Metal substrate with high thermal conductivity

A metal substrate, high thermal conductivity technology, used in circuit substrate materials, metal layered products, coatings, etc., can solve problems such as poor dielectric properties of copper clad laminates, achieve good adhesion, improve thermal conductivity, and efficiently conduct heat. channel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

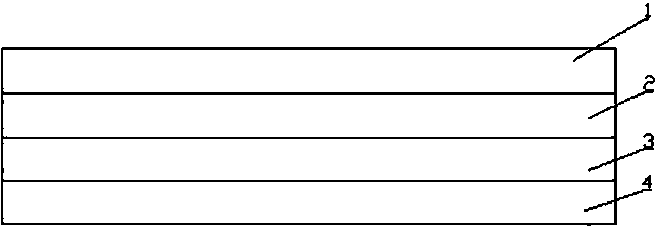

[0021] see figure 1 , in Embodiment 1 of the present invention, a metal substrate with high thermal conductivity, including a metal layer 4, an Al 2 o 3 h 2 O(6) film 3, coated on Al 2 o 3 h 2 The thermal conductivity insulating layer 2 and the metal foil layer 1 on the O(6) film 3 have a thermal conductivity of 0.2-4W / (m·K).

[0022] Al 2 o 3 h 2 The molecular structure of the O(6) film 3 is highly symmetrical, with low polarity and excellent dielectric properties. The present invention selects Al 2 o 3 h 2 O(6) film 3, which enables coating on Al 2 o 3 h 2 The thermally conductive insulating layer 2 above the O(6) film 3 passes through the pores, and the thermally conductive resin of the insulating layer can enter the Al 2 o 3 h 2 In the pores of the O(6) film 3, it acts as a pin, so that the heat-conducting insulating layer 2 and the Al 2 o 3 h 2 O(6) film 3 has good adhesion.

[0023] In the high thermal conductivity metal substrate of the present inve...

Embodiment 2

[0033] The main difference between this embodiment 2 and embodiment 1 is that in the highly thermally conductive metal substrate of the present invention, the thermally conductive insulating layer 2 can be a cyanate ester resin system, an epoxy resin system, a PTFE system, a hydrocarbon resin system, a polyester Any one of the phenylene ether resin system or the polyimide system is preferably a cyanate resin system.

[0034] The metal substrate, Al 2 o 3 h 2 The thermally conductive insulating layer 2 on the O(6) film 3 can effectively pass through Al due to its better fluidity. 2 o 3 h 2 O(6) film 3, so as to make better adhesion between layers; the entire insulating medium layer does not contain glass fiber cloth with large thermal resistance and poor dielectric properties, so the thermal conductivity of the entire metal substrate is high and the dielectric properties are high. Good electrical properties; ensure that the thermally conductive substrate has good peel stre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com