Process for producing tube member made of fiber-reinforced resin

A fiber-reinforced resin and manufacturing method technology, applied in vehicle parts, control devices, household components, etc., can solve the problems of fiber orientation disorder, simultaneous curing, and no disclosure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

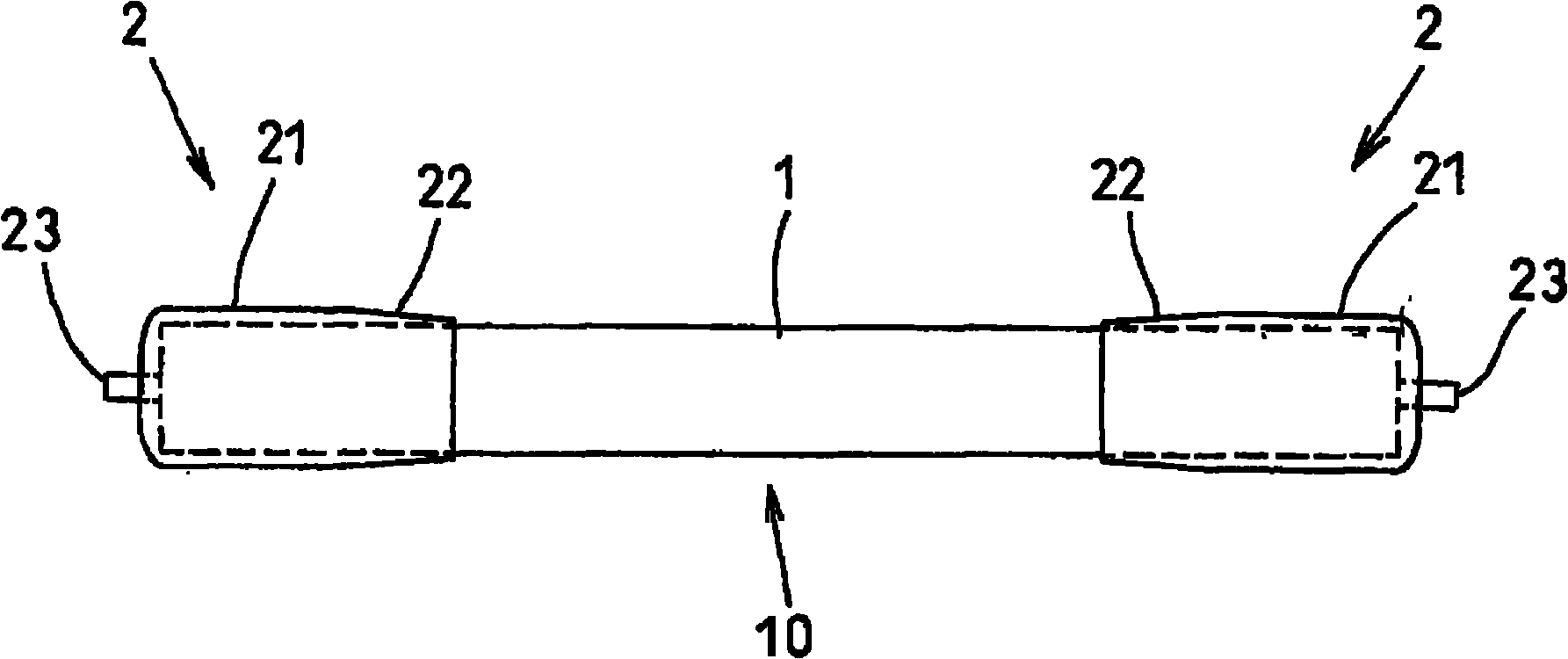

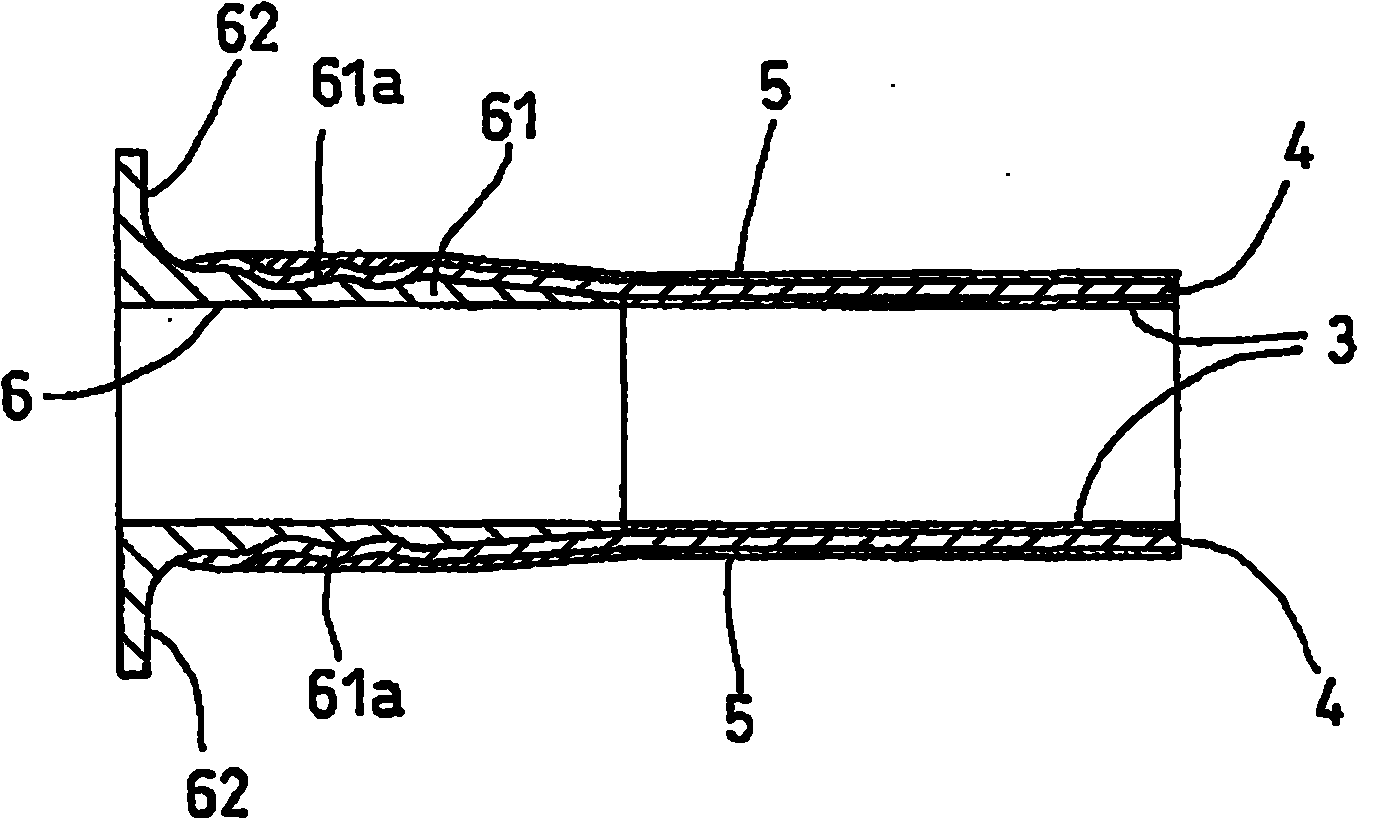

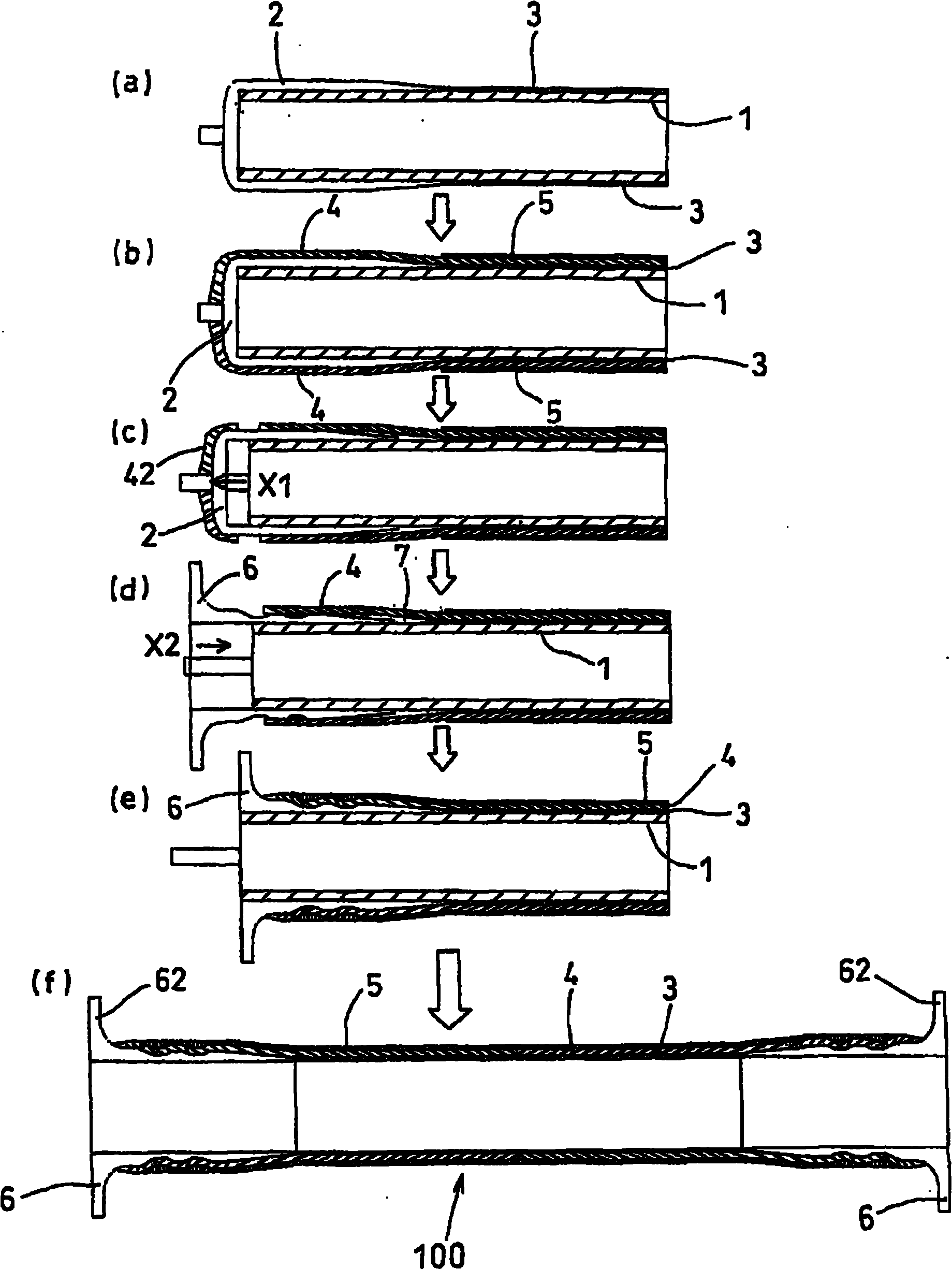

[0047] Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 1 is the front view of the base material including mandrel and end mounting material, figure 2 is a sectional view illustrating the end structure of the torque tube, image 3 (a) to (f) are flowcharts sequentially explaining the production method of the present invention. Figure 4 is description image 3 a perspective view of (a), Figure 5 , Figure 6 is explained in turn image 3 (b) Perspective view. Figure 7 It is a figure explaining the situation of inserting the reinforcing member into the end of the member, Figure 8 It is a cross-sectional view illustrating the end structure of the reinforced torque tube. In addition, the illustration of the bearing and the shaft inside the torque tube is omitted.

[0048] figure 1 A mold for manufacturing a torque tube as a carbon fiber-reinforced resin tube member is shown. The mold base 10 is composed of a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com