Finished steel strand harness propulsion device

A technology of propulsion device and finished steel, which is used in the erection/assembly of bridges, the processing of building materials, bridges, etc., can solve the problems of the traction head not fixing the traction wire rope, inconvenient to pull the traction wire rope, and the device does not have uniform specifications, so as to achieve the tightness of the hoop. Good effect, high construction efficiency, simple processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

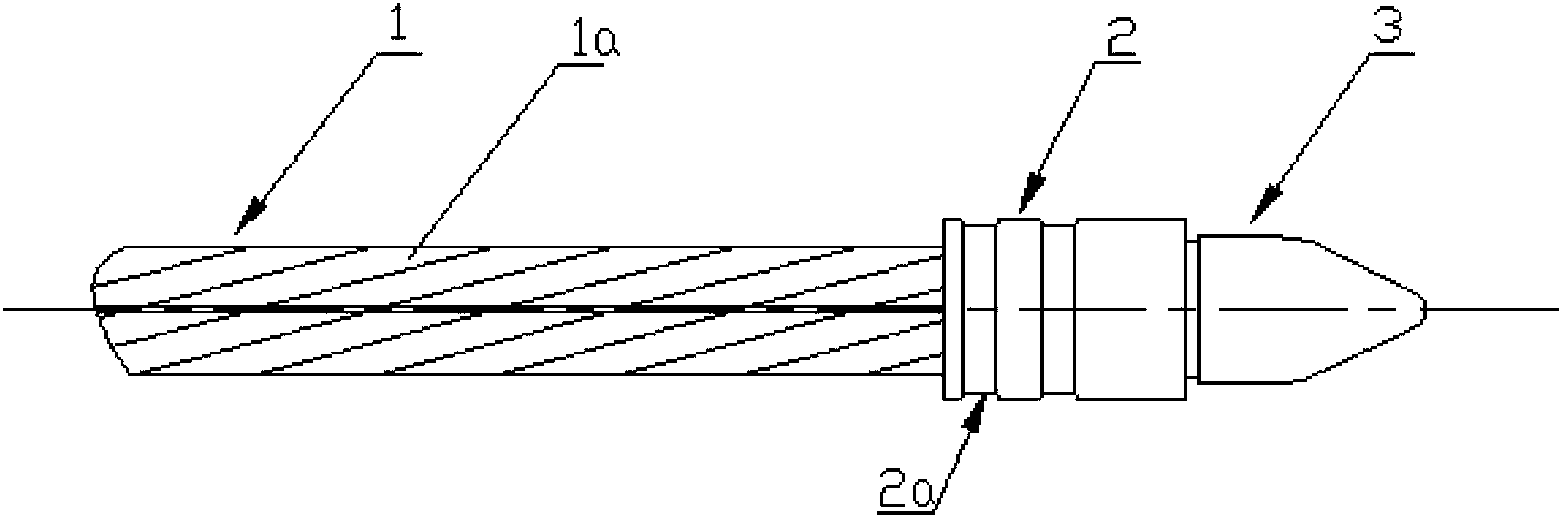

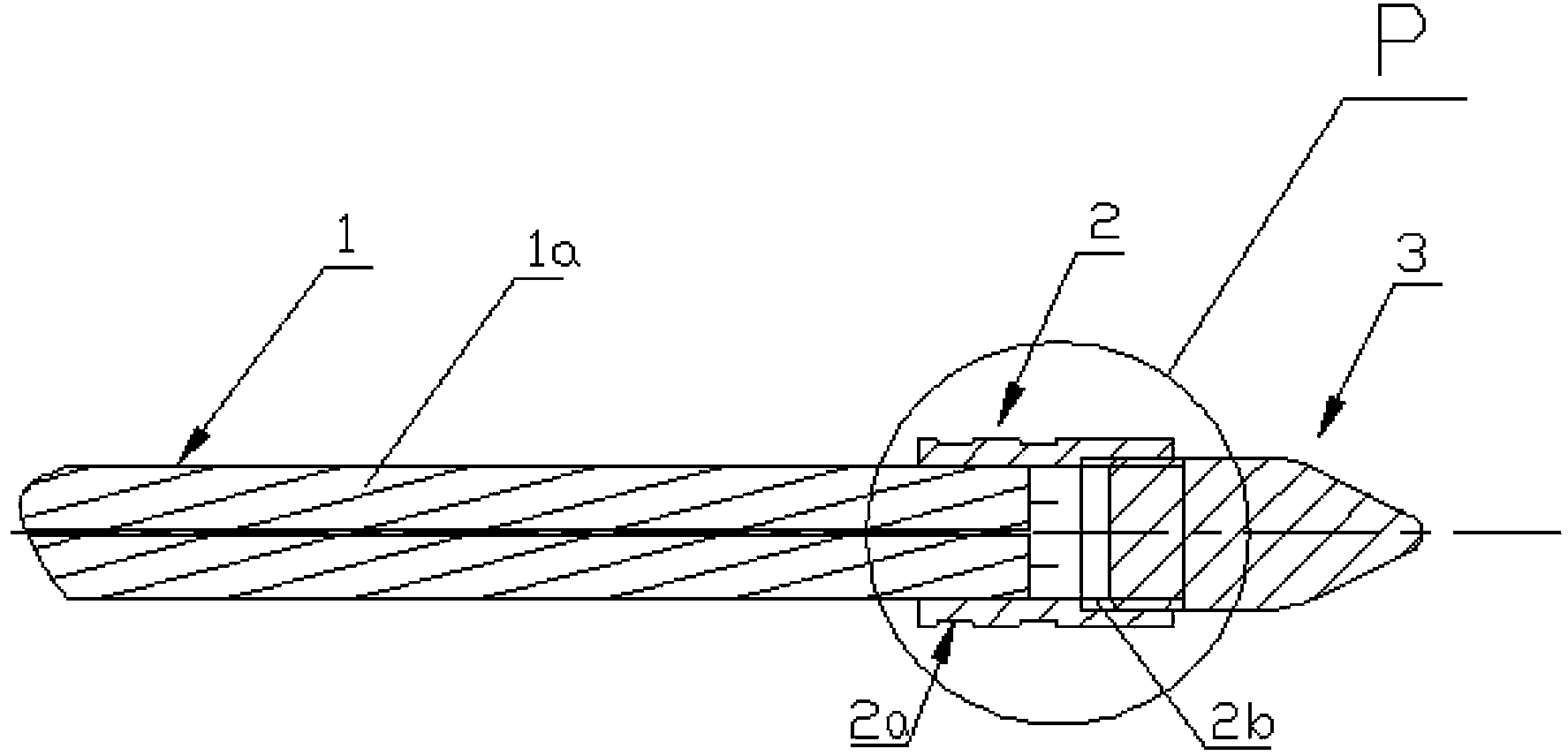

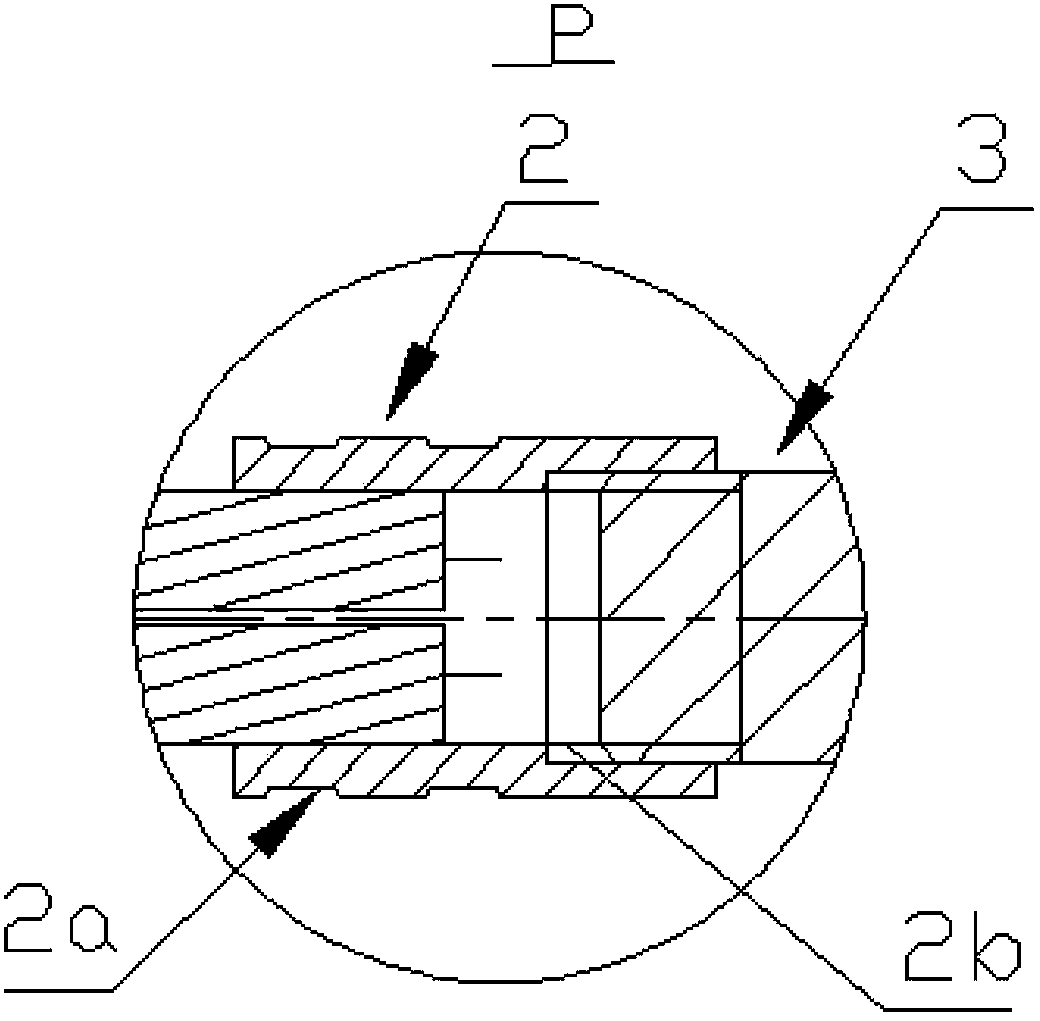

[0018] figure 1 It is a schematic diagram of the structure of the present invention assembled on the finished steel stranded wire harness; figure 2 Yes figure 1 Partial sectional view in the middle; image 3 Yes figure 2 Enlarged view of part P in.

[0019] As shown in the figure, the present invention provides a propulsion device for a finished steel stranded wire harness. The propulsion device includes: a tightening ring 2, a pushing head 3; one end of the tightening ring 2 is connected to one end of the pushing head 3, and the tightening The inner hole at the other end of the ring 2 is sheathed with the finished steel stranded wire harness 1 and clamped on one end of the finished steel stranded wire harness 1; the other end of the propelling head 3 is a cone; the outer contour size of the hoop ring 2 and the propelling head 3 It is smaller t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com