Finished prestressed steel stranded wire harness convenient for construction

A technology for prestressed steel strands and steel strand bundles, applied in the field of prestressed steel strands and finished prestressed steel strand bundles, can solve the problems of increasing the weight of the rib threading device, increasing the cost, complex structure, etc. Good effect, low cost, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below with reference to the drawings and specific embodiments.

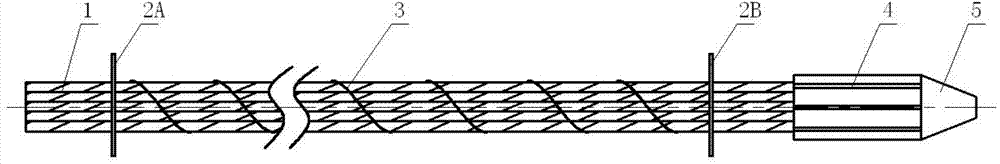

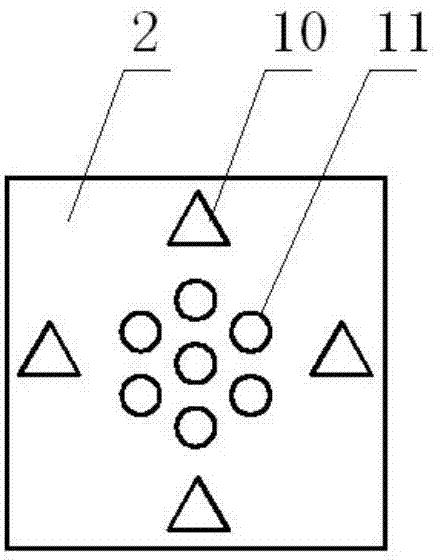

[0020] A finished prestressed steel stranded wire harness that is easy to construct, such as figure 1 As shown, it includes a steel stranded wire harness 1, a squeeze sleeve 5, a front marking plate 2B, a rear marking plate 2A, and a binding wire 3. A squeeze sleeve is coaxially crimped at the end, and a front mark board and a back mark board are respectively installed on the front and rear ends of the steel stranded wire bundle, and the lashing wire is spirally wound around the outer edge of the steel stranded wire bundle between the two mark boards.

[0021] The innovation of the present invention lies in:

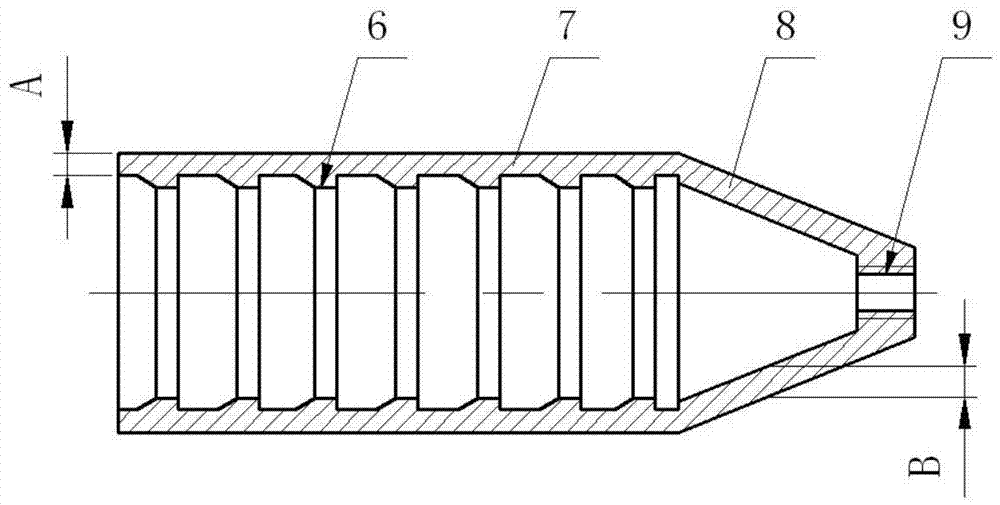

[0022] The structure of the extrusion sleeve is figure 2 As shown, the connecting section 7 and the traction section 8 are included, and one end of the connecting section has a traction section. The traction section is a frustum-shaped structure, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com