Fastening connection accessory for tubular product

A technology for fastening connections and pipes, applied in the field of assembly of pipe connections, can solve the problems of failure of fasteners, complicated installation steps, etc., and achieve the effect of preventing fracture, simple structure, and avoiding connection failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

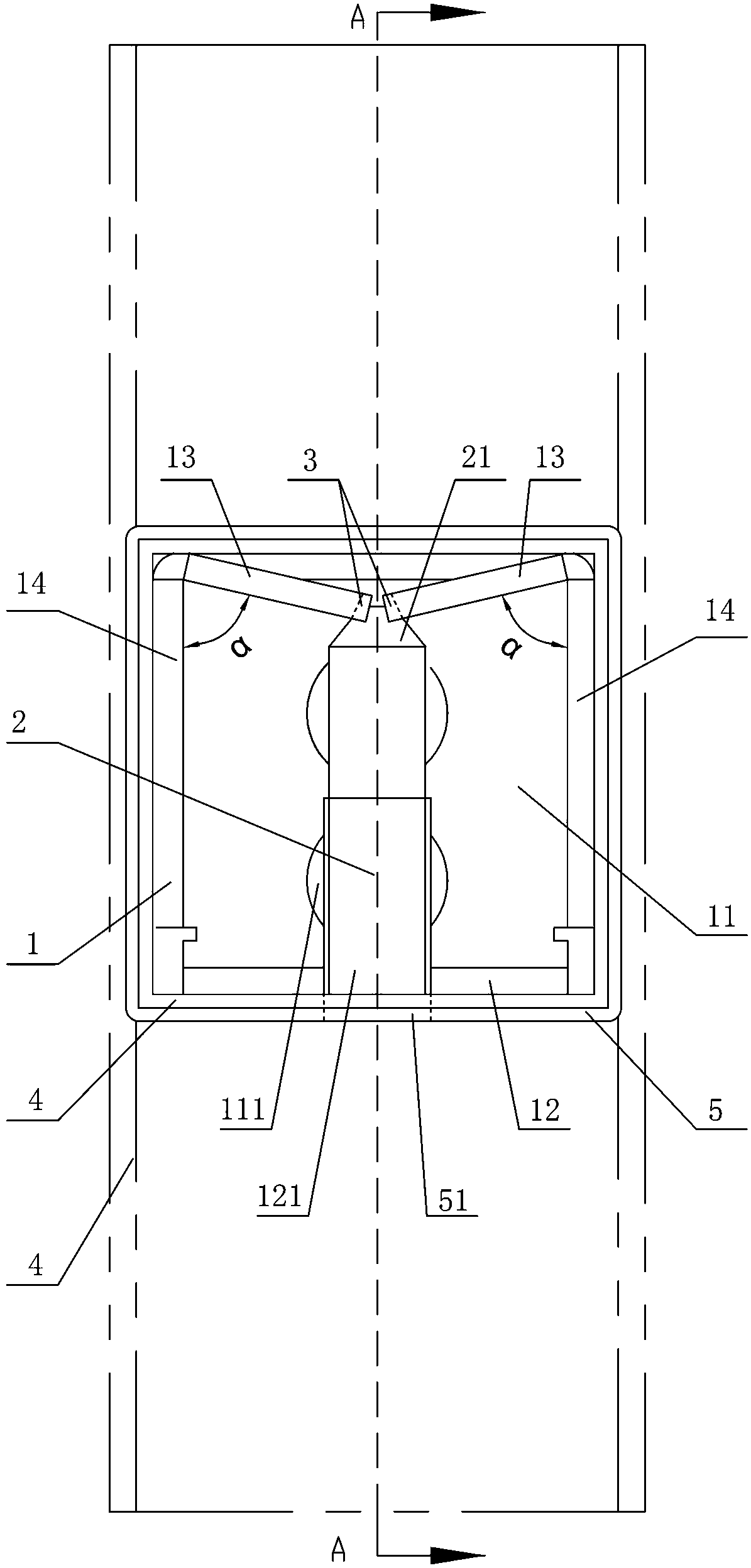

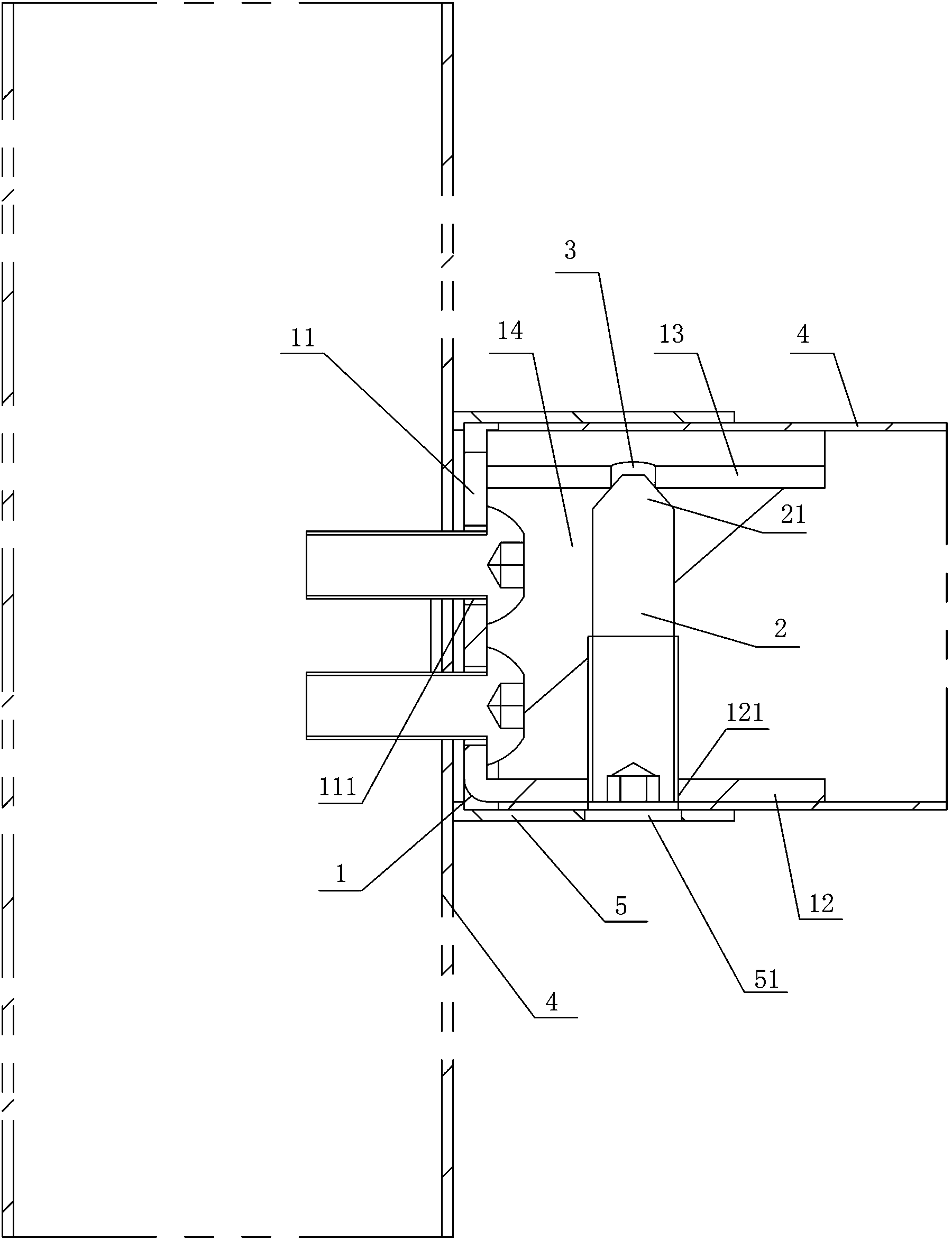

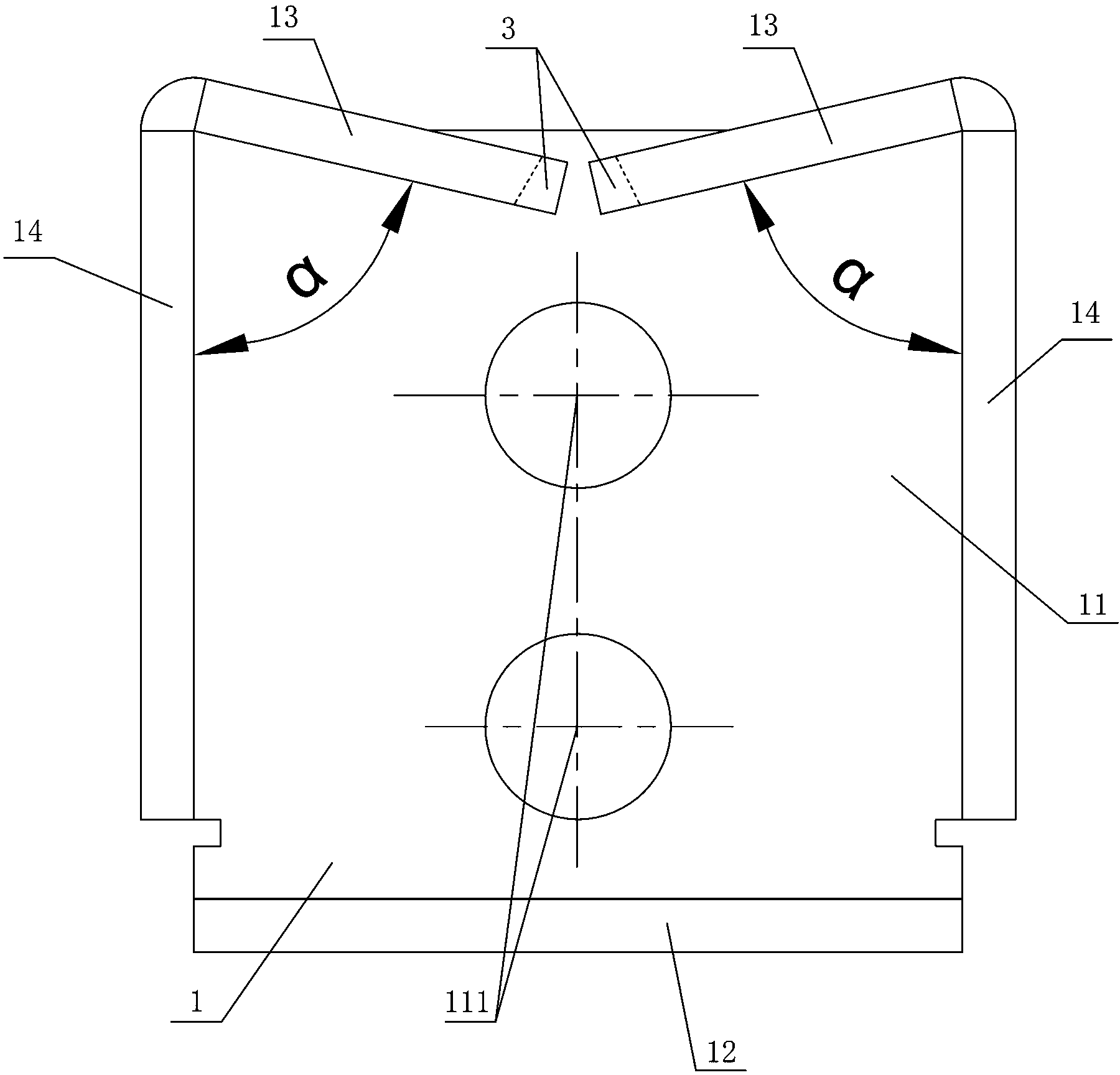

[0020] Figure 1 to Figure 5 It shows an embodiment of a fastening connection fitting for pipes according to the present invention. The connection fitting includes a joint 1 and a top wire 2. The joint 1 includes a connecting bottom plate 11. One end of the connecting bottom plate 11 is provided with a pull plate 12, and the other end is provided with a Top plate 13, one end of top wire 2 is threadedly connected with pull plate 12, the other end is in contact with top plate 13, top plate 13 is provided with top wire guide hole 3, and one end of top wire 2 connected with top plate 13 is provided with top wire guide hole 3 With the matching cone 21, when the top screw 2 is tightened, the top screw 2 will drive the pull plate 12 and the top plate 13 to expand under the guidance of the top screw guide hole 3 and expand and connect with the inner wall of the pipe 4. Its structure is simple and easy to install , Can effectively protect fasteners from damage. When assembling, the jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com