Tractor for finished steel strand and threading method of finished steel strand

A technology of finished steel and tractor, applied in the processing of building materials, erecting/assembling bridges, bridge materials, etc., can solve the problems of inconvenient processing, cumbersome construction steps, inconvenient use, etc., and achieve good clamping effect and save The effect of cutting processing time and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

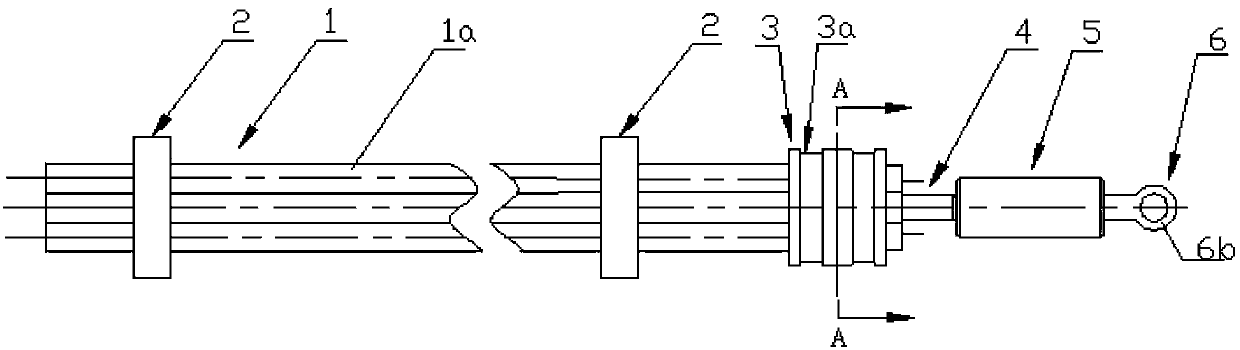

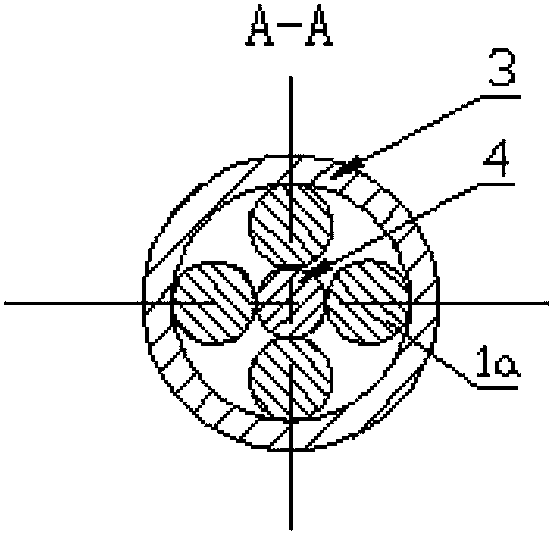

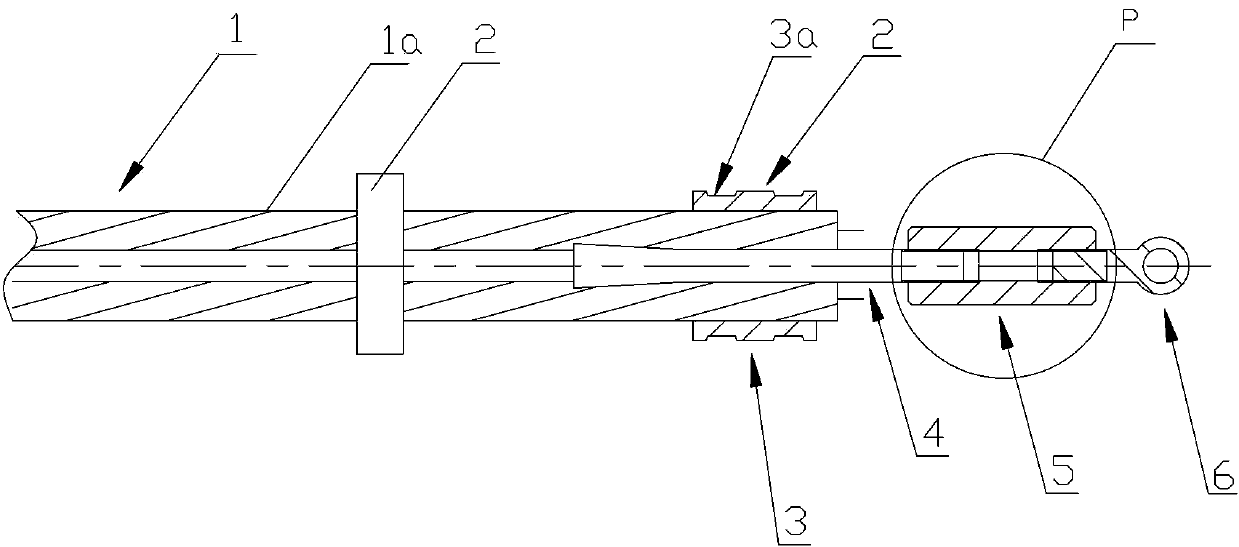

[0027] figure 1 It is a schematic diagram of the structure of the present invention assembled on the finished steel strand bundle; figure 2 yes figure 1 Middle A-A sectional view; image 3 yes figure 1 sectional view in Figure 4 yes image 3 Enlarged view of part P in ; Figure 5 yes figure 1 Schematic diagram of the side structure of the middle mark plate; Image 6 yes figure 1 Schematic diagram of the structure of the core rod.

[0028] The present invention provides a tractor for finished steel strands, the tractor includes: a tightening ring 3, a mandrel 4, a threaded connection sleeve 5 and a traction ring 6; the mandrel on one side of the mandrel 4 The conical end 4a is inserted into the central end of the finished steel strand bundle 1 composed of multiple single steel strands 1a, and the mandrel external thread end 4b on the other sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com