Blade combination method of crusher and combined blade of same

A combination method and pulverizer technology, applied in the direction of grain processing, etc., can solve the problems of difficult to achieve machining accuracy, complicated tool changing process, loose blades, etc., and achieve the effect of improving the reliability of cooperation, convenient installation and maintenance, and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention are given below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

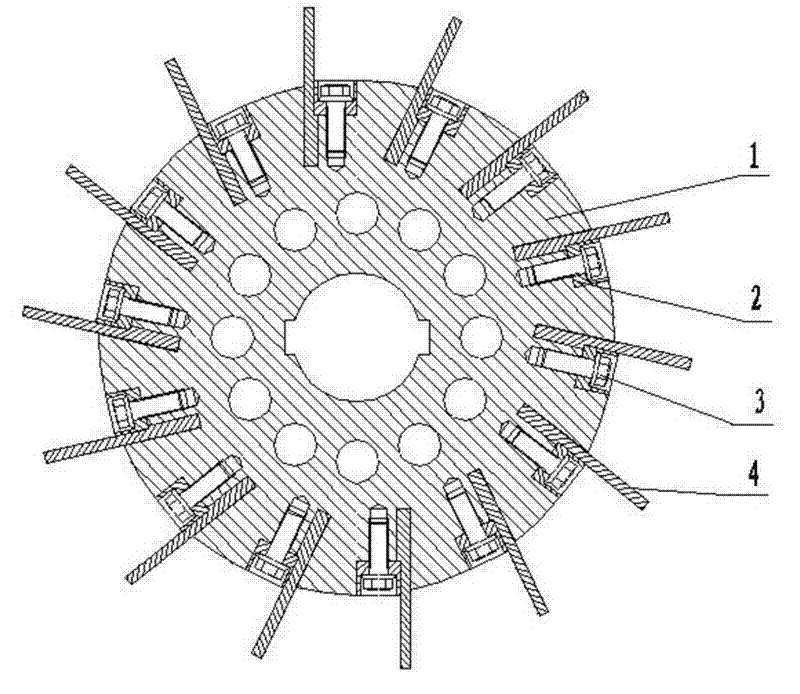

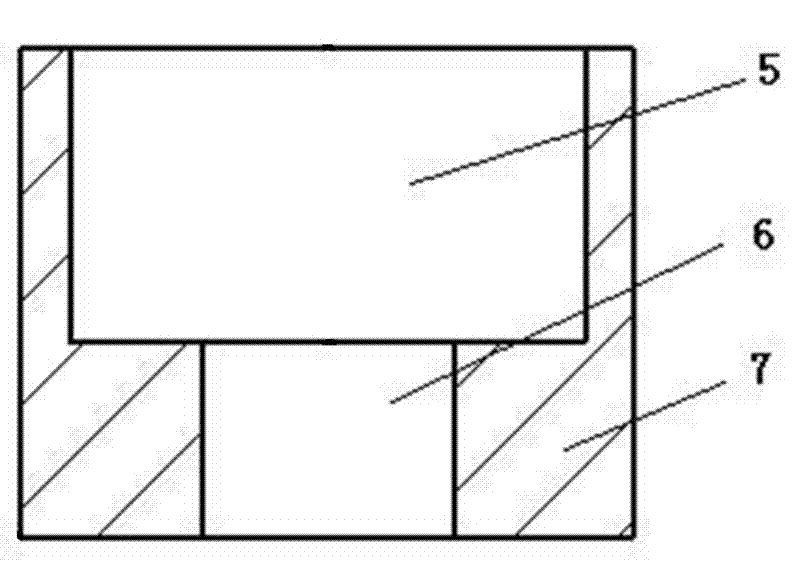

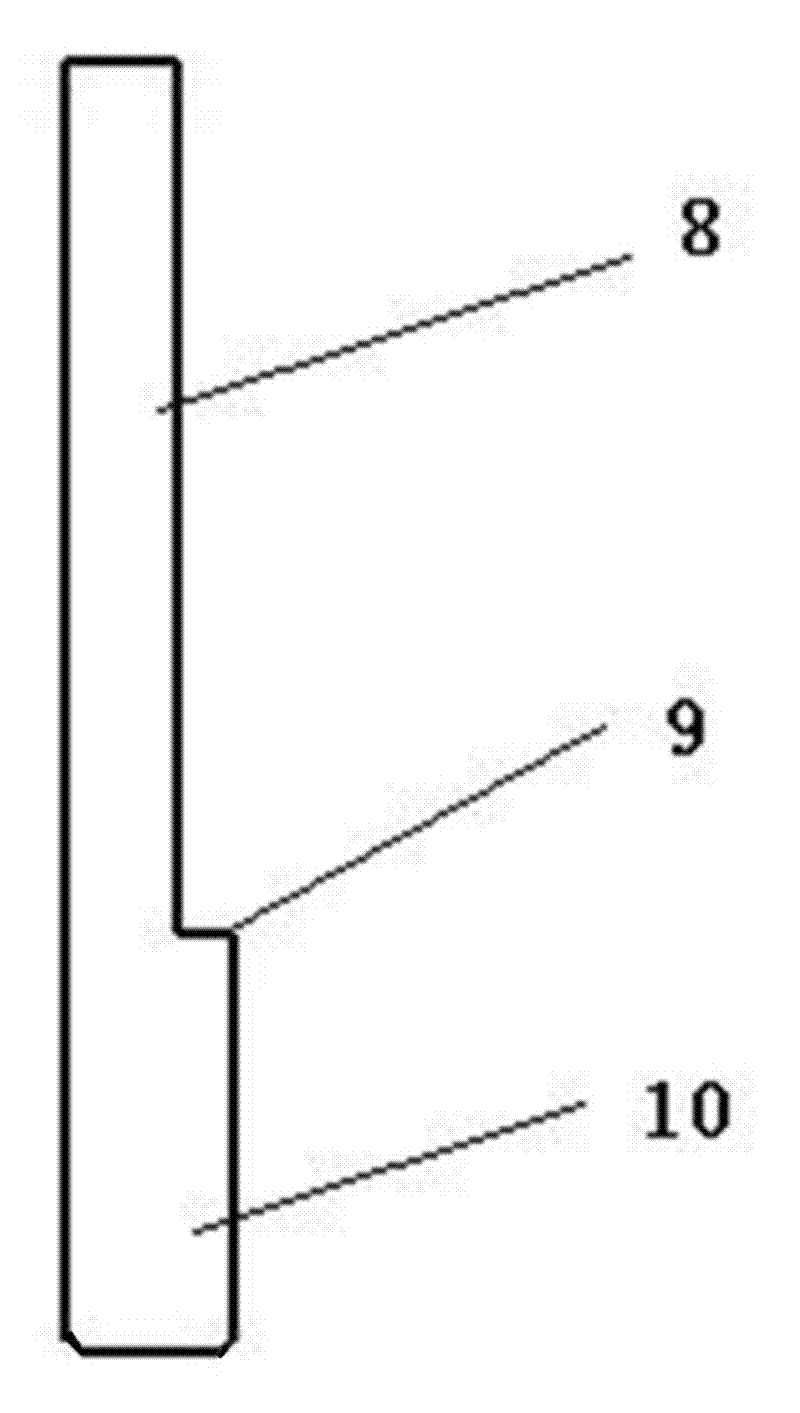

[0025] The main technical point of the blade combination method of a pulverizer in the present invention is: cut out parallel stepped grooves that are not synchronized with the angle of the cutter head to the center line on the edge of the cutter head cylinder toward the center of the circle (that is, the parallel stepped groove The centripetal line will not converge to the center point of the cutter head), insert the blade with a flat side and a concave-convex structure on the other side into the parallel stepped groove from the edge of the cutter head from the convex end, and the blades should be distributed in odd numbers. The distance between them should be equal, so that the installed blades are forward inclined, that is, the head o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com