Fastening kits and combined extensions for fastening kits

A fastening and kit technology, applied in the direction of threaded fasteners, locking fasteners, connecting components, etc., can solve problems such as unsatisfactory rigidity and toughness, achieve repeated use, improve fastening reliability, and save materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

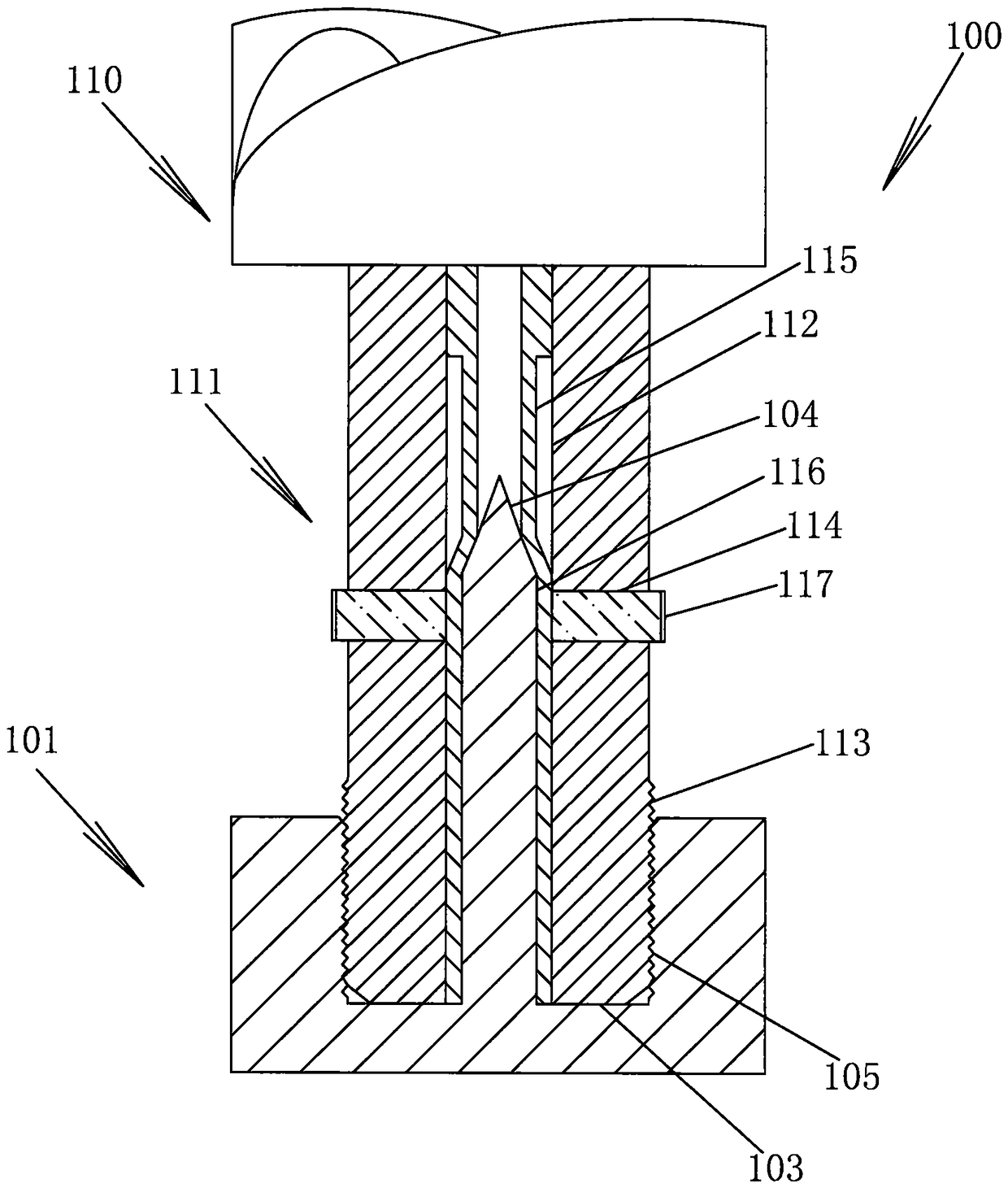

[0059] The fastening kit of the present invention includes a bolt and a nut, the bolt includes a head and a screw rod, and the screw rod includes a first end fixedly connected to the head, a second end threadedly connected to the nut, and two ends An elastic energy storage part combined with the upper part, the elastic energy storage part forms a deformation structure corresponding to the force of the threaded connection between the first end part and the second end part.

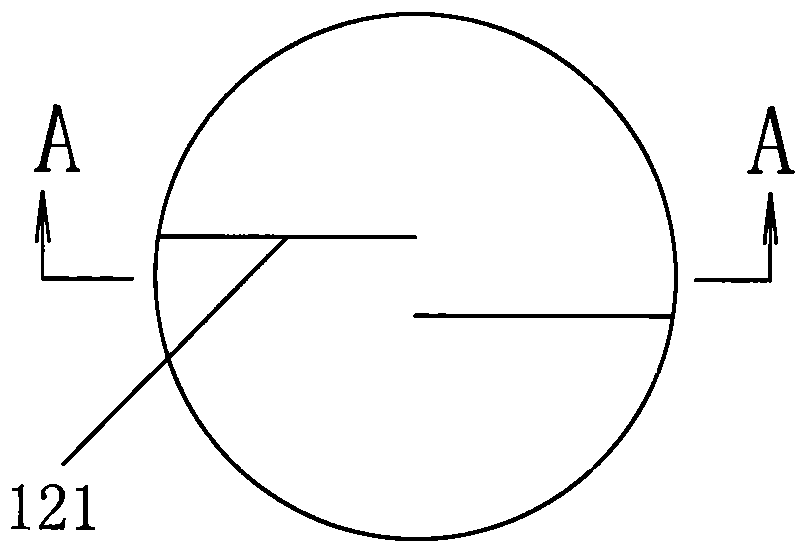

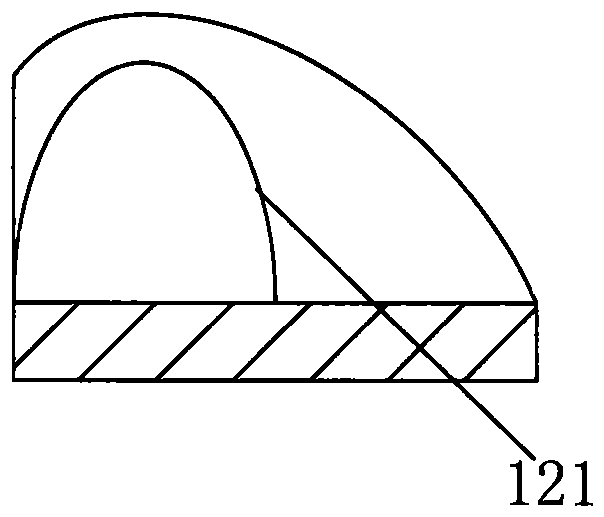

[0060] Such as figure 1 As shown, the two ends of the screw go through a through hole, the elastic energy storage component is fixed in the through hole, and the protruding part at the center of the nut is inserted into the elastic energy storage component. The two ends of the screw 111 are connected as a whole, and the elastic energy storage component is an extruded circular tube 115 , which further includes a first push rod 117 .

[0061] Such as Figure 9 As shown, the second end of the screw includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com