Patents

Literature

32results about How to "Guaranteed fastening force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

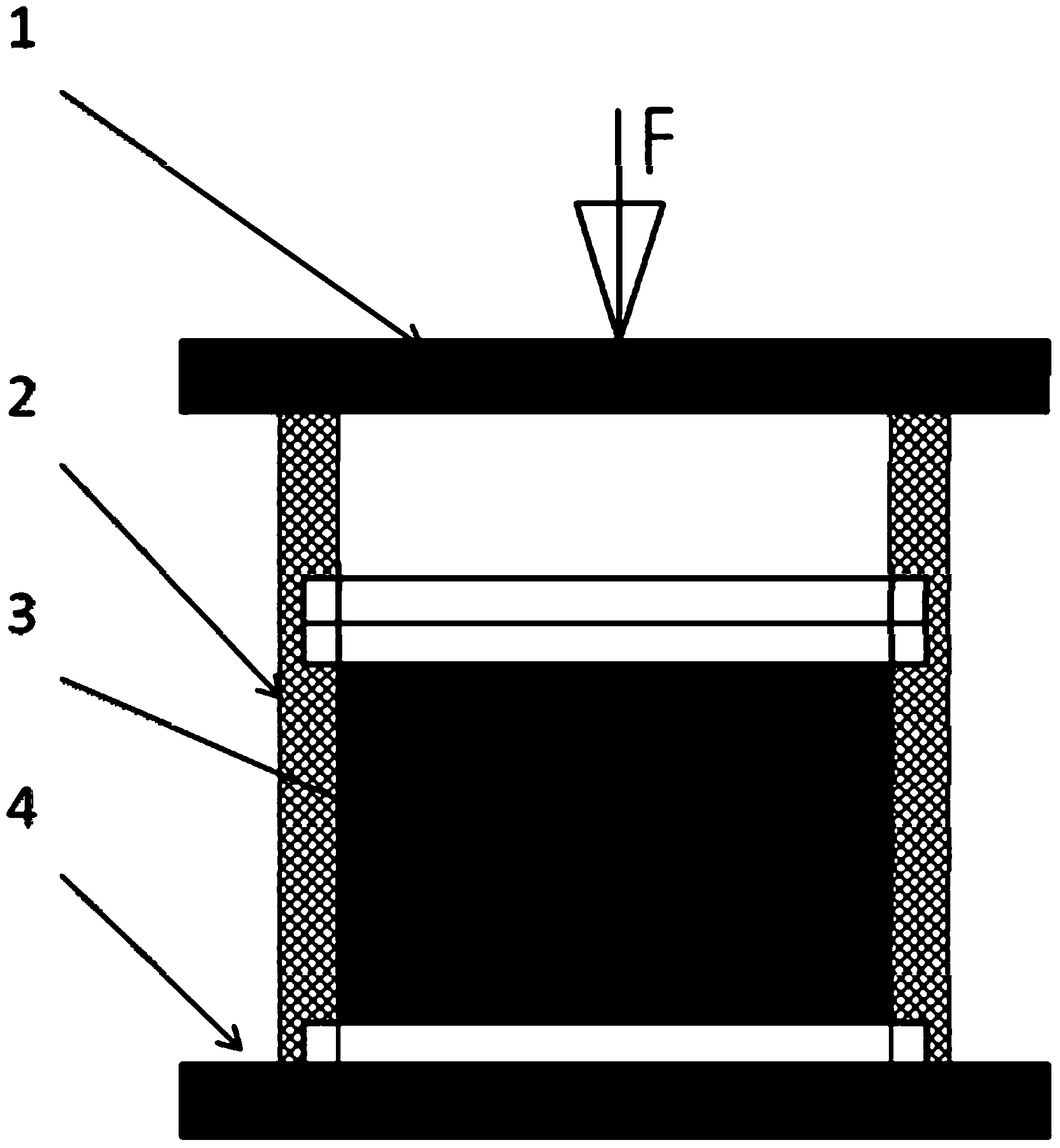

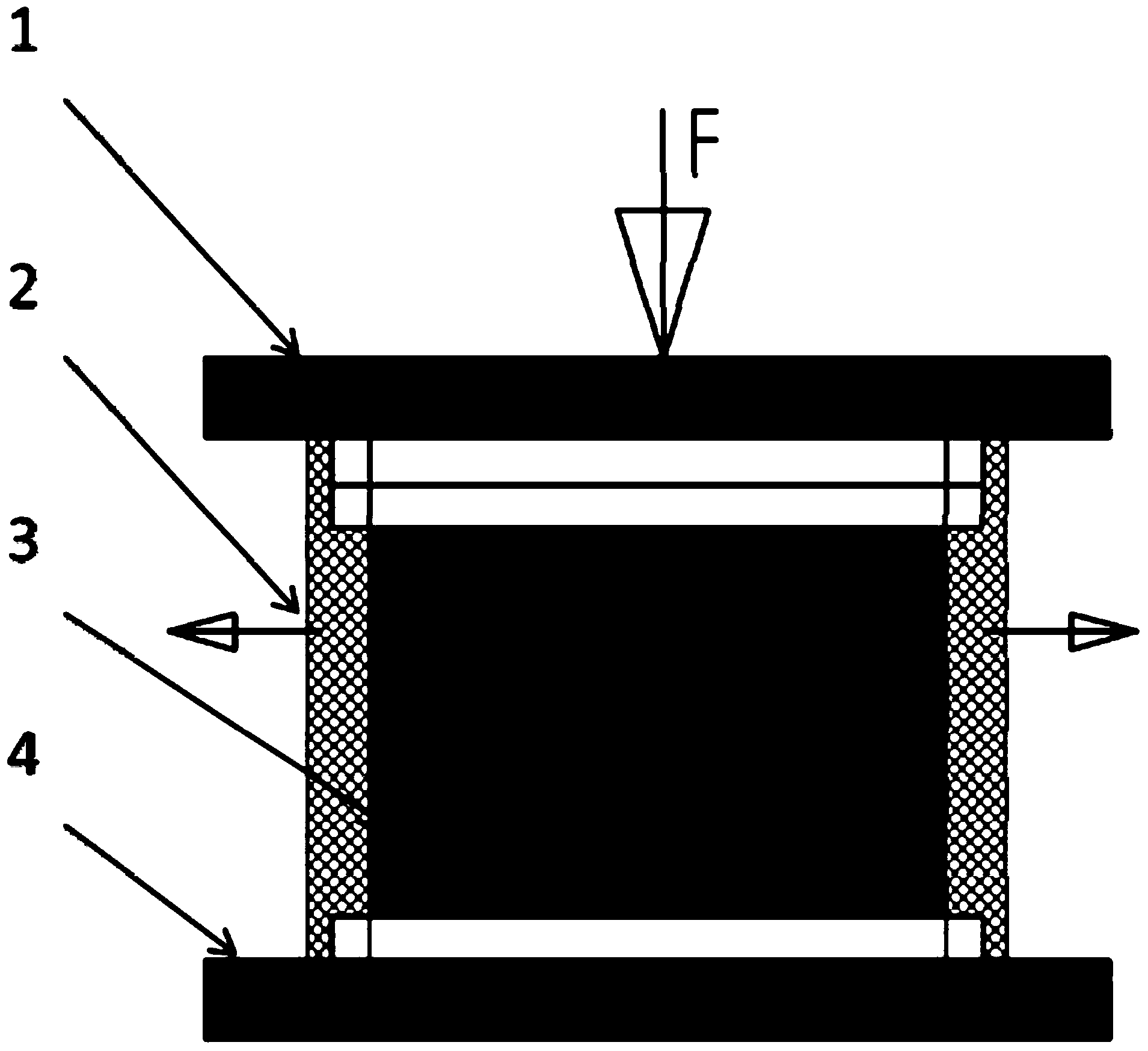

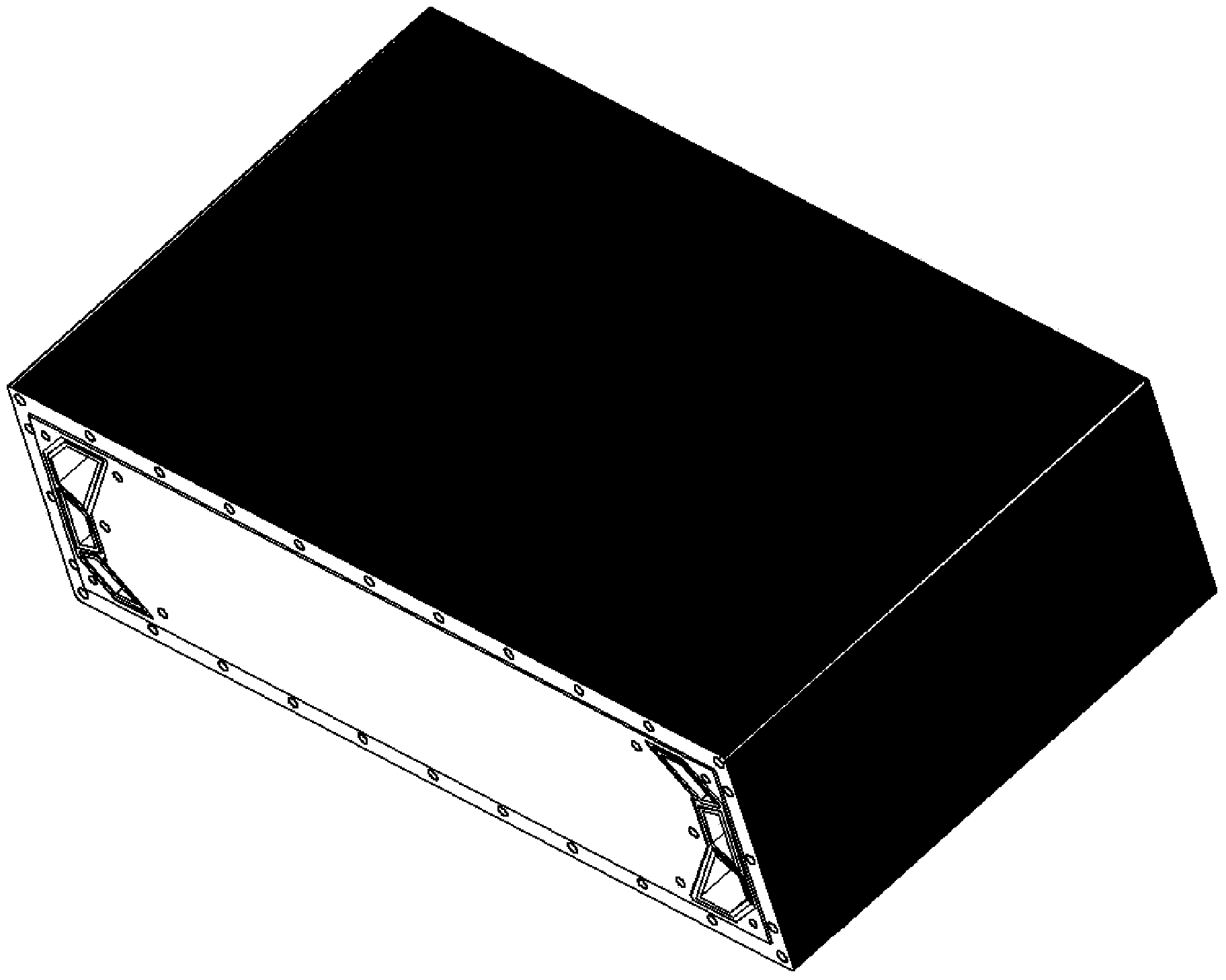

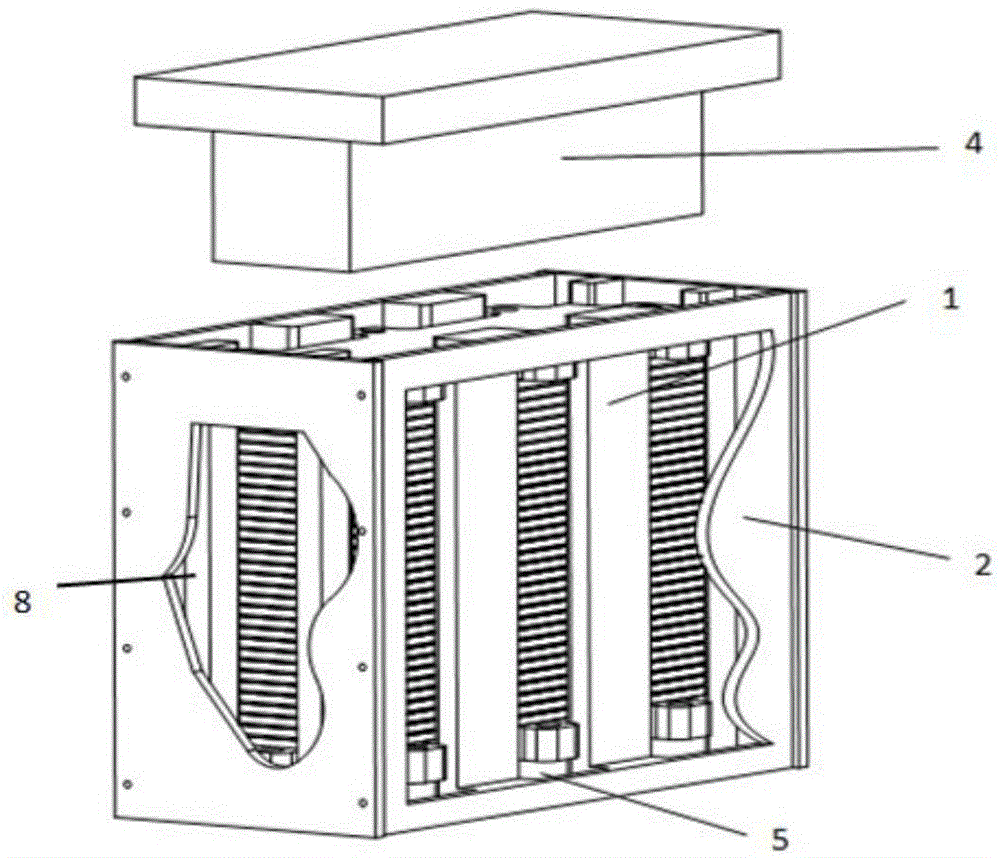

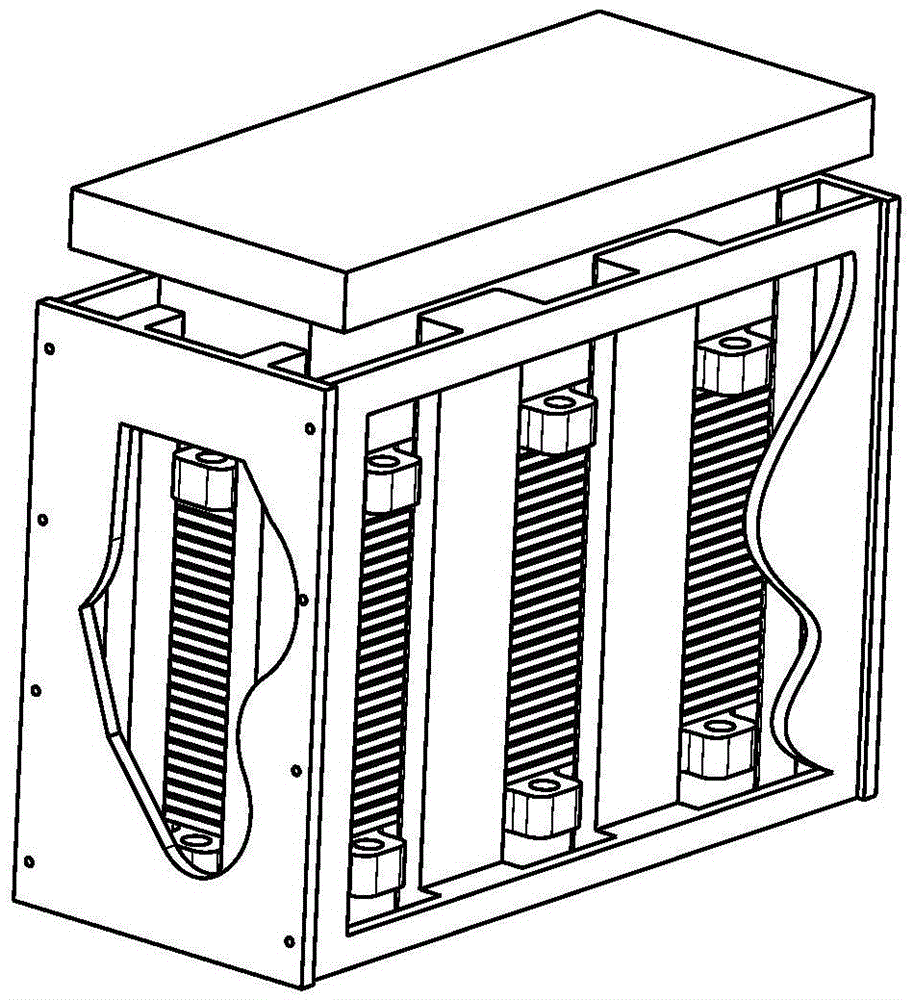

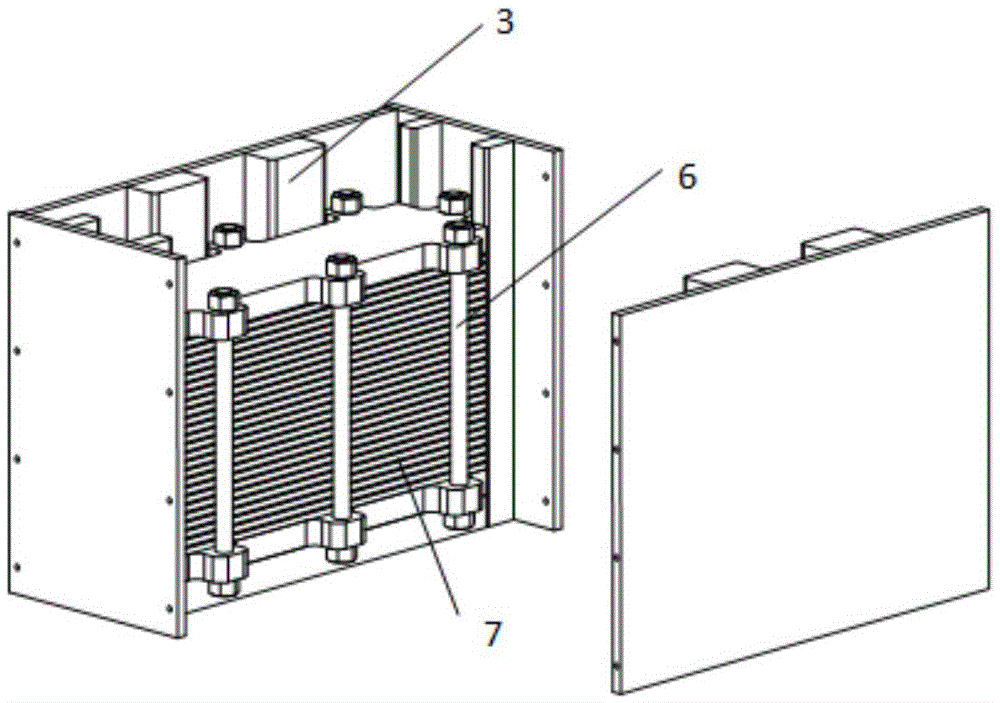

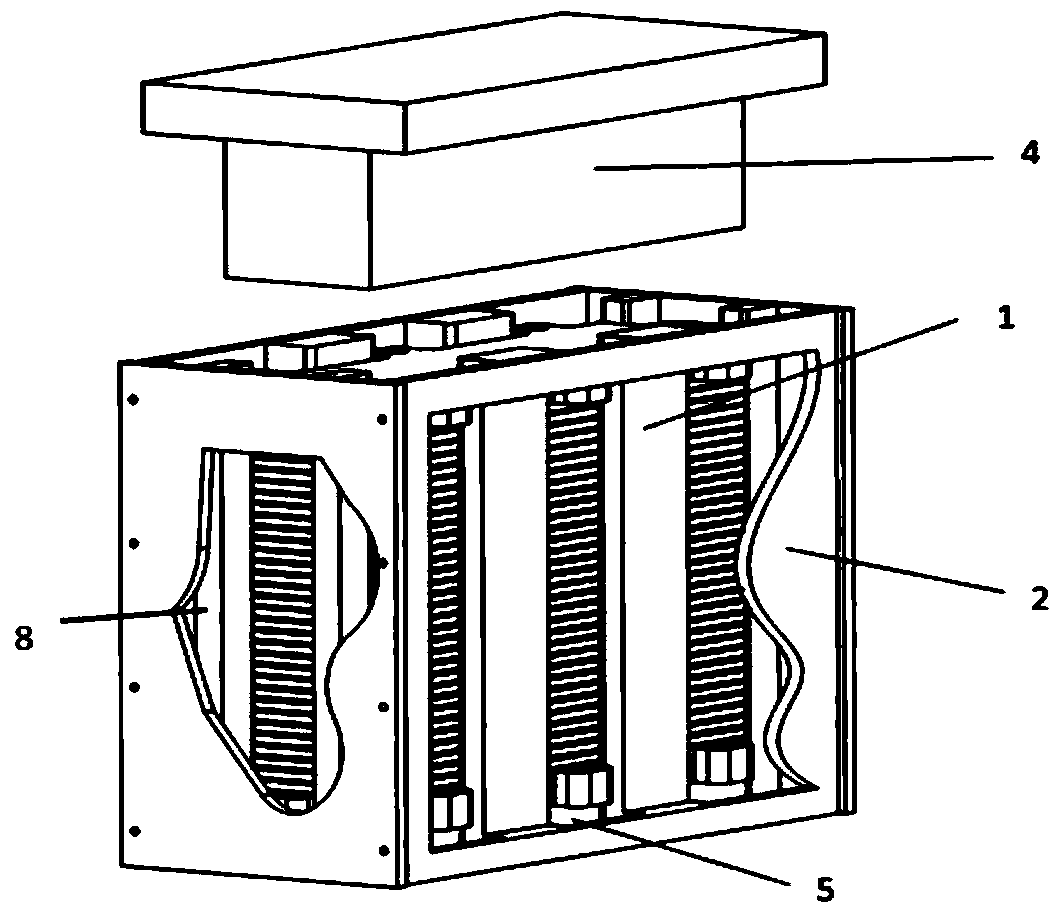

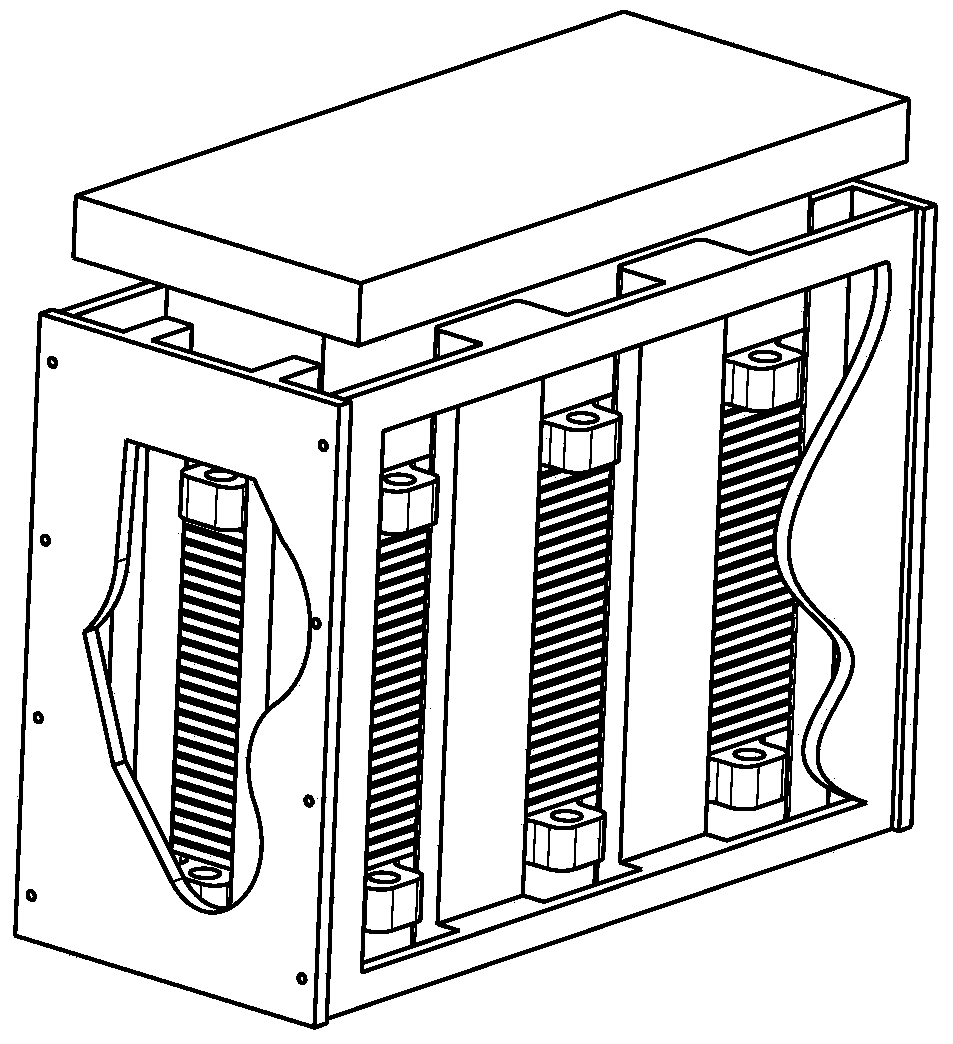

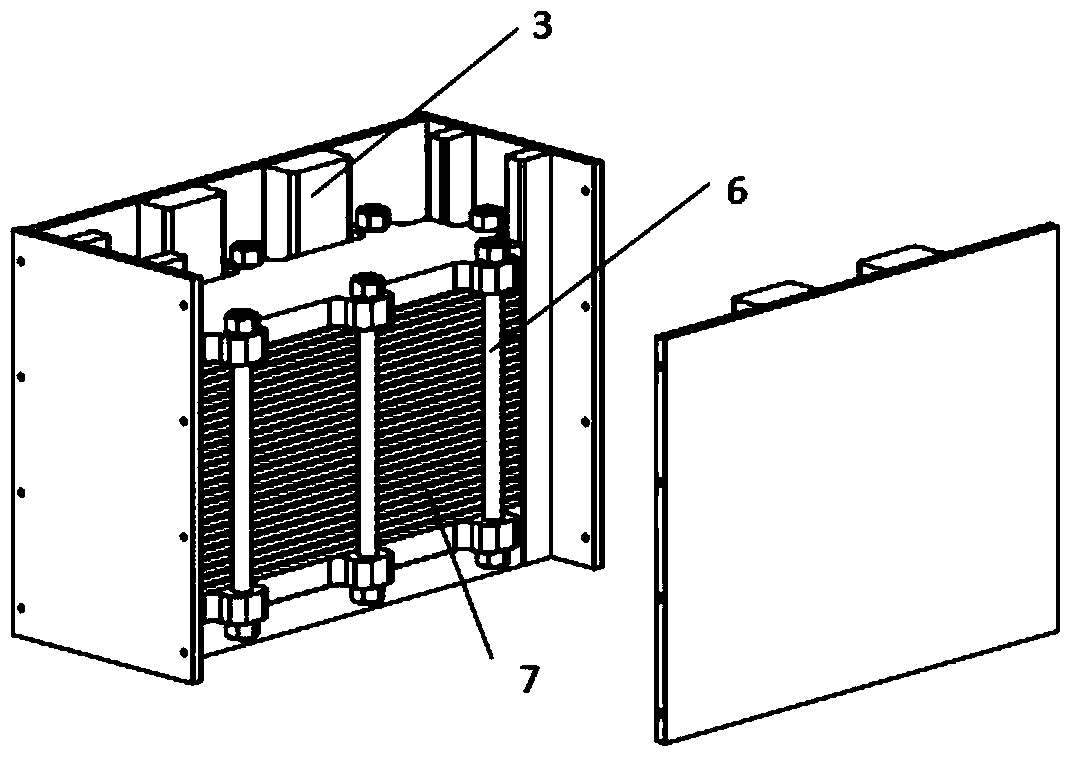

Fuel cell stack assembly method

InactiveCN103633359AImprove assembly efficiencyQuality assuranceFuel cells groupingFuel cell auxillariesFuel cellsEngineering

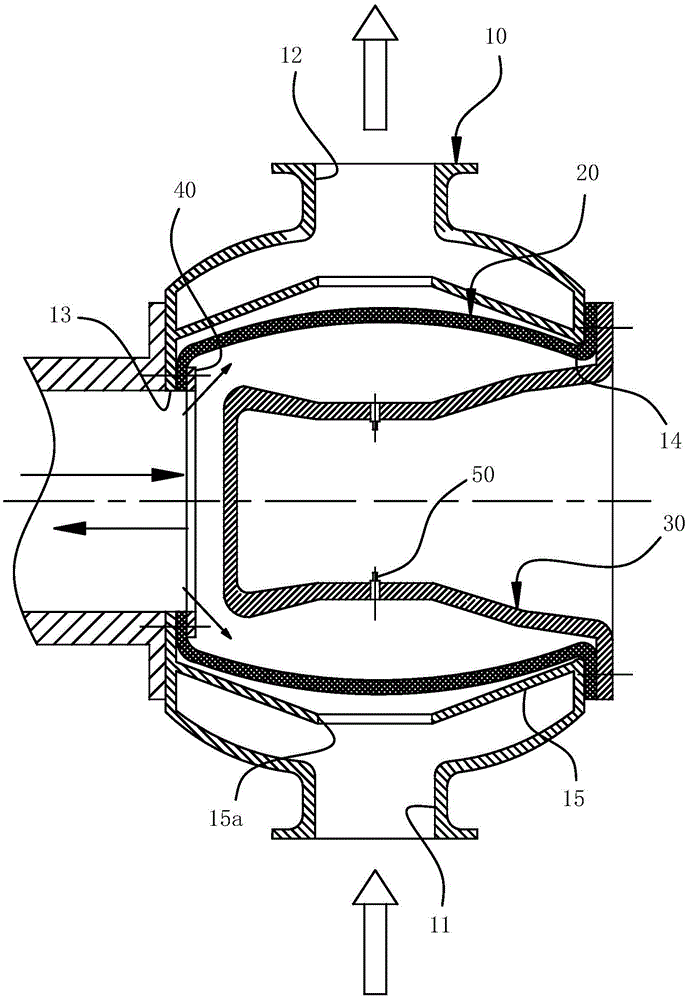

A fuel cell stack assembly method comprises the following steps: fixing an external locating tool for stack assembly on a pressure applying device, sequentially putting stack components into the external locating tool and piling up the stack components, enabling the pressure applying device to apply pressure to the piled stack components in the external locating tool to the set pressure value, respectively fastening integrated packaging side plates at the periphery of a stack for packaging at the pressure value, removing the pressure of the pressure applying device and the external locating tool, taking out the packaged stack, and completing the assembly. The fuel cell stack assembly method has the benefits that the fuel cell stack requiring large assembly force can be assembled only through simple operation, so that the assembly efficiency of the fuel cell stack is remarkably improved; external locating guarantees the alignment of the fuel cell stack components so as to be good for guaranteeing the quality of the stack; the packaging plates at the periphery of the stack does not deform easily when bearing the assembly force of the stack, so as to be good for guaranteeing the composite design value of the fastening force after the assembly of the stack, and the assembly force is applied at the periphery of the stack by the packaging plate compared with a screw or a bundling belt, the assembly force is better uniformly distributed.

Owner:SUNRISE POWER CO LTD

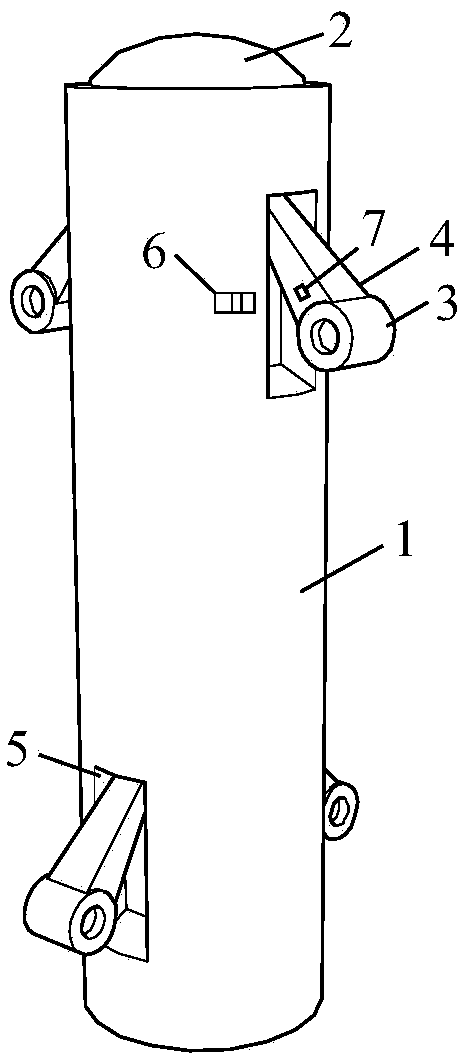

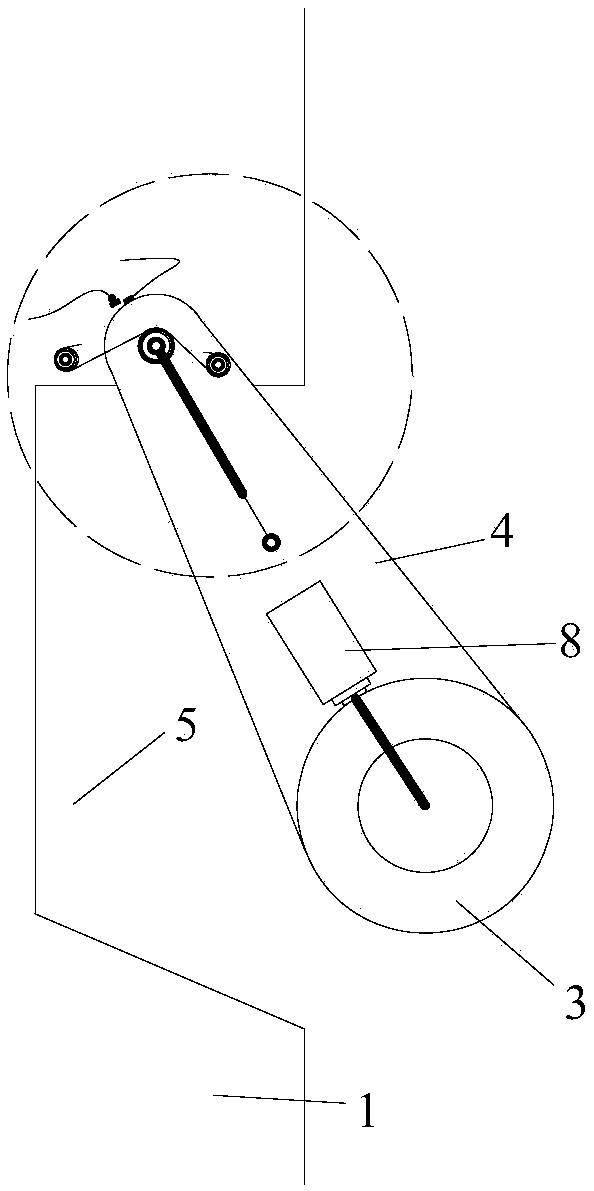

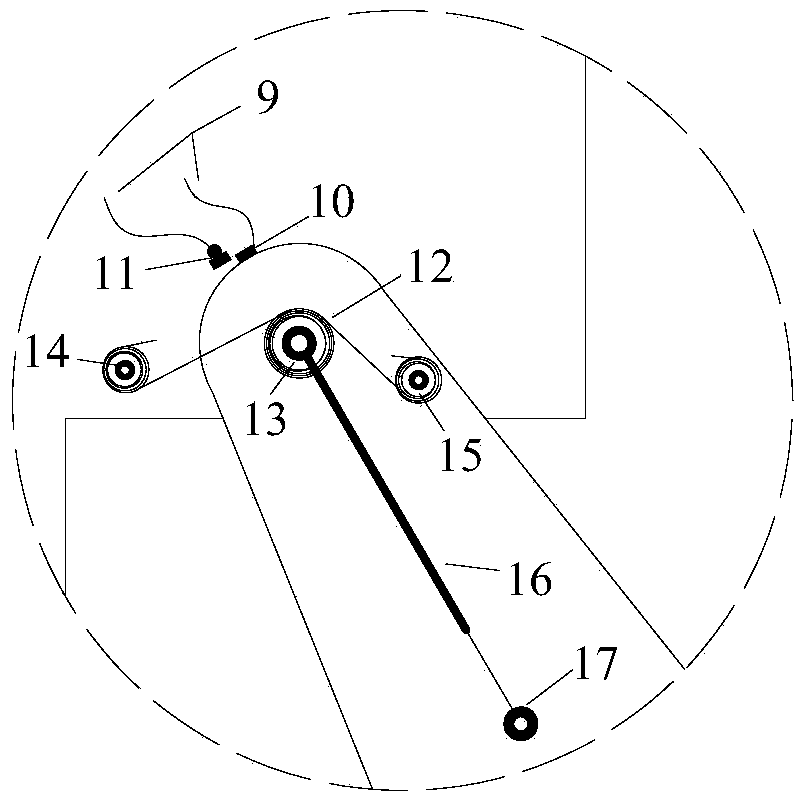

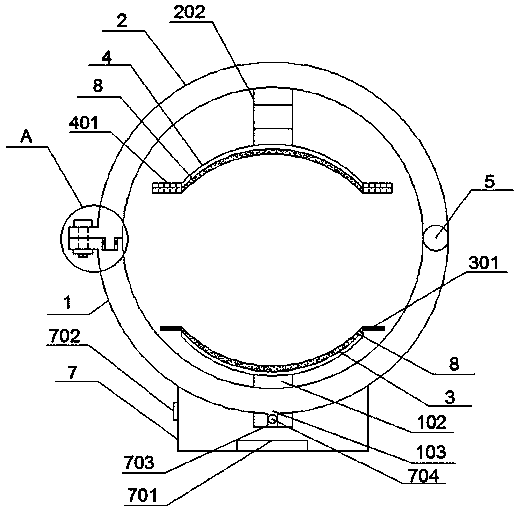

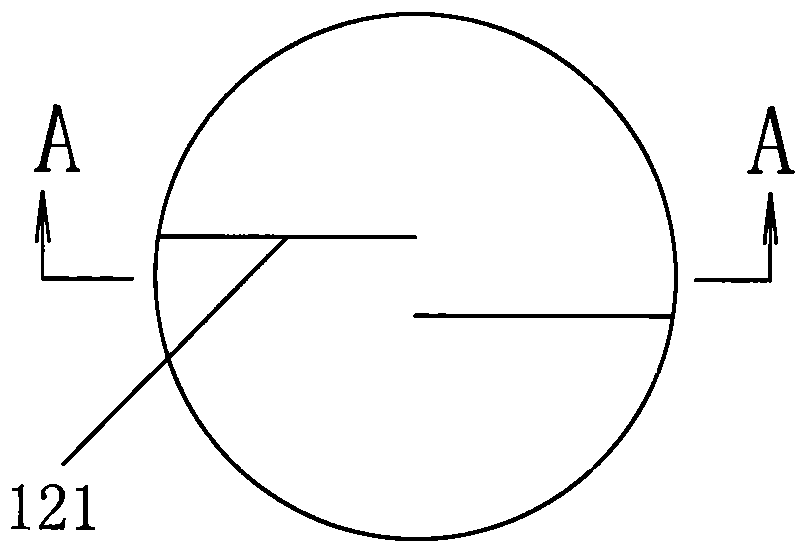

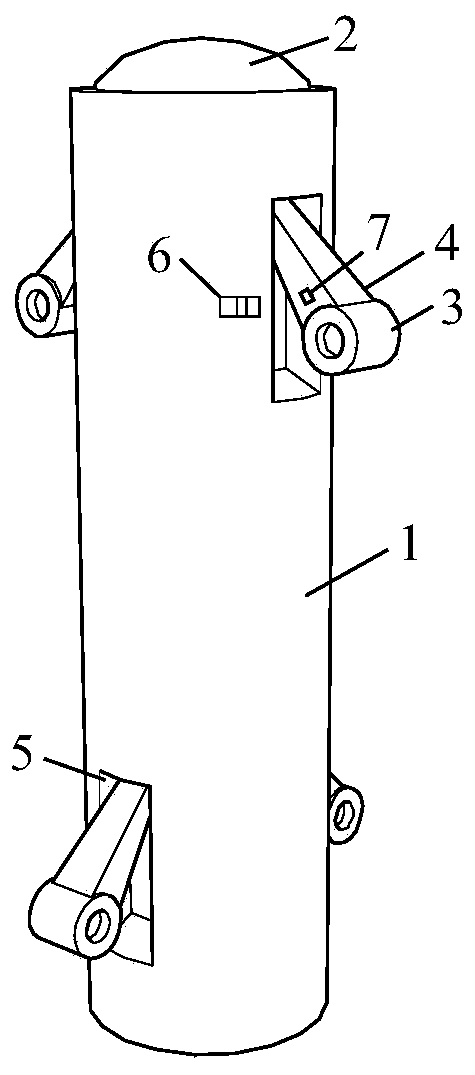

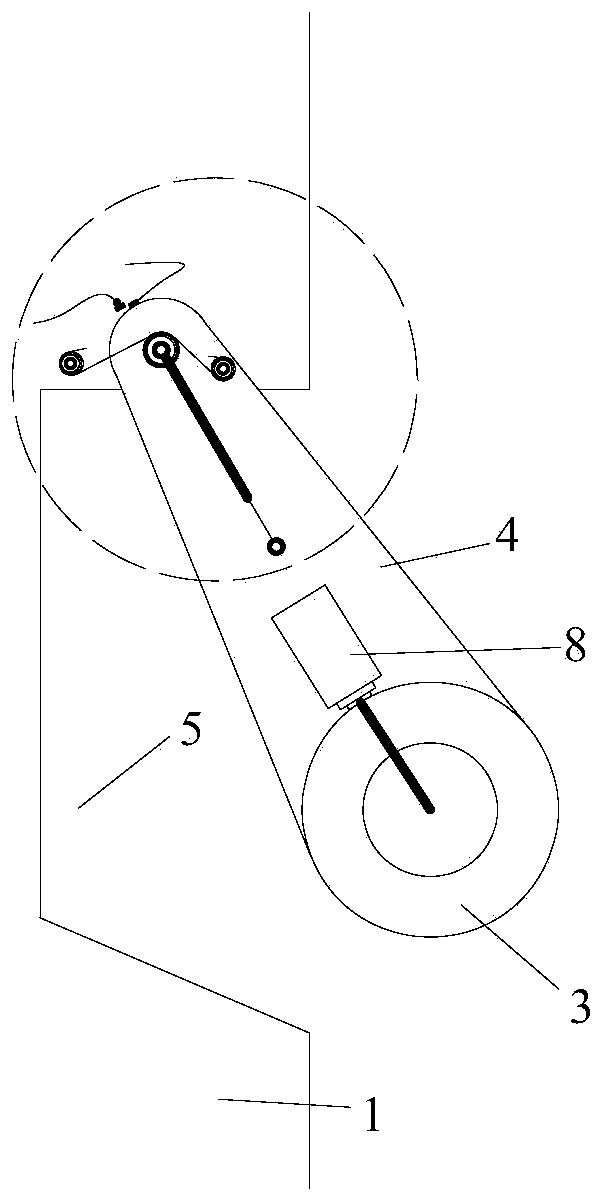

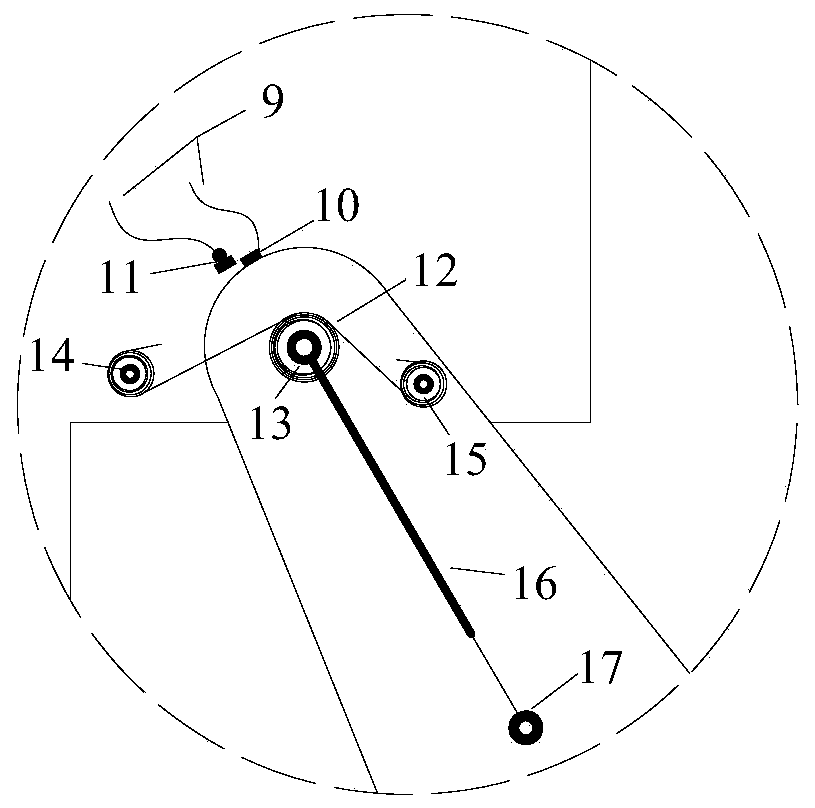

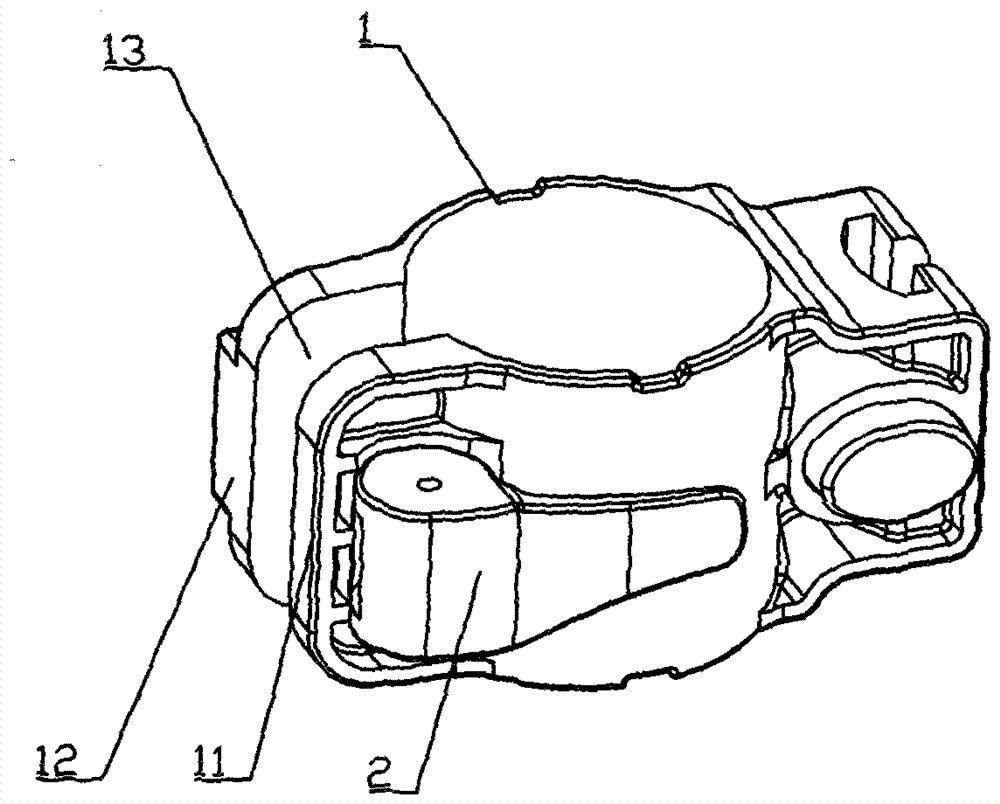

Self-propelled peeping probe adapted to different diameters of drill holes and peeping method thereof

The invention discloses a self-propelled peeping probe adapted to different diameters of drill holes and a peeping method thereof. The probe comprises a peeping probe body, a camera, walking wheels, rocker arms connected to the walking wheels, and an operating host. The rock arms can achieve a certain angle of damping opening and closing under the effects of internal torsion springs and gas springs and have alarm functions, and the rocker arms can be fixed in grooves of a peeping probe side through locking holes and locking blocks. The self-propelled function of the peeping probe in a drill hole can be achieved through an internal power supply, a driving motor, a video processing module, a control module, a WIFI module and the external operating host. The peeping probe has the advantages of centered drill hole, self-propelling and less workers in operation in a drilling peeping operation process, the complexity in a conventional drilling peeping operation is reduced, a push rod and a video transmission line are removed, auxiliary accessories are greatly reduced, and a new solution is provided for determining the fracture of a rock mass through drilling peeping in underground engineering.

Owner:CHINA UNIV OF MINING & TECH

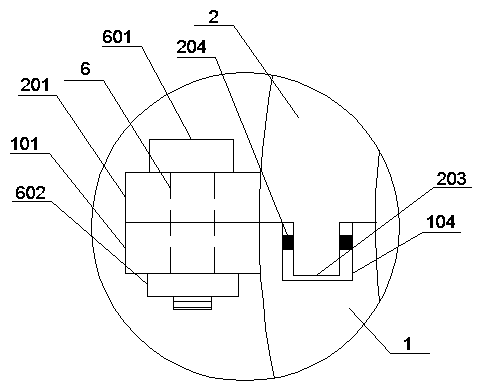

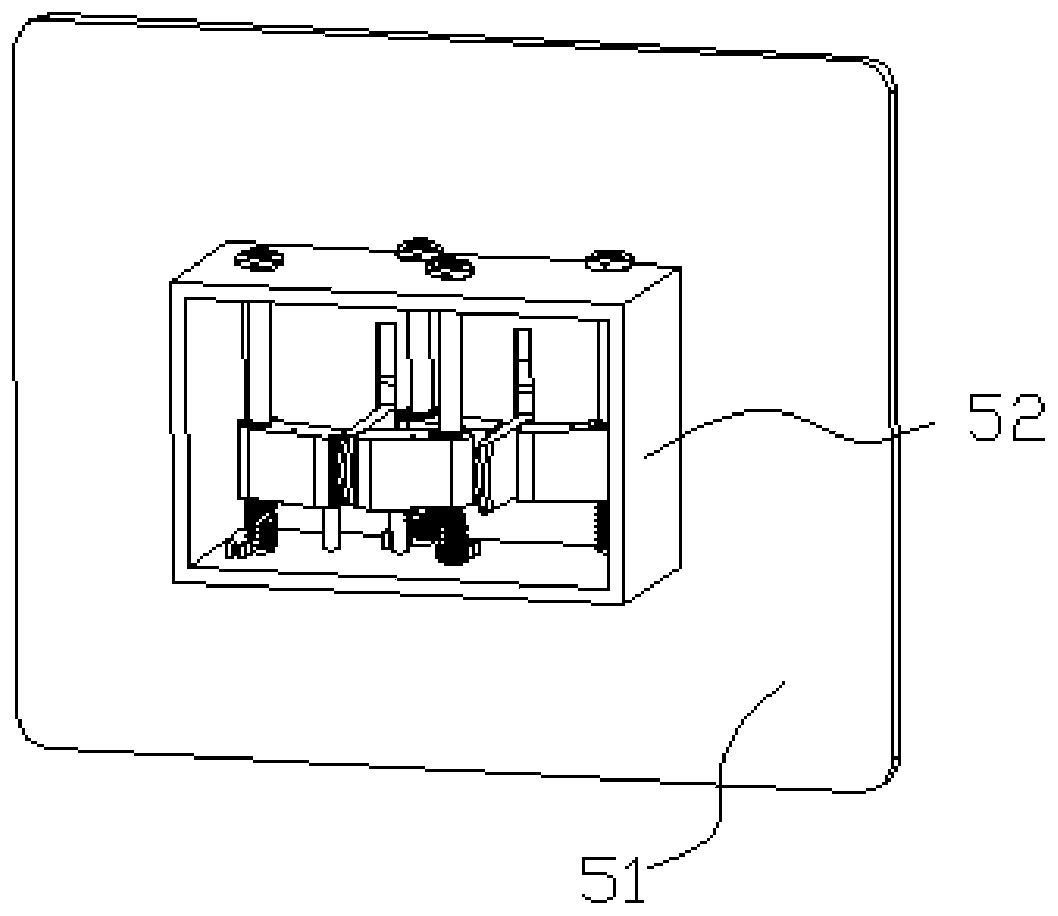

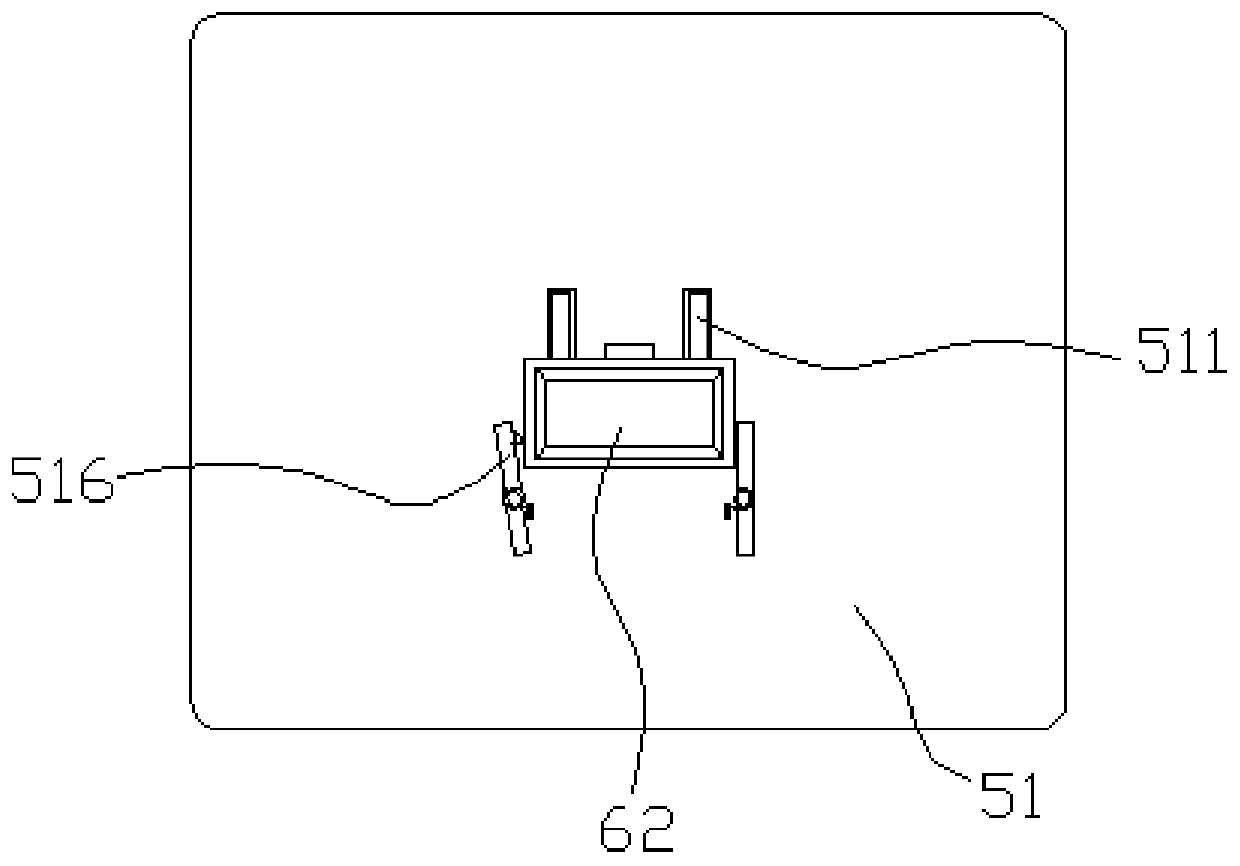

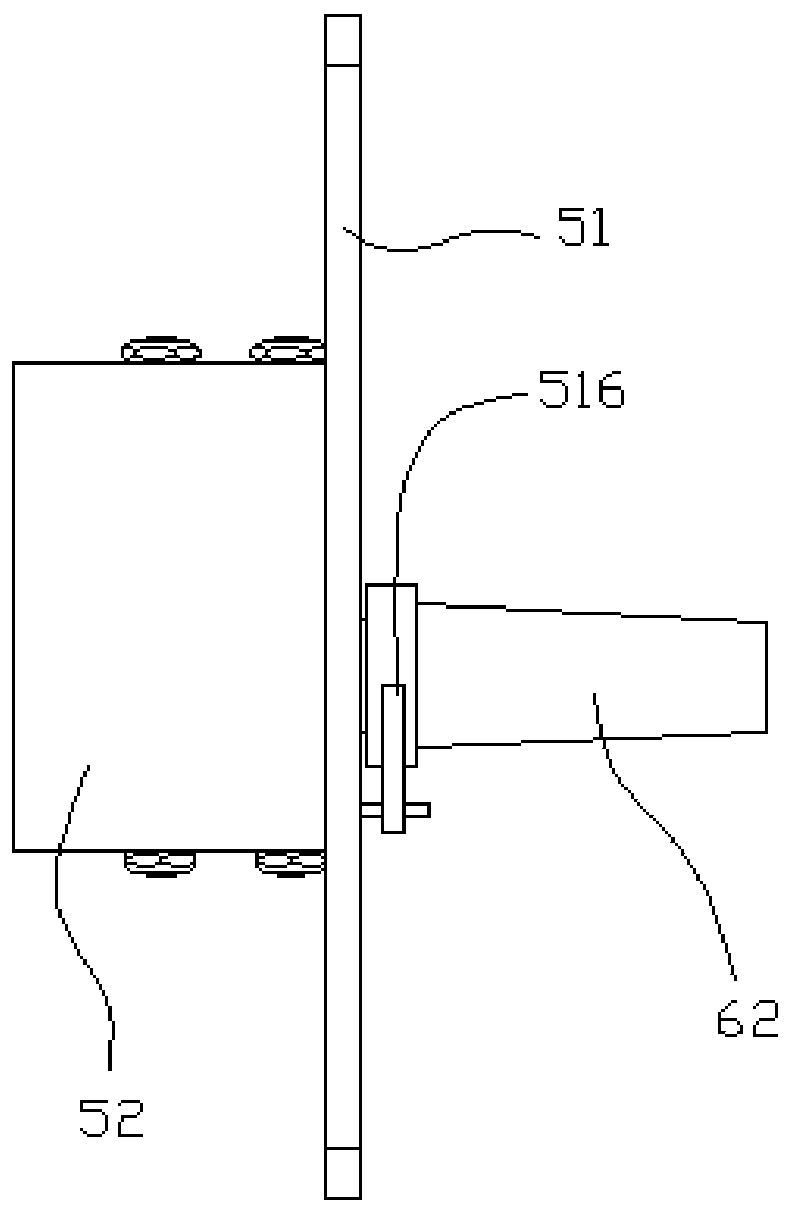

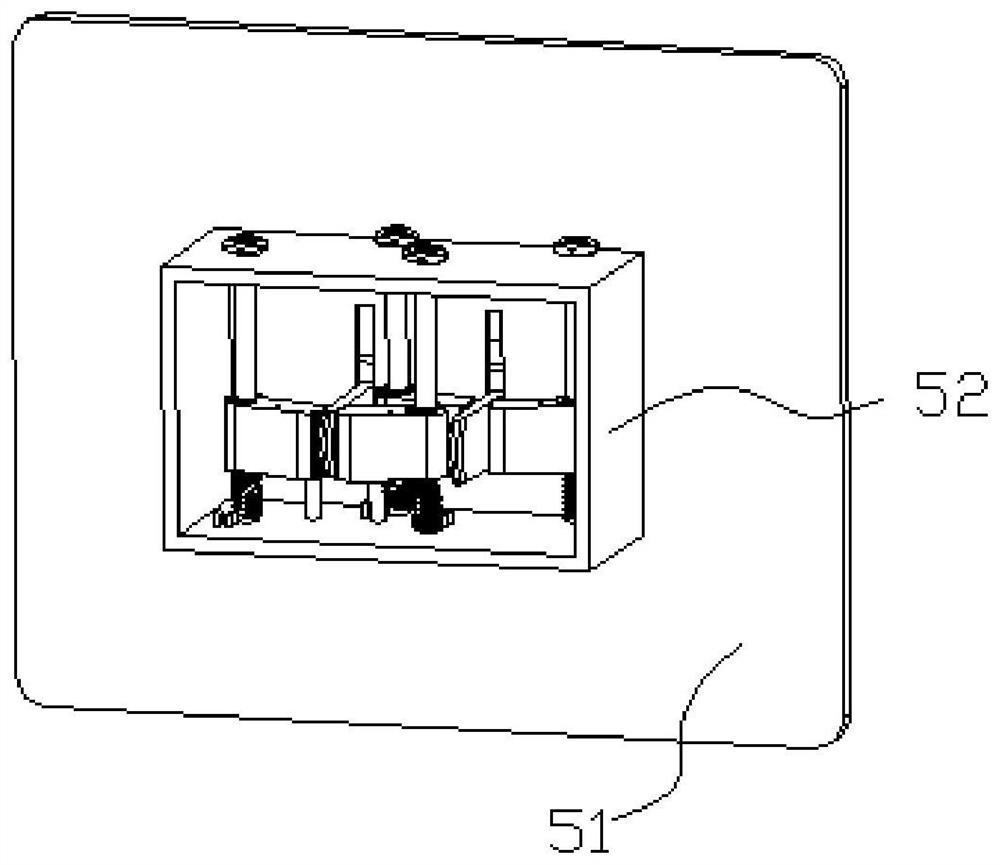

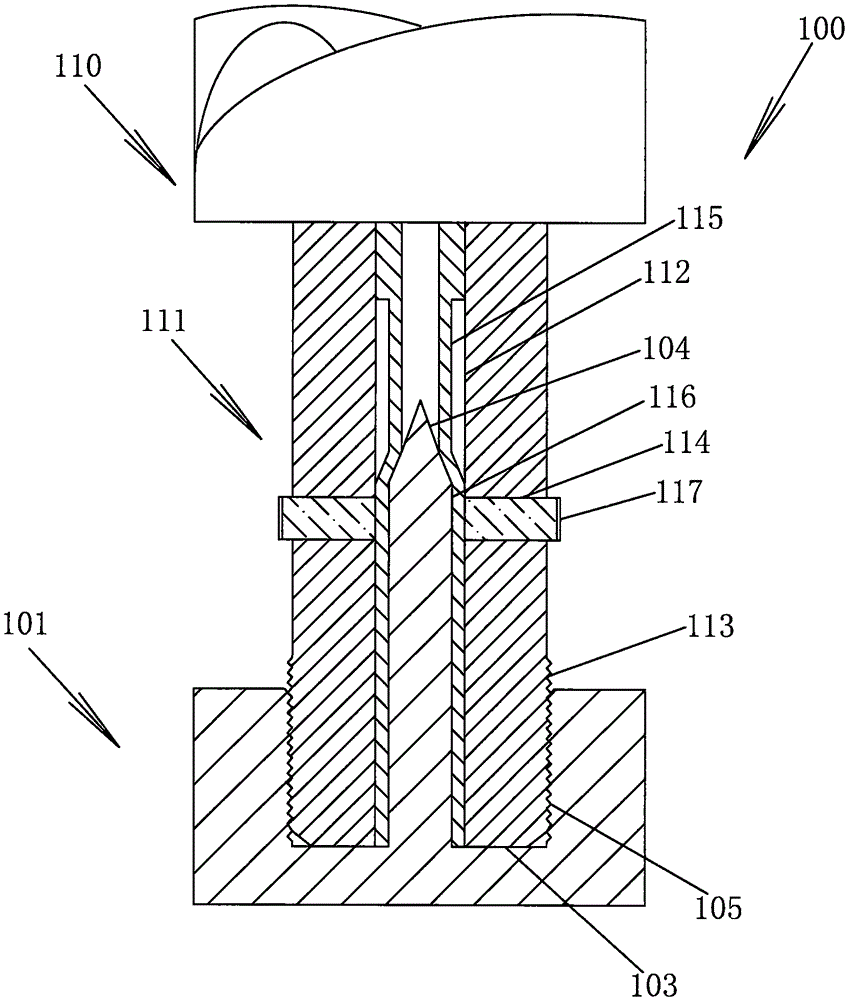

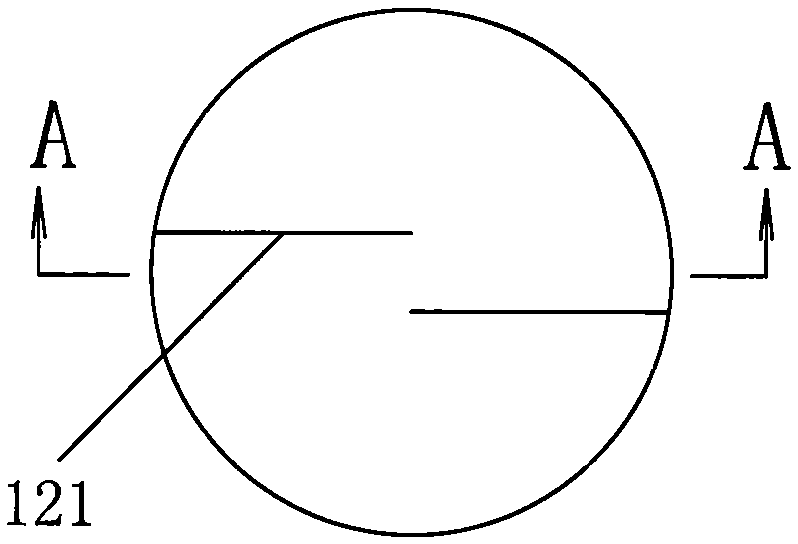

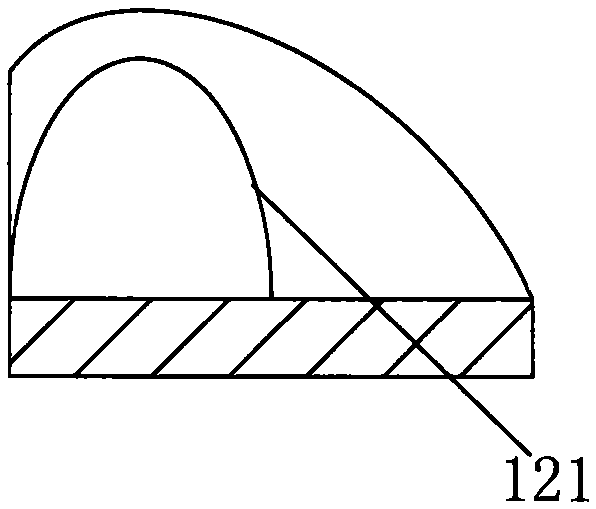

Method for assembling fuel cell stack

The invention relates to a method for assembling a fuel cell stack. The method comprises a step (1) of providing a fixing mechanism, a location mechanism, a pressure supply mechanism and a locking mechanism; a step (2) of successively placing a lower end plate, a current collecting plate, an assembly stack single cell, a current collecting plate and an upper end plate of the stack into the fixing mechanism in sequence, wherein each location post of the fixing mechanism is perpendicular to the stack to enable the periphery of the stack to be nested in a space defined by a second surface of each location post; a step (3) of utilizingpressure blocks of the pressure supply device to exert pressure in the direction perpendicular to the stack on the upper end plate and the lower end plate of stack parts to compress each part of the stack to meet set requirements; a step (4) of utilizing the locking mechanism to fix each part of the stack to achieve the purpose of assembling the stack; and a step (5) of removing the pressure, removing the fixing mechanism and the location mechanism and taking down the stack to finish the assembly of the stack. The method for locating and assembling the assembly stack is simple and convenient to operate, high in actionability and precise in location. The location mechanism ensures that all parts of the stack are in contact uniformly without deviation. The pressure blocks of the pressure supply device ensure each assembly of the assembly stack to be forced uniformly, and the quality of the assembly stack is guaranteed.

Owner:武汉理工新能源有限公司

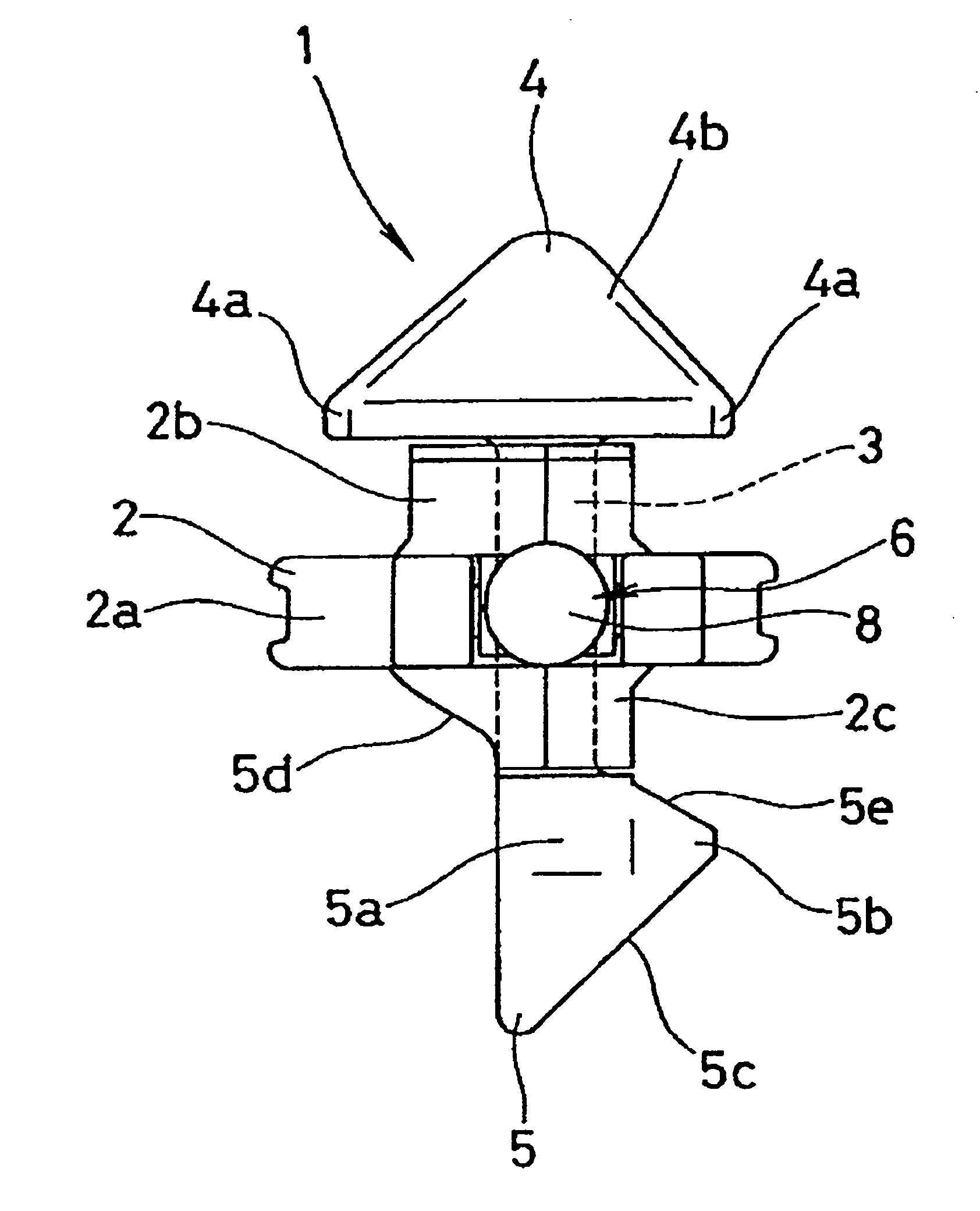

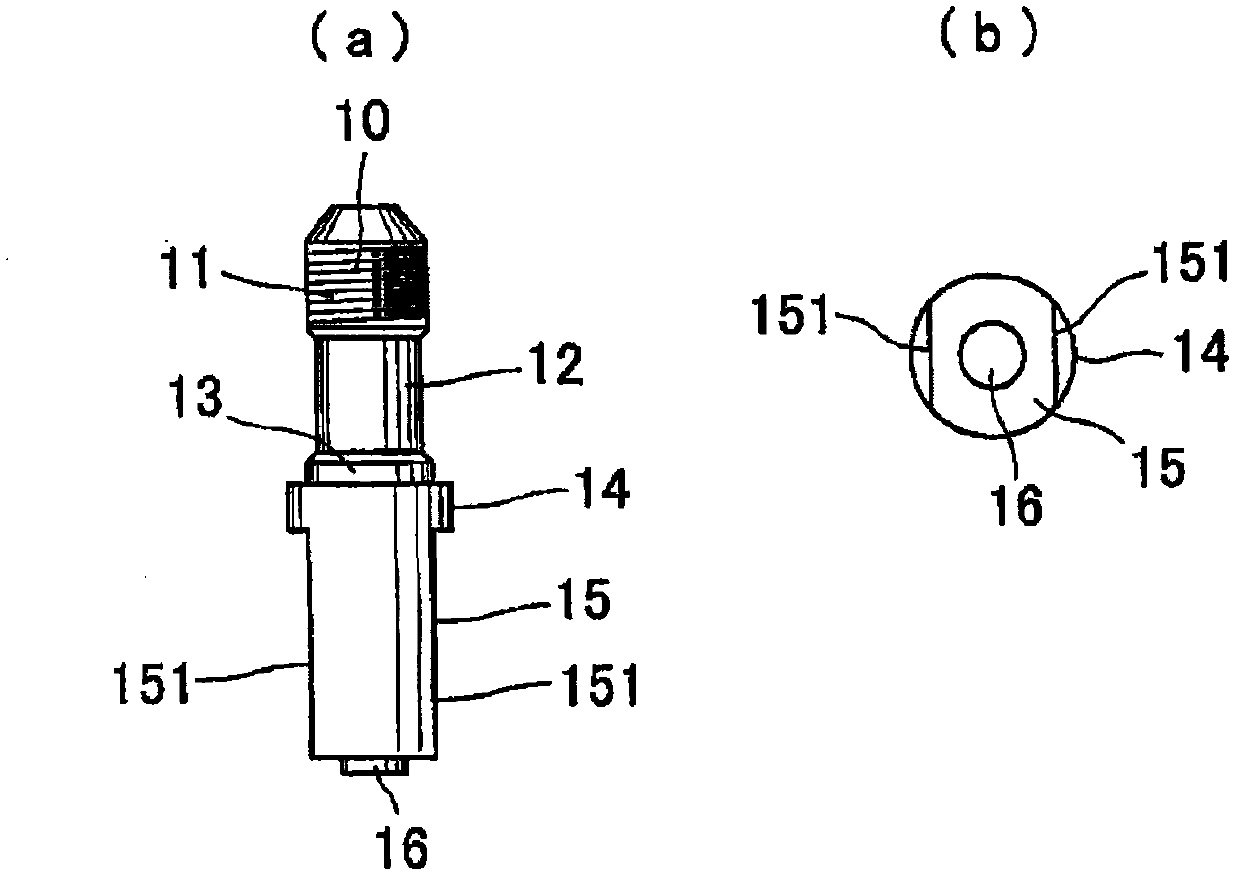

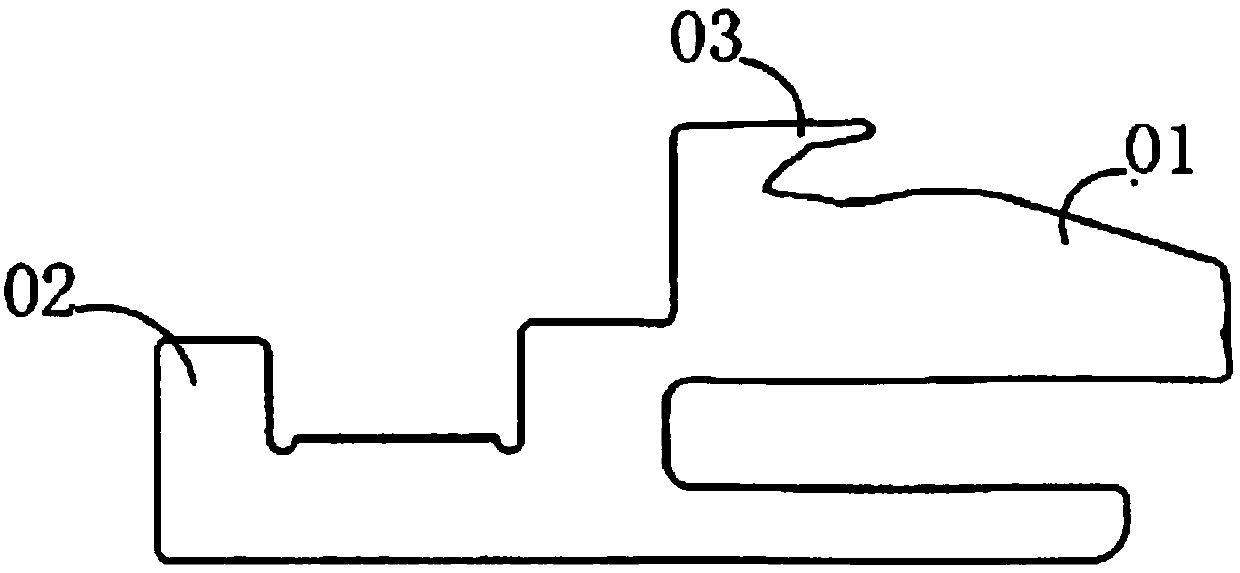

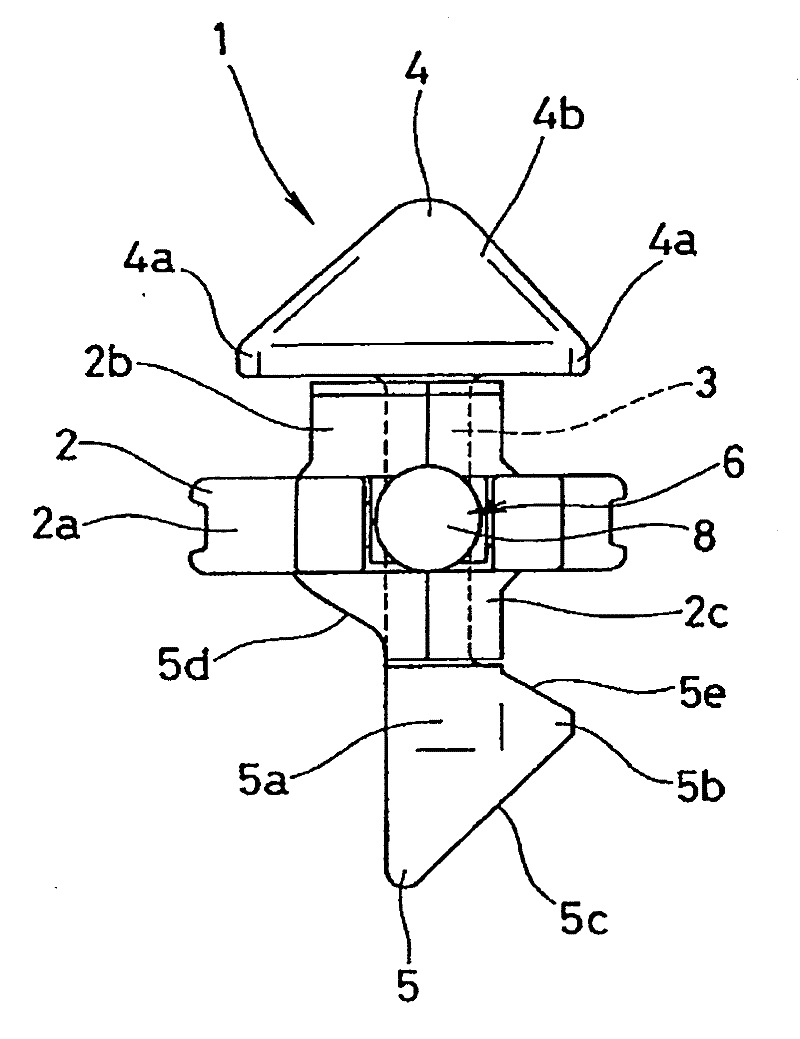

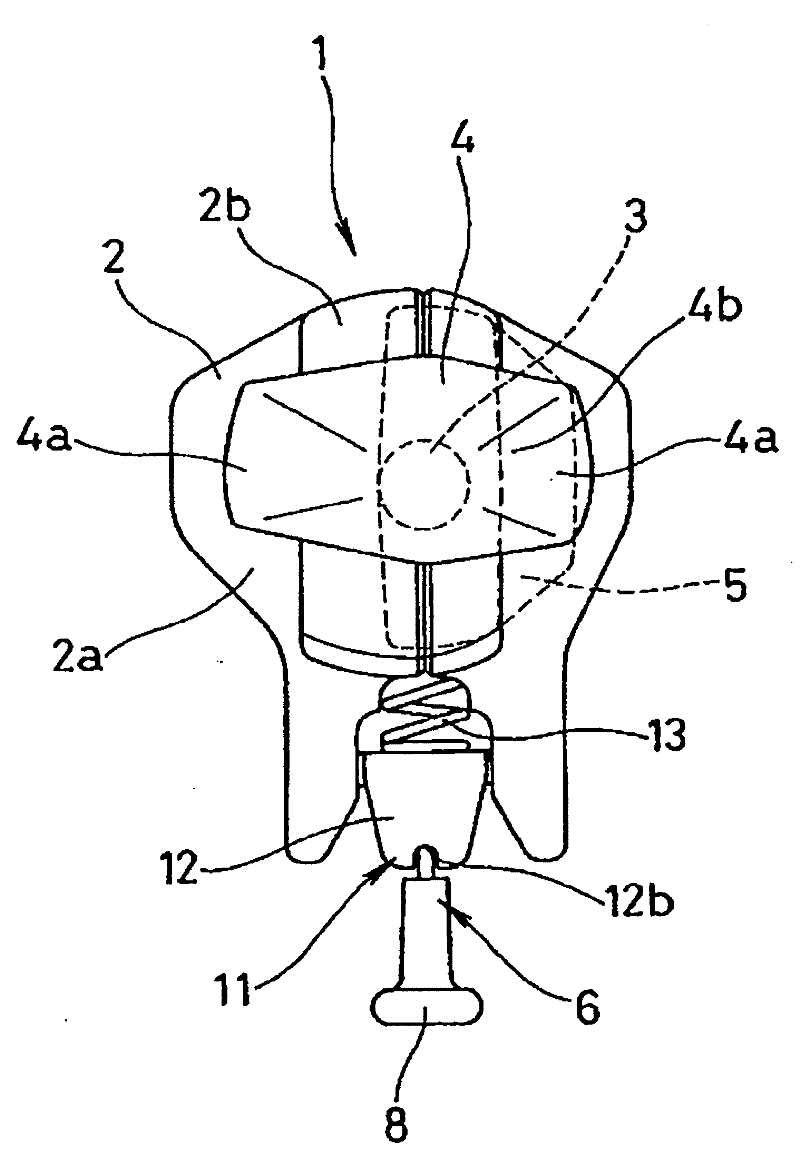

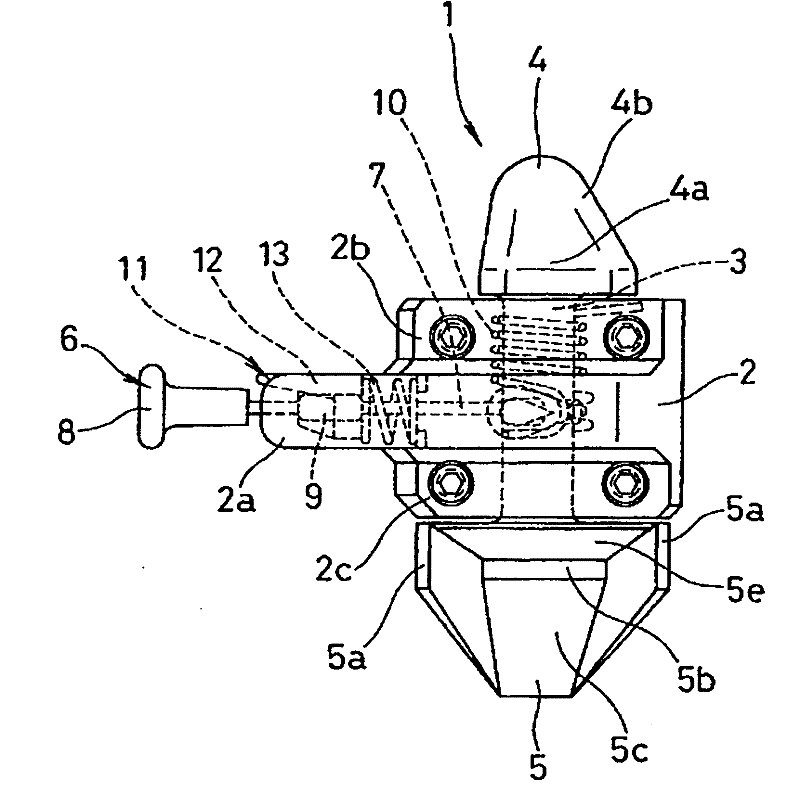

Container connector

InactiveCN101878168AImprove workabilityGuaranteed fastening forceLarge containersFor goodsEngineeringMechanical engineering

A container connector having cones at upper and lower parts of a shaft of the connector. The lower cone can be detached from an upper corner casting of a lower container or a socket on a deck board without manually rotating the lower cone. The construction enhances workability of load discharging and provides sufficient fastening force required in different situations. To achieve the above, the lower cone has a rotation engagement structure and a non-rotatable second engagement structure. The rotation engagement structure allows the lower cone to engage with an inner edge of an engagement hole when the lower cone is in inserted into the upper corner casting or the socket and rotated from a disengagement position to an engagement position. The second engagement structure allows a projection-like engagement section, which is arranged on a side face of the lower cone, to engage with the inner edge of the engagement hole even if the lower cone is not rotated when it is inserted into the upper corner casting or the socket.

Owner:NIPPON YOOSEN KABUSHIKI KAISHA +2

Clamping plate type fixer for orthopedics department

InactiveCN107595460AAvoid other problems caused by chronic poor blood flowStrong adaptability of clamping spaceElectrotherapyBathing devicesOrthopedic departmentSelf adjusting

Owner:陈雷

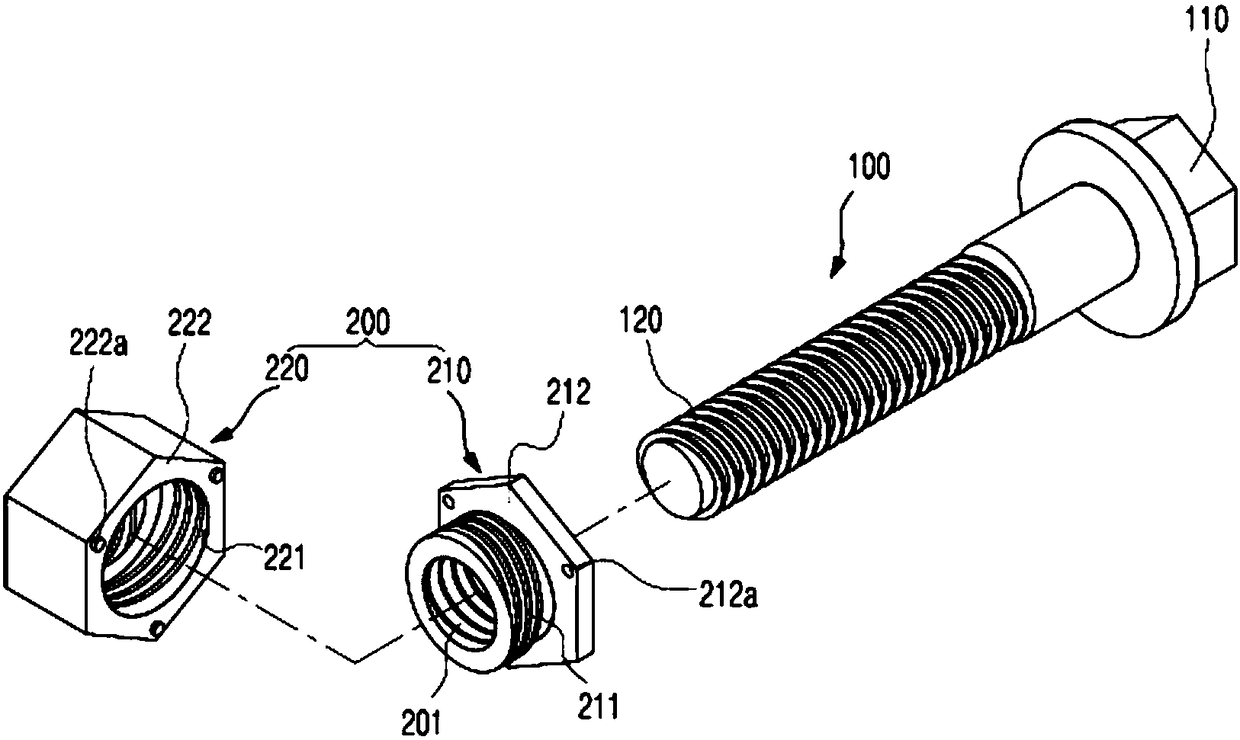

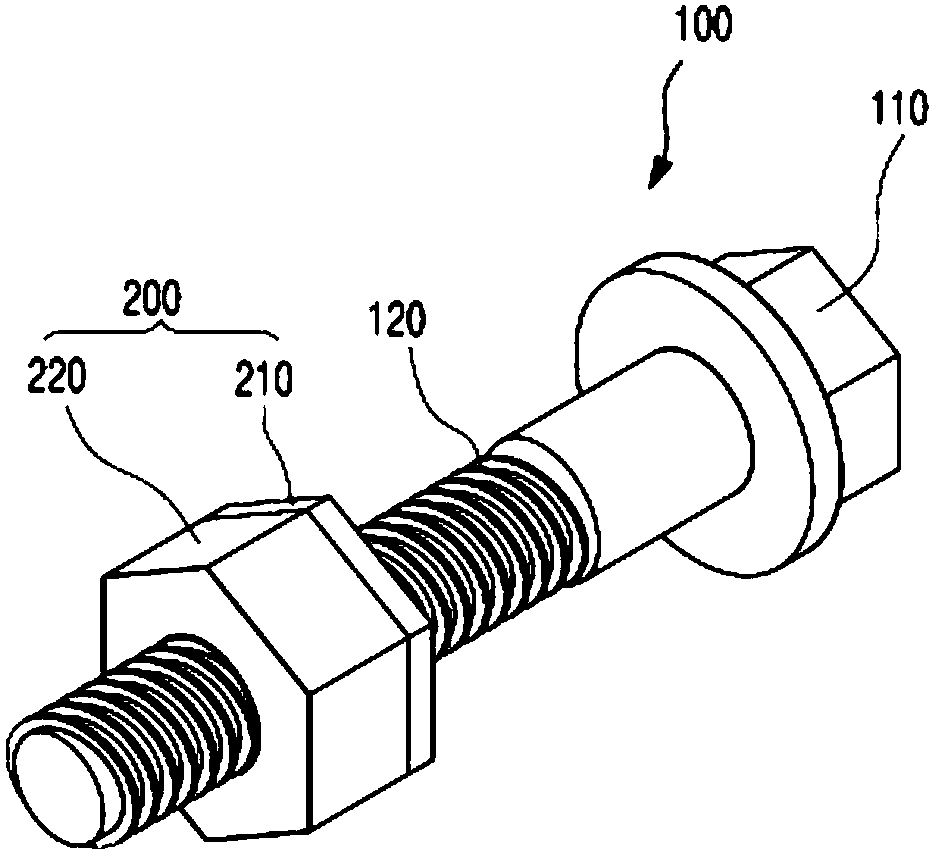

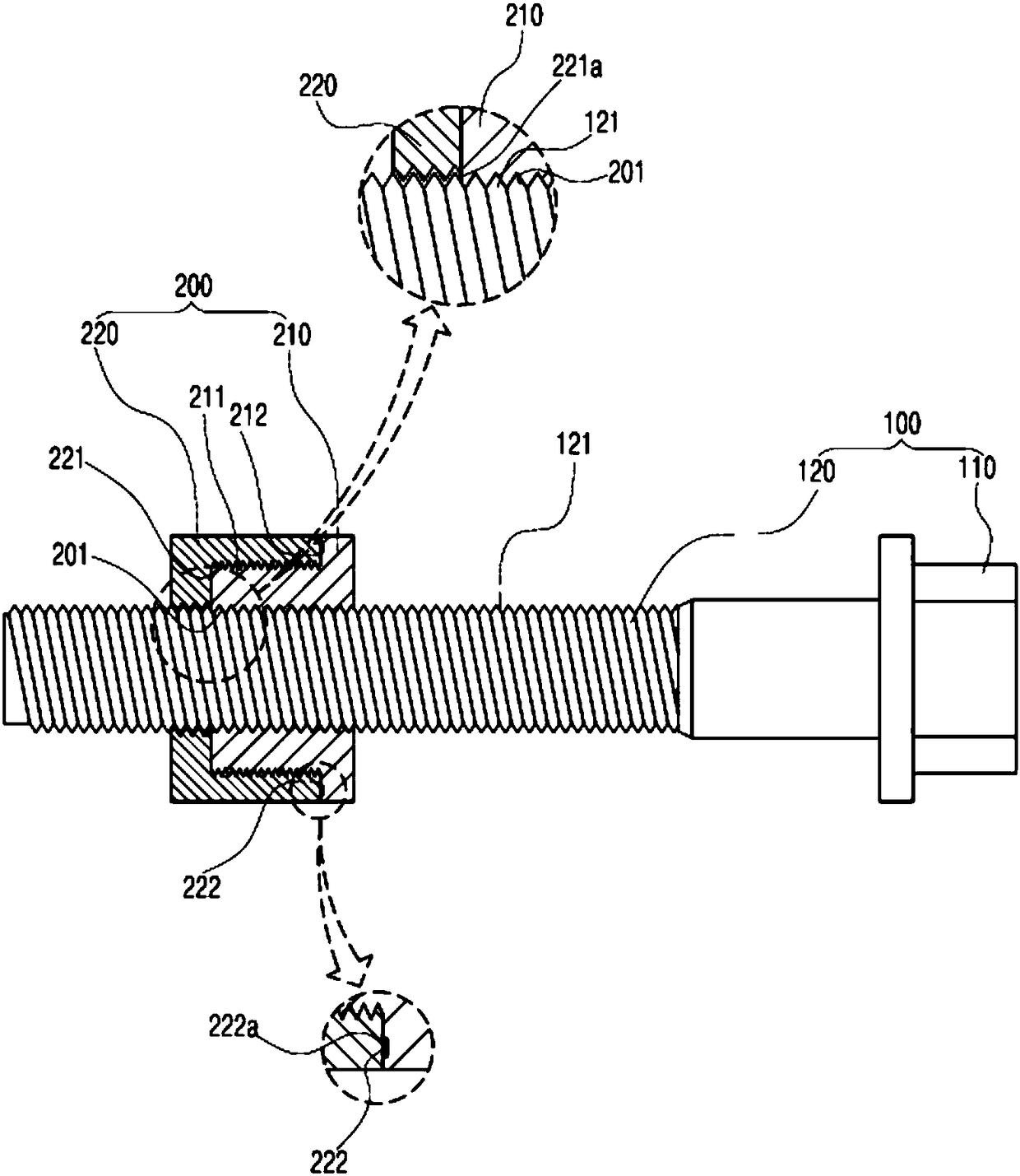

Bolt assembly having non-loosening nut

The present invention relates to a bolt assembly having a non-loosening nut and, more particularly, a bolt assembly having a non-loosening nut in which a pair of non-loosening nuts that move along a male thread pitch of a bolt are prepared so that the pair of non-loosening nuts press and spread to each side a pair of adjacent male threads of the bolt, thereby restricting the rotation of the bolt to suppress the loosening of the bolt. To this end, the present invention provides the bolt assembly having the non-loosening nut, the bolt assembly comprises the following components: a bolt includinga first male thread; a first nut, which has a first female thread screw-coupled to the first male thread of the bolt, and has, on the outer circumferential surface, a second male thread formed in thedirection opposite to the first male thread; and a second nut, which has a second female thread that is screw-coupled to the second male thread of the first nut, and has, in the center, a non-loosening female thread which corresponds to the first female thread and is screw-coupled to the first male thread via the first female thread. The bolt assembly having the non-loosening nut is characterizedin that the groove depth of the non-loosening female thread is formed deeper than the groove depth of the first male thread, thereby forming a gap between the first male thread and the non-looseningfemale thread, while preventing a gap from being formed between the first female thread and the first male thread.

Owner:芬莫尔德有限公司

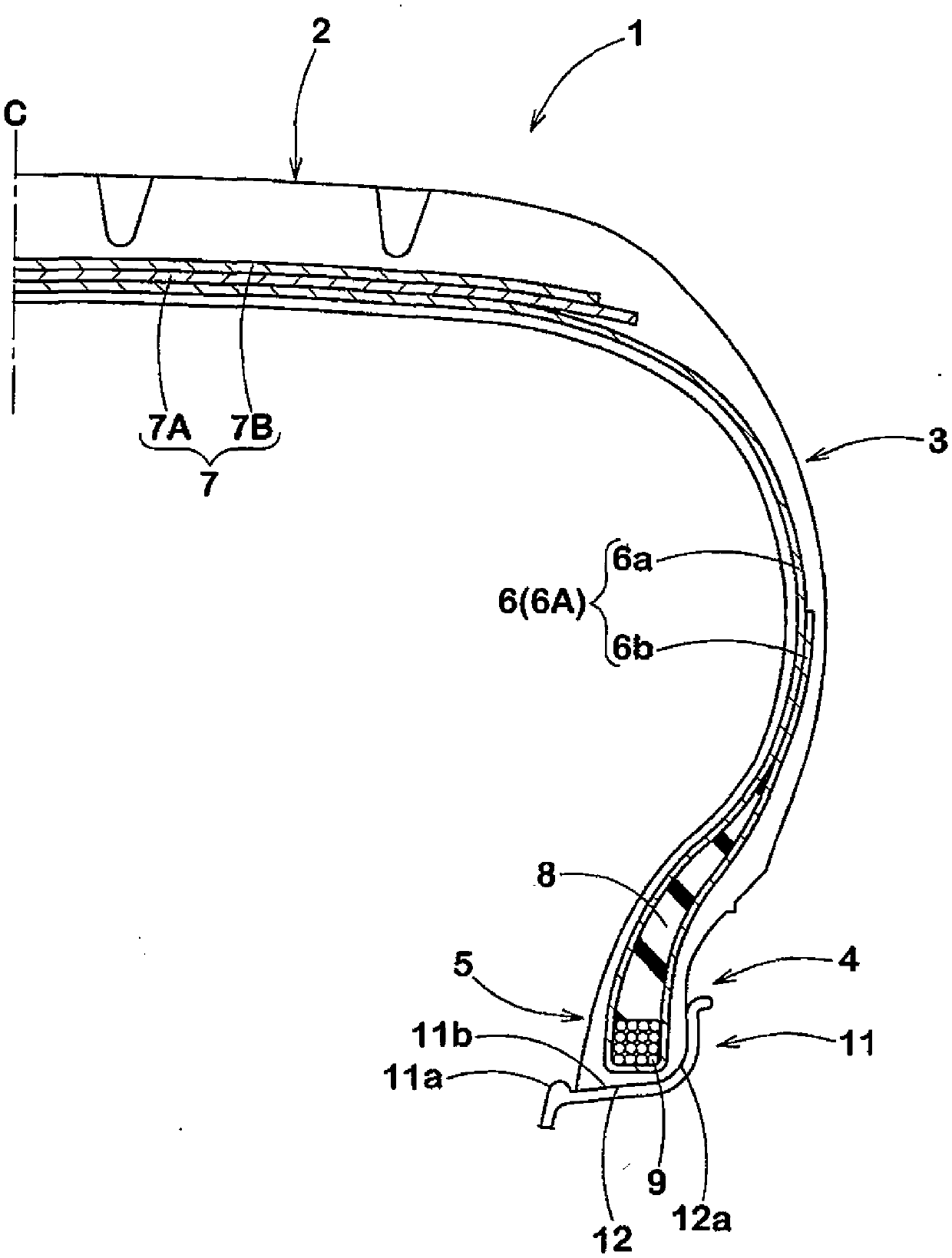

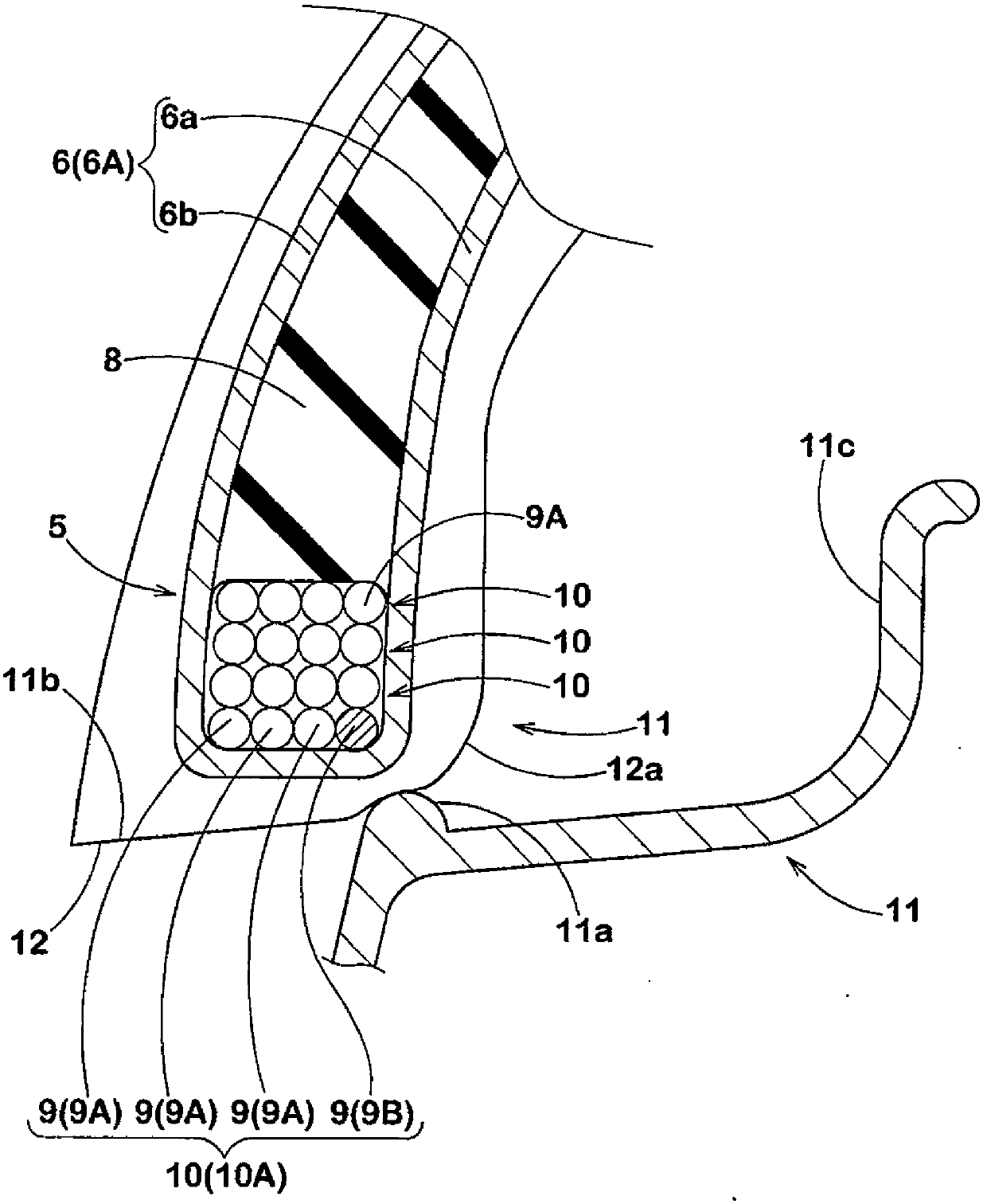

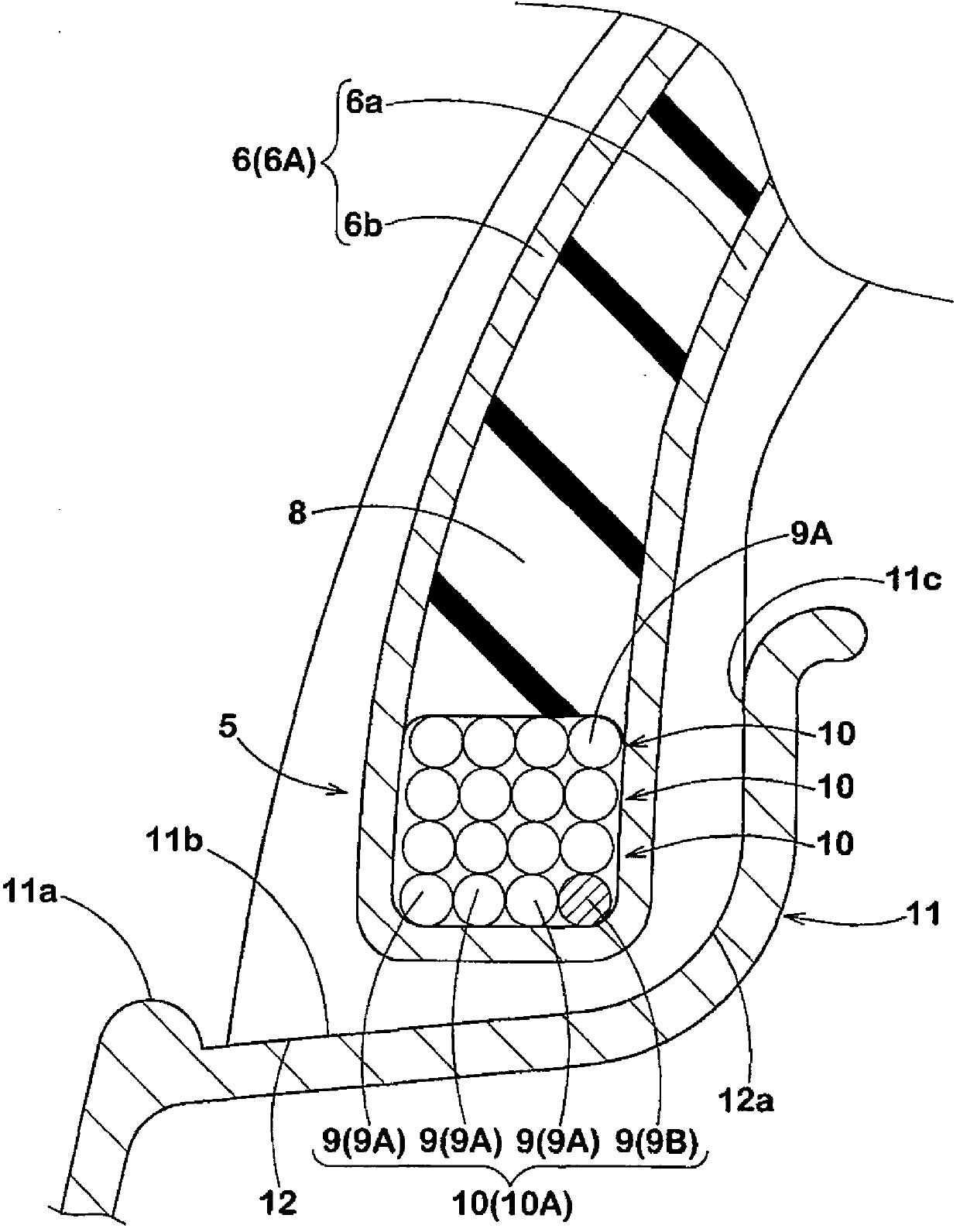

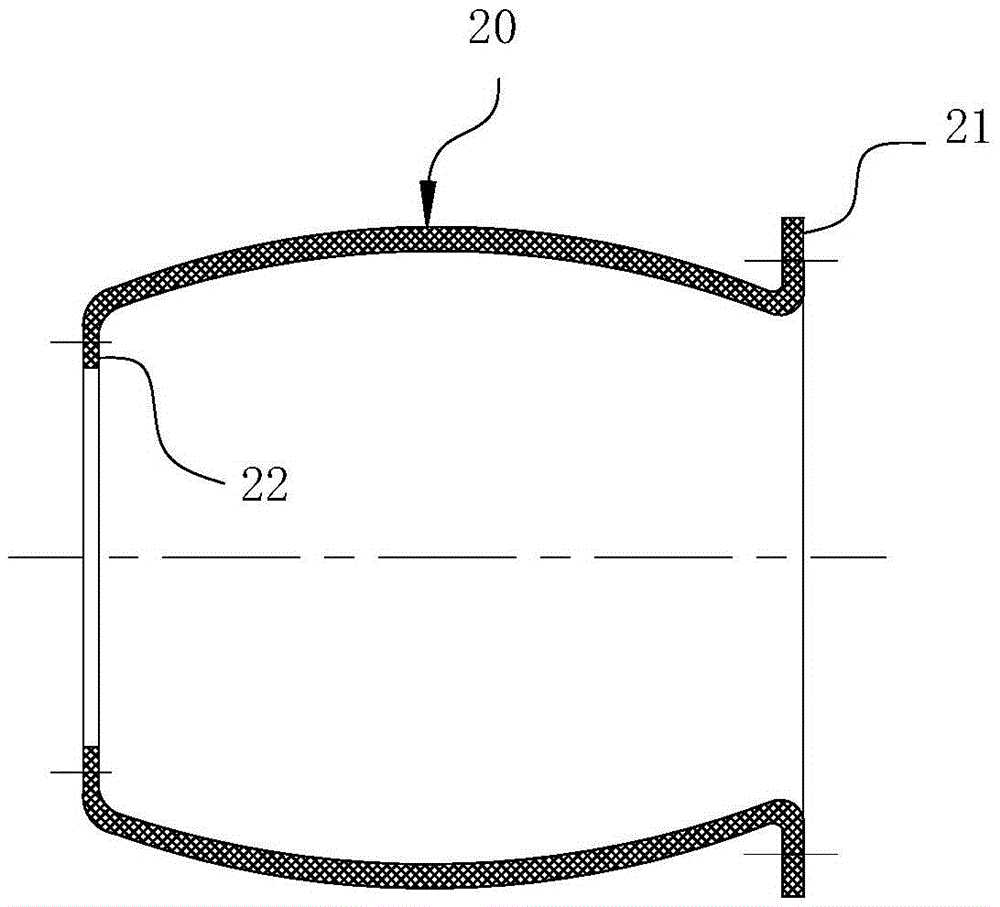

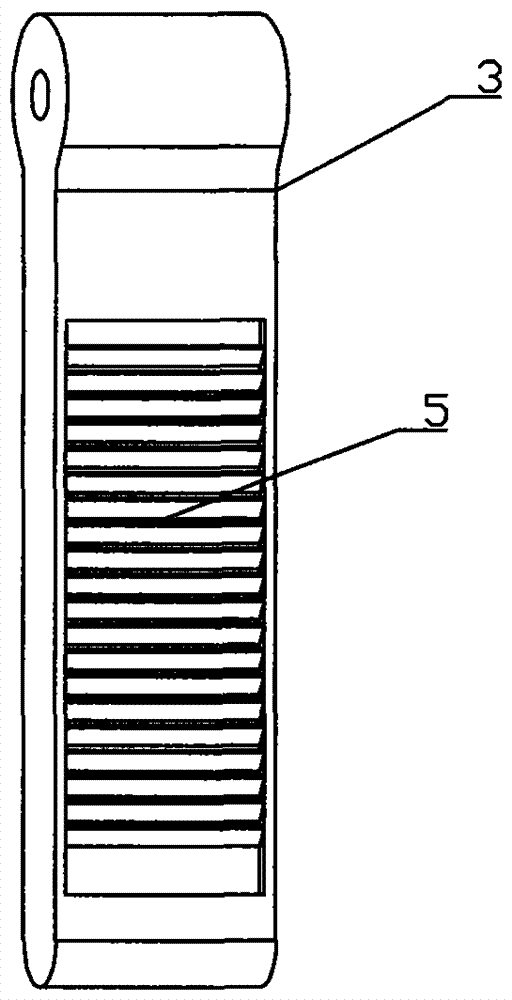

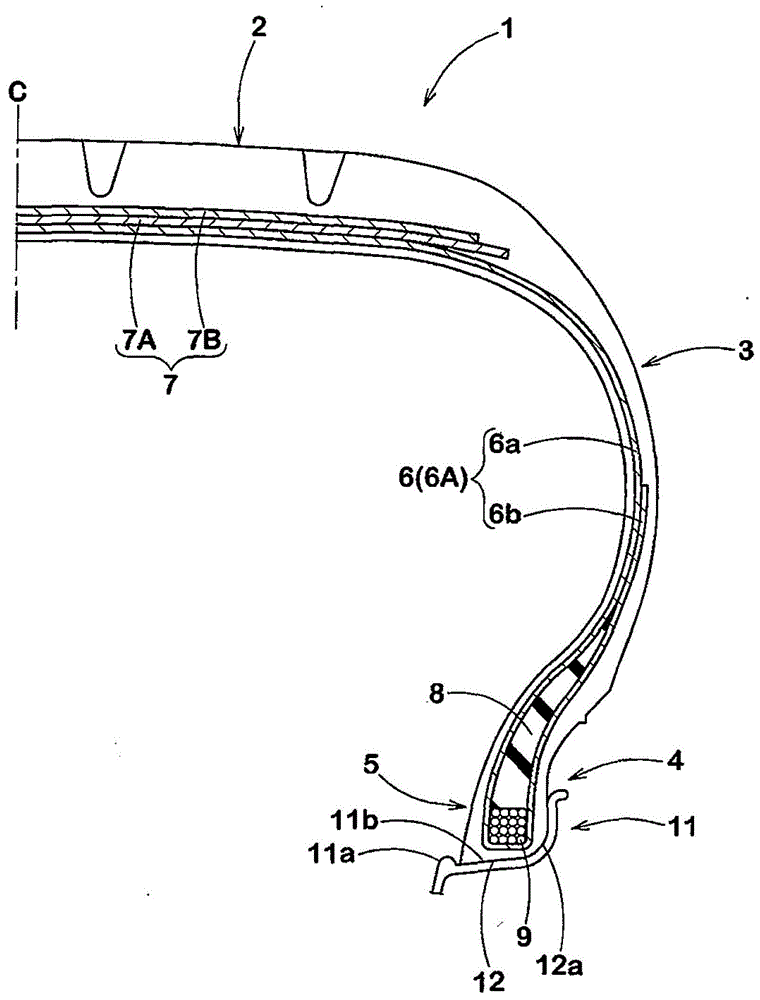

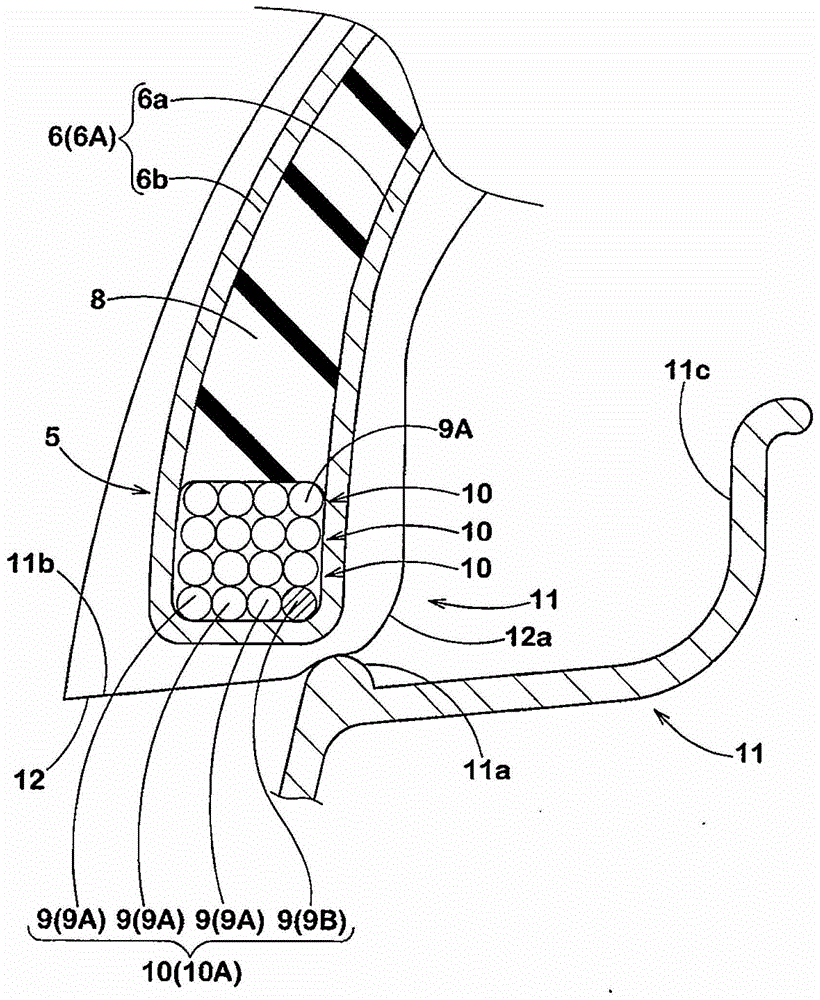

Pneumatic tire

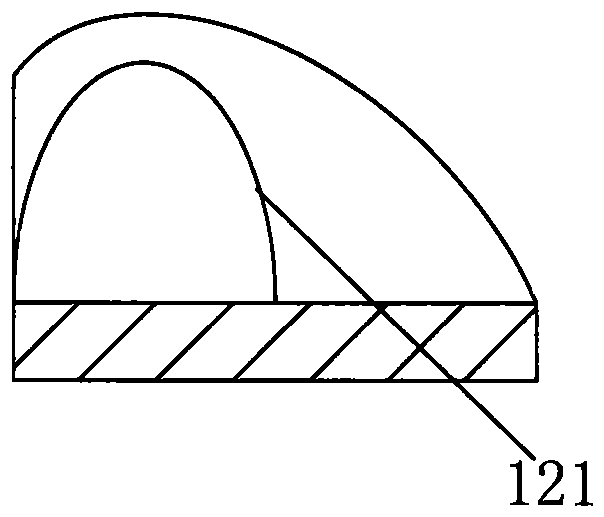

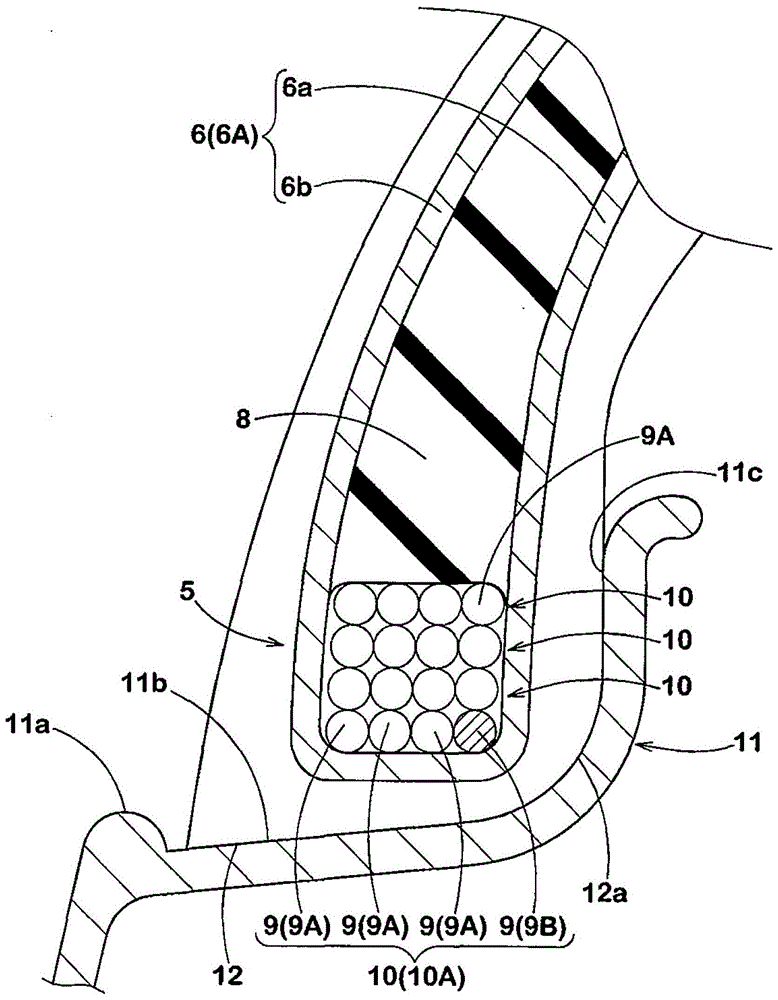

ActiveCN103213460AGuaranteed fastening forceIncreased durabilityTyre beadsWheelsEngineeringMechanical engineering

A pneumatic tire has bead cores provided in bead portions. The bead cores include a first bead wire, and a second bead wire having an elongation alpha, where alpha (%)=DeltaL / L100, L is a length of each of the bead wires under no load, and DeltaL is an elongation amount obtained when a unit load is applied. The elongation alpha of the second bead wire is greater than an elongation of the first bead wire. The number of the second bead wire provided in an innermost side portion in a tire radial direction is at least one.

Owner:SUMITOMO RUBBER IND LTD

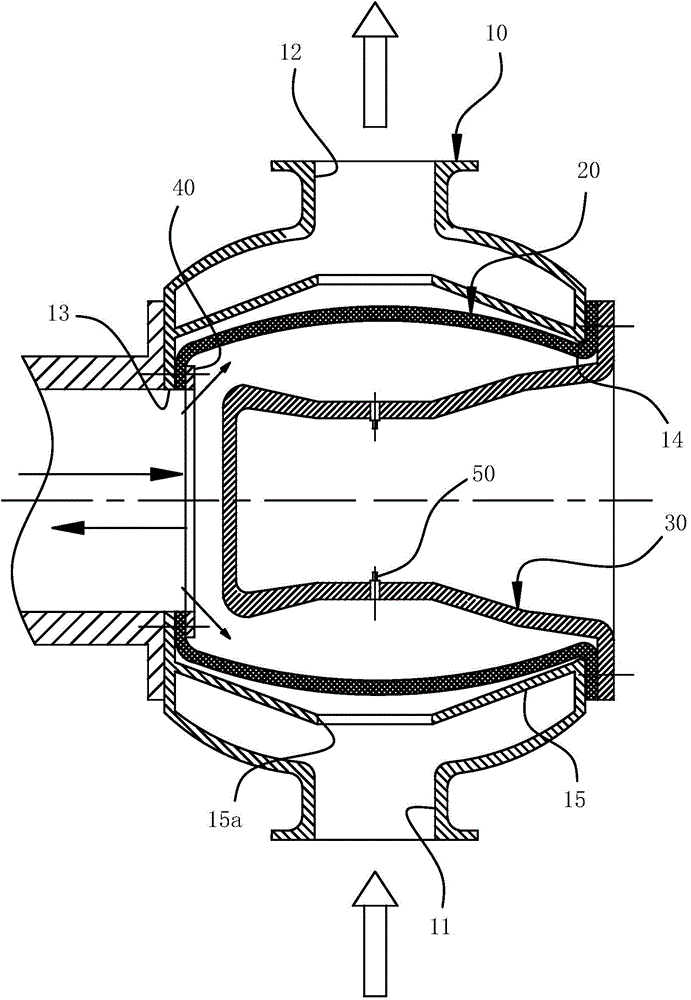

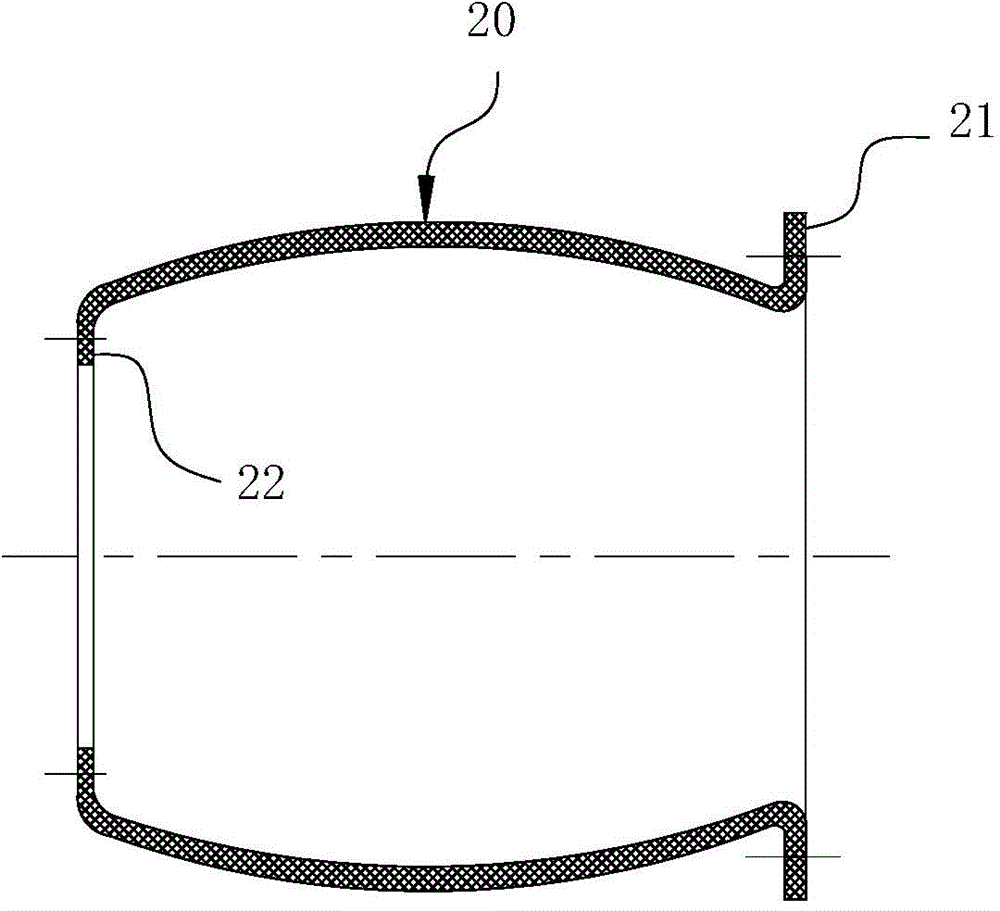

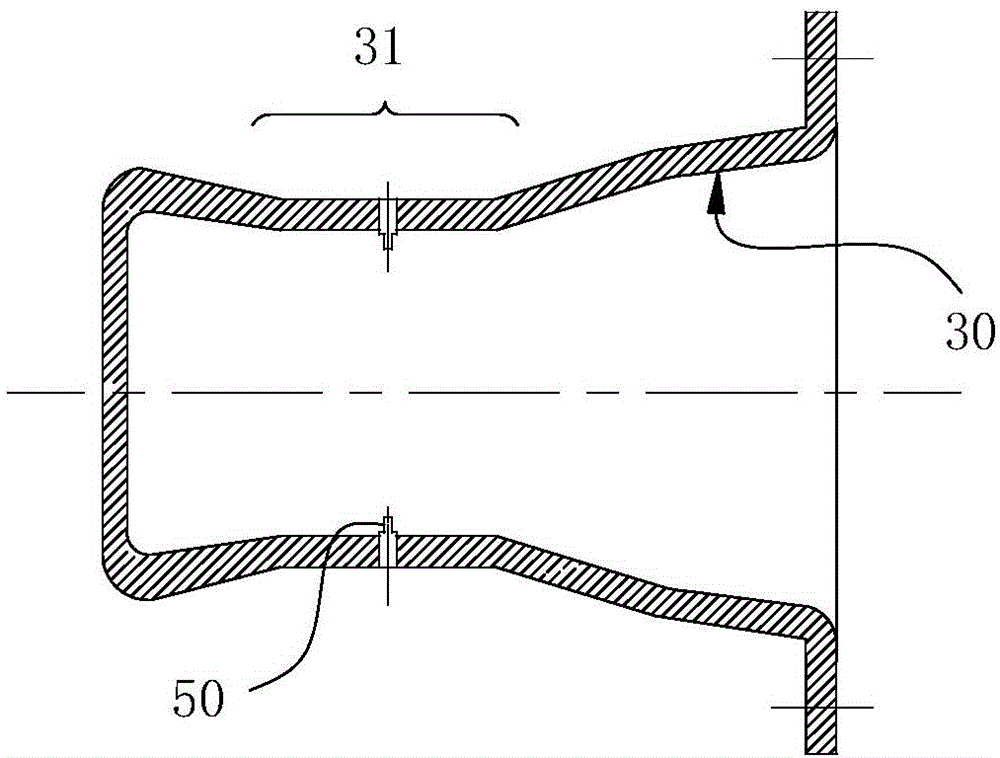

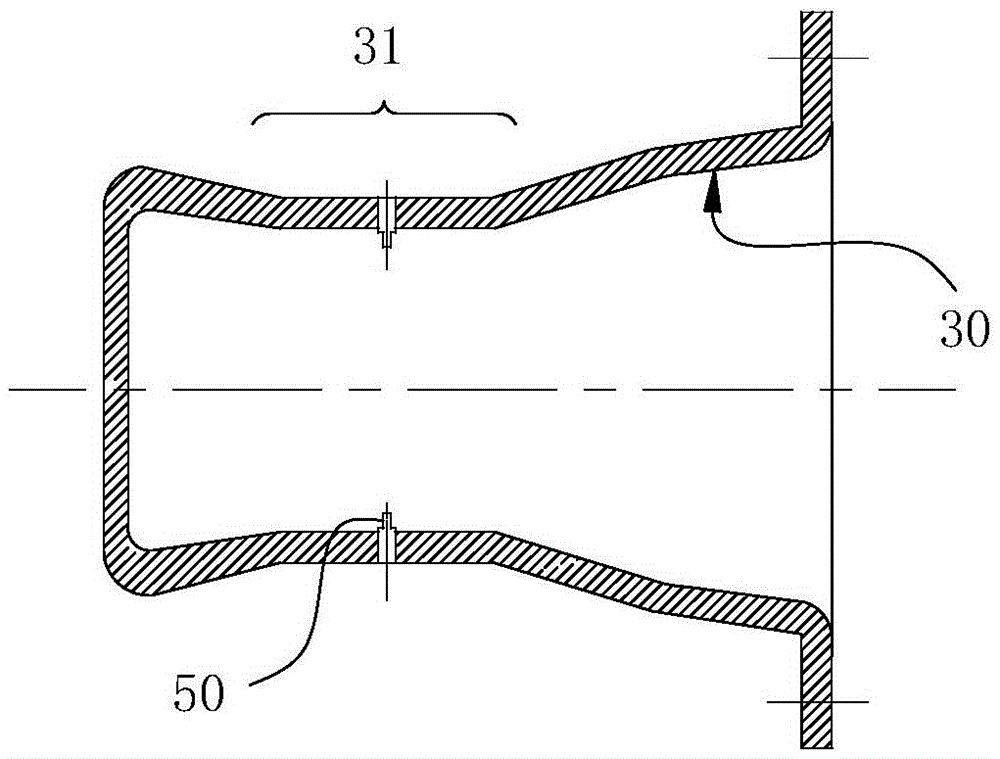

Convenient-to-dismount diaphragm pump

ActiveCN104358675AStrong resistance to tensile fatigueReduce labor intensityPositive displacement pump componentsFlexible member pumpsDiaphragm pumpEngineering

The invention belongs to the field of a volume pump, and particularly relates to a convenient-to-dismount diaphragm pump with the advantages that the monitoring can be realized in proper time, and a diaphragm leaf can be fast dismounted and replaced on line. The convenient-to-dismount diaphragm pump comprises a pump body and the diaphragm leaf, wherein liquid inlet and outlet holes and hydraulic holes are respectively formed in the pump wall of the pump body, a located pump cavity of the liquid inlet and outlet holes and a located pump cavity of the hydraulic holes are separated through the diaphragm leaf, the pump body also comprises a repair hole, the repair hole is sealed by an end cover, the appearance of the diaphragm leaf is of a sleeve-shaped structure, a pipe opening formed at one end of the diaphragm leaf is fixedly connected with the hole end surface of the hydraulic holes through screw bolts, a pipe opening formed in the other end of the diaphragm leaf extends towards the repair hole and is provided with an outer flange, the outer flange is arranged in a way of being matched with the surfaces between the hole ends, positioned at the outer wall parts of the the pump body, of the repair hole, and the end cover is pressed on the outer flange and is arranged in a way of being fixedly connected with screw bolts arranged between the pump walls of the pump body. The convenient-to-dismount diaphragm pump has the advantages that the monitoring and dismounting problems of the exiting conventional diaphragm pump can be effectively solved, the dismounting convenience and the maintenance replacement efficiency are high, and the work intensity of maintenance personnel can be greatly reduced.

Owner:HEFEI UNIV OF TECH +1

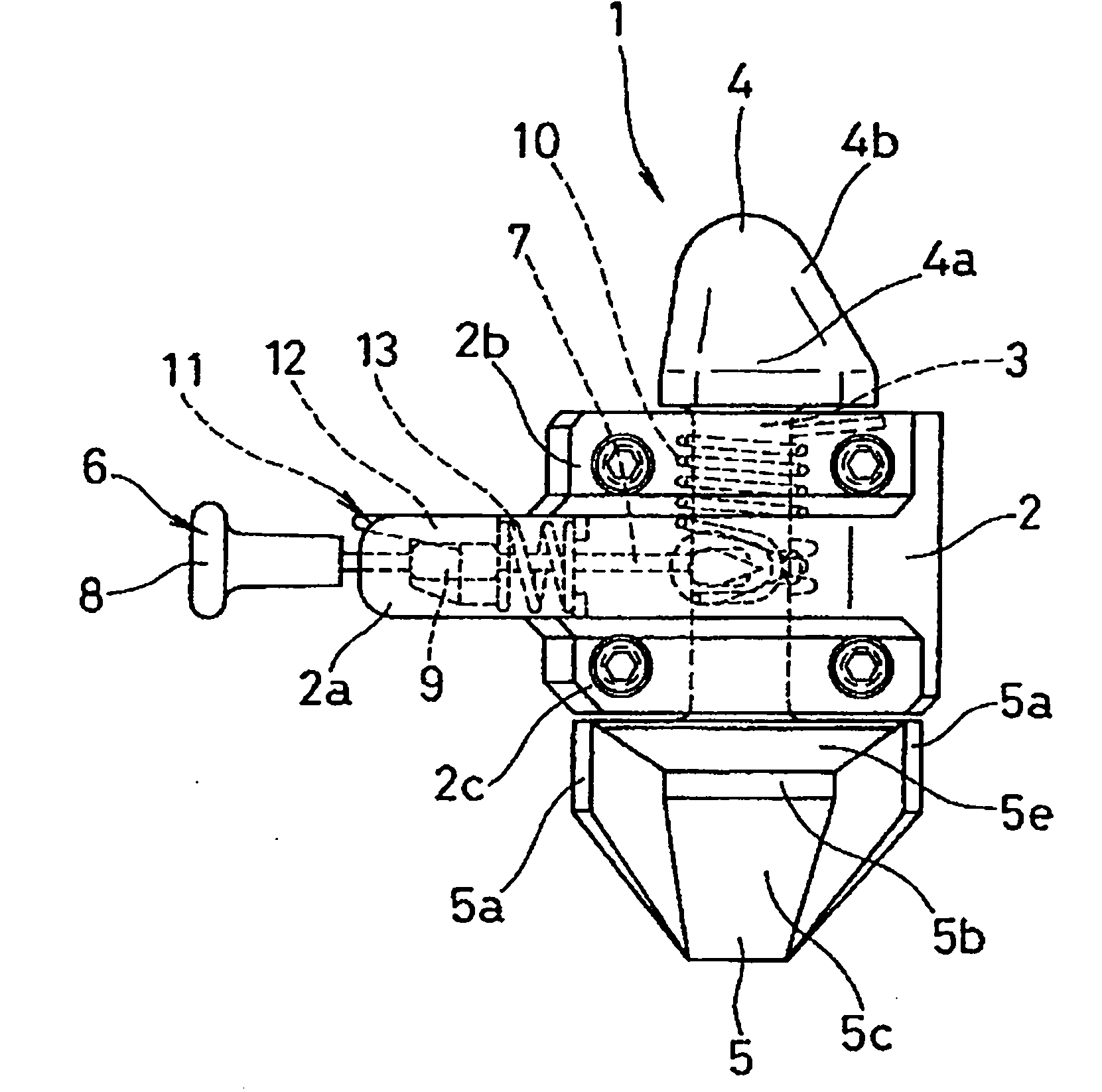

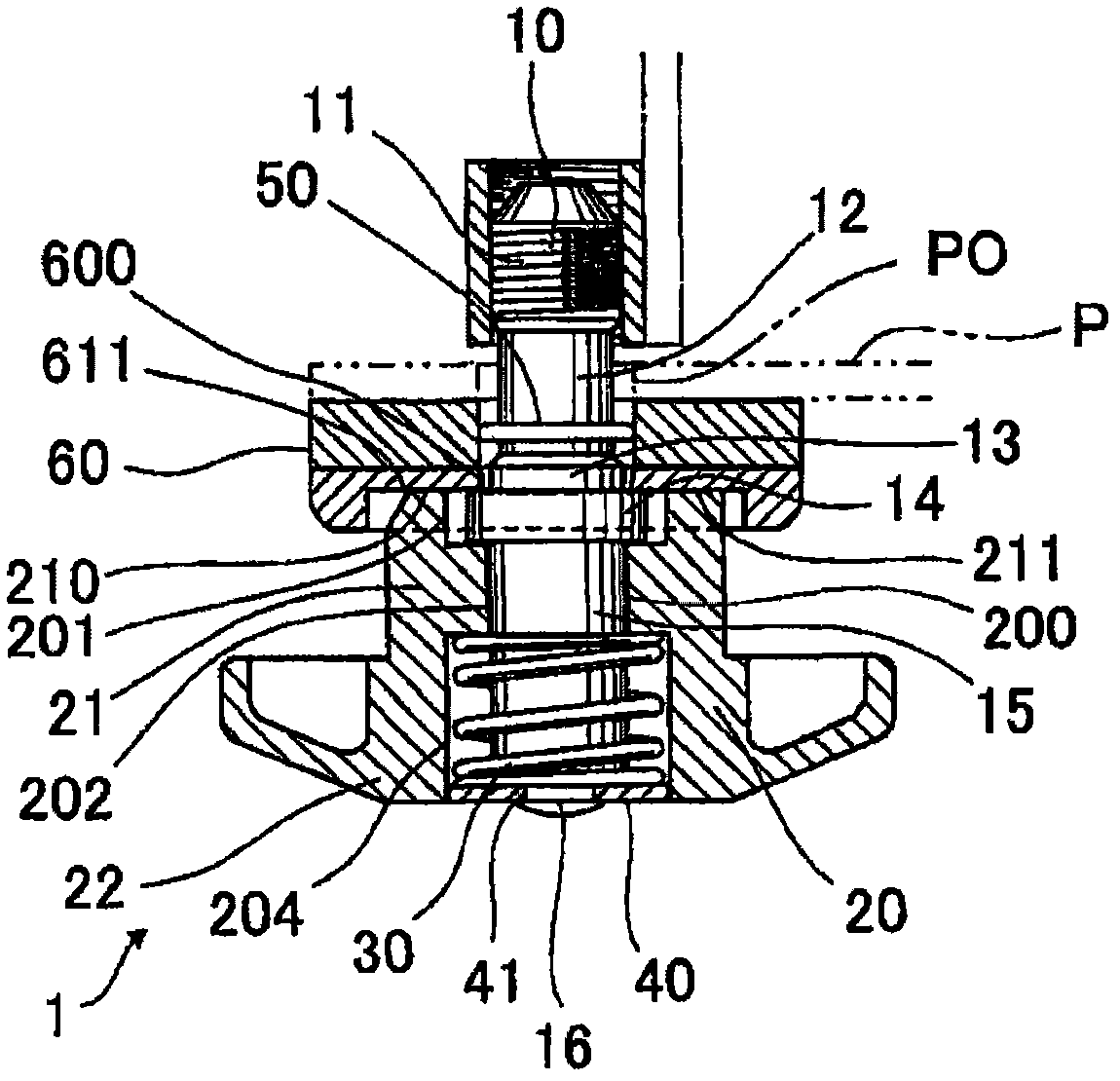

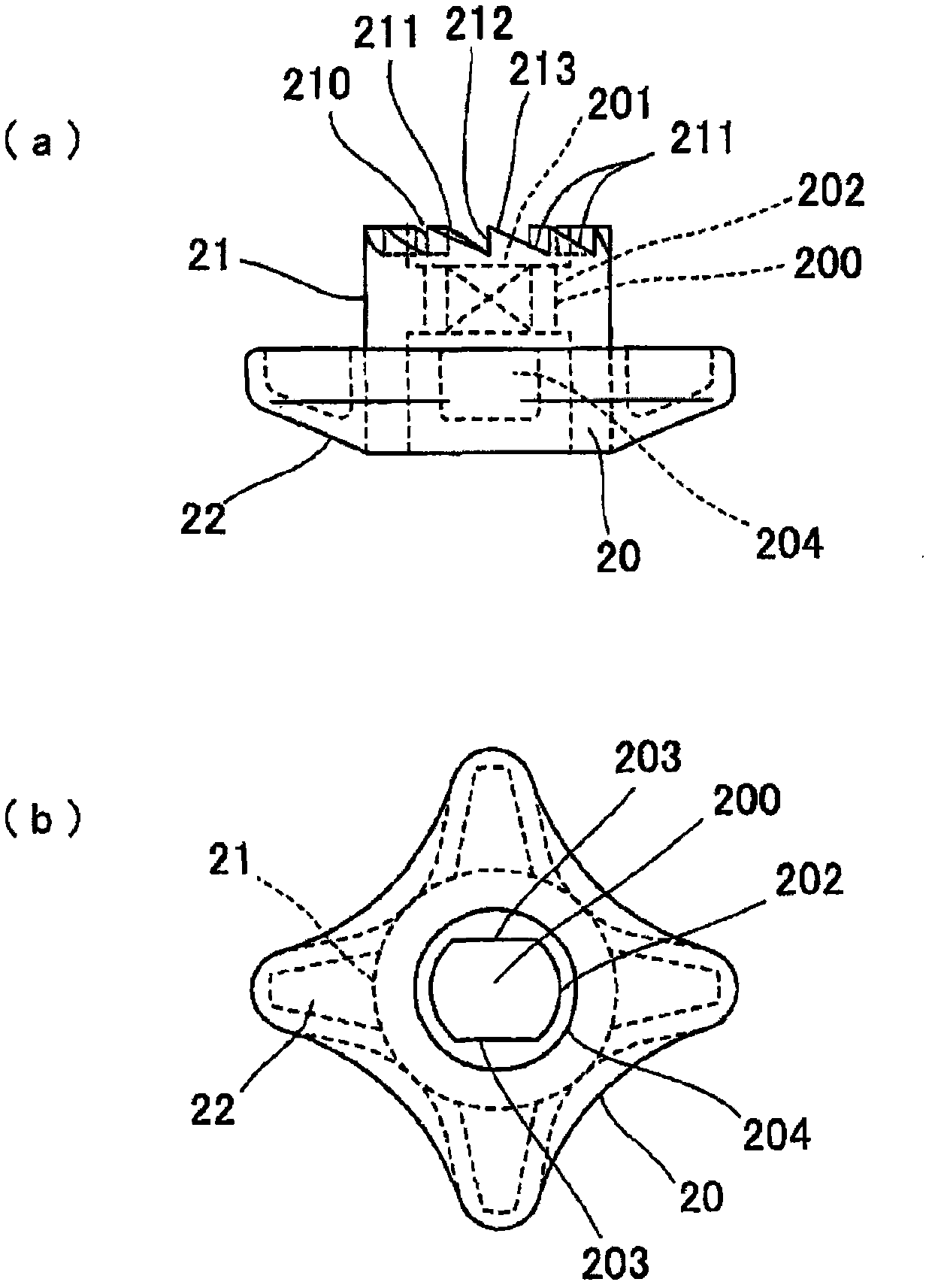

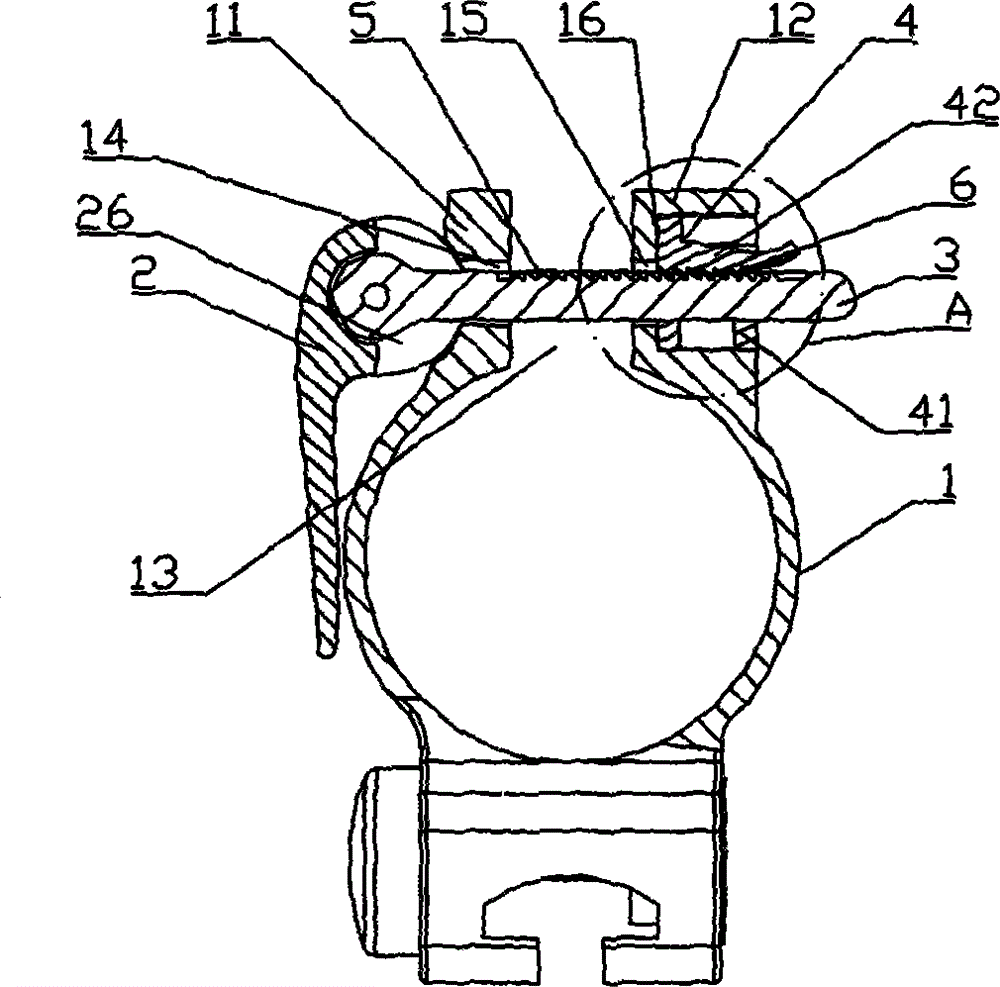

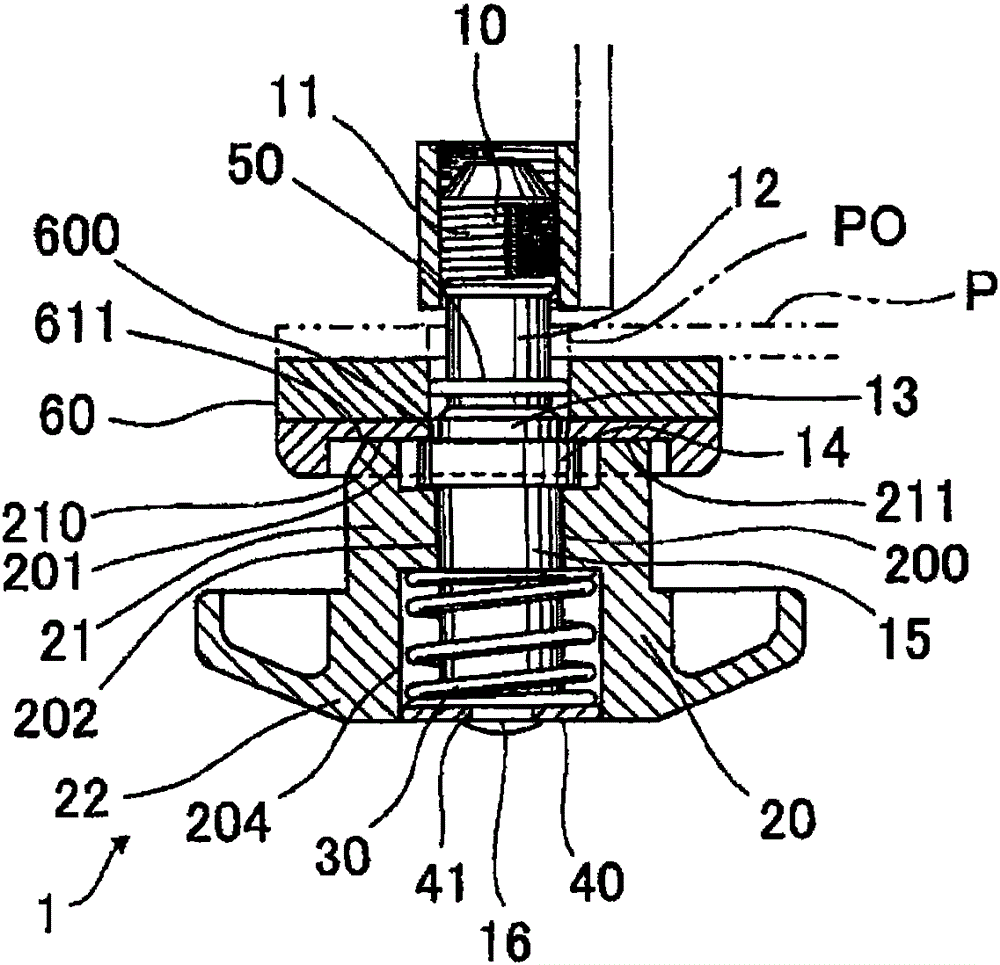

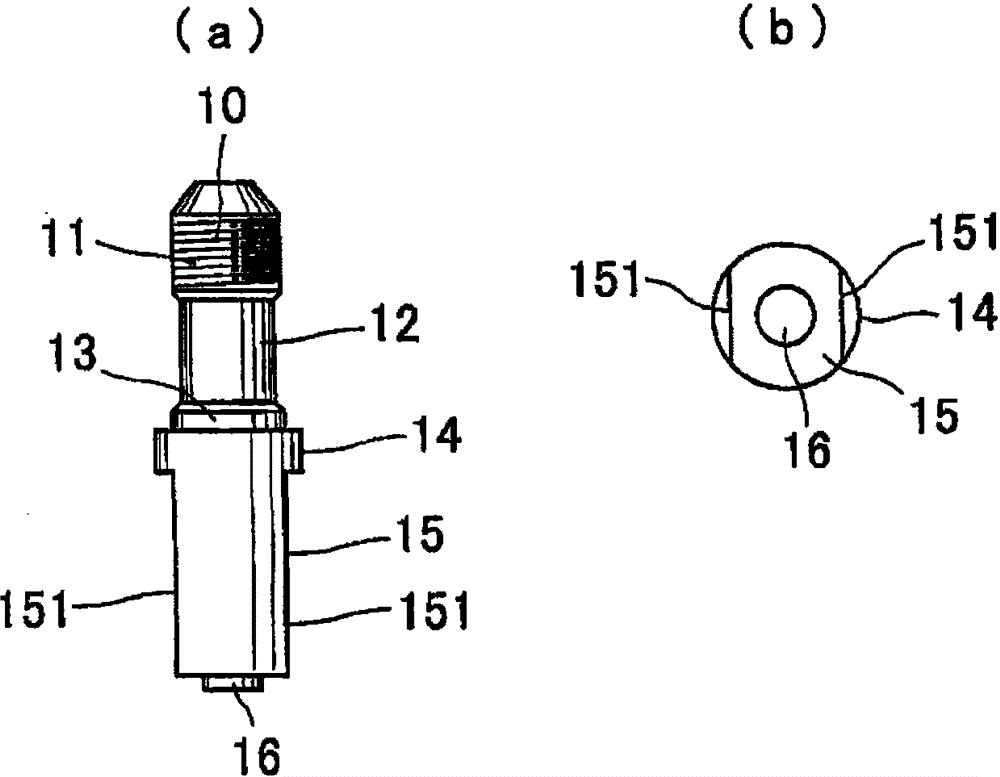

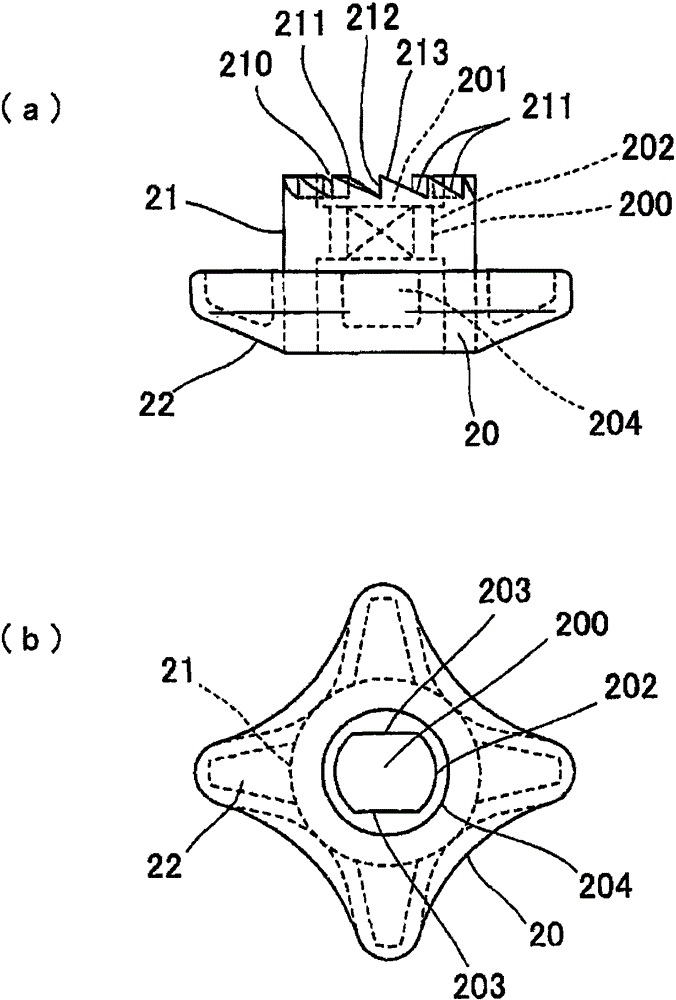

Bolt having a rotation preventing mechanism

This invention provides a bolt difficult to be loosened, and capable of maintaining a stable tightening force over a long period. The bolt 1 includes a shaft 10 having a male screw 11 in a front end side thereof, a head 20 attached on a base end side of the shaft 10 such that it is slidable on the shaft 10 in an axial direction and rotatable integrally with the shaft 10, and having teeth 211 on a seating surface 210 thereof, a spring 30 pressing and biasing the head 20 toward a tightened member P, and a detent base 60 fixed on the tightened member P and having a plurality of teeth 611, wherein the teeth 211 of the seating surface 210 of the head are pressed against and engaged with the teeth 611 of the detent base 60, so as to stop rotation of the shaft 10.

Owner:TAKIGEN MFG CO LTD

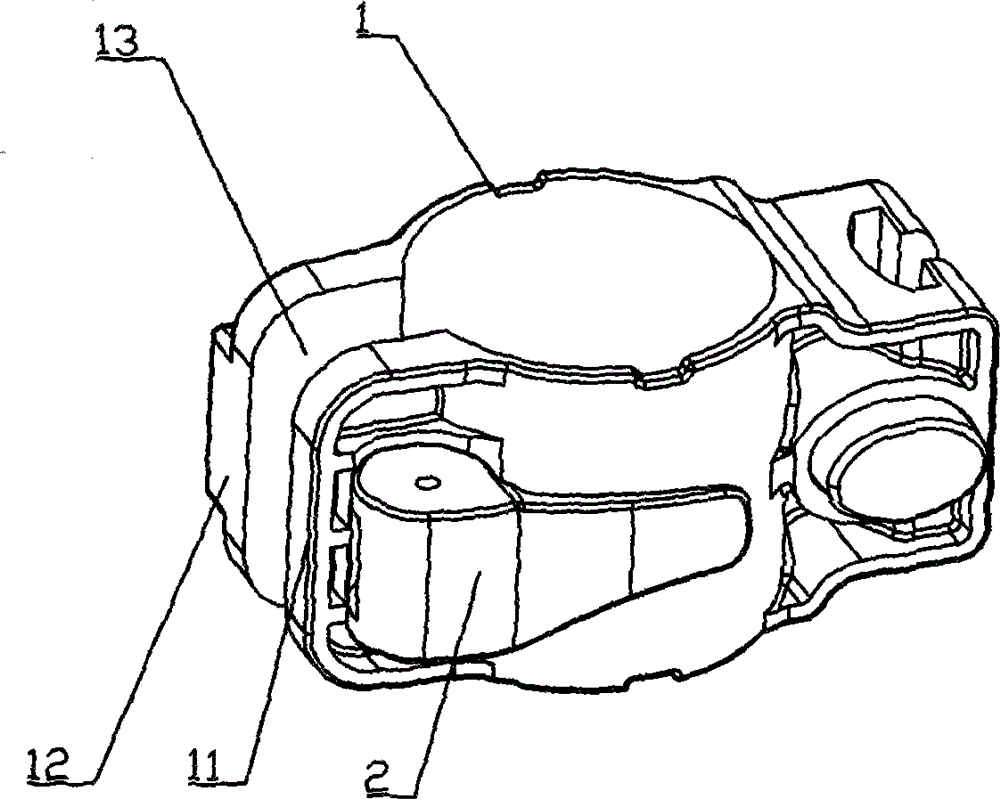

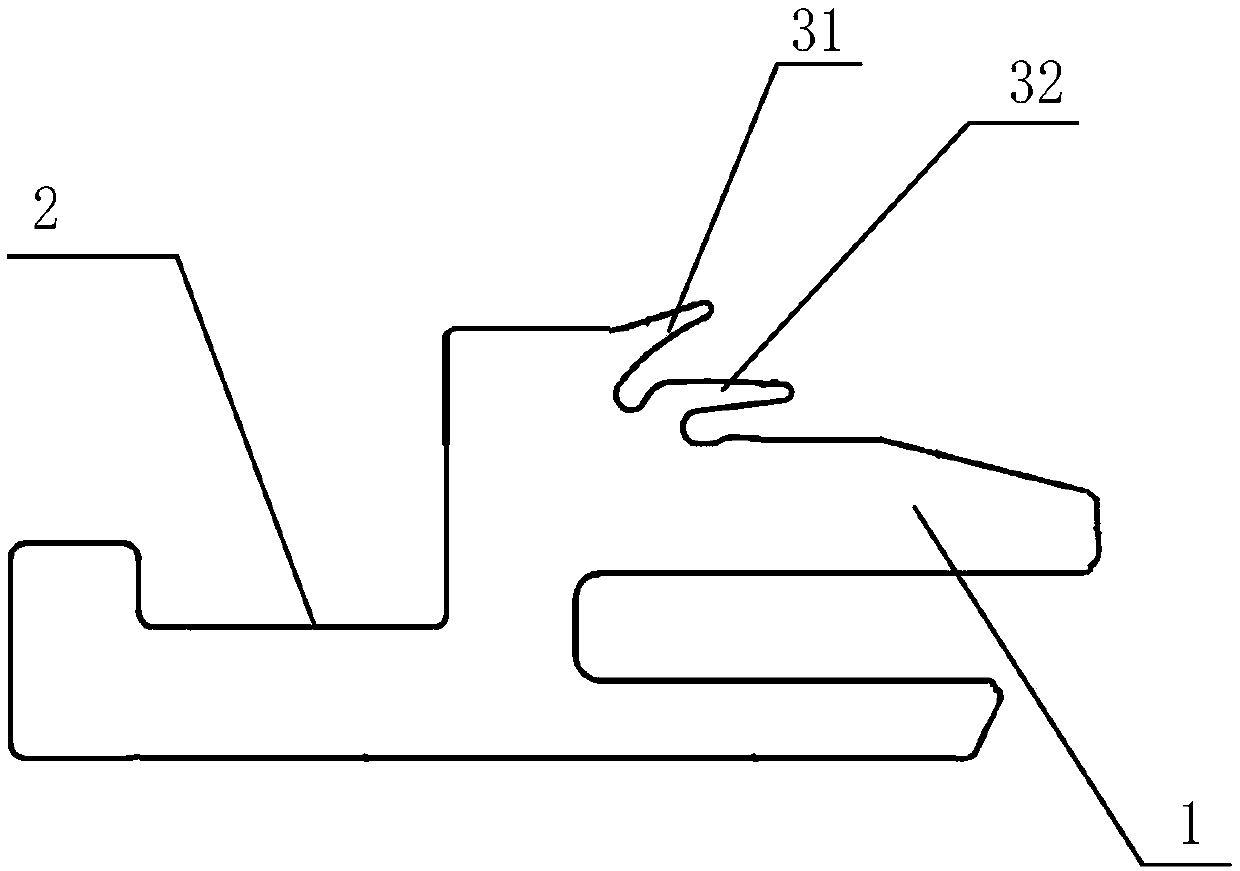

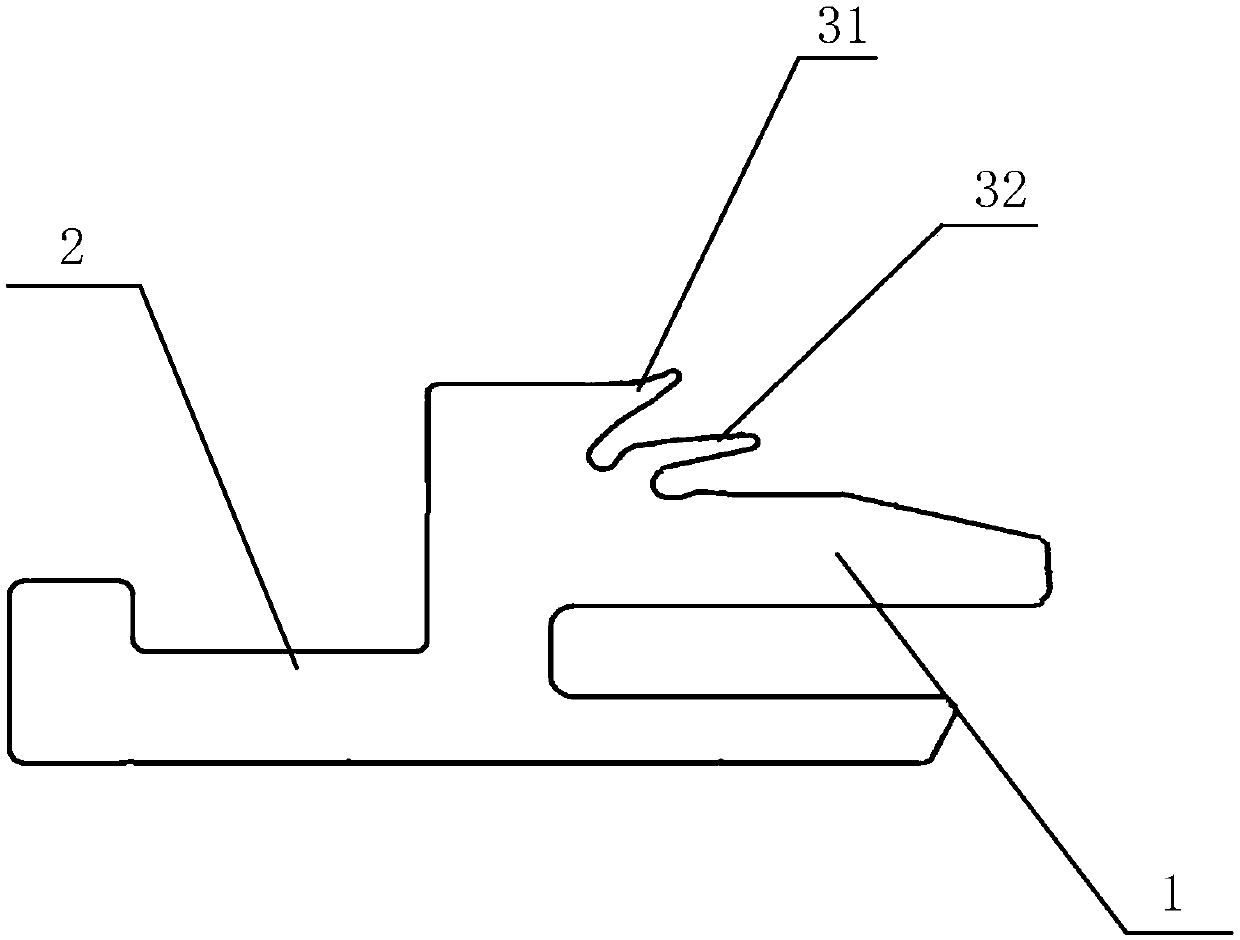

Fast mounting device

ActiveCN104564932AGuaranteed fastening forceEasy to assembleFriction grip releasable fasteningsMechanical engineeringEngineering

The invention discloses a fast mounting device which can be quickly assembled. The fast mounting device comprises a bundle coil, wherein a first lug and a second lug are arranged on the bundle coil; a notch is arranged between the first lug and the second lug on the bundle coil; a first through hole is formed in the first lug and a second through hole is formed in the second lug; a pull rod passes through the first and second through holes, one end of the pull rod is hinged with an eccentric wheel part of a handle, a buckle sleeves the pull rod, and leans against the outer periphery of the second through hole; a plurality of lower gears are arranged on the pull rod, a tongue is arranged on the buckle, an engaging part is arranged on the tongue, the engaging part on the tongue is engaged with the lower gears, and the lower gears are hooked by the engaging part when then pull rod moves in the direction of the handle.

Owner:WENZHOU JINJIAN INTELLIGENT LOCK CO LTD

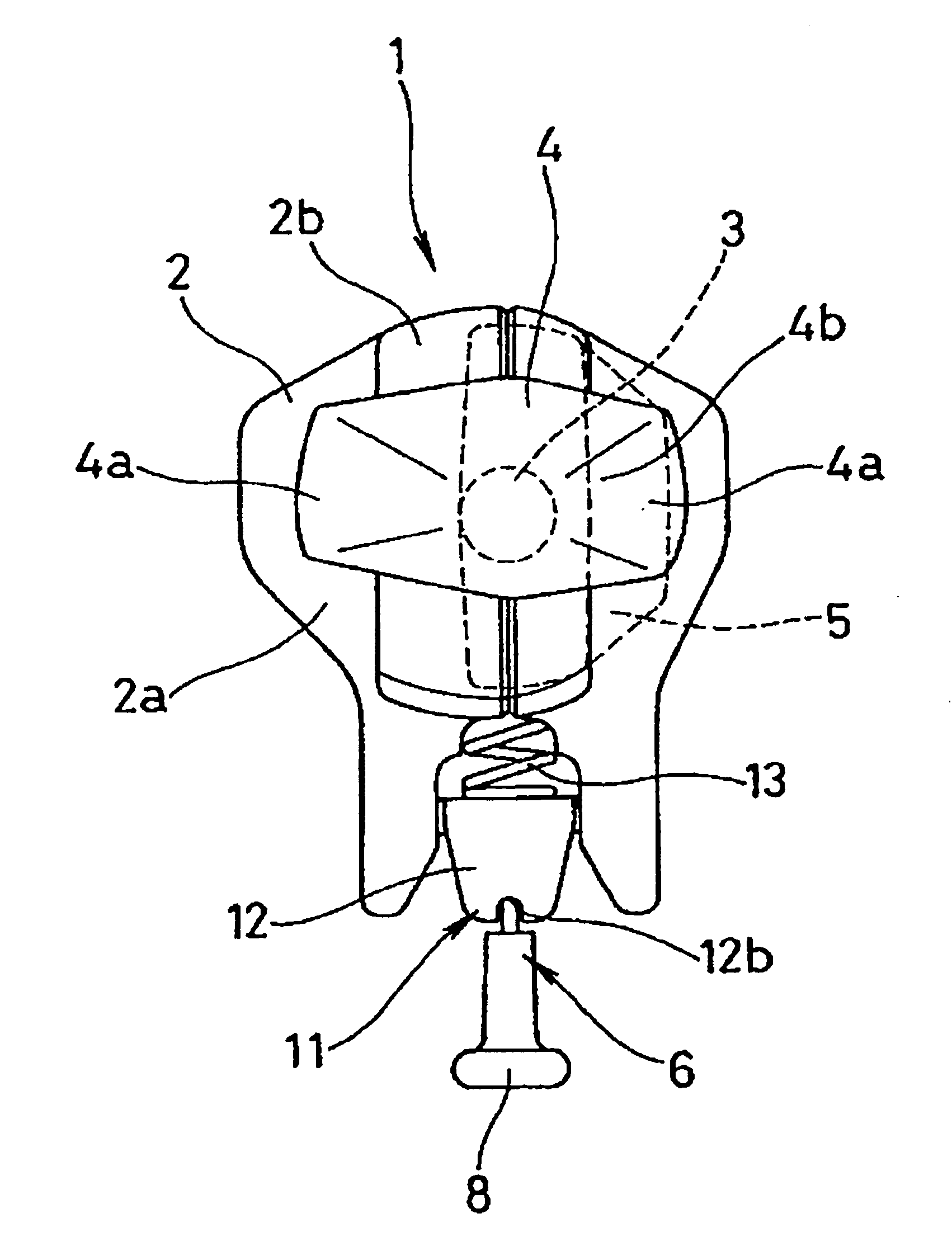

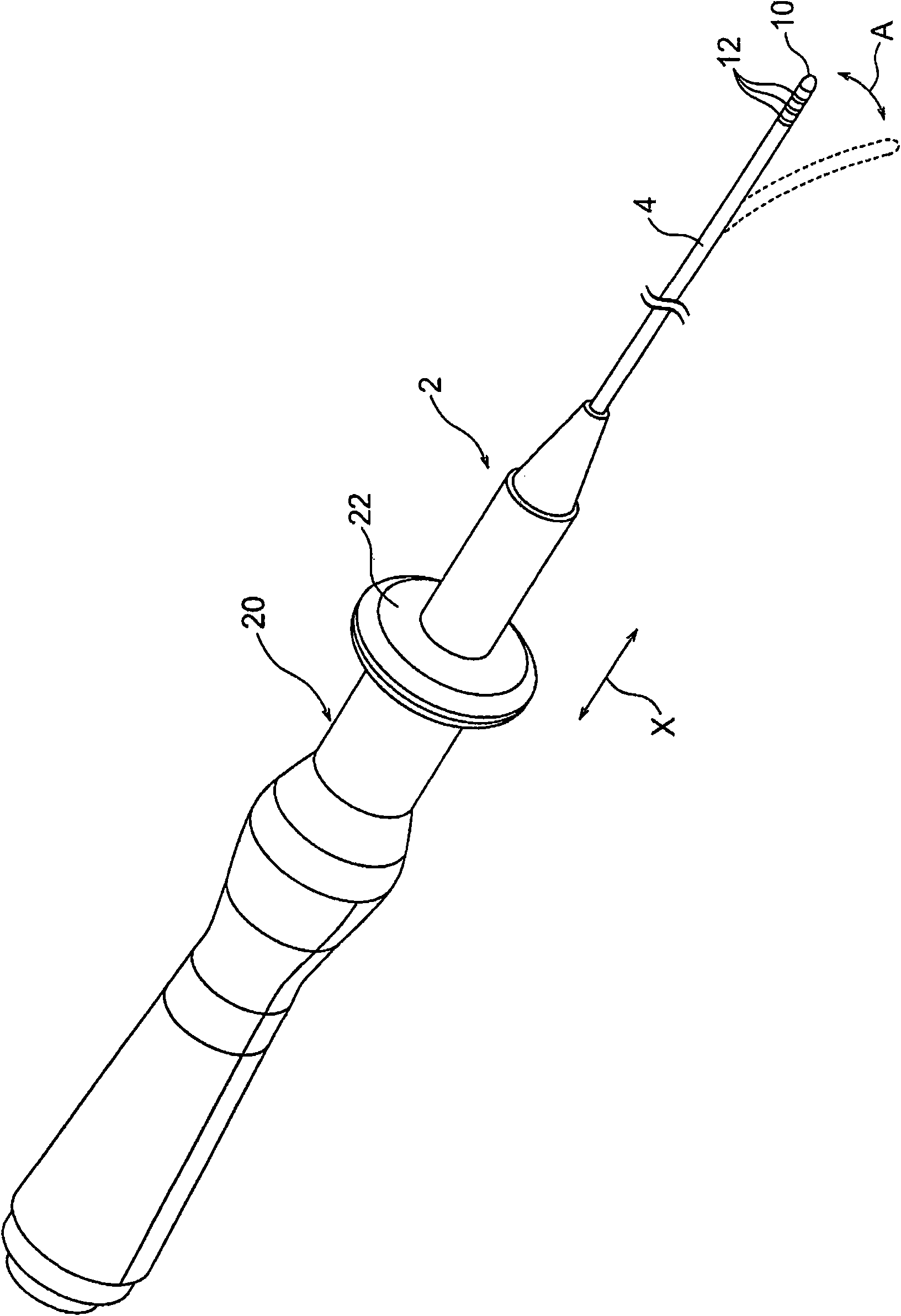

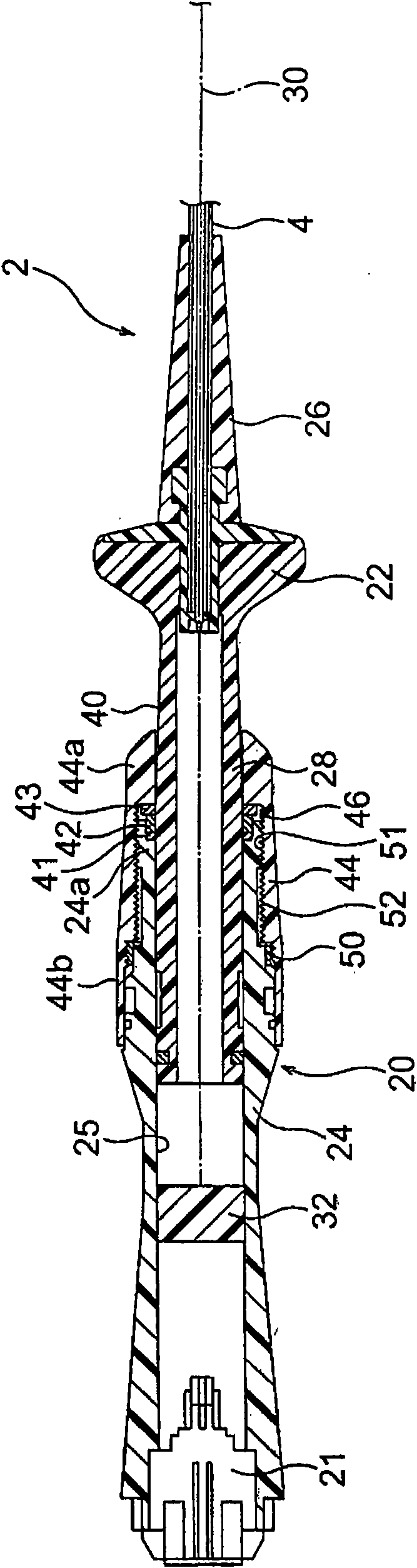

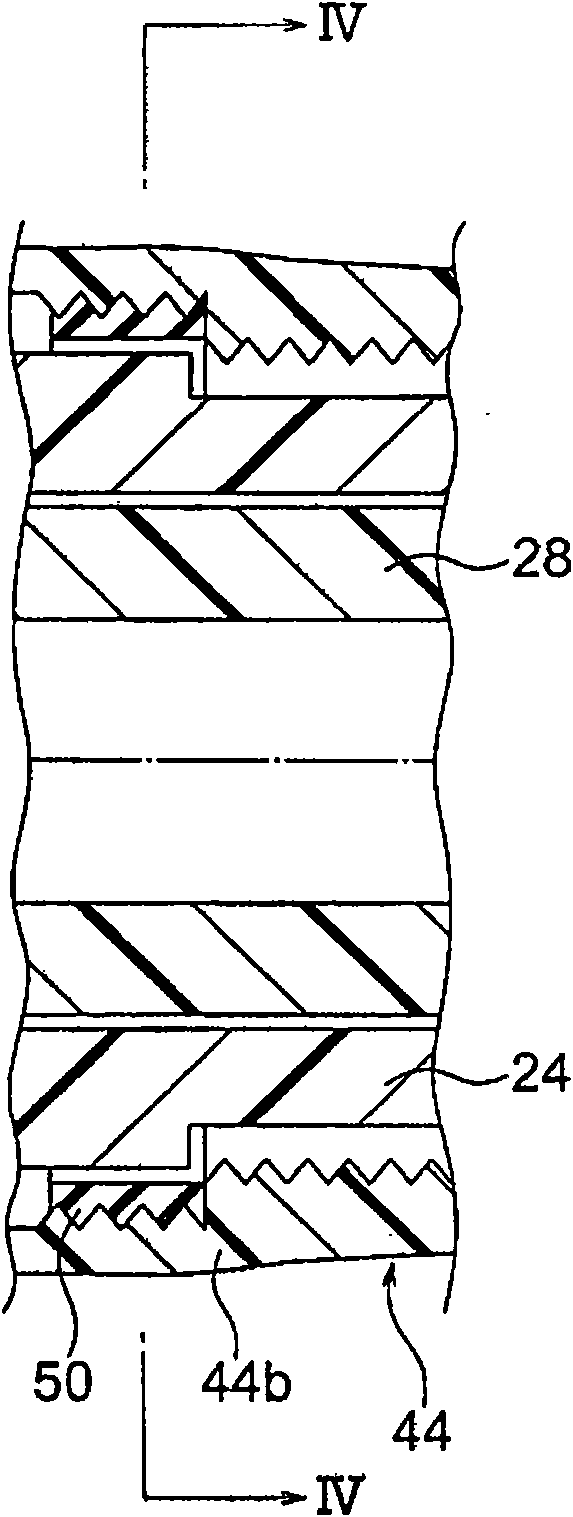

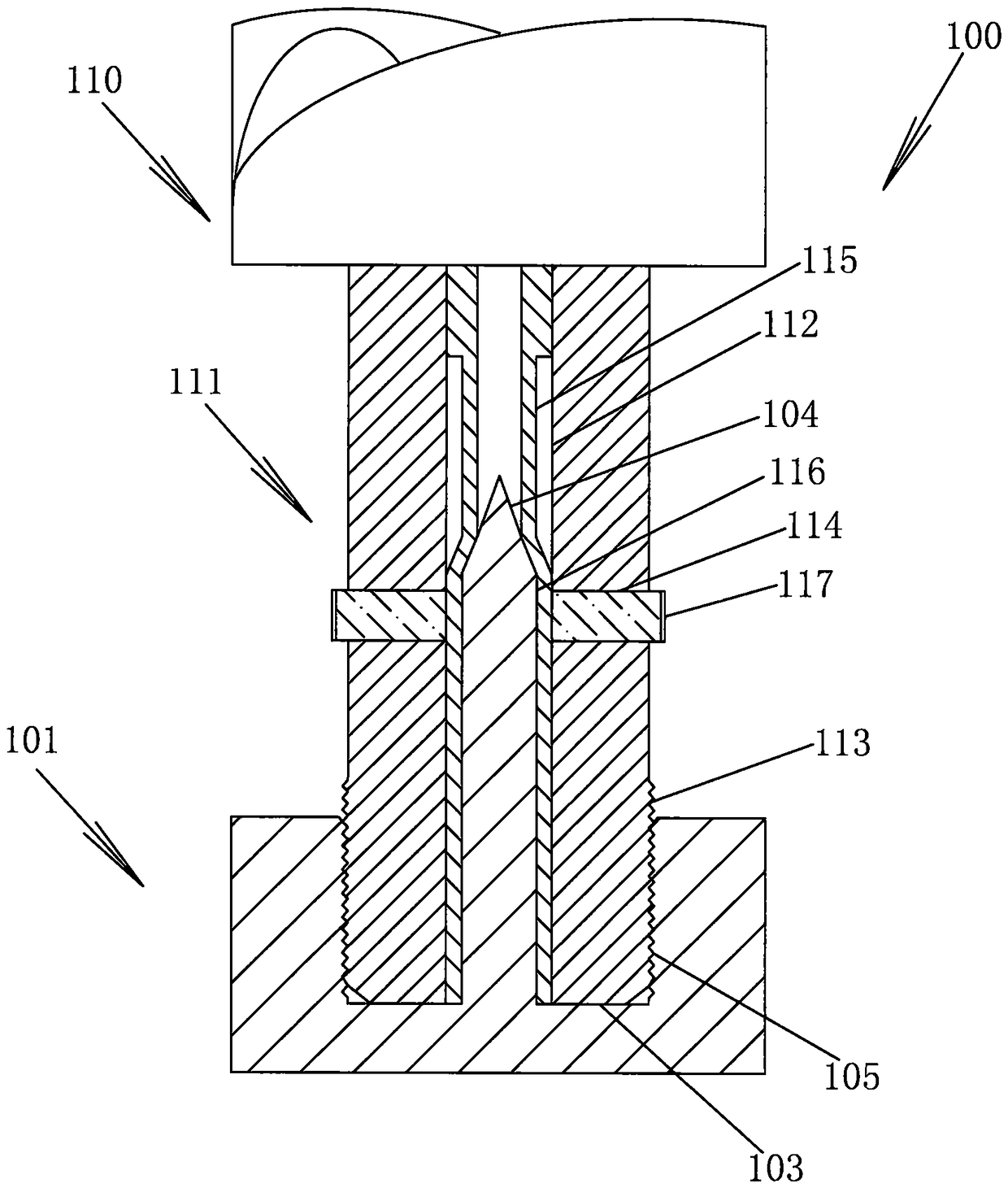

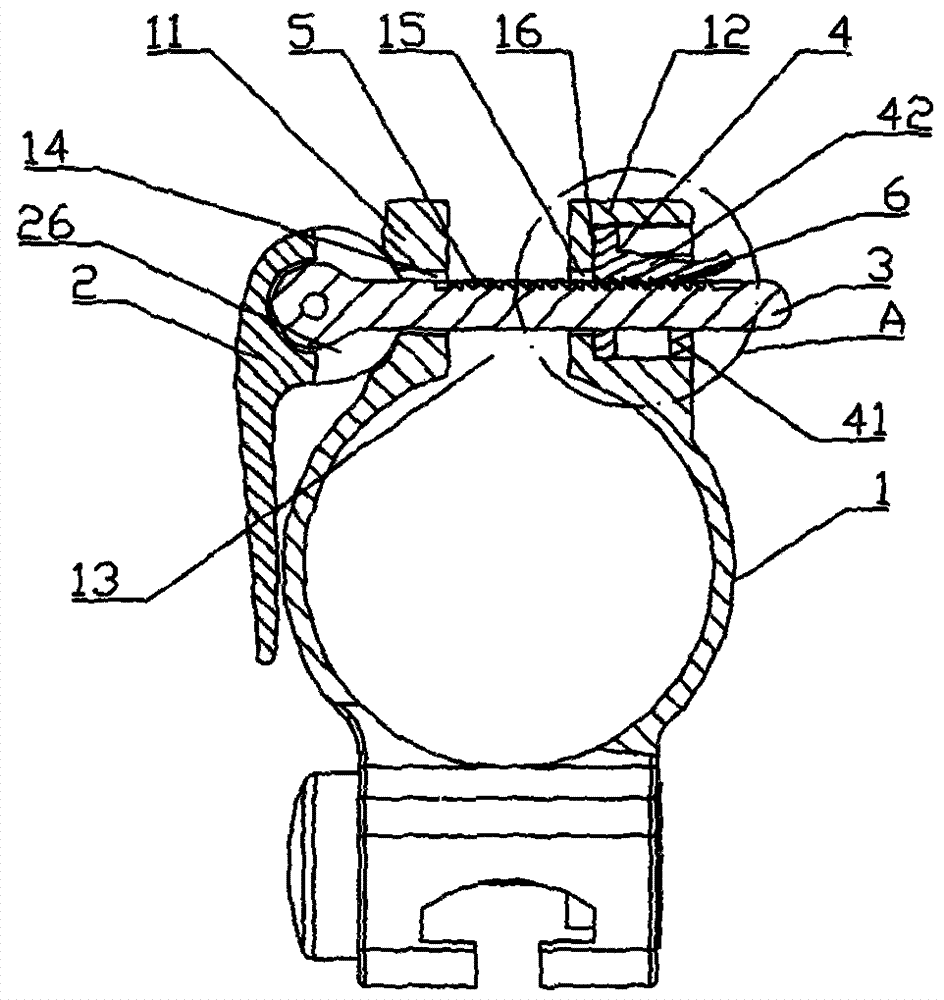

Handle for pipes

InactiveCN101584907AAdjust the tightening forceGuaranteed fastening forceCatheterDiagnostic recording/measuringRadial positionEngineering

The invention provides a handle for pipes, wherein an operation part can be easily stopped at any radial position, the operation force of the operation part can be in fine adjustment, and the ageing of fastening force is little changed once the fastening force is set. The handle for pipes has: a handle body (24); an button for operation (22) having a medial axle part (28) moved along the axial direction and freely installed in the axle hole of the handle body (24); a front end cover (44) positioned at the periphery of the medial axle part (28), freely moved along the axial direction, and rotationally bolt-jointed with the far end of the handle body (24) surrounding the axle core; an annular elastic component (42) between the far end of the handle body (24) and the far end of the front end cover (44) and positioned at the inner periphery of the front end cover (44) and the outer periphery of the medial axle part (28), in which the fastening force at the outer periphery of the medial axle part (28) is changed according to the axial bolt-jointed position relative to the front end cover (44) of the handle body (24); and ratchet feel endowing mechanisms (50, 54) installed between the front end cover (44) and the handle body (24) and endowing the ratchet feel according to the rotational pitch angle (theta).

Owner:JAPAN LIFELINE CO LTD

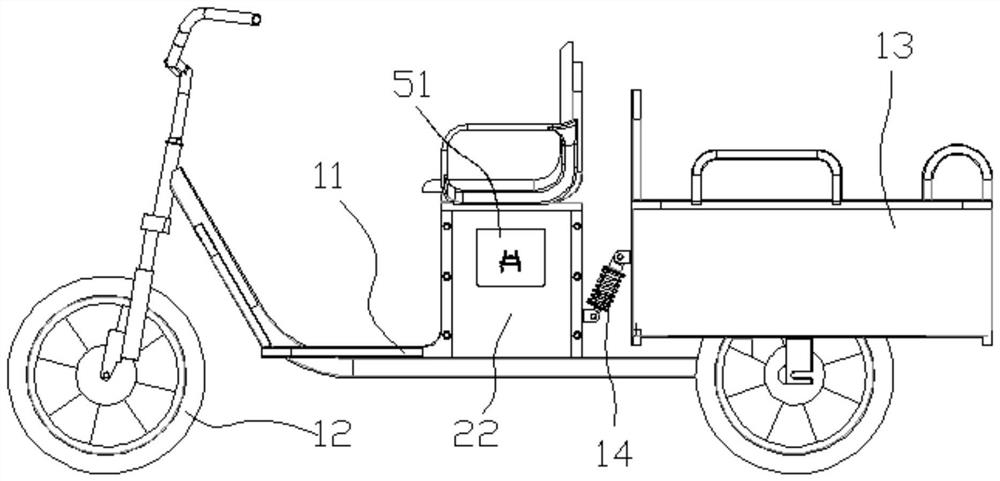

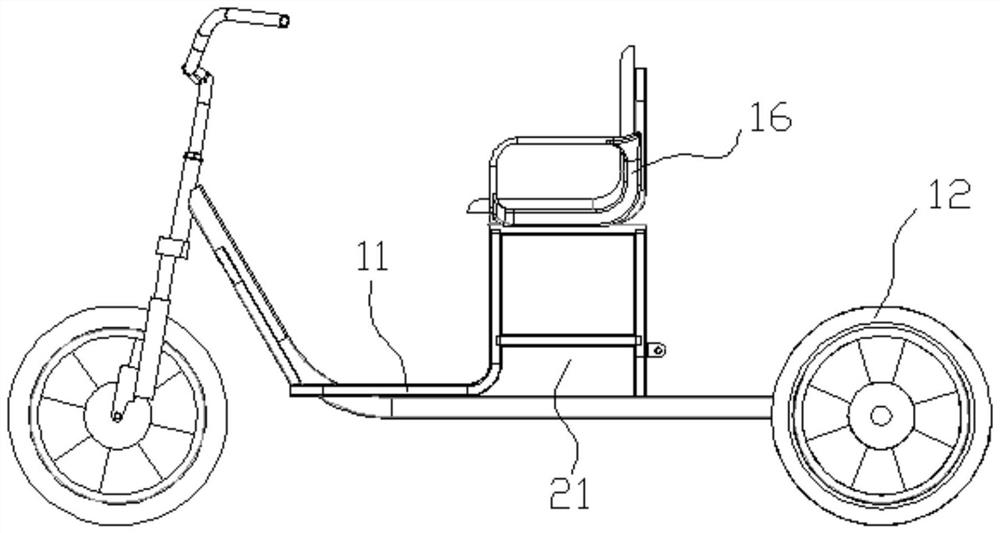

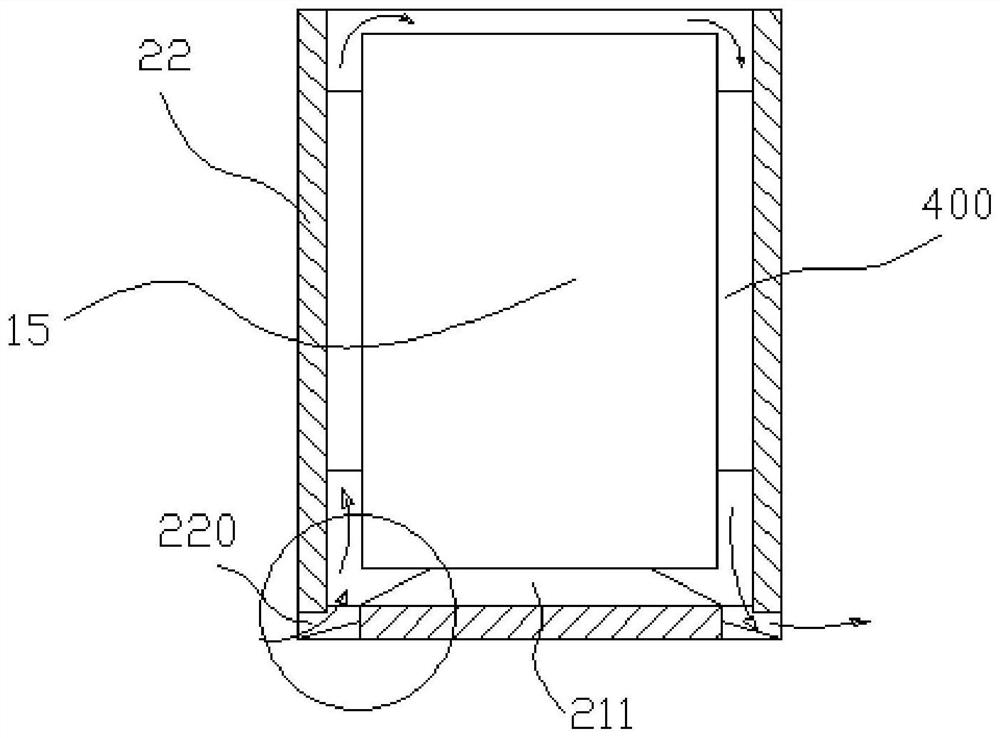

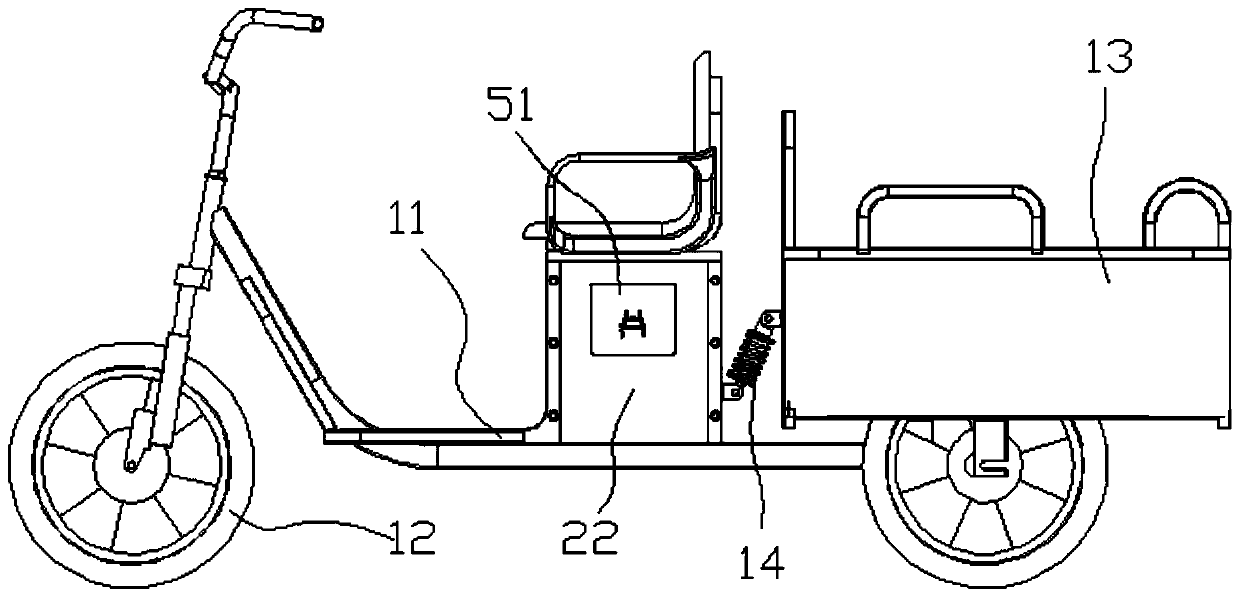

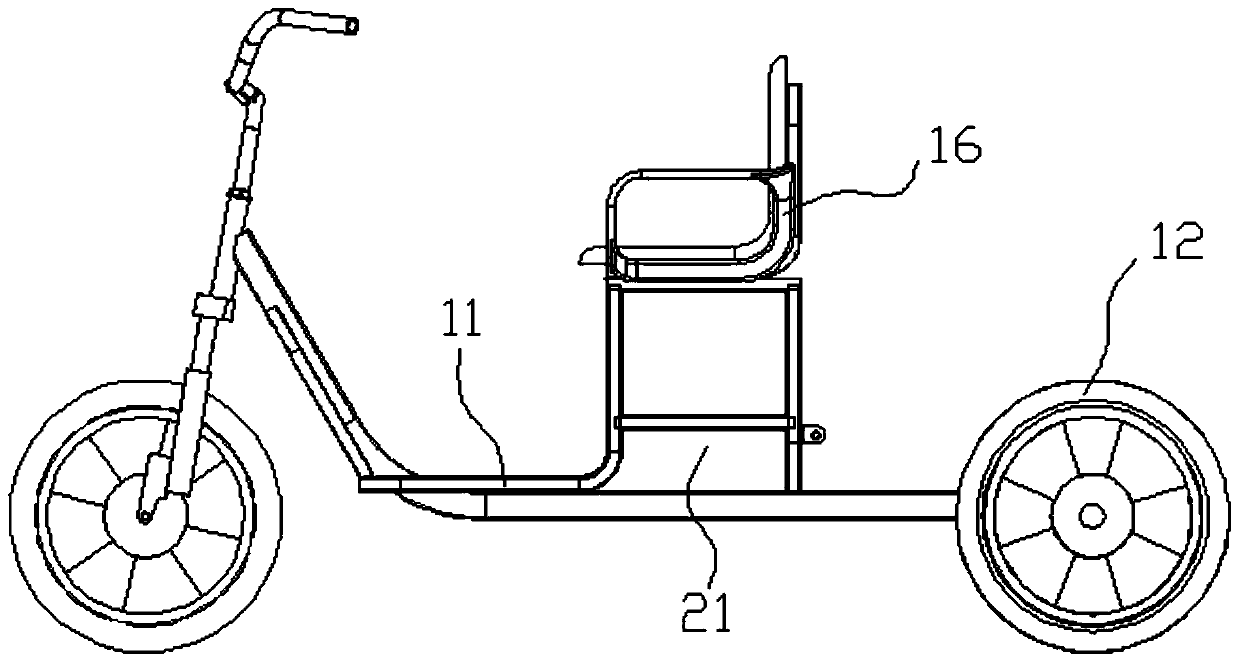

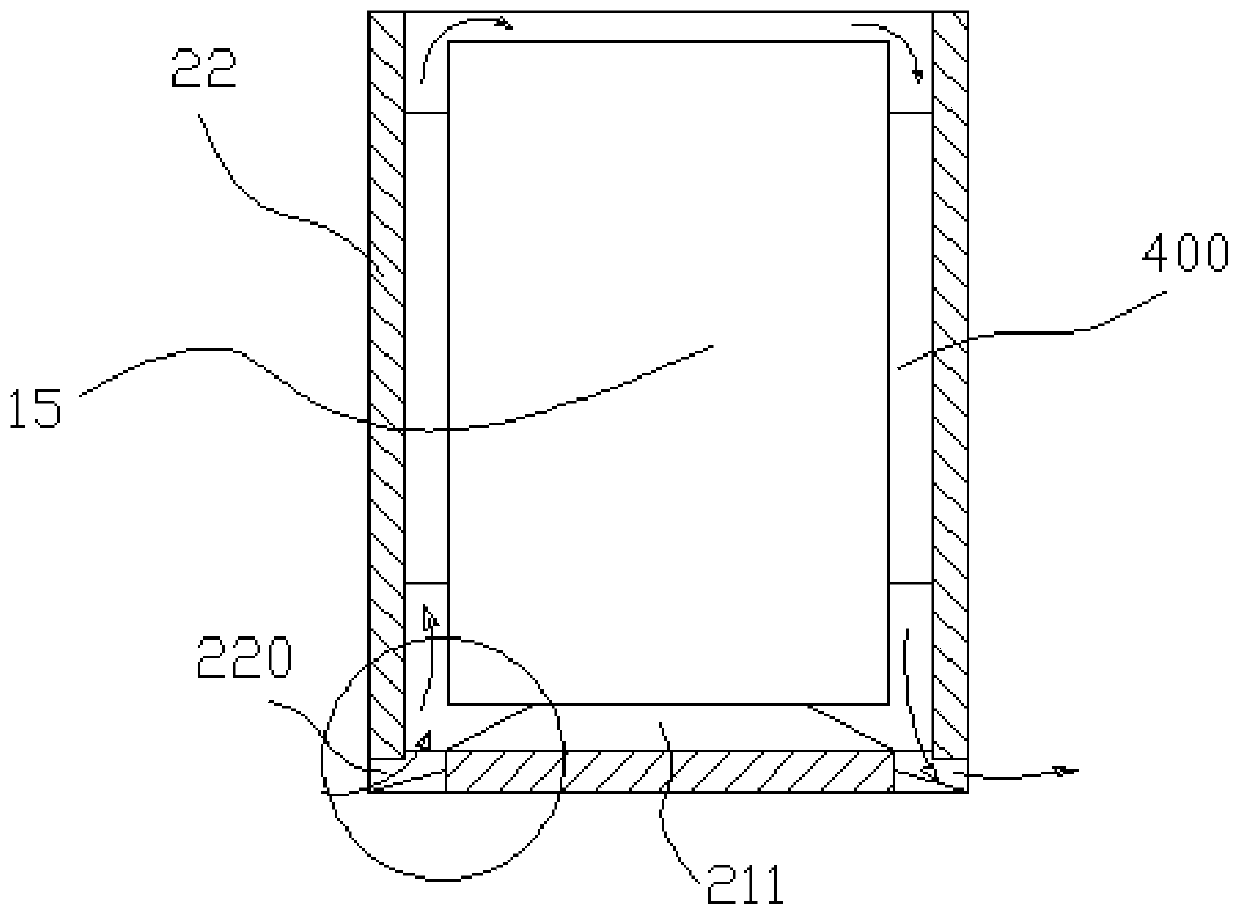

An electric tricycle structure

ActiveCN110834694BAdequate heat dissipationIncrease cooling areaCyclesSecondary cellsEngineeringMechanical engineering

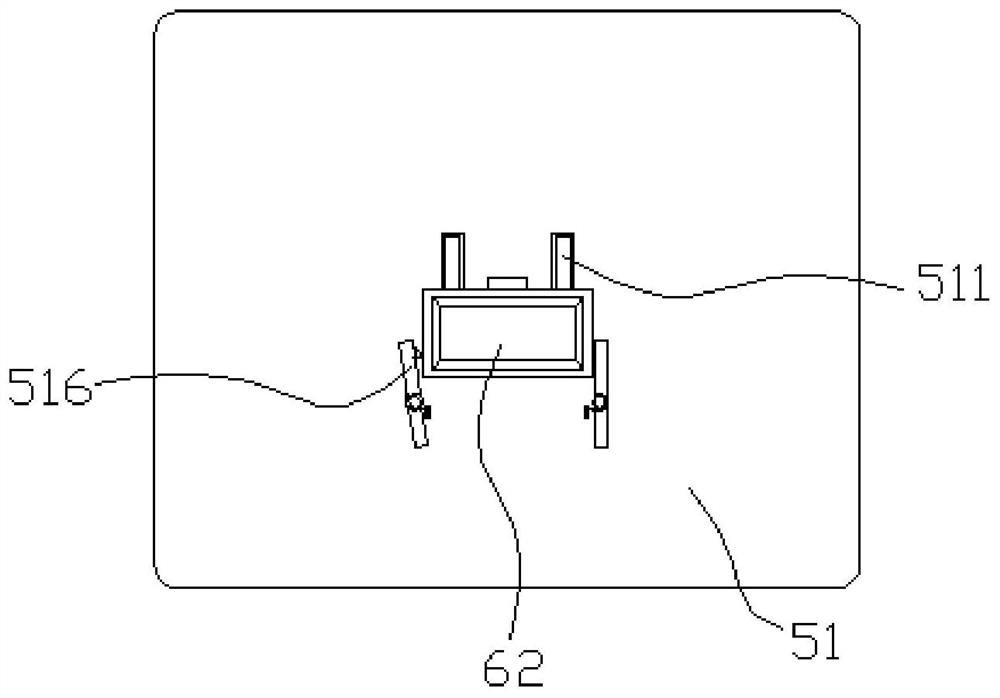

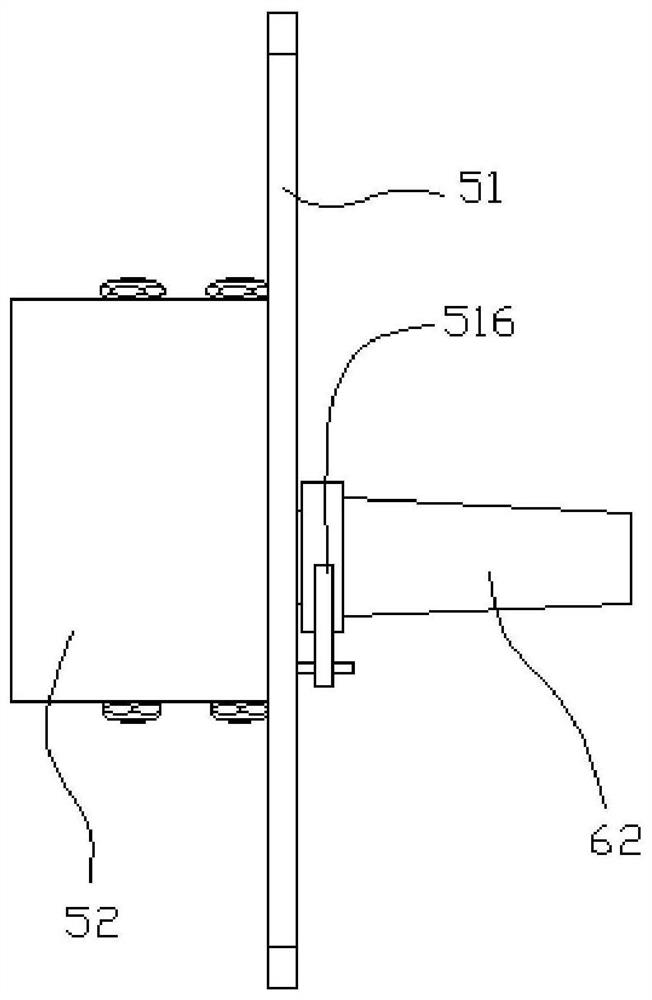

The invention discloses an electric tricycle structure. When the structure is used, heat dissipation holes communicate with heat dissipation gaps to form convection current, so that more sufficient heat dissipation is achieved for a battery pack, and the heat dissipation area is wider; the heat dissipation holes are formed in rectangular plates of the front end face and the rear end face of a rectangular frame, in the running process of a tricycle, the heat dissipation holes are windward, the heat dissipation holes on the two side faces form the convection current, and better heat dissipationis facilitated; inserting pieces are inserted from the parts above inserting grooves, at the moment, the inserting pieces are not in contact with an electrical contact, then the inserting pieces slidedown in the inserting grooves 511 until the inserting pieces abut against the bottom surfaces of the inserting grooves, and at the moment, the inserting pieces are just clamped between two contact blocks in the electrical contact; and the contact blocks tightly abut against the inserting pieces of a socket, so that the inserting pieces are prevented from falling off.

Owner:丰县杰兰特电动车有限公司

A detachable diaphragm pump

ActiveCN104358675BStrong resistance to tensile fatigueStrong expansion efficiencyPositive displacement pump componentsFlexible member pumpsDiaphragm pumpEngineering

The invention belongs to the field of a volume pump, and particularly relates to a convenient-to-dismount diaphragm pump with the advantages that the monitoring can be realized in proper time, and a diaphragm leaf can be fast dismounted and replaced on line. The convenient-to-dismount diaphragm pump comprises a pump body and the diaphragm leaf, wherein liquid inlet and outlet holes and hydraulic holes are respectively formed in the pump wall of the pump body, a located pump cavity of the liquid inlet and outlet holes and a located pump cavity of the hydraulic holes are separated through the diaphragm leaf, the pump body also comprises a repair hole, the repair hole is sealed by an end cover, the appearance of the diaphragm leaf is of a sleeve-shaped structure, a pipe opening formed at one end of the diaphragm leaf is fixedly connected with the hole end surface of the hydraulic holes through screw bolts, a pipe opening formed in the other end of the diaphragm leaf extends towards the repair hole and is provided with an outer flange, the outer flange is arranged in a way of being matched with the surfaces between the hole ends, positioned at the outer wall parts of the the pump body, of the repair hole, and the end cover is pressed on the outer flange and is arranged in a way of being fixedly connected with screw bolts arranged between the pump walls of the pump body. The convenient-to-dismount diaphragm pump has the advantages that the monitoring and dismounting problems of the exiting conventional diaphragm pump can be effectively solved, the dismounting convenience and the maintenance replacement efficiency are high, and the work intensity of maintenance personnel can be greatly reduced.

Owner:HEFEI UNIV OF TECH +1

Fastening kits and combined extensions for fastening kits

ActiveCN105257669BCannot be removedGuaranteed fastening forceNutsBoltsThermal expansionFailure causes

A fastening kit comprises a bolt and a nut. The bolt comprises a head part and a screw. The screw comprises a first end fixedly connected with the head part, a second end connected with the nut in a threaded mode, and an elastic energy storage component combined with the two ends. A deformation structure corresponding to threaded connection acting force is formed on the portion, between the first end and the second end, of the elastic energy storage component. The fastening force of the fastening kit can be effectively maintained after screwing and fastening are achieved in place through elastic deformation of the fastening kit, and fastening failures caused by vibration, heat expansion and cold contract of the environment after fastening is achieved in place are counteracted. Meanwhile, the single-directional screwing-in structure of the head part of the bolt is matched with the smooth top of the nut so that the fastening structure can not be deconstructed, fastening reliability can be effectively improved, and the fastening kit can not be detached without a destructive means. The invention further provides a combined expanding device utilizing the fastening kit.

Owner:XUZHOU FANGBO ENVIRONMENTAL PROTECTION EQUIP

Sinker and socks with loose welts

PendingCN109610084ATo achieve the effect of "pull"Change performanceWeft knittingPanty-hoseYarnEngineering

The invention provides a sinker and socks with loose welts, which belong to the field of weaving. The socks with the loose welts comprise welt parts and sock cylinder parts, wherein a basic coil of each of the welt parts is formed by a ground yarn, a concave straight bar of each of the welt parts is formed by an auxiliary yarn, and an elastic yarn is woven into each of the basic coils at an interval of a preset line number of first basic coils; a basic coil of each of the sock cylinder parts is formed by a ground yarn, a concave straight bar of each of the sock cylinder parts is formed by an auxiliary yarn, and an elastic yarn is woven into each of the basic coils at an interval of a preset line number of second basic coils; the line number of the second basic coils is less than that of the first basic coils. In the socks with the loose welts, which are provided by the invention, a structure that the elastic yarn is woven into the basic coils at an interval of a certain line number ofthe basic coils is adopted in each of the welt parts, so that a user can wear the socks comfortably on the premise of ensuring certain fastening force.

Owner:ZHEJIANG HUAER TEXTILE TECH

Electric tricycle structure

ActiveCN110834694AAdequate heat dissipationIncrease cooling areaCyclesSecondary cellsMechanical engineeringBattery pack

The invention discloses an electric tricycle structure. When the structure is used, heat dissipation holes communicate with heat dissipation gaps to form convection current, so that more sufficient heat dissipation is achieved for a battery pack, and the heat dissipation area is wider; the heat dissipation holes are formed in rectangular plates of the front end face and the rear end face of a rectangular frame, in the running process of a tricycle, the heat dissipation holes are windward, the heat dissipation holes on the two side faces form the convection current, and better heat dissipationis facilitated; inserting pieces are inserted from the parts above inserting grooves, at the moment, the inserting pieces are not in contact with an electrical contact, then the inserting pieces slidedown in the inserting grooves 511 until the inserting pieces abut against the bottom surfaces of the inserting grooves, and at the moment, the inserting pieces are just clamped between two contact blocks in the electrical contact; and the contact blocks tightly abut against the inserting pieces of a socket, so that the inserting pieces are prevented from falling off.

Owner:丰县杰兰特电动车有限公司

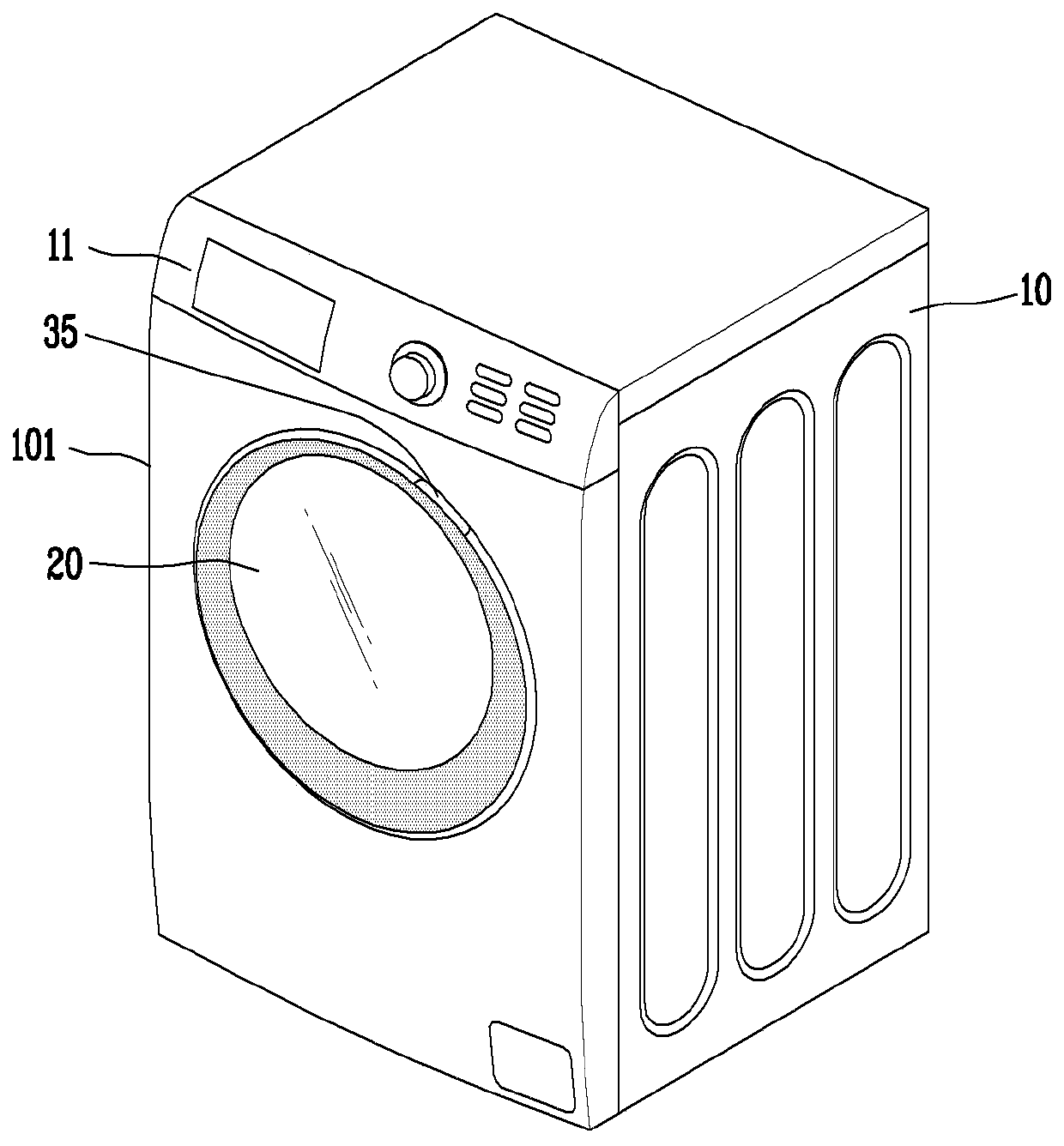

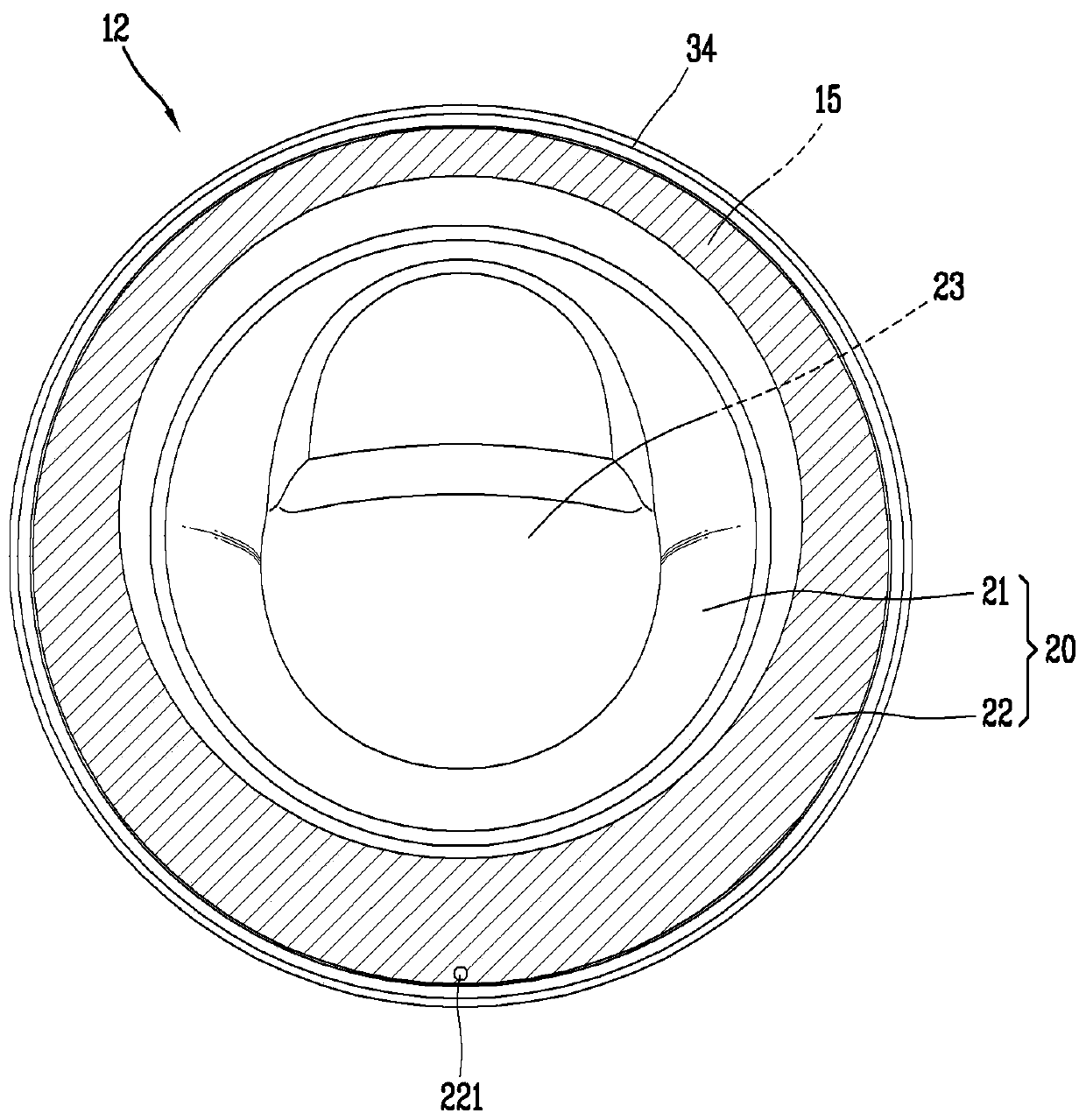

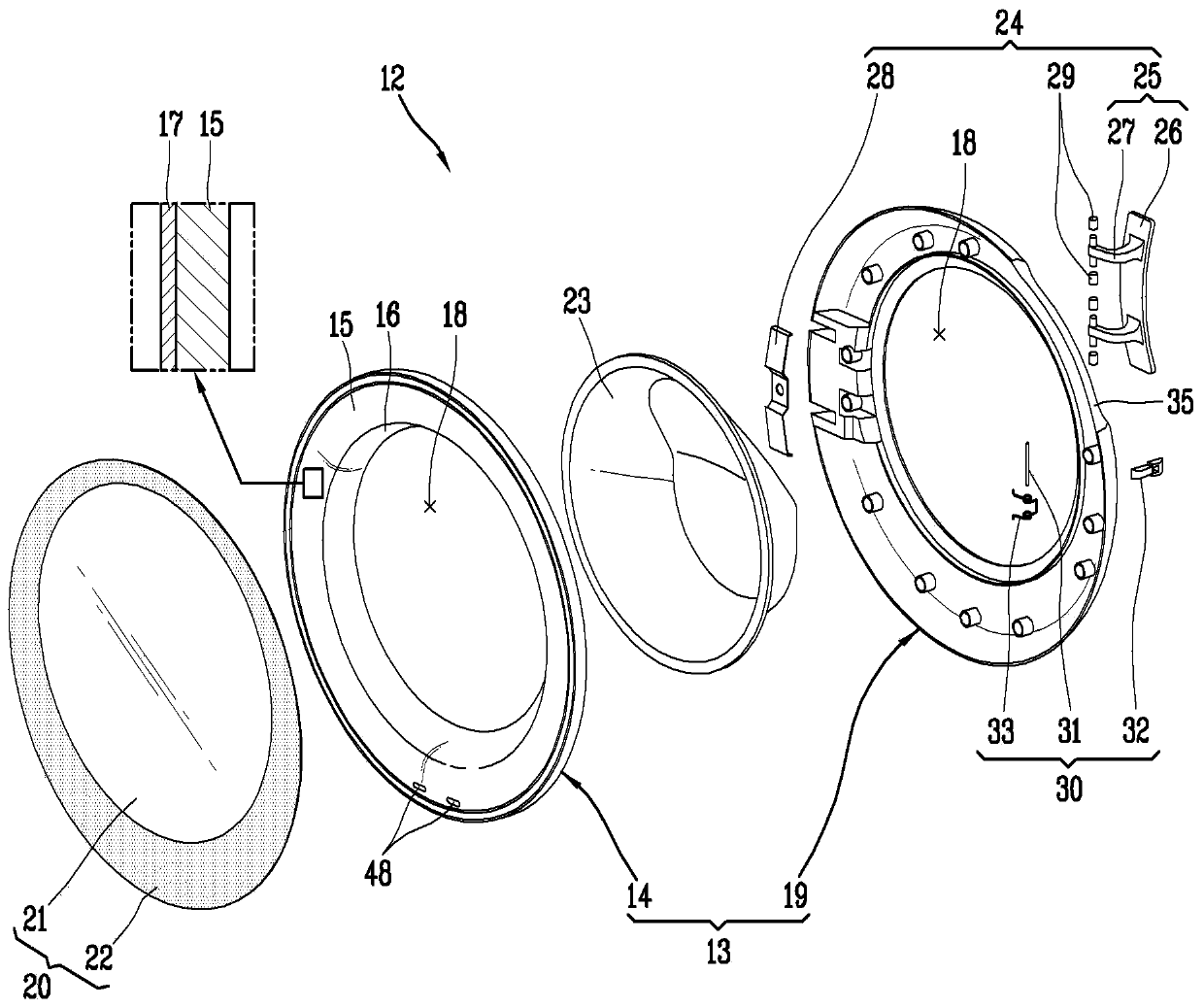

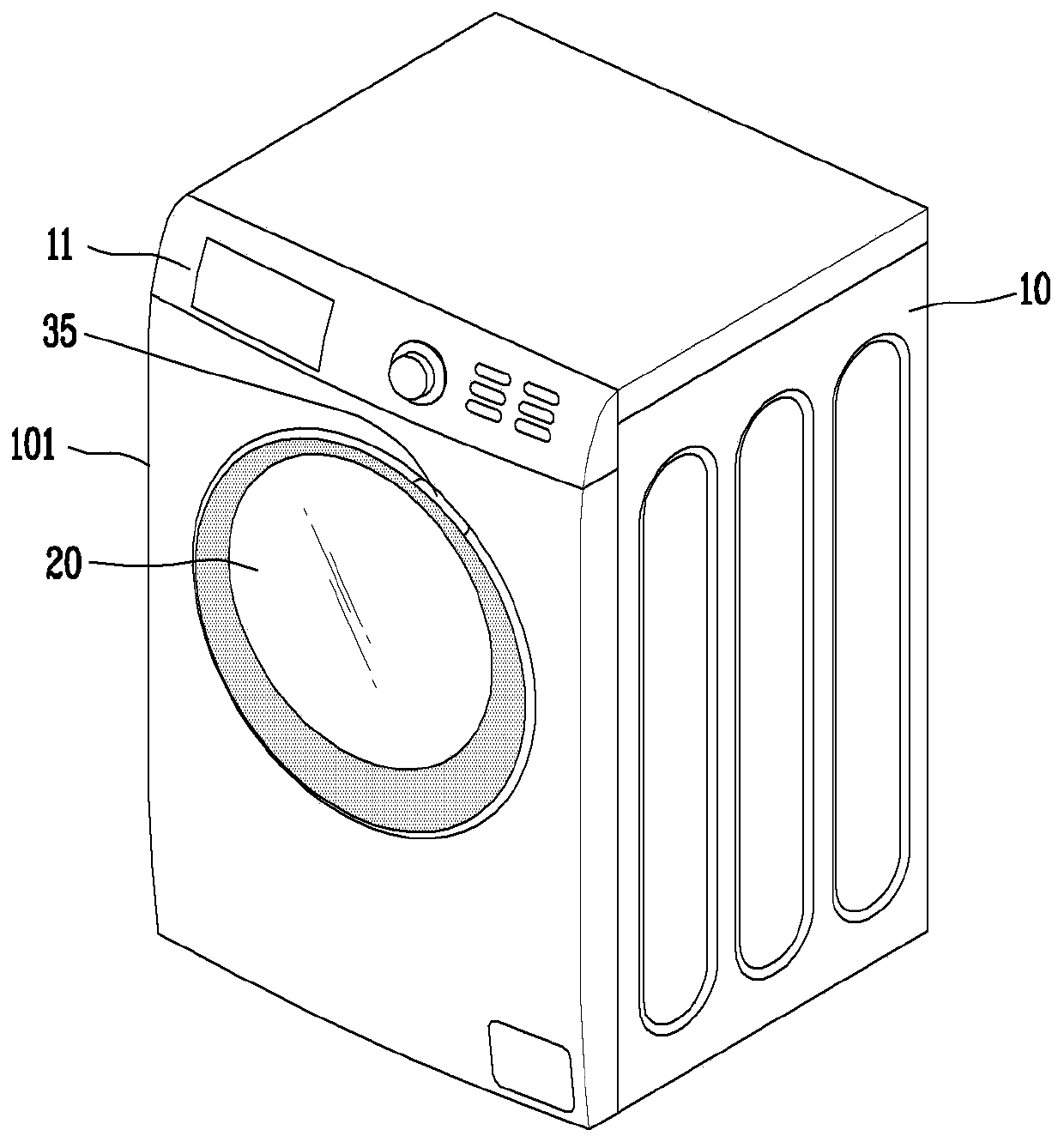

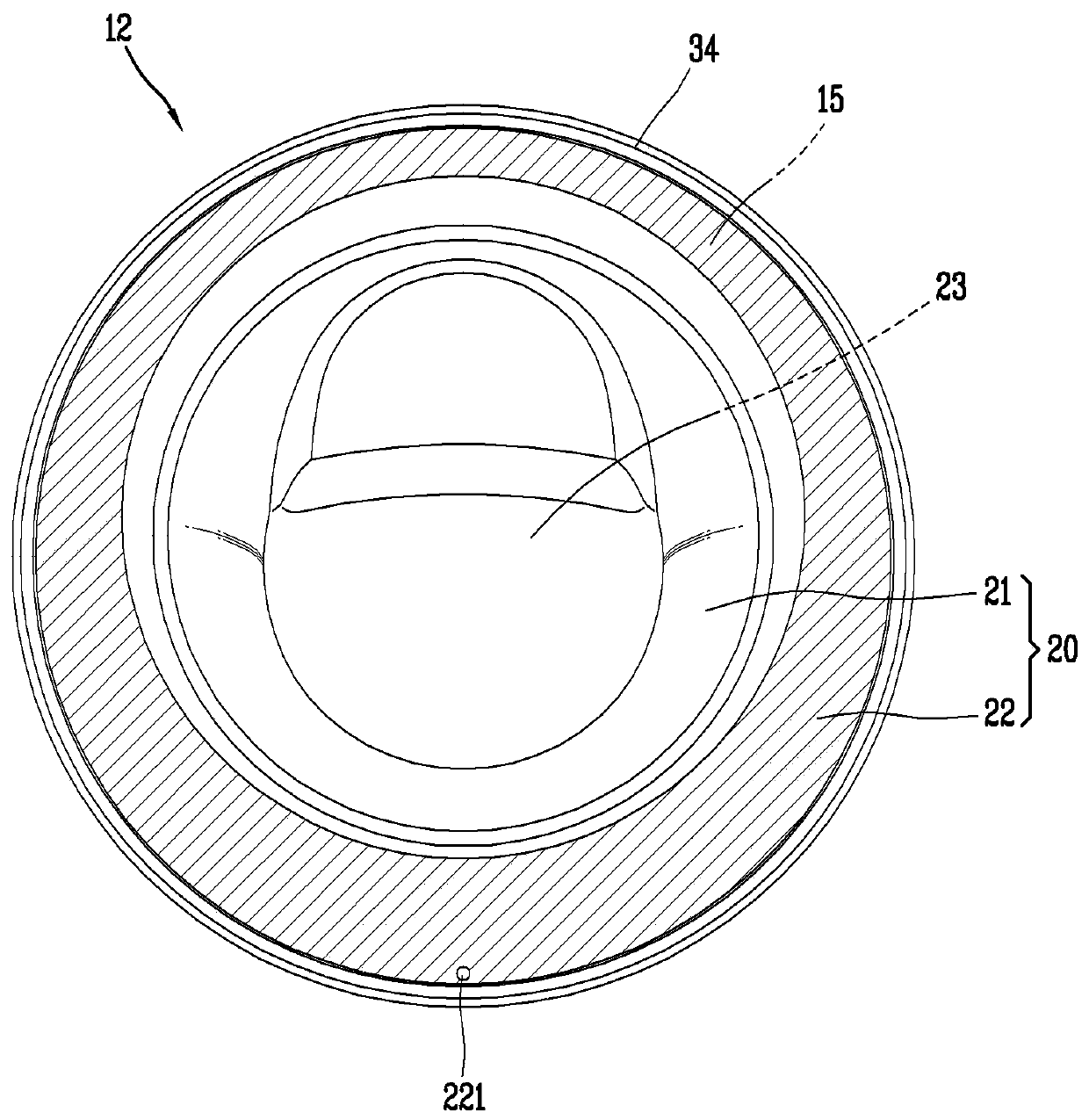

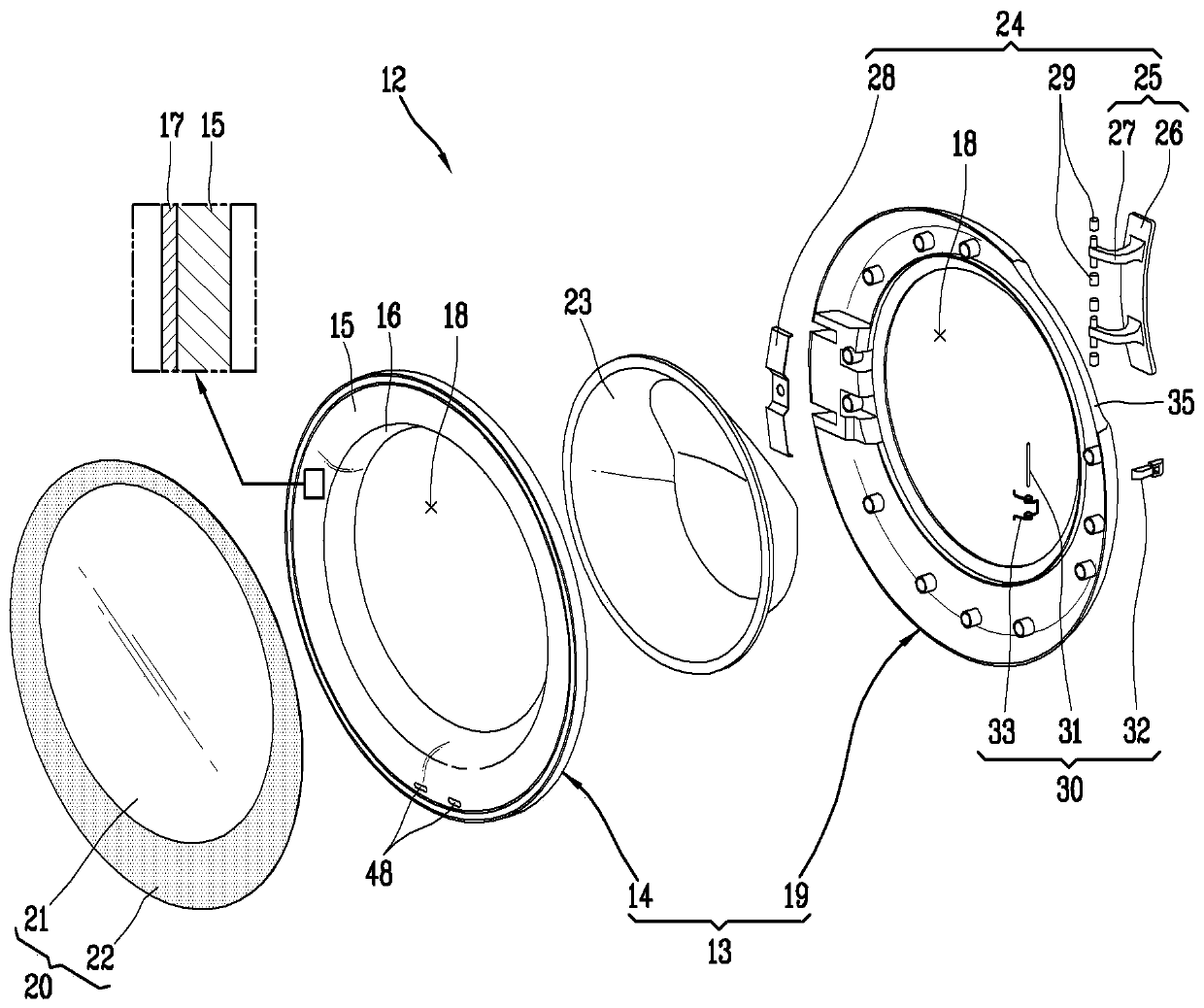

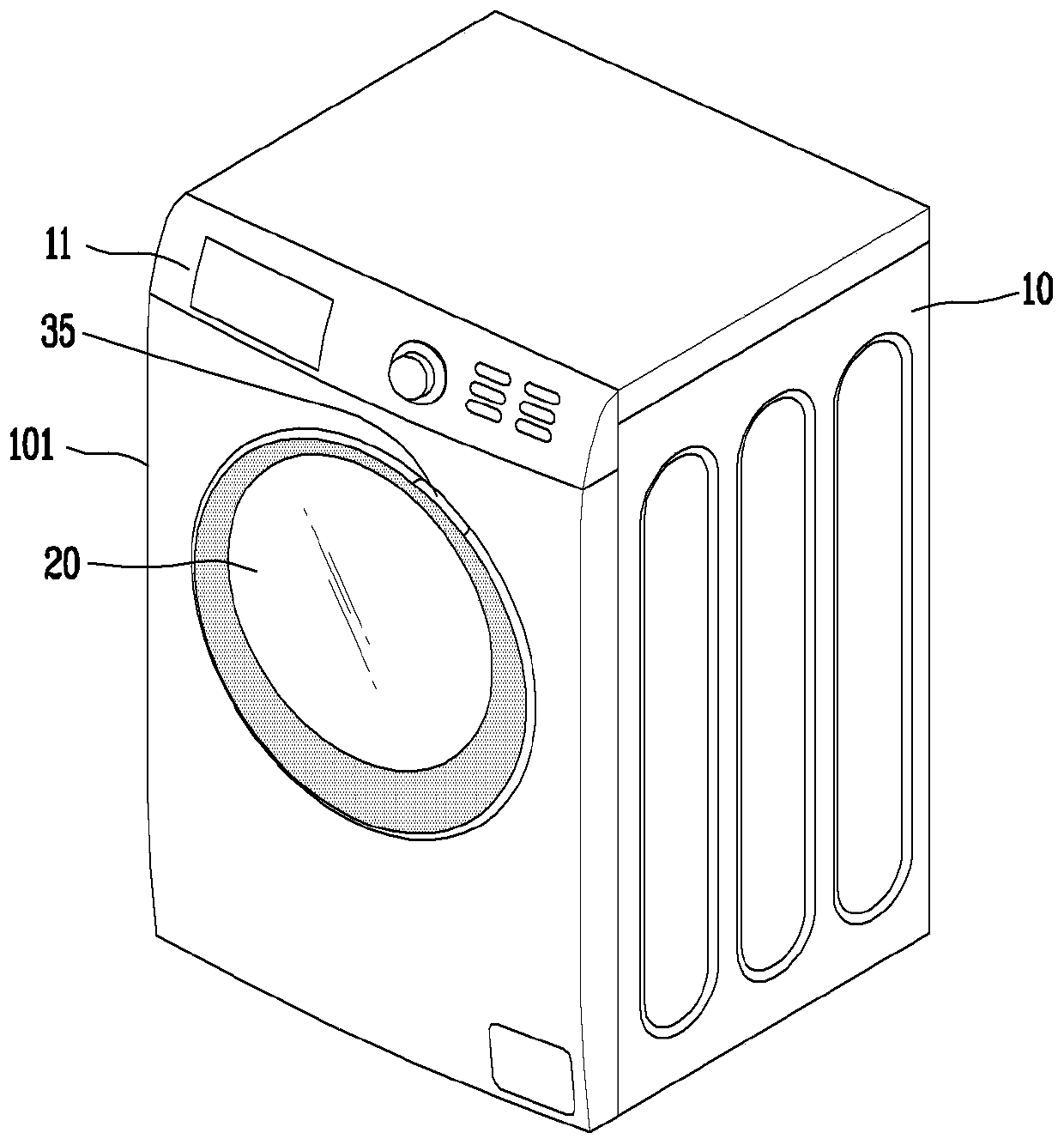

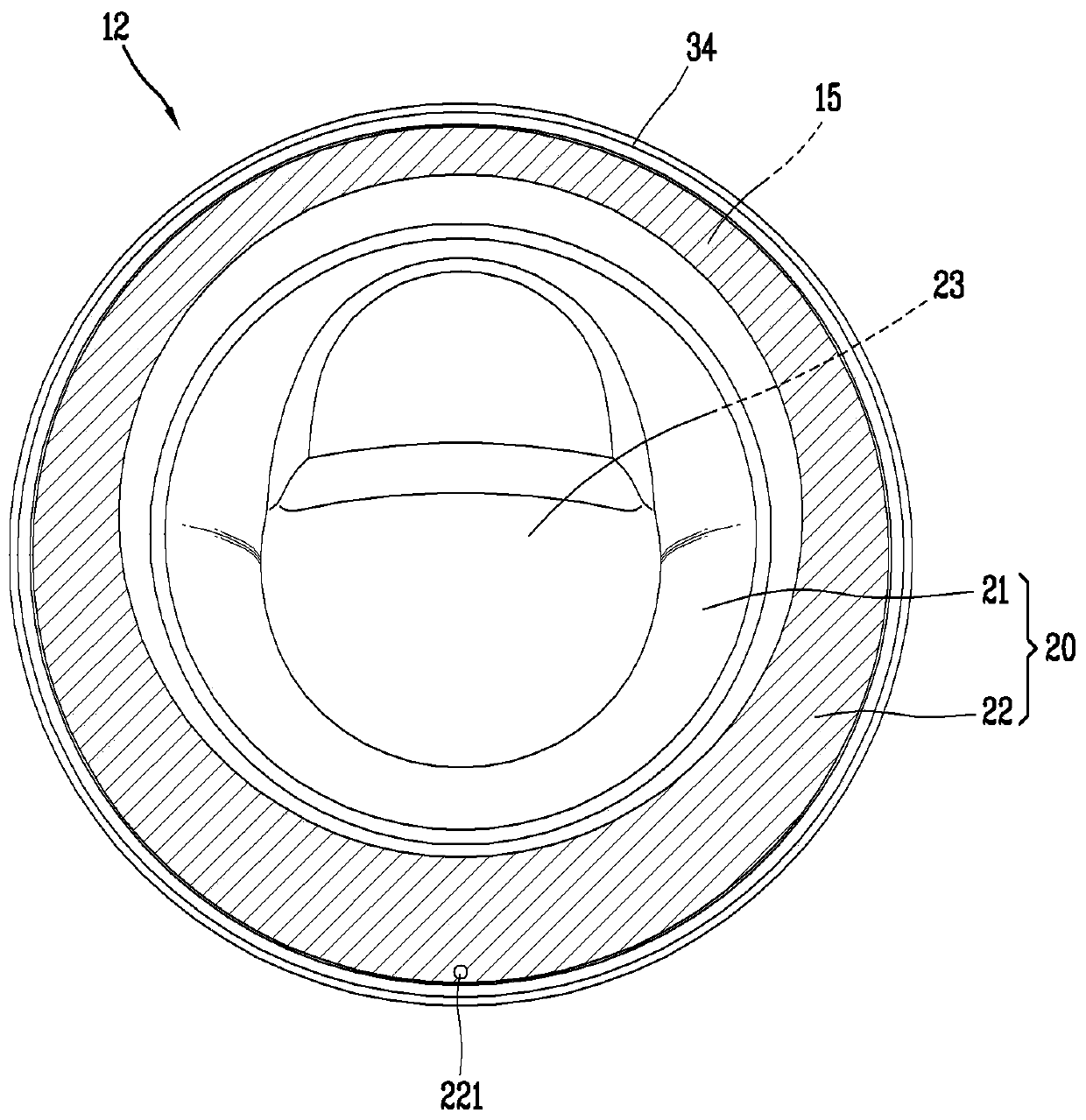

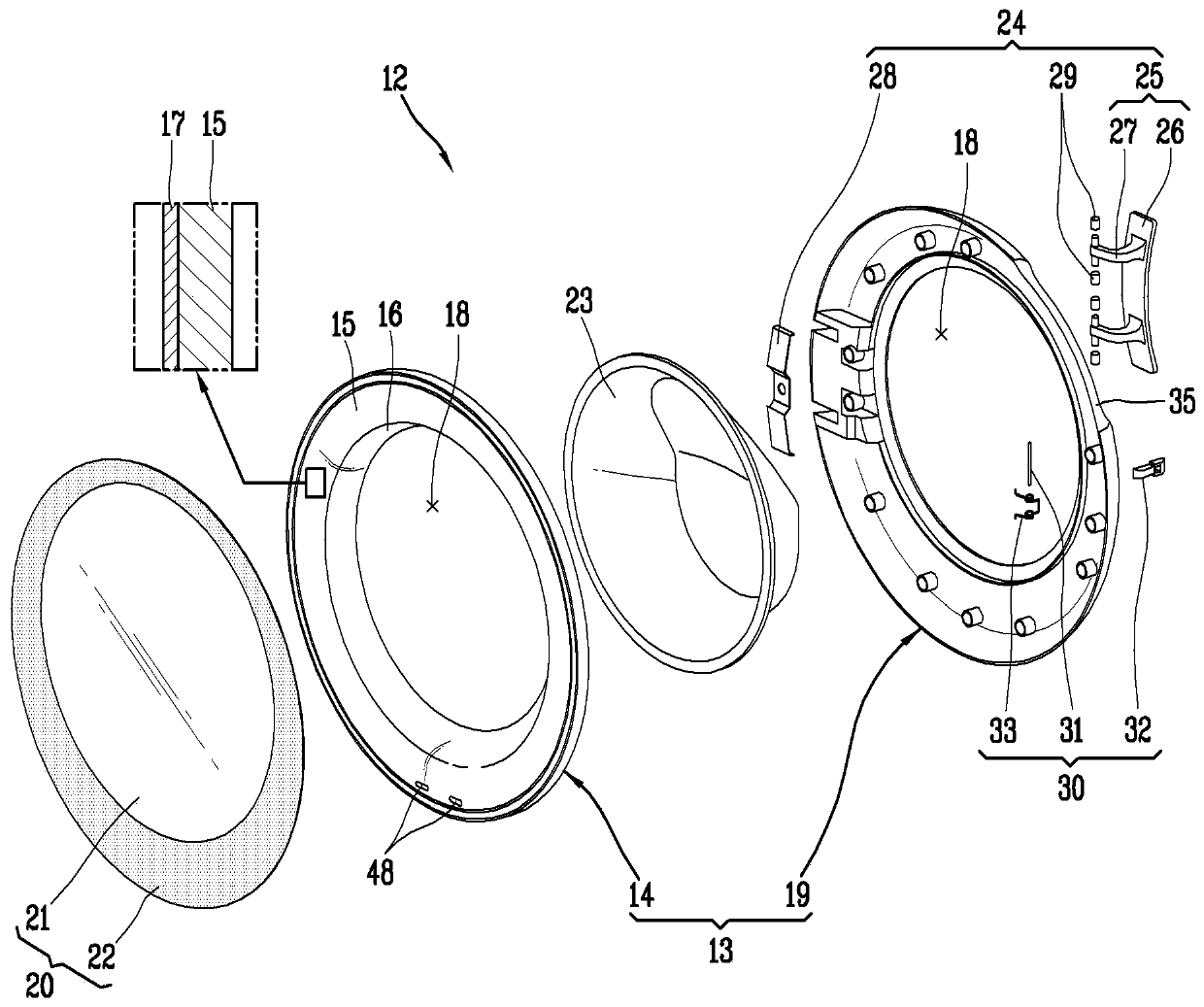

Laundry treating apparatus

PendingCN111519406AHigh strengthGuaranteed sealing performanceOther washing machinesWashing machine with receptaclesAdhesiveStructural engineering

The invention relates to a laundry treating apparatus that may include: a main body having a front panel having a laundry inlet port and a laundry receiving part by which laundry may be received via the laundry inlet port, and a door rotatably coupled to the front panel to open and close the laundry inlet port. The door may include: an outer frame provided with an opening and facing an outside ofthe main body; a front glass coupled to a front surface of the outer frame to cover the opening; an inner frame coupled to a rear surface of the outer frame and facing an inside of the main body; theouter frame includes: an adhesive filling part provided on the front surface of the outer frame and filled with an adhesive for attaching the front glass; a reinforcing part provided on the back surface of the outer frame and configured to enhance the rigidity of the outer frame corresponding to the adhesive filling part, and thus it can be expected to increase the fastening force between the outer frame and the inner frame.

Owner:LG ELECTRONICS INC

A self-propelled peeping probe and peeping method adapted to different borehole diameters

InactiveCN109162699BAvoid secondary popupGuaranteed opening and closing angleConstructionsVideo transmissionVideo processing

The invention discloses a self-propelled peeping probe and a method adapting to different borehole diameters. The probe includes a peeping probe main body, a camera, a walking wheel, a rocker arm connected to the road wheel, and a control host. The rocker arm twists a spring and a gas spring inside. Under the action, it can realize damping opening at a certain angle and has a warning function. The rocker arm can be fixed in the groove on the side of the peeping probe through the locking hole and the locking block. The peeping probe realizes the self-propelling function of the peeping probe in the borehole through an internal power supply, a driving motor, a video processing module, a control module, a WIFI module and an external control host. The peeping probe has the advantages of centering the drilling hole, self-propelled, and fewer operators during the drilling peeping operation, which reduces the complexity of the traditional drilling peeping operation, removes the push rod and video transmission line, and greatly reduces auxiliary accessories. Peeping through boreholes in underground engineering provides a new solution to determine rock mass fragmentation.

Owner:CHINA UNIV OF MINING & TECH

Quick release device

ActiveCN104564932BGuaranteed fastening forceEasy to assembleFriction grip releasable fasteningsEngineeringNotching

Owner:WENZHOU JINJIAN INTELLIGENT LOCK CO LTD

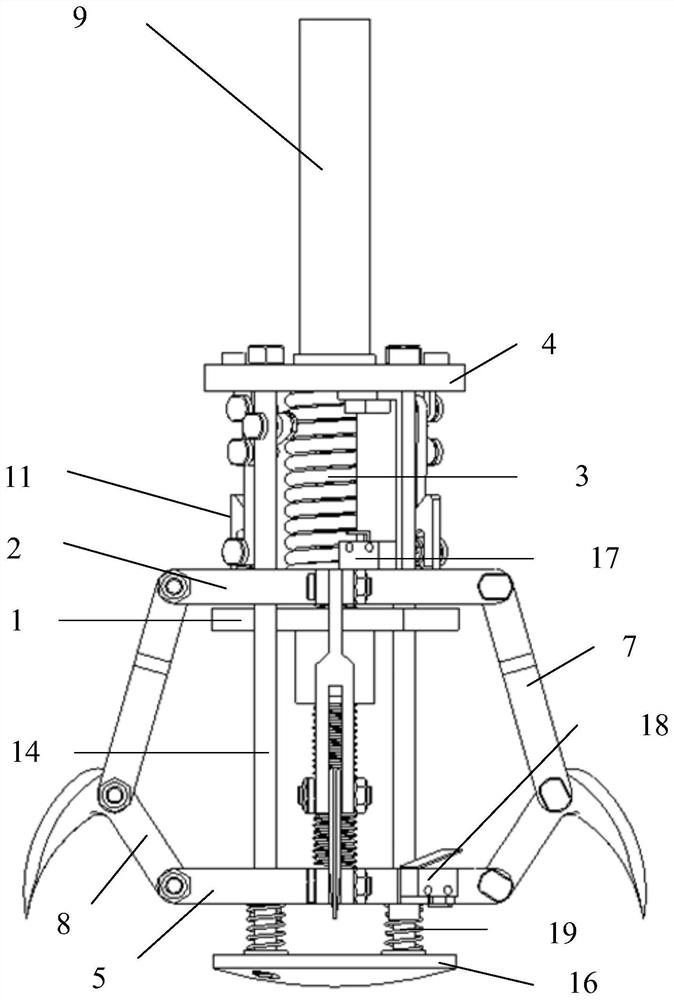

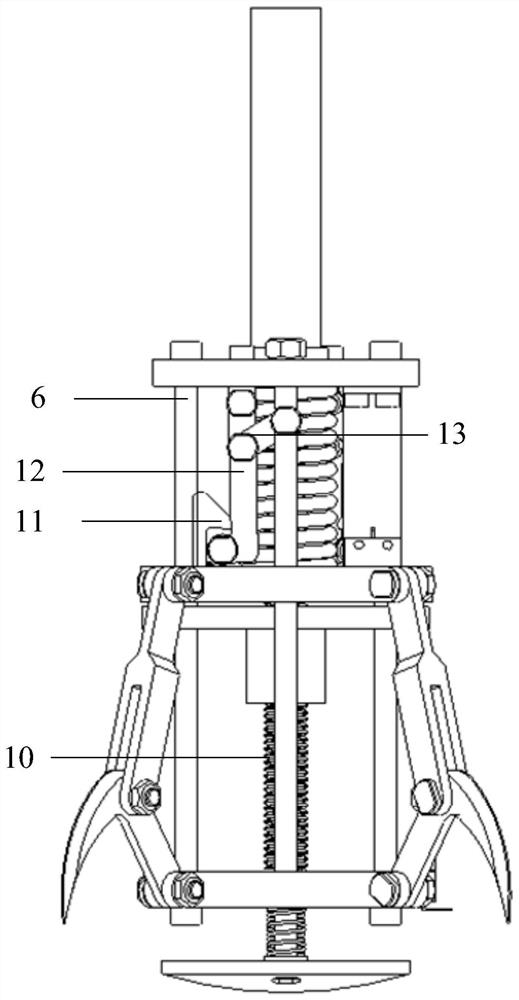

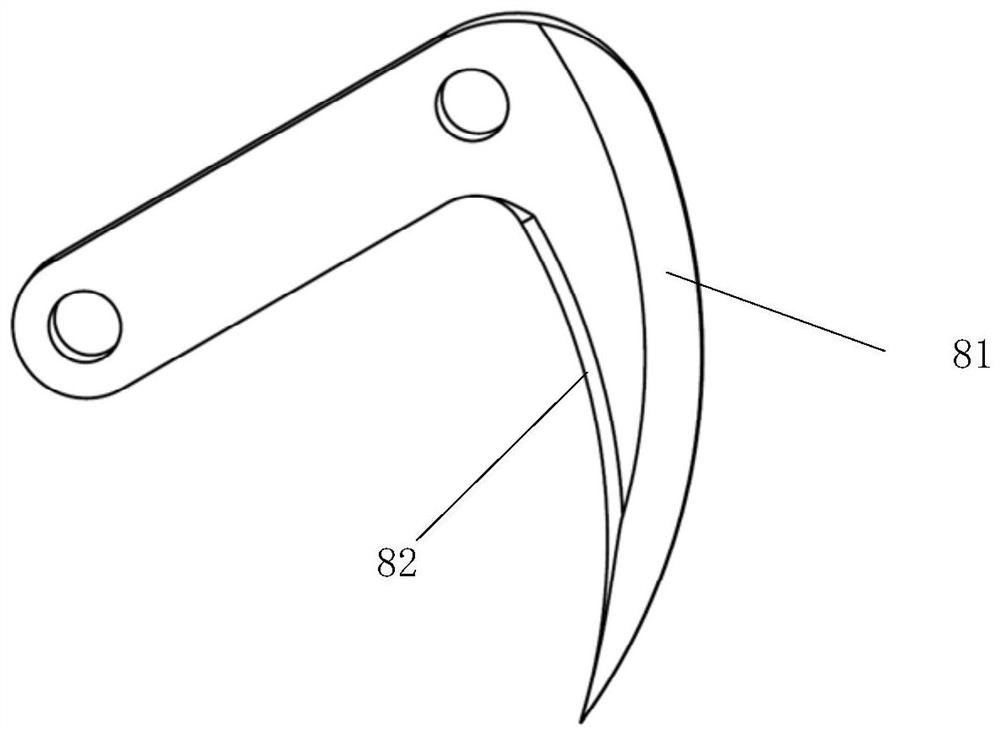

A Catching Mechanism Suitable for General Structure Surface of Spacecraft

InactiveCN108945532BCatch achievedImprove general performanceCosmonautic vehiclesCosmonautic partsUniversal structureAluminum honeycomb

The invention relates to an arresting mechanism suitable for a spacecraft universal structure surface, and belongs to the technical field of on-orbit service and robots. The arresting mechanism comprises a support assembly, a drive assembly, a push disk, a sliding plate, an arresting assembly, a spring and a locking and releasing assembly. The arresting assembly comprises a connecting rod and a claw spine. Under the triggering preparatory condition, the sliding plate locked in the first position is unlocked from the first position, the sliding plate is enabled to move towards the arresting target direction by using the spring, and thus the connecting rod is driven to move, so that the connecting rod drives the claw spine stabs towards the arresting targets, whether space cooperative targetor non-cooperative targets, most surfaces of a spacecraft is covered with the universal structure surfaces, that is, aluminum honeycomb plates, the claw spine can pierce the arresting target surfaceto realize arresting. The arresting mechanism is suitable for various spacecraft, has high universality and wide range of application without the need for providing cooperative arresting feature position, and the arresting mechanism can carry out repeated and effective arresting connection and releasing separation.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

Laundry treating apparatus

A laundry treating apparatus may include a main body having a laundry inlet port on the front panel; a laundry accommodating part which is arranged in the main body and is used for accommodating laundry; and a door rotatably provided on the front surface of the main body so as to open and close the laundry inlet port. The door may include an outer frame provided with an opening and facing an outside of the main body; front glass coupled to a front surface of the outer frame to cover the opening; an inner frame coupled to a rear surface of the outer frame and facing an inside of the main body;and a plurality of hooks used for fastening the outer frame and the inner frame, whereby an increase in fastening force between the outer frame and the inner frame can be expected.

Owner:LG ELECTRONICS INC

Pneumatic tires

InactiveCN103213460BGuaranteed fastening forceIncreased durabilityTyre beadsWheelsEngineeringMechanical engineering

In the pneumatic tire provided by the present invention, the fastening force of the bead wire can be maintained and the fitting pressure can be reduced, thereby improving the workability at the time of rim assembly and the durability of the bead portion. In a pneumatic tire (1), bead cores (5) are arranged in bead portions (4). The bead core (5) includes: a first bead wire (9A), and a second bead wire having an elongation (α) expressed by the formula (1) greater than the elongation of the first bead wire (9A). Circle the line (9B). At least one second bead wire (9B) is arranged on the innermost side in the tire radial direction, elongation α (%)=ΔL / L×100%... (1) L: bead wire length ΔL under no load: The amount of elongation after a unit load is applied.

Owner:SUMITOMO RUBBER IND LTD

Bolt with anti-rotation mechanism

Owner:TAKIGEN MFG CO LTD

Anti-drop plug for electric vehicle charger

The invention discloses an anti-drop plug for an electric vehicle charger, which comprises a panel, an installation shell, installation columns, contact blocks, torsion springs and a socket with an insertion sheet and an insulation head, wherein the installation shell is fixedly connected to the panel; four installation columns are fixed in the installation shell; a contact block and a torsion spring are inserted into each installation column; one end of each torsion spring is clamped on the corresponding contact block, the other end of each torsion spring is clamped on the inner wall of the installation shell, and the two contact blocks form an electric contact body; the panel is provided with two plugging grooves, and the two plugging grooves are correspondingly disposed at the rear sides of the two electric contact bodies. The plug disclosed in the invention is simple in structure, the plug can be effectively prevented from falling off from the jack, the structure is simple, realization is easy, and the use effect is good. The plug provided by the invention can ensure the fastening force, avoids the phenomenon that the power plug of the electro-tricycle falls off due to jolt, and is good in use effect.

Owner:丰县杰兰特电动车有限公司

A kind of anti-dropping plug for electric vehicle charger

ActiveCN110838642BInhibit sheddingIncrease frictionCoupling device detailsElectric carsElectric vehicle

The invention discloses an anti-falling plug for an electric vehicle charger, which includes a panel, a mounting shell, a mounting column, a contact block, a torsion spring and a socket with a plug and an insulating head. The mounting shell is fixedly connected to the panel, and the Four mounting columns are fixed inside the shell, and a contact block and a torsion spring are plugged into each mounting column, and one end of the torsion spring is clamped on the contact block, and the other end is clamped on the inner wall of the mounting shell. The block forms an electrical contact body; two insertion slots are arranged on the panel, and the two insertion slots are correspondingly arranged on the rear side of the two electrical contact bodies. The invention has a simple structure, can effectively prevent the plug from falling off from the socket, has a simple structure, is easy to realize, and has good use effect. The plug of the invention can ensure fastening force, eliminate the phenomenon that the power plug of the electric tricycle falls off due to bumps, and has good use effect.

Owner:丰县杰兰特电动车有限公司

Laundry treating apparatus

ActiveCN111519412APrevent moisture penetrationReduce sizeWing handlesOther washing machinesLaundryEngineering

A laundry treating apparatus may include a main body having a laundry inlet port on the front panel; a laundry accommodating part which is arranged in the main body and is used for accommodating laundry; and a door rotatably provided on the front surface of the main body so as to open and close the laundry inlet port. The door may include an outer frame provided with an opening and facing an outside of the main body; front glass coupled to a front surface of the outer frame to cover the opening; an inner frame coupled to a rear surface of the outer frame and facing an inside of the main body;and a plurality of hooks used for fastening the outer frame and the inner frame, whereby an increase in fastening force between the outer frame and the inner frame can be expected.

Owner:LG ELECTRONICS INC

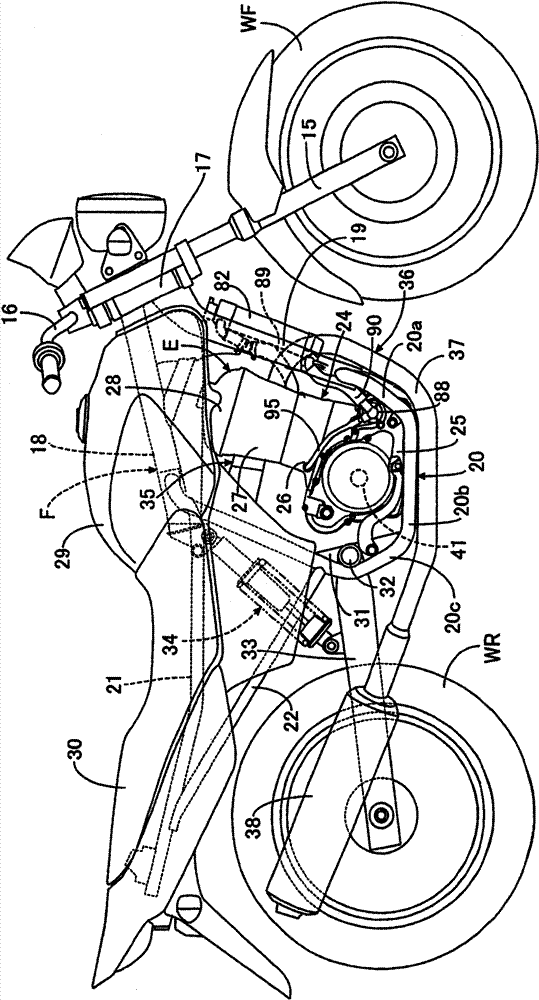

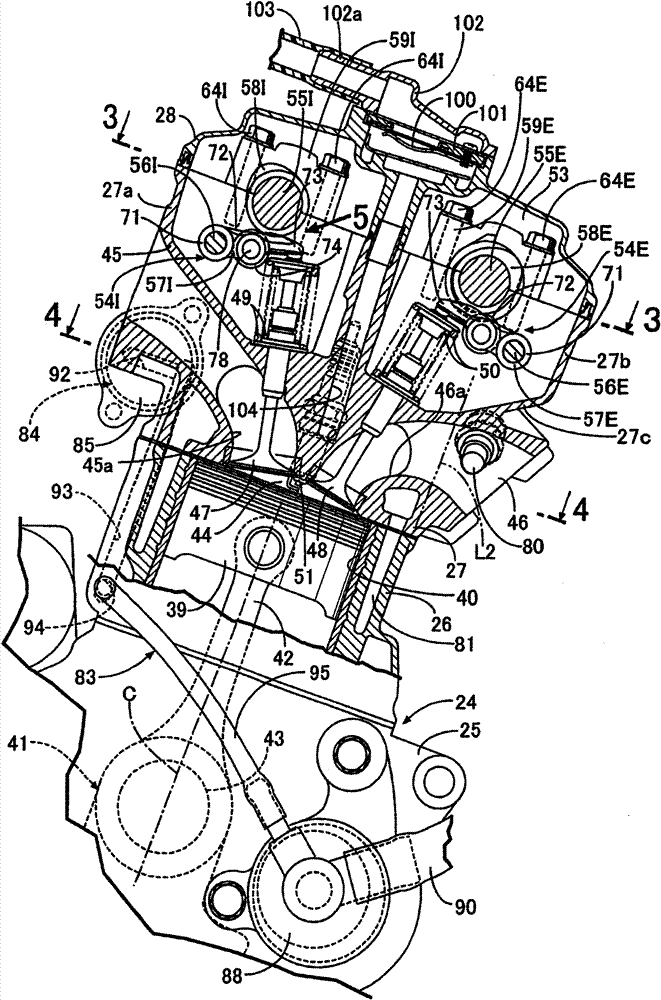

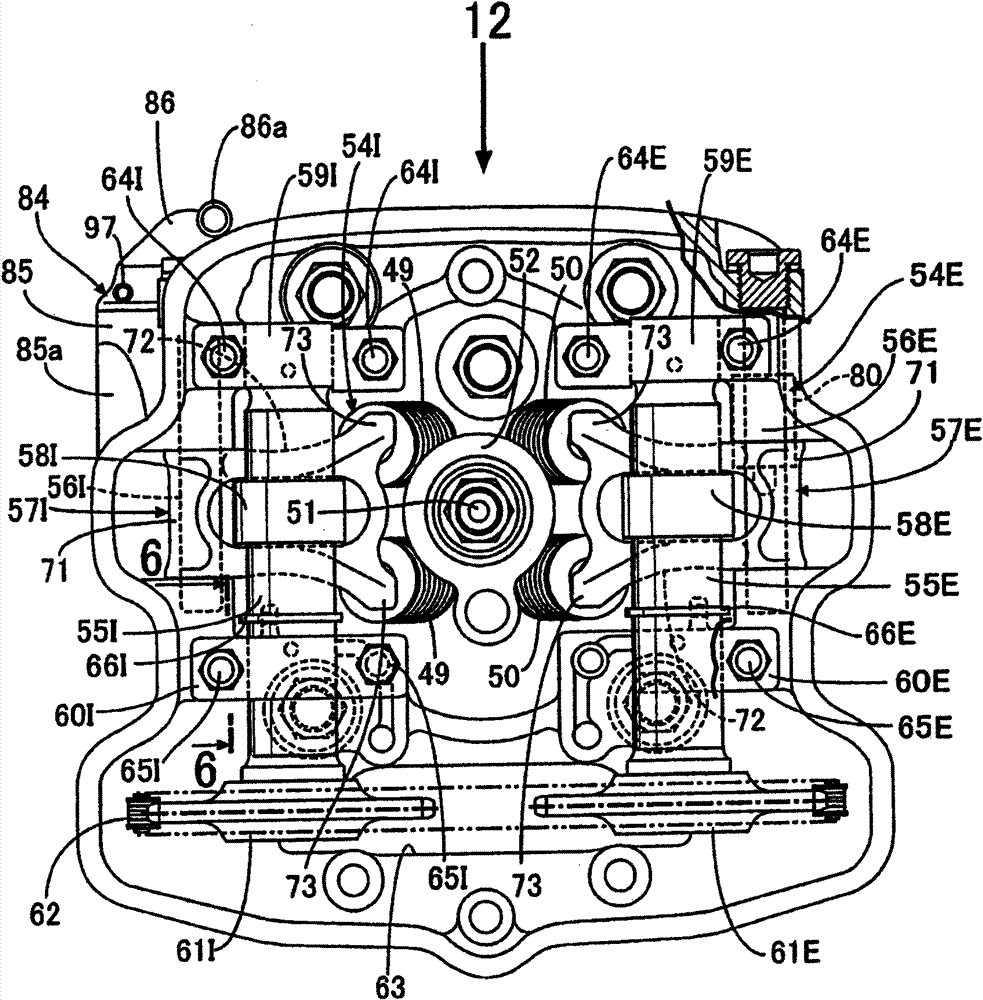

Internal combustion engine

ActiveCN101852141BAvoid oversizingReduce in quantityValve drivesCylinder headsExhaust valveExternal combustion engine

The invention provides an internal combustion engine, The invention provides an internal combustion engine. An exhaust side rocker arm has a valve connecting portion linked with an exhaust valve and a cam abutting portion abutted with a cam on a cam shaft and is swingingly supported by a rocker arm shaft supported by a cylinder cover. An exhaust outlet is arranged on a cylinder cover. In the internal combustion engine is equipped with an exhaust sensor which strives for miniaturization of the cylinder cover without increasing the number of parts. A valve connecting portion of the exhaust side rocker arm (57E), the cam abutting portion (74) and the rocker arm shaft (46) are arranged in order from upstream side to downstream side of the exhaust outlet (46); and an exhaust sensor (80) under the lower wall (27c) for detecting the property of the exhaust gas flowing in the exhaust outlet (46) is installed on the cylinder cover (27) which covers a side wall (27b) of the rocker arm shaft (56E) from the side surface and covers at least a part of the lower wall (27c) of the rocker arm shaft (56E) from the lower side.

Owner:HONDA MOTOR CO LTD

Connectors for containers

InactiveCN101878168BImprove workabilityGuaranteed fastening forceLarge containersFor goodsEngineeringMechanical engineering

The present invention provides a connector for a container, which arranges the cone above and below the shaft, and even if the lower cone is not rotated by manual operation, the lower cone can be cast from the upper corner of the lower container or on the deck. It is possible to improve the workability of unloading by removing the socket, and to ensure the necessary fastening force according to the situation. To achieve this, the lower cone has a rotational engagement structure in which the cone engages with the inner edge of the engagement hole when it is inserted into the upper corner casting or socket and rotated from the disengagement position to the engagement position. In addition, when inserted into the upper corner casting or socket, even if it does not rotate, the protrusion-shaped engaging part provided on one side of the cone will engage with the inner edge of the engaging hole. Two click structure.

Owner:NIPPON YOOSEN KABUSHIKI KAISHA +2

Fastening kit and combined expanding device utilizing fastening kit

A fastening kit comprises a bolt and a nut. The bolt comprises a head part and a screw. The screw comprises a first end fixedly connected with the head part, a second end connected with the nut in a threaded mode, and an elastic energy storage component combined with the two ends. A deformation structure corresponding to threaded connection acting force is formed on the portion, between the first end and the second end, of the elastic energy storage component. The fastening force of the fastening kit can be effectively maintained after screwing and fastening are achieved in place through elastic deformation of the fastening kit, and fastening failures caused by vibration, heat expansion and cold contract of the environment after fastening is achieved in place are counteracted. Meanwhile, the single-directional screwing-in structure of the head part of the bolt is matched with the smooth top of the nut so that the fastening structure can not be deconstructed, fastening reliability can be effectively improved, and the fastening kit can not be detached without a destructive means. The invention further provides a combined expanding device utilizing the fastening kit.

Owner:XUZHOU FANGBO ENVIRONMENTAL PROTECTION EQUIP

A method for assembling a fuel cell stack

The invention relates to a method for assembling a fuel cell stack. The method comprises a step (1) of providing a fixing mechanism, a location mechanism, a pressure supply mechanism and a locking mechanism; a step (2) of successively placing a lower end plate, a current collecting plate, an assembly stack single cell, a current collecting plate and an upper end plate of the stack into the fixing mechanism in sequence, wherein each location post of the fixing mechanism is perpendicular to the stack to enable the periphery of the stack to be nested in a space defined by a second surface of each location post; a step (3) of utilizingpressure blocks of the pressure supply device to exert pressure in the direction perpendicular to the stack on the upper end plate and the lower end plate of stack parts to compress each part of the stack to meet set requirements; a step (4) of utilizing the locking mechanism to fix each part of the stack to achieve the purpose of assembling the stack; and a step (5) of removing the pressure, removing the fixing mechanism and the location mechanism and taking down the stack to finish the assembly of the stack. The method for locating and assembling the assembly stack is simple and convenient to operate, high in actionability and precise in location. The location mechanism ensures that all parts of the stack are in contact uniformly without deviation. The pressure blocks of the pressure supply device ensure each assembly of the assembly stack to be forced uniformly, and the quality of the assembly stack is guaranteed.

Owner:武汉理工新能源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com