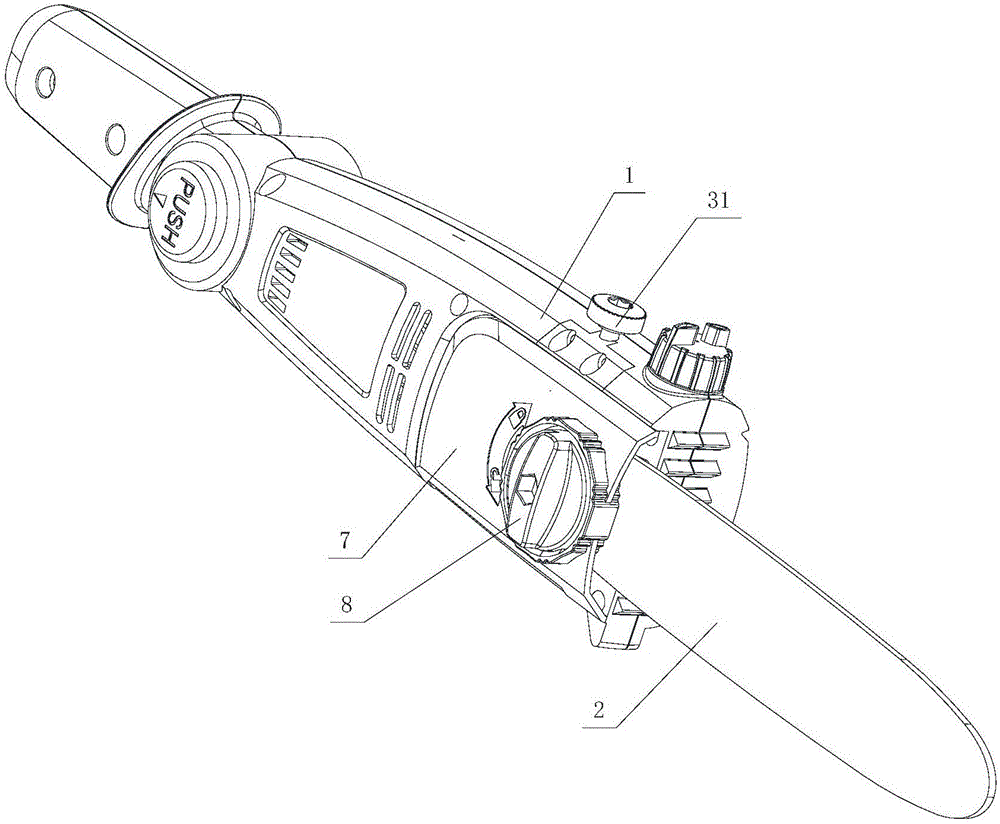

Chain tensioning mechanism of chain saw and assembly method of chain saw with such mechanism

A tensioning mechanism and chain saw technology, applied in the assembly of chain saws and chain saw chain tensioning mechanisms, can solve problems such as endangering personal safety, damage to the chain saw, and loose saw chains, achieving convenient operation, improving installation efficiency, Not easy to loosen effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

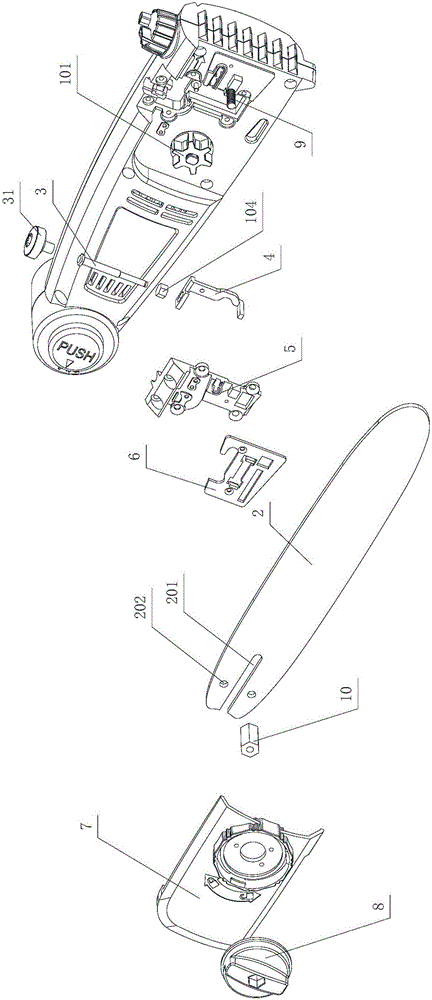

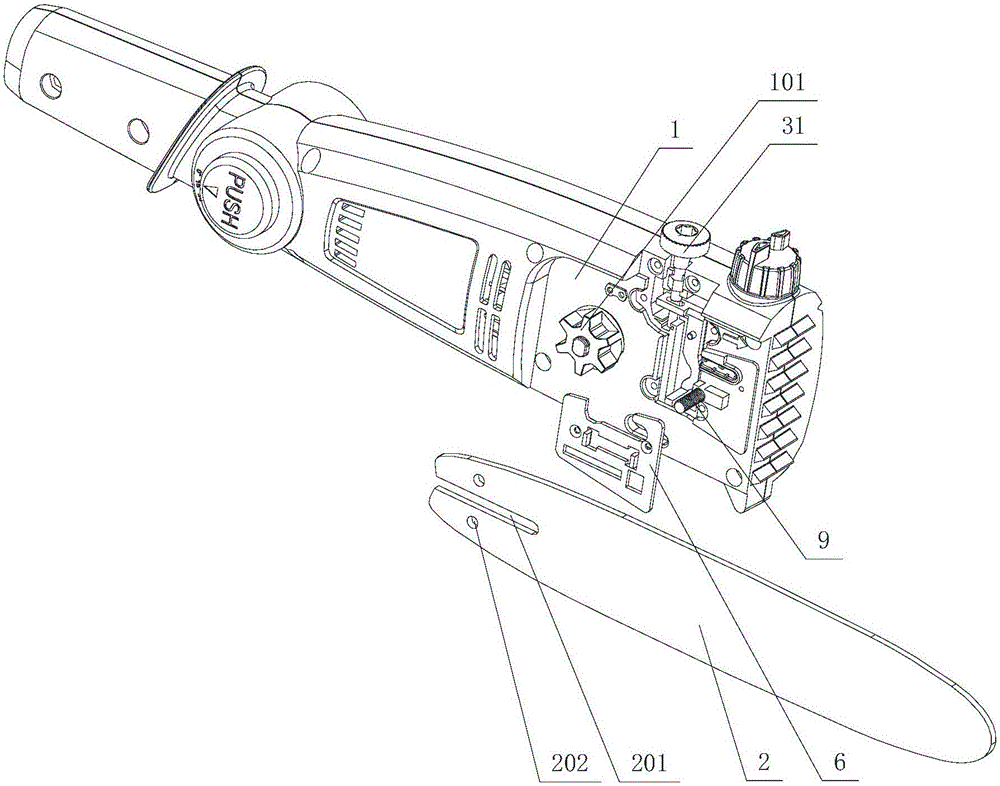

Embodiment 1

[0040] Embodiment 1: The adjusting bolt is provided with a limit block or limit plate for axial limit. The limit block or limit plate is circular as a whole. To move, its diameter is greater than the width of the strip groove, so it can contact the upper surface of the platen.

Embodiment 2

[0041]Embodiment 2: The end of the adjusting bolt is provided with a rod body that can be inserted into the bar groove, and a shaft shoulder for axial limitation is formed between the rod body and the threaded body of the adjusting bolt, that is, the diameter of the rod body is smaller than that of the bar groove. width, and the diameter of the threaded body at the lower end of the adjusting bolt is larger than the width of the bar groove, so the threaded body cannot be inserted into the bar groove, and a shoulder is formed between two cylinders with different diameters. When in use, the shoulder and the pressure plate contact with the upper surface.

[0042] A push hole 202 is provided on the chain saw guide plate 2. Preferably, there are two push holes symmetrically arranged on both sides of the strip chute, which can facilitate the installation of the chain saw guide plate, that is, both sides of the chain saw guide plate can be installed ; A push rod 402 that is parallel t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com