Method and apparatus for false twiting and drawing animal fibre

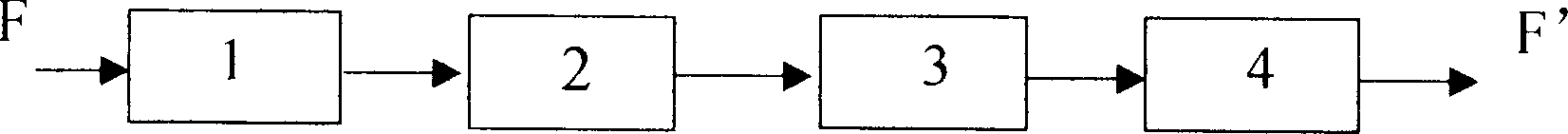

An animal fiber, false twisting technology, applied in drafting equipment, textile and papermaking, spinning machines, etc., can solve the problems of high energy consumption, complexity, affecting the working environment, etc., to improve efficiency or output, improve fiber quality, The effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

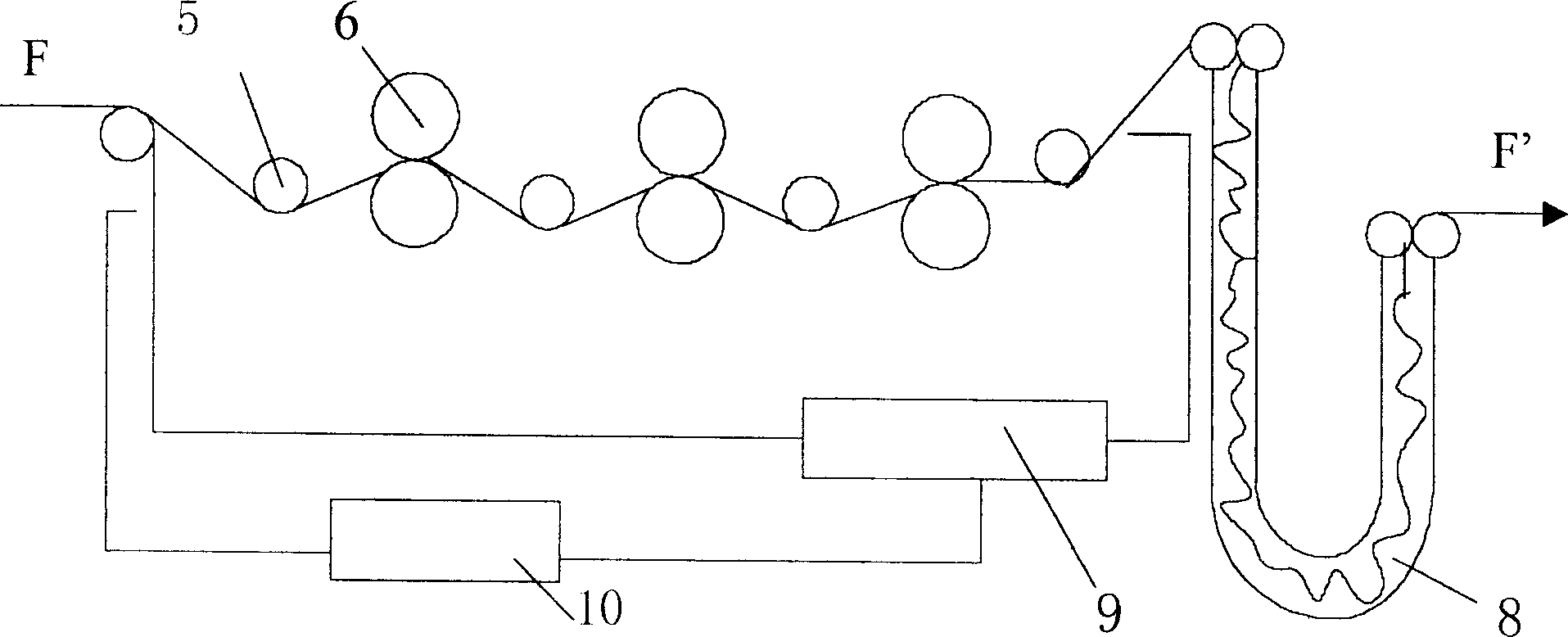

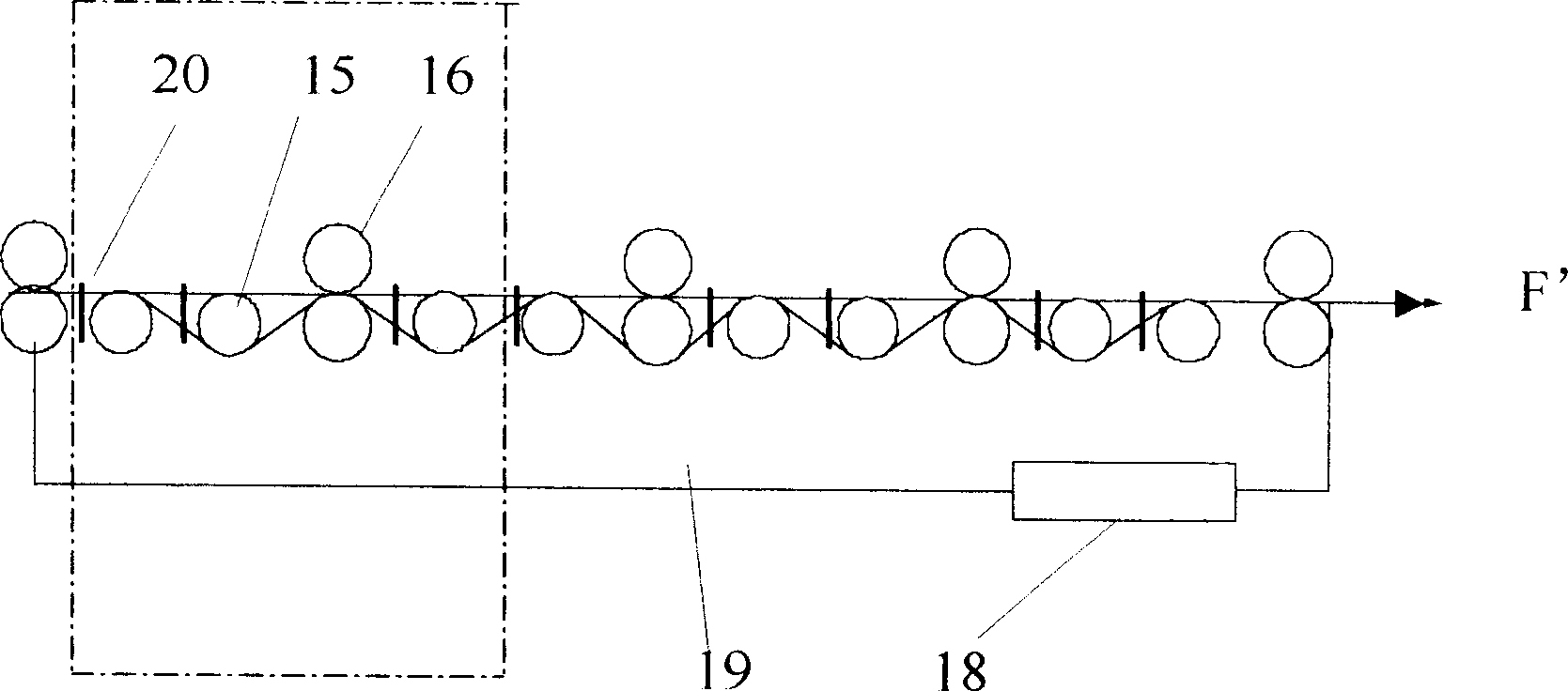

Embodiment 1

[0048] Raw materials: pure wool tops, average fiber fineness 21.35um, average length 85.4mm, strip weight 20g / m. Add NaHSO to the 80°C aqueous solution in the bath of pretreatment device 1 3 5% (weight), ph value is 9, soaks this wool top; With 10 m / min speed, wool top is fed into the damp heat storage box, deposits 40 minutes in the storage box. Then, the wool sliver is fed into the described 6-zone wet heat stretching equipment at the same speed for wet heat stretching. The stretching process parameters are as follows: 6 zones of stretching ratio are: 1.04 / 1.3 / 1.3 / 1.04 / 1.04 / 1.04; the temperature inside the stretching box is 100°C, and the humidity is 80%; The pressure is 400kg; the number of revolutions of the false twister is 260 rpm. After stretching, it is shaped by a three-slot sizing equipment. Among them, the first tank is rinsed with cold water, the second tank is boiled with 80°C hot water, and the third tank is washed with 60°C hot water, and the top is wound 6 ...

Embodiment 2

[0050] Processing condition is with embodiment 1. The difference is that after stretching, permanent setting is carried out by three-slot setting equipment. Wherein, the first tank is washed with cold water, the second tank is hot water at 80°C, and 1% (weight) of H is added to the water. 2 o 2 (35% concentration), boil and wash with 60 ℃ of hot water in the 3rd tank, and wool top is wound 10 circles on bar guide roller. Finally, it is dried by hot air to obtain the stretched top product. Through experiments, the average fineness of the product wool is 18.86um, and the length is 121.33mm; the boiling water shrinkage rate of the stretched wool top is 5%. Worsted wool yarn of 12.5dtex can be processed from this top.

Embodiment 3

[0052] Raw materials: pure wool tops, average fiber fineness 20.65um, average length 79.54mm, strip weight 20g / m. Add 3% (weight) of mercaptoacetic acid in the 100 ℃ aqueous solution in the bath of pretreatment device 1, ph value is 3.5, soaks this wool top; With 15 m / min speed, wool top is fed into the wet heat storage box, deposits in the storage box 60 minutes. Then, the wool sliver is fed into the described 6-zone wet heat stretching equipment at the same speed for wet heat stretching. The stretching process parameters are: stretching ratio of 6 zones: 1.02 / 1.2 / 1.2 / 1.04 / 1.04 / 1.04; the temperature inside the stretching box is 95°C, and the humidity is 90%; The pressure is 300kg; the number of revolutions of the false twister is 320 rpm. After stretching, it is shaped by a three-slot sizing equipment. Among them, the first tank is cold water washing, the second tank is 60°C hot water, and the third tank is washed with 60°C hot water, and the top is wound on the guide roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com