Bolt assembly having non-loosening nut

A technology of anti-loosening nut and bolt assembly, applied in the direction of nuts, bolts, threaded fasteners, etc., can solve the problems of reduced durability of fixed feet, increased production costs, increased operating hours, etc., to achieve the suppression of loosening, suppression of recovery, and restraint force-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] best practice

[0041] The terms or words used in this specification and claims should not be interpreted as the general meaning or the meaning defined in the dictionary, but should be based on the concept that the inventor can properly define the term in order to describe the present invention in the best way. The principles are interpreted as meanings and concepts consistent with the technical ideas of the present invention.

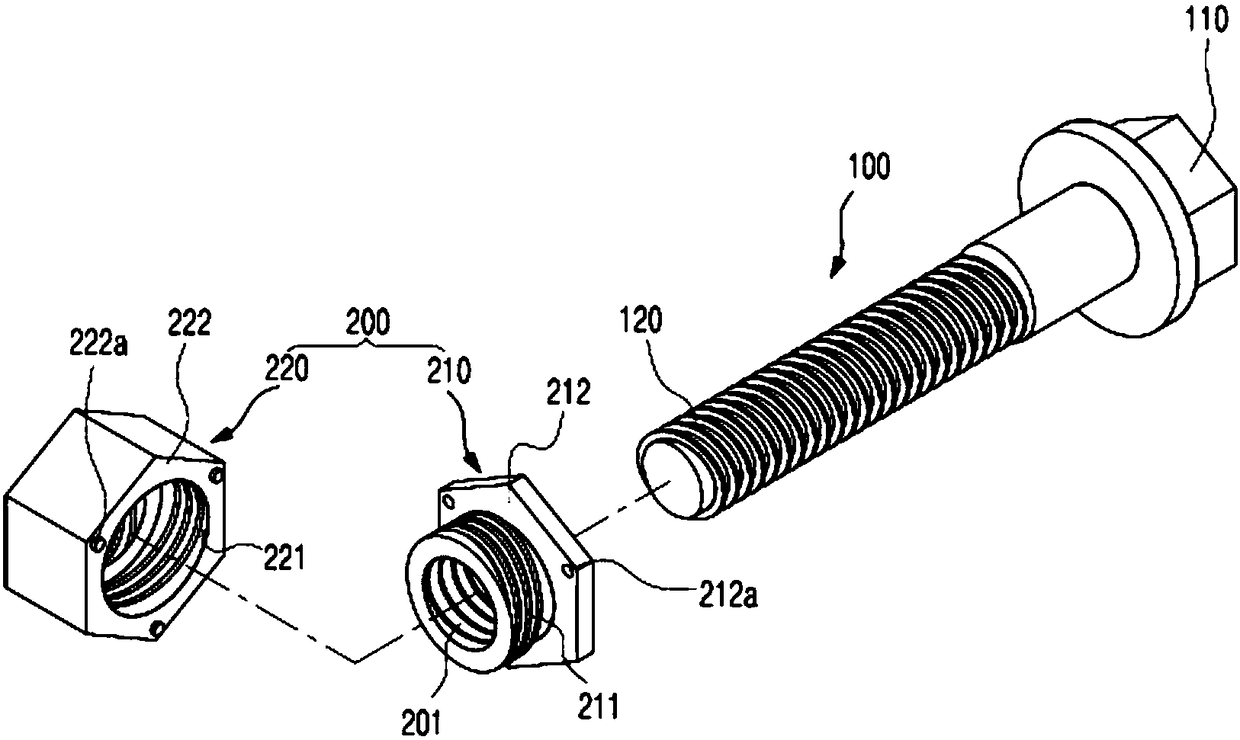

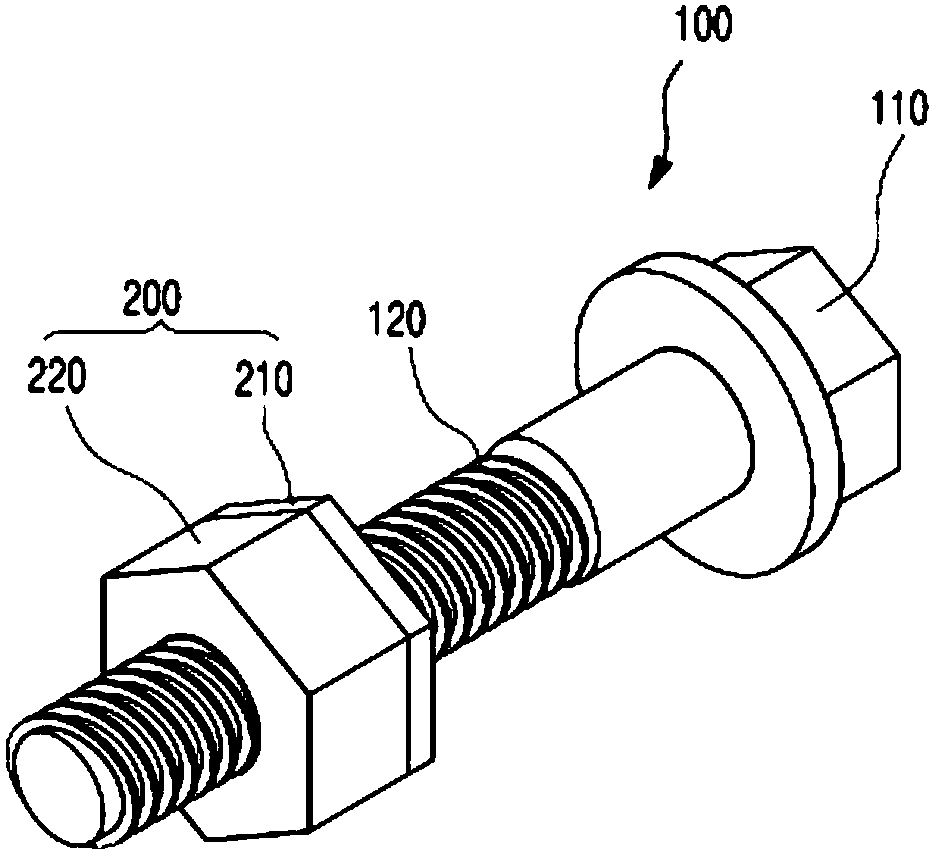

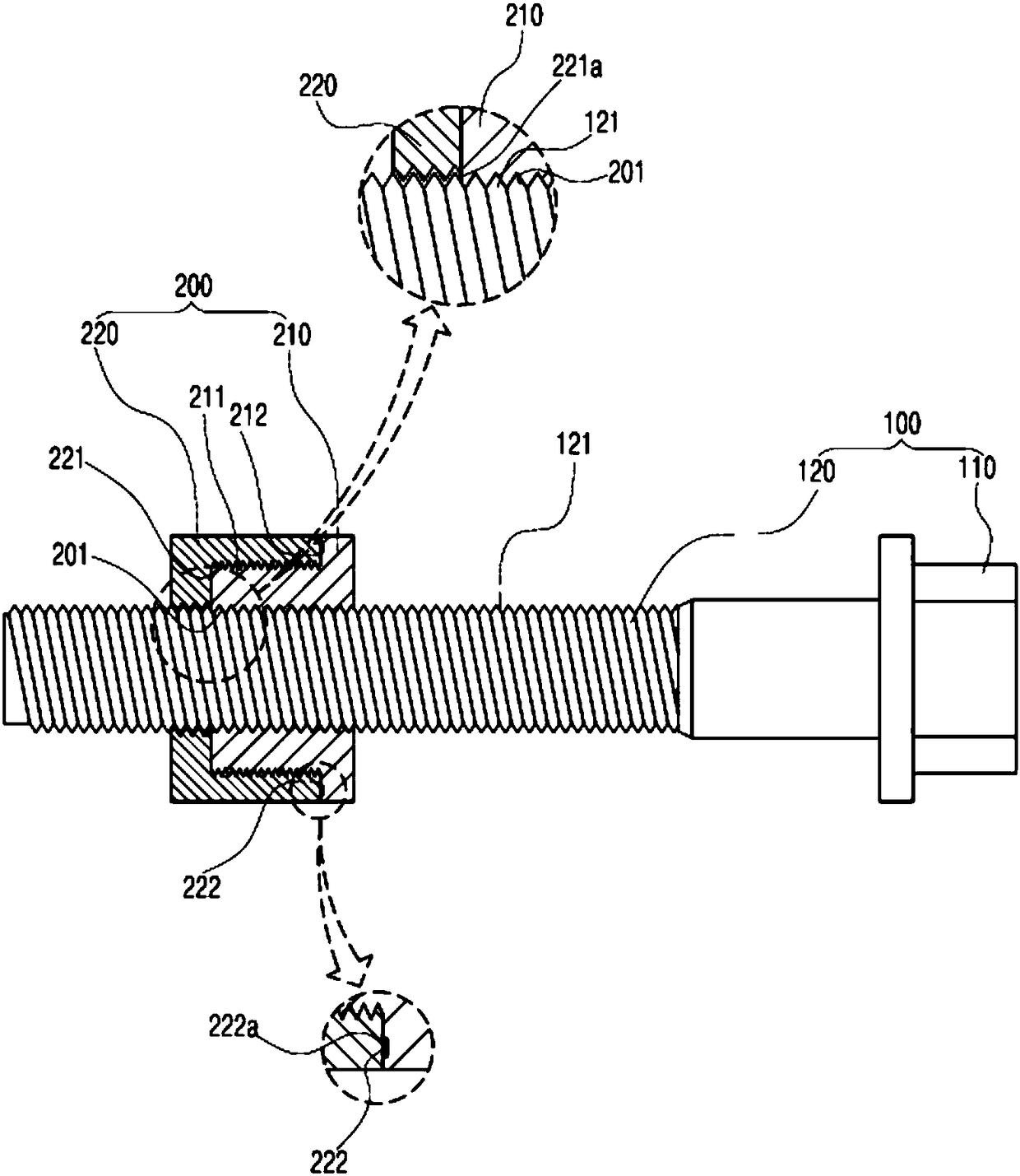

[0042] Below, refer to Figure 1 to Figure 6b A bolt assembly with a locknut (hereinafter referred to as "bolt assembly") according to a preferred embodiment of the present invention will be described.

[0043] The bolt assembly has the technical feature of including a pair of locknuts on the external thread of the bolt.

[0044] Regardless of the tightening of the bolts, the locknuts are composed of a pair of nuts tightened on the threads of the bolts, and the external threads are squeezed by the action of the pair of locknuts being pulled ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com