An adjustable plug-in pendant structure equipped with springs

An adjustable, plug-in technology, applied in building construction, covering/lining, construction, etc., can solve the problems of installation and disassembly difficult to locate, hidden safety hazards, difficult to repair, etc., to achieve the effect of convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

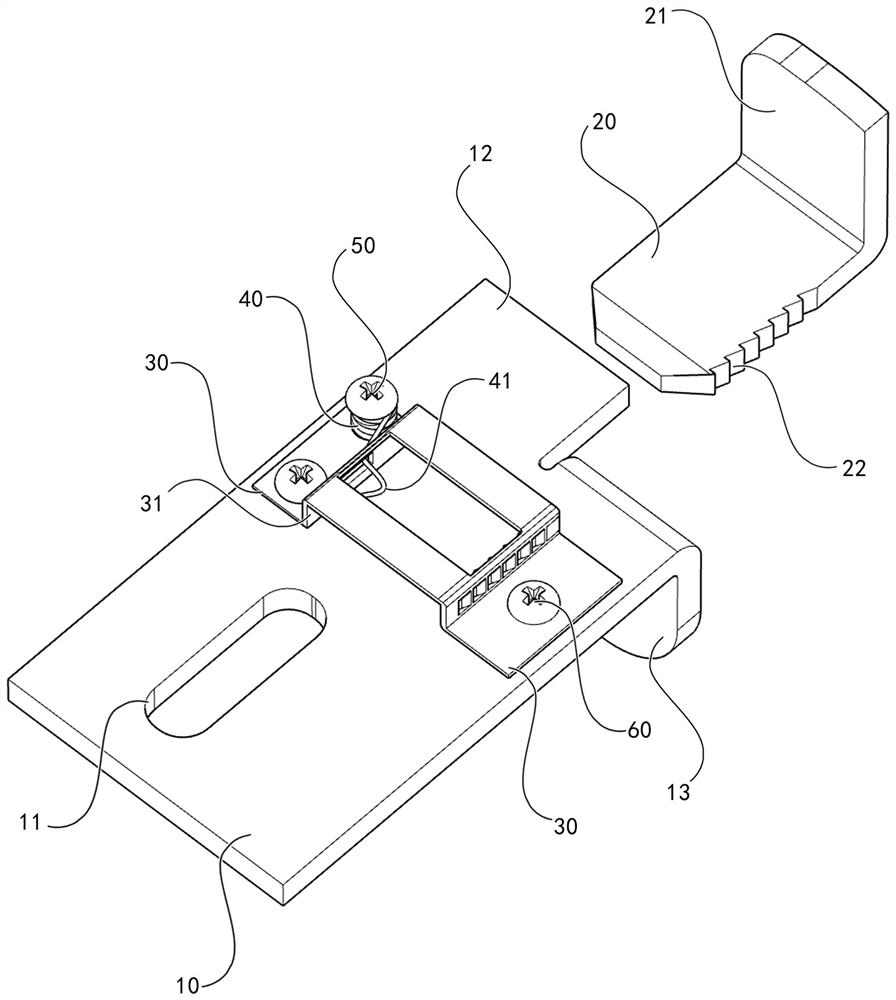

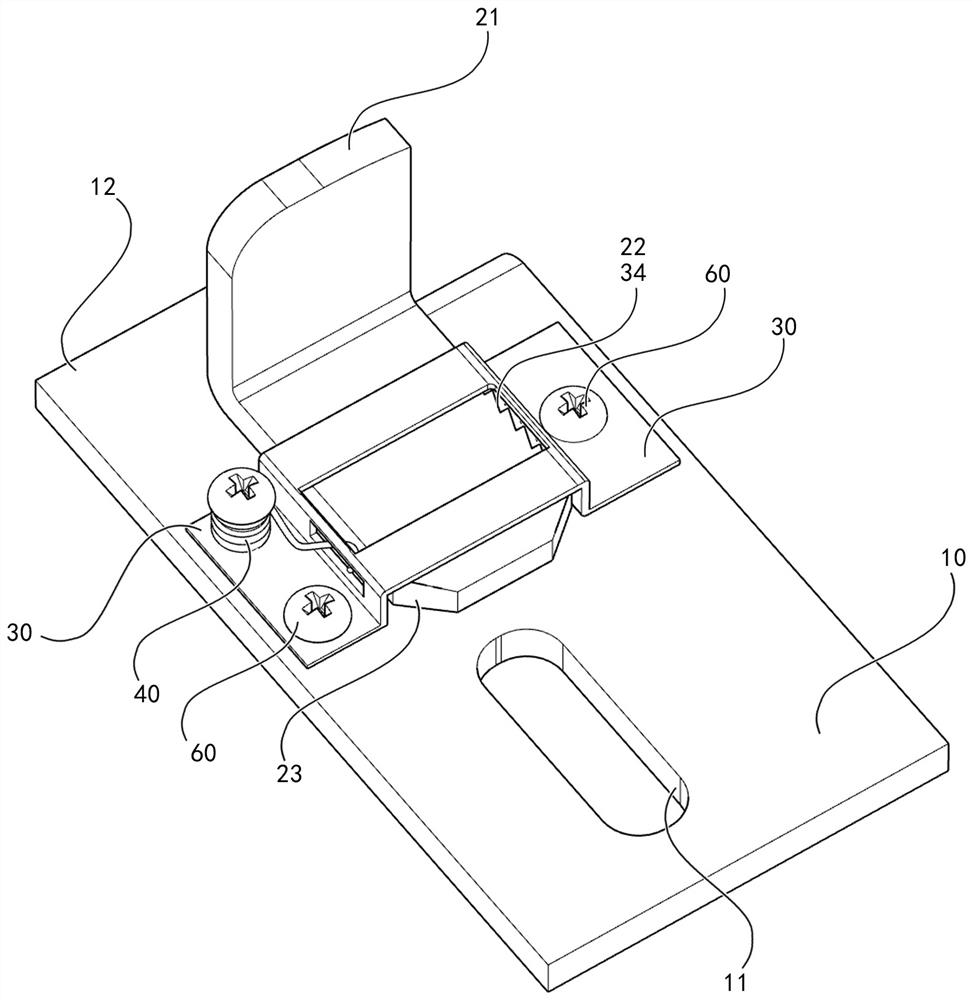

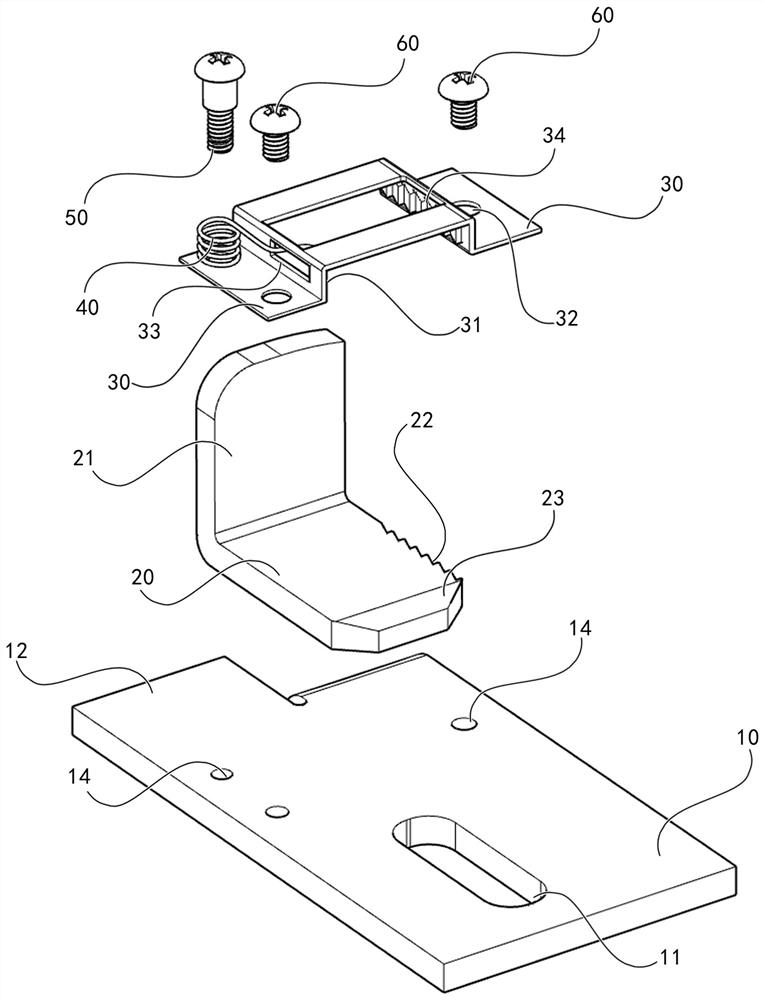

[0017]Next, the present invention will be further explained in conjunction with the accompanying drawings and examples:Figure 1 to 4As shown, an adjustable plug-in structure having a spring, including a pallet 10, a block 20, a positioning cover 30, a spring ring 40, a spring limit plug 50, a screw 60, which is characterized in that the support is The rear end of the plate 10 is provided with a positioning bolt hole 11, and the front end is provided with a strut 12 and a lower hook head 13, and the intermediate is provided with a threaded hole 14; the front end of the insert block 20 is provided with a hook head 21 rear end setting with a slope 23, right The side is provided with a positioning slope 22; a through hole 32 is provided on both sides of the positioning cover 30, and the intermediate is provided with a block passage 31, and the spring groove 33 is provided on one side of the block passage 31 is provided. The other side is provided with reverse Tottess 34; the screw 60 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com