Sinker and socks with loose welts

A technology of raw gram and sock cuffs, which is applied in the field of textile manufacturing, can solve the problems of single fabric performance and inability to gradually change the effect, and achieve the effect of comfortable wearing, easy manufacturing and improvement, and small technical transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The raw gram sheet of the present invention can use the following materials, and is not limited to the following materials, for example: fibers include cotton, combed cotton, mercerized cotton, spandex, Lycra, nylon, nylon, acrylic fiber, polypropylene fiber, polyester, viscose, natural Silk, Bamboo Fiber, Modal, Hemp, Puma Cotton, etc.

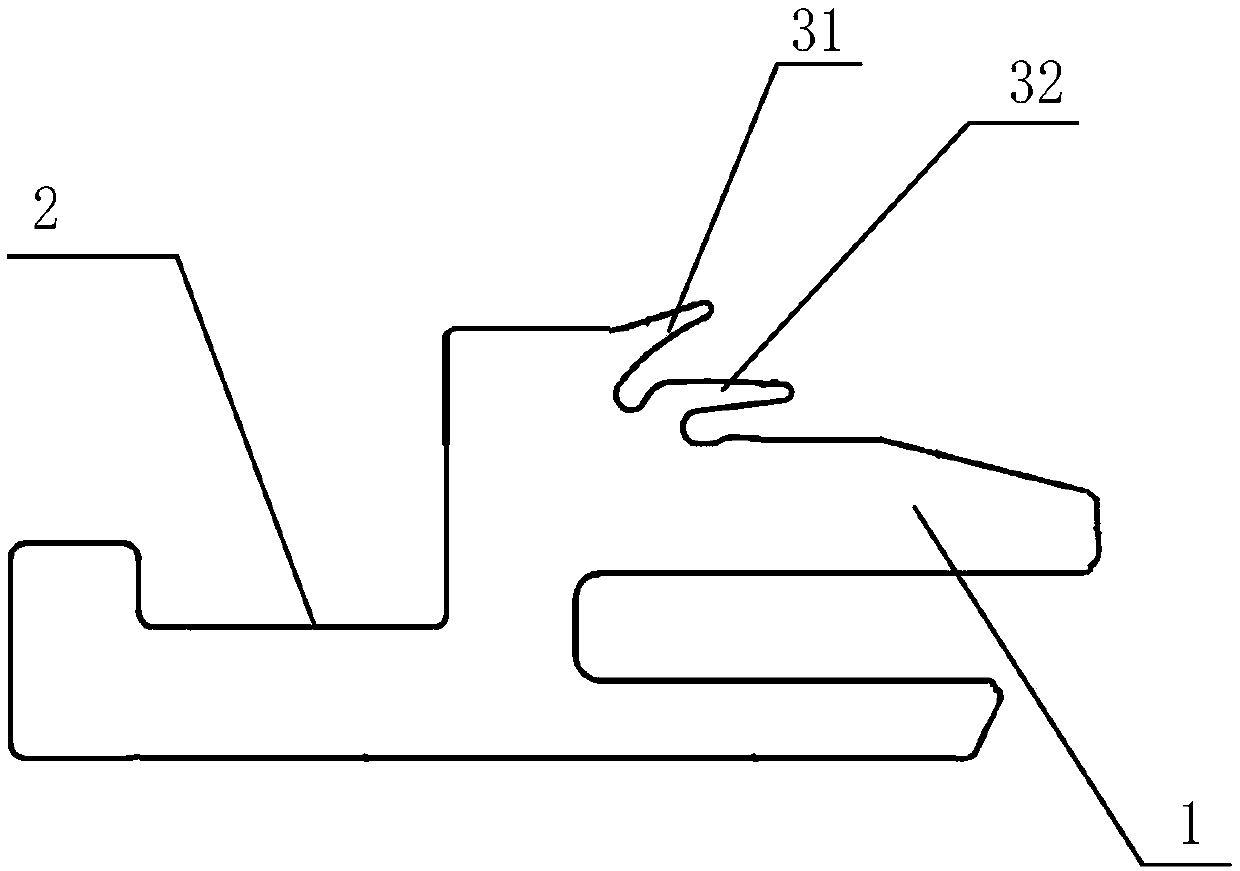

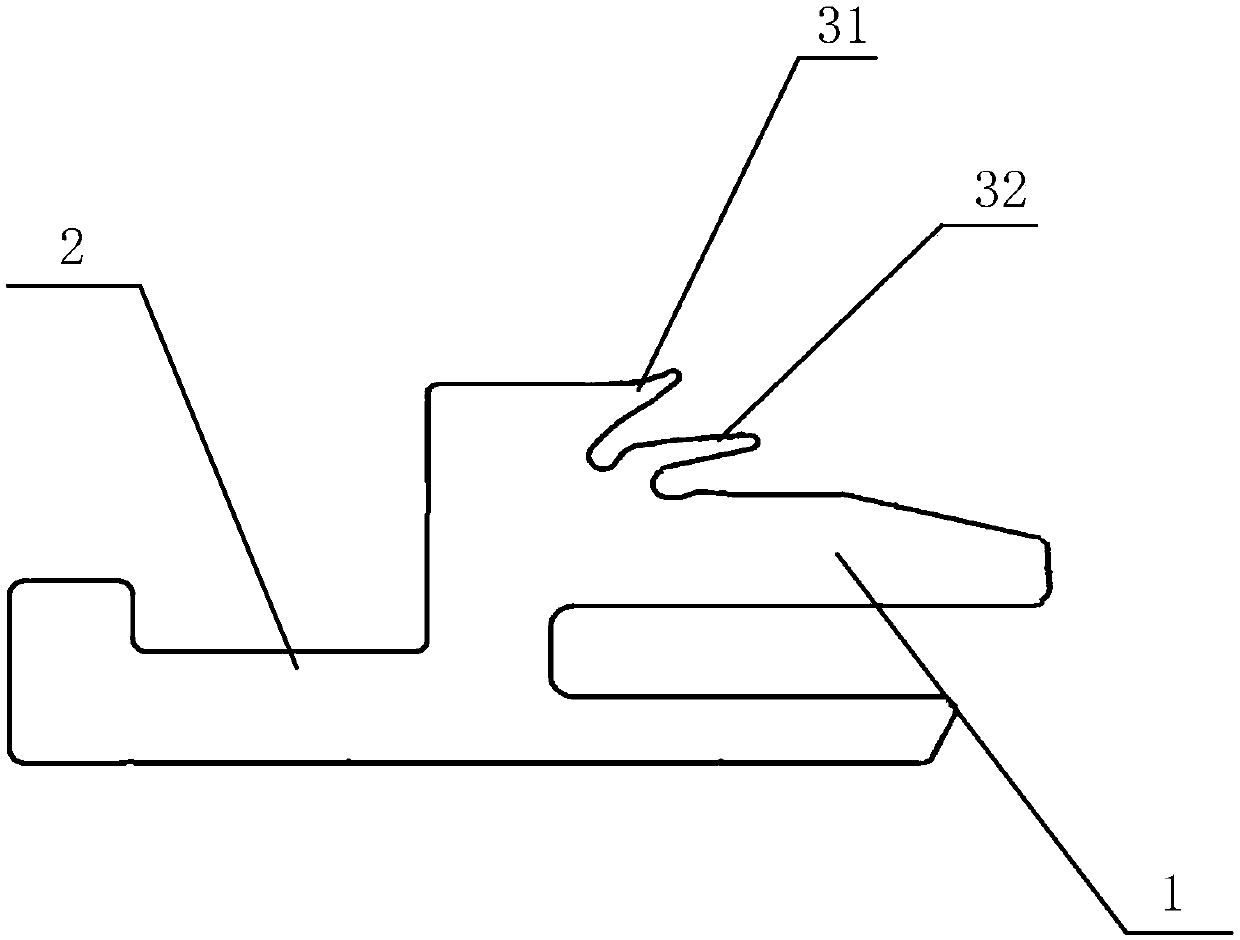

[0033] Such as figure 2 and image 3 Shown are the schematic diagrams of the two embodiments of the present invention; the embodiment of the present invention includes: a tablet forehead 1 and a tablet foot 2; above the tablet forehead 1, there are two tablet noses with different heights , are respectively the high piece nose 31 and the low piece nose 32; the opening of the high piece nose 31 and the opening of the low piece nose 32 are smooth curves.

[0034] There are two piece noses on the forehead of the slug of the present invention, and the two noses are arranged one high and one low, and are used to hang different yarns. When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com