Steel coil tensioning device of full-automatic uncoiler

A tensioning device and uncoiler technology, which is applied in the field of steel coil tensioning devices, can solve problems such as troublesome oblique expansion blocks, shortened service life, and large wear, and achieves increased application range, good tensioning effect, and low manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

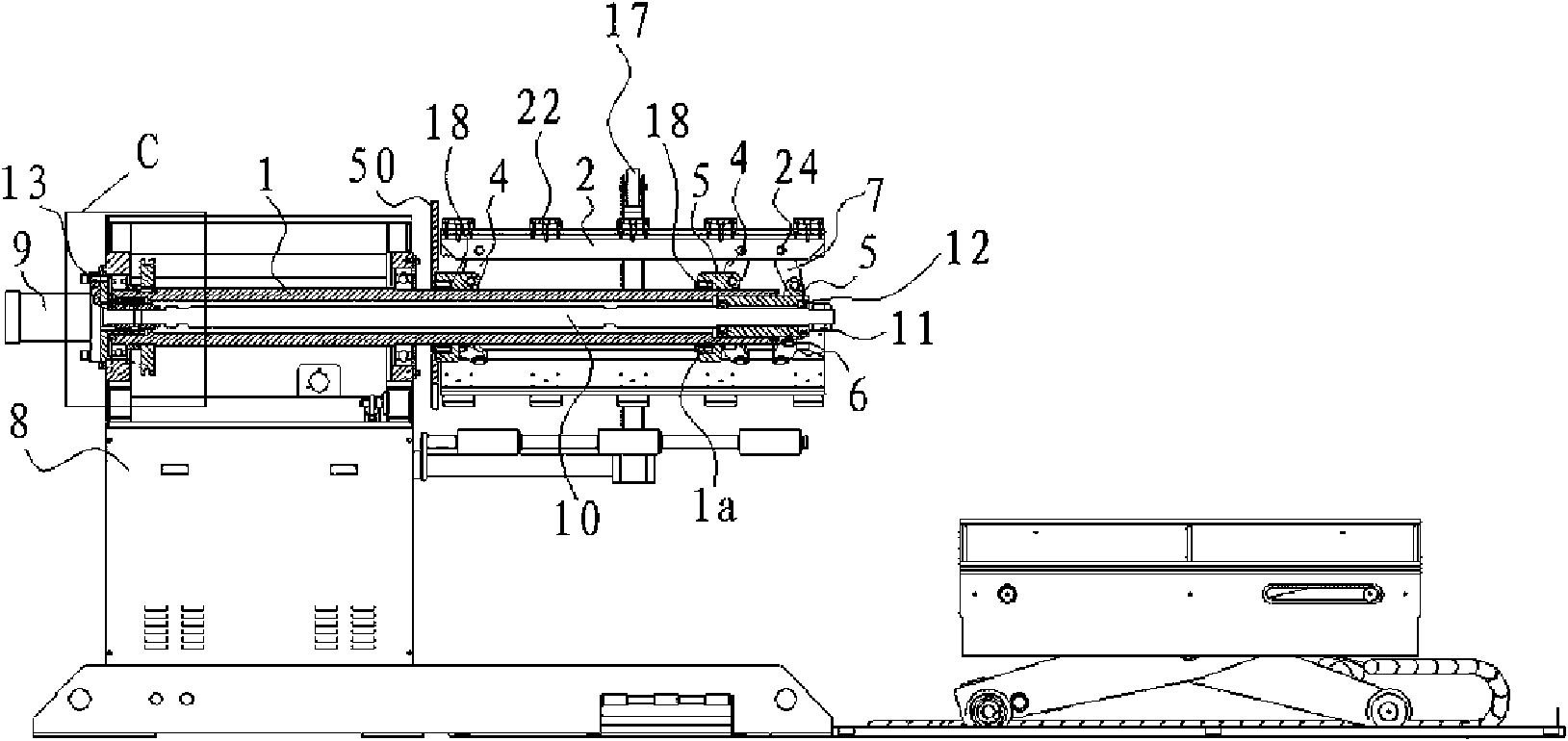

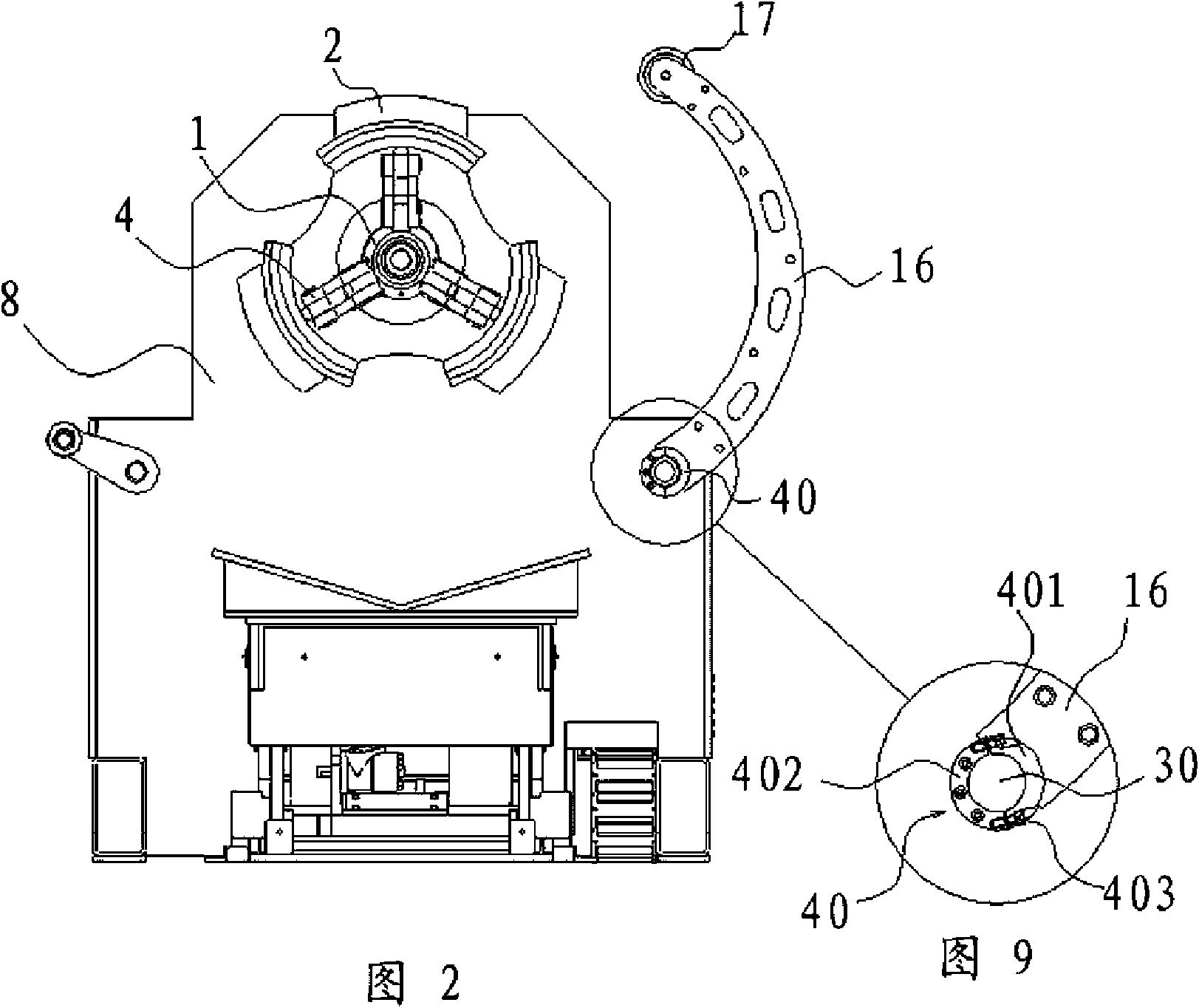

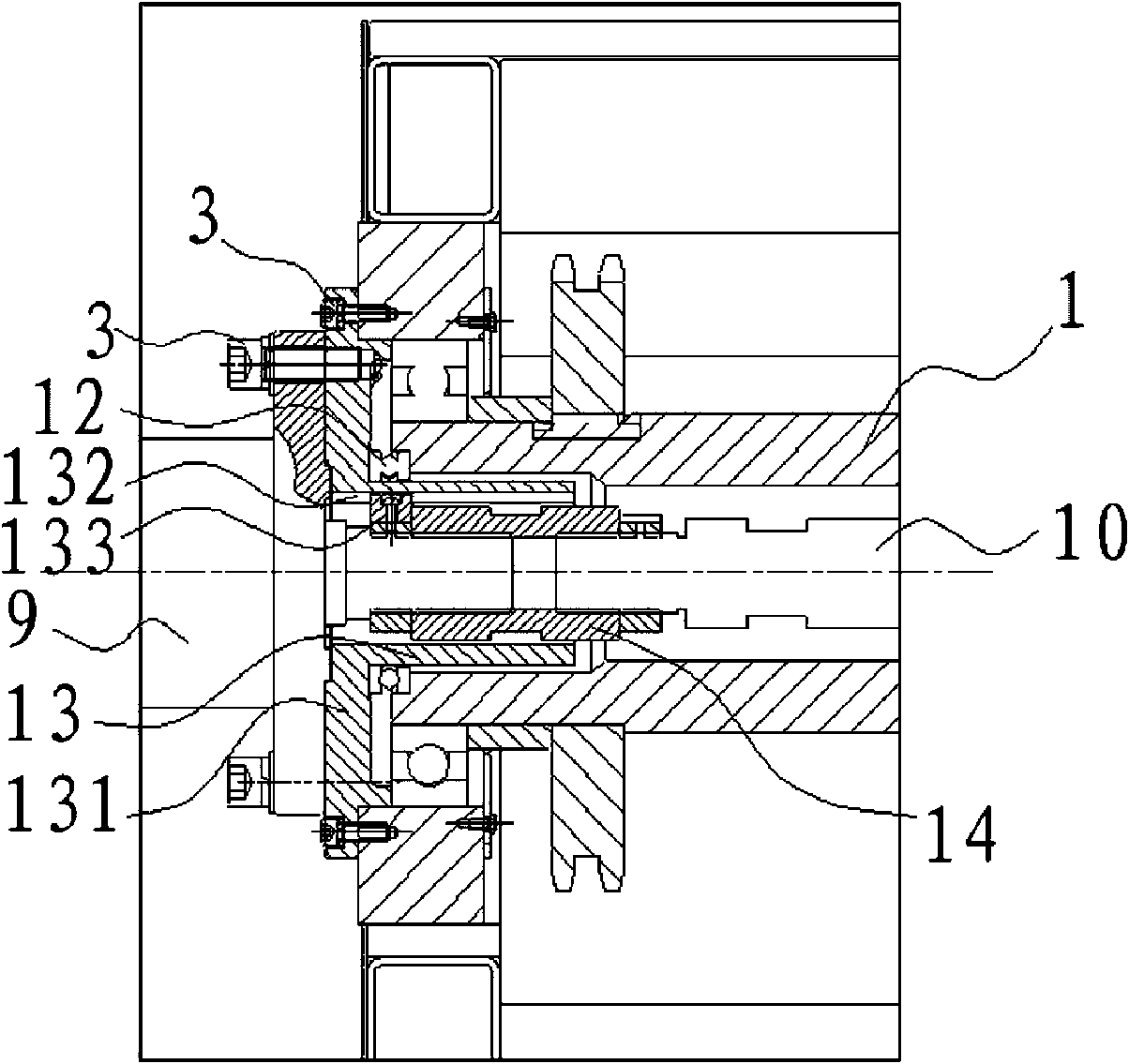

[0032] Such as figure 1 and figure 2As mentioned above, the steel coil tensioning device of the automatic uncoiler is arranged on the base 8 of the automatic uncoiler, including a hollow rotating shaft 1 and three tensioning plates 2 evenly distributed on the periphery of the rotating shaft 1, such as As shown in the figure, the tensioning plate 2 includes an arc-shaped inner brace 21 and five arc-shaped outer braces 22, the outer braces 22 are evenly distributed on the outer side of the inner brace 21 and screwed 3 fixed, in order to prevent the tension plate 2 from damaging the inner surface of the steel coil, and increase the friction and tension effect at the same time, the outer surfaces of the inner support plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com