Handle for pipes

A technology for handles and catheters, applied in catheters, applications, medical science, etc., can solve the problems of time-dependent changes in fastening strength, decrease in the fastening force of ring-shaped elastic parts, and difficult operation, and achieve the effect of less time-dependent changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, the present invention will be described based on the embodiments shown in the drawings.

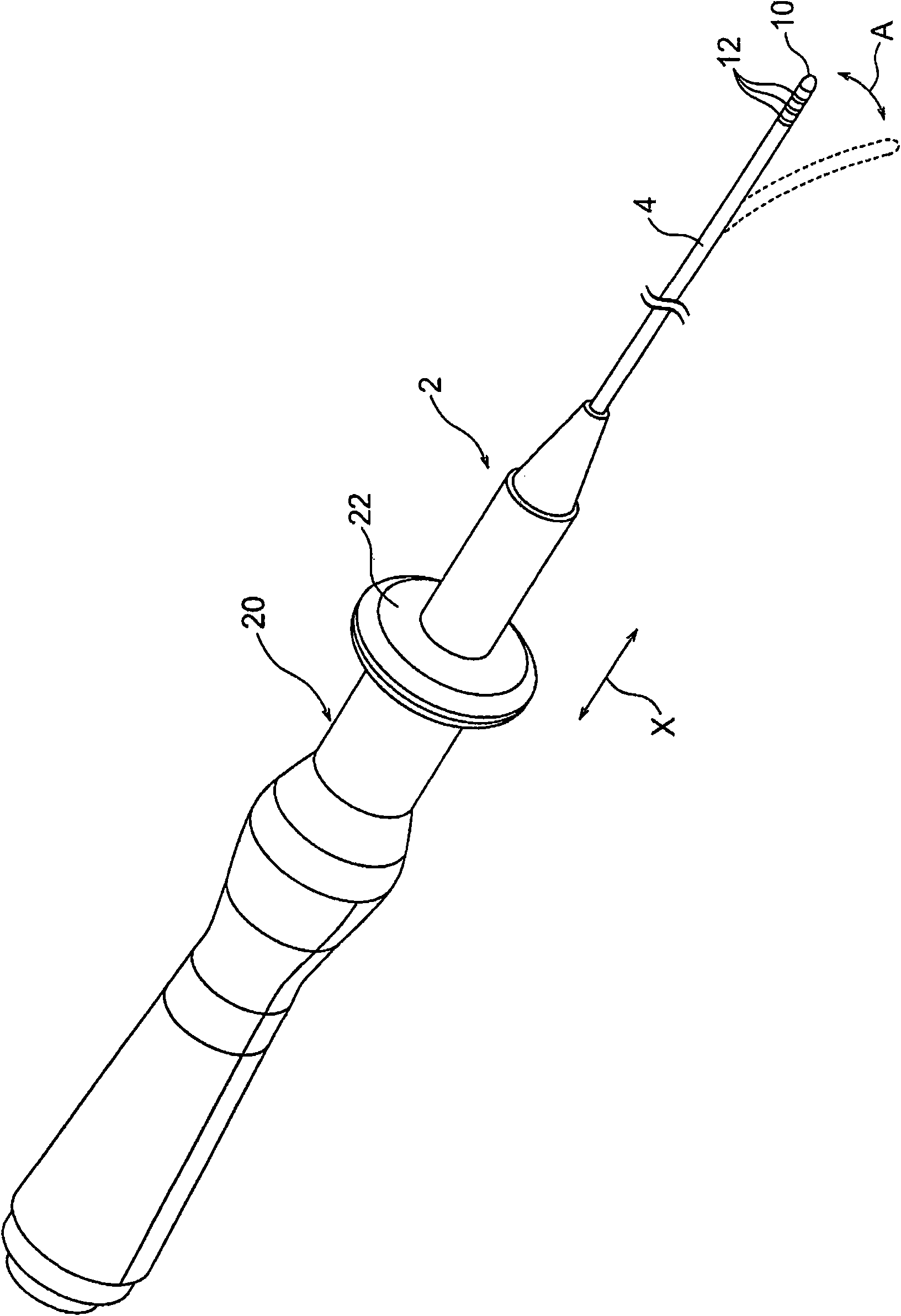

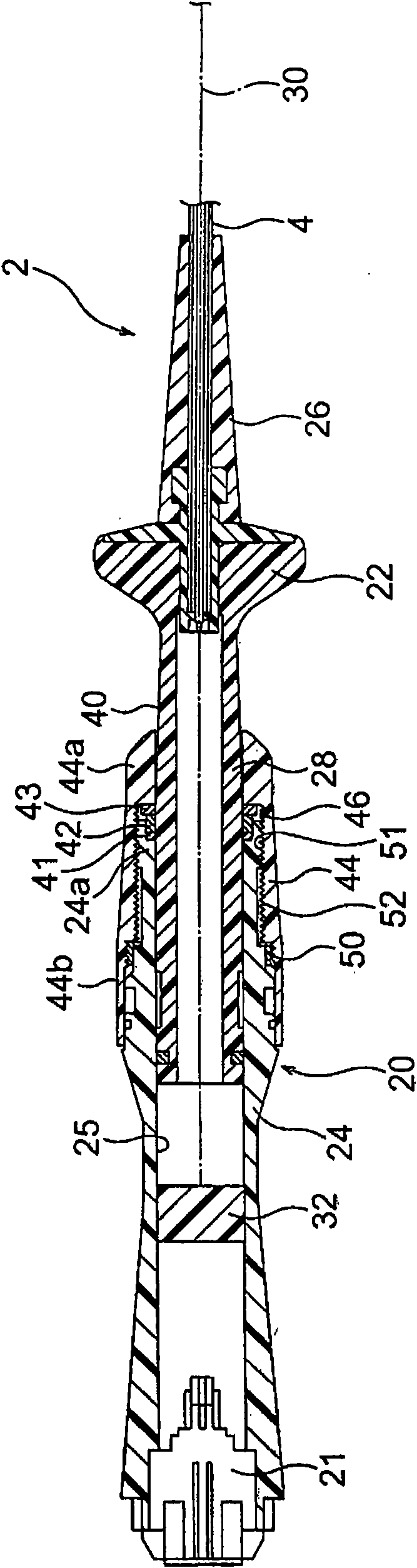

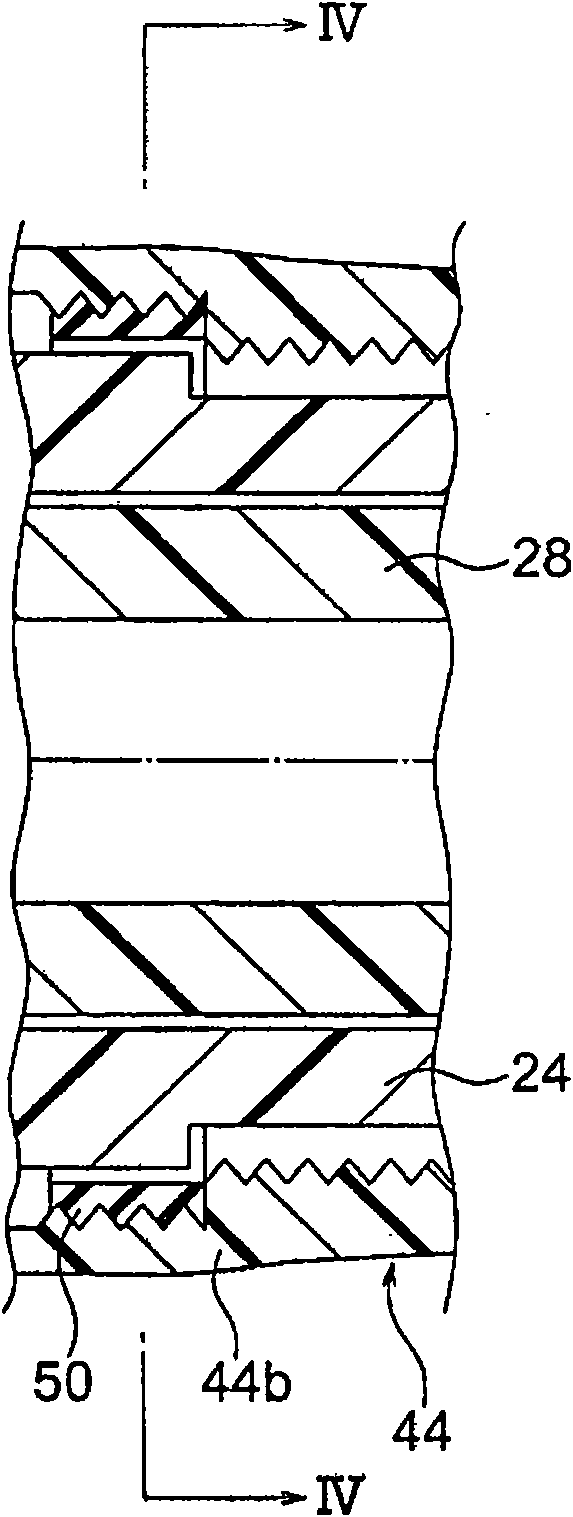

[0035] Such as figure 1 As shown, the front end involved in an embodiment of the present invention can be biased towards the operation catheter 2, such as for the diagnosis or treatment of arrhythmia, and the distal end of the catheter tube (tube part) 4 is equipped with a front end piece 10 and multiple 12 middle rings. The front end piece 10 and the intermediate ring 12 function as electrodes, and are connected and fixed to the catheter tube 4 by, for example, bonding with an adhesive.

[0036] A handle body 20 is installed at the proximal end of the catheter tube 4 . Wires are pulled through the inside of the catheter tube 4 and the handle body 20 , and the front ends of the wires are electrically connected to the front end piece 10 and the intermediate ring 12 that constitute electrodes. In addition, the base ends of these wires are fixed to the figure 2 A con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com