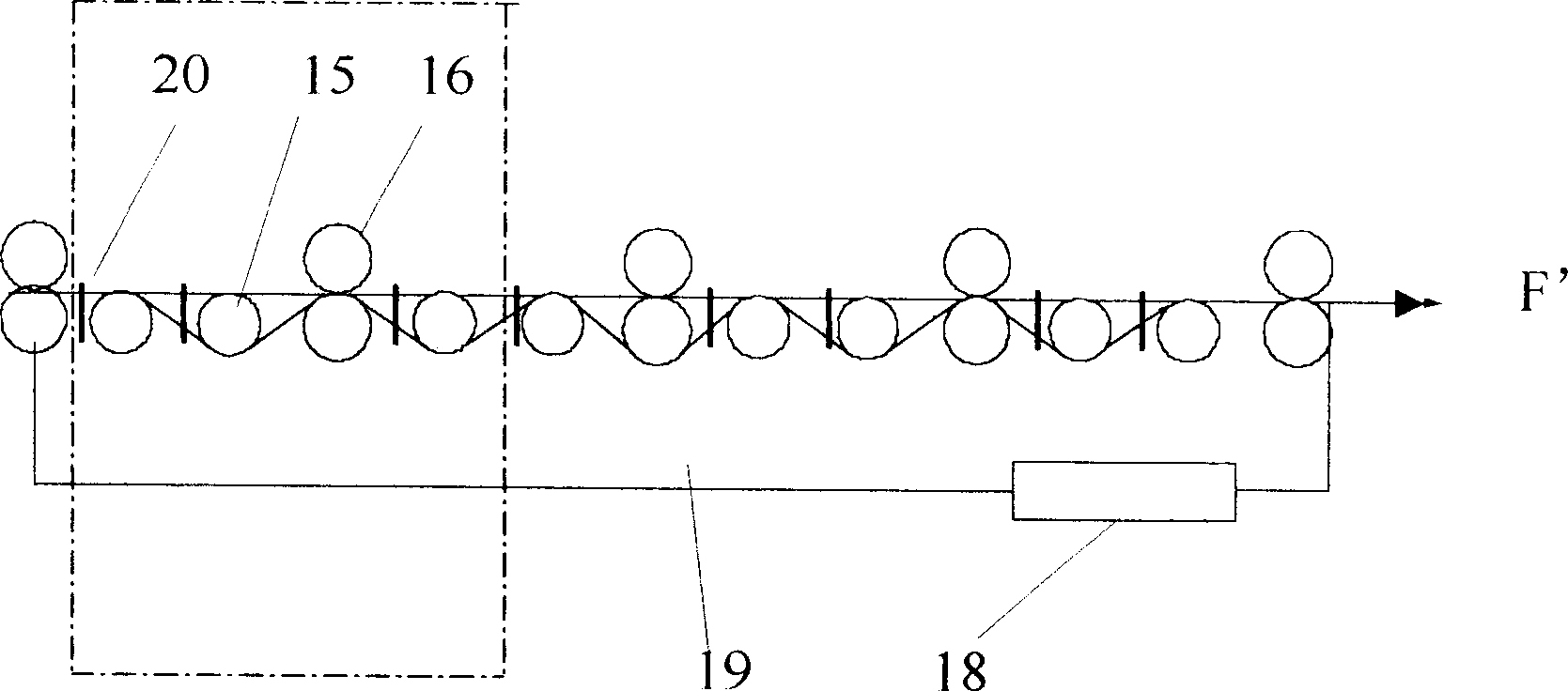

Method and apparatus for false twiting and drawing animal fibre

InactiveCN1401839AImprove fiber qualityImprove production and efficiencyDrafting machinesPre treatmentWetting

A false-twist stretching method for animal fibres includes wetting and rolling several times, wet and hot storage, false-twist stretching, shape fixating in cold water, and baking. Its apparatus consists of wetting and rolling unit, false-twist stretching unit, two guide rollers, and two squeeze rollers.

Owner:TIANJIN POLYTECHNIC UNIV +1

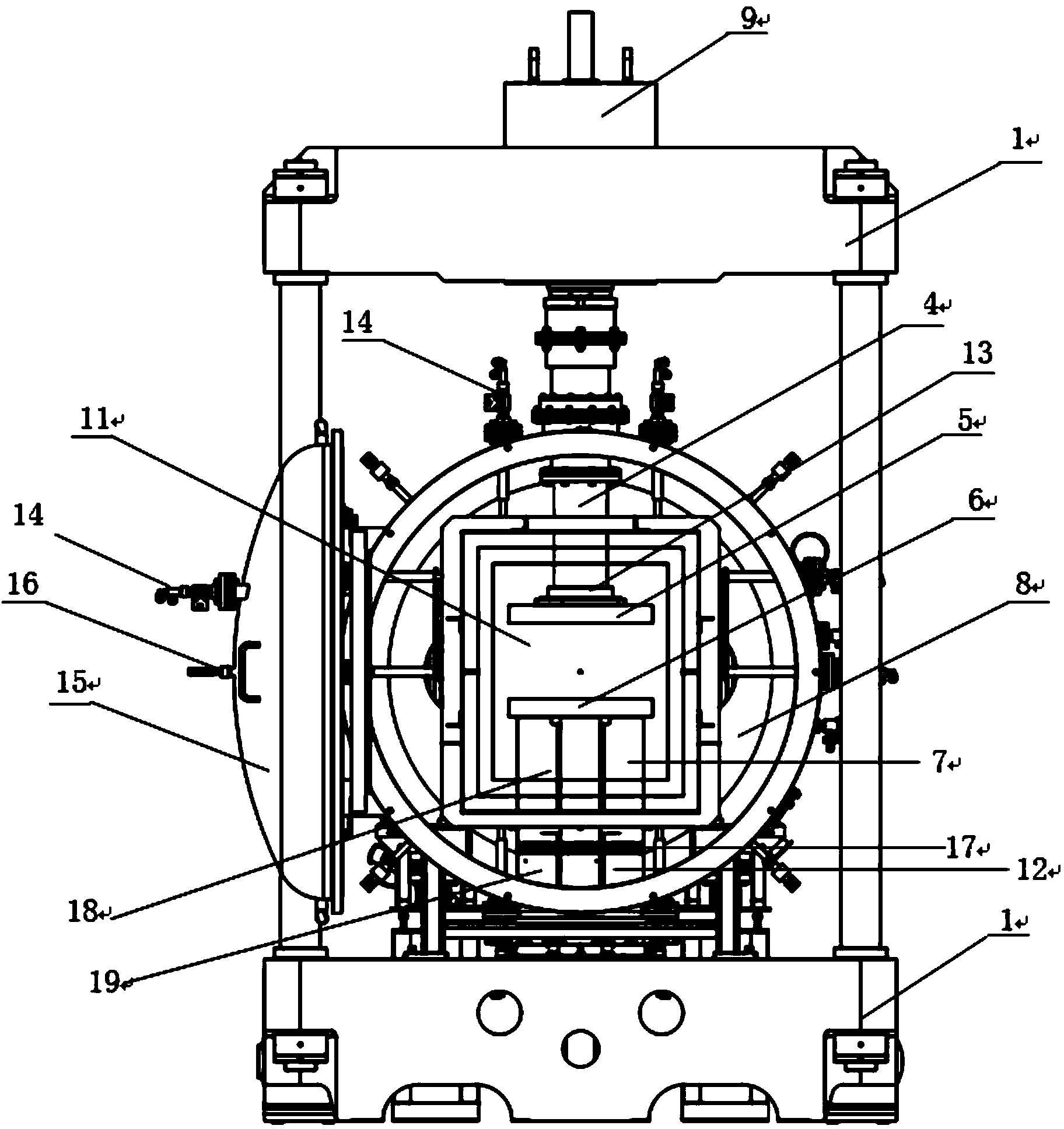

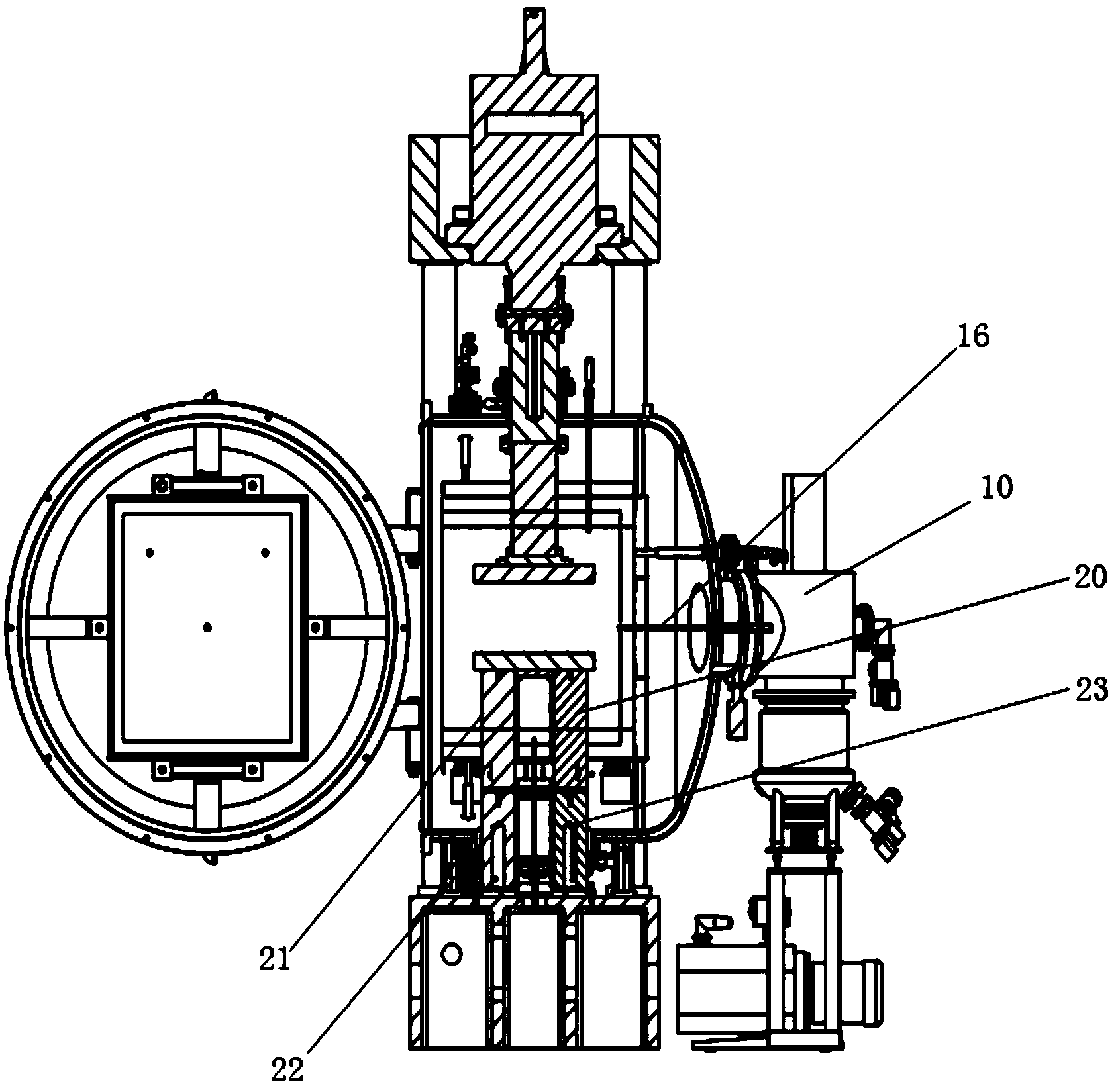

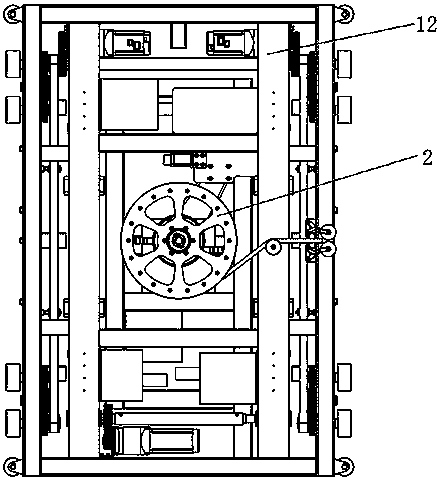

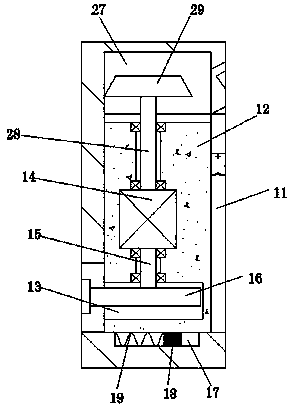

Large vacuum hot-pressing furnace

InactiveCN103586573APrecise Control of Temperature UniformityGuaranteed temperature uniformityNon-electric welding apparatusTemperature controlEngineering

The invention relates to a large vacuum hot-pressing furnace which comprises a furnace body framework, a vacuum chamber, an upper molybdenum press head sample table, a lower molybdenum press head sample table, a hydraulic system, a vacuum obtaining system and a heating chamber. The upper molybdenum press head sample table and the lower molybdenum press head sample table are respectively arranged on the upper portion and the lower portion in the vacuum chamber. The lower molybdenum press head sample table is supported by four molybdenum columns. Six-zone temperature control heating is adopted for the heating chamber. A heating chamber metal heat-insulating reflection screen is composed of molybdenum screens and stainless steel screens. The hydraulic system is arranged at the upper end of the furnace body framework. According to the large vacuum hot-pressing furnace, the molybdenum screens and the stainless steel screens are used for shielding in the periphery of the heating chamber, and the six-zone temperature control heating is adopted, so that the heating evenness of the heating chamber is improved, the temperature control precision is +-1DEG C, and the mean temperature of the heating chamber is +-2 DEG C; the displacement precision of the hydraulic system reaches 0.015mm, and the largest tonnage of a hydraulic punch is 200 tons. The large vacuum hot-pressing furnace is favorable for machining precise instruments and large components and has the advantages of being good in heating evenness, high in temperature control precision, quick in temperature rise, high in hydraulic precision, and the like.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

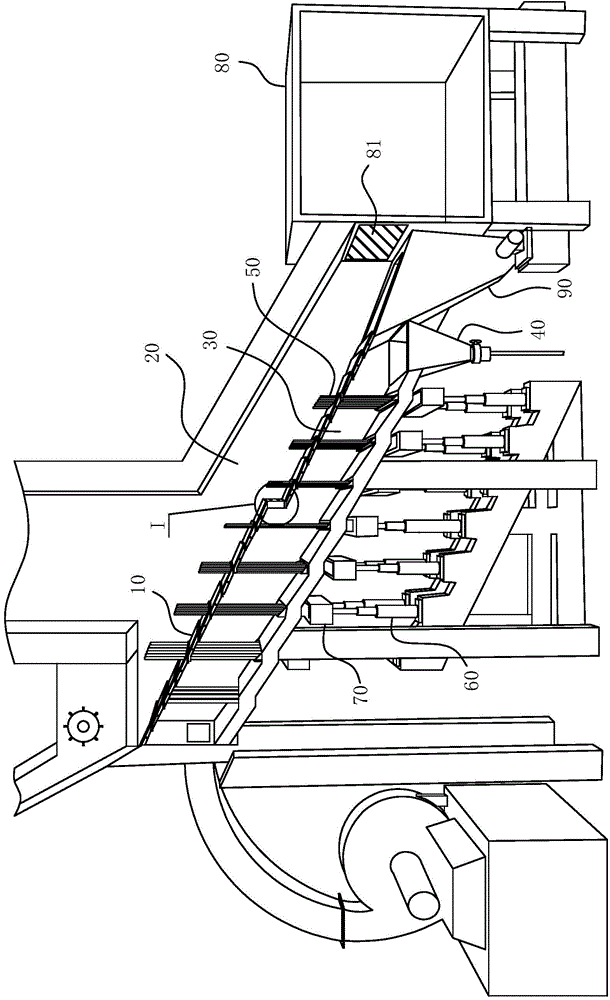

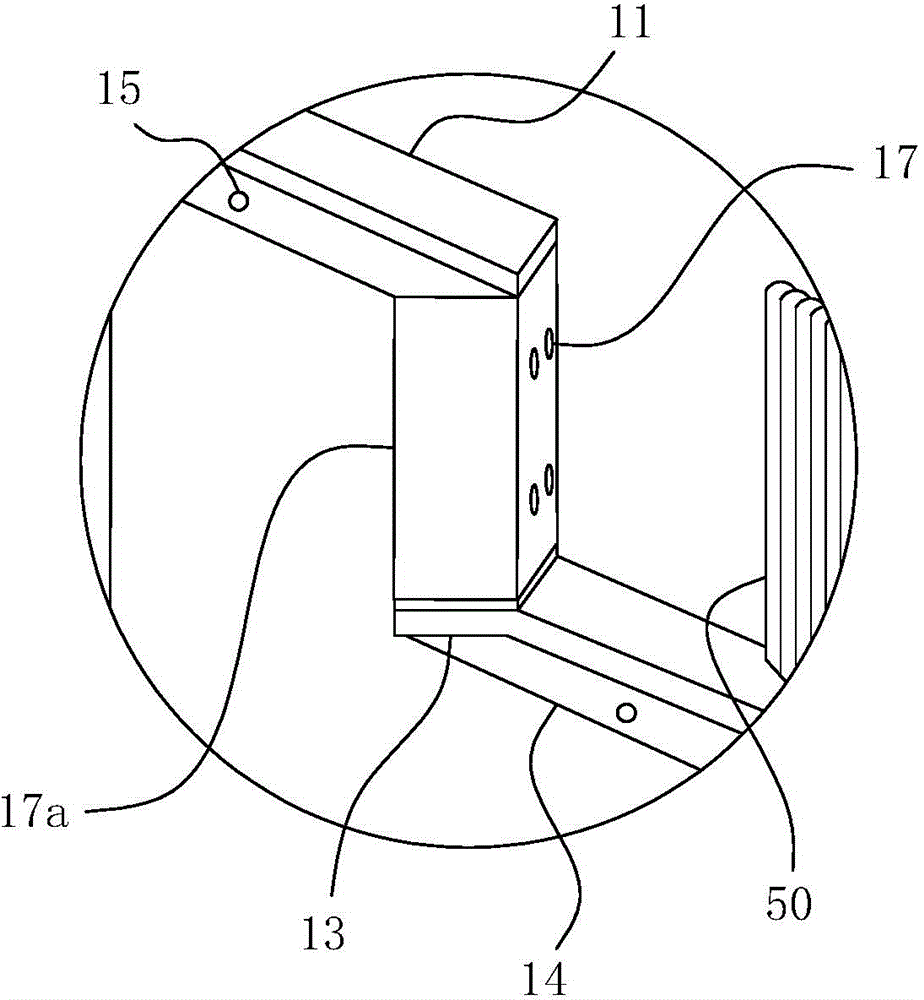

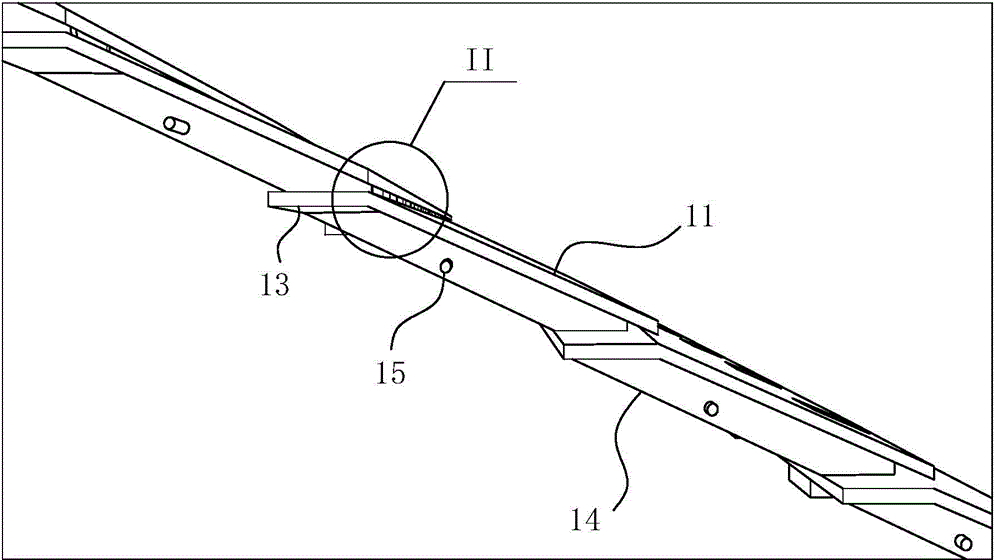

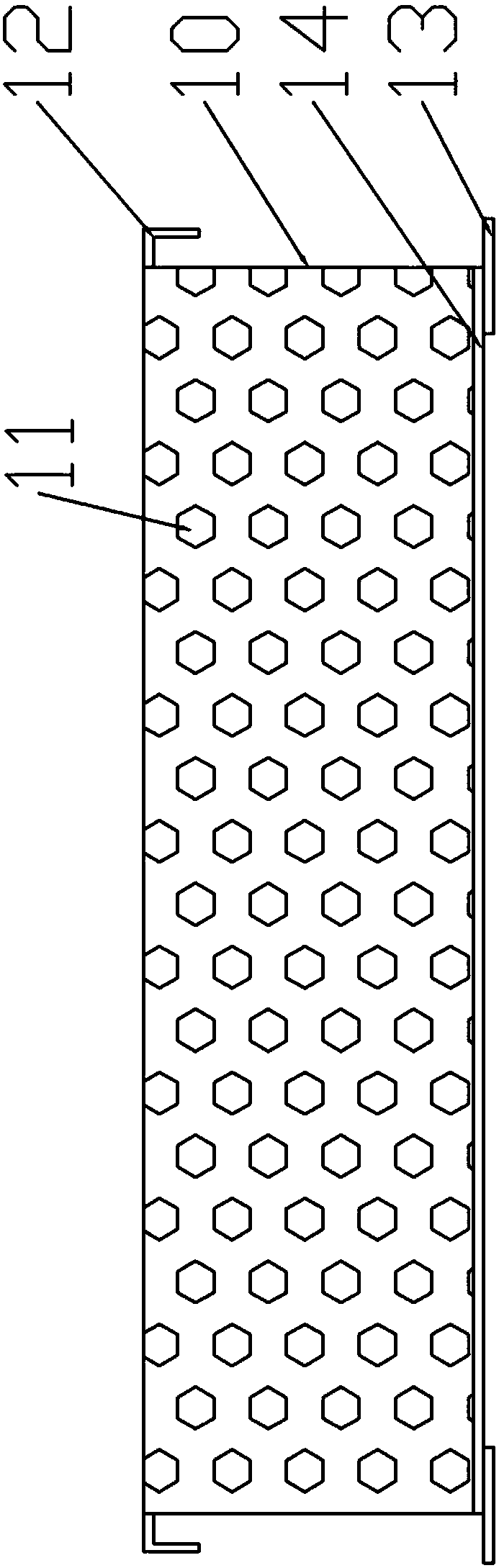

Fixed grate and incineration system applying same

InactiveCN104595907AGuaranteed structural rigidityGuaranteed to be constantInclined grateIncinerator apparatusCombustion chamberHot blast

The invention belongs to the field of waste incineration equipment and particularly relates to a fixed grate and an incineration system applying the same. The fixed grate at least comprises grate plates; the arrangement heights of the grate plates are gradually reduced so as to form a step type grate body structure of the fixed grate; a spacing is formed between plate bodies of each two adjacent grate plates in the perpendicular direction so as to form a ventilation pore running through a grate body; the grate plates are provided with extending plates; the plate faces of each extension plate and the plate body of the previous grate plate are crossed mutually to form a wind guide port structure. The incineration system comprises a main combustion chamber, the fixed grate and a grate ejector rod, wherein the main combustion chamber is isolated and divided into a combustion cavity and a hot blast cavity by the fixed grate; the air inlet end of the hot blast cavity is also the feed end of the fixed grate; the grate ejector rod is used for overturning and ejecting materials on the incineration face; the grate ejector rod passes through a through hole and runs through the material layer on the fixed grate in the maximum lift range. The fixed grate and the incineration system have reasonable and practical structures; the grate body has a good ventilation effect; material incineration efficiency is high.

Owner:安徽盛燃焚烧炉科技有限公司

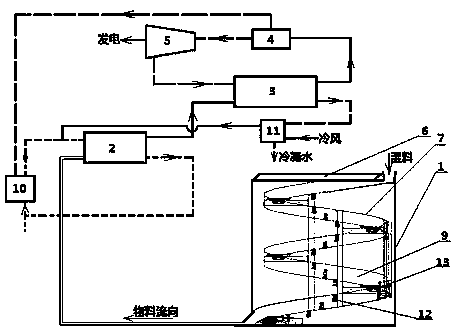

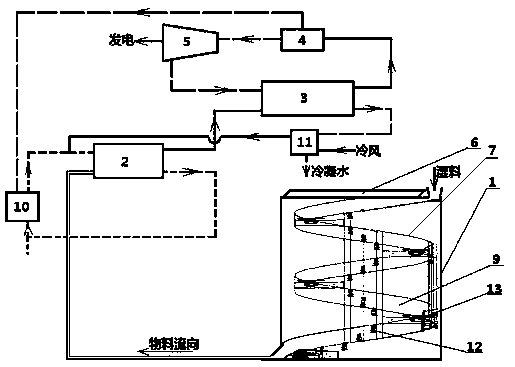

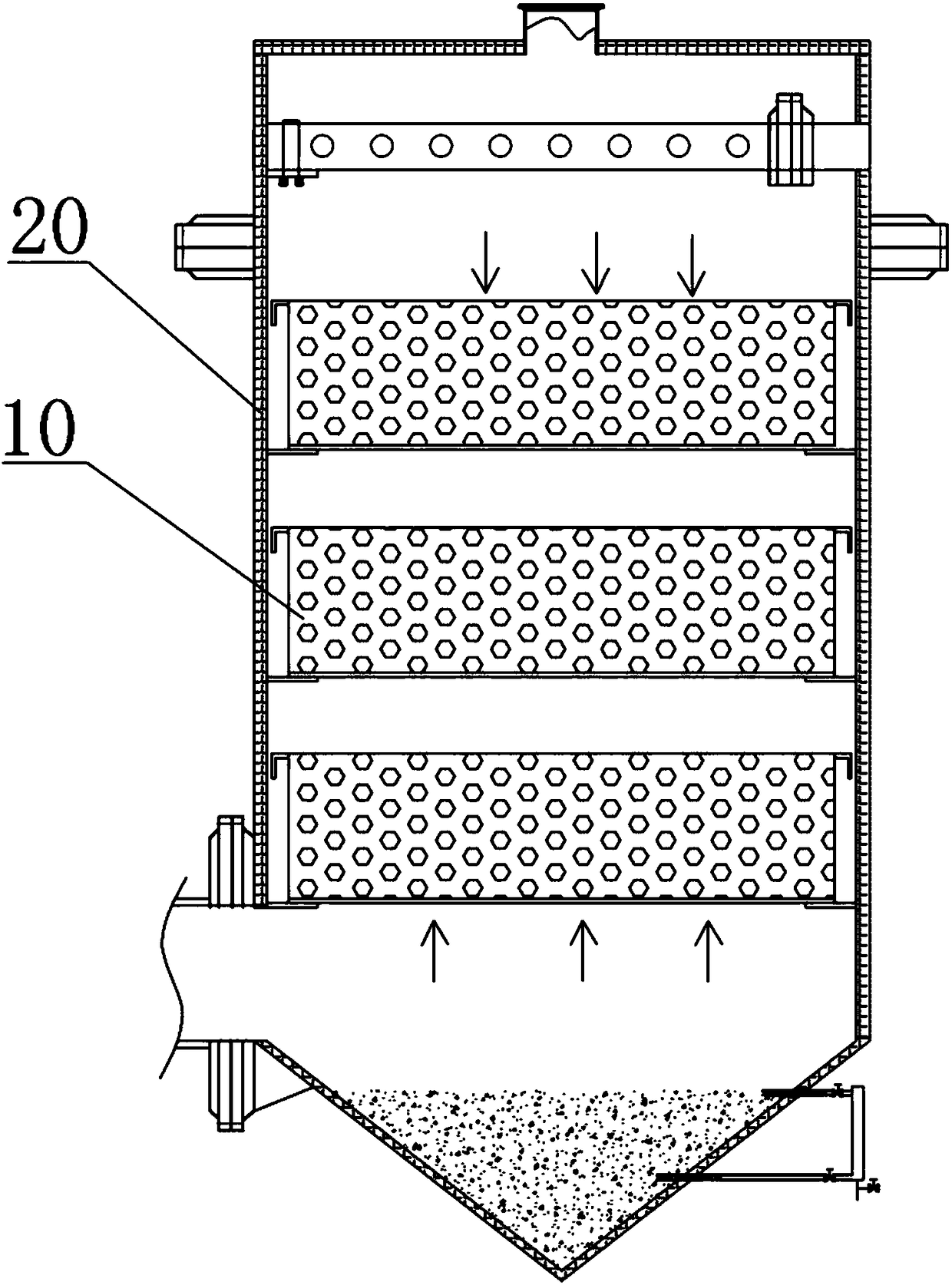

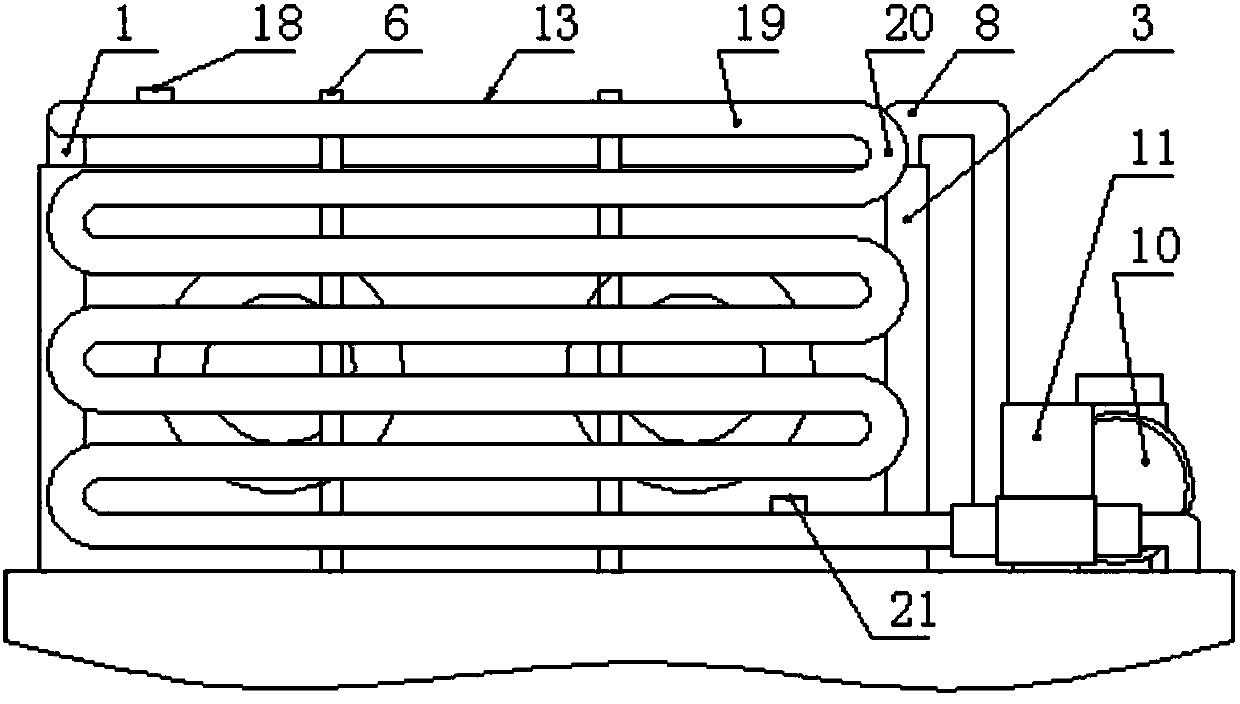

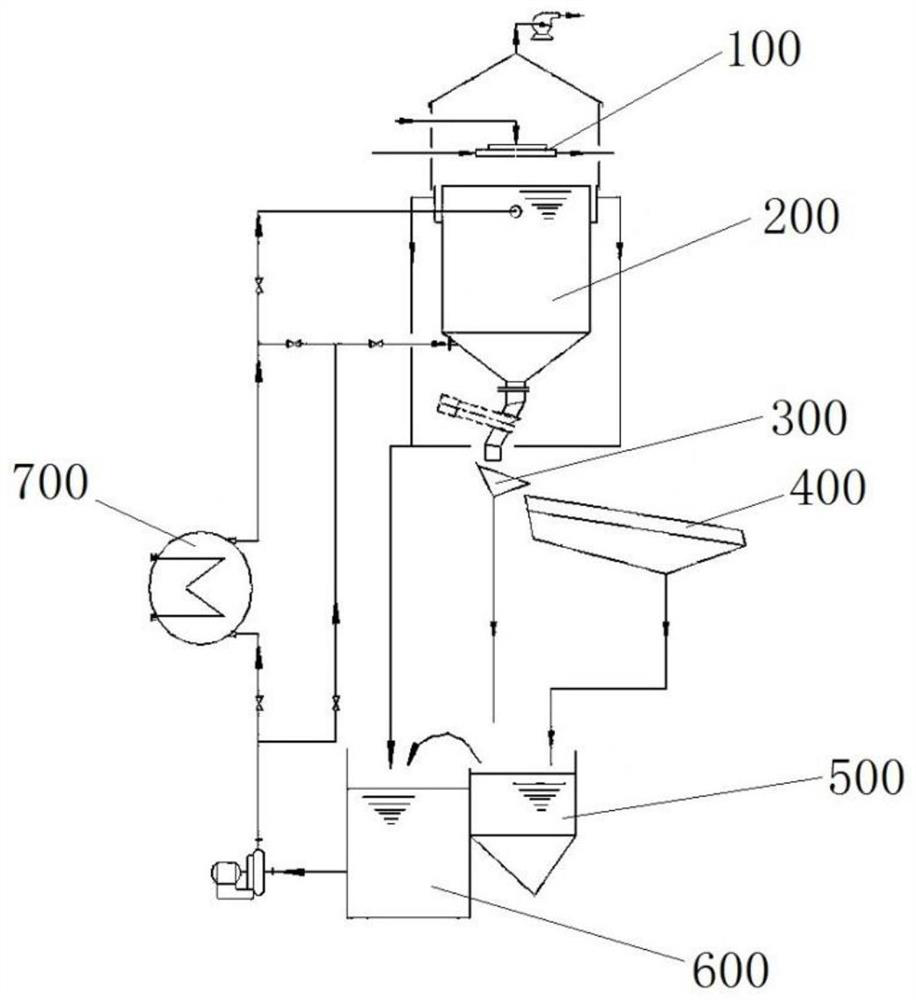

Biomass drying system

InactiveCN109442872ACreate pollutionReduce travel speedDrying solid materials with heatDrying gas arrangementsSolar dryingPower station

The invention provides a biomass drying system, and belongs to the field of biomass fuel drying. The biomass drying system solves the technical problem that power generation efficiency of existing biomass power plants is low. The exhaust gas of a boiler tail of a biomass power plant and the waste heat of the low pressure steam after the steam turbine works are fully utilized. Solar preliminary drying, first-stage rotary drum drying, and second-stage rotary drum drying are adopted. Clean energy is adopted to the whole drying process, and no pollution is produced to the environment. A solar drying room is internally provided with a spiral material conveying channel. Lugs are arranged at a heat dissipating channel in the spiral material conveying channel at intervals. The travel speed of biomass fuel in the material conveying channel is lowered, the standing time is prolonged, heat exchange between the biomass fuel and hot water in the heat dissipating pipe is enhanced, and drying efficiency is improved.

Owner:陈燕

Road de-icing device and de-icing method suitable for loader

The invention relates to a road de-icing device and de-icing method suitable for a loader, which belongs to the technical field of road de-icing and particularly relates to a detachable de-icing device which is conveniently mounted on the loader. The detachable de-icing device comprises a de-icing mechanism and an ice layer thickness detecting mechanism, the advance speed of the loader and the rotation speed of a milling drum can be automatically adjusted according to the thickness of an ice layer, the de-icing thickness range is large, and the mechanical motion of the ice layer thickness detecting mechanism and the mechanical motion of a limiting device can be automatically controlled by a hydraulic device, thereby realizing intelligent measurement for the road icing thickness. The loader used by the invention is a common operation machine of the road maintenance department, thereby having wide scope of popularization; the loader is used as a power source, thereby avoiding the problem of relatively high cost of a vehicle body of a dedicated de-icing vehicle. Meanwhile, an icebreaking device can be separated from the loader, so that other applications of the loader are not influenced outside the operational period.

Owner:WUHAN UNIV OF TECH

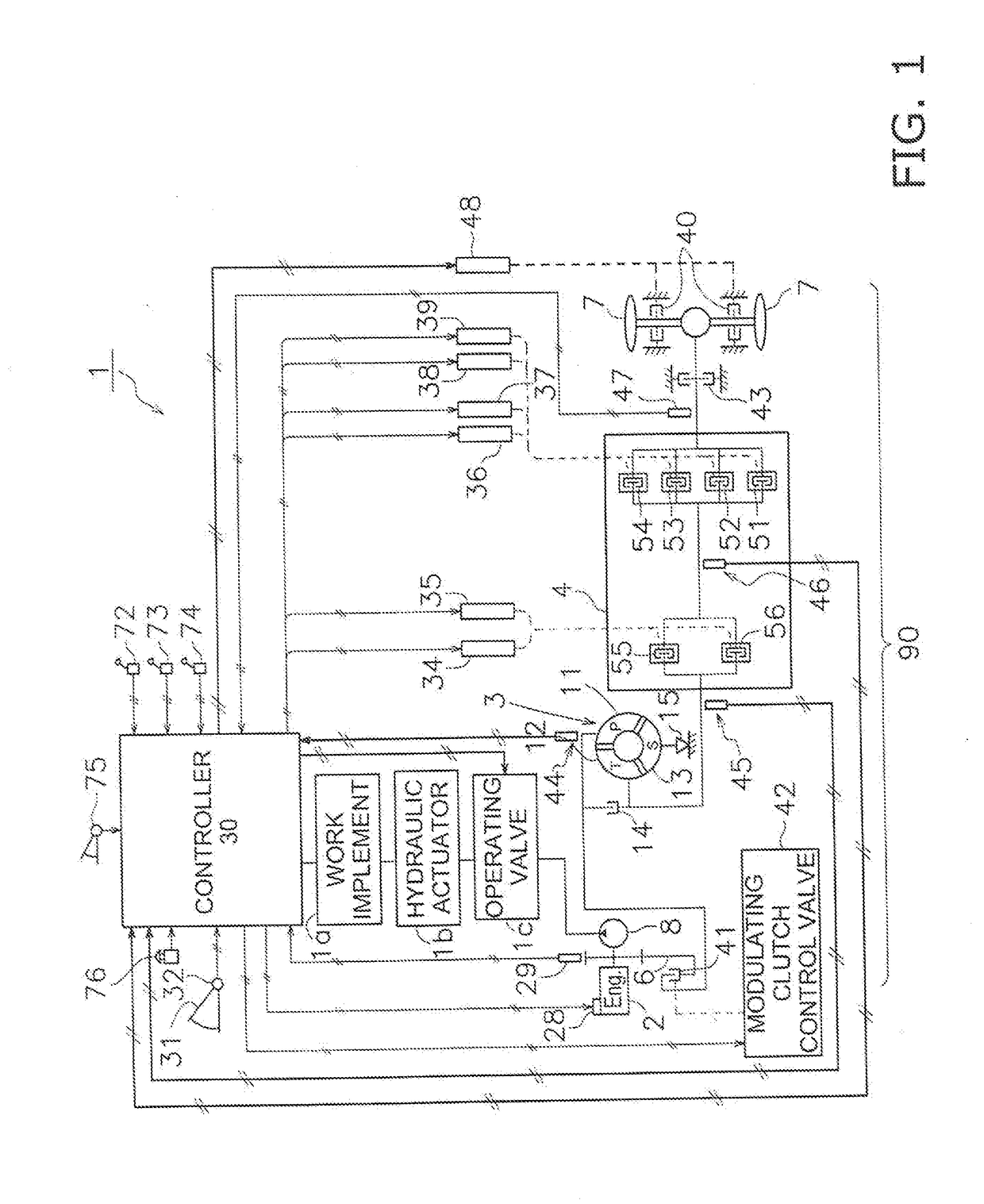

Work vehicle

InactiveUS20190039577A1Speed target speed be reducedReduce travel speedClutchesAutomatic initiationsClutch

A work vehicle includes a target speed setting unit configured to set a desired target speed, a travel speed detecting unit configured to detect a travel speed of a vehicle body, an engine, a work implement attached to the vehicle body and driven by an output of the engine, a travel device, a brake disposed between the travel device and the engine and configured to brake the travel device, a clutch disposed between the engine and the brake and configured to transmit or interrupt power from the engine to the travel device, and a controller configured to reduce a difference between the travel speed and the target speed by controlling an engagement pressure of the clutch and an engagement pressure of the brake.

Owner:KOMATSU LTD

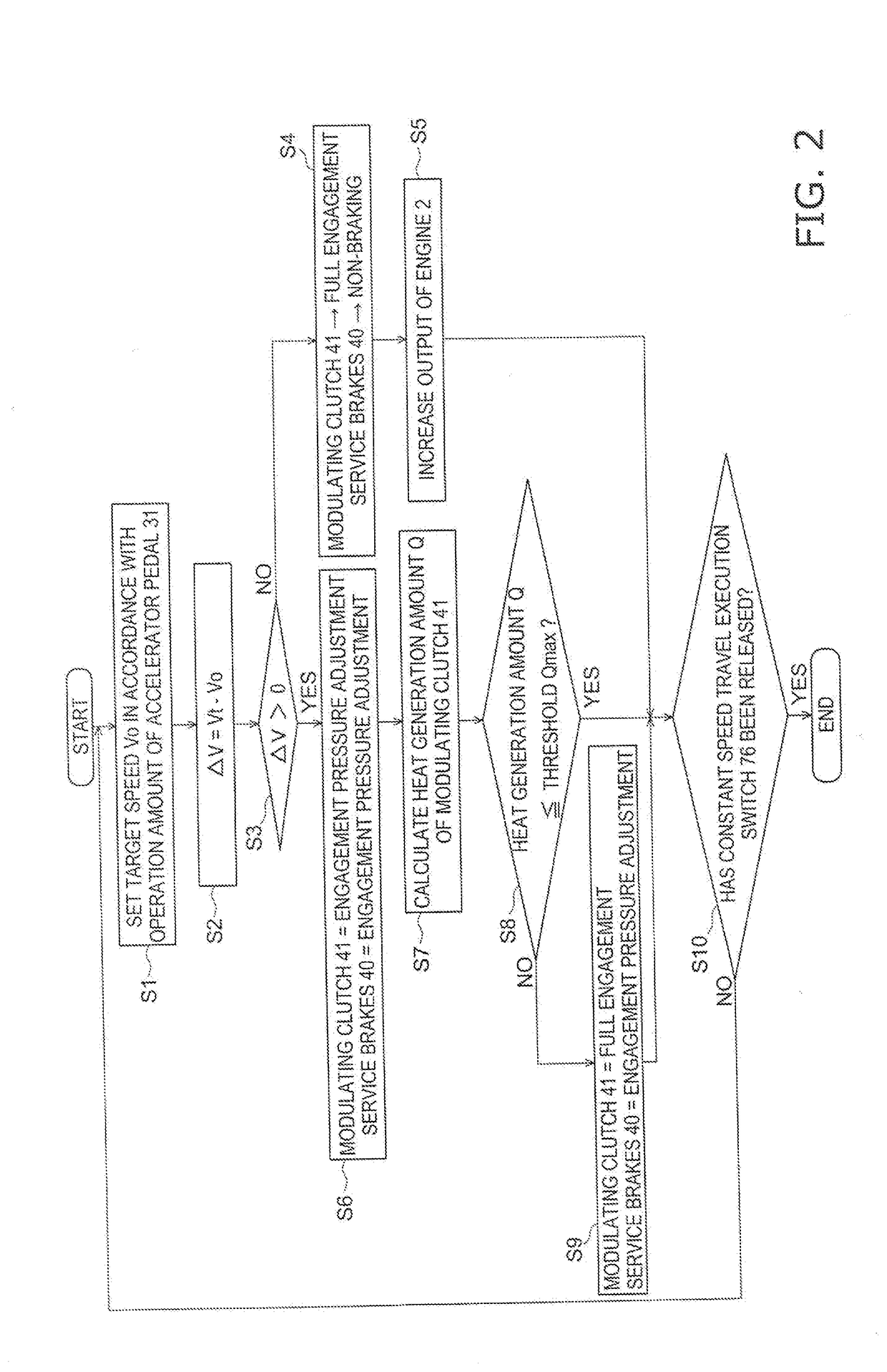

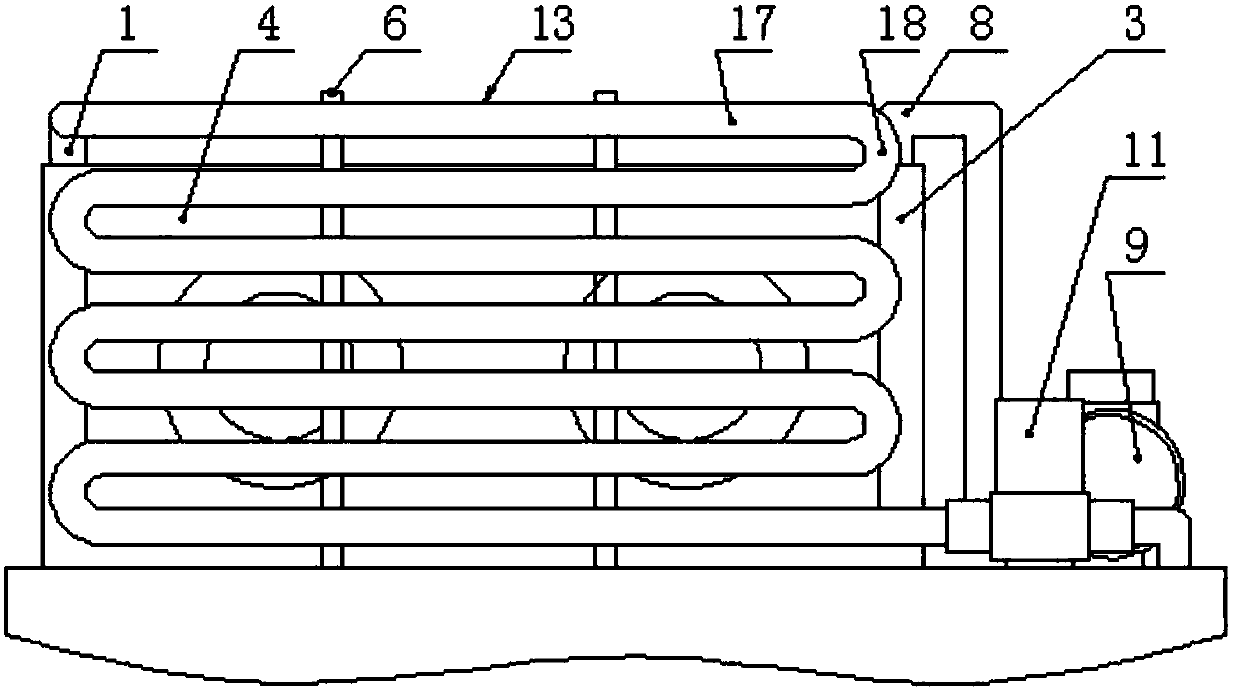

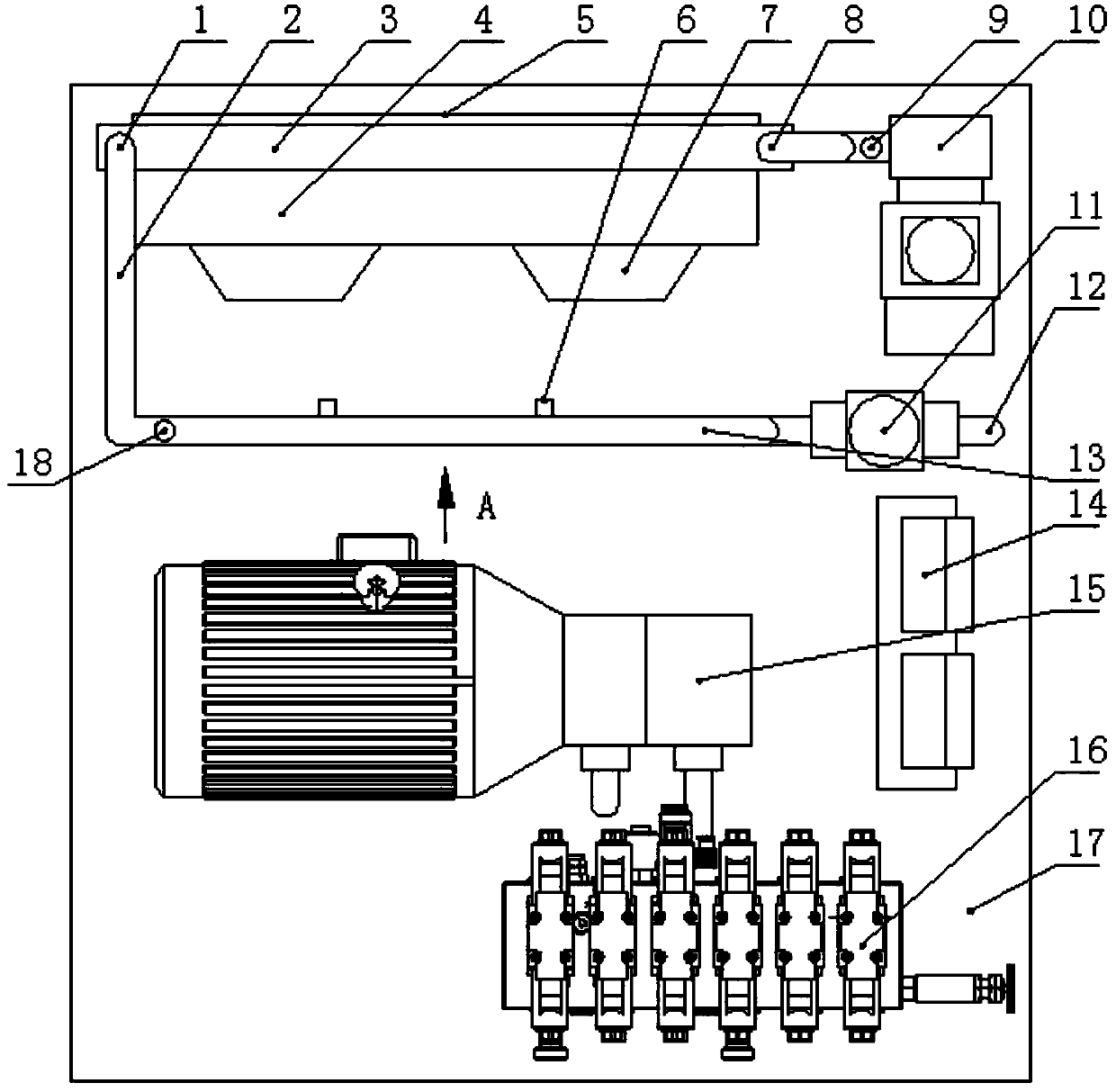

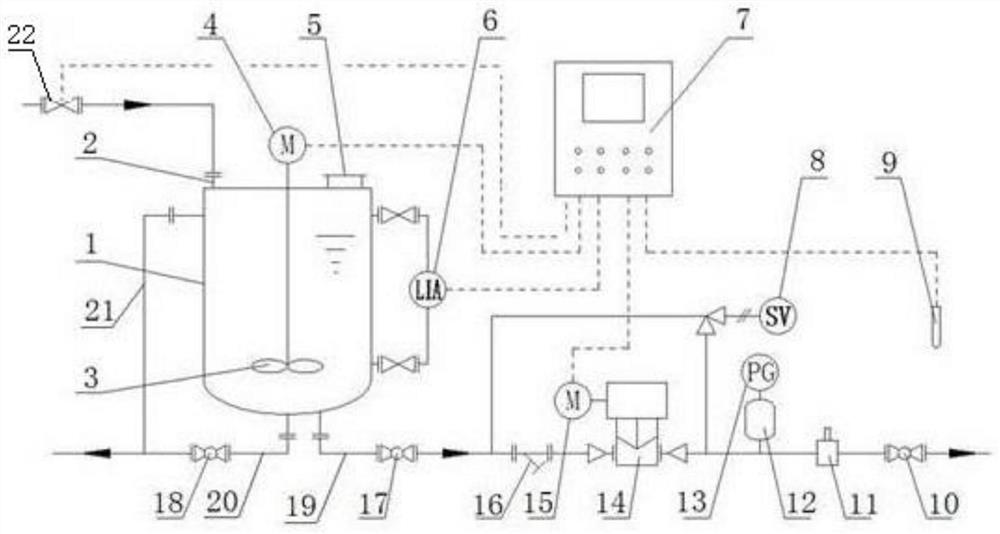

Air cooling hydraulic station with secondary heat dissipating pipeline

ActiveCN105952729AGood cooling effectReduce travel speedFluid-pressure actuator componentsEngineeringFuel tank

The invention relates to an air cooling hydraulic station with a secondary heat dissipating pipeline. A switch valve group is arranged at the front end of the upper end face of an oil tank; an oil supply power source is arranged on the upper end face of the oil tank at the rear part of the switch valve group; a fan casing is arranged at the rear end of the upper end face of the oil tank; a heat dissipater is arranged at the outer side, facing the oil tank, of the fan casing; at least one fan is arranged at the inner side, facing the oil tank, of the fan casing; and the secondary heat dissipating pipeline with multiple bends in the vertical direction is arranged on the upper end face of the oil tank between the oil supply power source and the fan casing. According to the air cooling hydraulic station disclosed by the invention, the fans suck cold air from the upper end face direction of the oil tank, and then the cold air is blown out by the outward heat dissipater, so that the heat of other hydraulic components on the upper end face of the oil tank can be taken way when air flows; the secondary heat dissipating pipeline can be produced into a thicker pipeline or can be arranged into multiple layers, so that the advancing speed of oil is reduced, and a secondary heat dissipating effect is better.

Owner:TIANJIN URANUS HYDRAULIC MACHINERY

Biomass drying method

InactiveCN109442871ACreate pollutionAvoid accumulationDrying solid materials with heatDrying gas arrangementsPower stationFlue gas

The invention provides a biomass drying method, and belongs to the field of biomass fuel drying. The technical problem of low power generation efficiency of an existing biomass power plant is solved.According to the biomass drying method, flue gas on the tail part of a boiler of the biomass power plant and low-pressure steam waste heat after a steam turbine does work are fully utilized, and solarenergy primary drying, primary drum drying and secondary drum drying are adopted, and clean energy is used in the whole drying process, and the environment is not polluted. A spiral material conveying channel is arranged in a solar energy pre-drying chamber, and convex pieces are arranged at intervals on a heat dissipation pipeline in the spiral material conveying channel, so that the traveling speed of biomass fuel in the material conveying channel is slowed down, the residence time is improved, the heat exchange between the biomass fuel and hot water in the heat dissipation pipeline is enhanced, and the drying efficiency is improved.

Owner:陈燕

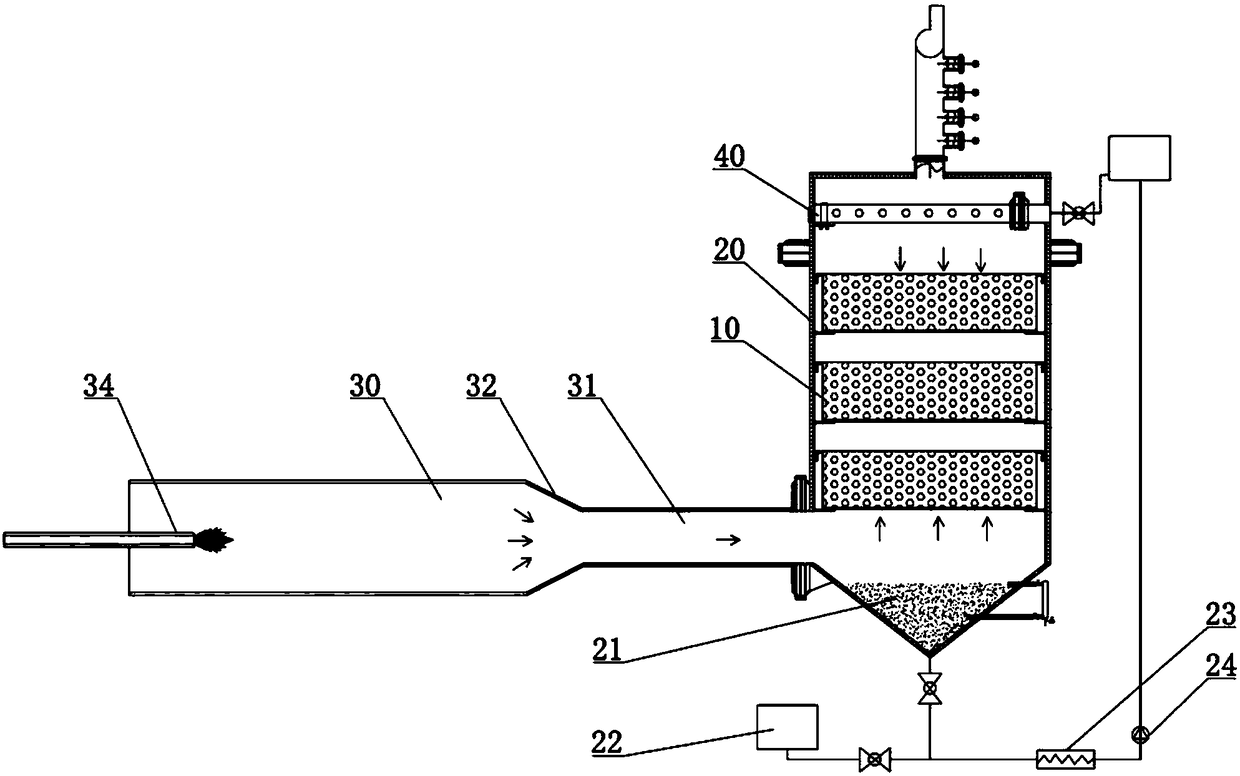

High-temperature flue gas quenching device

PendingCN108534564AGuaranteed to proceed normallyWon't accumulateWaste heat treatmentFlue gasElectromagnetic pump

The invention discloses a high-temperature flue gas quenching device which comprises a flue gas input mechanism and a quenching mechanism arranged in a heat exchange furnace; the flue gas input mechanism comprises a flue which is communicated with a flue gas source and the heat exchange furnace; the quenching mechanism comprises a dispersion disc, a filler unit, a hydrops pool and a circulation unit used for realizing quenching liquid circulation; the circulation unit comprises a heat exchanger which is communicated with the hydrops pool and an electromagnetic pump used for driving the quenching liquid to flow; one end of the electromagnetic pump is communicated with the heat exchanger, and the other end of the electromagnetic pump is communicated with the dispersion disc; the filler unitcomprises heat dissipation drums and heat exchange balls filled in the heat dissipation drums respectively, wherein the top surface and the bottom surface of each heat dissipation drum are arranged ina hollowed manner; the dispersion disc comprises a disc-shaped main body; the disc-shaped main body comprises a main pipe which is communicated with the electromagnetic pump and a plurality of branchpipes which are communicated with the main pipe; and the branch pipes are distributed on the two axial sides of the main pipe respectively. The invention is intended to provide the high-temperature flue gas quenching device capable of effectively lowering the energy consumption and the production cost.

Owner:北京宏帆态金节能科技有限公司

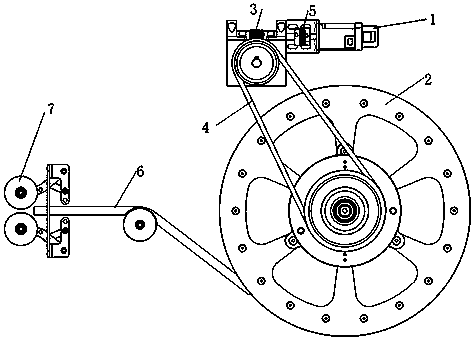

Wire-dragging device of rail shuttle vehicle matched with shuttle storage rack in use

InactiveCN107555053AReduce loadLighten the loadStorage devicesMechanical conveyorsCapacitanceDrive motor

The invention relates to the mechanical field and relates to wire-dragging device. The wire-dragging device of a rail shuttle vehicle matched with a shuttle storage rack in use comprises a wire-dragging device which comprises a wiring assembly, a winding assembly and a coil fixing wheel shaft; the wiring assembly comprises a slide contact disc and a wiring disc; the winding assembly comprises a driving motor, a winding disc, a winding guide tube and two guide wheels; the driving motor is linked to a coil screw of the winding disc through a synchronous belt, a power supply line winds the winding disc, and the power supply line extending out of the winding disc, penetrating through the winding guide tube, penetrates through a gap between the two guide wheels; the circular slide contact railis arranged on the slide contact disc, and a wiring head in contact with the slide contact rail is arranged on the wiring disc. Furthermore, the wire-dragging device is mounted on the rail shuttle vehicle, so that the rail shuttle vehicle shuttles bidirectionally in the shuttle storage rack in a certain distance range without a battery or a capacitor, so that the manufacturing, using and maintenance costs are lowered, the energy consumption is reduced, and the efficiency, stability and durability are improved, the load of the storage rack is reduced, and therefore, the goods bearing capacity of the storage rack is prevented from being reduced.

Owner:上海麦堡信息科技有限公司

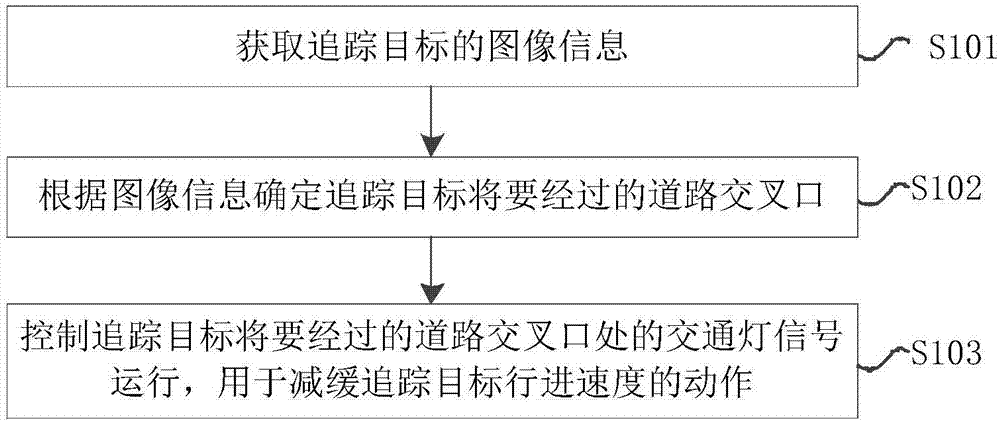

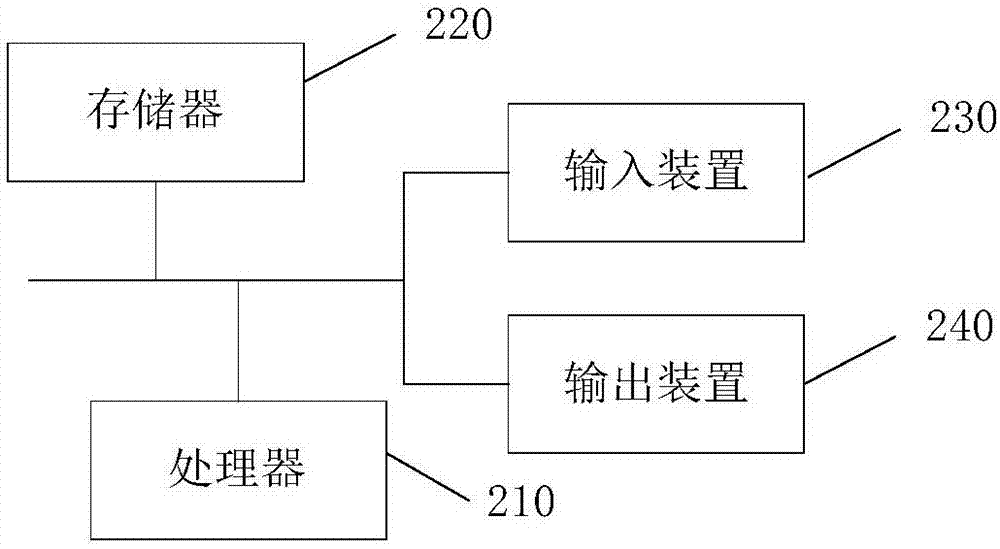

Traffic signal lamp control method and equipment

InactiveCN107545739AReduce travel speedQuick interceptControlling traffic signalsRoad crossingVehicle inspection

The invention provides a traffic signal lamp control method and equipment. The method comprises the steps of acquiring image information of a tracked target, determining a road intersection which thetracked target is about to pass according to the image information, controlling the operation of a traffic lamp at the road intersection which the tracked target is about to pass to slow down the running speed of the tracked target. Through obtaining the image information of a tracked target, combined with the position positioning technology, the road intersection which the tracked target is aboutto pass is determined, then the running speed of the tracked target is reduced through controlling the traffic lamp at the road intersection so as to facilitate relevant departments to quickly intercept the tracked target, and a problem of low efficiency of tracking and intercepting an illegal vehicle in illegal vehicle inspection in the prior art is solved.

Owner:ROAD TRAFFIC SAFETY RES CENT THE MINIST OF PUBLIC SECURITY OF THE PEOPLES REPUBLIC OF CHINA

Manufacturing technology of package print

InactiveCN107650200AReduce cutting costsAvoid pullingMetal working apparatusManufacturing technologyTransmission belt

The invention discloses a process for producing packaging printed matter. The process includes the following steps: the first step is to cover the film and attach the film to the conveyor belt body, and the transmission speed of the conveyor belt body is 3-5m / min; the second step is to cut , start the water cutting machine and shut it down quickly, the water jet is ejected and contacts the film to cut the hole, the whole process takes 0.01‑0.02s; the third step is to repeat steps 1 to 2, and so on until the film is finished. hole cutting operation. The invention is convenient and practical.

Owner:CHONGQING SAN CHUANG PRINTING CO LTD

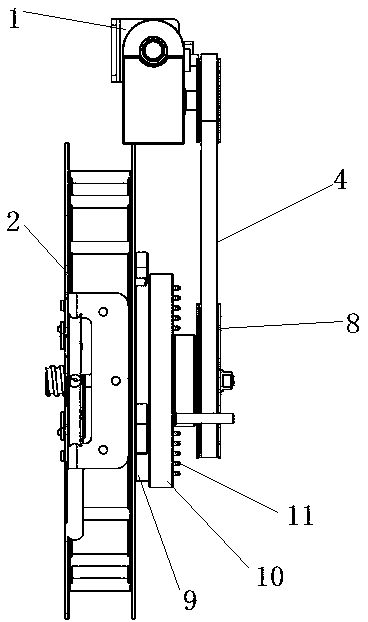

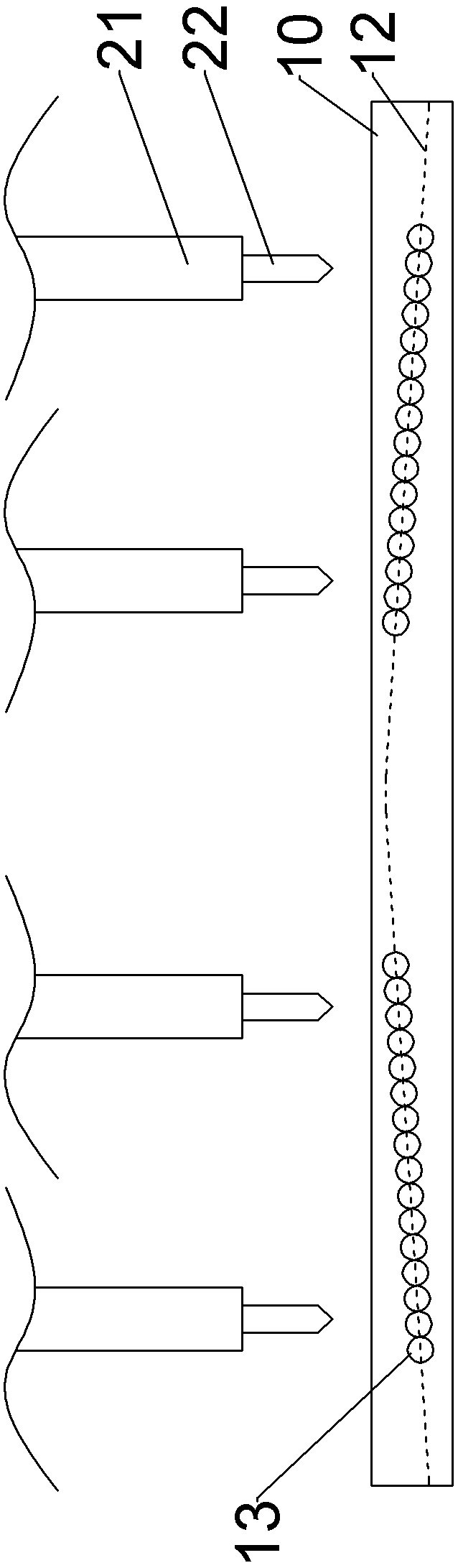

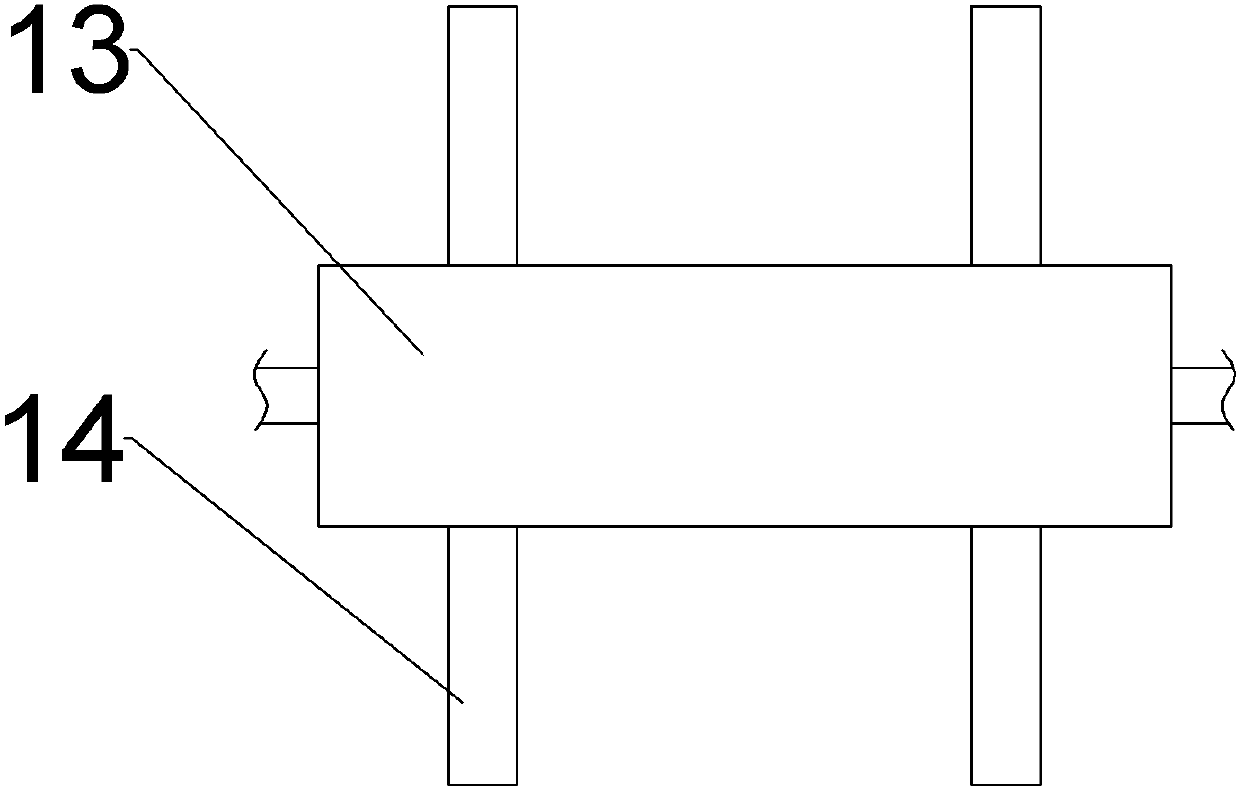

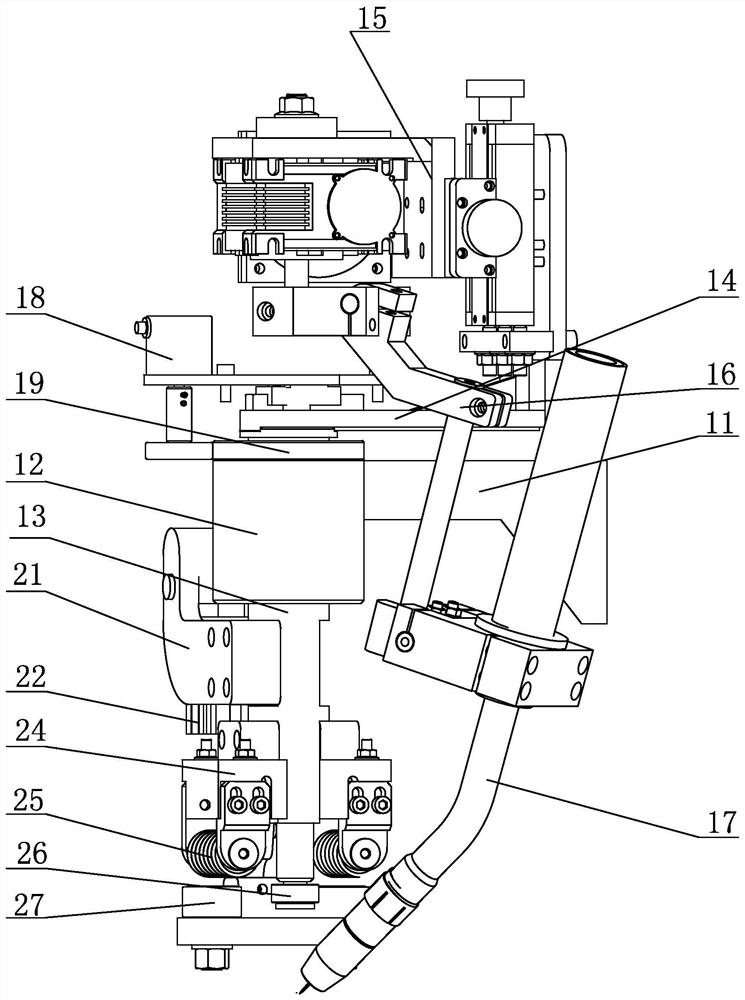

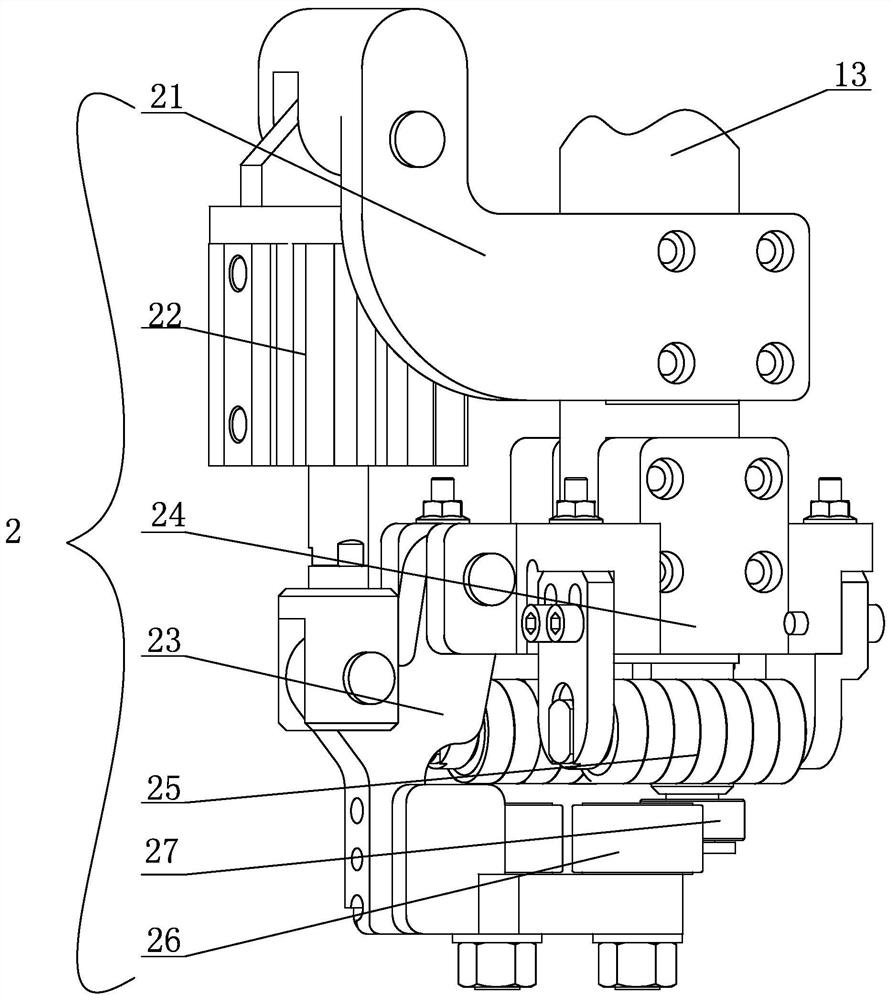

H-shaped beam longitudinal joint automatic welding machine and welding machine head

ActiveCN112157329AReduce travel speedGuaranteed to proceed normallyHeating appliancesSoldering ironShaped beamEngineering

The invention discloses an H-shaped beam longitudinal joint automatic welding machine and a welding machine head. The welding machine head comprises an installation frame, wherein a sleeve is arrangedat one end of the installation frame, a vertical shaft is installed in the sleeve in a matched mode, and an installation plate is fixedly connected to the upper end, extending out of the sleeve, of the vertical shaft. The H-shaped beam longitudinal joint automatic welding machine and the welding machine head have the beneficial effects that a weldment clamping device and an angle adjusting devicewhich can rotate synchronously are installed on the vertical shaft of the welding machine head, and the weldment clamping device can rotate along with the shape of a weld joint while clamping and positioning a weldment, so that a welding gun on the angle adjusting device is synchronously adjusted along with the shape of the weld joint, normal welding operation is guaranteed on the premise of nothalting, welding efficiency is improved, and overall welding quality is greatly improved. A rotary encoder on the welding machine head can also detect a bending angle of the weld joint in the weldingoperation process, and if the bending angle is too large, the advancing speed of the welding machine head can be reduced, so that the quality of the welding machine is further ensured.

Owner:SHANDONG SHUIBO WELDING & CUTTING EQUIP MFG CO LTD

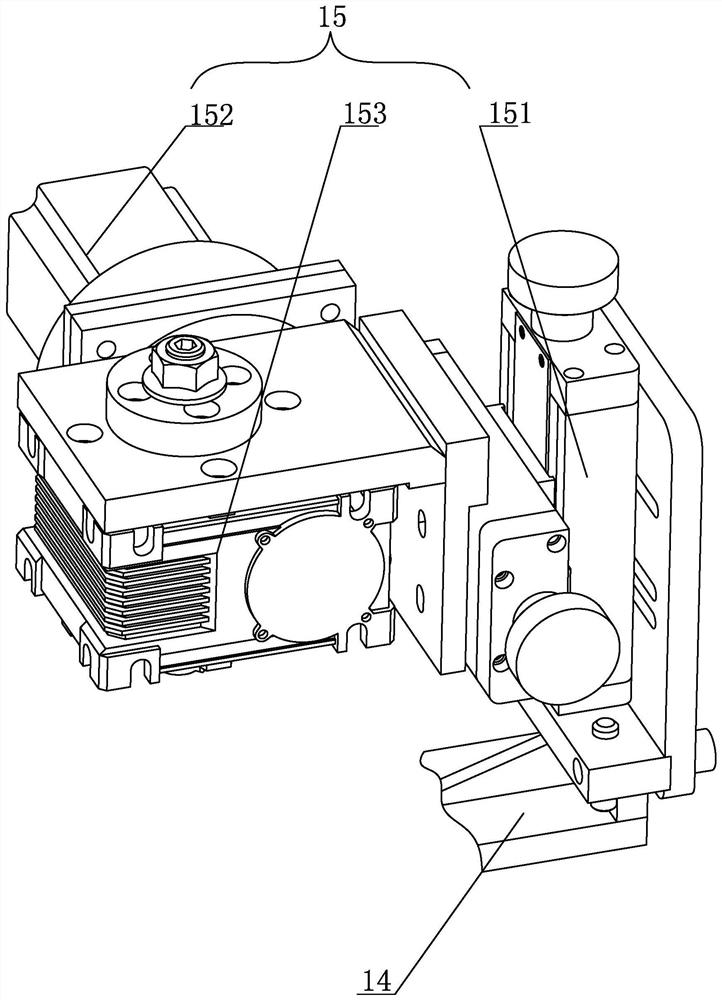

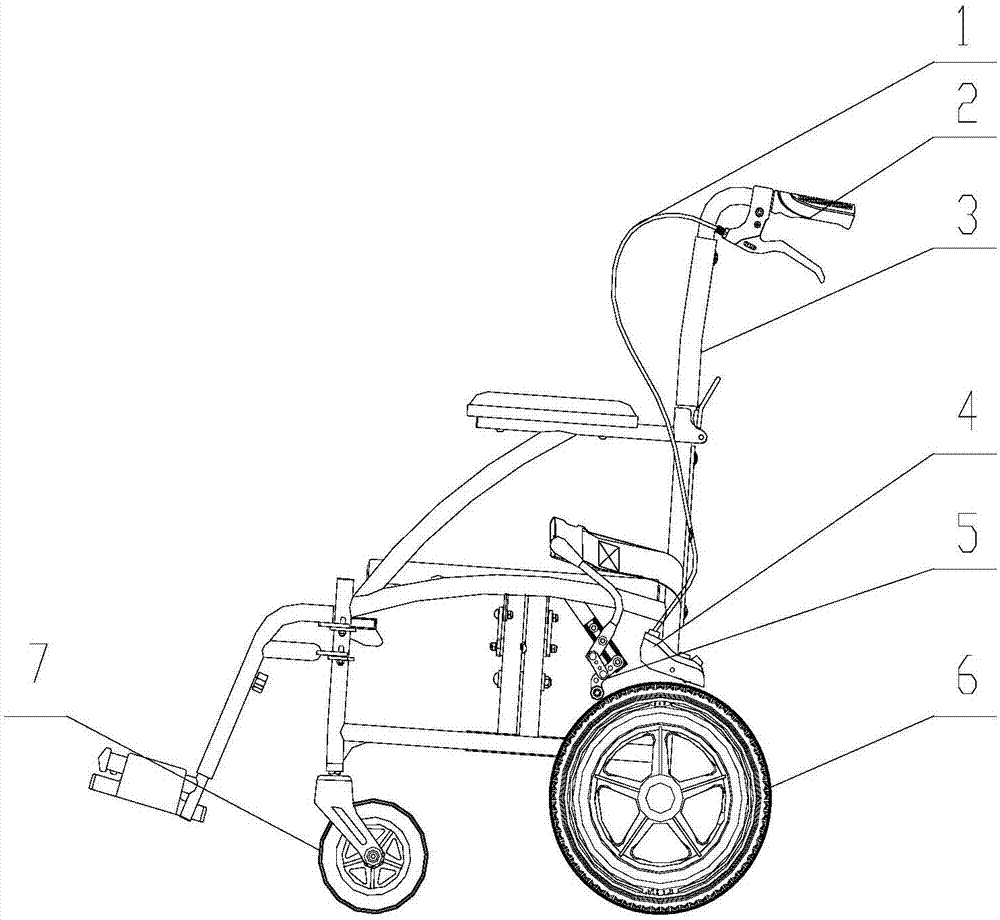

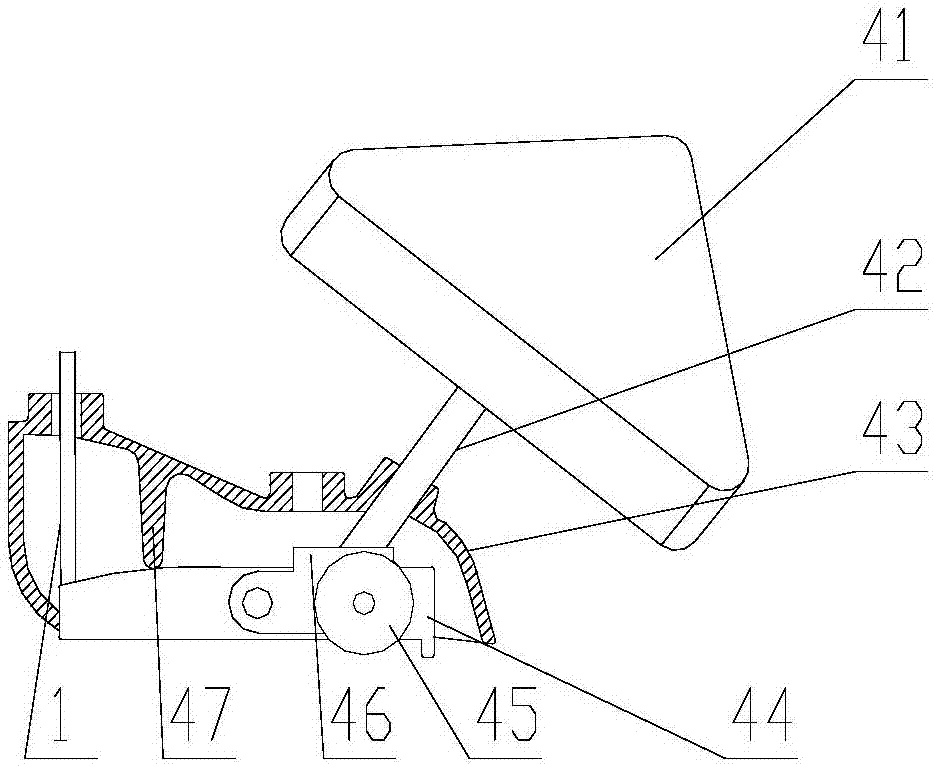

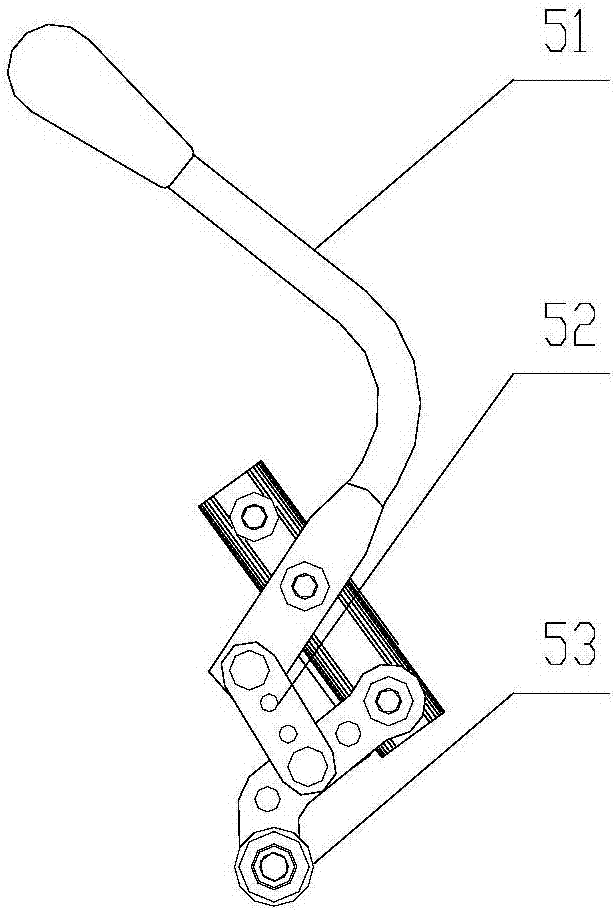

Wheelchair with novel brake devices

PendingCN107374841AReduce travel speedWith brake functionWheelchairs/patient conveyanceVehicle frameWheelchair

The invention relates to the field of wheelchair equipment, in particular to a wheelchair with novel brake devices. The wheelchair comprises a frame, front wheels and rear wheels, the front wheels and the rear wheels are mounted on the lower portion of the frame, the brake devices are mounted on the upper portions of the rear wheels and comprise brake shells, the brake shells are mounted on the frame, parking brake strips are arranged in the brake shells and rotatably mounted on the inner walls of the brake shells, and friction wheels are arranged in the brake shells and can vertically move. The wheelchair with the novel brake devices can solve the problem that the moving speed of an existing wheelchair cannot be reduced.

Owner:张国良

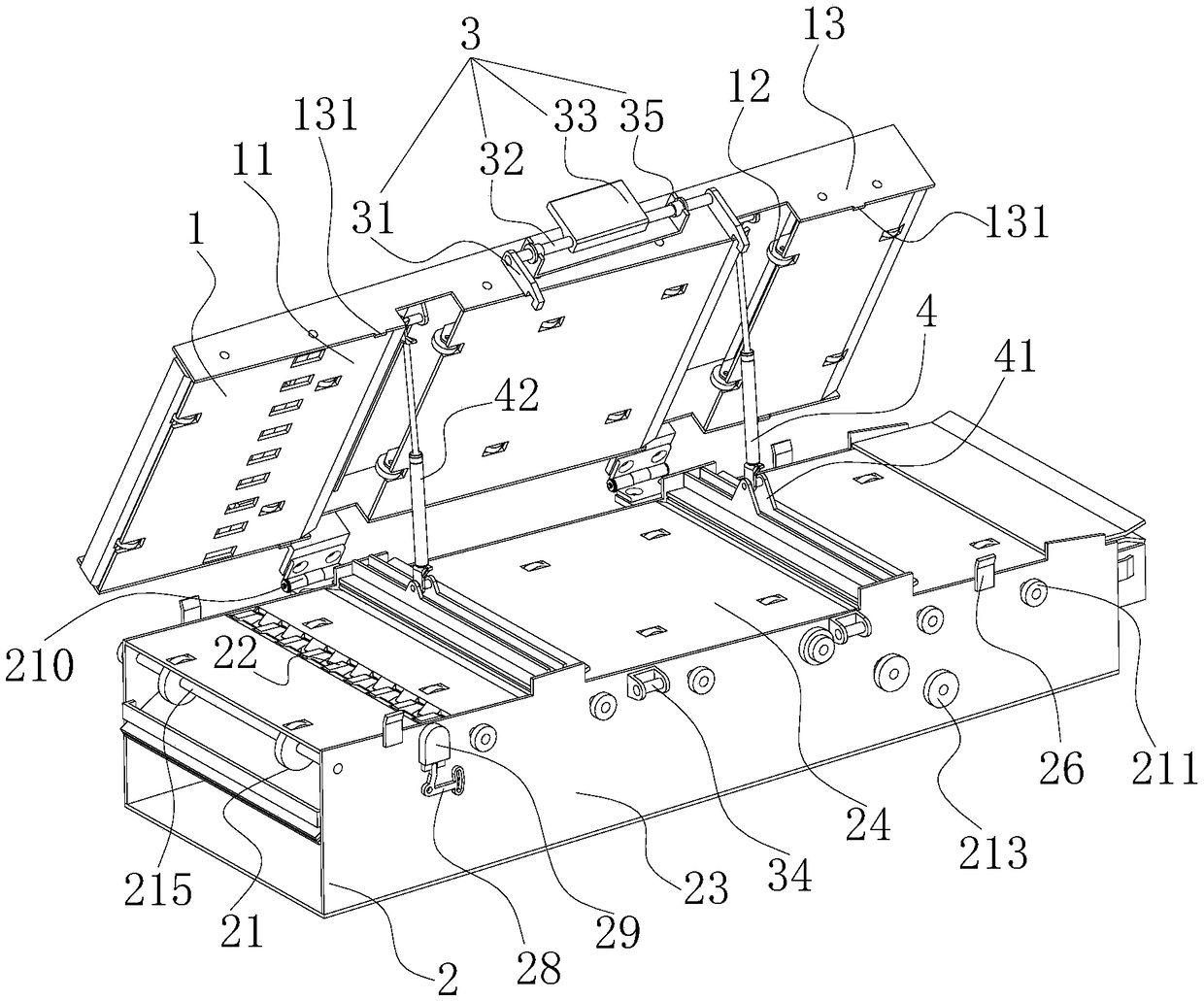

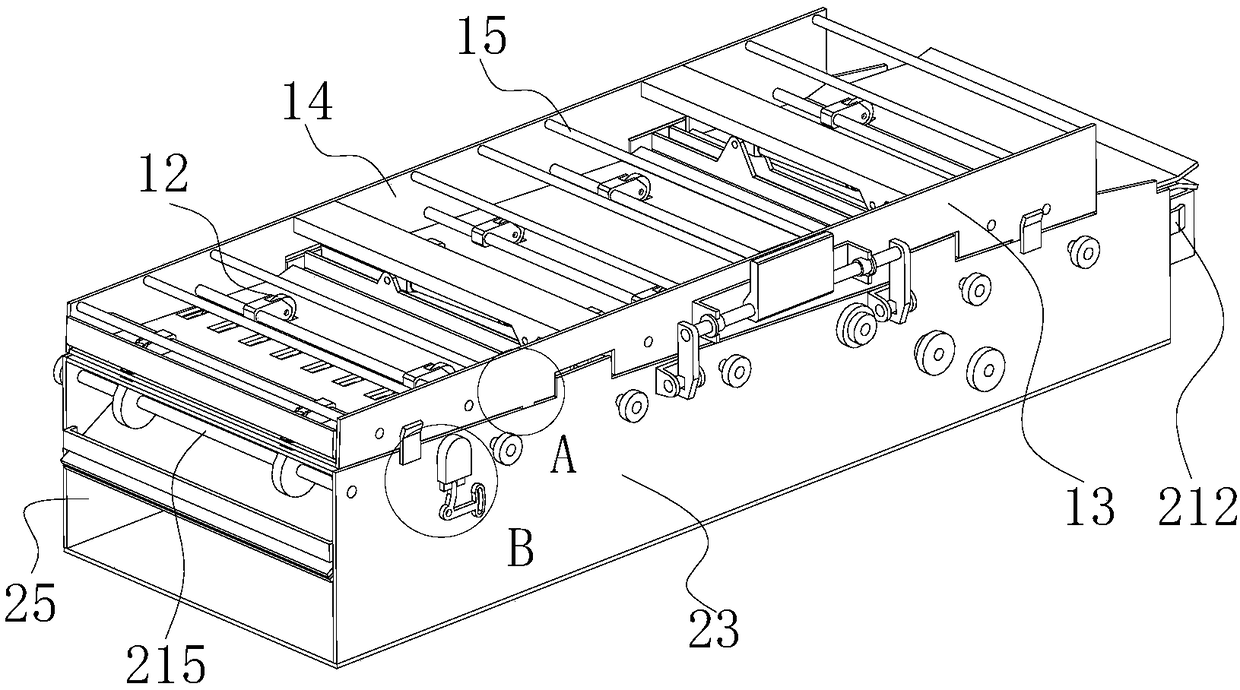

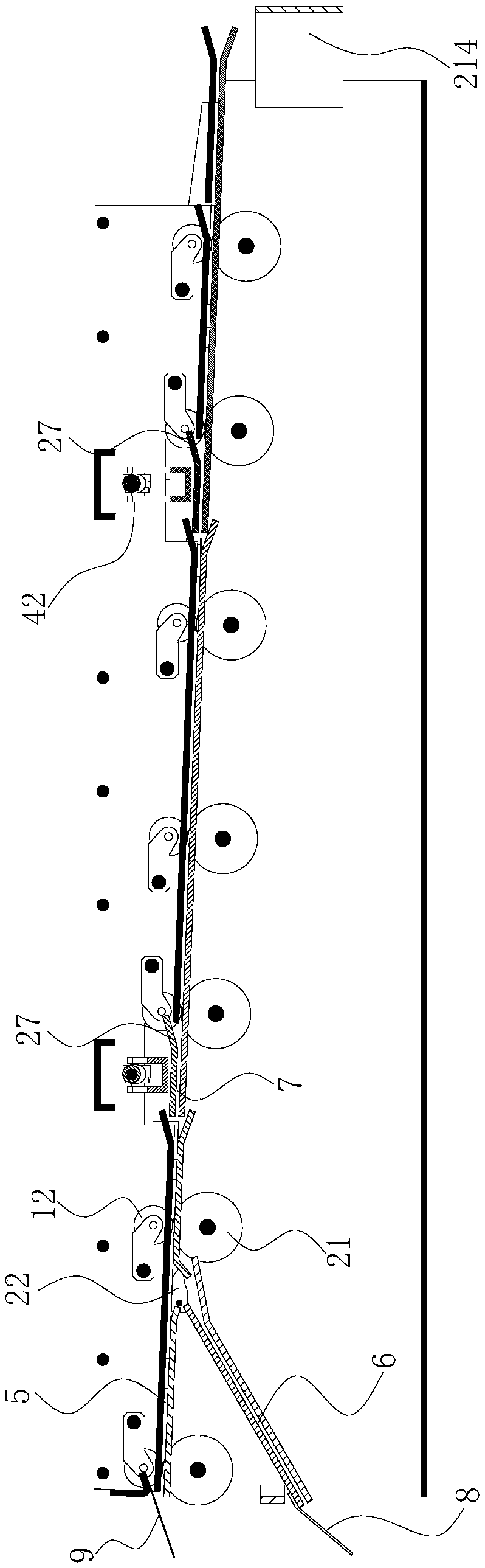

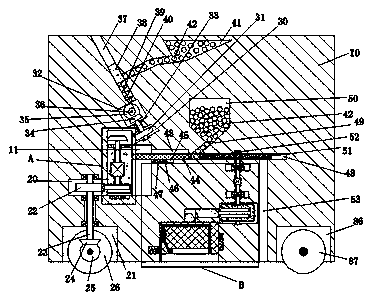

Ballot sorting module adopting side open paper feeding channel

InactiveCN109272632AAvoid human errorImprove sorting efficiencyVoting apparatusPoint of entryHuman error

The invention belongs to the technical field of ballot counters, and discloses a ballot sorting module adopting a side open paper feeding channel. The ballot sorting module comprises a first channel,wherein a positioning connection structure is arranged between the first channel and a reader, so that an inlet of the first channel is in direct communication with an outlet of the reader; a second channel and a third channel are respectively arranged at one end, far away from the reader, of the first channel; a rotary sorting element is arranged between inlets of the second channel and the thirdchannel, and is connected with a first driving device for driving the sorting element to rotate; when the sorting element is positioned at a starting position, the second channel is communicated withthe first channel to form a first sorting channel, and when the sorting element is positioned at a final position, the third channel is communicated with the first channel to form a second sorting channel. The ballot sorting module can complete the automatic sorting of ballots, avoid human errors, and improve the sorting efficiency.

Owner:CHENGDU CAS INFORMATION TECH CO LTD

Mine control device for automatic mine laying cars and use method thereof

The invention discloses a mine control device for automatic mine laying cars and a use method thereof. The device used in the method includes a mine laying car body, a power device disposed in the mine laying car body, a projectile mine laying device disposed in the mine laying car body, and a falling mine laying device disposed in the mine laying car body. The device is characterized in that thepower device comprises a first switching cavity disposed in the mine laying car body, and the first switching cavity is disposed with a first switching power block that is slidable left and right; a first gear cavity is disposed in the first switching power block. The invention aims to design fully automatic mine-laying, which can be ensured by the detecting device before the mine-laying to ensurethat the minefield is not repeated, and the minefield is scientifically evenly distributed. At the same time, the mine can also be placed into an unreachable area by ejecting, and the mine control device of an automatic mine laying car and its use method can be achieved at the maximum to reduce the speed of the enemy.

Owner:诸暨沐菲产品设计有限公司

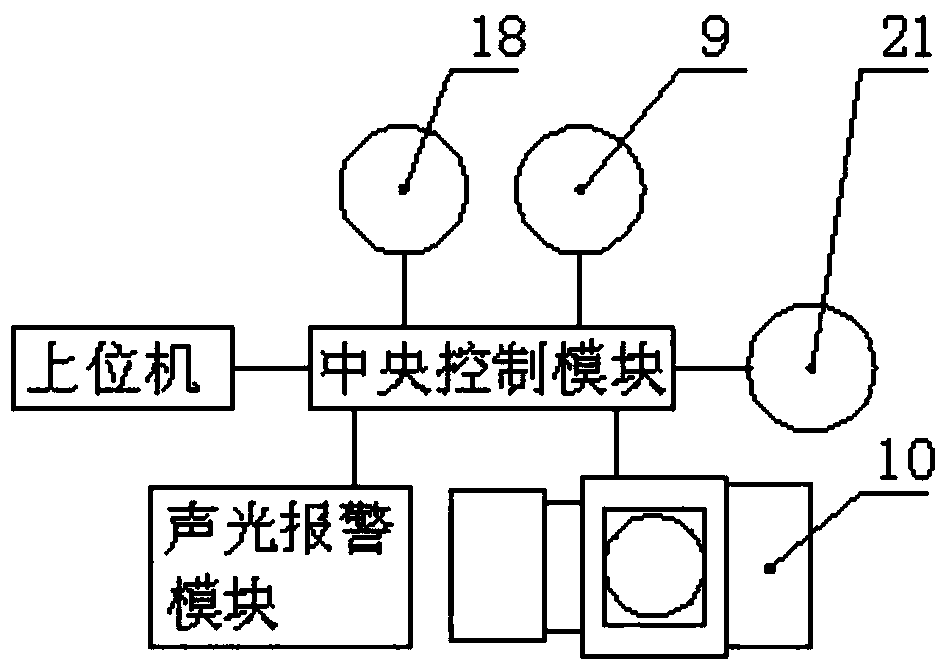

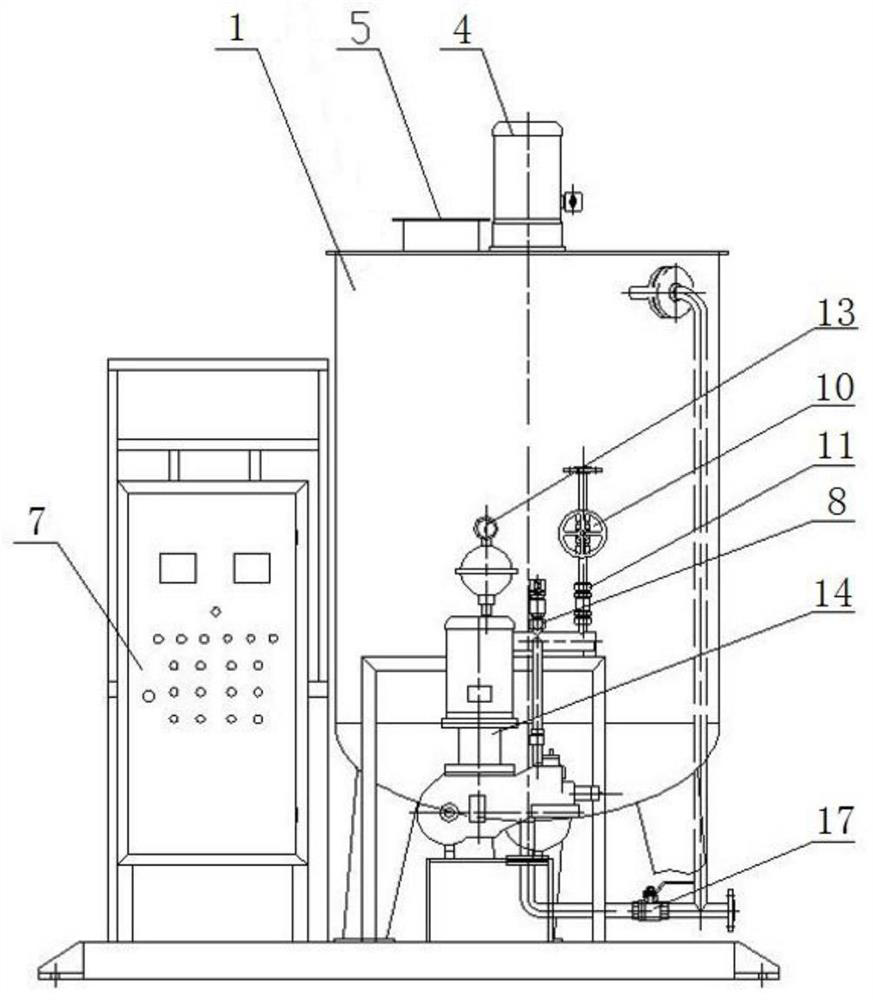

Air-cooled oil cooling system capable of automatically detecting temperature

ActiveCN105952730AReduce travel speedGood secondary cooling effectFluid-pressure actuator componentsAutomatic controlInput/output

The invention relates to an air-cooled oil cooling system capable of automatically detecting the temperature. The system is characterized in that a cooler is mounted on the outer side, facing an oil tank, of a fan casing; at least on fan is mounted on the inner side, facing the oil tank, of the fan casing; a secondary cooling pipeline provided with multiple bends in the vertical direction is arranged on the oil tank upper end surface between an oil supply power source and the fan casing; output ends of three temperature sensors are connected with an input / output interface of a central control module; the input / output interface of the central control module is connected with a control terminal of a circulating power source. According to the air-cooled oil cooling system capable of automatically detecting the temperature, the cooler and the secondary cooling pipeline realize cooling on two sides, so that the temperature of oil is sufficiently decreased; the temperature of three positions can be transmitted to an automatic control device at any time by the three temperature sensors, the automatic control device controls the circulating power source to increase or decrease flow velocity of oil, accordingly, the circulating power source works according to the actual temperature, energy is saved, scene alarm and monitoring center alarm can be performed when the temperature is overhigh, and work safety is guaranteed.

Owner:TIANJIN URANUS HYDRAULIC MACHINERY

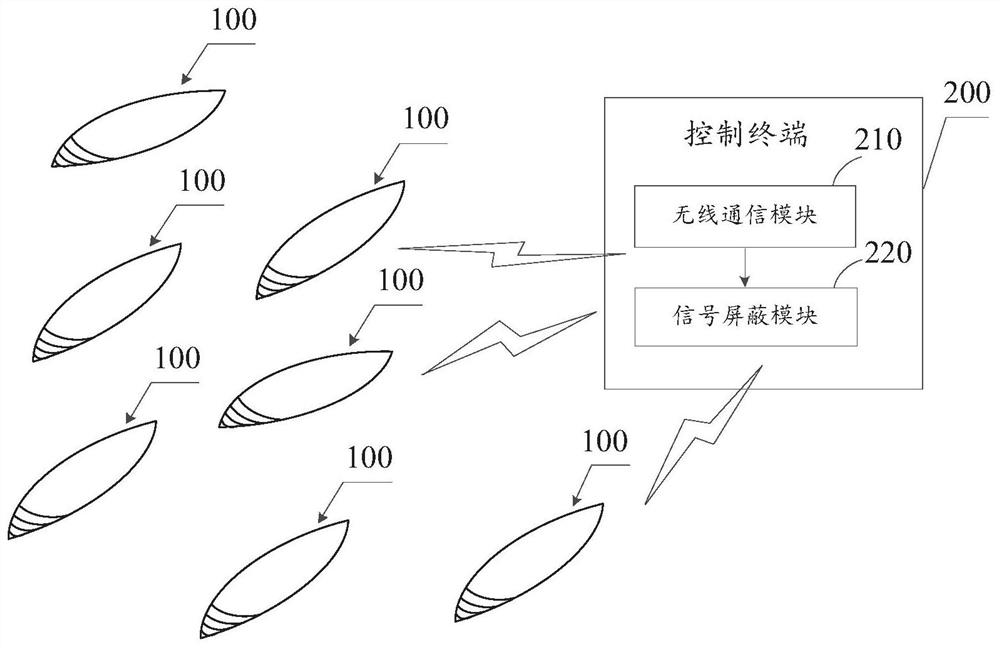

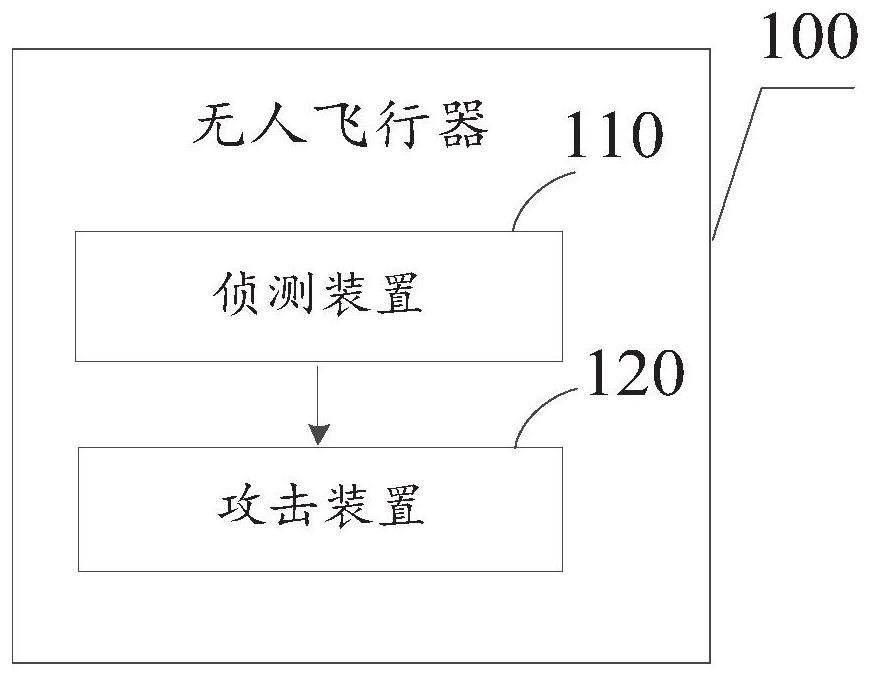

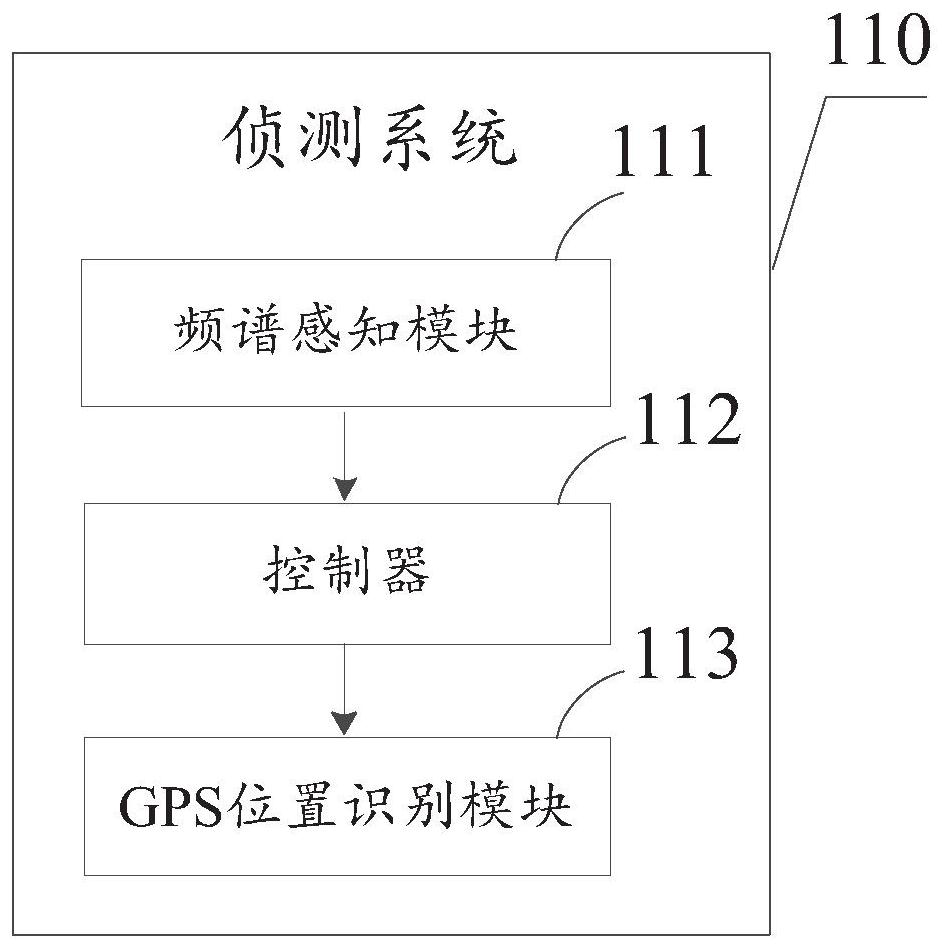

Intelligent command and control system for cooperative combat of multiple underwater detectors

PendingCN113124717AReduce travel speedStrong resistanceMarine torpedoesSatellite radio beaconingControl systemSimulation

The invention discloses an intelligent command and control system for cooperative combat of multiple underwater detectors. The intelligent command and control system comprises underwater detectors and a control terminal in wireless communication connection with the underwater detectors, wherein the underwater detectors are shaped like leeches and are used for carrying out patrol detection in a cluster transmission manner; if the underwater detectors detect an enemy, the detected enemy information is transmitted to the control terminal, a warning prompt is given to the control terminal, intensive attacks are carried out, and the underwater detectors rush to an enemy aircraft carrier and / or naval craft in a self-explosion manner to destroy a power system of the enemy aircraft carrier and / or naval craft; and the control terminal is used for shielding signals in the set territorial sea area so as to interfere with a combat command system of the enemy. The intelligent command and control system for cooperative combat of the multiple underwater detectors is low in manufacturing cost and high in applicability; the cluster patrol detection effect is good, and the defense safety coefficient is high; the operation and maintenance price is low; and the target destroying accuracy is high.

Owner:湖南翰坤实业有限公司

Sulfur wet forming system

PendingCN113800477AAvoid corrosionExtended service lifeSulfur preparation/purificationLiquid storage tankProcess engineering

The invention relates to the field of sulfur wet forming, in particular to a sulfur wet forming system which comprises a water tank used for containing process water, a liquid storage tank used for storing alkali liquor, a pH detector used for detecting the pH value of process water in the water tank, a liquid injection pipeline connected to the liquid storage tank and a controller. The liquid injection pipeline is used for injecting the alkali liquor in the liquid storage tank into the water tank, and is provided with a metering pump. The controller is used for controlling the metering pump to be opened or closed according to a detection value of the pH detector. According to the sulfur wet forming system, the pH value of process water is always kept in a proper range in the production process, equipment and pipelines are prevented from being corroded, the service life of the sulfur wet forming system is prolonged, and the forming quality of sulfur particles is improved.

Owner:CHINA PETROLEUM & CHEM CORP +2

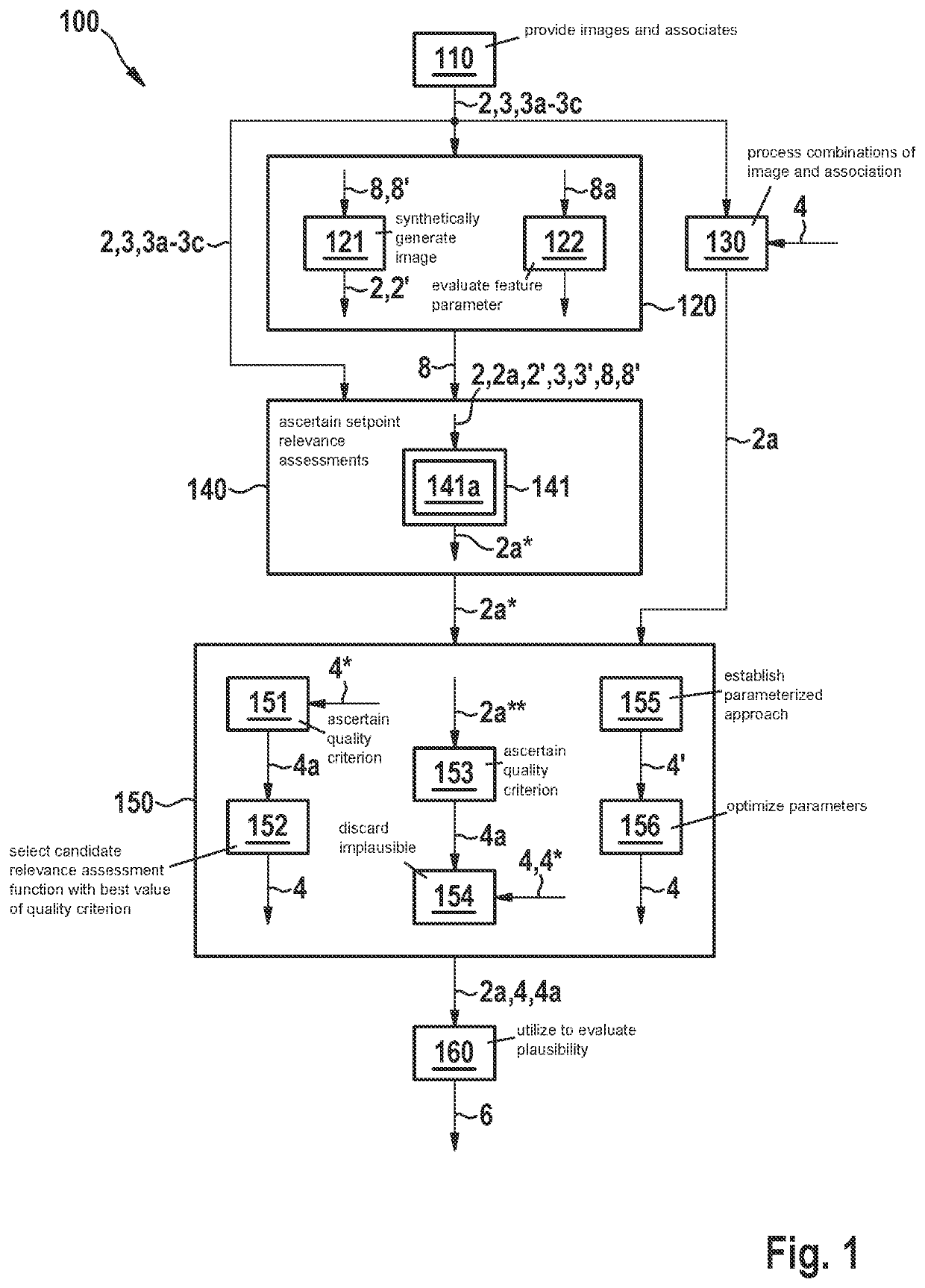

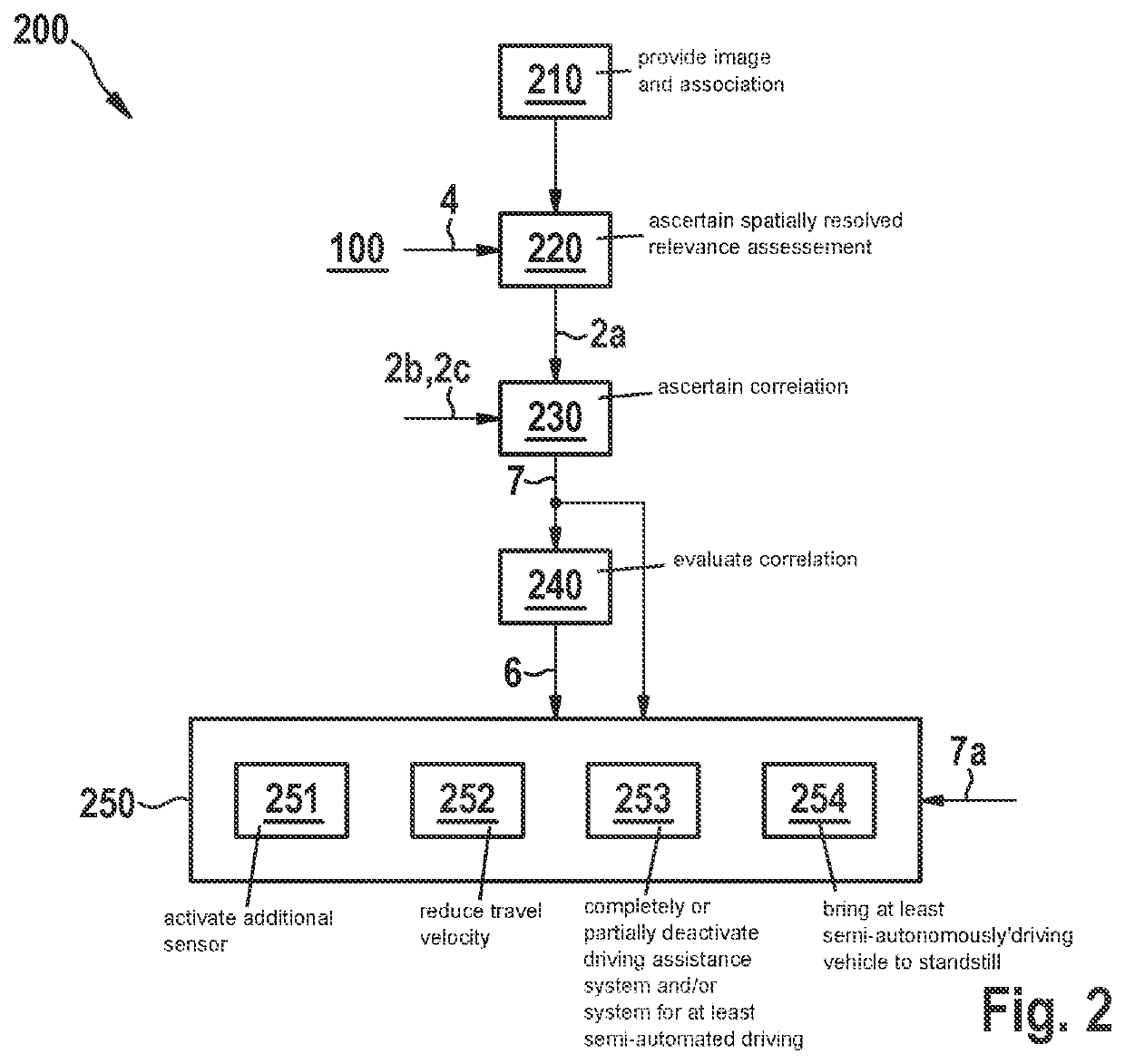

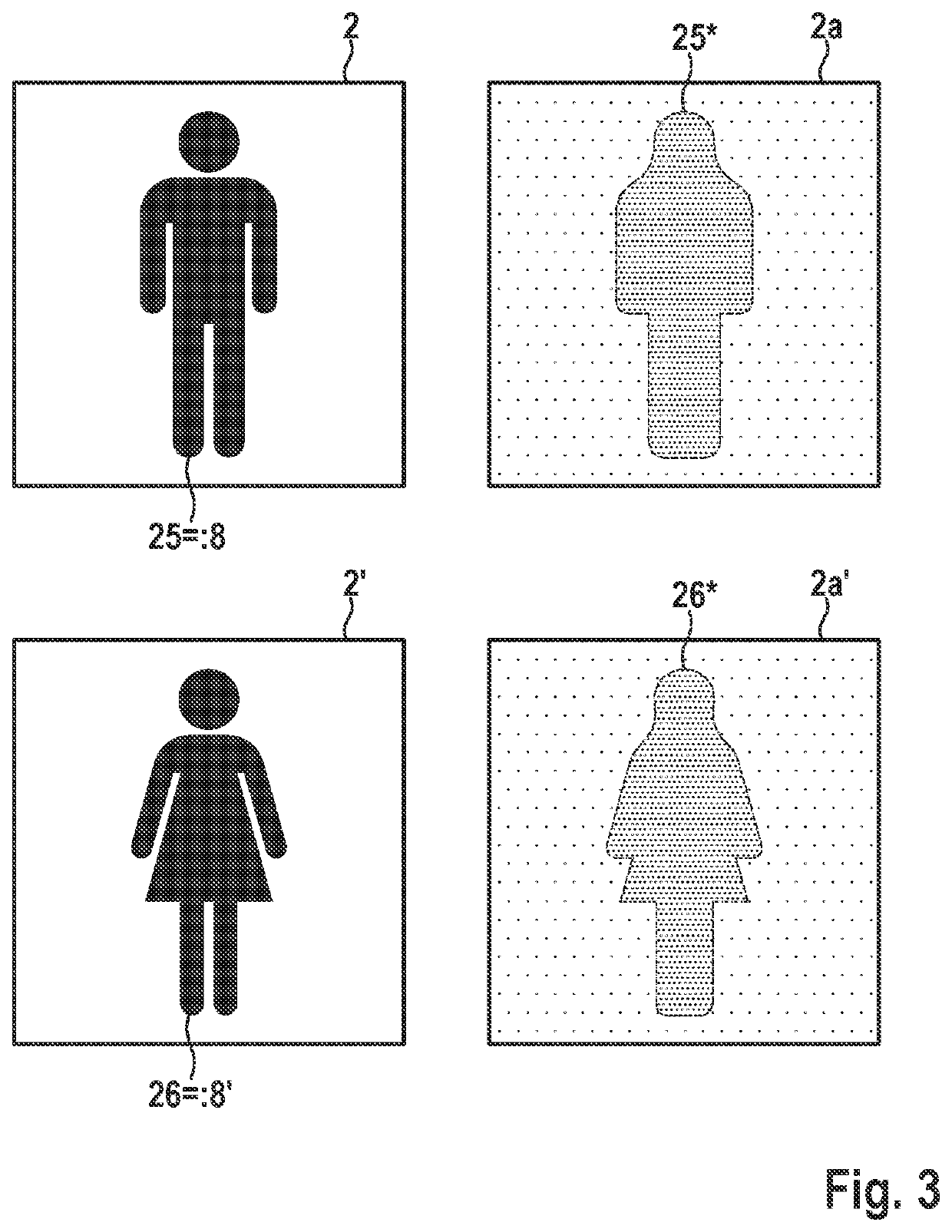

Plausibility check of the output of neural classifier networks based on additional information about features

ActiveUS20210295106A1Reduce disadvantagesDisadvantageous consequenceBiological neural network modelsCharacter and pattern recognitionFeature parameterMachine learning

A method for a plausibility check of the output of an artificial neural network (ANN) utilized as a classifier. The method includes: a plurality of images for which the ANN has ascertained an association with one or multiple classes of a predefined classification, and the association that is ascertained in each case by the ANN, are provided; for each image at least one feature parameter is determined which characterizes the type, the degree of specificity, and / or the position of at least one feature contained in the image; for each combination of an image and an association, a spatially resolved relevance assessment of the image is ascertained by applying a relevance assessment function; a setpoint relevance assessment is ascertained for each combination, using the feature parameter; a quality criterion for the relevance assessment function is ascertained based on the agreement between the relevance assessments and the setpoint relevance assessments.

Owner:ROBERT BOSCH GMBH

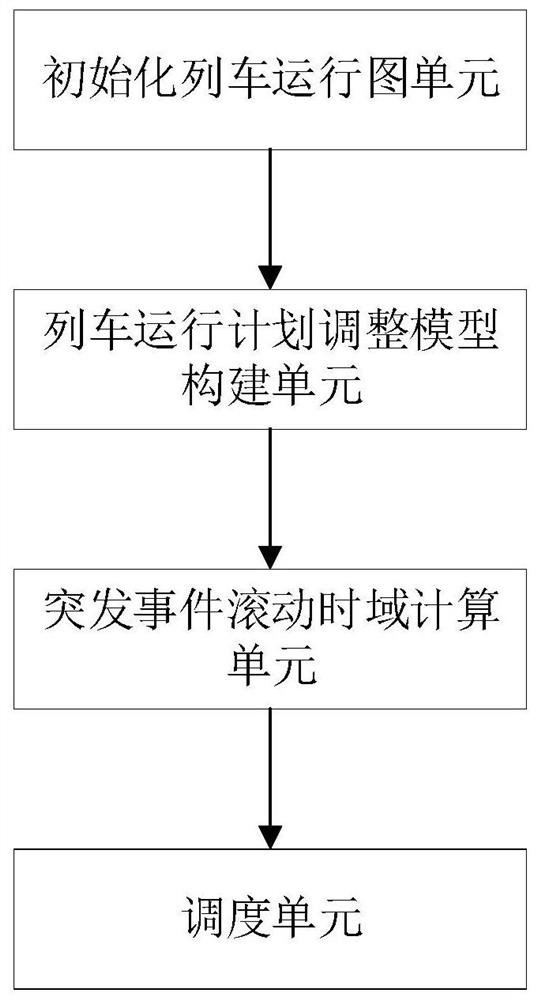

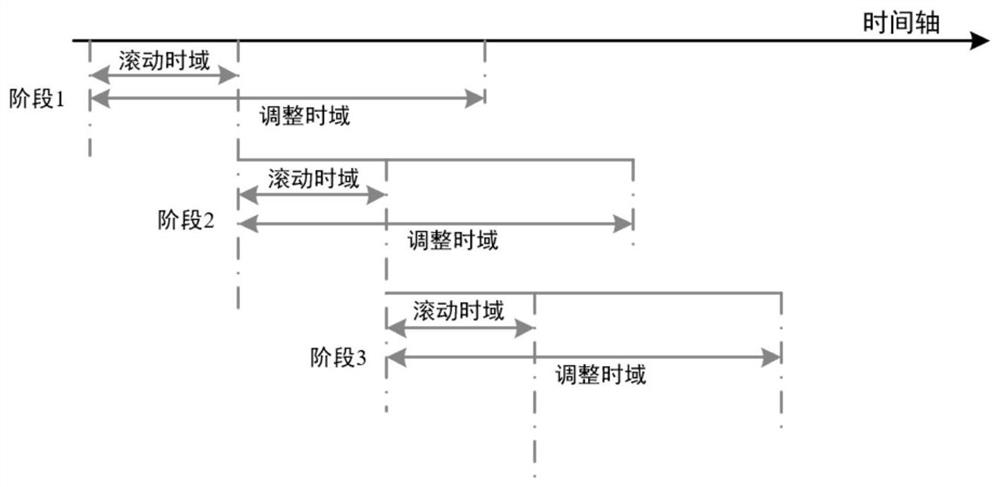

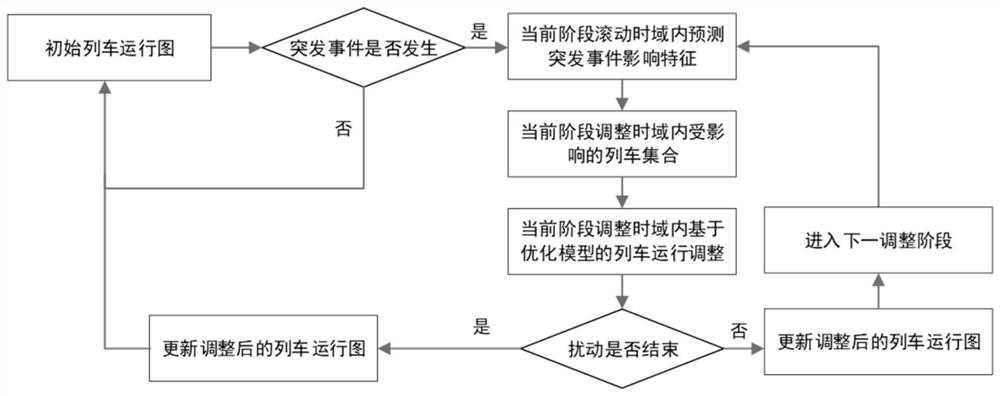

Freight train scheduling method and system based on rolling time domain event influence analysis

PendingCN113935581AOvercome the outputIdeal scheduling resultResourcesLogisticsTime domainFreight trains

The invention discloses a freight train scheduling method and system based on rolling time domain event influence analysis. According to the method, firstly, an initial train working diagram is compiled, and then when an emergency occurs, according to feature data corresponding to the emergency, train working diagrams corresponding to rolling time domains are sequentially calculated in a rolling mode through a train operation plan adjusting model. According to the method, adjustment on the train operation plan can be simulated in a rolling calculation mode until an output result capable of overcoming the influence of emergencies is obtained. Therefore, the most direct scheduling adjustment scheme can be automatically screened out according to the characteristic values of the emergencies. According to the train operation plan adjustment model, an ideal scheduling result can be quickly obtained by using simple calculation steps in an iteration mode.

Owner:INST OF COMPUTING TECH CHINA ACAD OF RAILWAY SCI

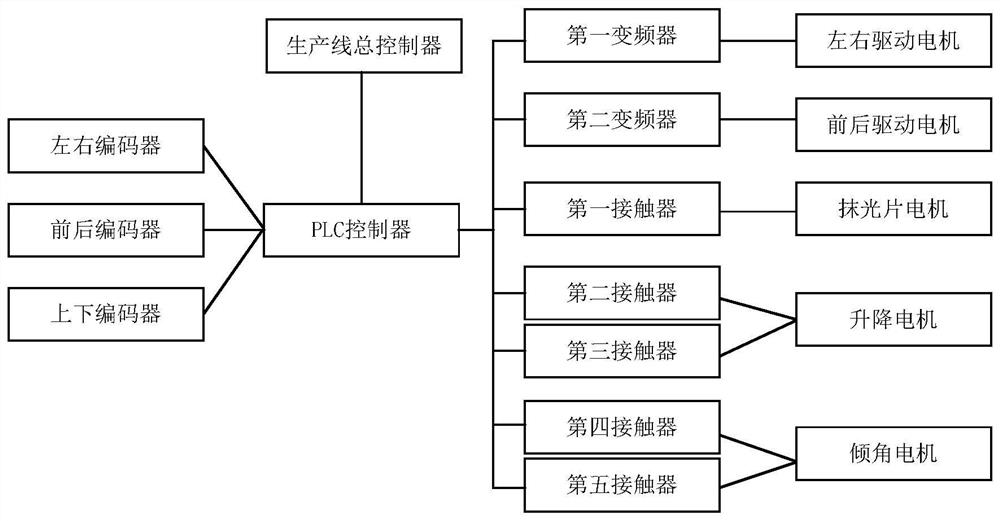

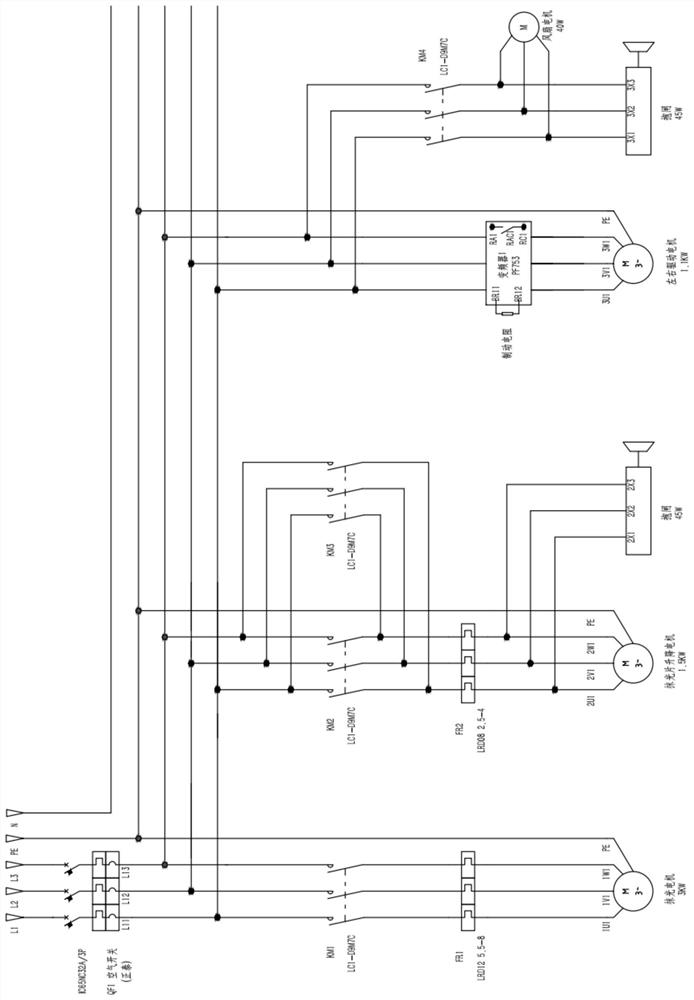

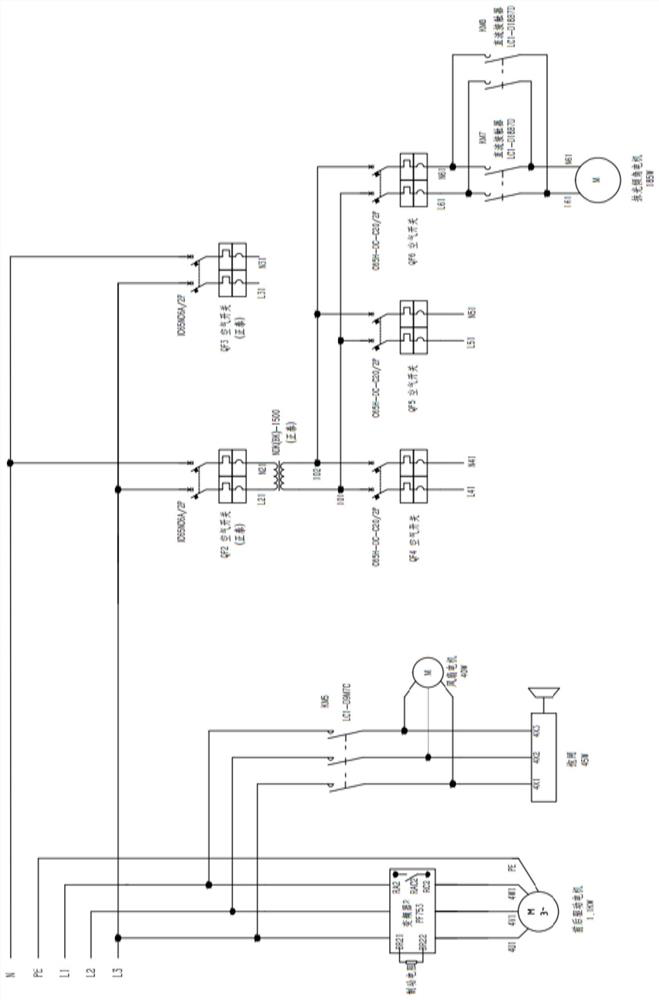

Automatic control system and automatic control method for trowelling machine

InactiveCN112223520AReduce the amount of wiringShorten construction commissioning timeAuxillary shaping apparatusFrequency changerAutomatic control

The embodiment of the invention provides an automatic control system and an automatic control method for a trowelling machine. The automatic control system comprises a production line main controllerwhich is in communication connection to a PLC through an industrial Ethernet; the PLC is in communication connection to a first frequency converter and a second frequency converter through the industrial Ethernet, the first frequency converter is in control connection to a left-right driving motor, and the second frequency converter is in control connection to a front-back driving motor; the PLC is in control connection to a troweling piece motor through a first contactor, is in forward and reverse rotation control connection to a lifting motor through a second contactor and a third contactor,and is in forward and reverse rotation control connection to an inclination angle motor through a fourth contactor and a fifth contactor; and a left-right encoder, a front-back encoder and an up-downencoder are in communication connection to the PLC. By applying the scheme, automatic troweling of a wallboard can be realized, the troweling efficiency is improved, and the labor cost is saved.

Owner:22MCC GRP PRECISION FORGING

A motor stator smc soft magnetic powder core production equipment

ActiveCN110289160BGuaranteed production accuracyQuality improvementInorganic material magnetismInductances/transformers/magnets manufactureElectric machineEngineering

The invention discloses a motor stator SMC soft magnetic powder core production equipment, which comprises a first shell and a second shell, a first feeding hopper is installed on the top of the first shell, and the top of the first shell corresponds to the first A feeding port is provided at the position of the feeding hopper, the first feeding hopper communicates with the first housing through the feeding port, a crushing device is provided at the position below the top feeding port in the first housing, and the right side wall of the first housing is A crushing motor is installed to provide power for the crushing device. A grinding device is installed below the crushing device in the first housing. A feeder is installed at the bottom of the first housing below the grinding device. The feeder communicates with the grinding device through a small material tube. , the feeder is connected with a feeding pipe. In the present invention, by setting a ball-shaped grinding device, when the soft magnetic raw material is crushed, its crushing stroke is greatly increased compared with the traditional roller crushing or ball mill, so that the raw material can be crushed more fully, thereby ensuring The quality of the soft magnetic powder core.

Owner:NANTONG ZHONGXING MAGNETIC IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com