Patents

Literature

239results about How to "Improve tightening effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

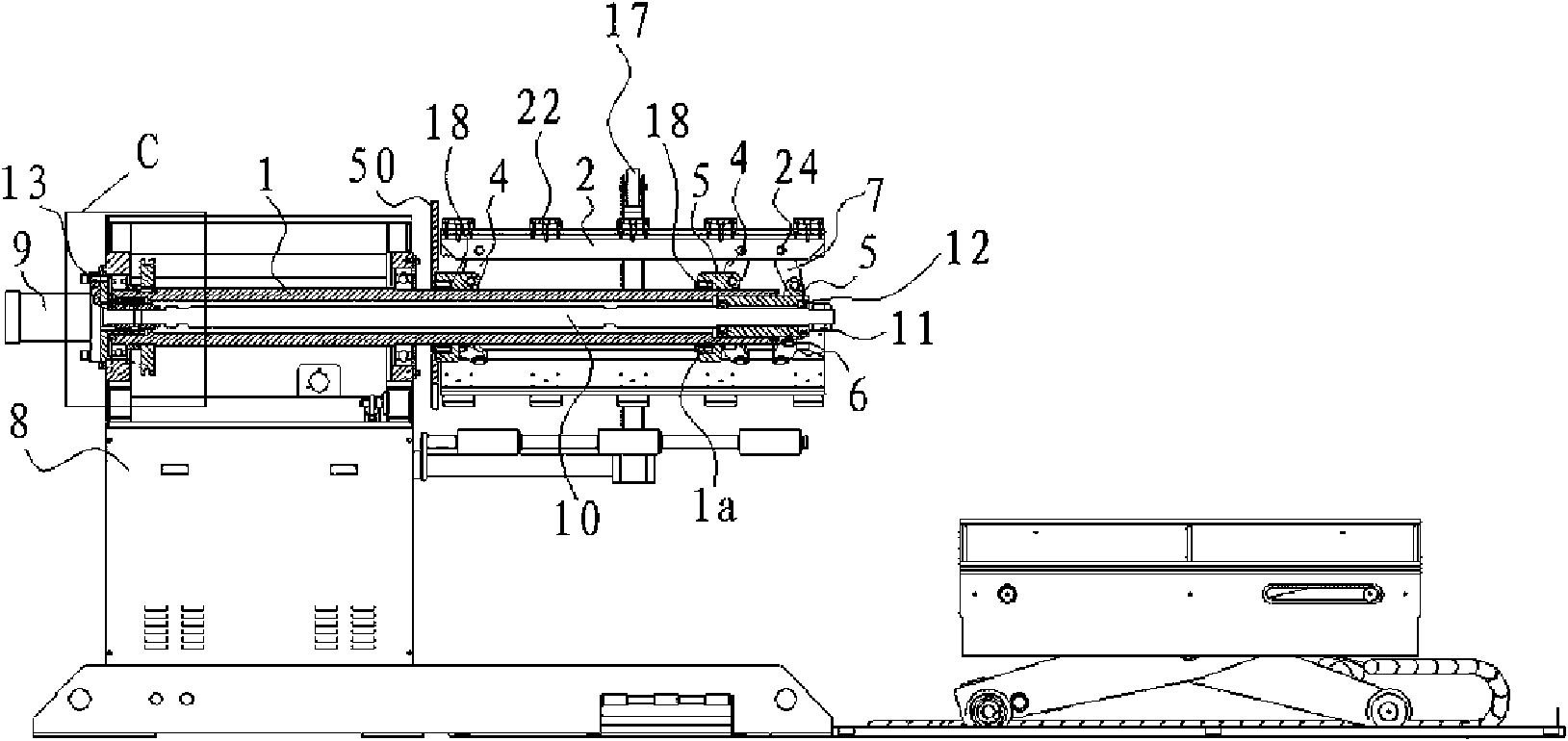

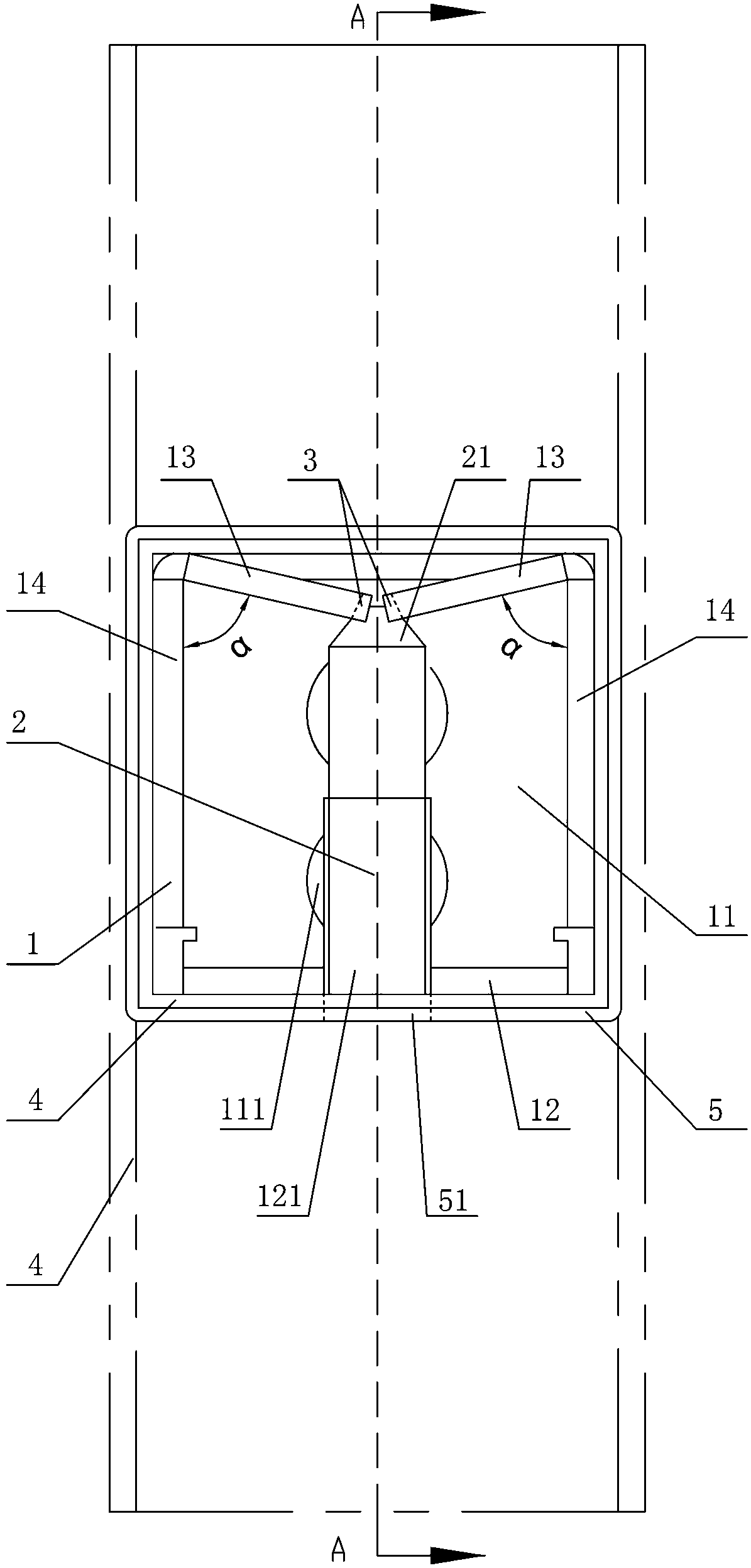

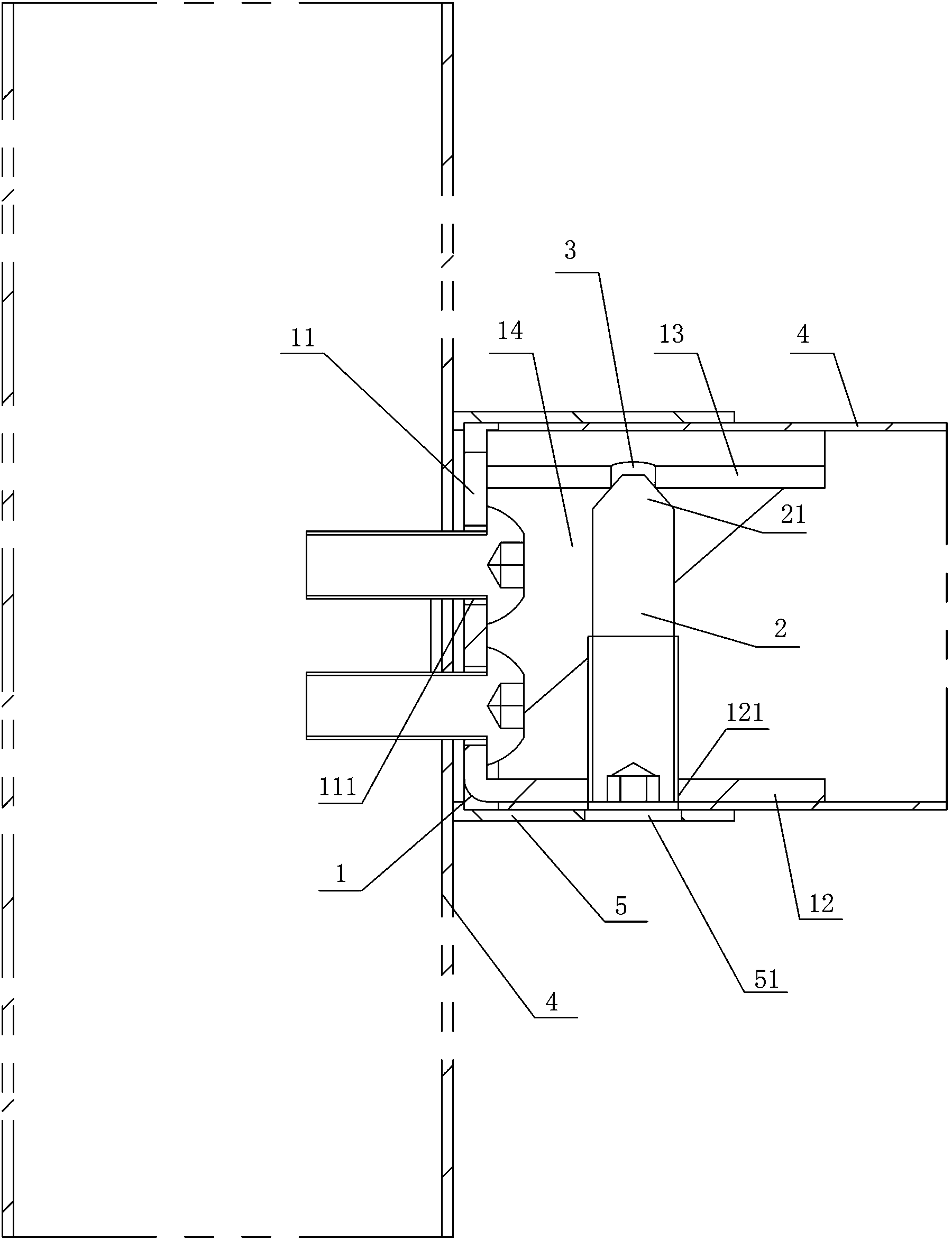

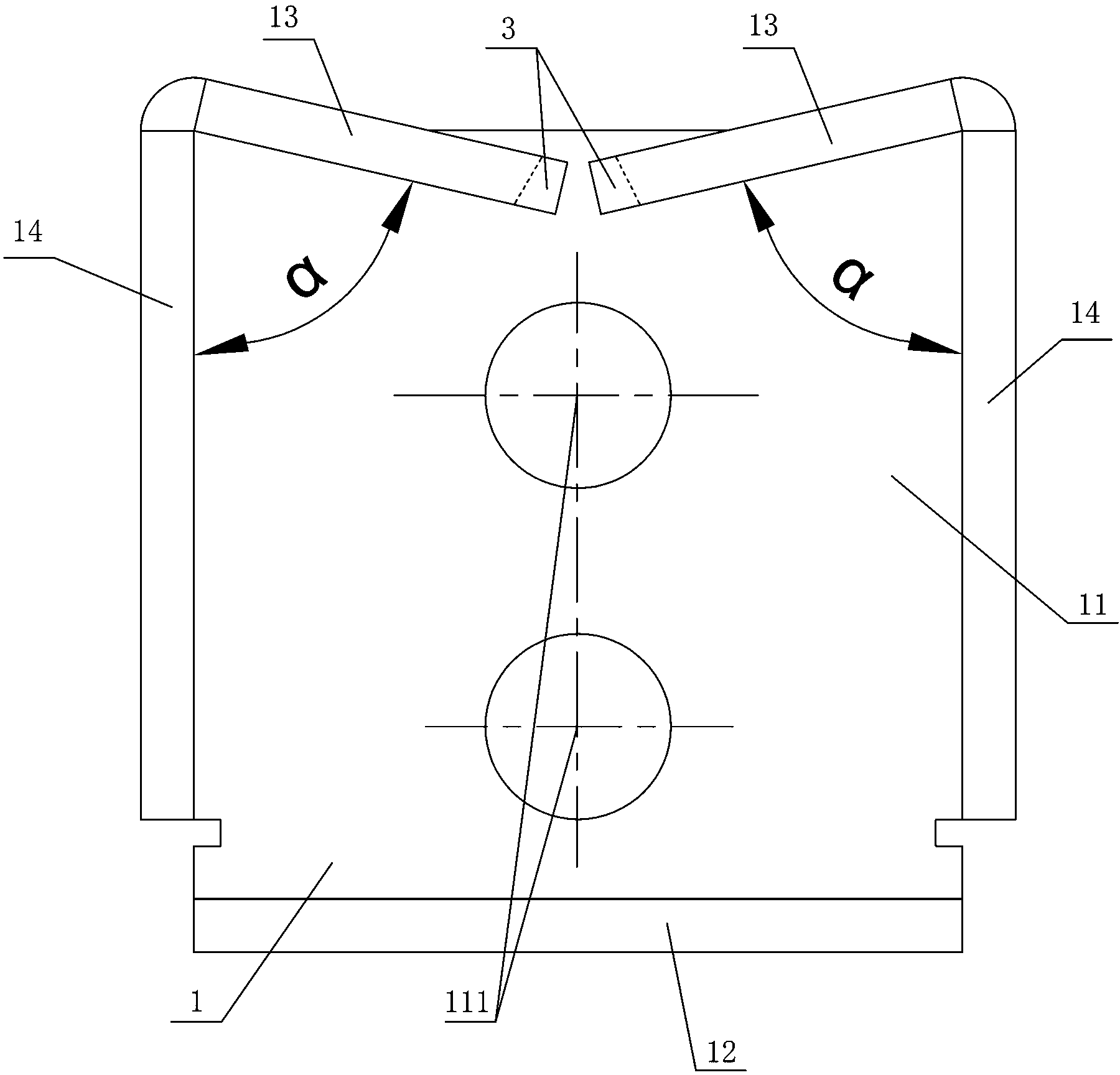

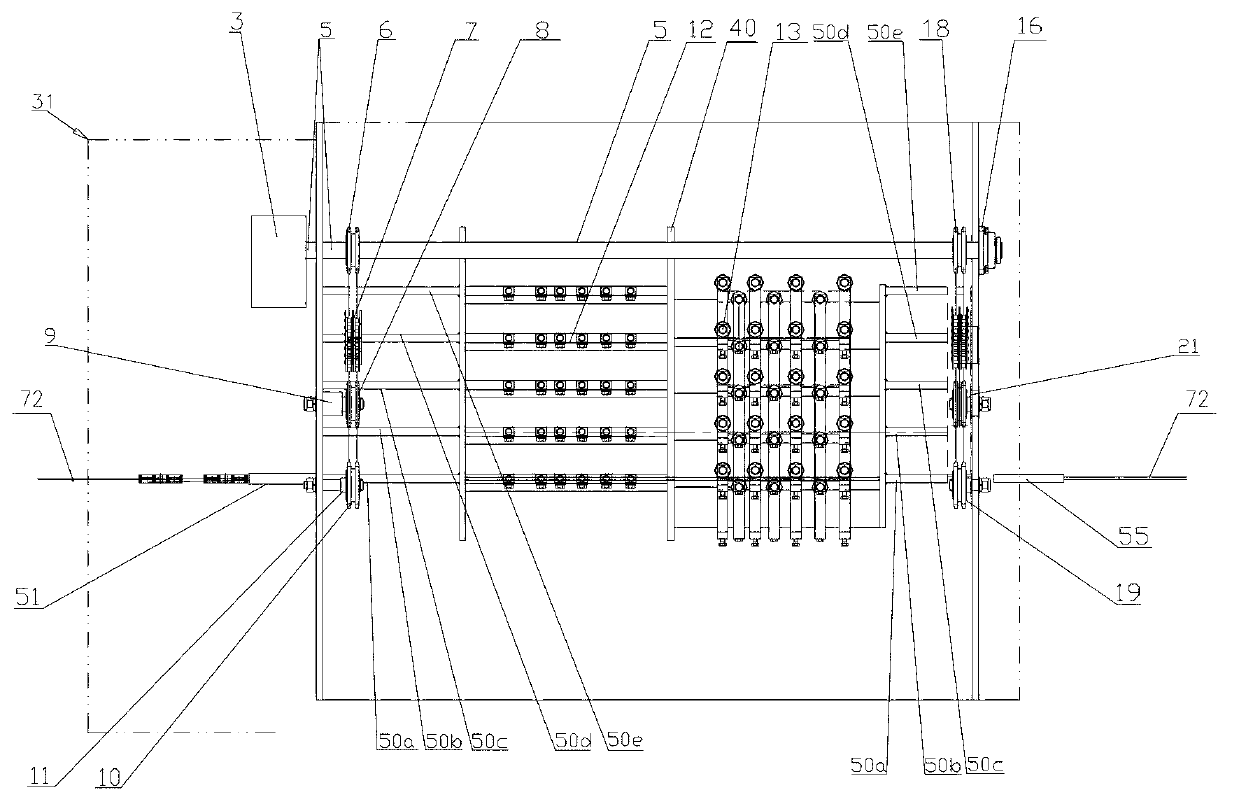

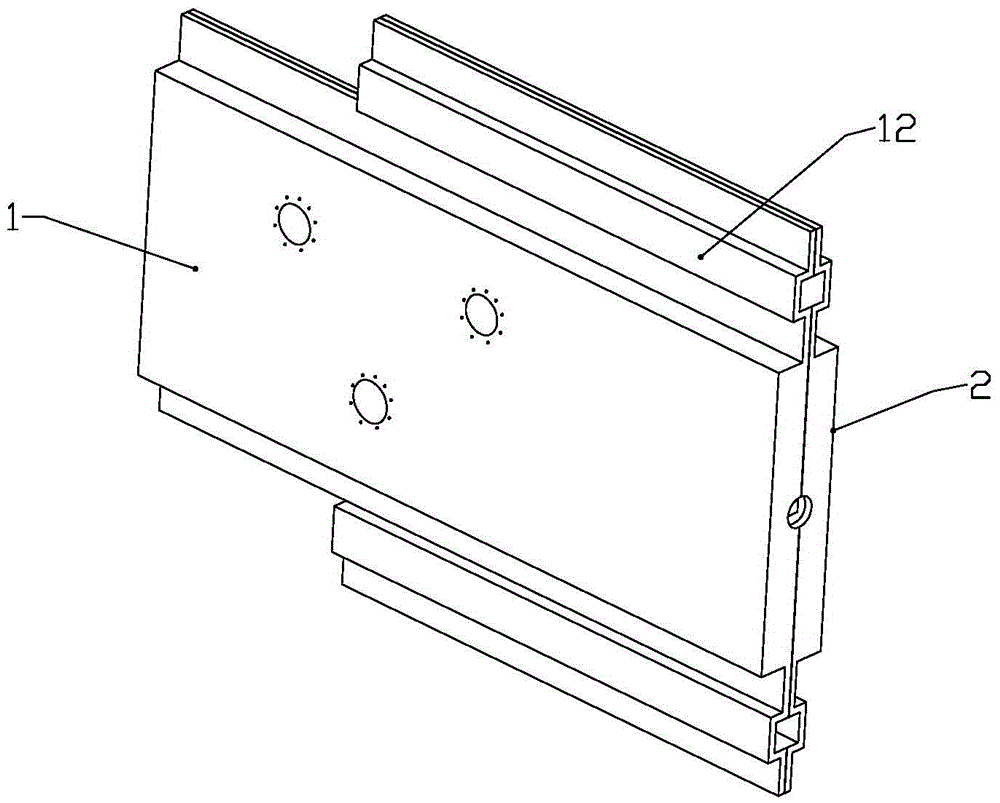

Steel coil tensioning device of full-automatic uncoiler

The invention provides a steel coil tensioning device of a full-automatic uncoiler, belongs to the technical field of uncoilers and overcomes the defects of high price, huge volume, difficult popularization and application and short service life of a conventional large heavy-duty uncoiler. The steel coil tensioning device of the full-automatic uncoiler comprises a hollow rotary shaft of which one end part serves as a construction section and the other end serves as a cantilever section, and a plurality of tensioning plates distributed at the periphery of the cantilever section of the rotary shaft; the construction section of the rotary shaft is connected to a base; a connection rod is arranged between each tensioning plate and the rotary shaft; one end of the connection rod is hinged to the corresponding tension plate, while the other end is hinged to the rotary shaft; and the tensioning plate is connected with a spreading / shrinking mechanism capable of driving all tensioning plates to spread or shrink at the same time. The tensioning device has the advantages of low manufacturing cost, adaptability to various steel coils with different specifications and relatively light weight, less abrasion, good tensioning effect and long maintenance period.

Owner:ZHEJIANG JINGGONG SCI & TECH

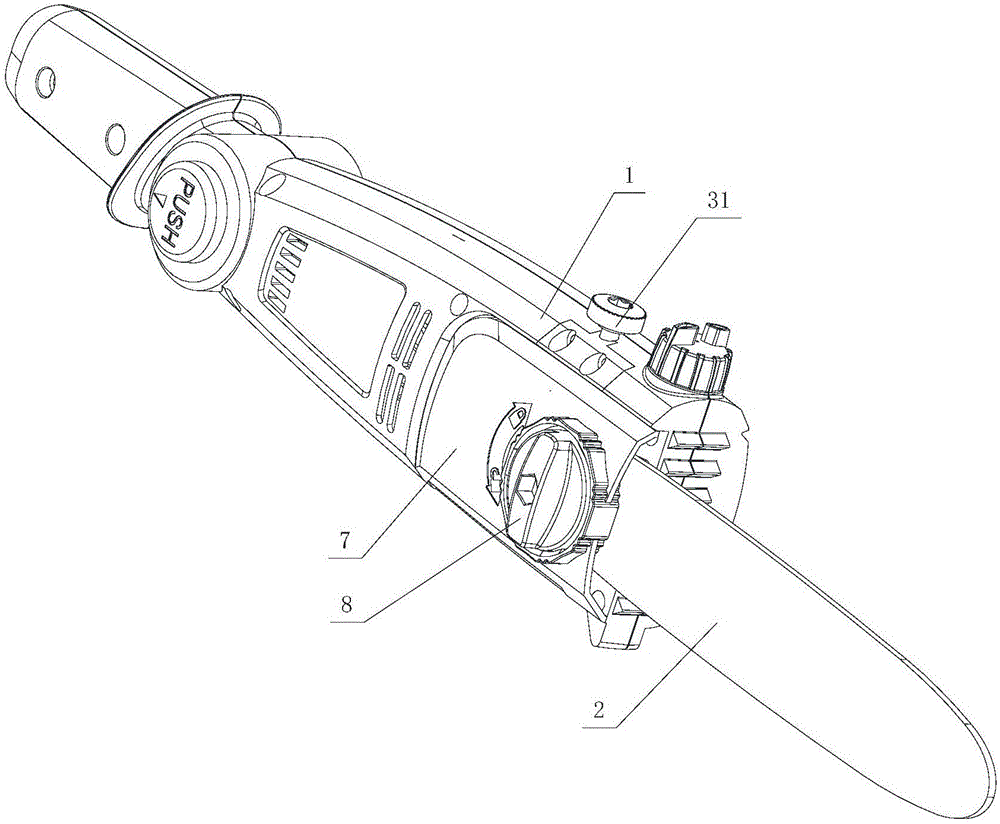

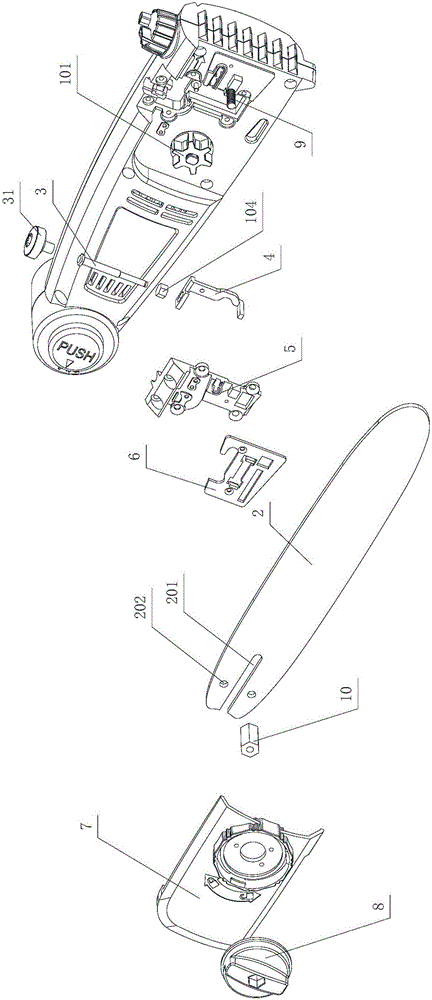

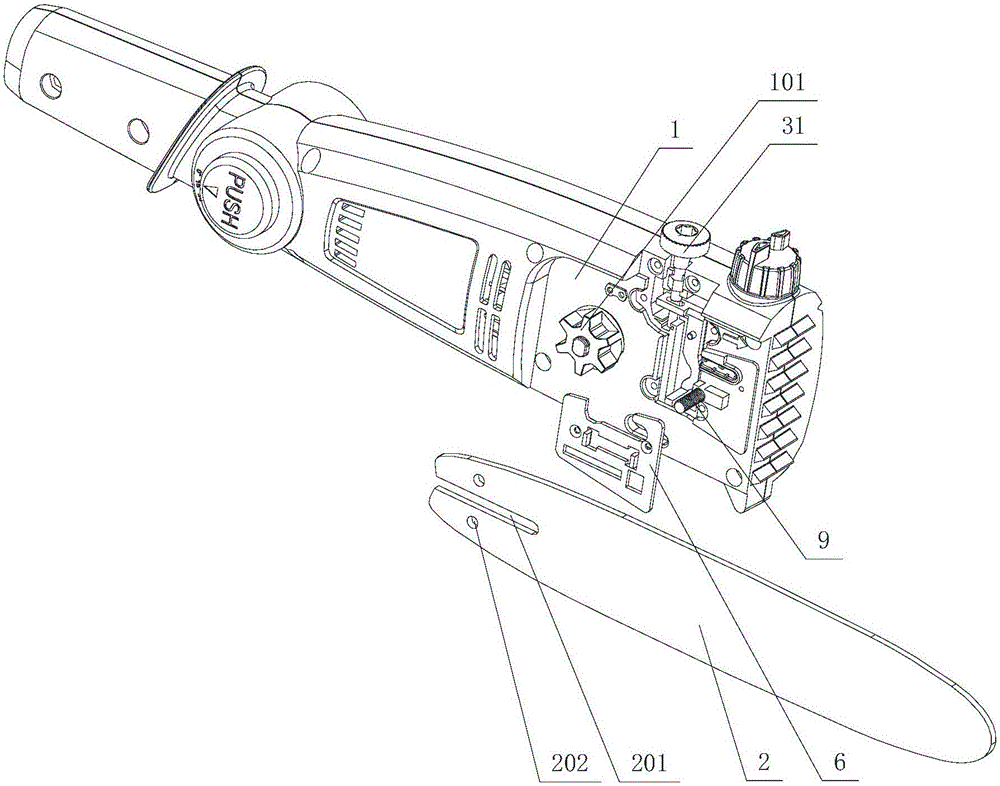

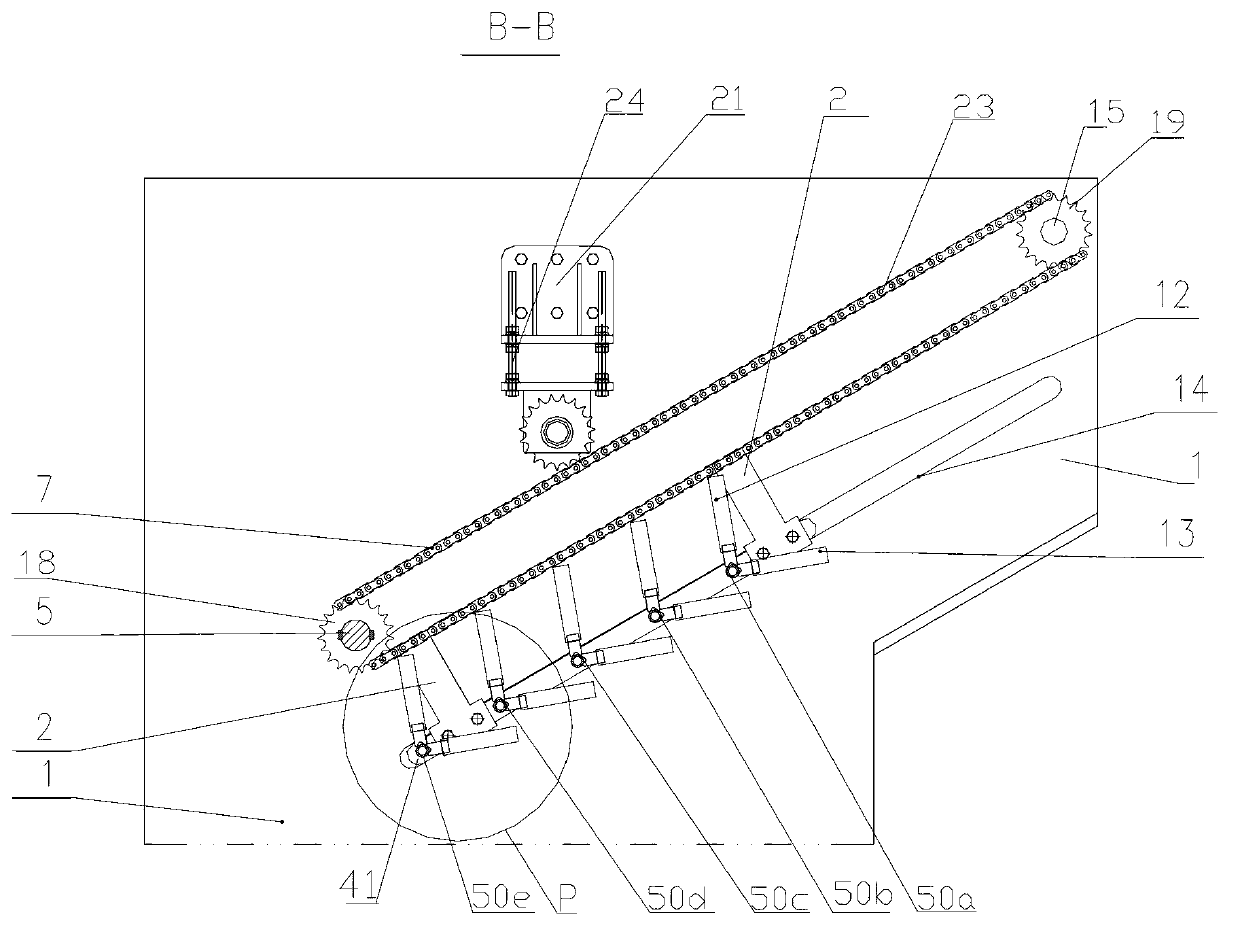

Chain tensioning mechanism of chain saw and assembly method of chain saw with such mechanism

The invention provides a chain tensioning mechanism of a chain saw. The chain tensioning mechanism comprises a housing, a chain saw guide plate, an adjusting bolt and a lever; a driving chain wheel is arranged in the housing; the chain saw guide plate is in slide fit with the housing, and a sliding direction of the chain saw guide plate is perpendicular to and intersects an axis of the driving chain wheel; the adjusting bolt is in threaded connection with the housing, and an axis of the adjusting bolt forms an included angle with the sliding direction of the chain saw guide plate; the lever is rotationally mounted in the housing; a head portion of the lever is connected with the adjusting bolt, while a tail portion of the lever is connected with the chain saw guide plate; and when the adjusting bolt is tightened, the lever pushes the chain saw guide plate to move towards a side far away from the driving chain wheel. Meanwhile, the present invention also provides an assembly method of a chain saw. The chain tensioning mechanism of the chain saw provided by the present invention is simple and compact in structure, convenient to operate, good in tensioning effect and reliability, and not prone to slip, thereby greatly improving the safety.

Owner:NINGBO ENERGY POWER TOOLS

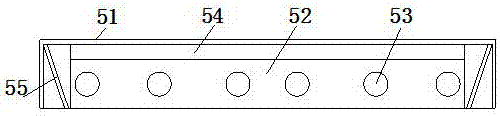

Automatic solar photovoltaic surface cleaning device and cleaning method thereof

ActiveCN106944395AEasy to cleanImprove cleaning efficiencyPhotovoltaicsCleaning using toolsSurface cleaningCleaning methods

The invention discloses an automatic solar photovoltaic surface cleaning device and a cleaning method thereof. The automatic solar photovoltaic surface cleaning device comprises a supporting frame (2); an attachment monitoring unit (3) is arranged at the upper end of the supporting frame (2); cleaning units (4) are arranged on the two sides of the supporting frame (2); a supplemental lighting unit (5) is arranged at the lower end of the supporting frame (2); the attachment monitoring unit (3) comprises a scanner (31); the scanner (31) is connected with a computer processing unit (6); the computer processing unit (6) is connected with a controller (7) and a photosensitive sensor (32); and the controller (7) is connected with the supplemental lighting unit (5) and the cleaning units (4). The cleaning method is characterized in that the surface of a photovoltaic panel is scanned by using the scanner, the quantity n of attachments in a unit area is calculated through the computer processing unit, and the cleaning units are controlled to work through the controller. The automatic solar photovoltaic surface cleaning device has the characteristics that the cleaning efficiency can be improved, the cleaning of the photovoltaic panel is facilitated, the cleaning effect is improved, potential safety hazards are eliminated, and the influence on power generation of the photovoltaic panel can be reduced.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

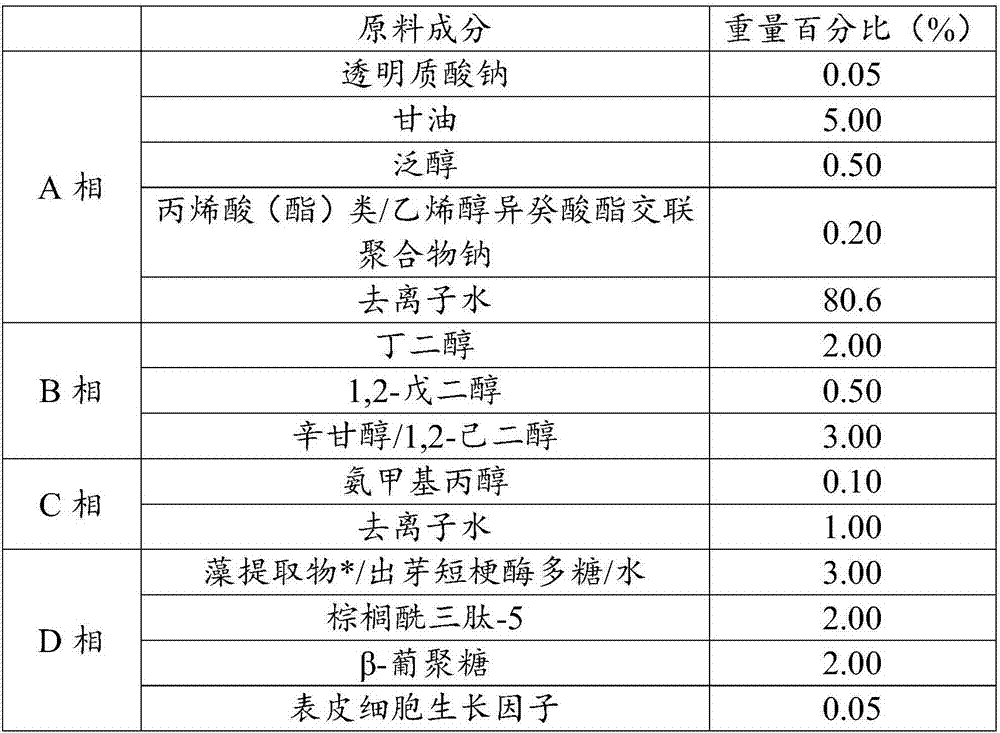

Wrinkle resisting and brightening algal mask and its preparation method

InactiveCN103110558AImprove tightening effectIncrease elasticityCosmetic preparationsToilet preparationsSkin tighteningWrinkle

The invention relates to a mask, and especially relates to a wrinkle resisting and brightening algal mask and its preparation method. The algal mask is prepared through using 50-80 parts by weight of algal powder, 5-15 parts by weight of pearl powder, 40-60 parts by weight of loquat leaf, 15-25 parts by weight of rose and 1-5 parts by weight of menthol. The algal mask has the advantages of scientific and reasonable formula, easily available raw materials and low price, and has the effects of face cleaning, skin moistening, blood circulation invigorating, stasis transforming, skin tightening property and elasticity increasing, recovering of lax skins to a young state, ageing delaying and human body metabolism adjusting, so the wrinkle removing and whitening purposes can be reached, and the needs of users can be greatly satisfied.

Owner:毛雪莲

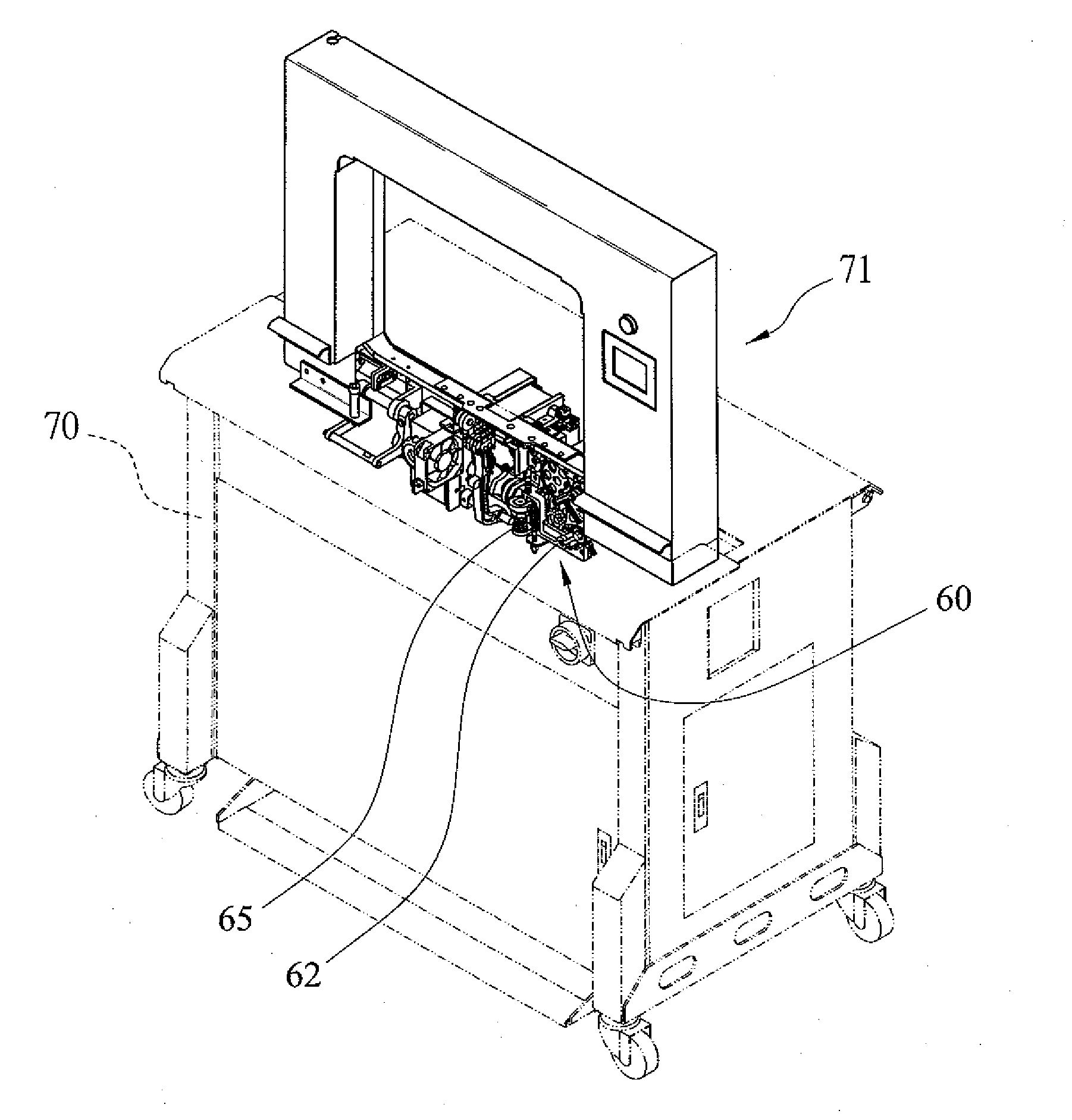

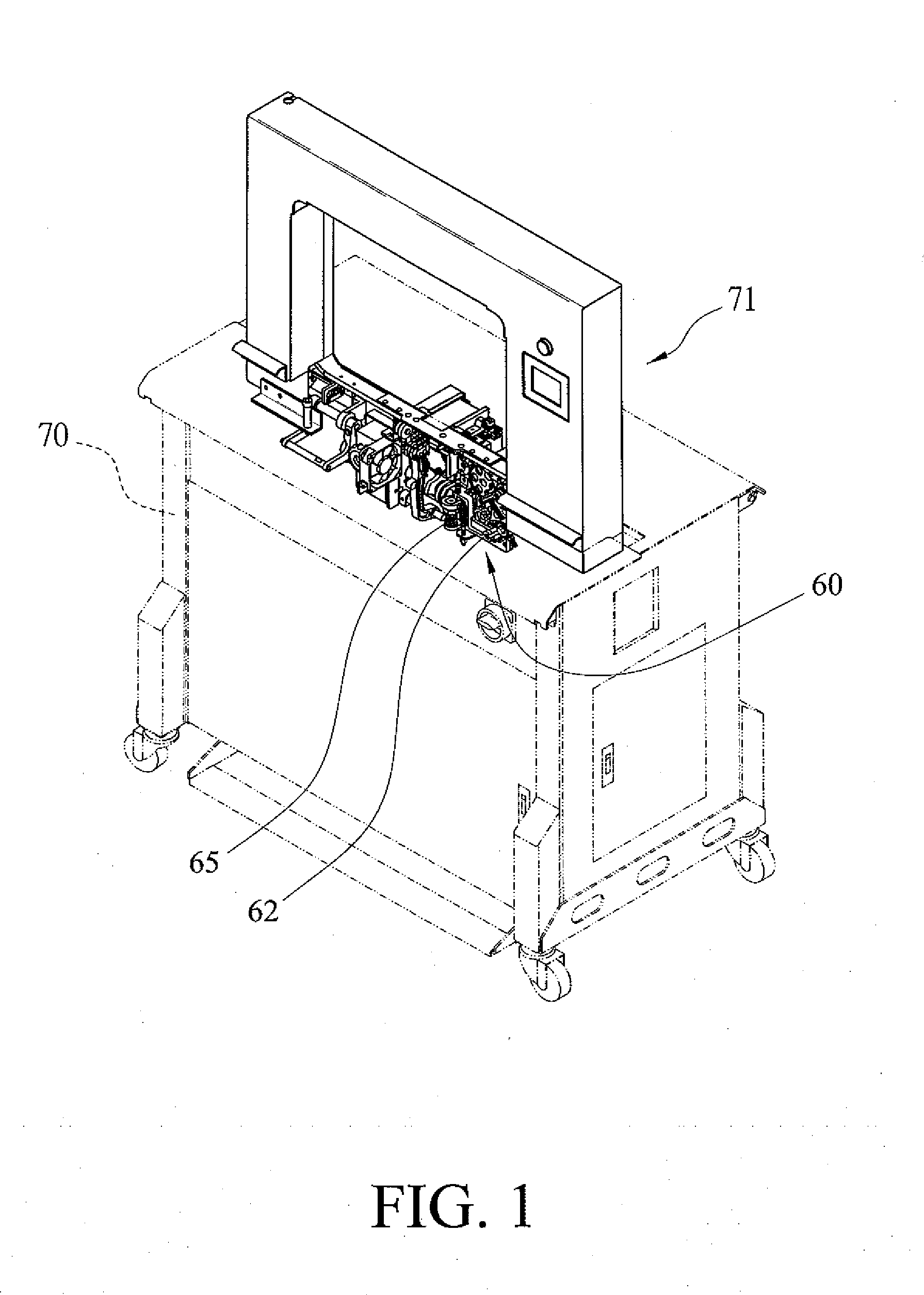

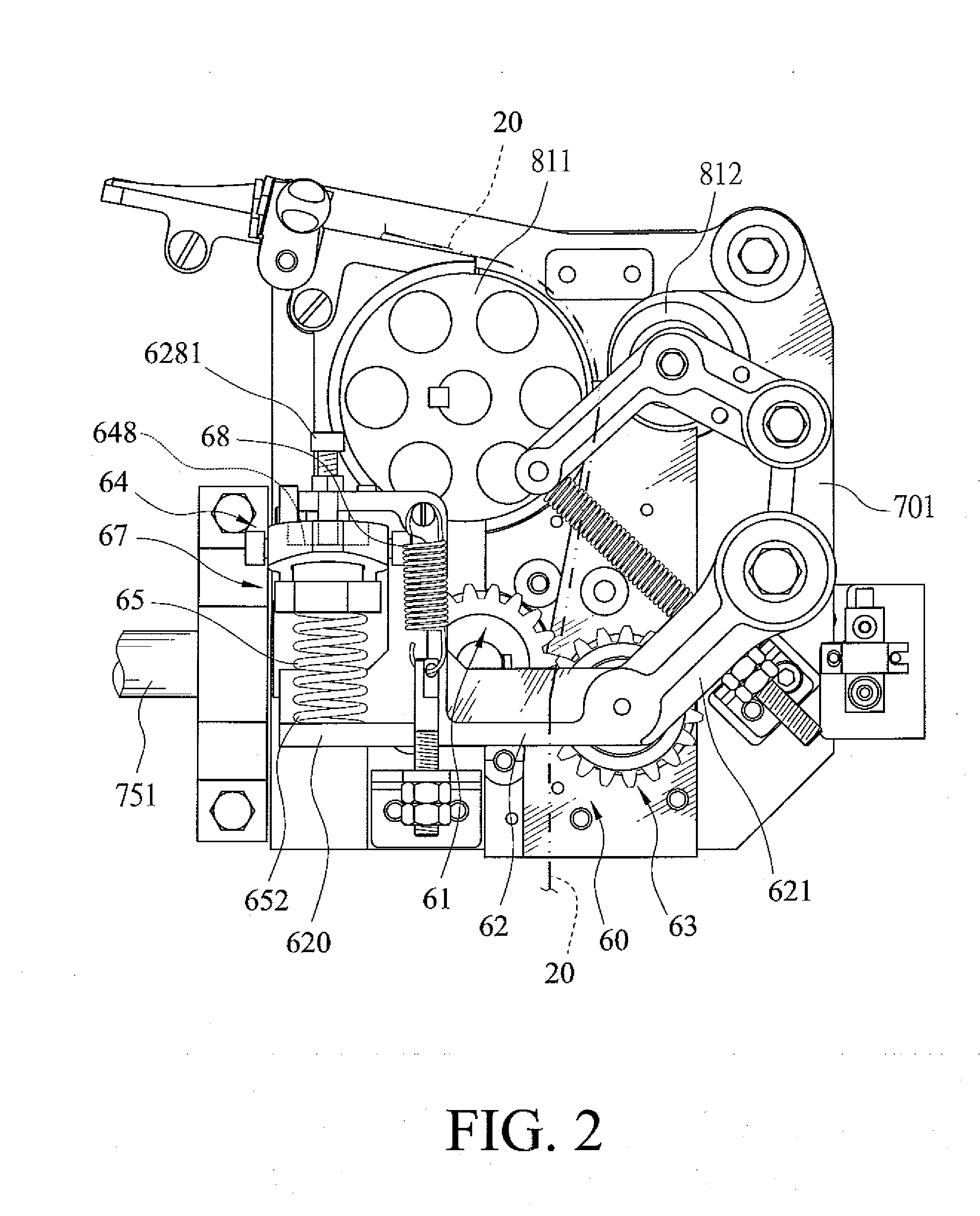

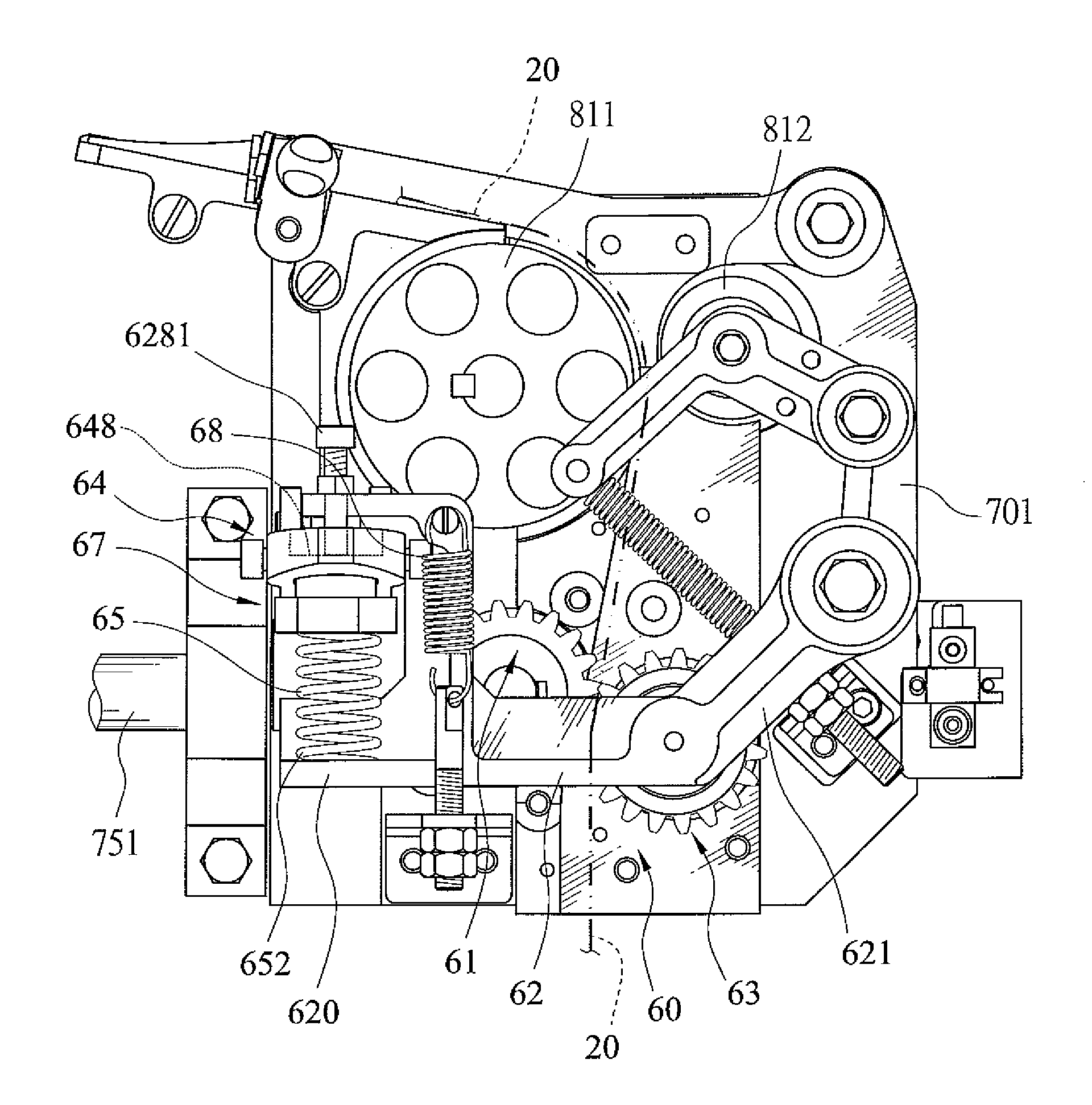

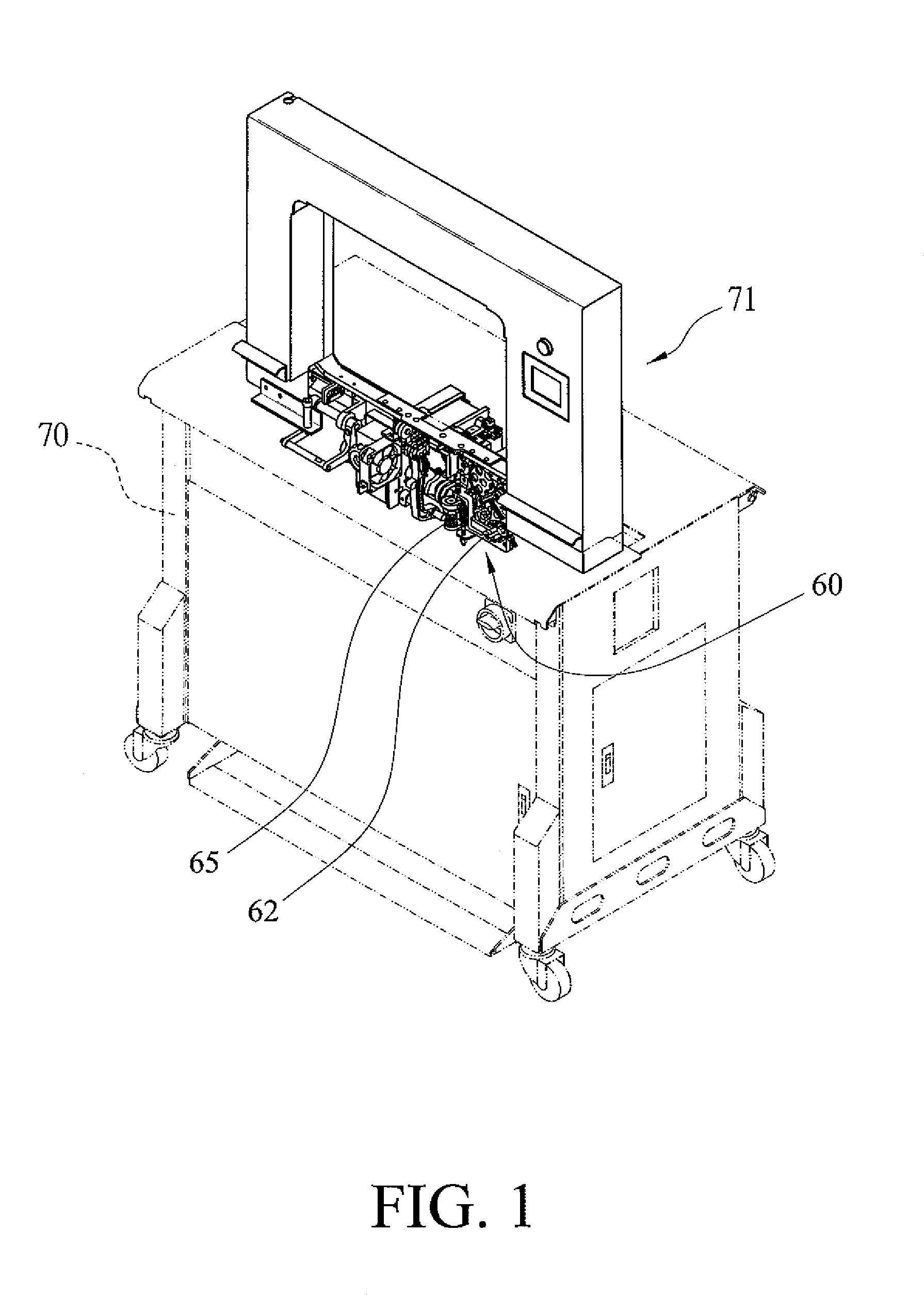

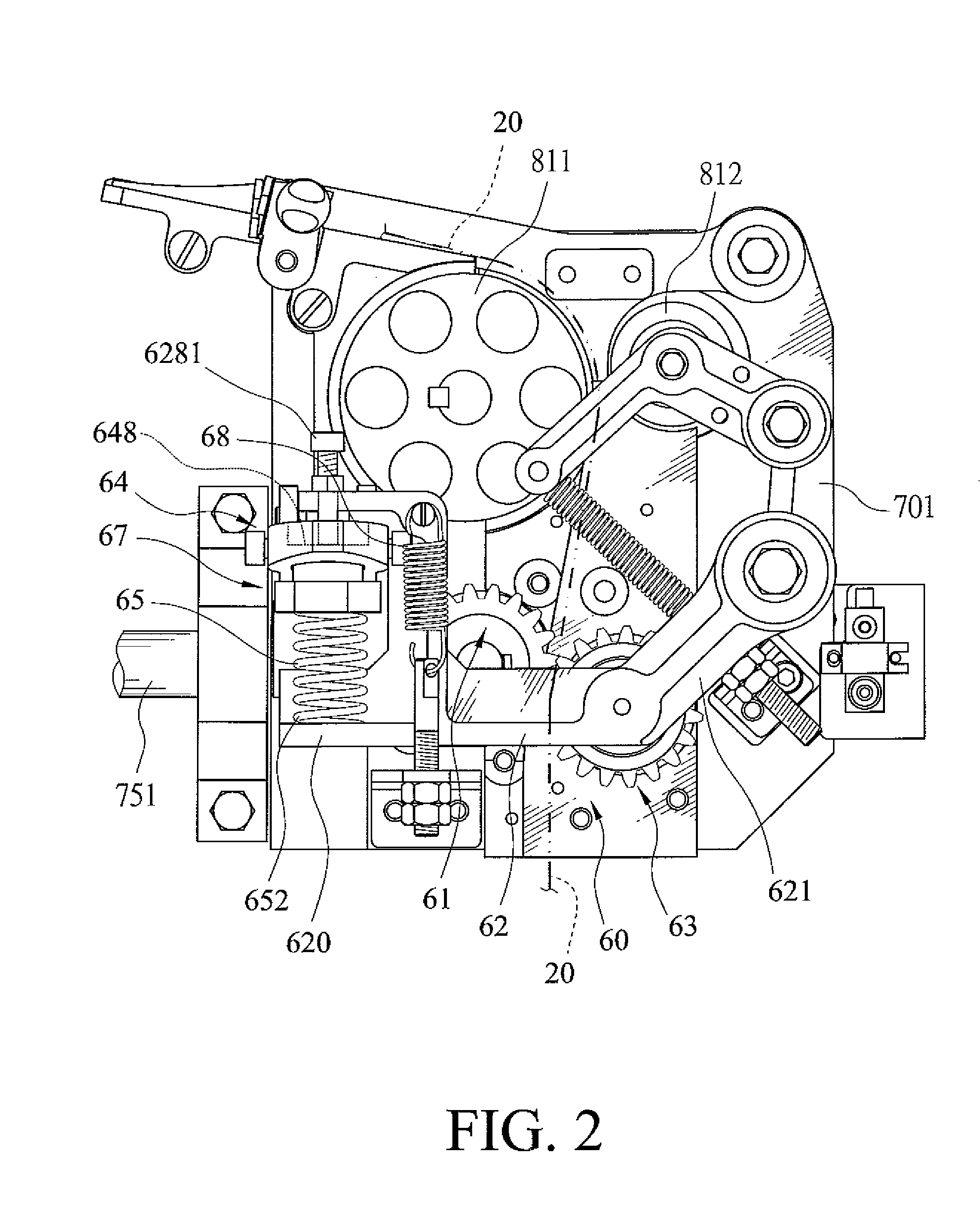

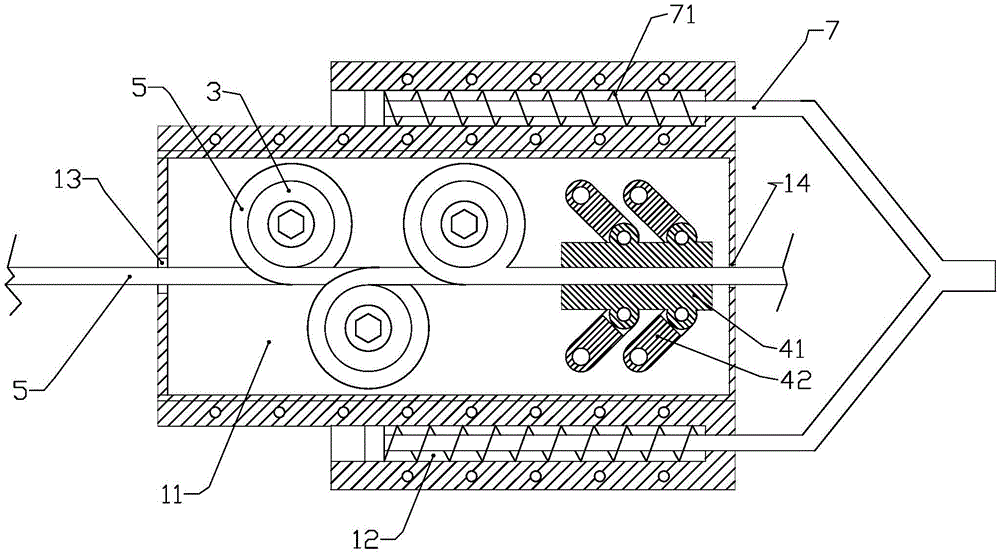

Reverse Tension Mechanism for a Strapping Machine

ActiveUS20130014654A1Small sizeImprove tightening effectBinding material applicationBundling machine detailsStructural engineeringMachine

A reverse tension mechanism for a strapping machine includes an active wheel, a supporting arm installed with a passive wheel, a lever, and a spring. The supporting arm can be moved relative to the active wheel so that a strapping band which passes through between the passive wheel and the active wheel is clamped to control retracting and tightening of the strapping band. A first end of the lever is pivotably connected to a section of the supporting arm, and the spring is vertically installed between a second end of the lever and the section of the supporting arm. The first end of the lever can be activated by a cam to press the spring vertically to produce pushing force to swing the supporting arm.

Owner:LAI CHIEN FA

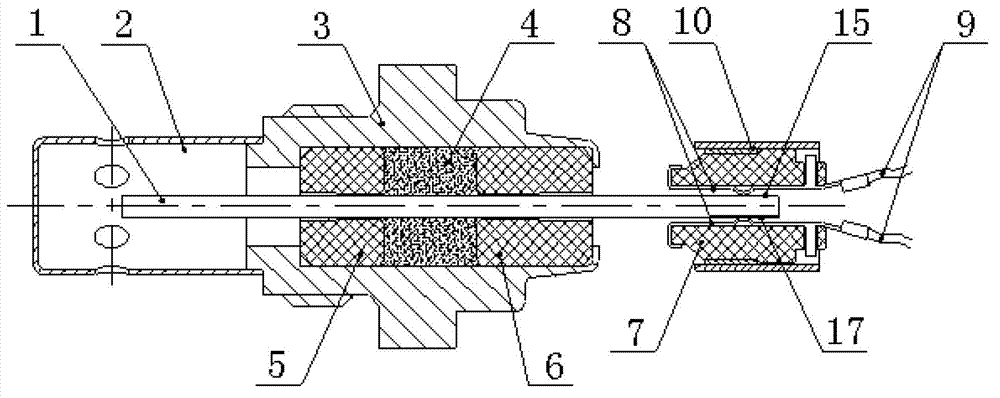

Packaging structure of flat plate type oxygen sensor

InactiveCN103196953AHigh precisionEfficient conductionMaterial analysis by electric/magnetic meansOxygen sensorElectrical and Electronics engineering

The invention discloses a packaging structure of a flat plate type oxygen sensor. The packaging structure is mainly characterized in that a socket and the structure of an upper positioning ceramic piece are structurally improved, wherein the socket is used for positioning and sealing an oxygen sensor chip, the conduction structure of chip electrode pins and wire terminals is improved, and a probe cover for protecting the head of the chip is improved, so that the oxygen sensor chip is simple in assembly process and easy to assemble, a signal of a packaged chip can be effectively conducted, the leakage of gas can be effectively prevented on the basis of effectively detecting the gas, and the detection accuracy of the oxygen sensor is greatly improved.

Owner:WUXI LONGSHENG TECH

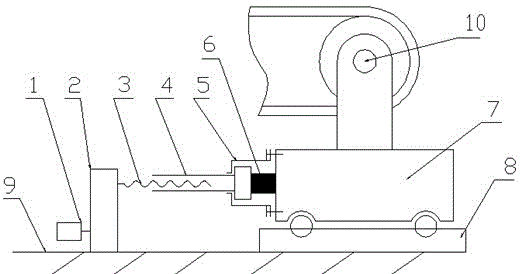

Tightening mechanism of conveyer belt

The invention relates to a tightening mechanism of a conveyer belt. A guide rail is arranged on a rack, a scooter is arranged on the guide rail, a belt fixing transmission device is fixed on an upper plane of the scooter, a screw tube sleeve is fixed on one end of the scooter through a fixation device; a pressure sensor is arranged between the end part of the screw tube sleeve and the scooter body; a screw rod is arranged in the screw tube sleeve; an outer end part of the screw rod is connected and fixed with an output shaft of a speed reducer; the speed reducer is mounted and fixed on the rack; and a servo motor is mounted and fixed on a speed reducer box body. The tightening mechanism of the conveyer belt has the advantages of simple structure, higher degree of automation, and better tightening effect.

Owner:SUZHOU BLUE KING MACHINE TOOL TECH CO LTD

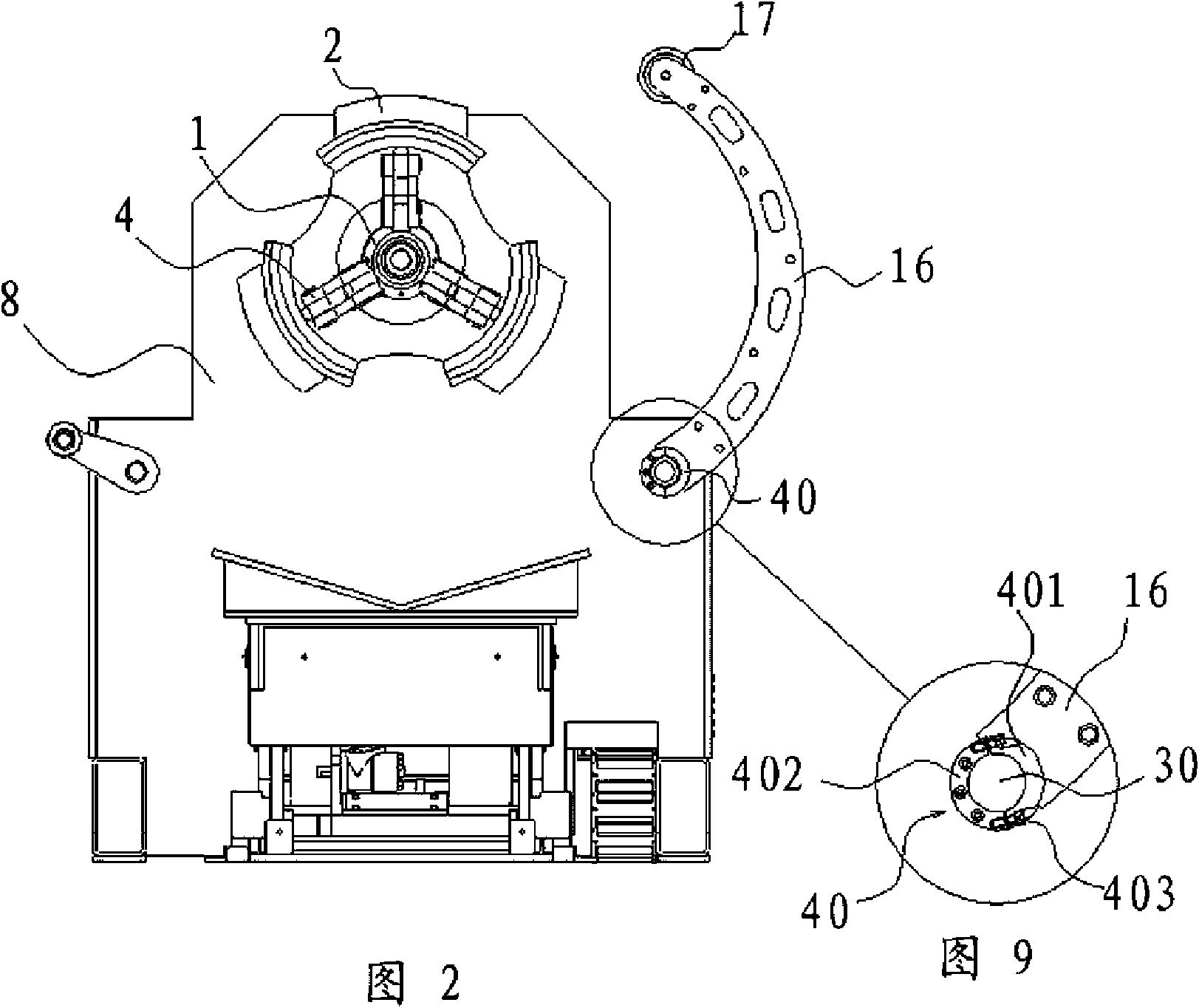

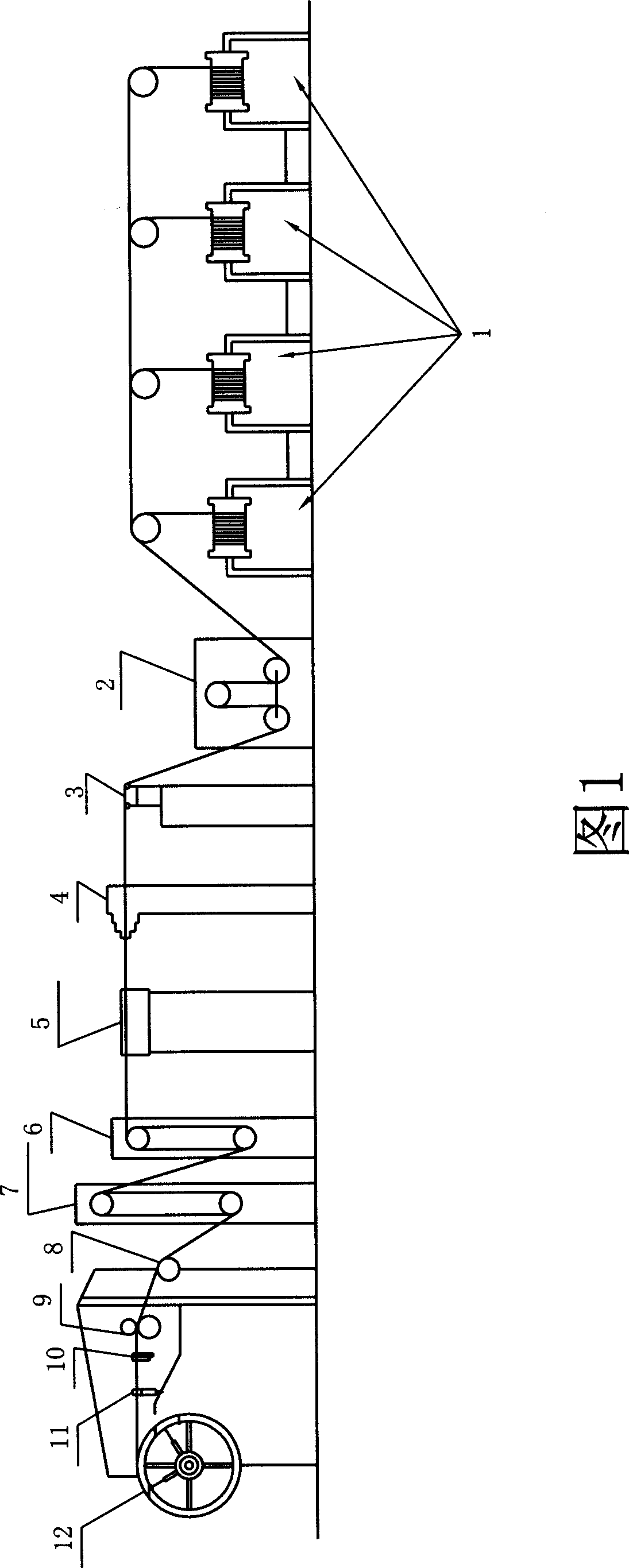

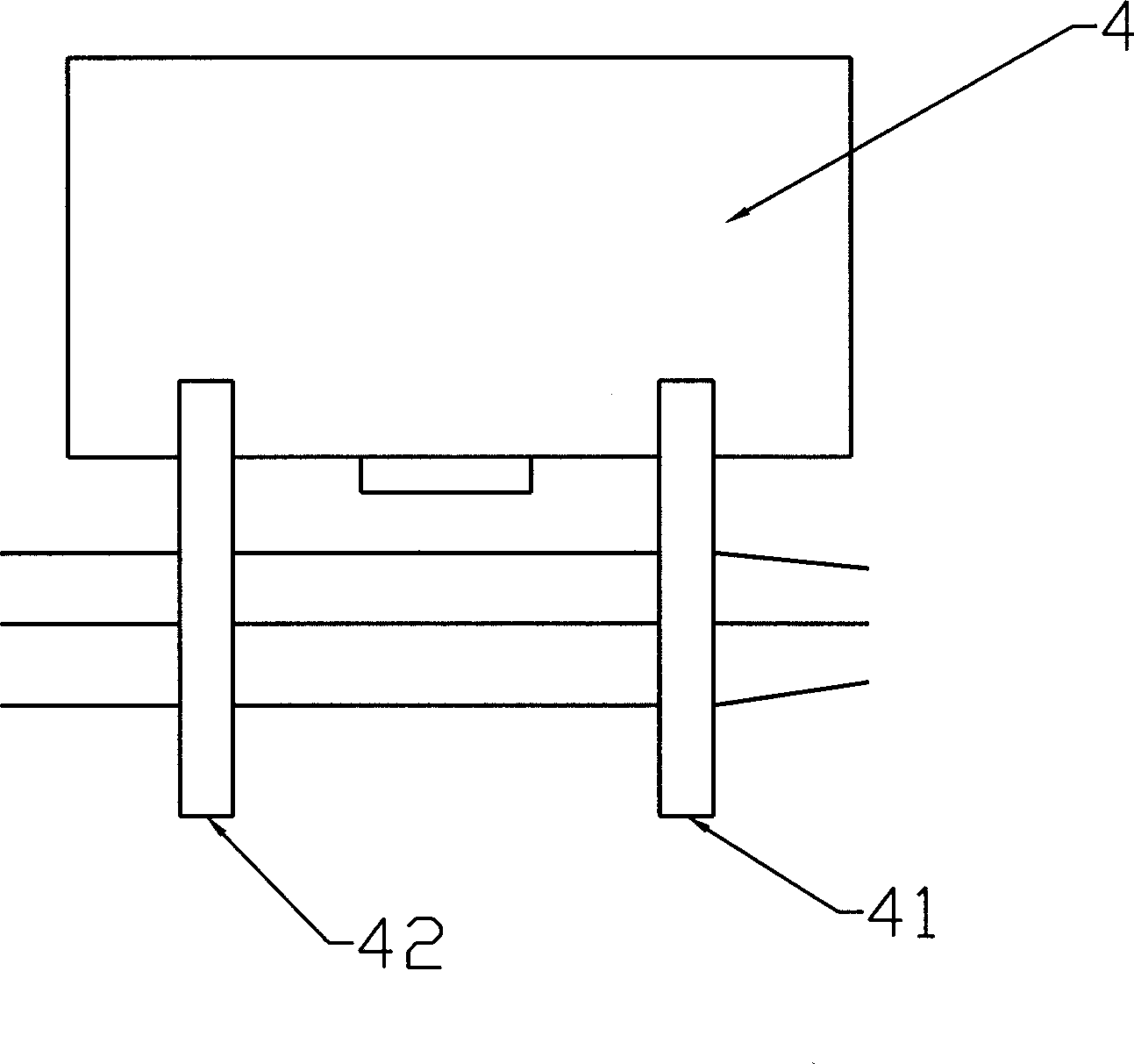

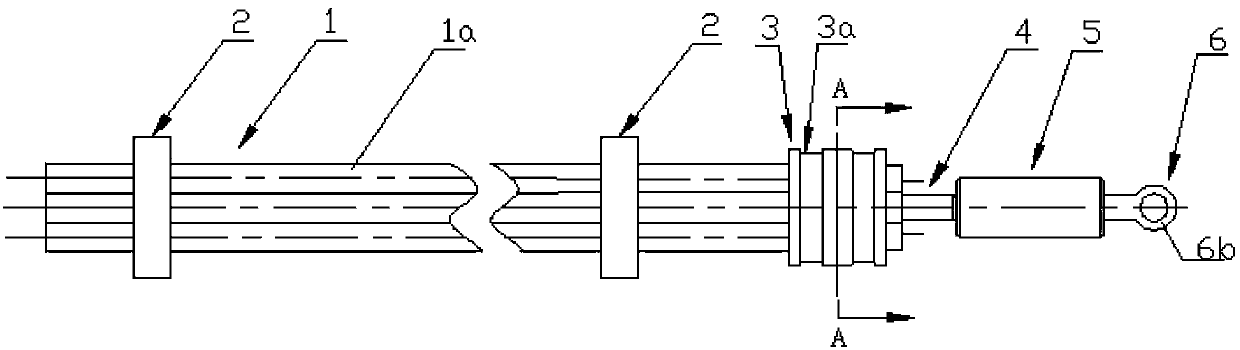

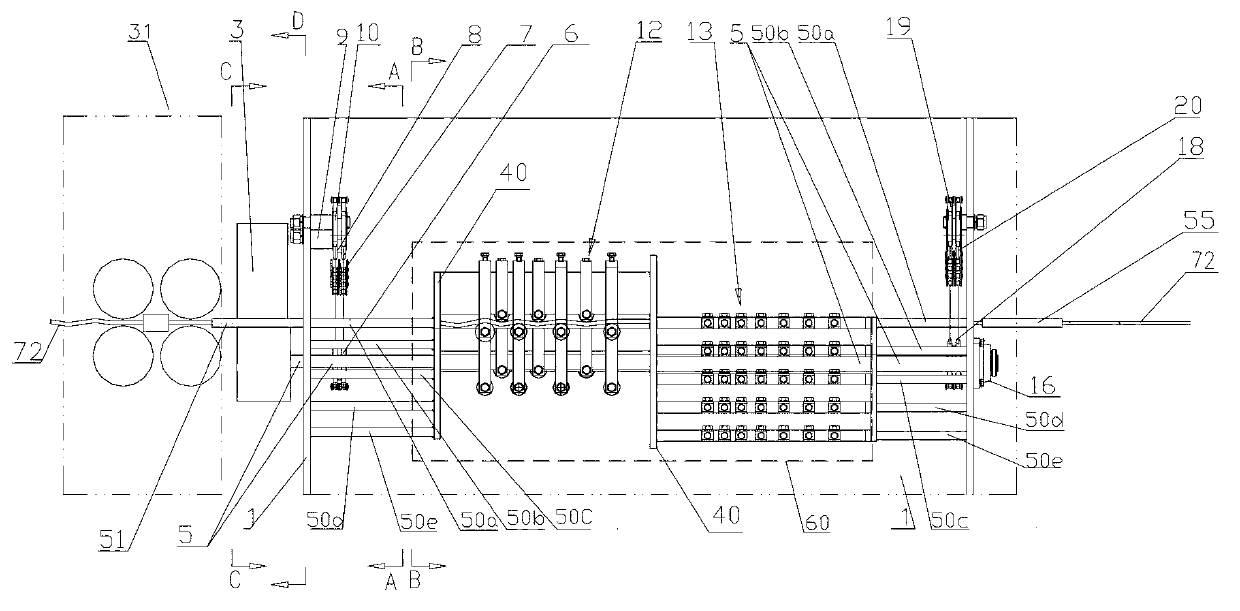

Tyre belt layer extrusion method production process and equipment

InactiveCN101428481ASimplify complex processesSimple production processTyresCoatingsHigh volume manufacturingEngineering

The invention relates to a production technology of tire belted layers of a vehicle and a device thereof, particularly a production technology of novel meridian tire belted layers and a device thereof. The production technology comprises the following steps: a, pre-heating steel wires; b, rubberizing a steel wire and forming a rubberized steel wire through an extrusive process, or distributing a plurality of steel wires at certain intervals and rubberizing, and forming a rubberizing steel wire through the extrusive process; c, cooling the rubberizing steel wires; and d, coiling the rubberizing steel wire belt at certain intervals to form a belted layer. The production technology can be completed by the following devices: a steel wire cord spindle frame, a preheating device, an extrusive device, a cooling device, a towing device and a winding device which are arranged in sequence, wherein, a distance-adjusting device, a cutting device and a winding plate are mounted on the winding device in sequence. The invention provides a simple and efficient production technology for the mass production of zero belted-layer tires.

Owner:HANGZHOU ZERO DEGREE TIRE TECH

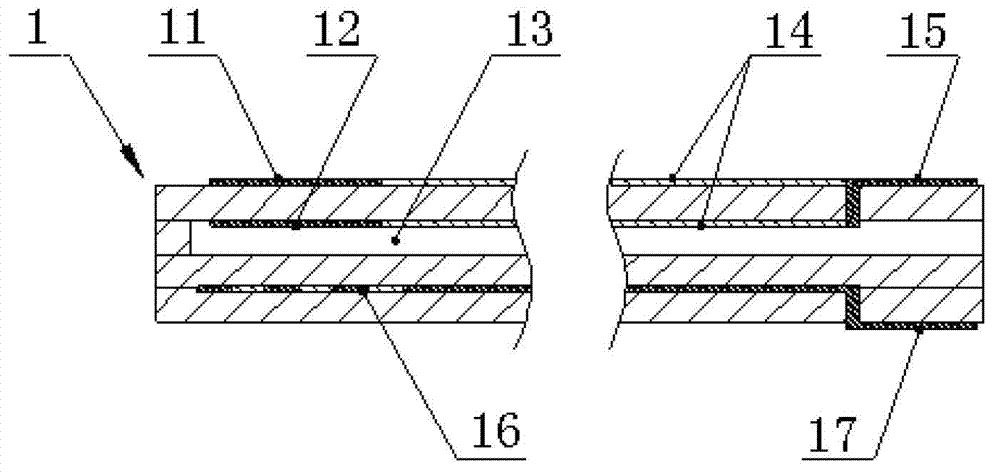

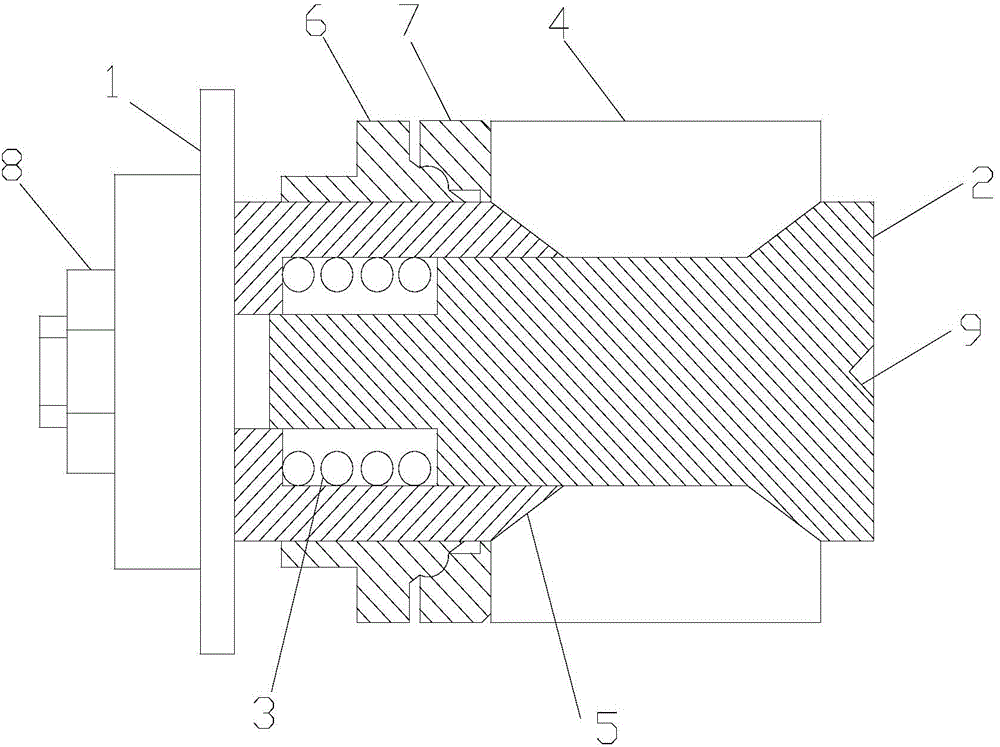

Fastening connection accessory for tubular product

The invention discloses a fastening connection accessory for a tubular product. The fastening connection accessory comprises a joint and a top thread, wherein the joint comprises connecting baseplates; pulling plates are arranged at one ends of the connecting baseplates, and crown plates are arranged at the other ends; one ends of the crown plates are in threaded connection with the pulling plates, and the other ends re in contact with the crown plates; top thread guide holes are formed in the crown plates; a frustum matched with the top thread guide hole is arranged at one end where the top thread is connected to the crown plates; and when the top thread is screwed, the top thread drives the pulling plates and the crown plates to distend under the guiding of the top thread guide holes to be in closely distended connection with the inner wall of the tubular product. The fastening connection accessory for the tubular product has the advantages of simple structure and easiness in installation, can effectively protect a fastener from damage.

Owner:HUNAN GOLDWELL NEW MATERIALS TECH CO LTD

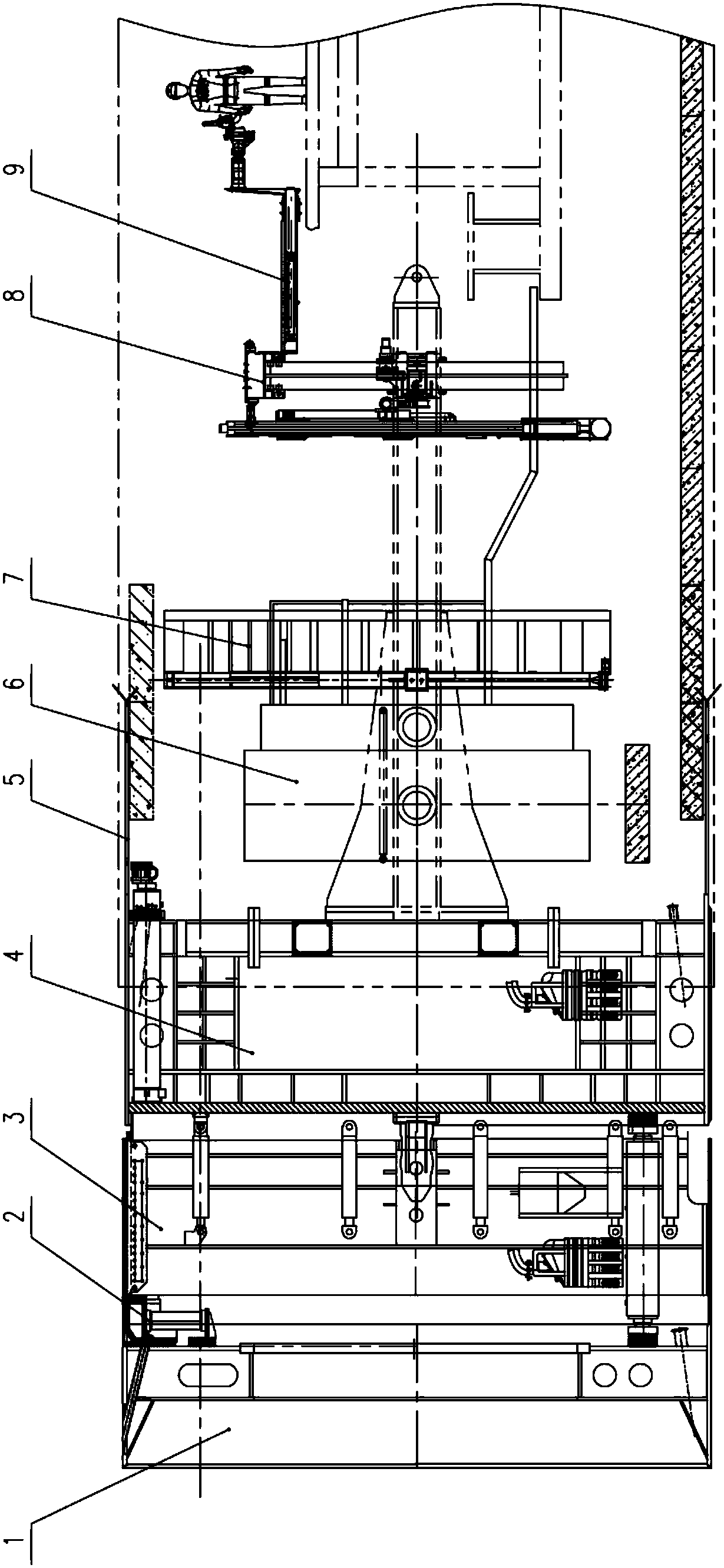

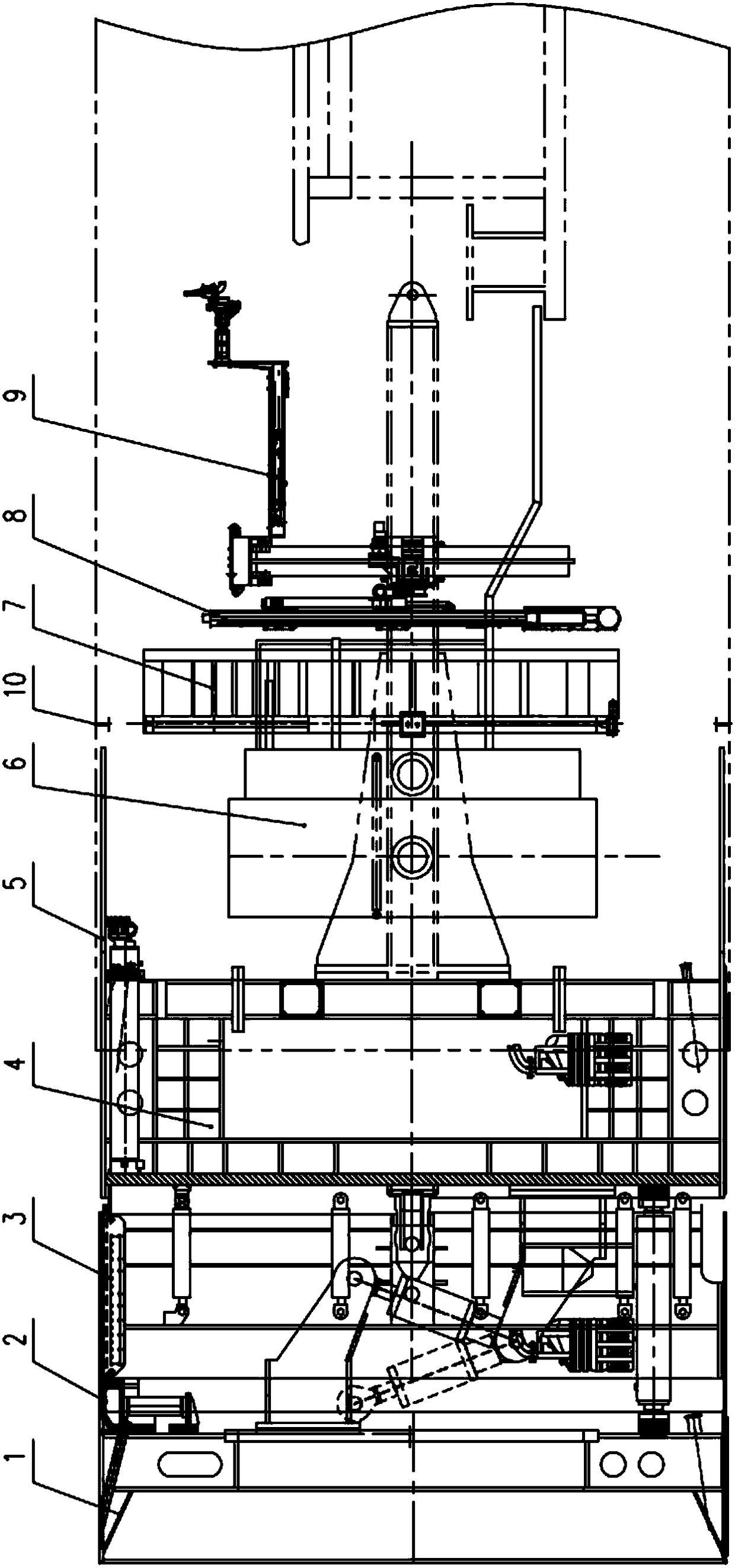

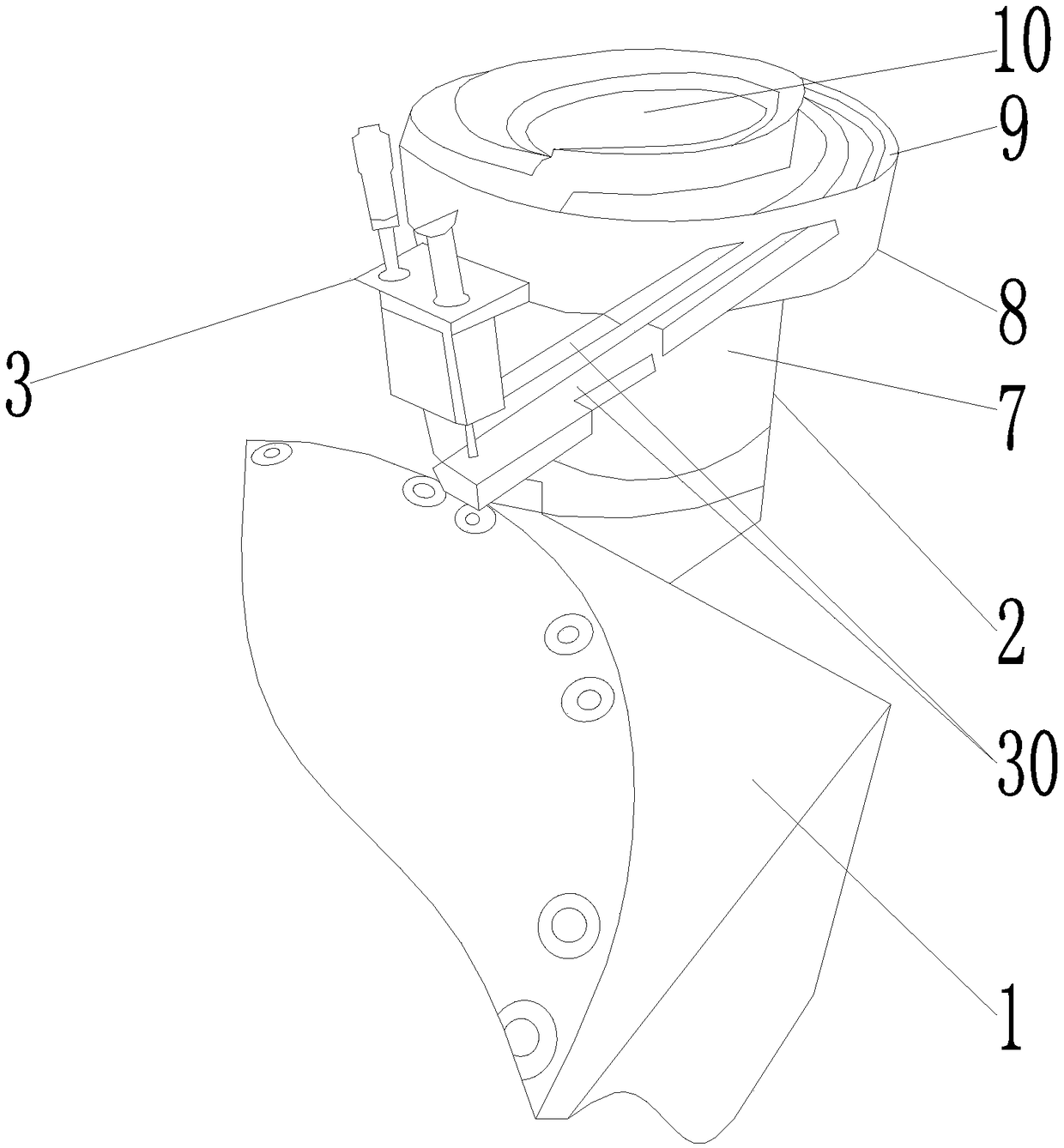

Double-shield TBM

PendingCN108397208AImplement assembly modeImprove tightening effectUnderground chambersTunnel liningShotcreteTunnel wall

The invention discloses a double-shield TBM which comprises a front shield, a telescopic shield, a tight-supporting shield and a tail shield which constitute a main frame. One end of a main pushing oil cylinder is connected to the tight-supporting shield. The double-shield TBM further comprises a plurality of stabilizers, a segment assembling machine, a steel arch frame mounting device, an anchorrod drilling rig and a concrete spraying device. The stabilizers are used for fixing the positions of the front shield and a cutterhead during step-changing operation and arranged in the front shield,can stretch out of the front shield and are supported with a tunnel wall; the segment assembling machine is used for assembling segments carried by a segment hoisting system, and arranged on the mainframe; the steel arch frame mounting device is used for mounting a steel arch frame, arranged on the segment assembling machine and located on the rear portion of the segment assembling machine; theanchor rod drilling jig is used for conducting temporary anchor rod supporting on the tunnel wall and connected with the steel arch frame mounting device and a control device; and the concrete spraying device is used for spraying concrete towards the tunnel wall and arranged on a track of the main frame. The double-shield TBM has a segment mode and an anchor rod supporting mode and is wider in application range.

Owner:CHINA RAILWAY CONSTR HEAVY IND +1

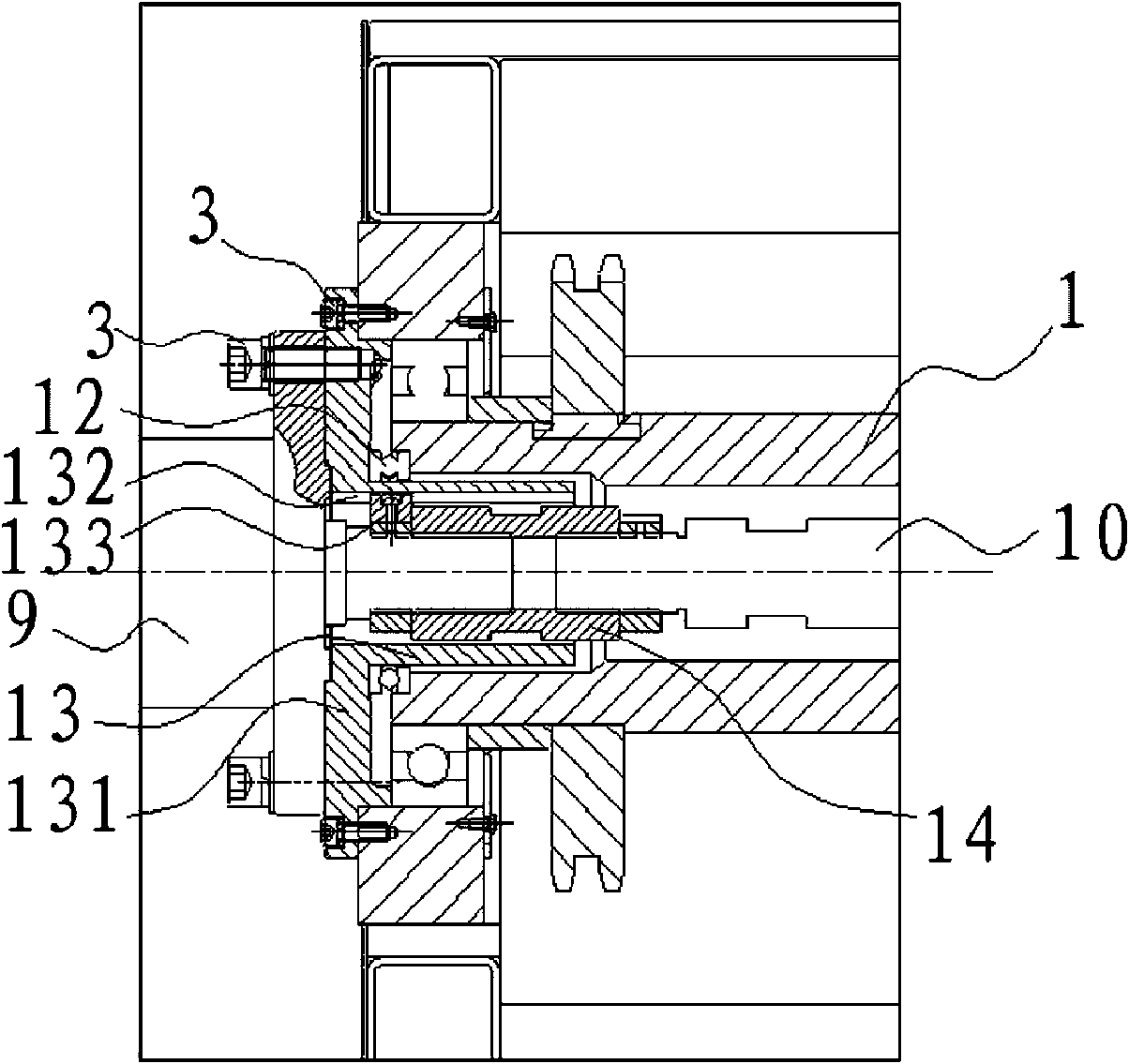

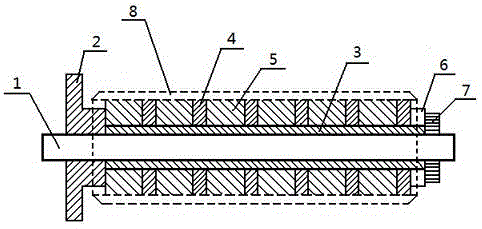

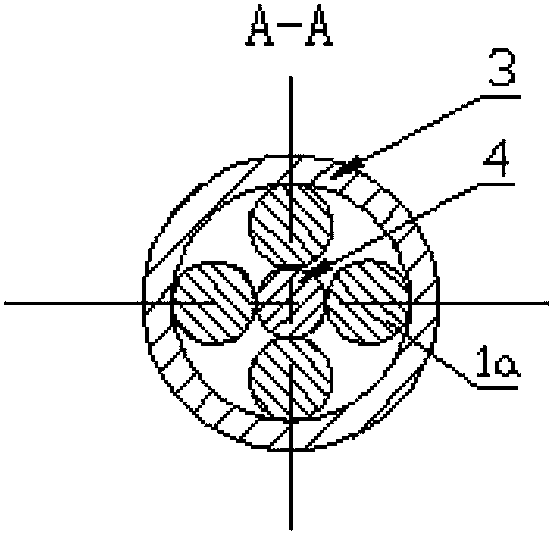

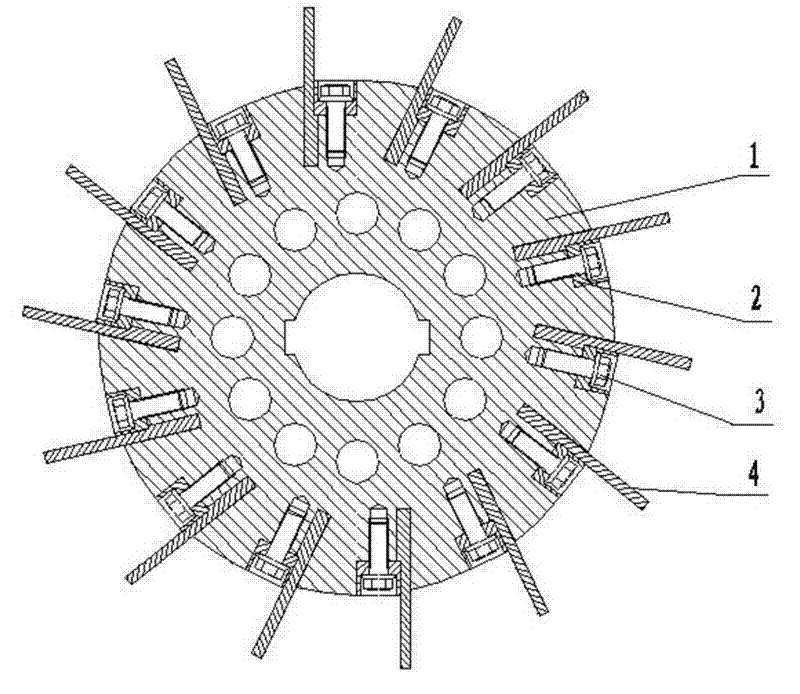

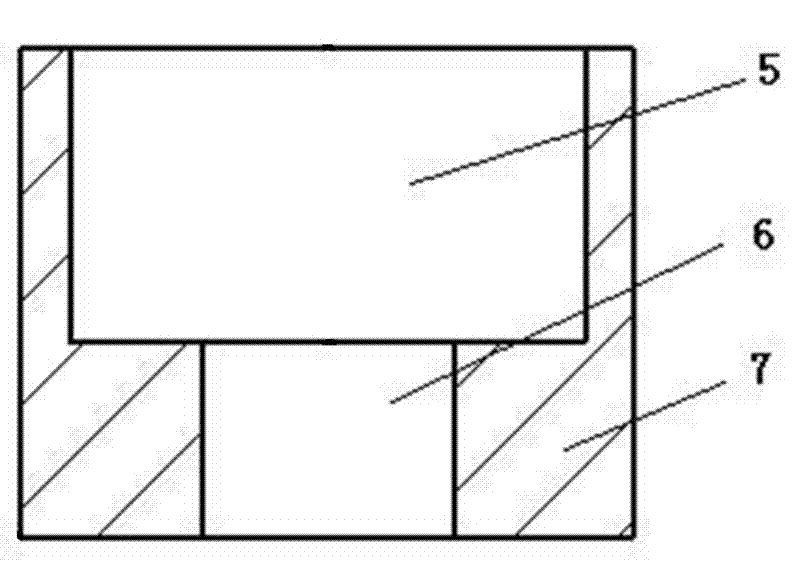

Novel clamp for machining thin-wall cylinder part

The invention discloses a novel clamp for machining a thin-wall cylinder part. The novel clamp comprises a mandrel, a positioning plate, connecting pipes, spacer bushes, expansion components and a pressing plate. The positioning plate is fixed to one end of the mandrel. The connecting pipes are fixed to the mandrel and tightly attached to the positioning plate. The spacer bushes, the expansion components and the pressing plate are installed on the connecting pipes. The novel clamp for machining the thin-wall cylinder part is easy to manufacture, operation is convenient, multiple supporting points exist on the clamp, the area is large, the good expansion performance is achieved, the part can be prevented from deforming and vibrating in the machining process, the machining precision of the part is effectively ensured, and the use requirement of the part is effectively met.

Owner:SUZHOU HUACHONG PRECISION MACHINERY

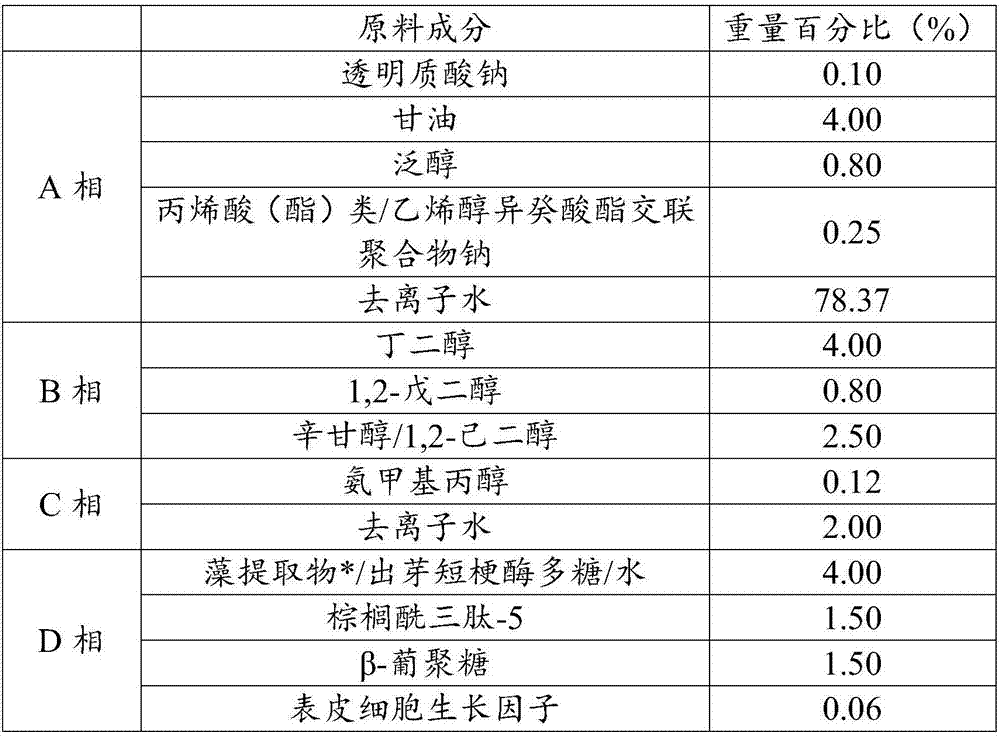

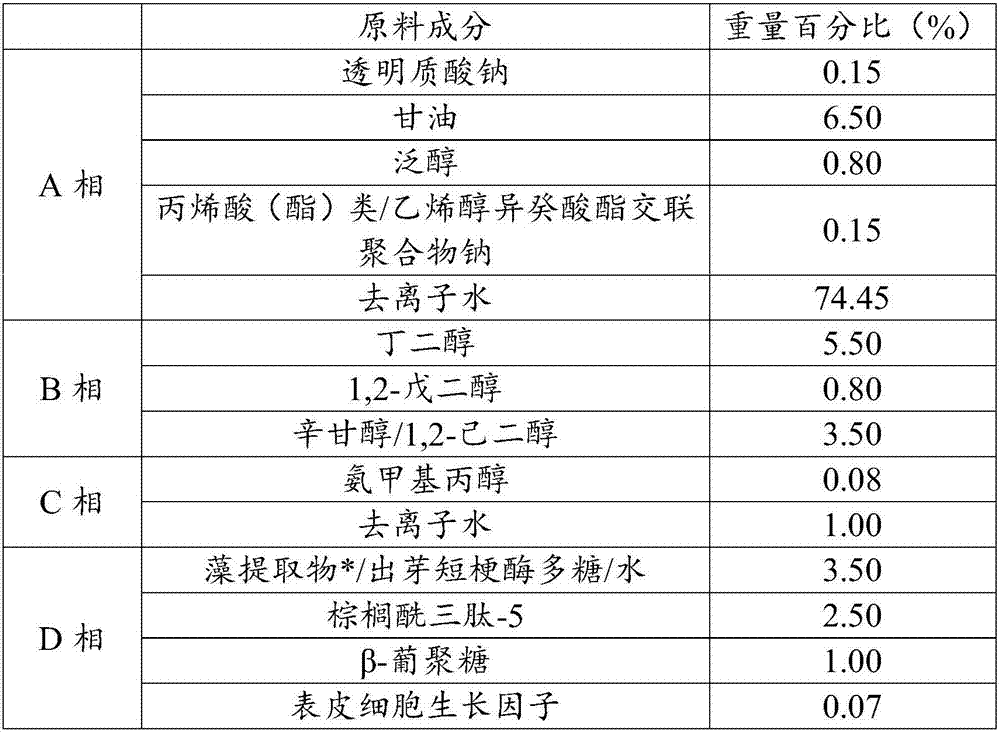

Eye essence as well as preparation method and application thereof

InactiveCN107412026APromote regenerationImprove nursing effectCosmetic preparationsToilet preparationsWrinkle skinCuticle

The invention discloses eye essence as well as a preparation method and an application thereof, relates to the technical field of skin care products and aims to improve a nursing effect on eye skin and effectively solve the problems of saggy eye skin and proneness to wrinkles. The eye essence contains palmitoyl tripeptide-5, algae extract* / pullulan / water, sodium hyaluronate, panthenol, epidermal growth factor and other substances and can provide nutrients for skin, stimulate fibroblast proliferation and collagen synthesis, promote skin regeneration and tighten the skin, wherein palmitoyl tripeptide-5 can be beneficial to rapid relaxing of mimetic muscle, and a wrinkle relieving effect is realized; algae extract* / pullulan / water can ensure that a physical film is formed on the skin surface instantly by the eye essence, the periocular skin is tightened instantly, and the instantaneous wrinkle relieving effect is enhanced. The eye essence can effectively improve the nursing effect on the eye skin and delay eye skin aging, and beautiful appearance is maintained for a longer time.

Owner:广州丸美生物科技有限公司

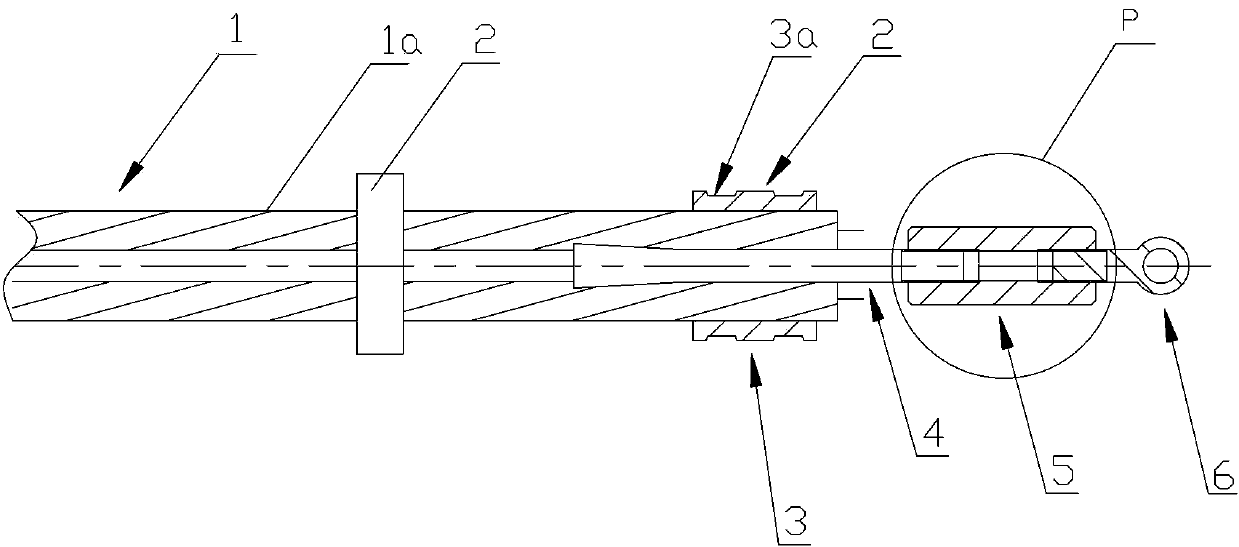

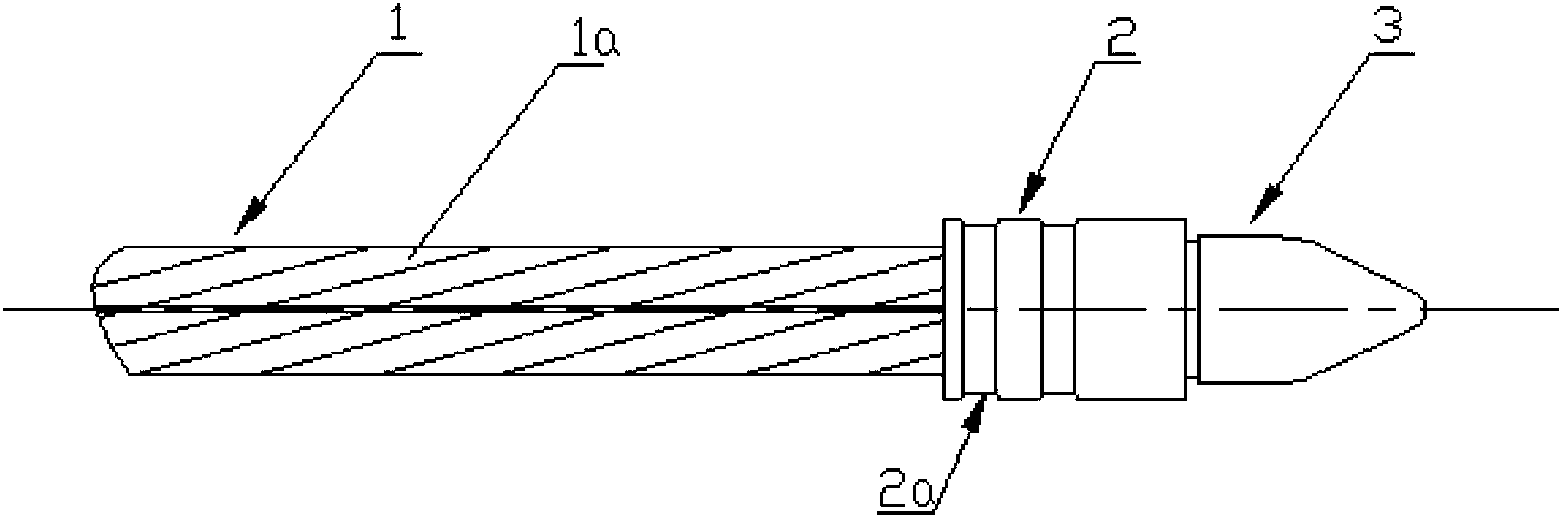

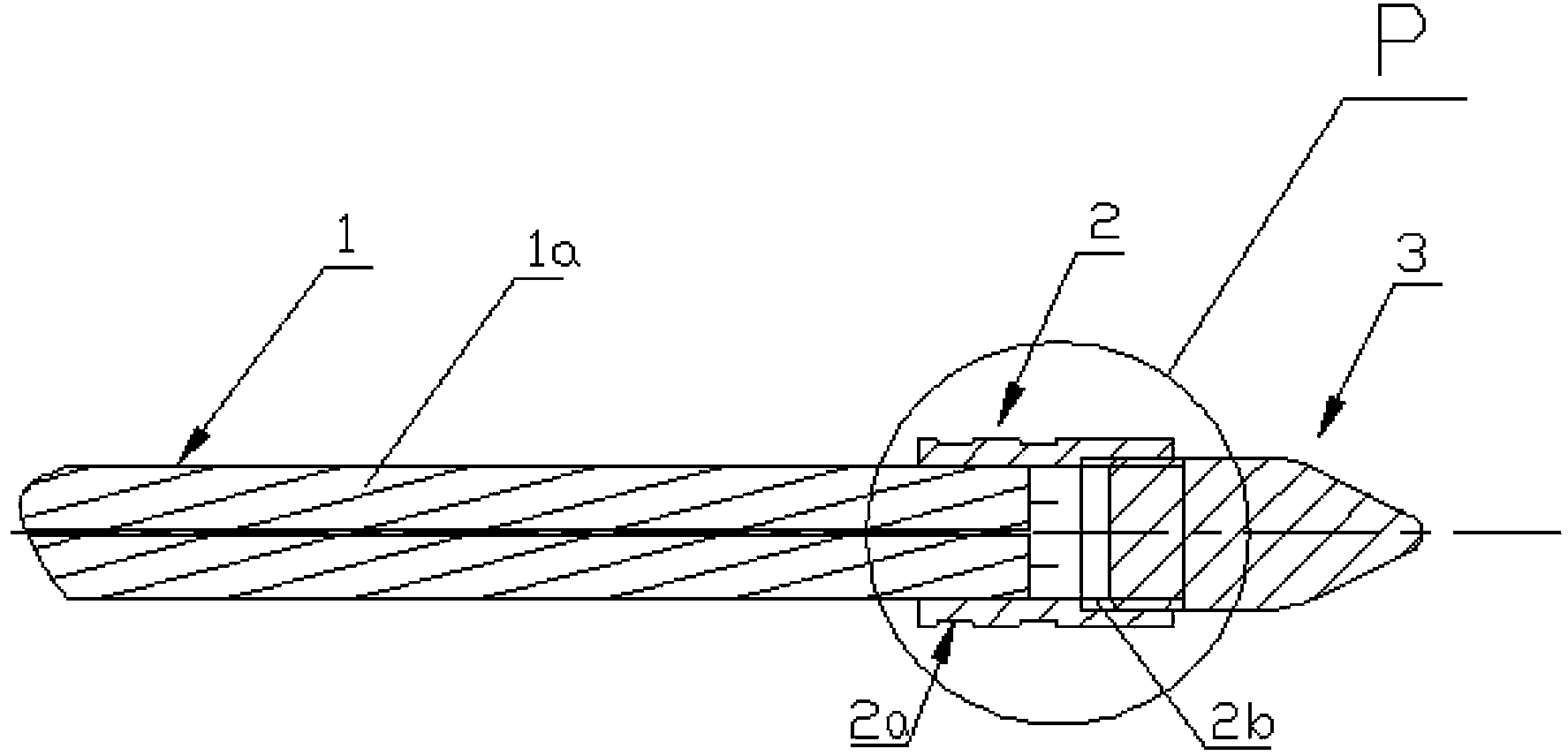

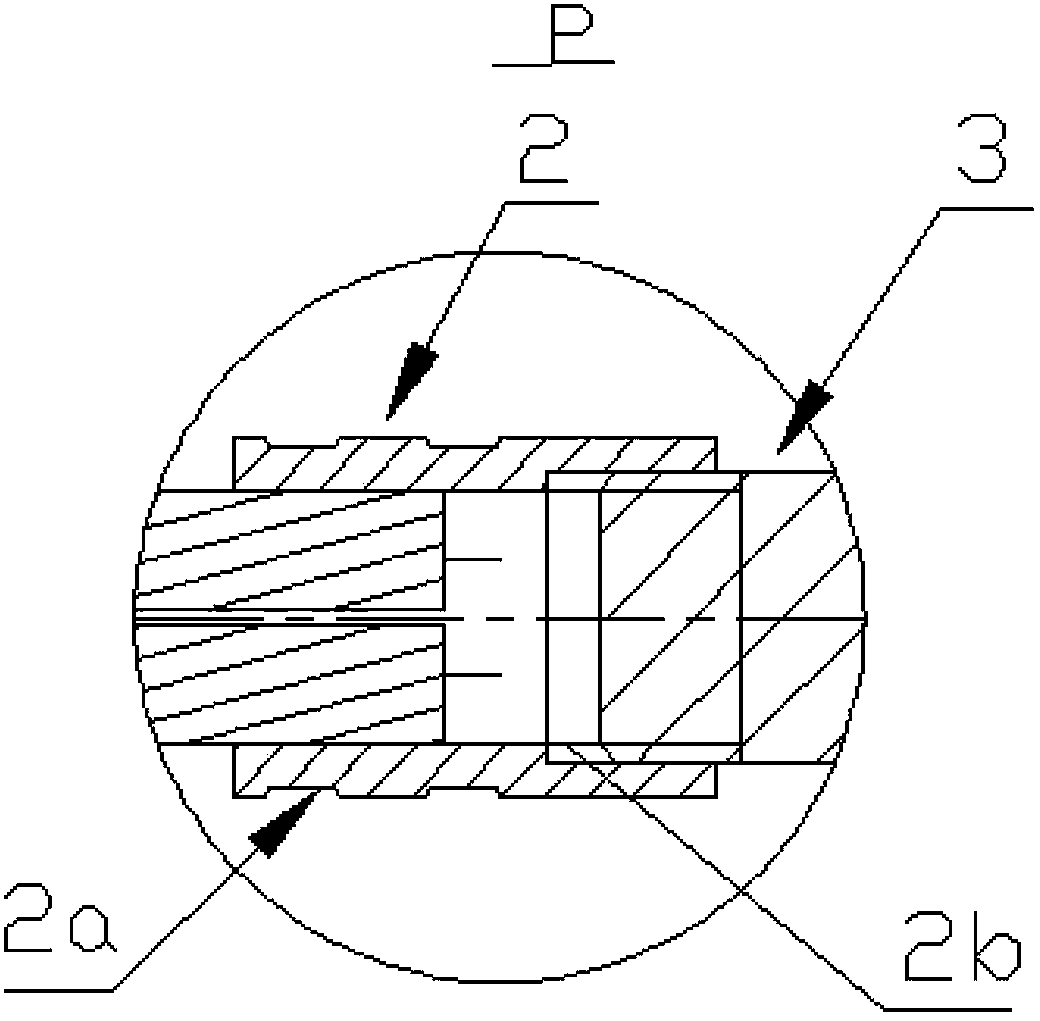

Tractor for finished steel strand and threading method of finished steel strand

InactiveCN103362310AEffectively pass throughPass safelyBridge erection/assemblyBuilding material handlingScrew threadUltimate tensile strength

The invention discloses a tractor for a finished steel strand and a threading method of the finished steel strand. The tractor comprises a hoop, a mandrel, a threaded connection sleeve and a traction pull ring. One side of the mandrel is inserted in the center of the finished steel strand, the other side of the mandrel is arranged at one end of the threaded connection sleeve, the other end of the threaded connection sleeve is arranged at one end of the traction pull ring, the other end of the traction pull ring is provided with a pull ring connected with traction equipment, the hoop is arranged on the end portion of the finished steel strand in a sleeved mode, and the size of the periphery of the tractor is smaller than the inner diameter of a construction hole channel. The threading method includes the steps: (1) braiding the finished steel strand, (2) sleeving mark plates at the two ends of the finished steel strand, (3) inserting the conical end of the mandrel into the center of the finished steel strand and squeezing the hoop, and (4) connecting the mandrel and the traction pull ring with the two ends of the threaded connection sleeve respectively. The tractor and the threading method have the advantages that the tractor is high in connecting strength and convenient to replace, winding and torsion among steel strand bodies are avoided, and the finished steel strand is threaded out of a corrugated tube of the construction hole channel effectively and safely.

Owner:TIANJIN SHINKUNTAI ADVANCED PRESTRESSING TECH

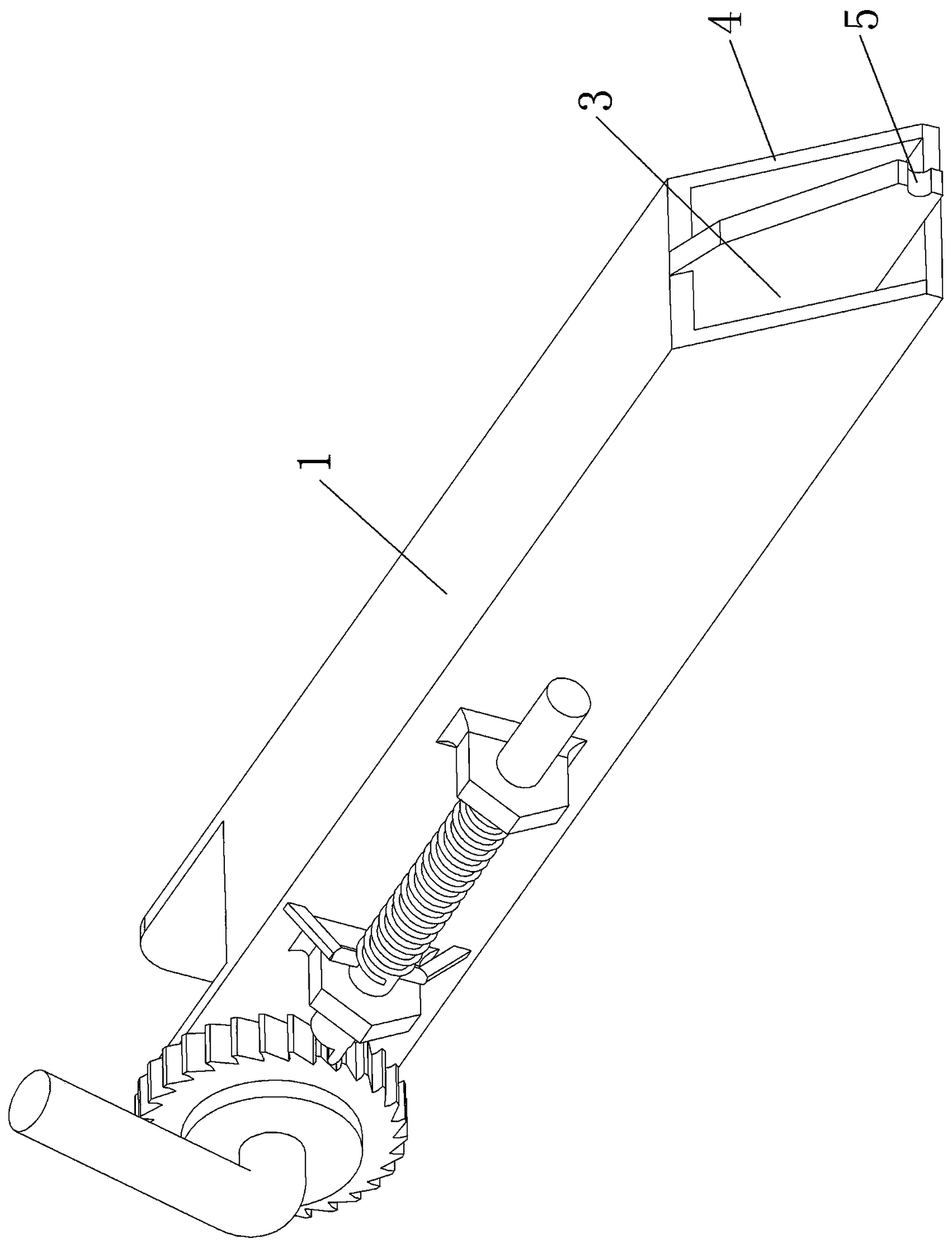

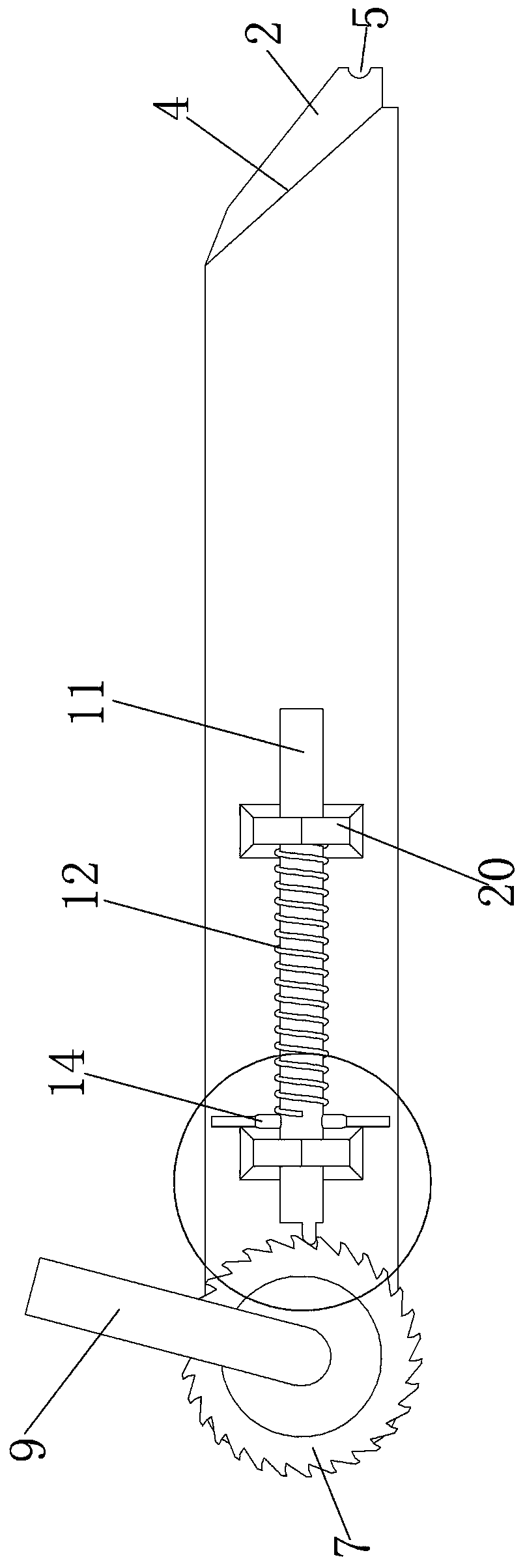

Wrapping-type iron wire binding tool for sleeve joint of soft pipe and hard pipe and binding method

The invention relates to a wrapping-type iron wire binding tool for sleeve joint of a soft pipe and a hard pipe and a binding method. One end of a tool body is provided with an iron wire ejecting pressing groove, and the other end is provided with a winding shaft; the winding shaft is provided with a slit and is connected with a ratchet; the ejecting pressing groove on the tool body tightly presses an iron wire bending place and the free end is clamped in the slit of the winding shaft; through rotating the winding shaft to tighten the free end of the iron wire, tightening on the iron wire wound on a soft pipe is realized; one-way fixing on the winding shaft is realized through match between a telescopic rod of a positioning device on the side wall of the tool body and the ratchet, and thephenomenon that the winding shaft stops tensioning the iron wire to result in looseness can be prevented. The majority of the tensioning force at the free end of the iron wire can be converted to theradial pulling force of the iron wire wound on the soft pipe, the conversion efficiency between the tensioning force at the free end and the radial pulling force of the iron wire wound on the soft pipe is high, the tensioning effects are good, and time and labor are saved.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

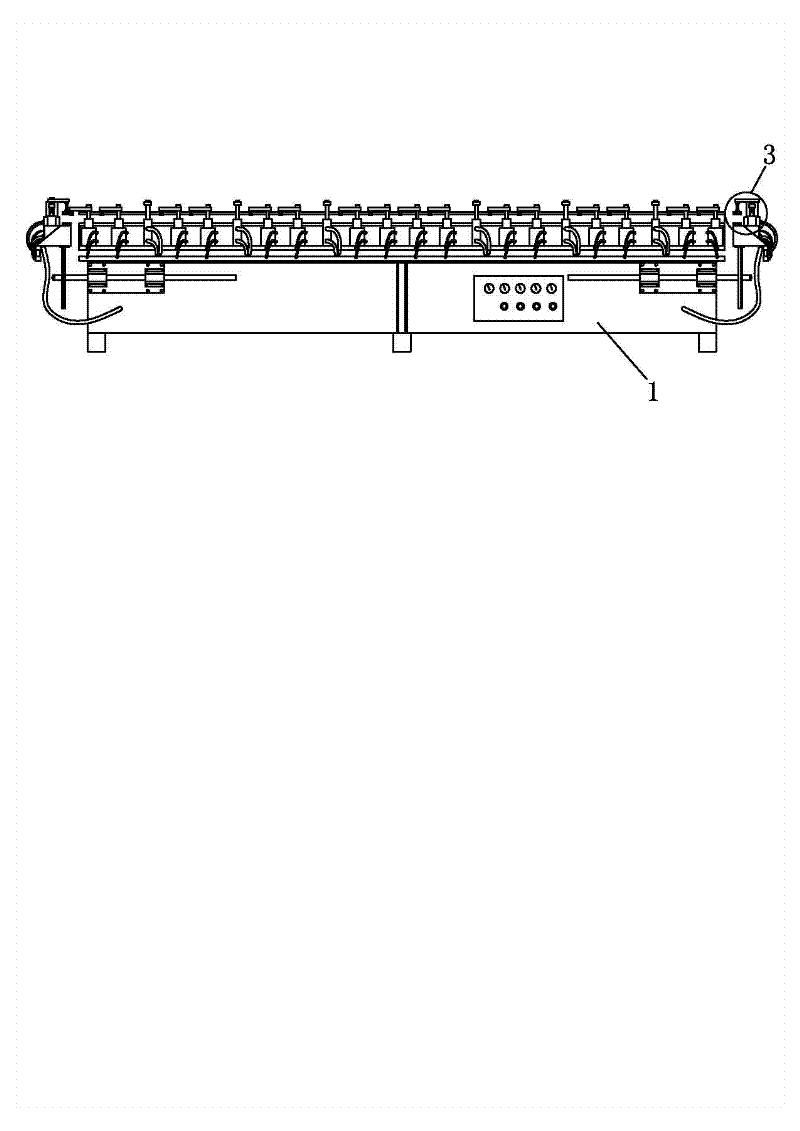

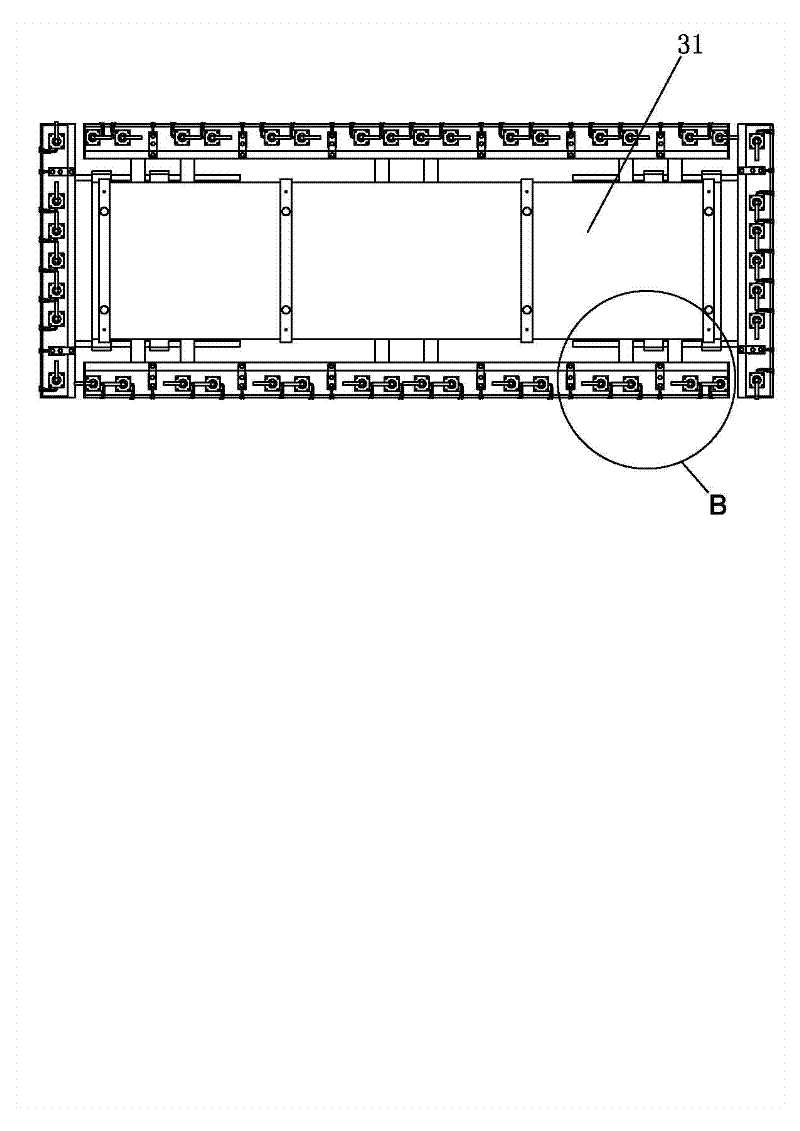

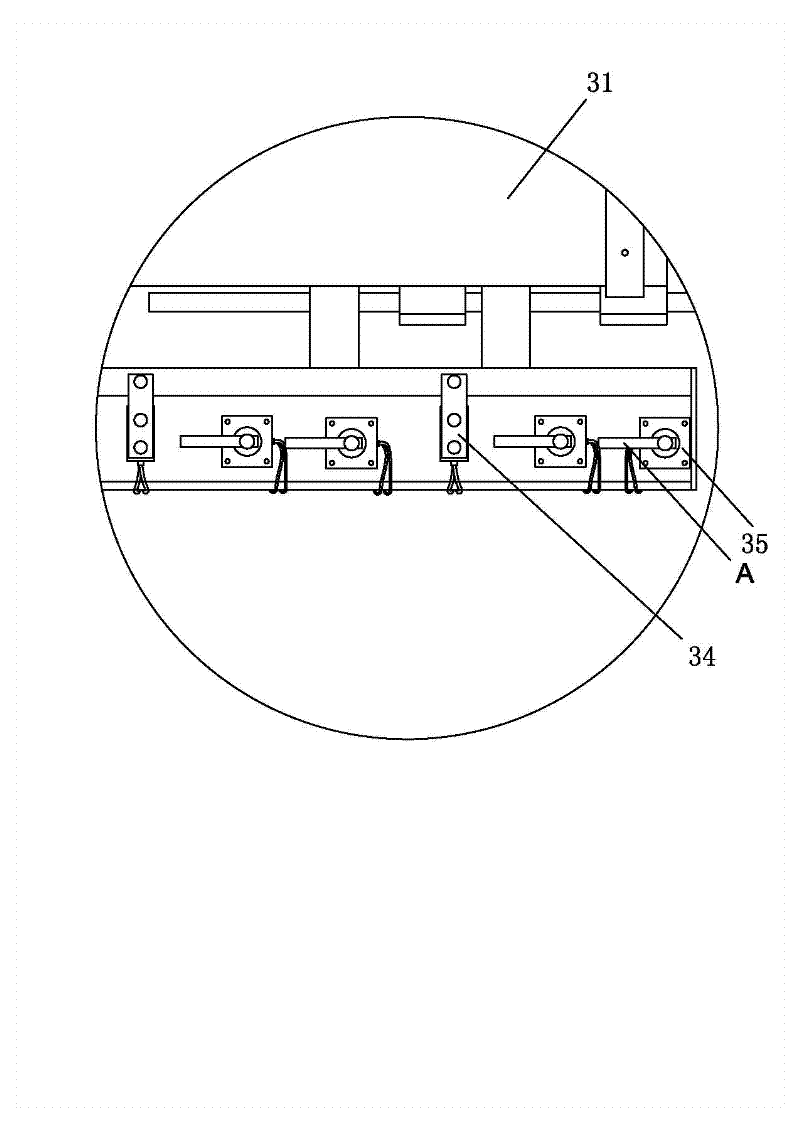

Automatic precision net puller

Owner:GUANGDONG YINCAI TECH CO LTD

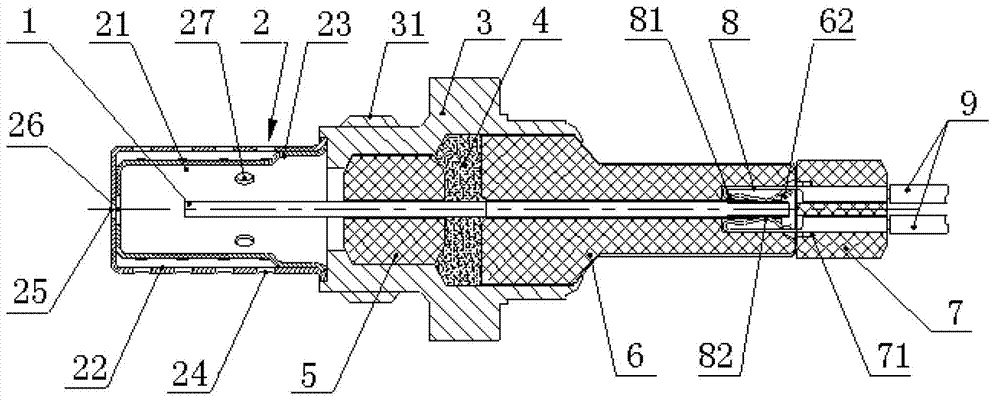

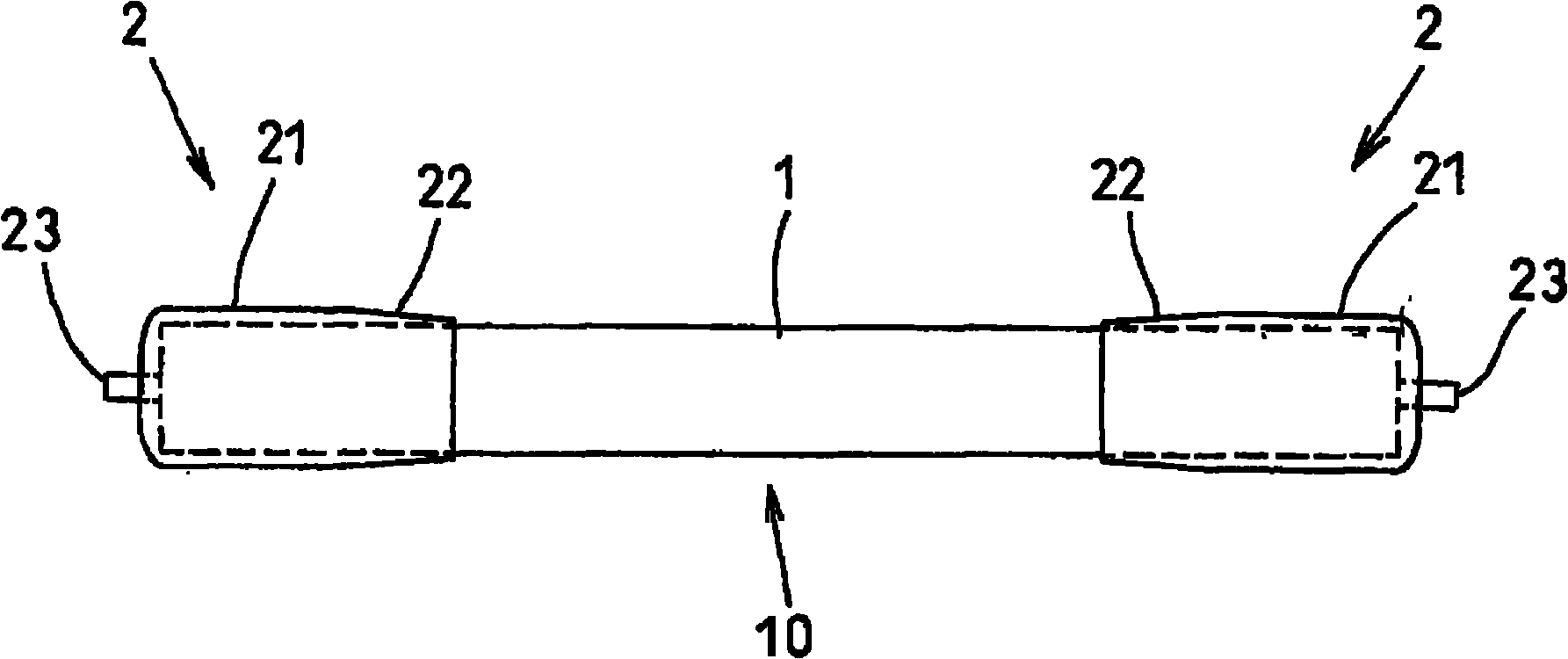

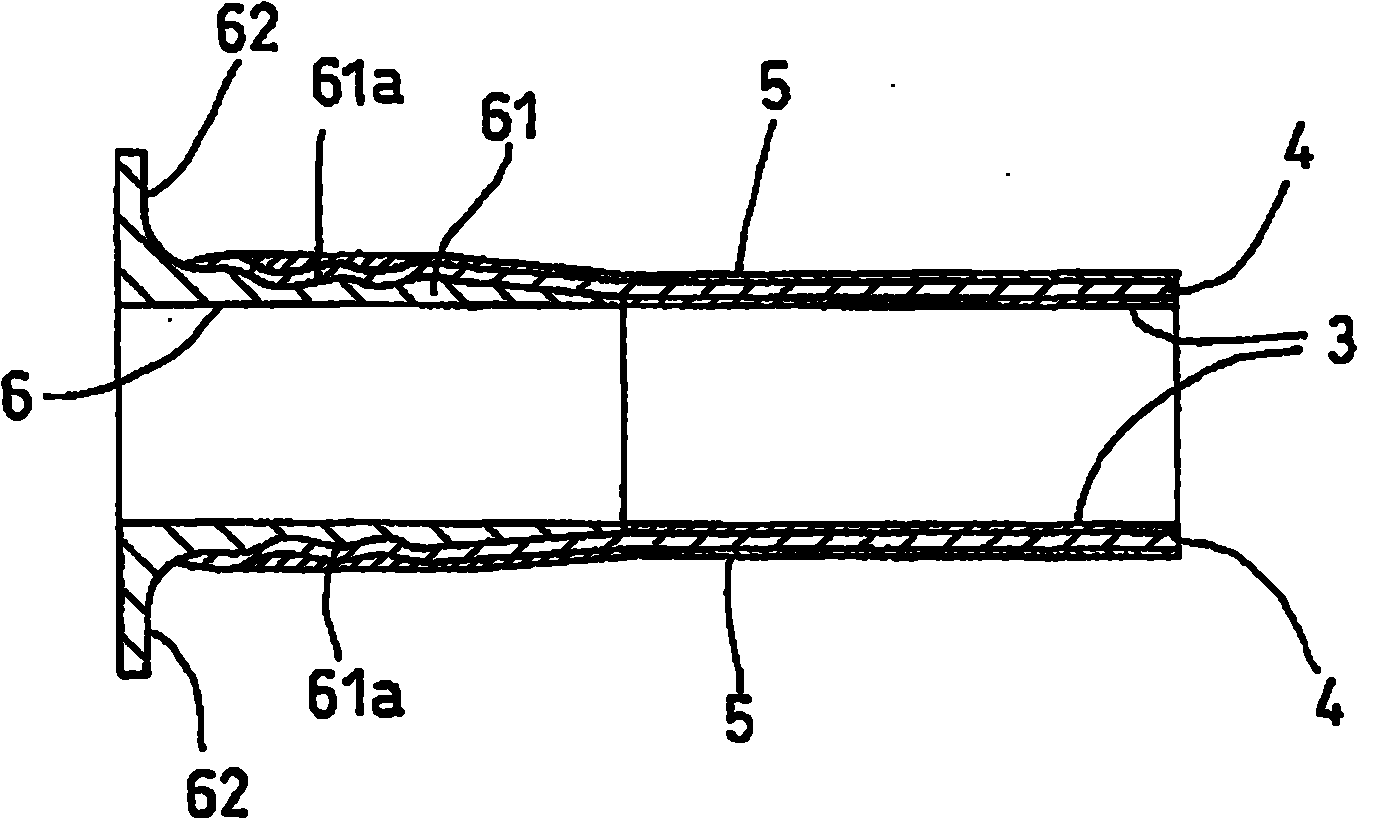

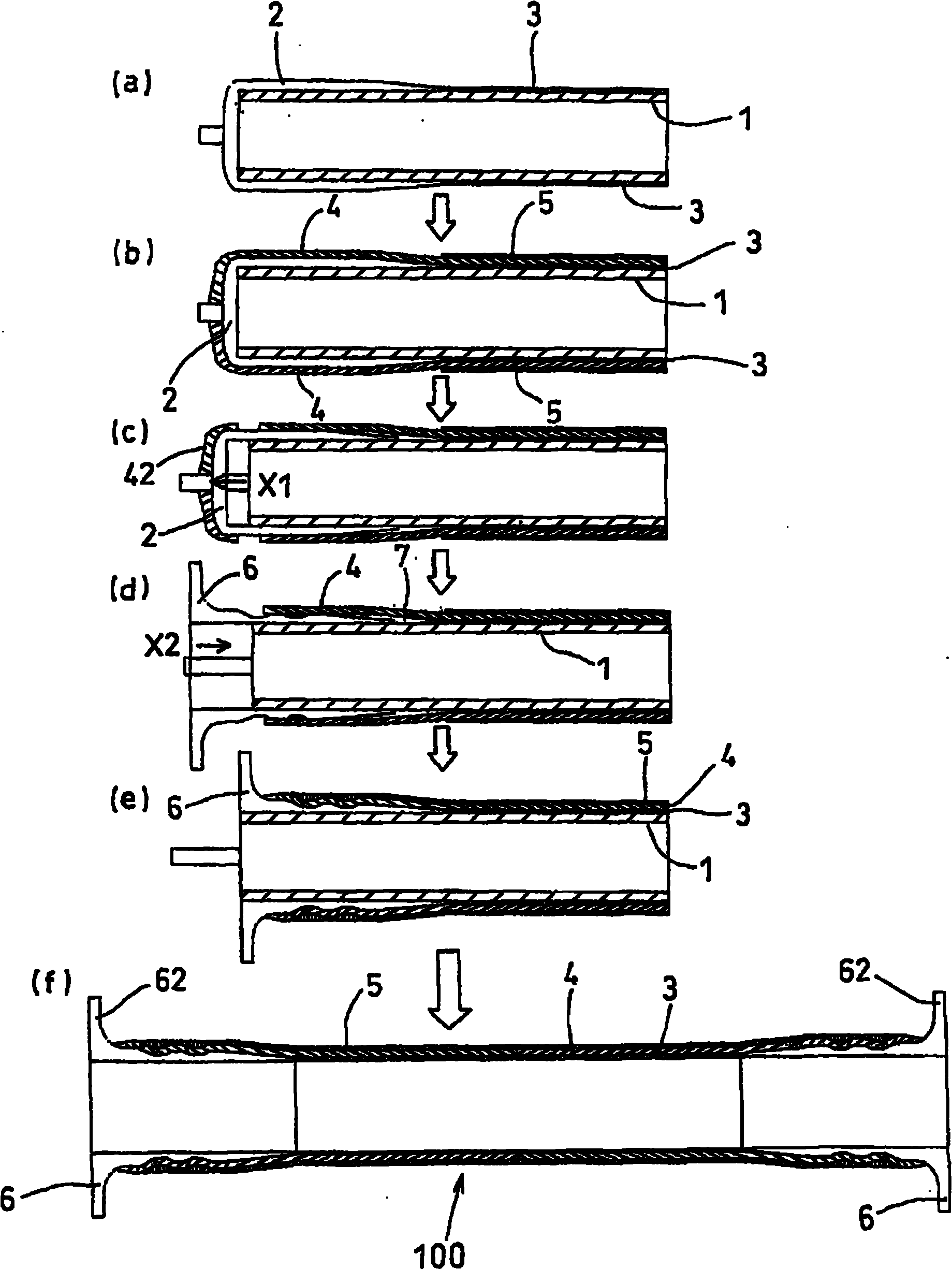

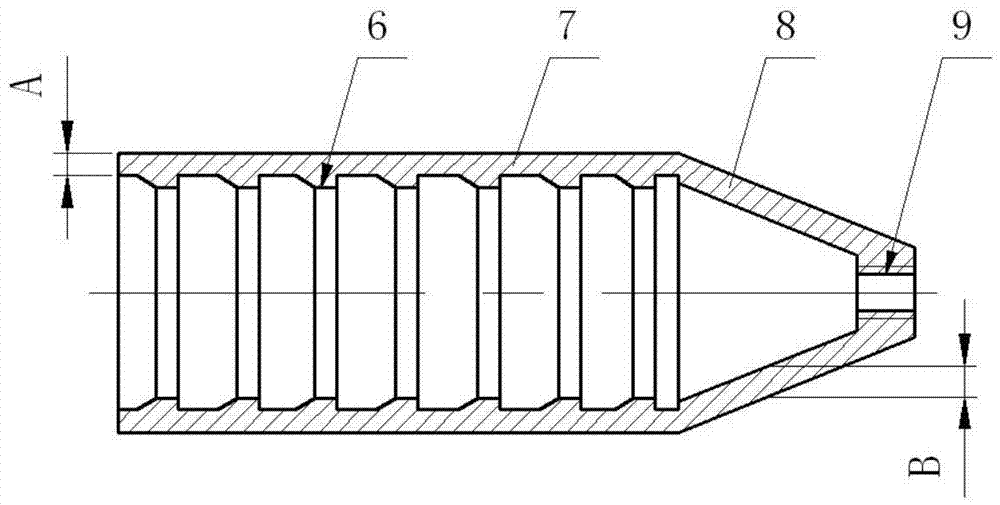

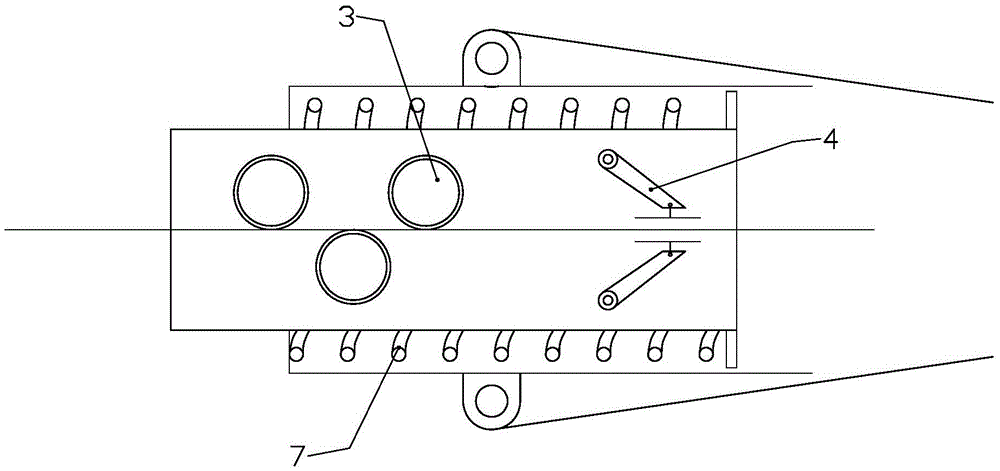

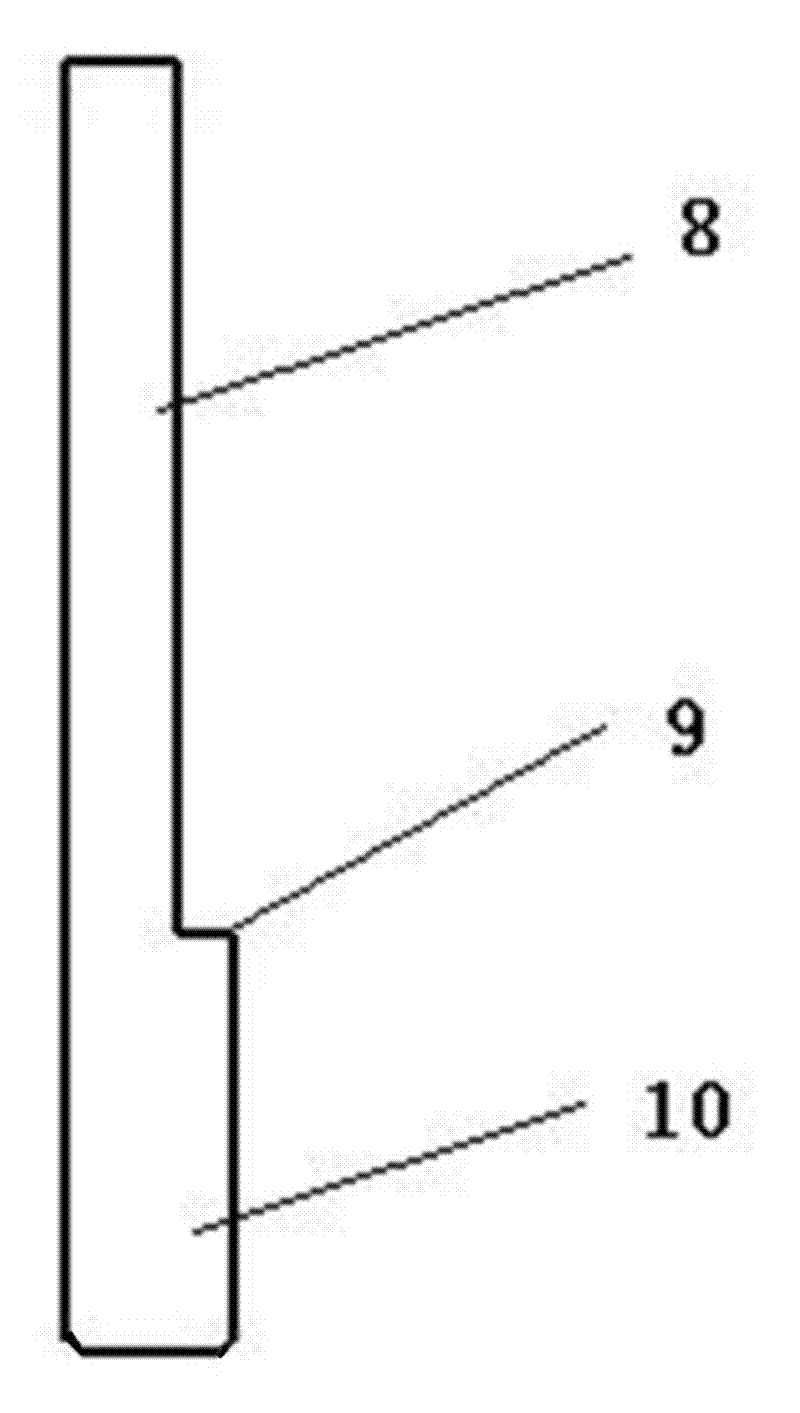

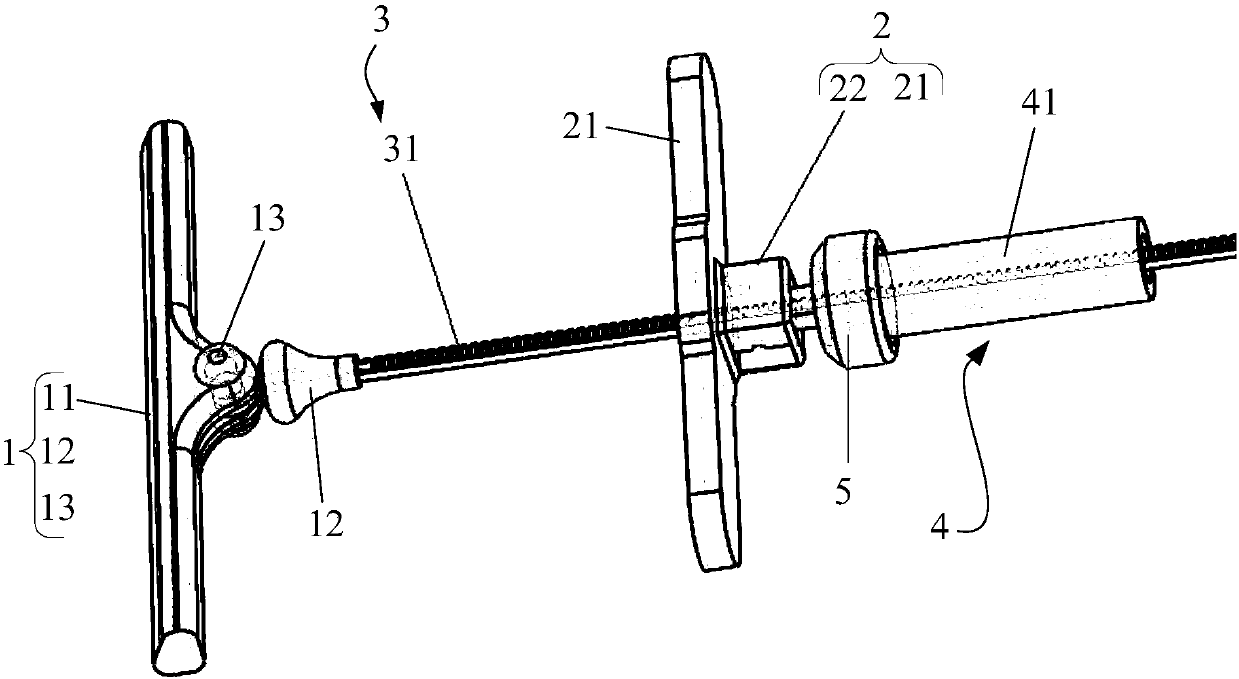

Process for producing tube member made of fiber-reinforced resin

InactiveCN101778714AImprove tightening effectImprove bending strengthDomestic articlesTubular articlesConductor CoilFiber orientation

A process for producing a tube member made of fiber-reinforced resin, in which without the need to fold back an end portion of a fiber layer impregnated with an uncured resin, while maintaining a fiber orientation at an initial orientation posture, a tube member of resin fiber and a flanged tube material permitting direct rigid bonding to an engine box, etc. can be bonded together through extremely easy procedure. In the process, a base material (10) consisting of a mandrel (1) and, fitted to one end thereof, an end-fitted material (2) having an expanded-diameter portion with diameter expanded as compared with that of the mandrel and a projection is provided. A first winding layer (3) is formed by hoop winding of a fiber impregnated with an uncured resin around the outer circumference of the mandrel (1). Further, a second winding layer (4) is formed by helical winding of a fiber around the outer circumference thereof. An end portion of the second winding layer (4) is cut, and the end portion and the end-fitted material (2) are cut off from the mandrel (1) to thereby form an insertion space (7). A flanged tube material (6) is inserted in the insertion space (7). A third winding layer (5) is formed by hoop winding of a fiber around the outer circumference of the second winding layer (4), followed by heating treatment.

Owner:TOYOTA JIDOSHA KK +1

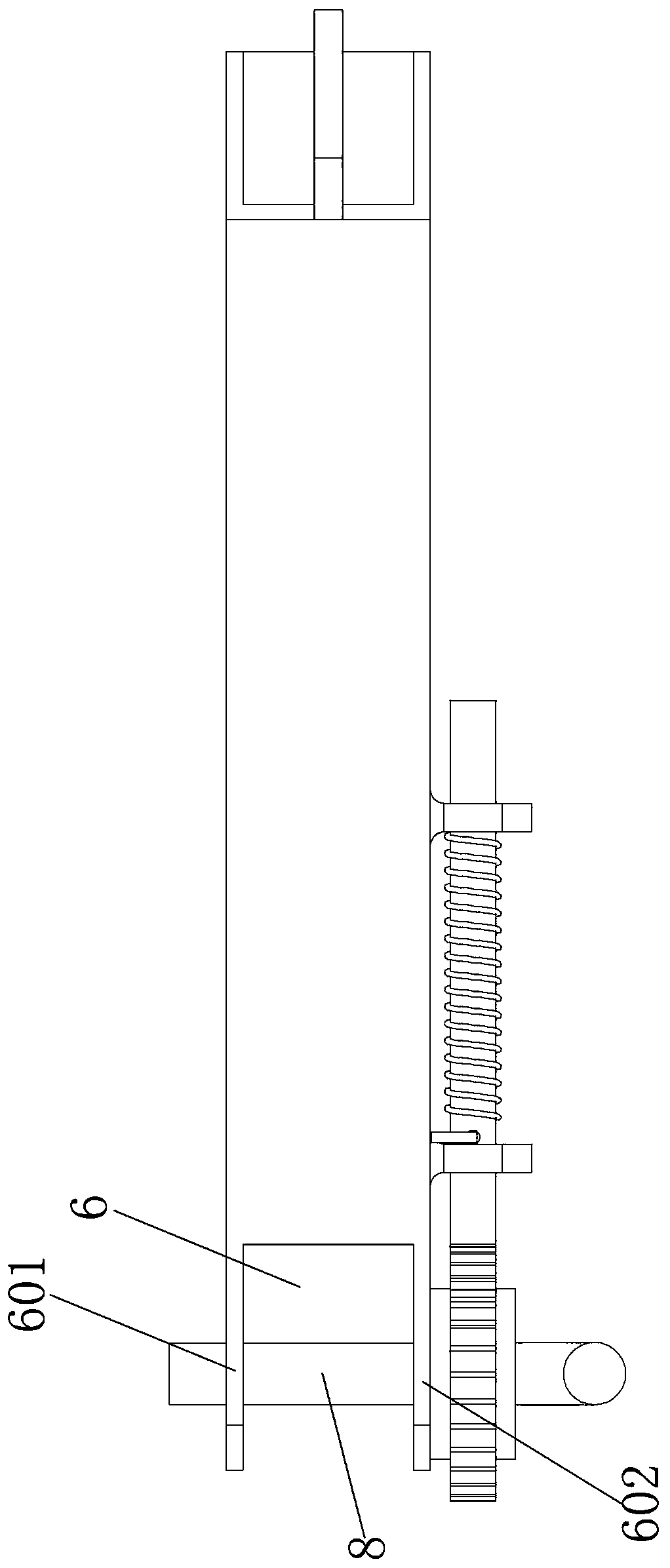

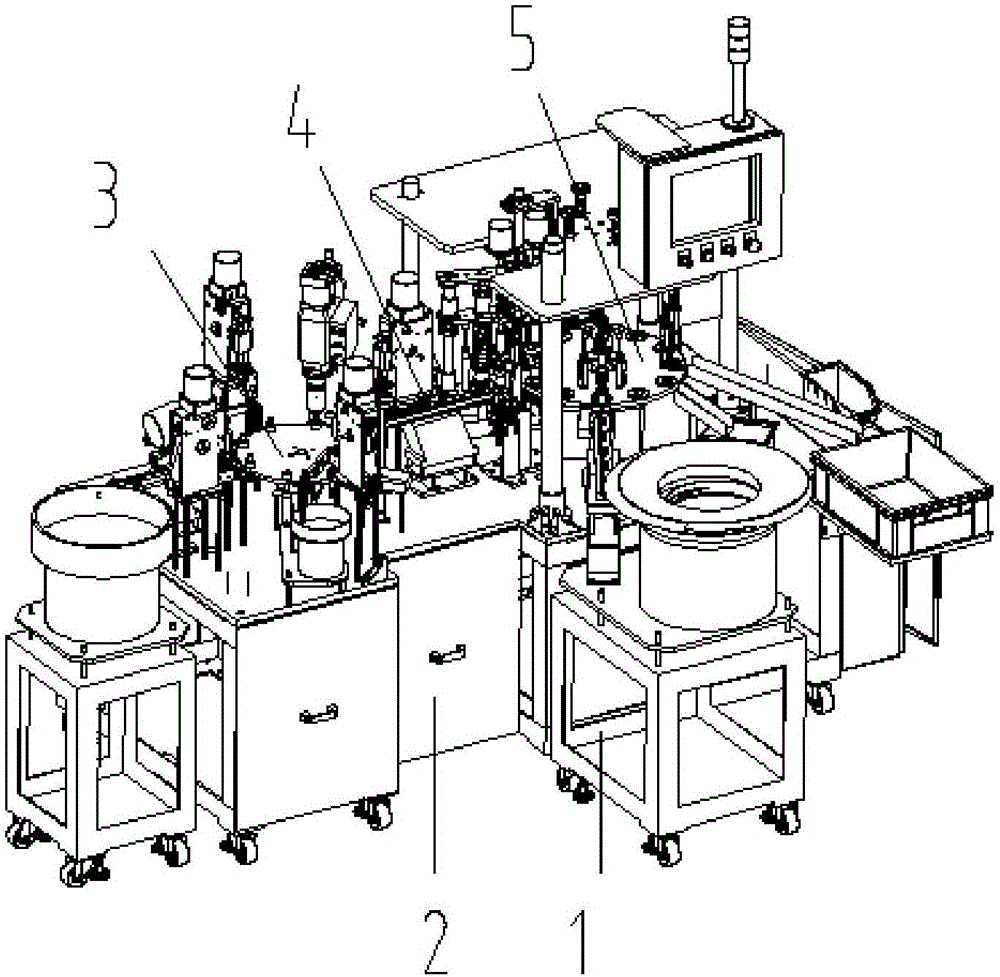

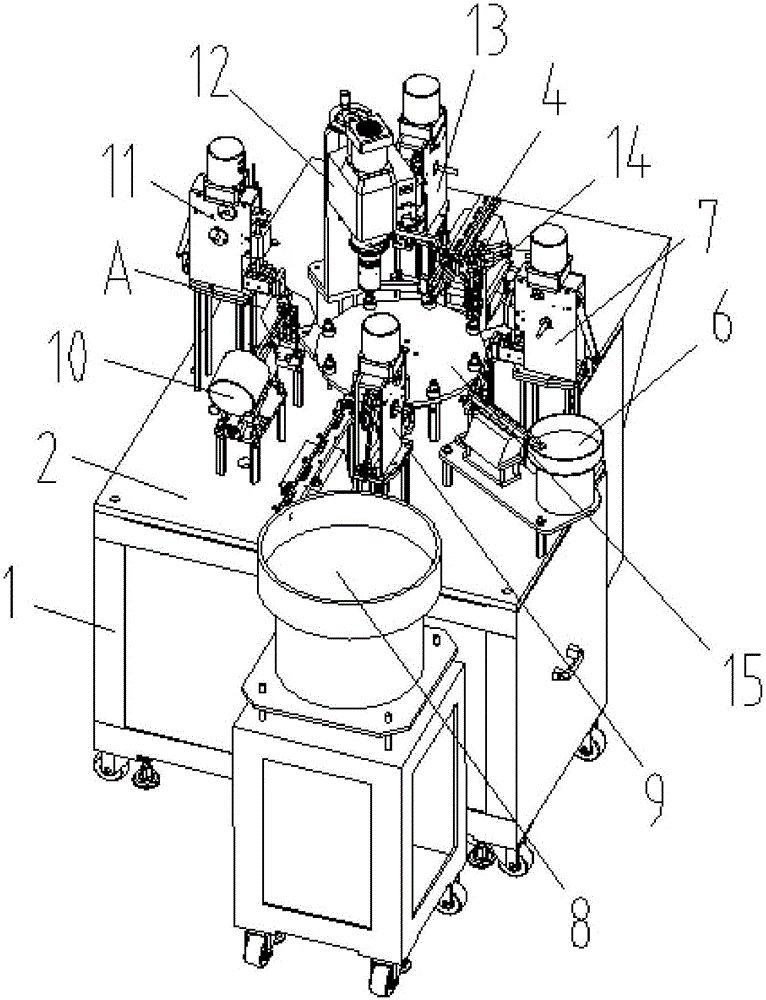

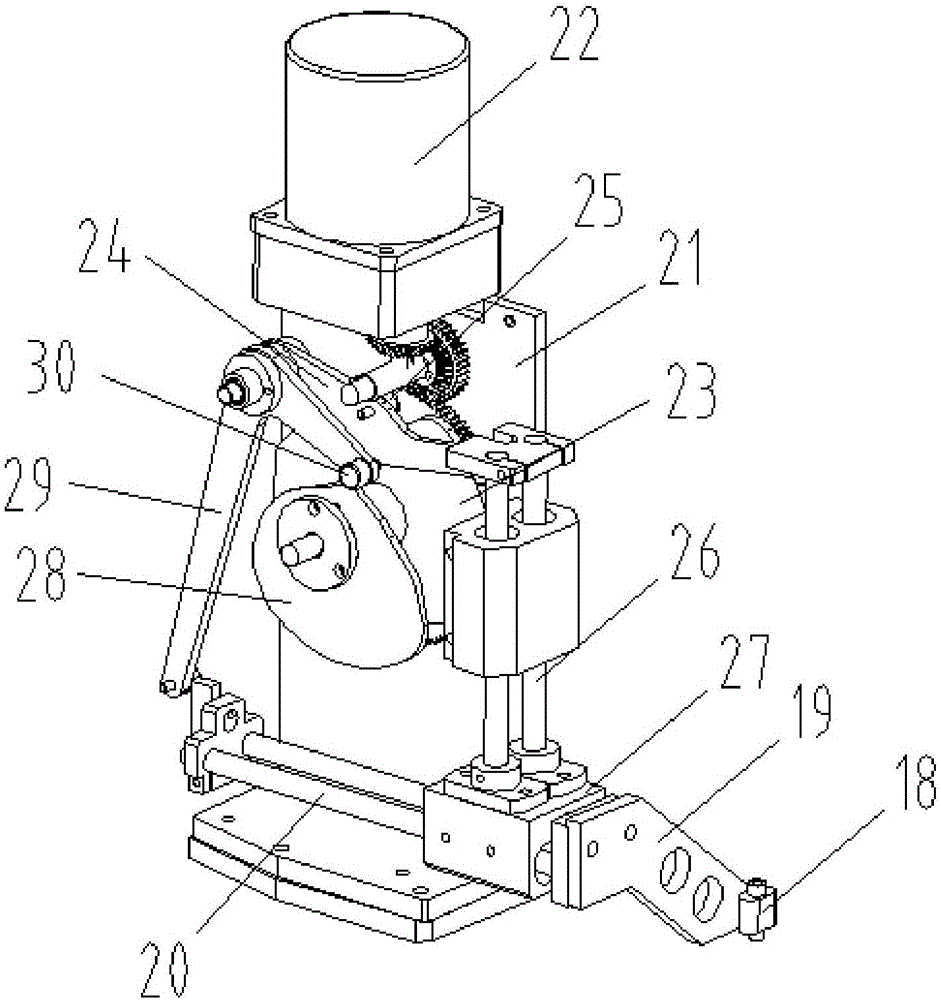

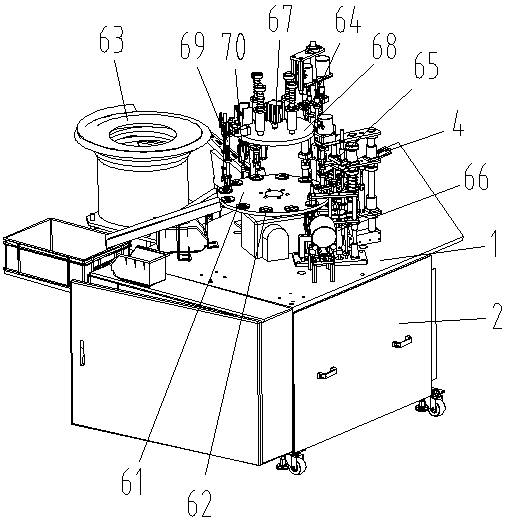

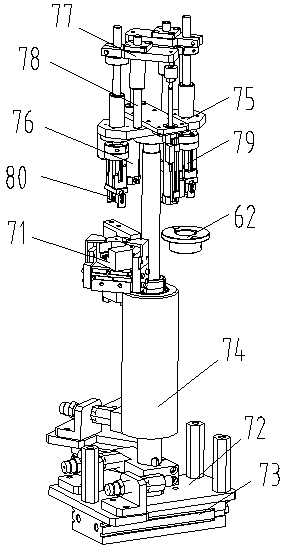

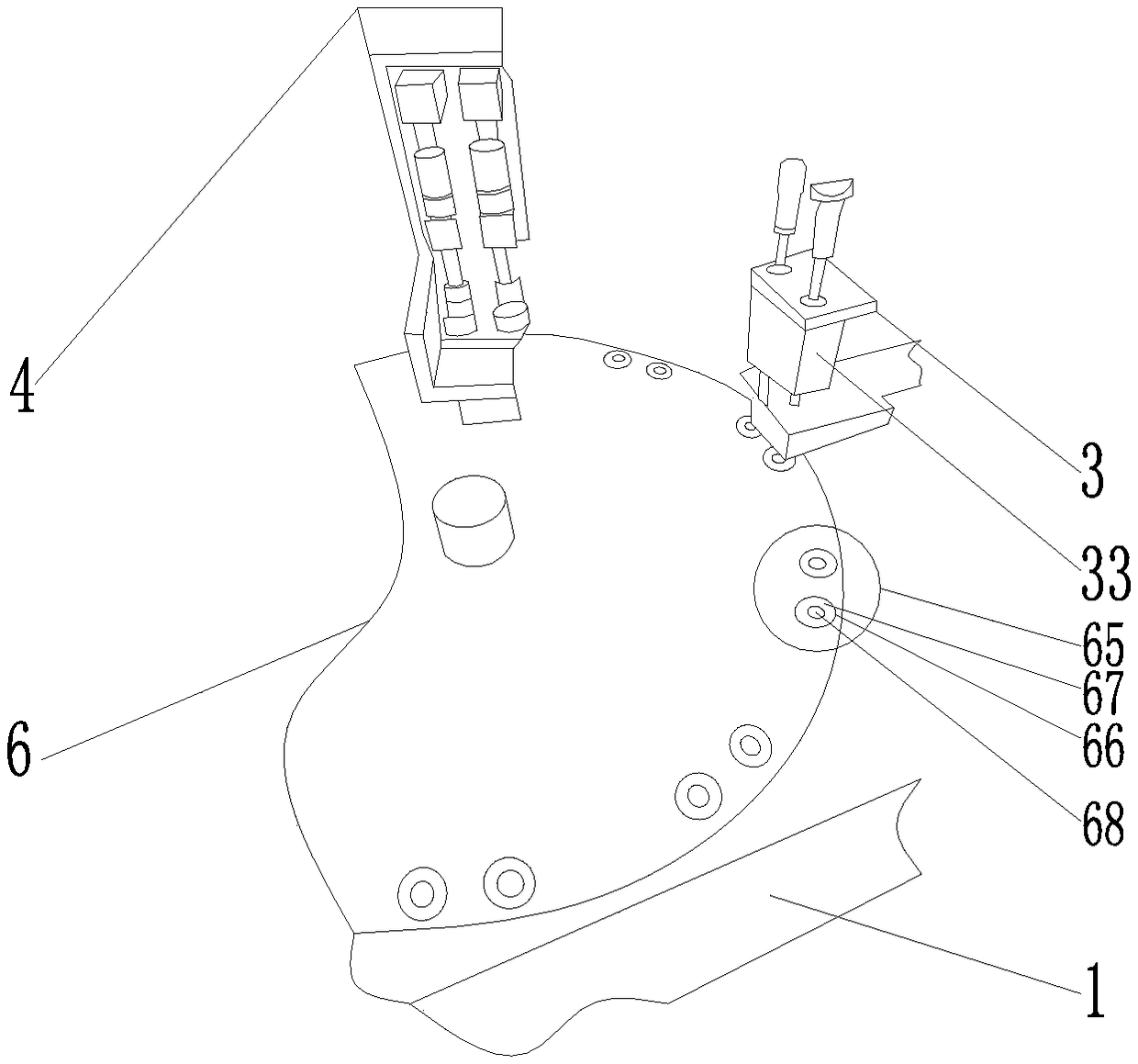

Full-automatic assembly machine of mechanical shaft

ActiveCN106736505AImprove installation efficiencyImprove the efficiency of installation, but also improve the utilization of equipmentAssembly machinesMetal working apparatusDistribution controlGear wheel

The invention relates to a full-automatic assembly machine of a mechanical shaft. The machine comprises a frame and a power distribution control box; the frame is provided with a shaft sleeve mounting mechanism and a gear mounting mechanism connected through a product conveying groove; a shaft sleeve mounting turntable is uniformly provided with loading holes matched with the shaft, and the outer side is provided with a shaft loading device, a shaft sleeve loading device, a screw rod loading device, a shaft sleeve pressing device and a shaft sleeve unloading device matched with the loading holes and connected to the power distribution control box in sequence; the gear mounting mechanism includes a gear mounting turntable arranged on the frame; the gear mounting turntable is uniformly provided with emptying holes matched with the shaft; and the outer side of the gear mounting turntable is provided with a gear loading device, a product loading device, a gear tightening device and a product unloading device matched with the emptying holes or a gear mounting carrier in sequence. The shaft sleeve mounting mechanism and the gear mounting mechanism are connected through the product conveying groove, so that the integral automatic installation is realized, and the mounting efficiency is greatly improved.

Owner:DONGGUAN UNIV OF TECH

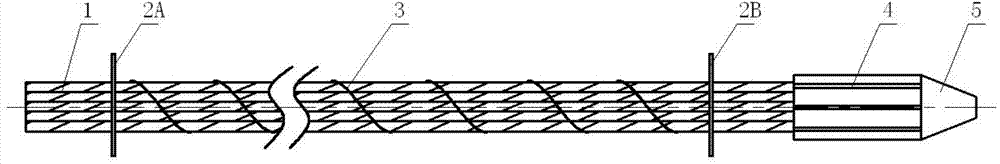

Finished prestressed steel stranded wire harness convenient for construction

InactiveCN104499652ANo loosenessSimple structureBuilding reinforcementsPre stressArchitectural engineering

The invention relates to a finished prestressed steel stranded wire harness convenient for construction. The finished prestressed steel stranded wire harness comprises a steel stranded wire harness, an extruding sleeve, a front marking board, a rear marking board and a binding wire, wherein the steel stranded wire harness is composed of a plurality of steel stranded wires through combing and twisting in an ordered manner, the extruding sleeve is coaxially buckled at the pulling end of the steel stranded wire harness, the front end and the rear end of the steel stranded wire harness penetrate through the front marking board and the rear marking board, respectively, the binding wire is spirally wound on the outer edge of the steel stranded wire harness between the two marking boards, the extruding sleeve comprises a connecting section and a pulling section, wherein the pulling section is integrated at one end part of the connecting section, the pulling section is of a cone-frustum shaped structure, a threaded hole is formed coaxially in the minor-diameter end of the cone-frustum shaped structure, and a plurality of barb bulge loops are uniformly and integrally arranged on the inner wall of the connecting section in a spacing manner. The steel stranded wire harness can penetrate into a corrugated pipe of a construction hole safely, twisting and deformation among the single steel stranded wires are avoided during penetrating, the pulling section of the extruding sleeve is of a conical structure design and has the strong guiding property, and the construction efficiency is effectively improved.

Owner:TIANJIN SHINKUNTAI ADVANCED PRESTRESSING TECH

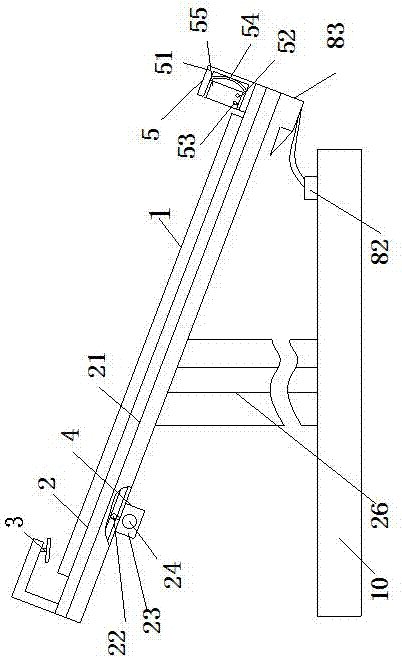

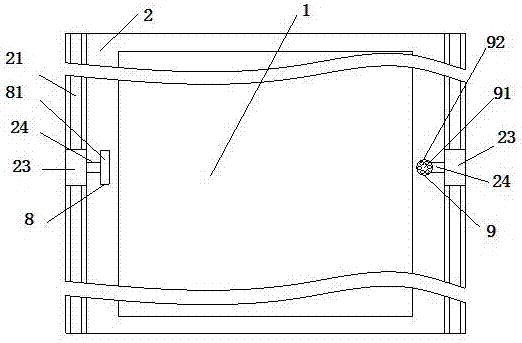

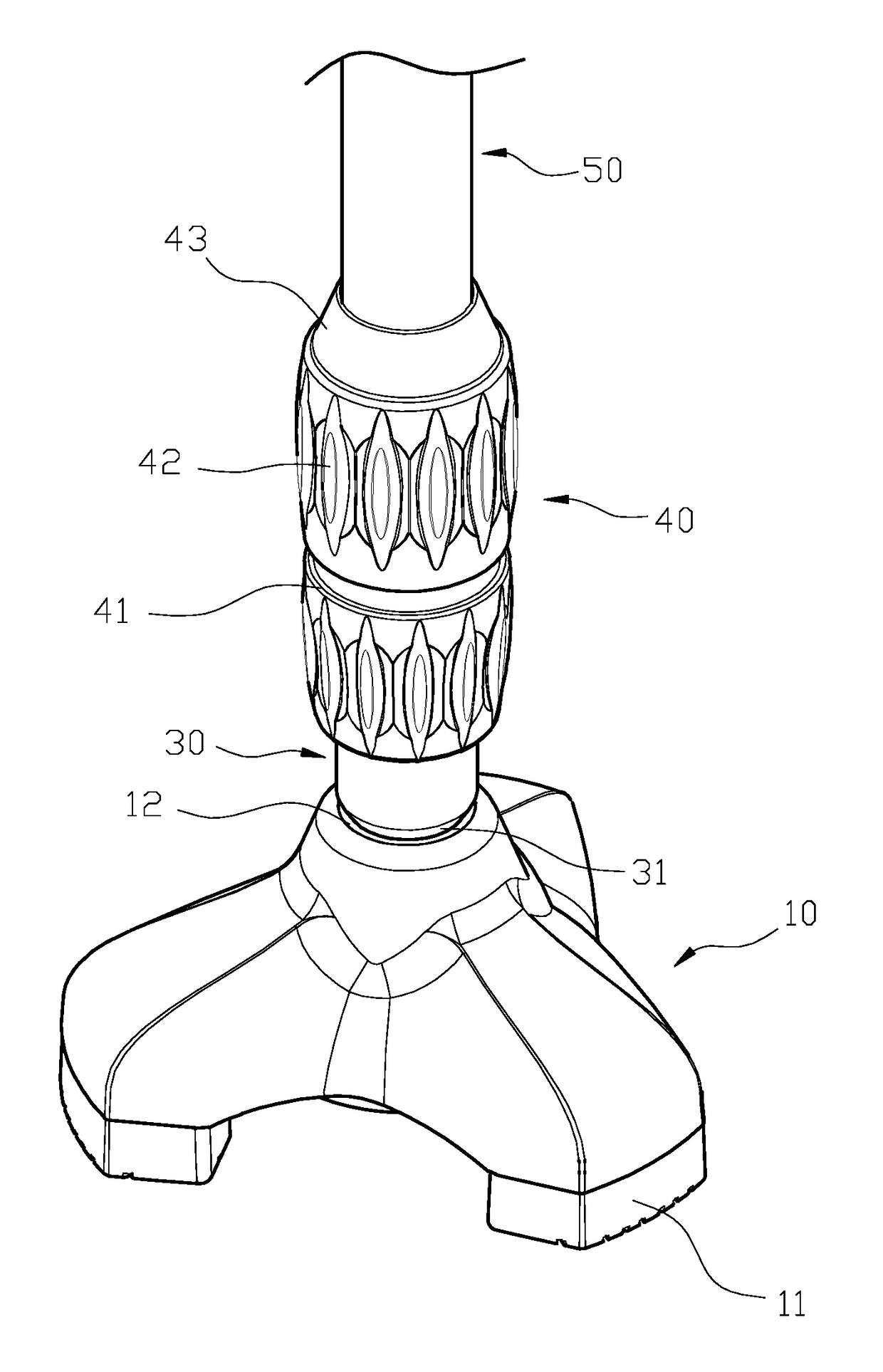

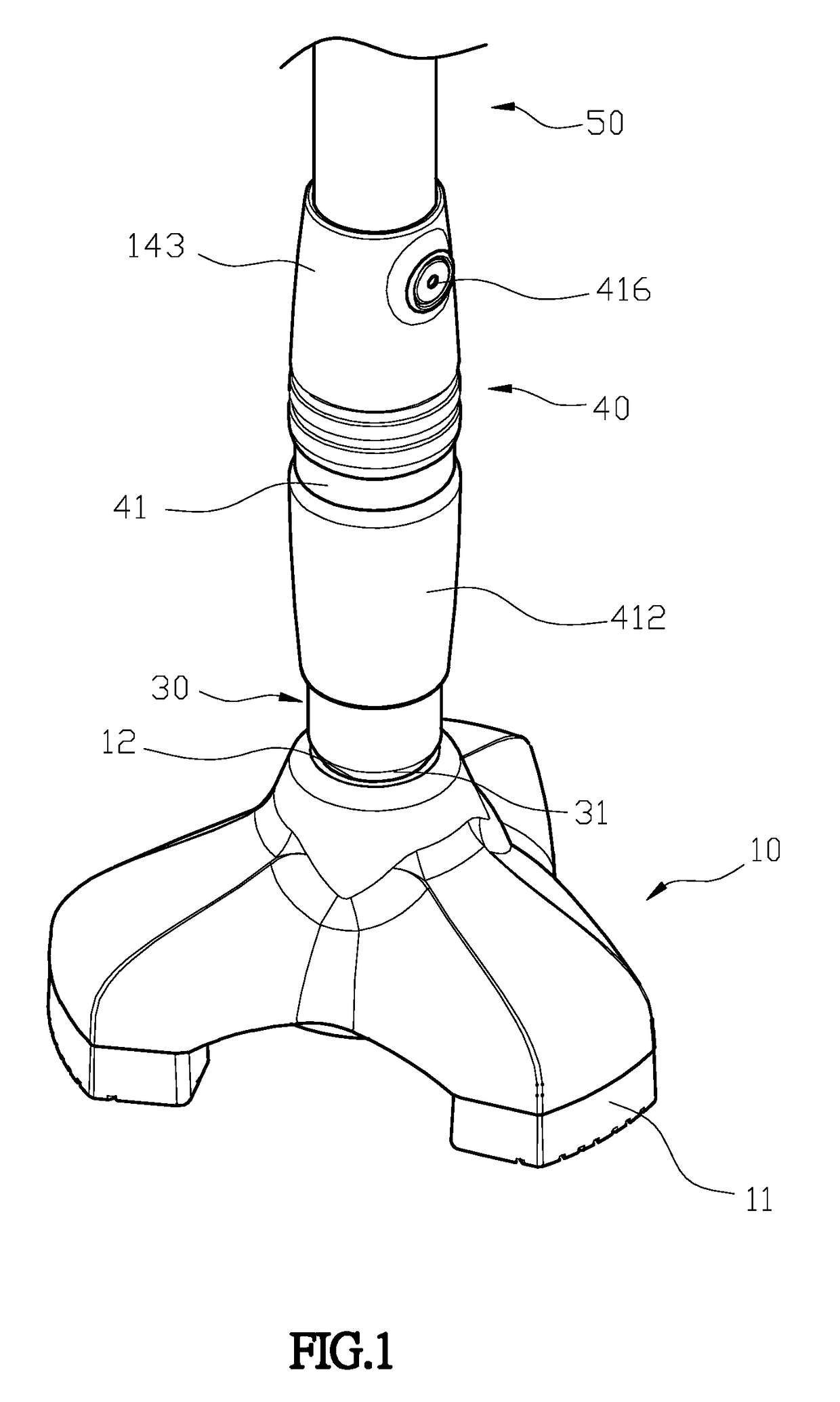

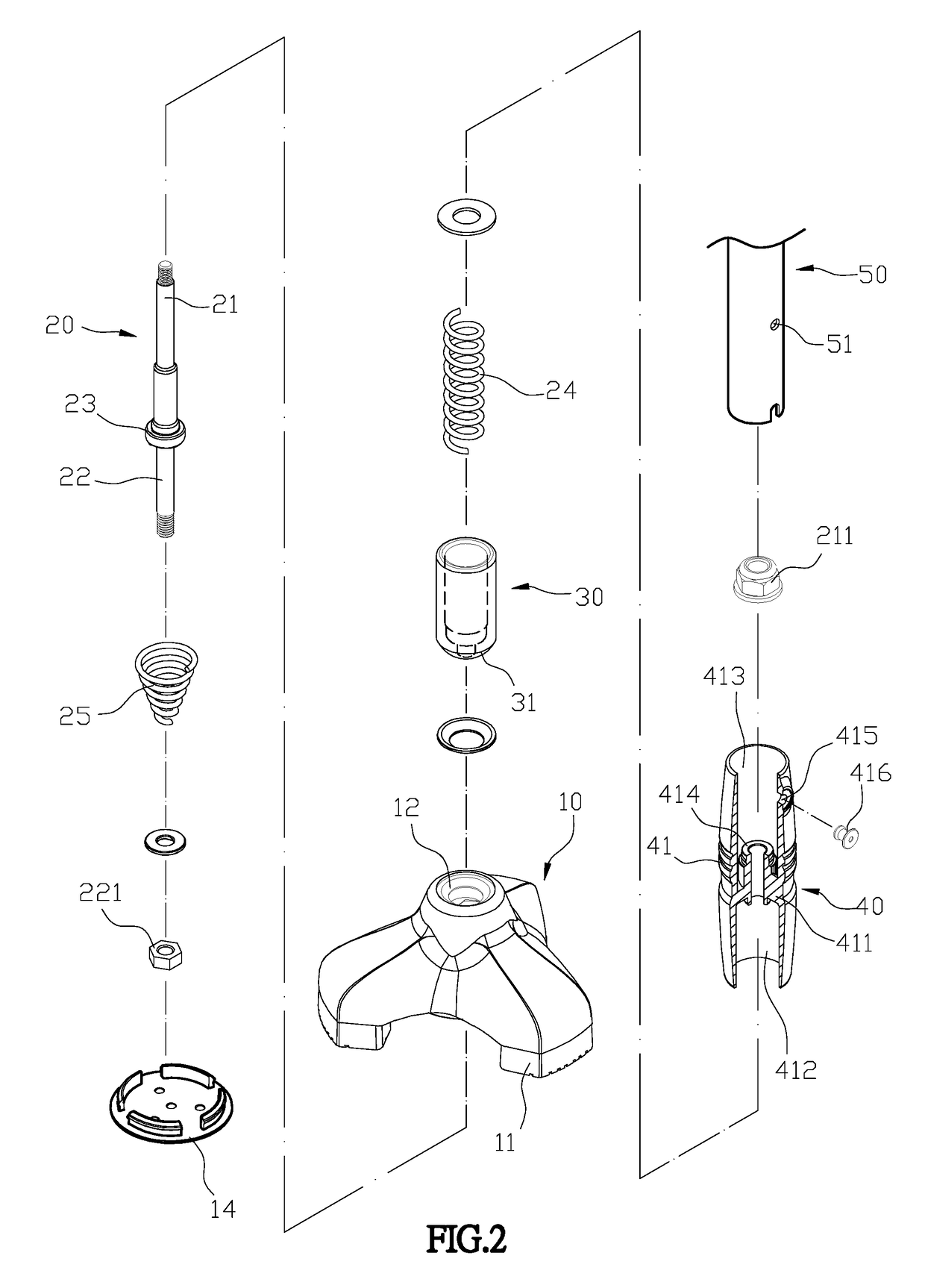

Base structure for walking stick

ActiveUS9974367B2Improve tightening effectStand steadyWalking sticksCrutchesEngineeringWalking stick

Owner:HOMECARE ENTERPRISE

Reverse tension mechanism for a strapping machine

ActiveUS8931405B2Simple structureSmall sizeBinding material applicationBundling machine detailsEngineeringMechanical engineering

A reverse tension mechanism for a strapping machine includes an active wheel, a supporting arm installed with a passive wheel, a lever, and a spring. The supporting arm can be moved relative to the active wheel, so that a strapping band which passes between the passive wheel and the active wheel is clamped to control retracting and tightening of the strapping band. A first end of the lever is pivotably connected to a section of the supporting arm, and the spring is vertically installed between a second end of the lever and the section of the supporting arm. The first end of the lever can be activated by a cam to press the spring vertically to produce a pushing force to swing the supporting arm.

Owner:LAI CHIEN FA

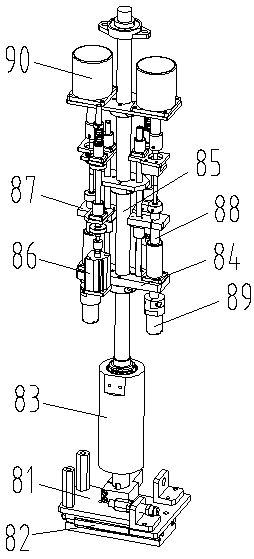

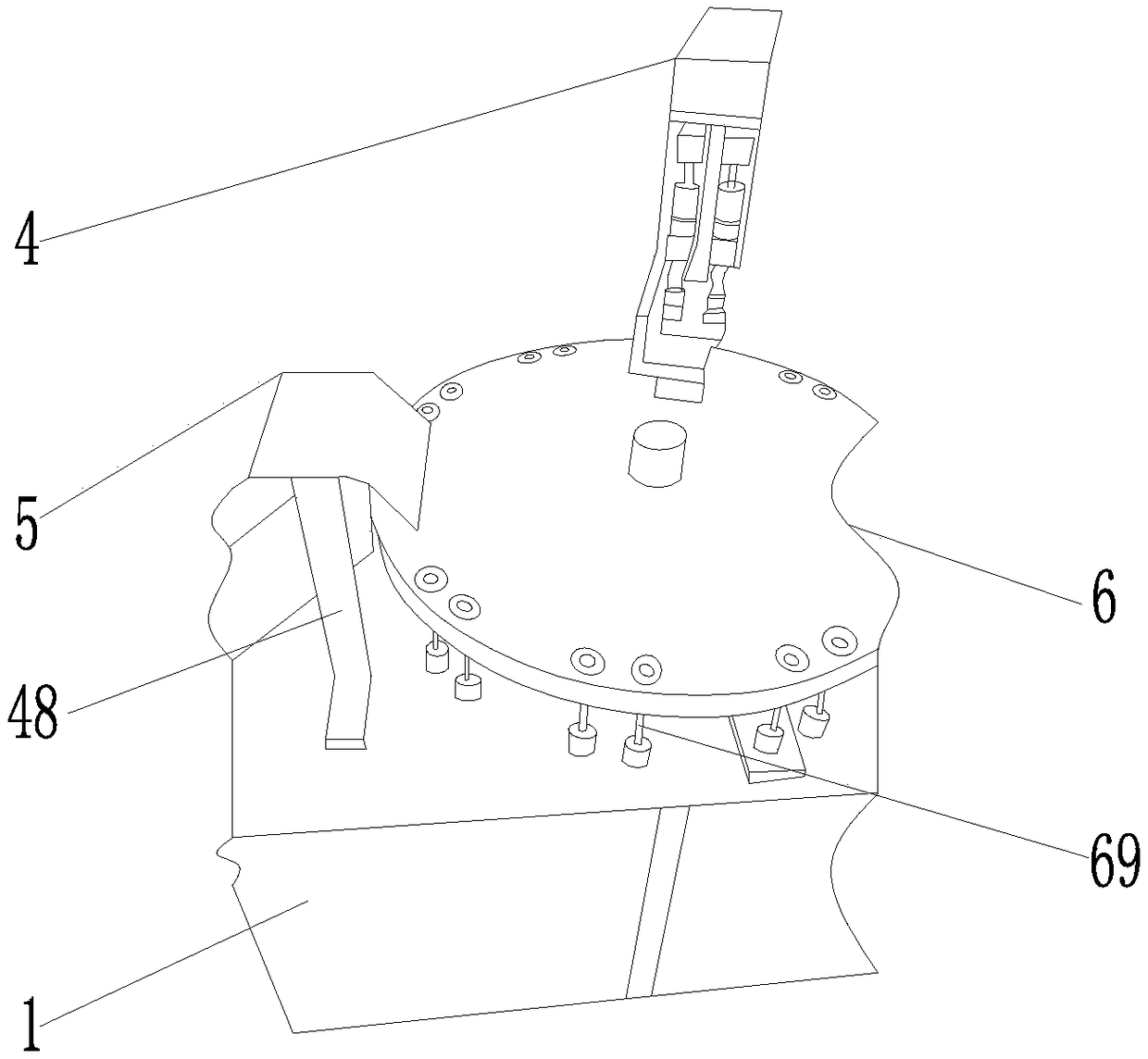

Automatic shaft gear assembling machine convenient for picking materials

ActiveCN108637684AImprove installation efficiencyIncrease profitAssembly machinesMetal working apparatusDistribution controlGear wheel

Owner:双环传动(嘉兴)精密制造有限公司

Expanding sleeve centering clamp

The invention relates to an expanding sleeve centering clamp which comprises a clamp body, an expanding sleeve round petal body and a guide sliding pillar. The guide sliding pillar is arranged in the clamp body in a sleeved mode, a cavity is formed in the position where the guide sliding pillar and the clamp body are connected, and a spring which is connected with the guide sliding pillar and the clamp body is arranged in the cavity. A groove is formed in the surface of the outside of the position where the guide sliding pillar and the clamp body are connected, the expanding sleeve round petal body is arranged in the groove in a sleeved mode, and the two sides of the groove are arranged to be inclined planes. A center hole is formed in the end face of the tail portion of the guide sliding pillar. The clamp body is further provided with a ball nut, and a ball gasket is further arranged between the ball nut and the expanding sleeve round petal body. The expanding sleeve centering clamp has the advantages that automatic correction can be achieved, centering is achieved, dismounting and mounting are convenient, precision is high, and parts of different inner diameters can be machined.

Owner:CHANGZHOU YINBAO NICKEL NETWORK

Multi-specification movement alignment mechanism of reinforcement bar straightening machine

ActiveCN103128197AAchieve straighteningStraightening saves time and effortReciprocating motionEngineering

The invention discloses a multi-specification movement alignment mechanism of a reinforcement bar straightening machine. The multi-specification movement alignment mechanism of the reinforcement bar straightening machine comprises a rack, and a multi-thread steel-bar straightening group is arranged between an inlet guide pipe and an outlet guide pipe. Two sides of the multi-thread steel-bar straightening group are fixed at a connecting board of an alignment group, two outer side faces of the connecting board of the alignment group are respectively fixed at one ends of multiple steel-bar guide pipes with different hole diameters, and the other ends of the multiple steel bars are respectively fixed at two movable blocks, the two movable blocks are respectively arranged at two sliding channels of the rack in a sliding mode, and the two movable blocks are respectively connected with two reciprocating motion mechanisms which are operated synchronously. The multi-specification movement alignment mechanism of the reinforcement bar straightening machine has the advantages that when steel bars of different diameters are aligned, only the two movable blocks needing to be moved and one of the specification steel-bar guide pipes and one of specification steel-bar alignment roller ways are enabled to be directly faced at the inlet guide pipe and the outlet guide pipe to achieve alignment of steel bars of different specifications, the multi-specification movement alignment mechanism of the reinforcement bar straightening machine is small in impaction, stable in transmission, and labor-saving and time-saving in alignment, and a tensioning roller arranged on the rack enables a chain to achieve a best tensioning effect.

Owner:TJK MACHINERY TIANJIN

10KV distribution line cable erection fixture and application method

ActiveCN105655952AWon't fall offHow to use short answerSuspension arrangements for electric cablesArrangements for reliveing mechanical tensionChinese charactersLocking mechanism

The invention discloses a 10KV distribution line cable erection fixture and an application method and provides a convenient and fast device capable of effectively avoiding adverse impact caused by wind vibration. The 10KV distribution line cable erection fixture comprises a shell, wherein a main cavity is formed at the middle of the shell, and two assistant cavities are formed on the two sides; three rope sheaves and a pair of assistant locking mechanisms are mounted in the main cavity; the three rope sheaves are arranged in a shape of Chinese character 'Pin'; the rope sheaves are close to an entrance, and the locking mechanism is close to an exit. When a cable passes by, a clamping force is formed against the cable under the effect of reversed tension of the cable; a pull rod is mounted in each assistant cavity, and the tensioning effect is good; and three rope sheaves are arranged inside, the cable is wound on the three rope sheaves which are mutually bent in a roundabout manner, and locking and fixing are formed in the roundabout bending process to firmly lock the cable inside and form a relatively good locking effect.

Owner:CHUZHOU KERNUM ELECTRIC CO LTD

Frozen pipe cover mounting mechanism

InactiveCN108862146AReasonable quantityImprove delivery efficiencyCapsThreaded caps applicationEngineeringDrive motor

The invention relates to the technical field of biomedical equipment, and in particular, discloses a frozen pipe cover mounting mechanism. The frozen pipe cover mounting mechanism comprises a cover loading machine, a cover pressing machine, a cover screwing machine, a pipe unloading machine and a feeding machine; the cover loading machine comprises a first arc conveying rail, a second arc conveying rail, a third arc conveying rail, a fourth arc conveying rail and a fifth arc conveying rail; the cover pressing machine comprises a T-shaped plate, a through hole, an air blowing pipe, a first cylinder, a metal plate and a photoelectric induction switch; the cover screwing machine comprises a second cylinder, a driving mechanism and a third cylinder; a driving mechanism comprises a first driving motor and a rotating mechanism; the pipe unloading machine comprises a fourth cylinder, an unloading hopper, a push plate, a horizontal baffle plate and an inclined baffle plate; the feeding machinecomprises a turntable and a cutter; and the turntable is provided with a mounting column, an assembly hole, a push rod, a push block and a third spring. The frozen pipe cover mounting mechanism has the characteristics of higher conveying efficiency, lower labor cost, no unqualified product, better cover screwing effect, higher collecting efficiency and higher automation degree.

Owner:ZHEJIANG SORFA MEDICAL PLASTIC

Finished steel strand harness propulsion device

InactiveCN103352431AEasy to processEasy to installBridge erection/assemblyBuilding material handlingBuilding constructionAerospace engineering

The invention discloses a finished steel strand harness propulsion device. The propulsion device comprises a hoop and a propulsion head; one end of the hoop is connected with one end of the propulsion head; a finished steel strand harness is sleeved in the inner hole in the other end of the hoop and then is fastened by the hoop; the other end of the propulsion head is a cone; the outline dimensions of the hoop and the propulsion head are smaller than the internal diameter of a construction aperture passage in which the follow-up finished steel strand harness is pushed. The propulsion device has the benefits that the hoop and the propulsion head are fastened and connected into a whole, so that the processing and mounting are convenient and the construction efficiency is high; the front end of the propulsion head is conic, so that the pushing process is more smooth when propulsion equipment is used for pushing; the propulsion device has the advantages of simplicity in processing, convenience in replacement, low cost and the like. The hoop is fastened at the end part of the finished steel strand harness before leaving a factory; so long as the corresponding propulsion head is screwed onto the hoop on a construction site, the propulsion device can be used to push the finished steel strand harness to penetrate through the construction aperture passage corrugated pipe.

Owner:TIANJIN SHINKUNTAI ADVANCED PRESTRESSING TECH

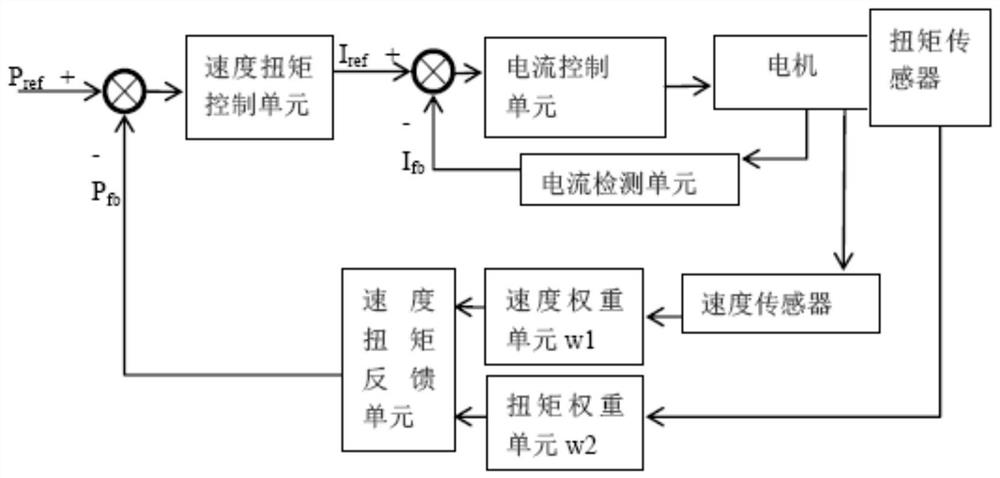

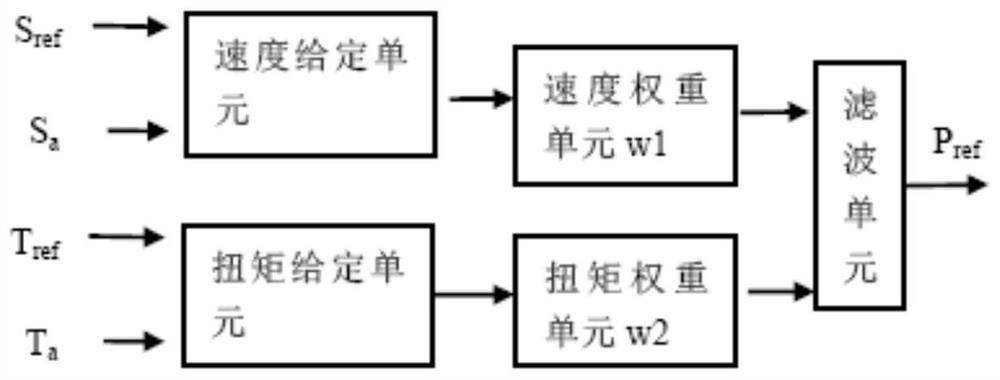

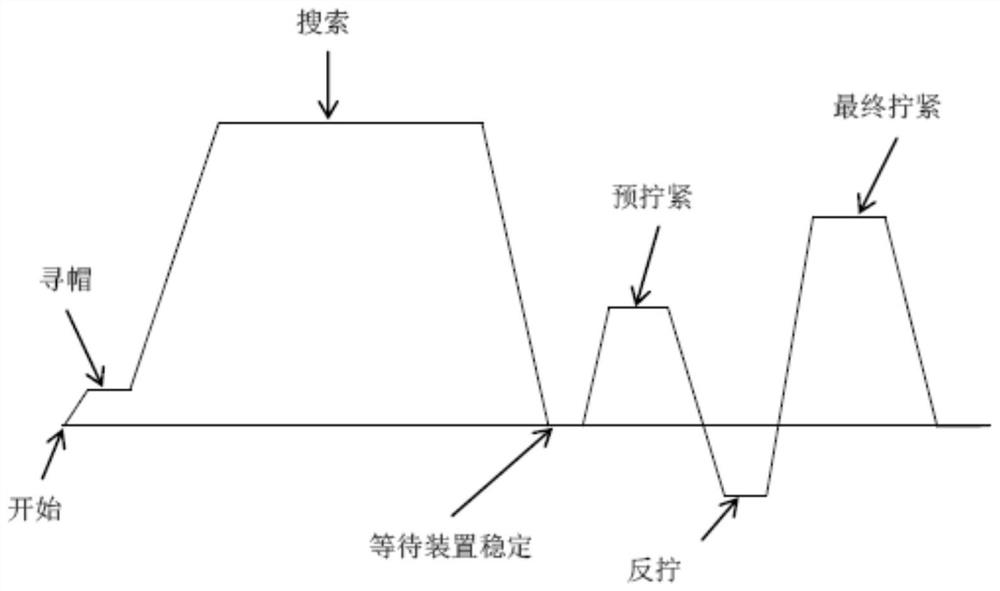

Screw fastening system and method

ActiveCN112536754AImprove tightening effectReduce shock torqueElectric motor controlSpannersMotor speedControl engineering

The invention discloses a screw fastening system and method. The screw fastening system comprises a speed giving unit, a torque giving unit, a filtering unit, a speed torque control unit, a speed torque feedback unit, a current control unit, a speed weight unit, a torque weight unit, a motor, a current detection unit, a speed sensor, and a torque sensor; an electric wrench is connected to one endof the motor; the input end of the speed sensor, the input end of the torque sensor and the input end of the current detection unit are respectively connected with the motor; the output end of the current detection unit is connected with the current control unit and provides a current feedback value for the current control unit; the speed torque control unit is connected with the current control unit; and the current control unit is connected with the motor. According to the screw fastening system and method, by arranging the speed torque control unit, the speed torque feedback unit and the current control unit, the construction torque of the to-be-fastened screw and the rotating speed of the motor are controlled at the same time, so that the impact torque is reduced, higher torque precision is guaranteed, and the screw tightening effect is effectively improved.

Owner:GOOGOL PARADOX (DONGGUAN) INTELLIGENT TECH CO LTD

Blade combination method of crusher and combined blade of same

The invention relates to the technical field of crushing machinery, in particular to a blade combination method of a crusher and a combined blade of the same. The combined blade is characterized in that a parallel-type stepped slot asynchronous with the angle of a centripetal line of a cutter is cut on the edge of a cutter cylinder, which is in the circle center direction, for holding blades; onesurface of each blade is of a concave-convex structure, the blades are embedded into the parallel-type stepped slot starting from convex surfaces of the blades, concave-convex shoulders of the bladesare parallel to the parallel-type stepped slot in a micro-interference manner, pressing blocks press the concave-convex shoulders of the blades in the parallel-type stepped slot in a radial clearancemanner and the pressing blocks are fastened on the edge of the cutter with backstop screws, and the tail parts of the tightened backstop screws are hidden in screw grooves of the pressing blocks; andan odd number of blades are distributed on the cutter at equal intervals. The invention has the positive effects that the blades are more easily fastened due to the arrangement mode, thereby effectively preventing the blades from being loosened in case of vibration, and the blades are conveniently installed, maintained and replaced, thus improving the operating efficiency of the crusher.

Owner:SHANGHAI DIANJI UNIV +1

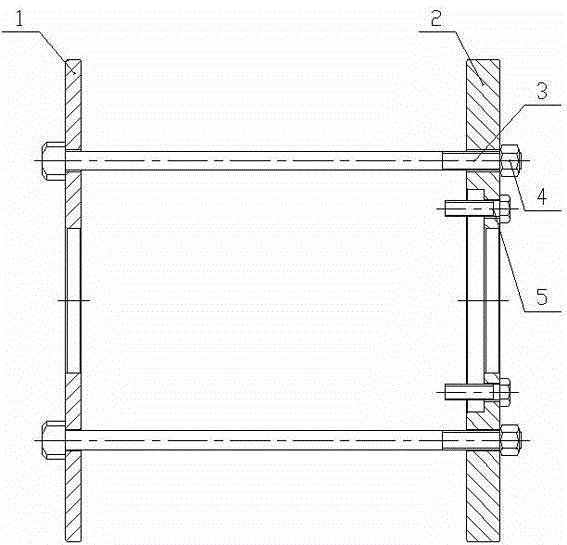

Clamp for assembling and expanding conducting bar of motor rotor

InactiveCN105656257AImprove tightening effectHigh positioning accuracyManufacturing stator/rotor bodiesElectric machineSmall footprint

The invention relates to a clamp for assembling and expanding a conducting bar of a motor rotor, especially to a clamp for assembling and expanding the conducting bar of the copper bar rotor of a motor, and aims at solving the problems that the length of the rotor bar stretching out of two ends of a rotor core is determined through marking lines when a present electric machine copper rotor bar is assembled and expanded, operation is complex, the rotor bar cannot be accurately positioned, lengths, stretching out of two ends of a rotor core, of the rotor bar are different, two ends of the rotor bar are not fixed when the rotor bar is expanded, and the rotor bar is easy to slip off a rotor core groove when the expanding force is over large or the direction is inclined. A circular-ring-shaped non-driving end pressure plate is connected to a driving end pressure plate through four screws, the inner circle of the non-driving end pressure plate is provided with a circular-ring-shaped stage, and four bolts are uniformly connected to the periphery of the ring stage. By adopting the clamp, the labor intensity is reduced, positioning precision of the rotor bar and the expanding effect are improved, the size is small, the weight is low, the floor space is small, and the clamp is suitable for assembling and expanding a batch of copper rotor bars at the same time.

Owner:襄阳中车电机技术有限公司

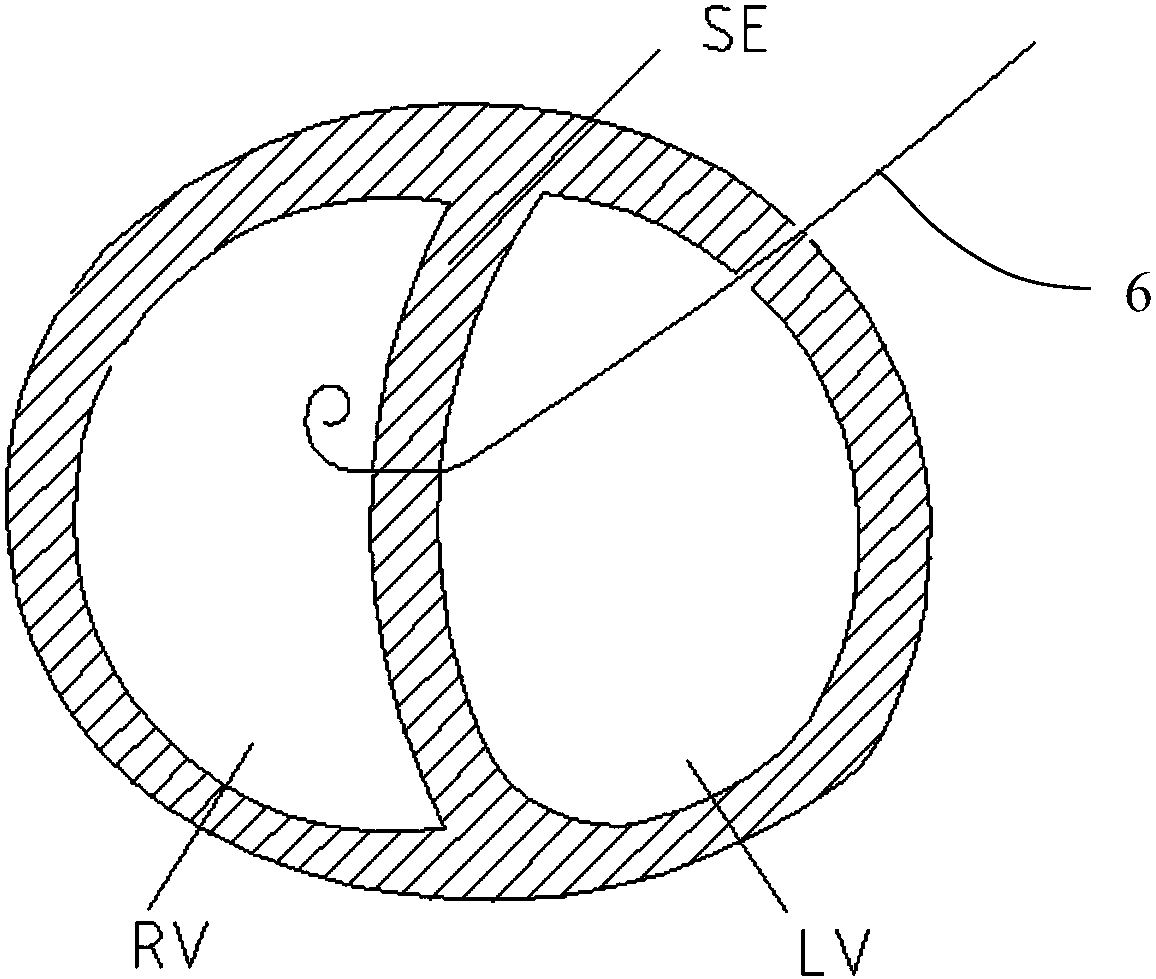

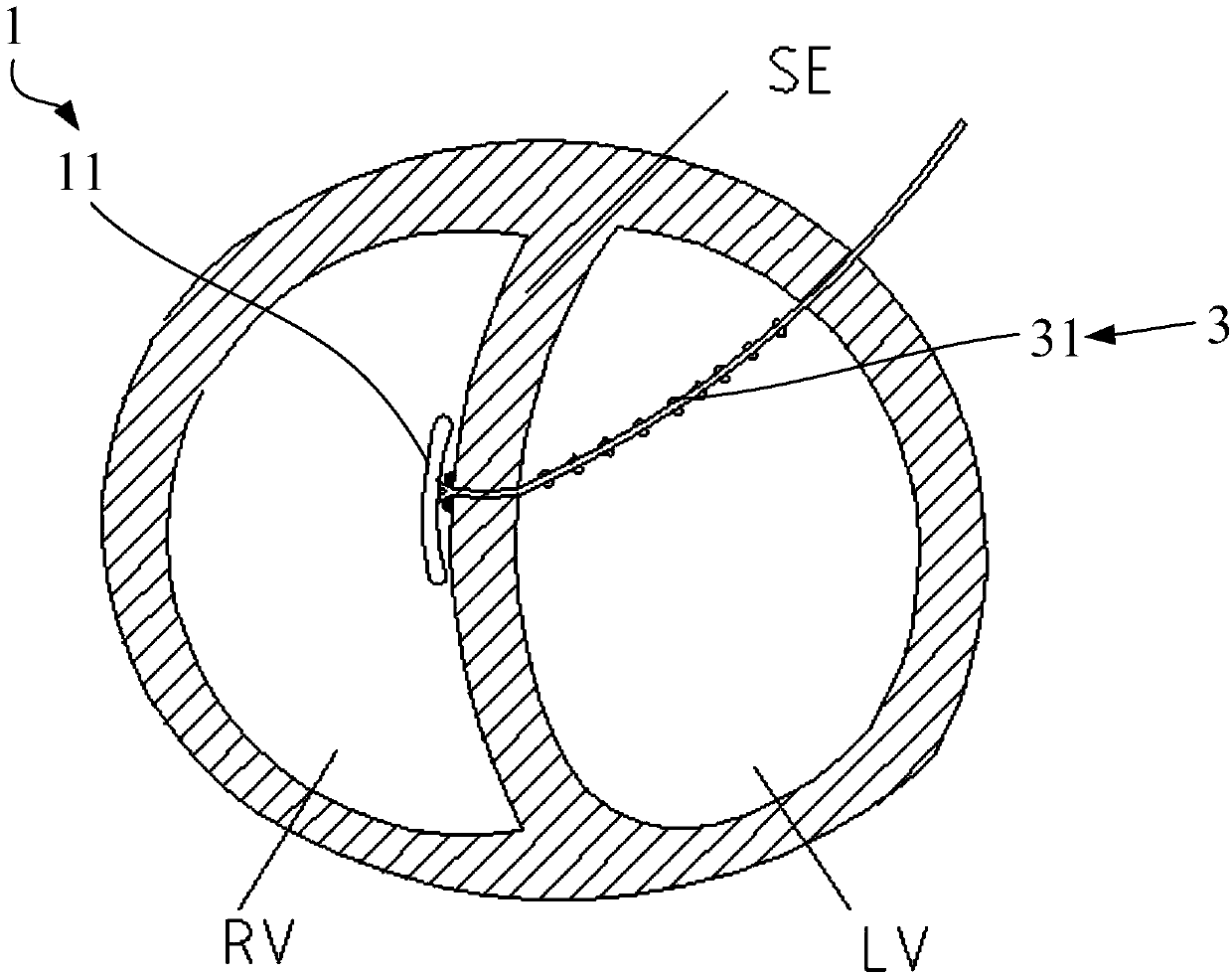

Medical device

The invention provides a medical device helpful to improve the effectiveness and stability of anchoring in myocardial fixation and improve the effect of myocardial tightening. The medical device includes a first implant for making contact with a first wall of an implanted object, a second implant for making contact with a second wall of the implanted object, and a tightening mechanism for being connected with the first implant; the tightening mechanism passes through a locking mechanism, the locking mechanism is in cooperative connection with the tightening mechanism, and the second implant can move in a direction approaching the first implant along the tightening mechanism. The second implant can move in the direction away from the first implant along the tightening mechanism when the tightening mechanism and / or the locking mechanism are deformed.

Owner:SHANGHAI MICROPORT MEDICAL (GROUP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com