Automatic precision net puller

A precision stretching machine and frame technology, applied in the field of stretching machines, can solve the problems of affecting efficiency, waste of mesh cloth, unqualified mesh cloth, etc., and achieve the goal of improving production efficiency, avoiding loosening, and good clamping and fixing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The invention will be described in further detail below in conjunction with the accompanying drawings.

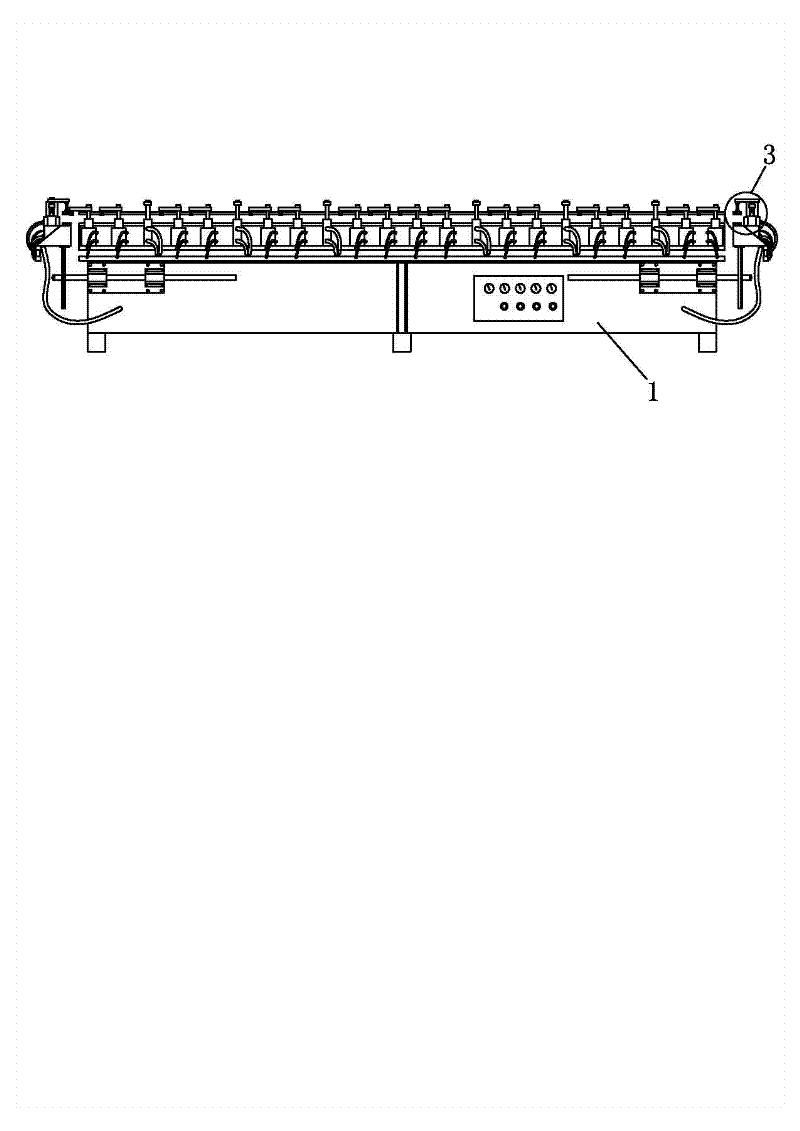

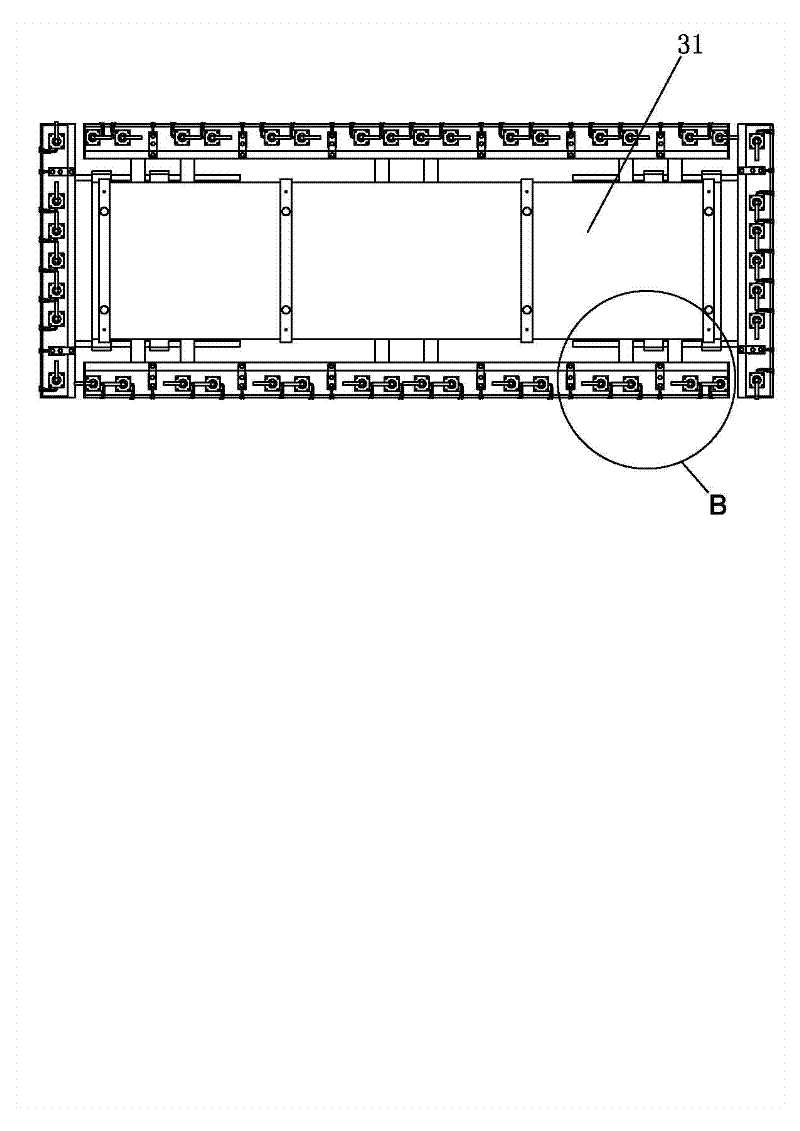

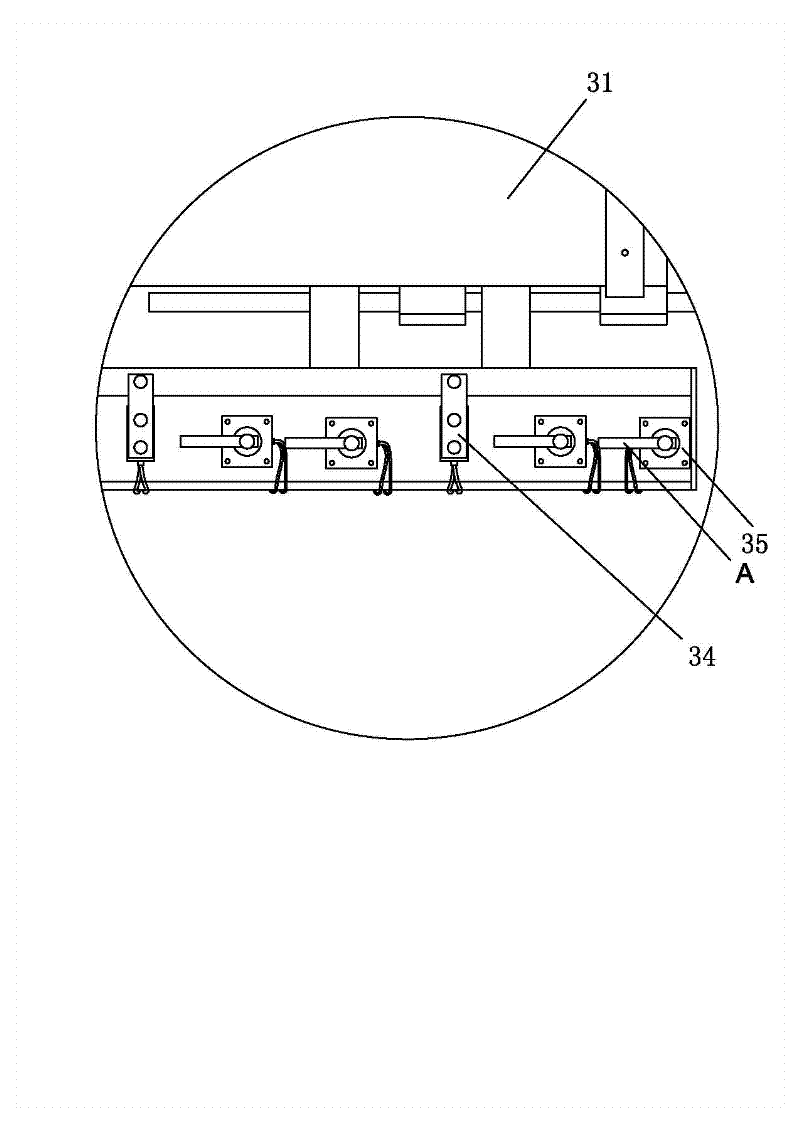

[0020] like Figure 1 to Figure 5 As shown, a kind of automatic precision stretching machine includes a frame 1 and a wire mesh chuck mechanism 3 installed on each outer periphery of the frame 1. It is characterized in that the wire mesh chuck mechanism 3 is mainly composed of a moving seat 31 , bottom plate 32, splint 33, lifting cylinder 34 and rotary cylinder 35, the moving seat 31 is installed on the outer periphery of the frame 1 in a slidable manner through the guide rail, and the side of the moving seat 31 near the outer periphery of the frame 1 is fixed with a bottom plate 32. Lifting cylinder 34 and rotating cylinder 35 are respectively installed on the mobile seat 31 next to the base plate 32. The lifting end of the lifting cylinder 34 is connected to the splint 33, and the splint 33 is located above the base plate 32. Head, the rotating end A of the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com