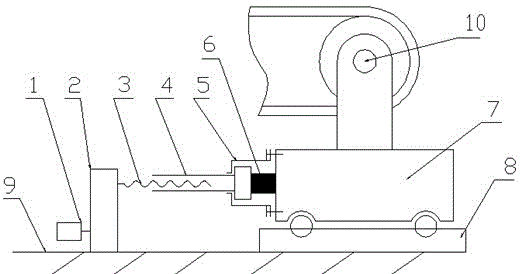

Tightening mechanism of conveyer belt

A tensioning mechanism and conveyor technology, applied in the field of conveyors, can solve the problems of low automation, poor tensioning effect, complex structure, etc., and achieve the effect of high automation, good tensioning effect and simple knot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] A conveyor belt tensioning mechanism, which includes: a servo motor (1), a reducer (2), a lead screw (3), a wire sleeve (4), a fixing device (5), a pressure sensor (6), Scooter (7), guide rail (8), frame (9), belt transmission device (10), guide rail (8) is set and installed on the frame (9), and scooter is set and installed on the guide rail (8) (7), the scooter (7) has the degree of freedom to move along the guiding direction of the guide rail (8), and the fixed belt transmission device (10) is installed on the upper plane of the scooter (7), and the wire sleeve (4) passes through the fixing device (5) Install and fix on one end of the scooter (7), and set a pressure sensor (6) between the end of the wire sleeve (4) and the body of the scooter (7), the wire sleeve (4) only has an axis There is a small amount of movement in the direction but no degree of freedom of rotation. A screw (3) is arranged inside the wire sleeve (4), and the outer end of the screw (3) is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com