A self-propelled peeping probe and peeping method adapted to different borehole diameters

A peeping probe, adapting to different technologies, applied in the field of peeping probes, can solve the problems of difficult pushing, poor imaging accuracy, complicated operation process, etc., and achieve the effect of speeding up the peeping operation efficiency, reducing the labor intensity, and avoiding the extension of the push rod.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

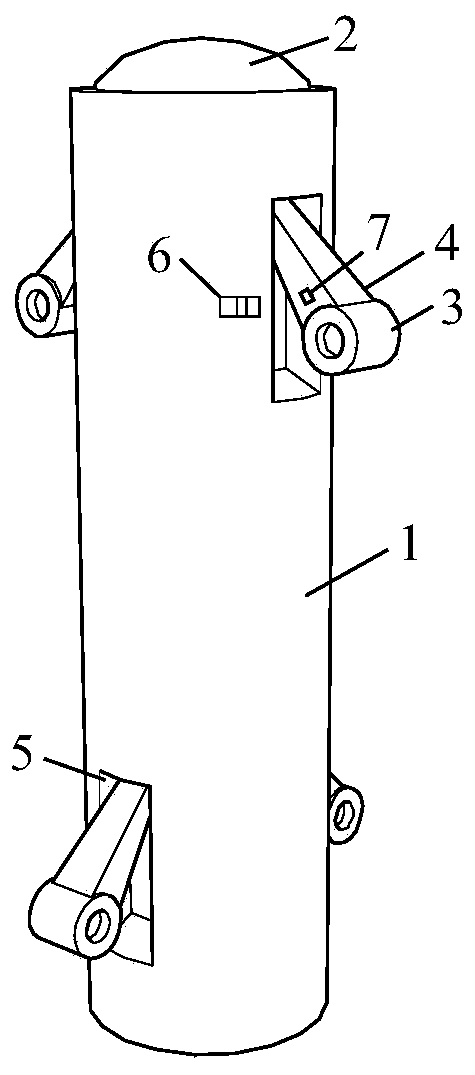

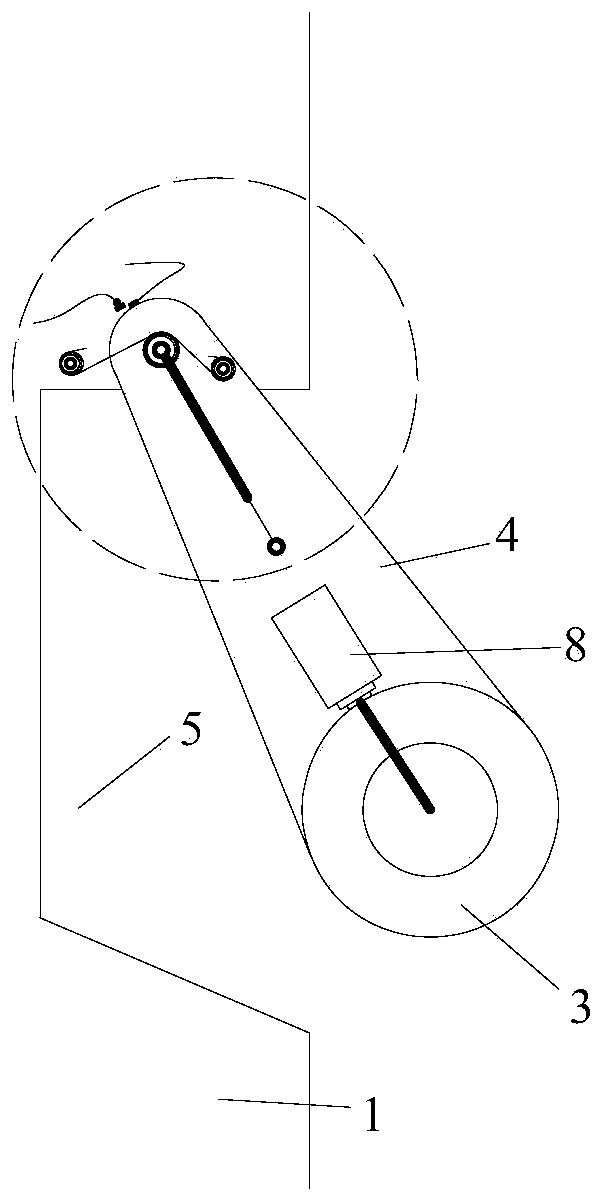

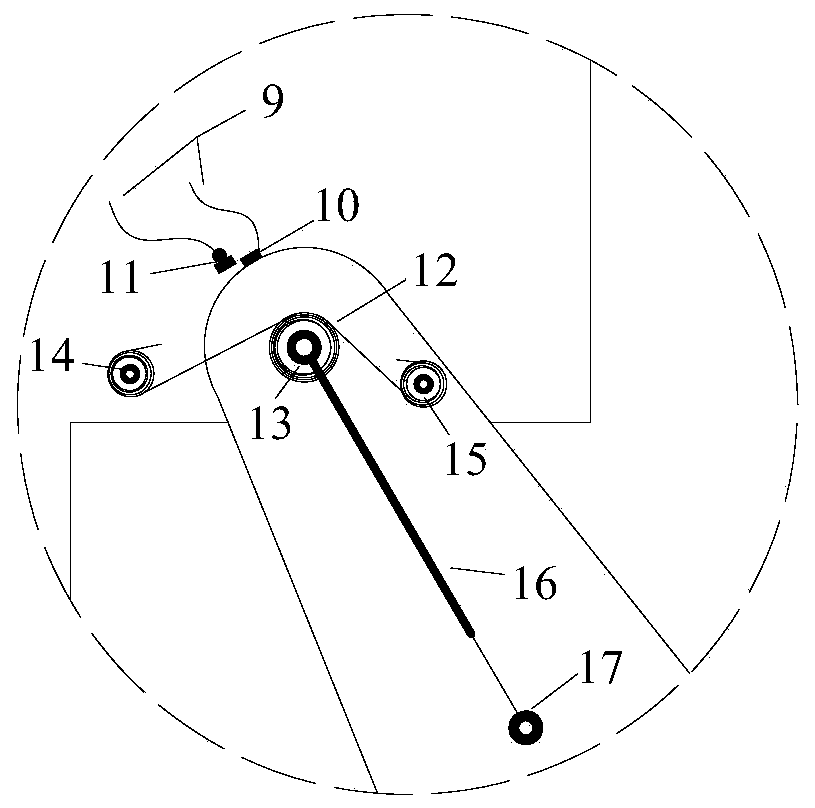

[0037] Such as figure 1 As shown, a self-propelled peeping probe adapted to different borehole diameters includes a cylindrical peeping probe body 1, a protruding camera 2 is provided on the top of the peeping probe body 1, and a connecting directional WIFI receiving line 28 is provided at the bottom The directional WIFI receiving line interface 23 and the emergency rope connection column 24 connected to the emergency rope 27, the diameter of the peeping probe main body 1 of the cylindrical shape is 35 ~ 45 mm, and the height is 300-400 mm; the peeping probe main body 1 is in The advance control in the borehole 25 is completed by the control host 30, and the control host is connected with a directional WIFI emission line 29, such as Figure 6 As shown; the length of the directional WIFI receiving line 28 is 2-3 m, and the length of the directional WI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com