Data line auxiliary embedding device

A technology for data lines and equipment, applied in the field of auxiliary embedded equipment for data lines, can solve the problems of heavy workload, deviation of the inner diameter of connecting holes, and difficulty in fixing screws passing through the embedded connecting holes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

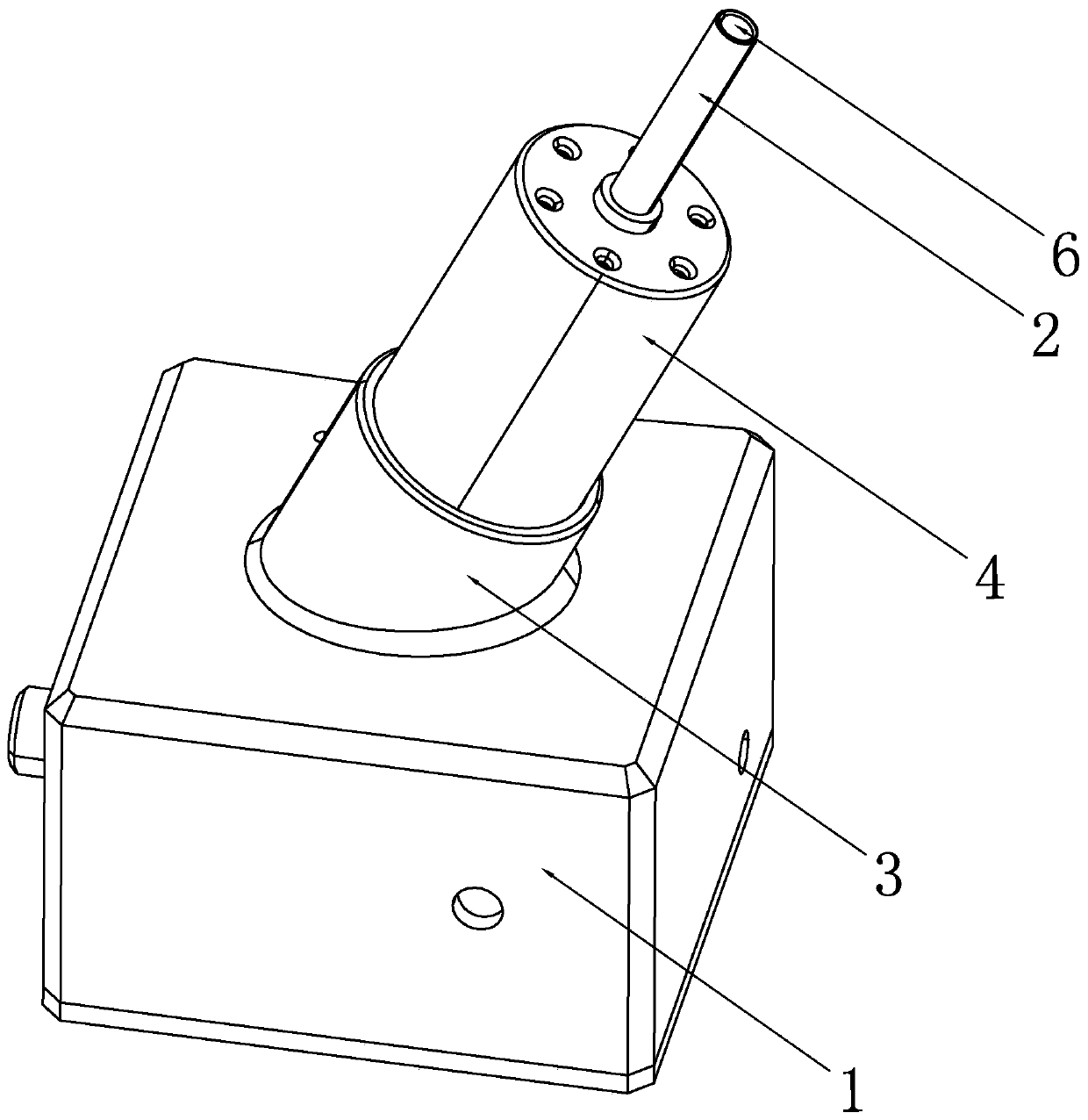

[0019] see figure 1 , a data line auxiliary embedding device of the present invention includes a base 1 and a drive shaft 2, a guide cylinder 3 is installed on the base 1, and the guide cylinder 3 is inclined relative to the base, and the guide cylinder 3 and the base The included angle between 1 is 45°-75°, and the guide cylinder 3 is provided with a sleeve 4 that can move along the axial direction of the guide cylinder 3 .

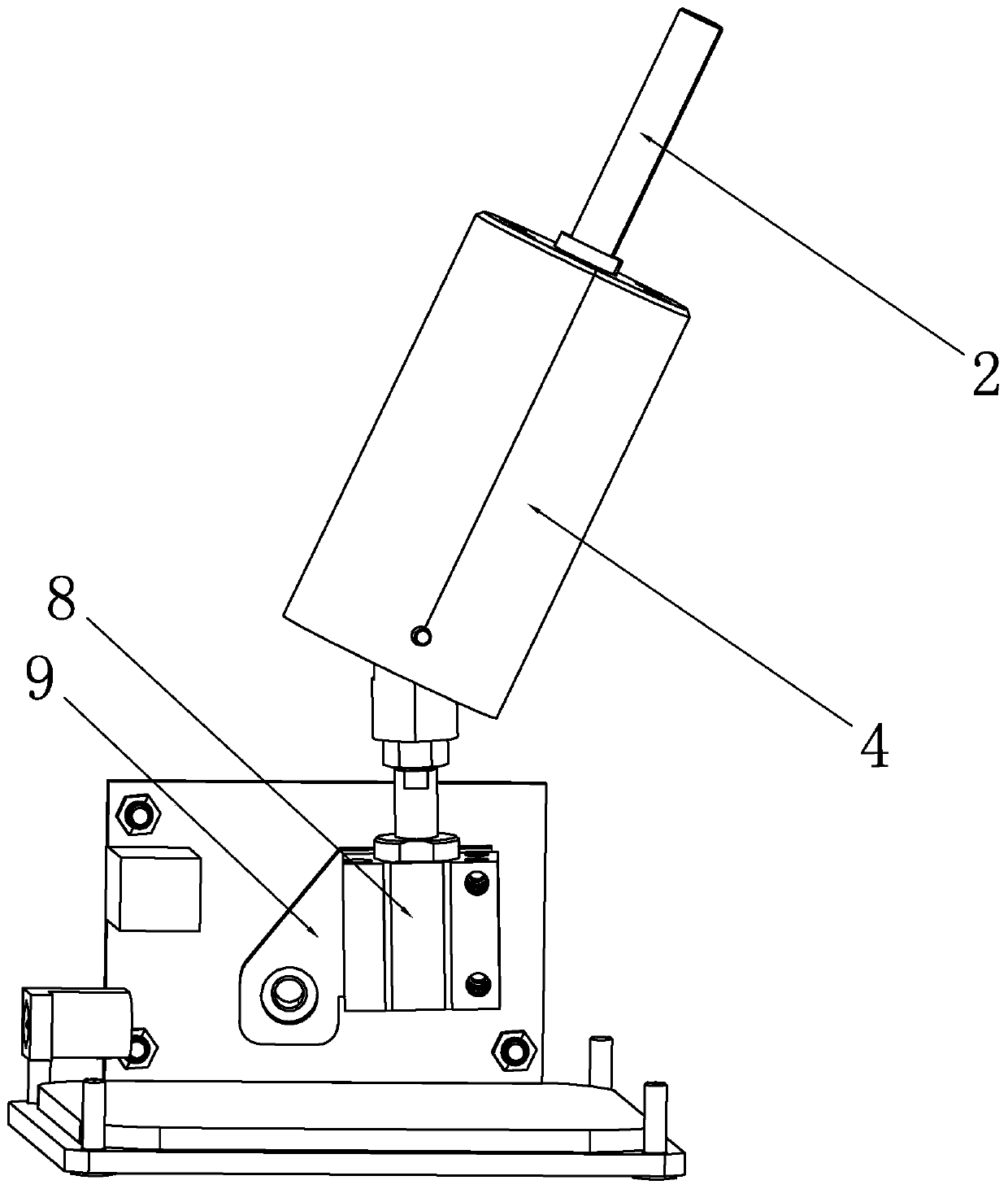

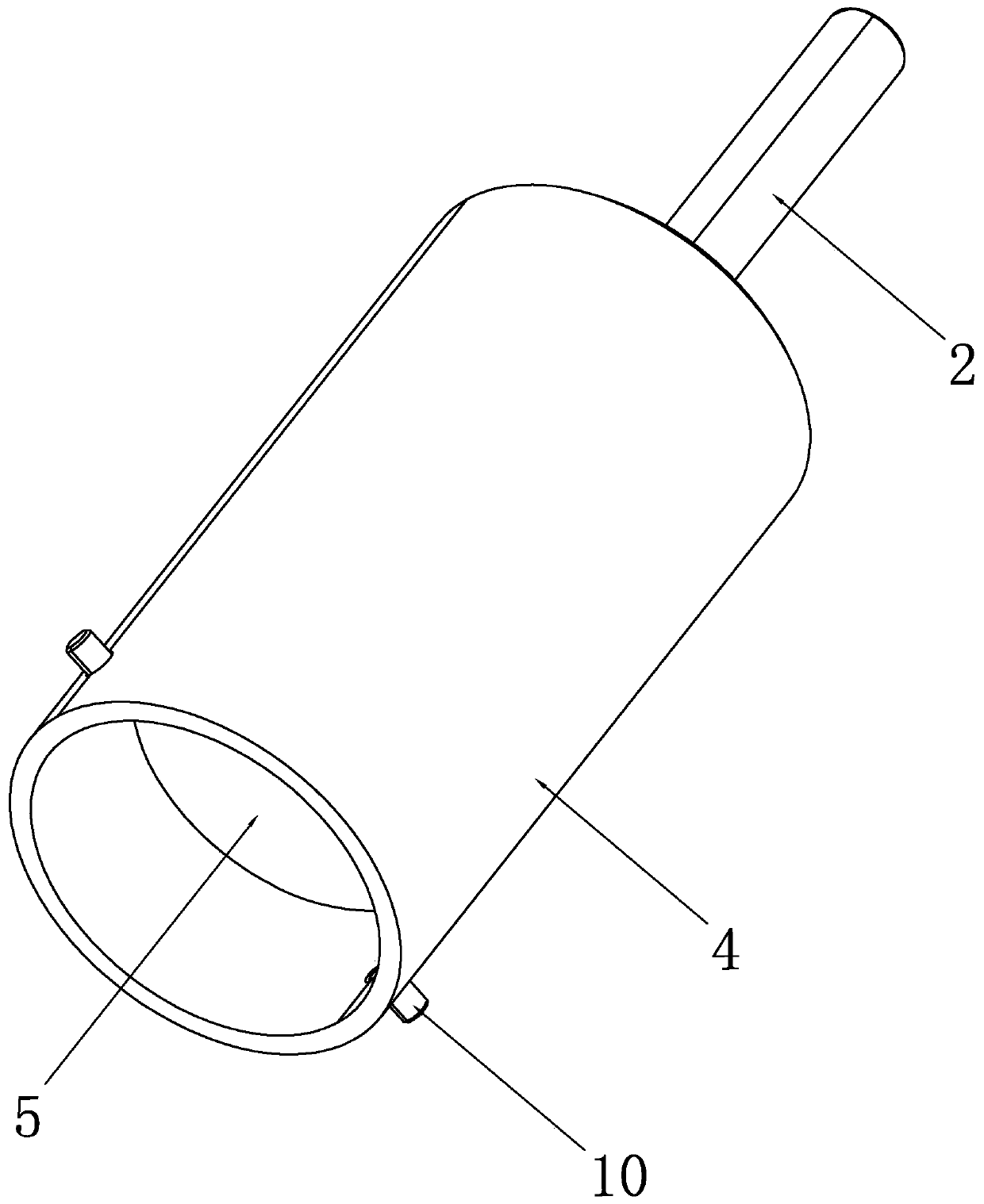

[0020] see further figure 2 , image 3 and Figure 4 A reduction motor 5 is installed in the sleeve 4, one end of the drive shaft 2 extends into the sleeve 4 and is connected to the output end of the reduction motor 5, and the other end is provided along the axial direction of the drive shaft 2 for guiding and inserting The positioning guide hole 6 of the fixing screw, the bottom of the positioning guide hole 6 is provided with a slotted head or a cross head, and the slotted head or the cross head can be matched with the slotted slot or the crossed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com